A Glove-Based Form Factor for Collecting Joint Acoustic Emissions: Design and Validation

Abstract

:1. Introduction

2. Methods

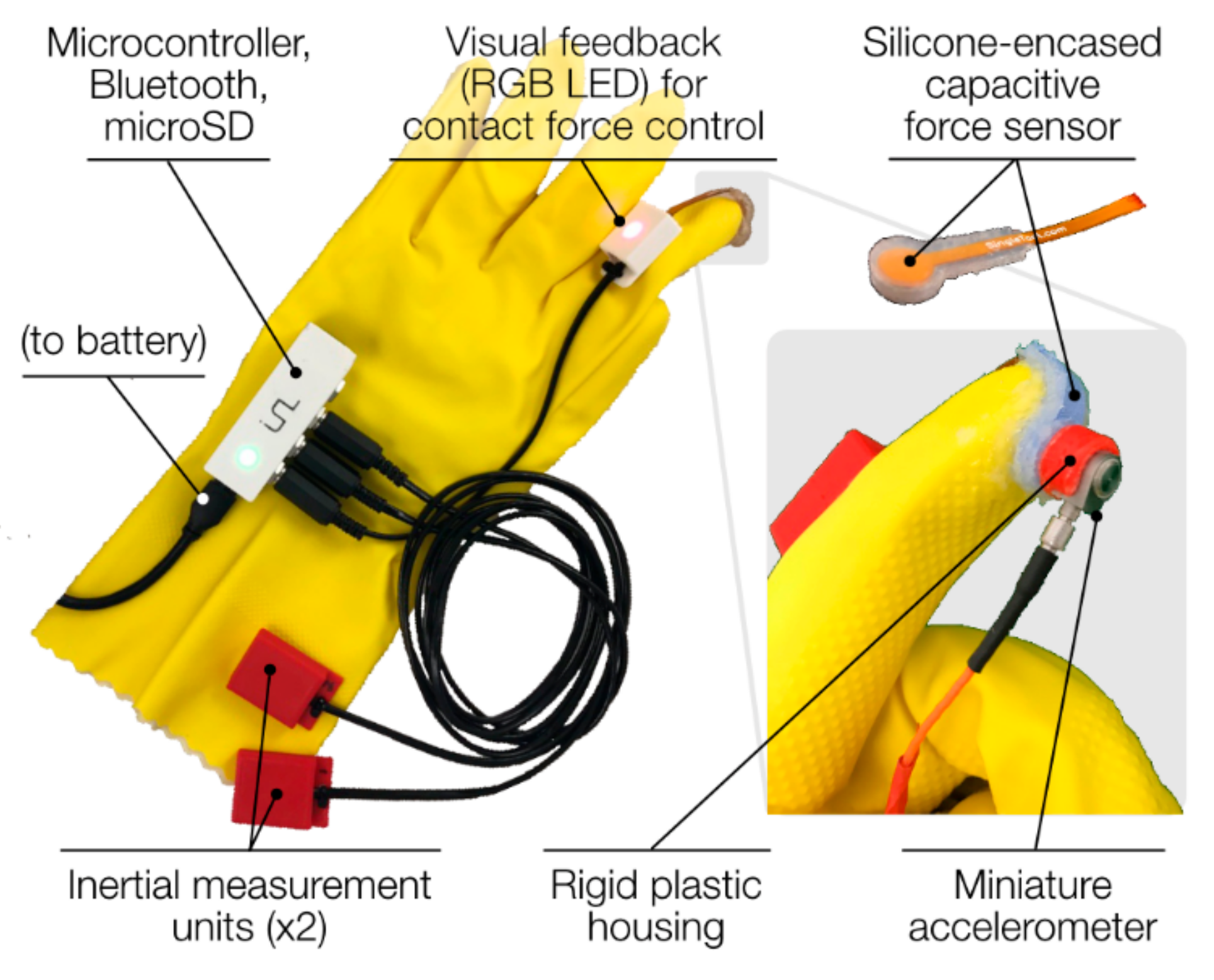

2.1. Design of a Glove-Based Form Factor

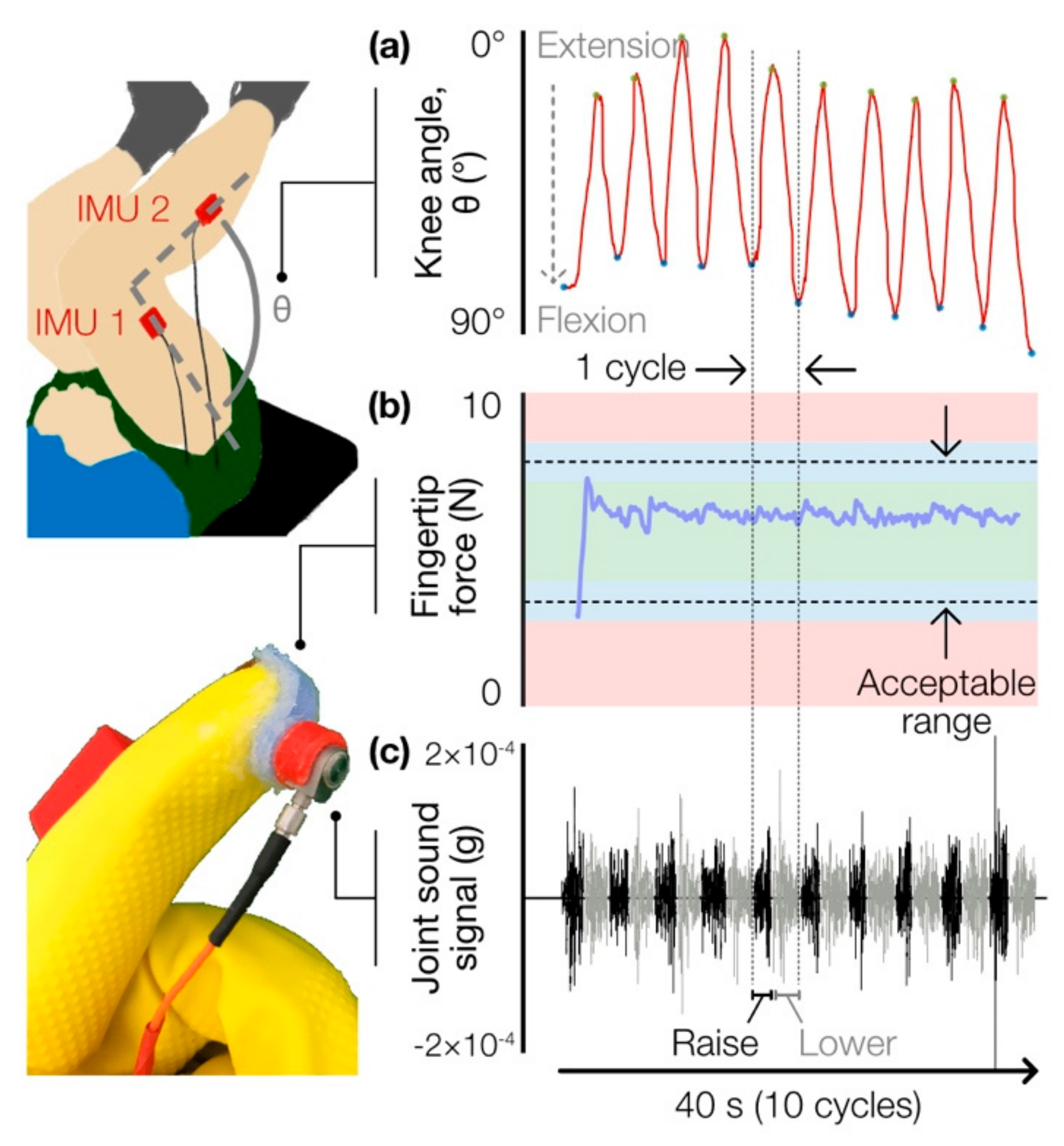

2.2. Loading Experiment Protocol

2.3. Signal Processing and Data Analysis

