A Recent Progress of Steel Bar Corrosion Diagnostic Techniques in RC Structures

Abstract

1. Introduction

2. Evaluation Index of Steel Bar Corrosion

2.1. Gravimetric Weight Loss (GWL)

2.2. Corrosion Current Density (CCD)

3. Visual Inspection

4. Empirical Analysis

5. Physical Method

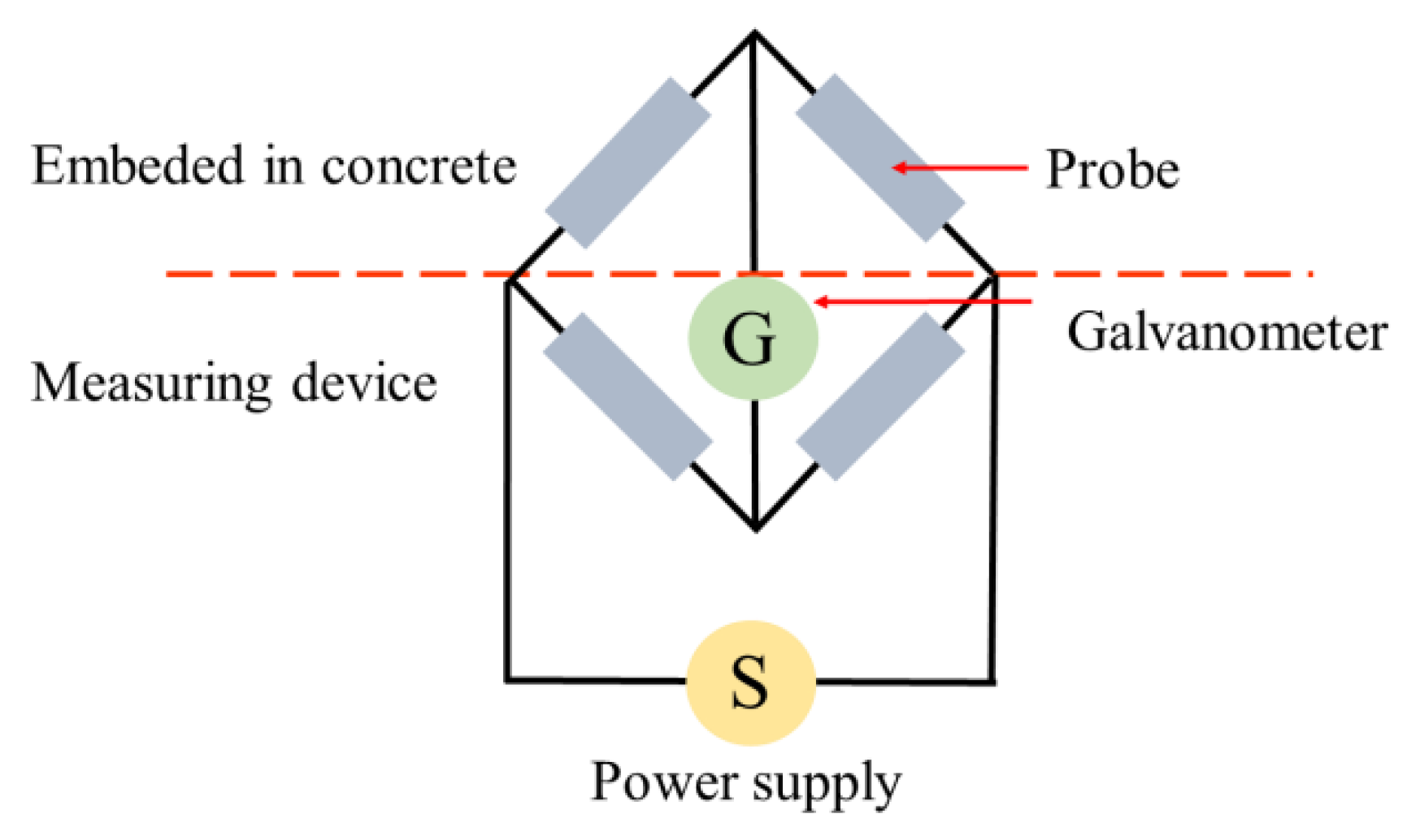