2.4. Repeatability Testing: Protocol and Analysis

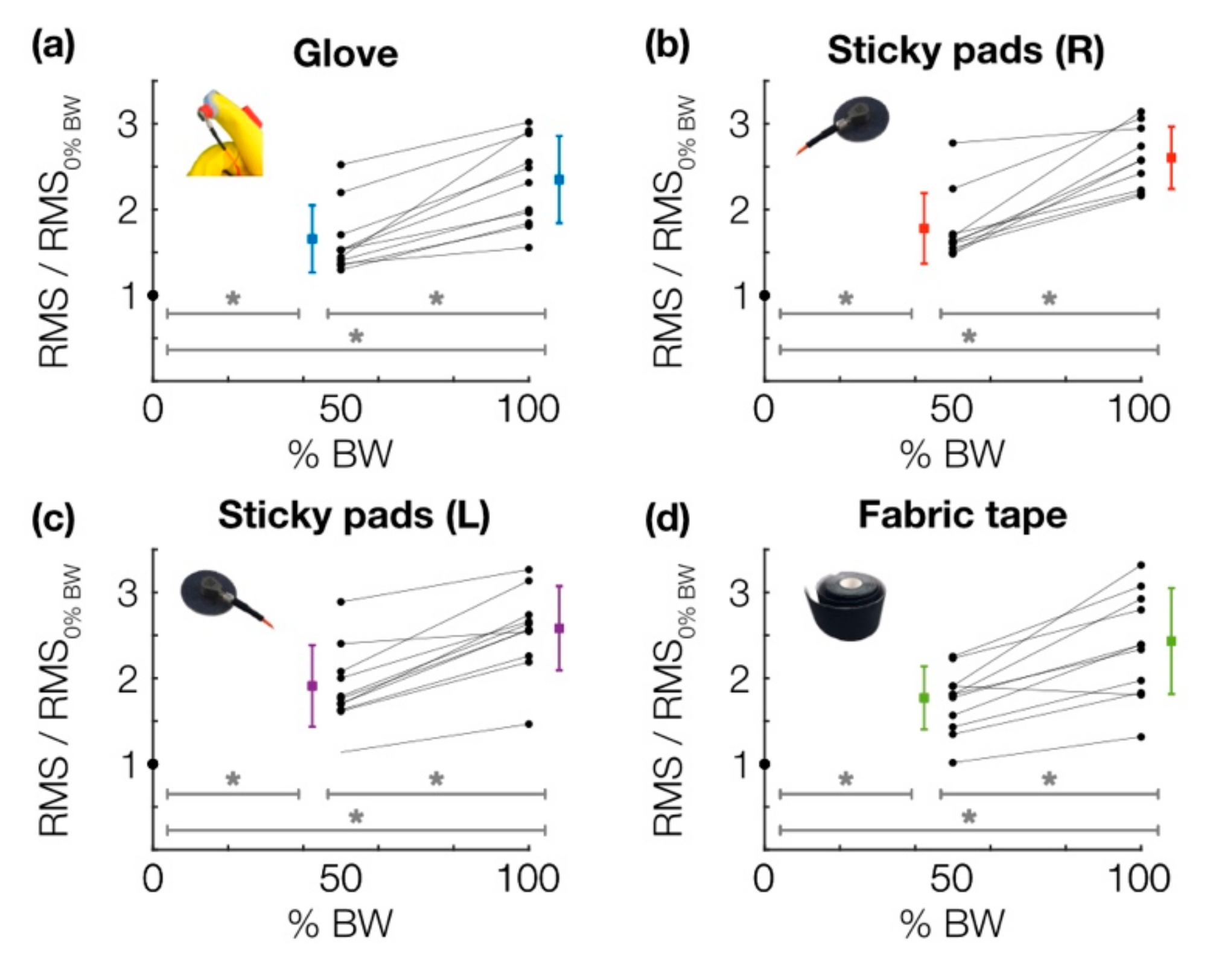

2.4.1. Comparison of Repeatability between Mounting Techniques

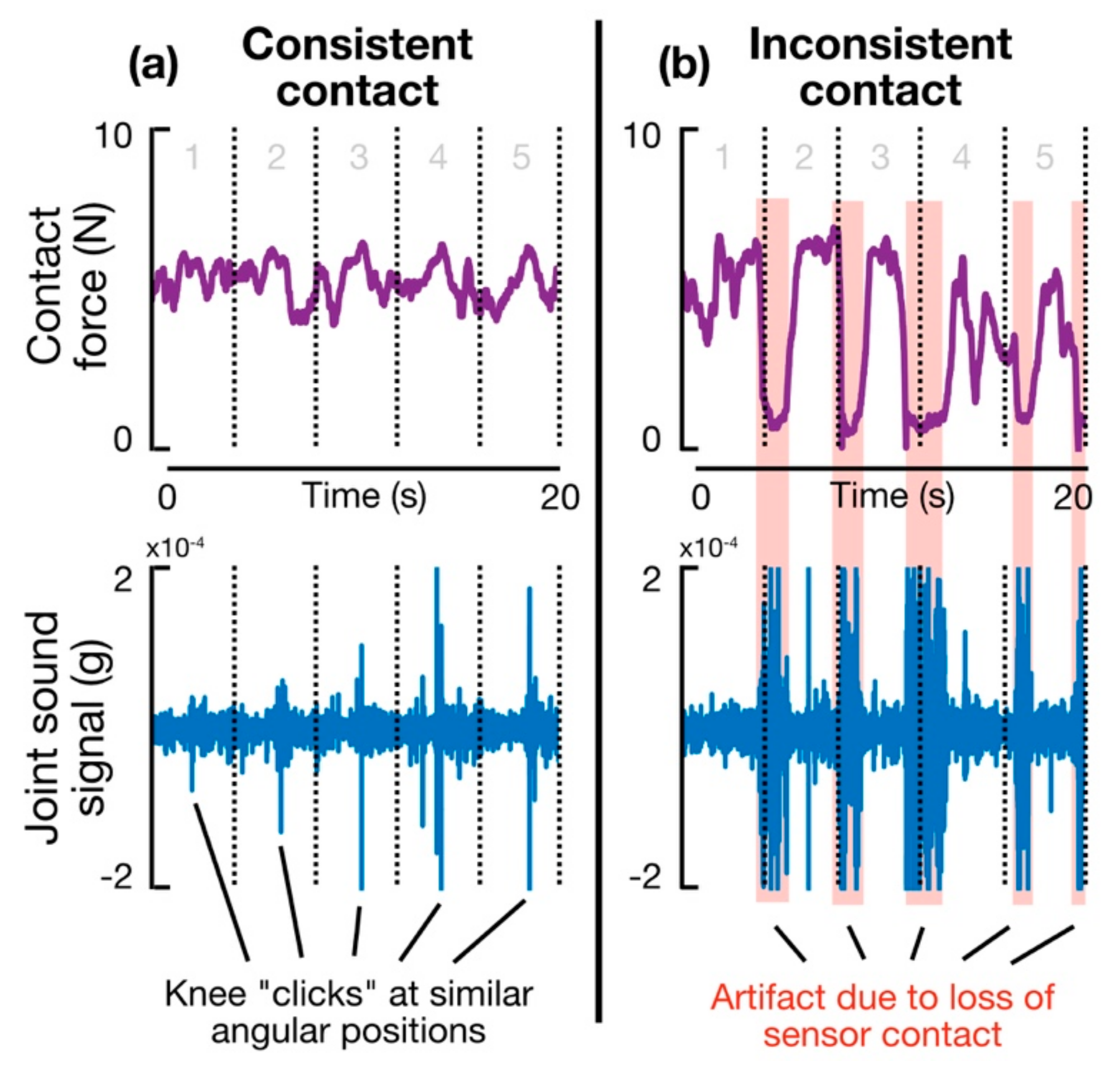

2.4.2. Effect of Fingertip Contact Force Consistency on Repeatability

3. Results and Discussion

3.1. Effect of Leg Press Load on Knee Grinding Loudness

3.2. Repeatability of Glove Versus Conventional Techniques

3.3. Consistent Contact Force Improves Consistency of Results

3.4. Considerations for a Hand-Worn Acoustic Sensing System

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Majewski, M.; Susanne, H.; Klaus, S. Epidemiology of athletic knee injuries: A 10-year study. Knee 2006, 13, 184–188. [Google Scholar] [CrossRef] [PubMed]

- Hootman, J.M.; Helmick, C.G.; Barbour, K.E.; Theis, K.A.; Boring, M.A. Updated projected prevalence of self-reported doctor-diagnosed arthritis and arthritis-attributable activity limitation among US adults, 2015–2040. Arthritis Rheumatol. 2016, 68, 1582–1587. [Google Scholar] [CrossRef] [PubMed]