5.1. Electrical Resistance Probe (ERP)

5.2. Eddy Current Testing (ECT)

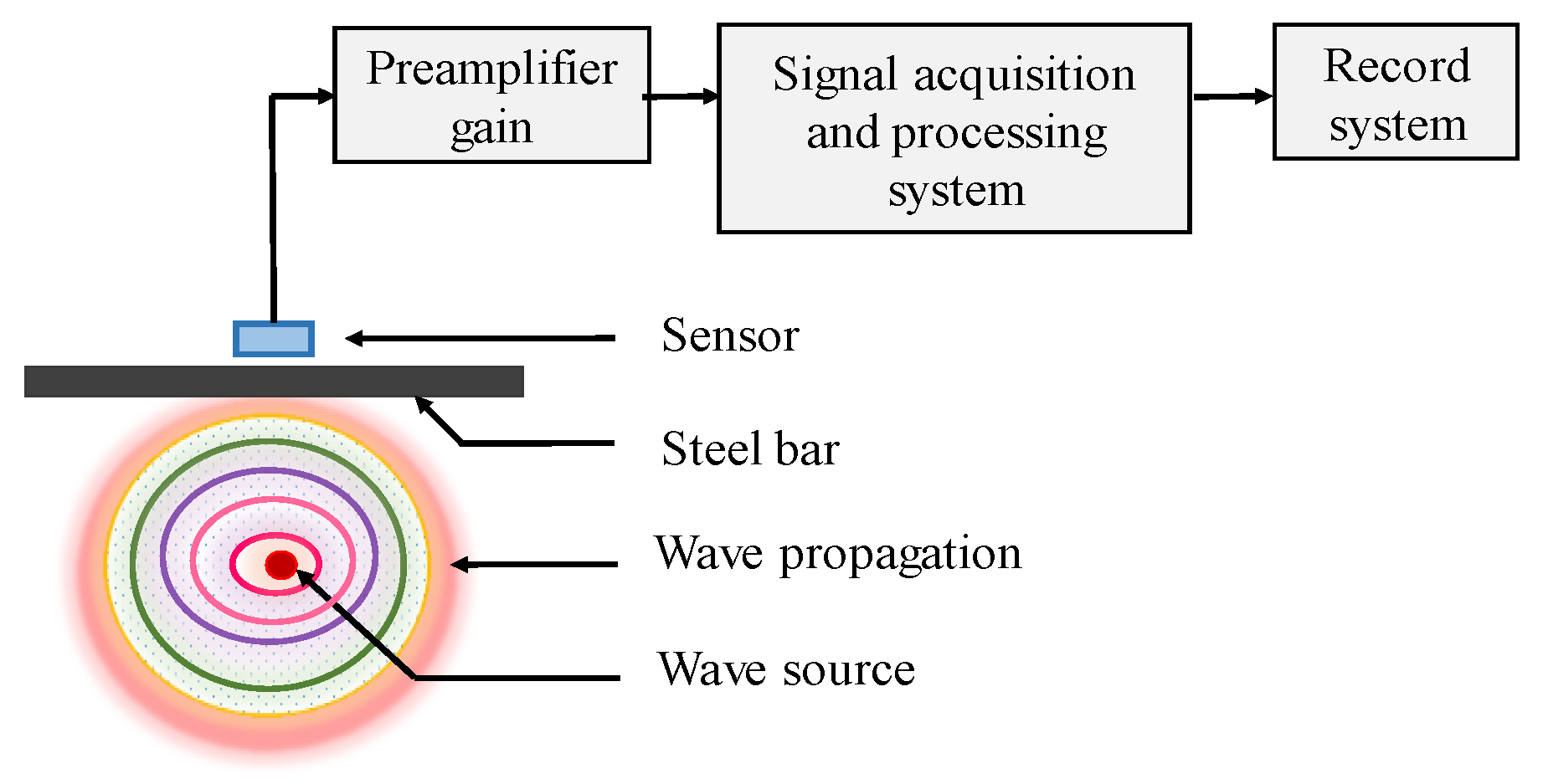

5.3. Acoustic Emission (AE)

5.4. Radiography

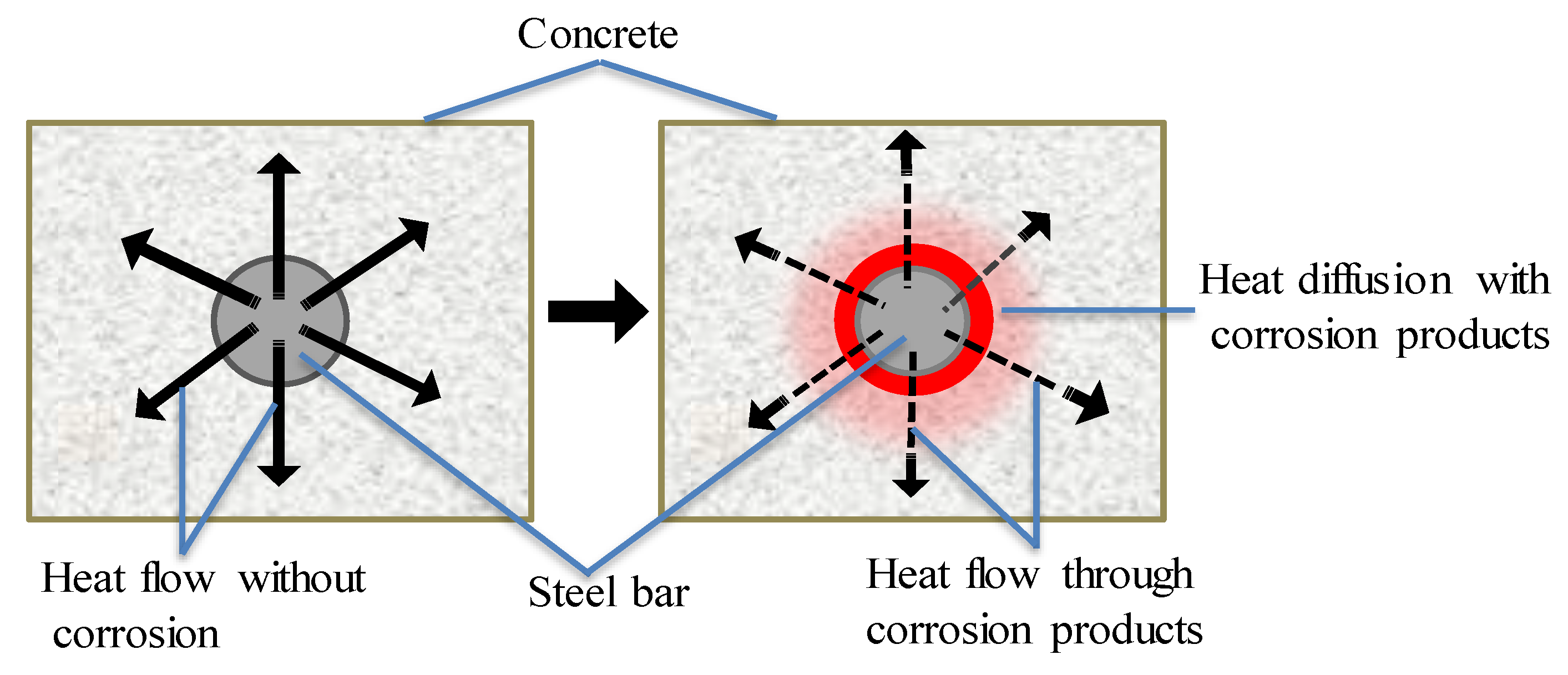

5.5. Infrared Thermograph (IT)

5.6. Fiber Optical Corrosion Sensors (FOCS)

5.6.1. Fiber Bragg Grating (FBG) Based on Strain Sensors

5.6.2. Long Period Fiber Grating (LPFG) Based on RI Sensors

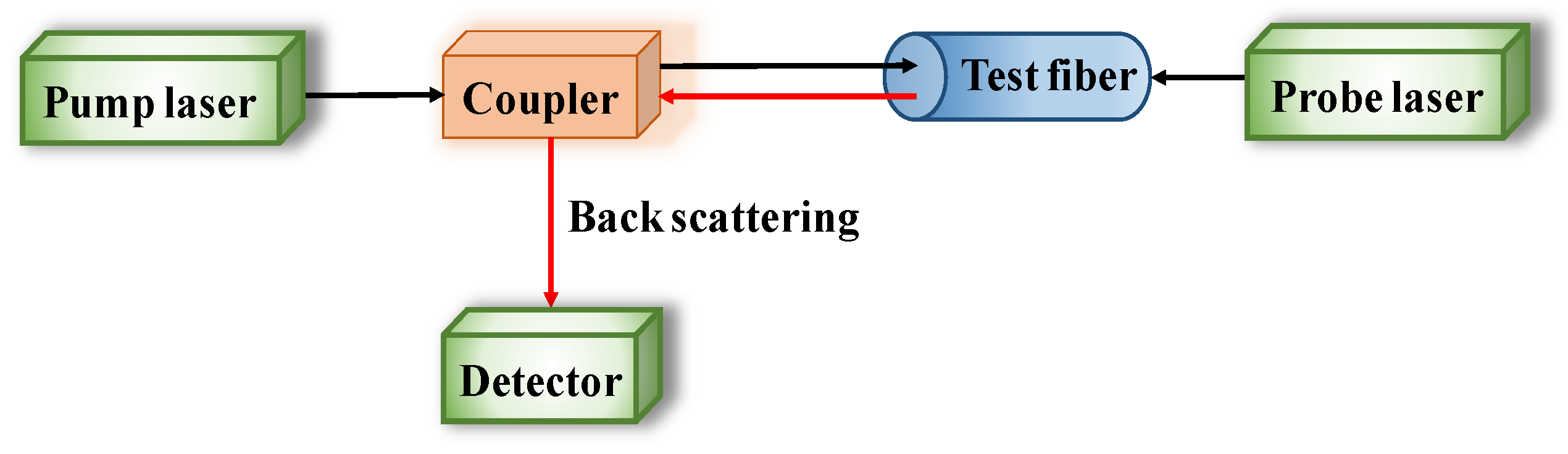

5.6.3. Brillouin Optical Time Domain Reflectometer/Analysis (BOTDR/A)

6. Electrochemical Method