- Woolf, A.D.; Åkesson, K. Understanding the burden of musculoskeletal conditions: The burden is huge and not reflected in national health priorities. BMJ Br. Med. J. 2001, 322, 1079. [Google Scholar] [CrossRef] [PubMed]

- McCoy, G.F.; McCrea, J.D.; Beverland, D.E.; Kernohan, W.G.; Mollan, R. Vibration arthrography as a diagnostic aid in diseases of the knee. A preliminary report. J. Bone Jt. Surg. Br. Vol. 1987, 69, 288–293. [Google Scholar] [CrossRef]

- Chu, M.L.; Gradisar, I.A.; Railey, M.R.; Bowling, G.F. Detection of knee joint diseases using acoustical pattern recognition technique. J. Biomech. 1976, 9, 113–114. [Google Scholar] [CrossRef]

- Shark, L.-K.; Chen, H.; Goodacre, J. Discovering differences in acoustic emission between healthy and osteoarthritic knees using a four-phase model of sit-stand-sit movements. Open Med. Inform. J. 2010, 4, 116–125. [Google Scholar] [CrossRef] [PubMed]

- Frank, C.B.; Rangayyan, R.M.; Bell, G.D. Analysis of knee joint sound signals for non-invasive diagnosis of cartilage pathology. IEEE Eng. Med. Biol. Mag. 1990, 9, 65–68. [Google Scholar] [CrossRef] [PubMed]

- Töreyin, H.; Jeong, H.K.; Hersek, S.; Teague, C.N.; Inan, O.T. Quantifying the consistency of wearable knee acoustical emission measurements during complex motions. IEEE J. Biomed. Health Inform. 2016, 20, 1265–1272. [Google Scholar] [CrossRef] [PubMed]

- Teague, C.N.; Hersek, S.; Töreyin, H.; Millard-Stafford, M.L.; Jones, M.L.; Kogler, G.F.; Sawka, M.N.; Inan, O.T. Novel methods for sensing acoustical emissions from the knee for wearable joint health assessment. IEEE Trans. Biomed. Eng. 2016, 63, 1581–1590. [Google Scholar] [CrossRef] [PubMed]

- Hersek, S.; Pouyan, M.B.; Teague, C.N.; Sawka, M.N.; Millard-Stafford, M.L.; Kogler, G.F.; Wolkoff, P.; Inan, O.T. Acoustical emission analysis by unsupervised graph mining: A novel biomarker of knee health status. IEEE Trans. Biomed. Eng. 2018, 65, 1291–1300. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.-K.; Pouyan, M.B.; Whittingslow, D.C.; Ganti, V.; Inan, O.T. Quantifying the Effects of Increasing Mechanical Stress on Knee Acoustical Emissions Using Unsupervised Graph Mining. IEEE Trans. Neural Syst. Rehabil. Eng. 2018, 26, 594–601. [Google Scholar] [CrossRef] [PubMed]

- Semiz, B.; Hersek, S.; Whittingslow, D.C.; Ponder, L.A.; Prahalad, S.; Inan, O.T. Using Knee Acoustical Emissions for Sensing Joint Health in Patients with Juvenile Idiopathic Arthritis: A Pilot Study. IEEE Sens. J. 2018, 18, 9128–9136. [Google Scholar] [CrossRef] [PubMed]

- Teague, C.; Hersek, S.; Töreyin, H.; Millard-Stafford, M.L.; Jones, M.L.; Kogler, G.F.; Sawka, M.N.; Inan, O.T. Novel approaches to measure acoustic emissions as biomarkers for joint health assessment. In Proceedings of the 2015 IEEE 12th International Conference on Wearable and Implantable Body Sensor Networks (BSN), Cambridge, MA, USA, 9–12 June 2015; pp. 1–6. [Google Scholar]

- Whittingslow, D.; Semiz, B.; Ponder, L.; Vega-Fernandez, P.; Inan, O.; Prahalad, S. Knee Joint Sounds: A Non-Invasive Modality for Classifying Knee Joint Health in Juvenile Idiopathic Arthritis. In Proceedings of the 2017 ACR/ARHP Annual Meeting, San Diego, CA, USA, 3–8 November 2017. [Google Scholar]

- Tavathia, S.; Rangayyan, R.M.; Frank, C.B.; Bell, G.D.; Ladly, K.O.; Zhang, Y.-T. Analysis of knee vibration signals using linear prediction. IEEE Trans. Biomed. Eng. 1992, 39, 959–970. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.K.; Whittingslow, D.; Inan, O.T. b-Value: A Potential Biomarker for Assessing Knee-Joint Health Using Acoustical Emission Sensing. IEEE Sens. Lett. 2018, 2, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Koo, T.K.; Li, M.Y. A guideline of selecting and reporting intraclass correlation coefficients for reliability research. J. Chiropr. Med. 2016, 15, 155–163. [Google Scholar] [CrossRef] [PubMed]

- Koch, G.G. Intraclass Correlation Coefficient. Available online: https://doi.org/10.1002/9781118445112.stat02461 (accessed on 1 May 2019).

| Glove | Tape | Sticky Pads | Glove, Tape, and Sticky Pads | |||||

|---|---|---|---|---|---|---|---|---|

| ICC | 95% CI * | ICC | 95% CI * | ICC | 95% CI * | ICC | 95% CI * | |

| Acoustic Energy | 0.984 | 0.972–0.992 | 0.928 | 0.877–0.962 | 0.937 | 0.893–0.967 | 0.982 | 0.972–0.989 |

| Acoustic Entropy | 0.947 | 0.905–0.975 | 0.735 | 0.648–0.859 | 0.776 | 0.672–0.871 | 0.836 | 0.742–0.903 |

| Median Frequency Power | 0.954 | 0.916–0.977 | 0.922 | 0.867–0.958 | 0.921 | 0.865–0.959 | 0.976 | 0.962–0.986 |

| Within Trial (Cycle-to-Cycle) | Across Trials | ||||||

|---|---|---|---|---|---|---|---|

| Mean | SD * | CV ** | Mean | SD * | CV ** | ||

| Consistent contact | trial 1 | 8.98 × 10−3 | 7.10 × 10−4 | 0.079 | 1.02 × 10−2 | 1.34 × 10−3 | 0.131 |

| trial 2 | 9.63 × 10−3 | 1.56 × 10−3 | 0.162 | ||||

| trial 3 | 1.09 × 10−2 | 7.64 × 10−4 | 0.070 | ||||

| trial 4 | 1.14 × 10−2 | 4.13 × 10−4 | 0.036 | ||||

| Inconsistent contact | trial 1 | 1.93 × 10−2 | 5.22 × 10−3 | 0.270 | 3.24 × 10−2 | 1.78 × 10−2 | 0.550 |

| trial 2 | 2.32 × 10−2 | 7.07 × 10−3 | 0.305 | ||||

| trial 3 | 4.58 × 10−2 | 2.15 × 10−2 | 0.469 | ||||

| trial 4 | 4.11 × 10−2 | 1.73 × 10−2 | 0.422 | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bolus, N.B.; Jeong, H.K.; Whittingslow, D.C.; Inan, O.T. A Glove-Based Form Factor for Collecting Joint Acoustic Emissions: Design and Validation. Sensors 2019, 19, 2683. https://doi.org/10.3390/s19122683

Bolus NB, Jeong HK, Whittingslow DC, Inan OT. A Glove-Based Form Factor for Collecting Joint Acoustic Emissions: Design and Validation. Sensors. 2019; 19(12):2683. https://doi.org/10.3390/s19122683

Chicago/Turabian StyleBolus, Nicholas B., Hyeon Ki Jeong, Daniel C. Whittingslow, and Omer T. Inan. 2019. "A Glove-Based Form Factor for Collecting Joint Acoustic Emissions: Design and Validation" Sensors 19, no. 12: 2683. https://doi.org/10.3390/s19122683

APA StyleBolus, N. B., Jeong, H. K., Whittingslow, D. C., & Inan, O. T. (2019). A Glove-Based Form Factor for Collecting Joint Acoustic Emissions: Design and Validation. Sensors, 19(12), 2683. https://doi.org/10.3390/s19122683