6.1. Half-Cell Potential Measurements (HCP)

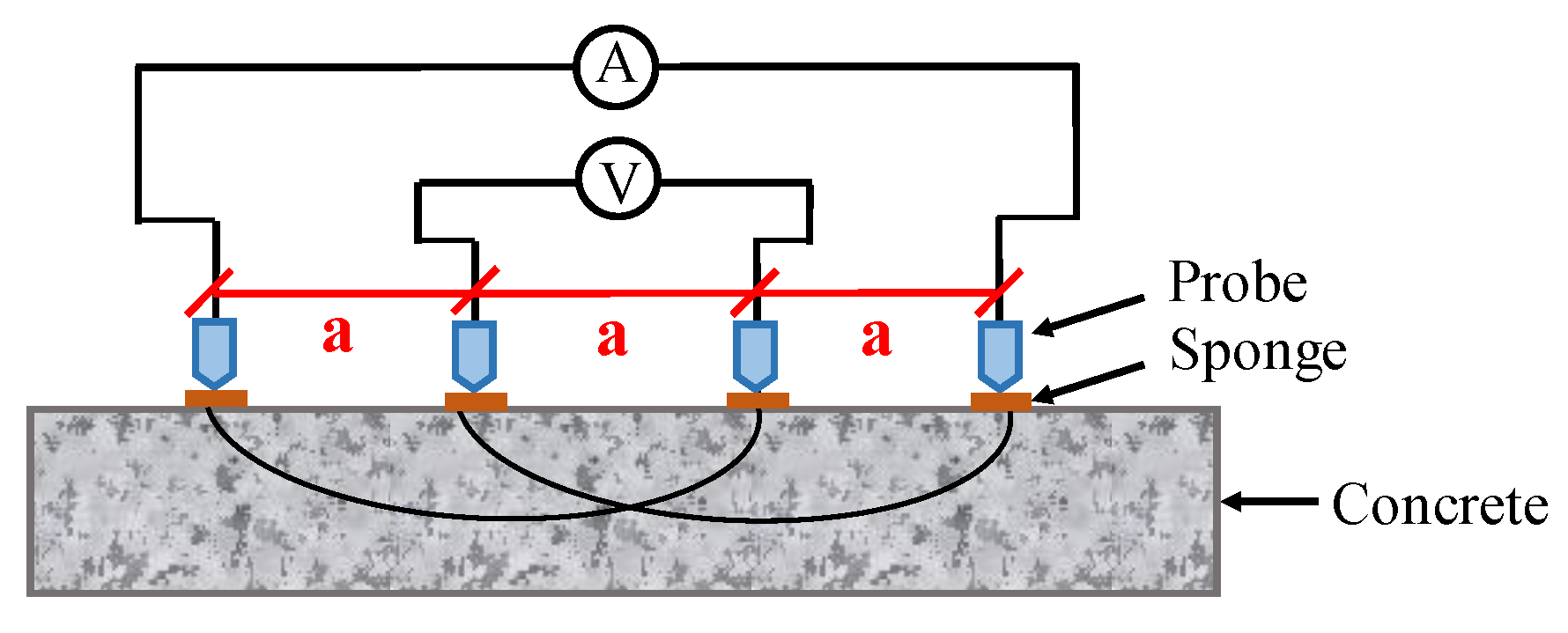

6.2. Concrete Resistivity Measurement

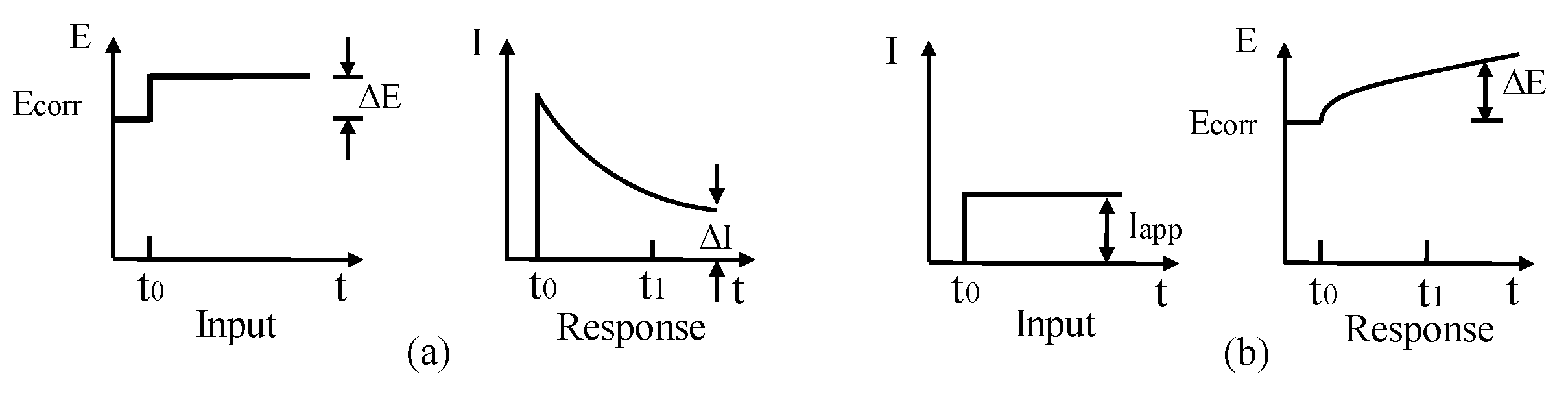

6.3. Linear Polarization Resistance (LPR) Measurement

6.4. Tafel Extrapolation (TE)

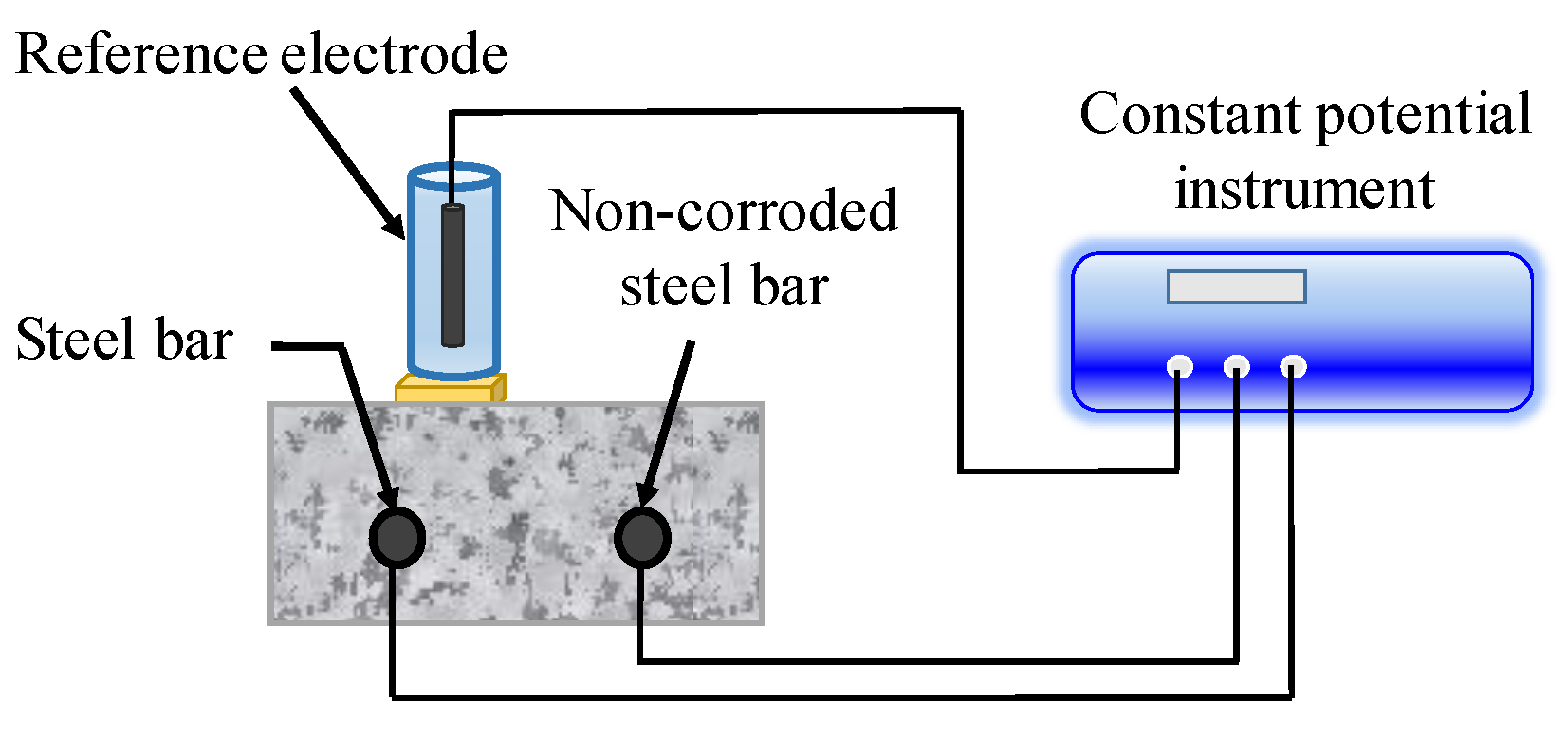

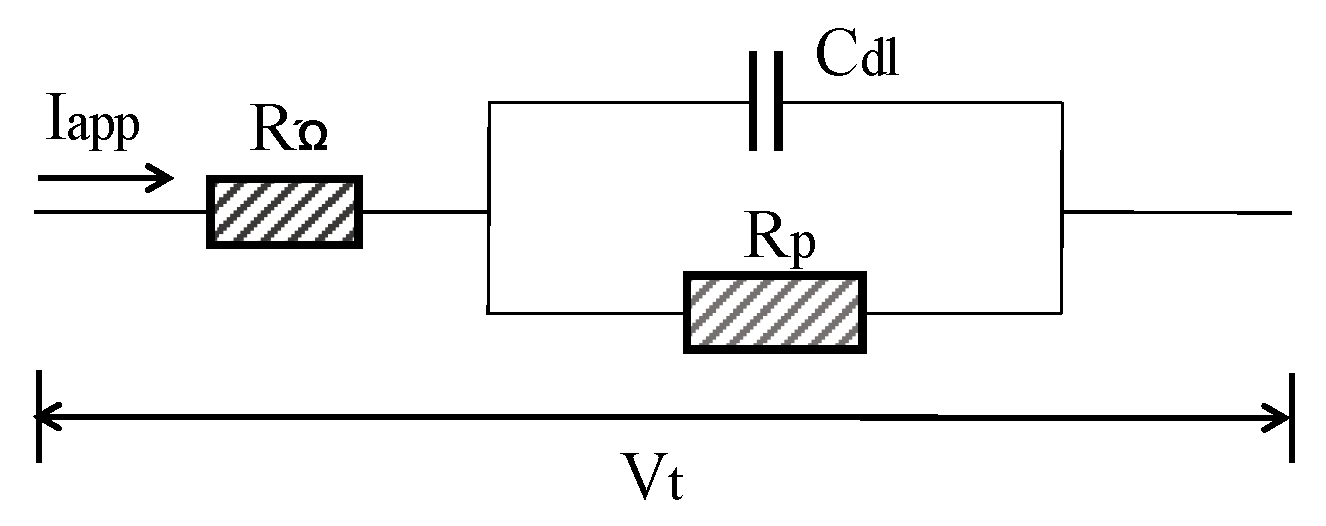

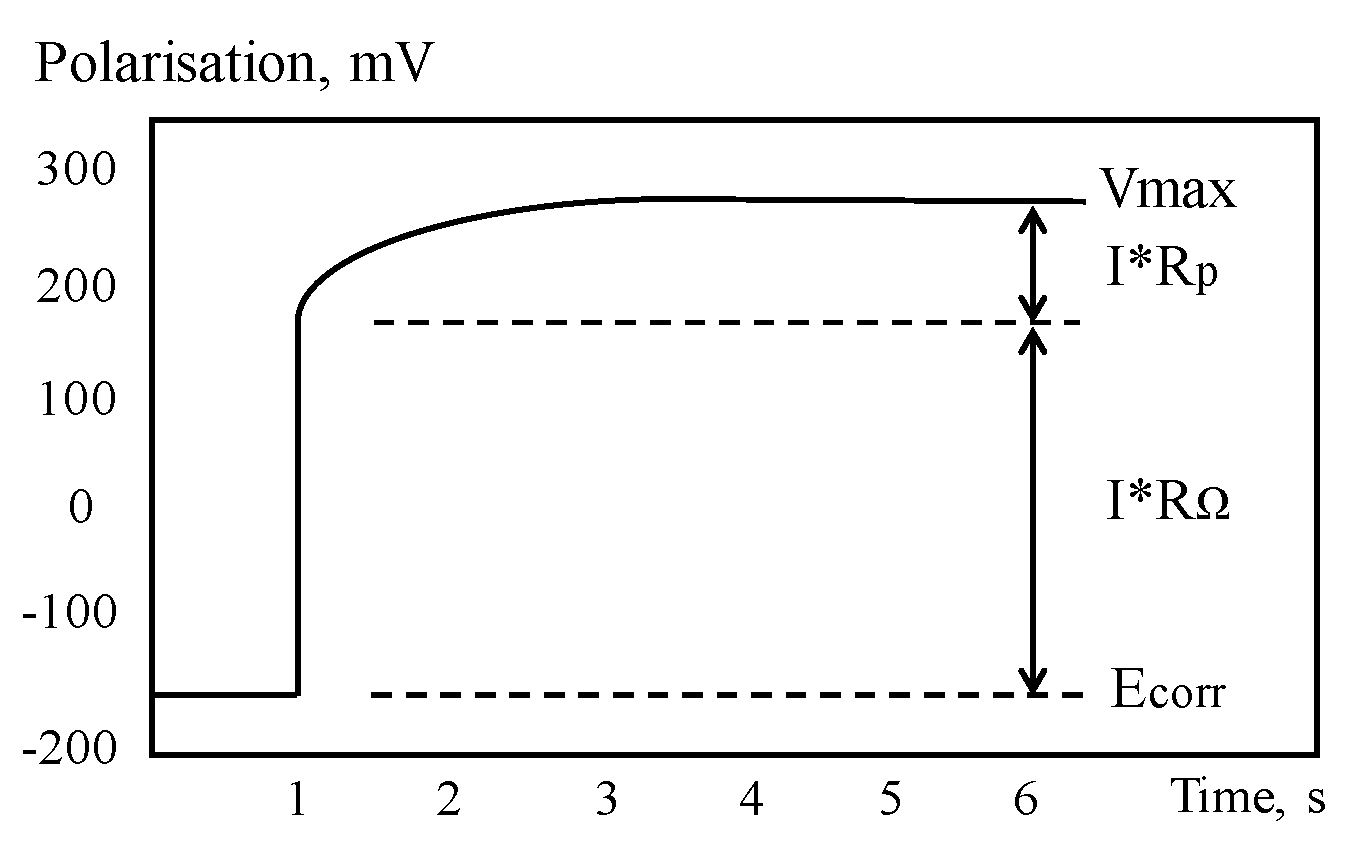

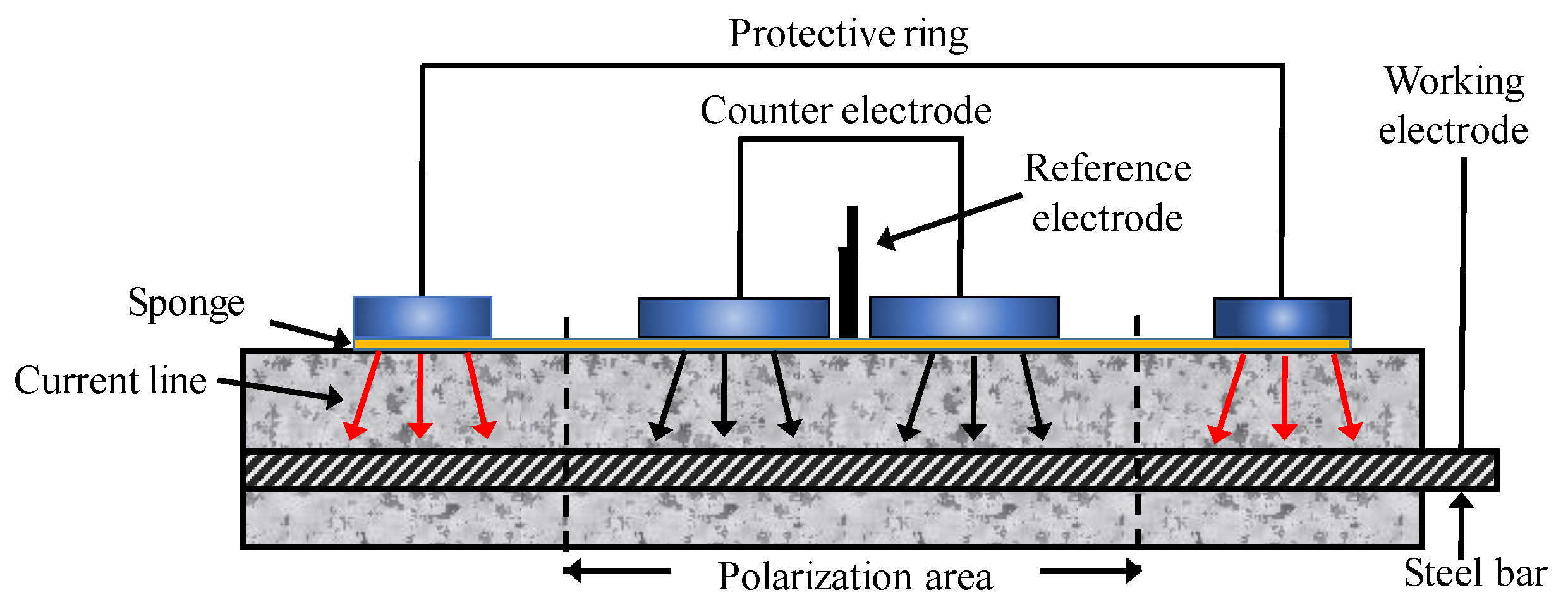

6.5. Galvanostatic Pulse Transient Method (GPT)

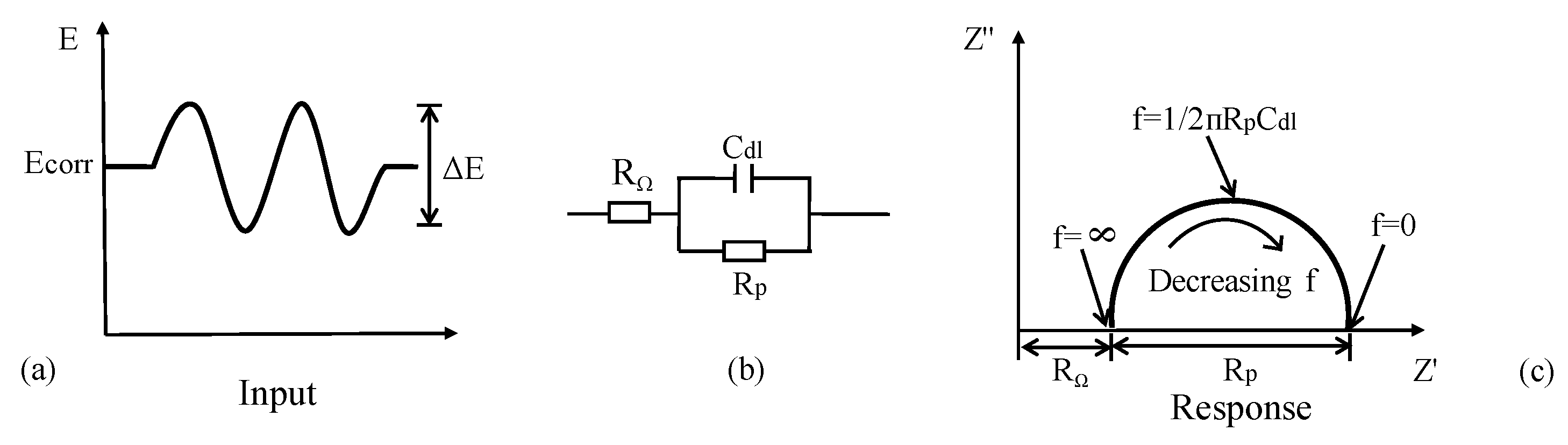

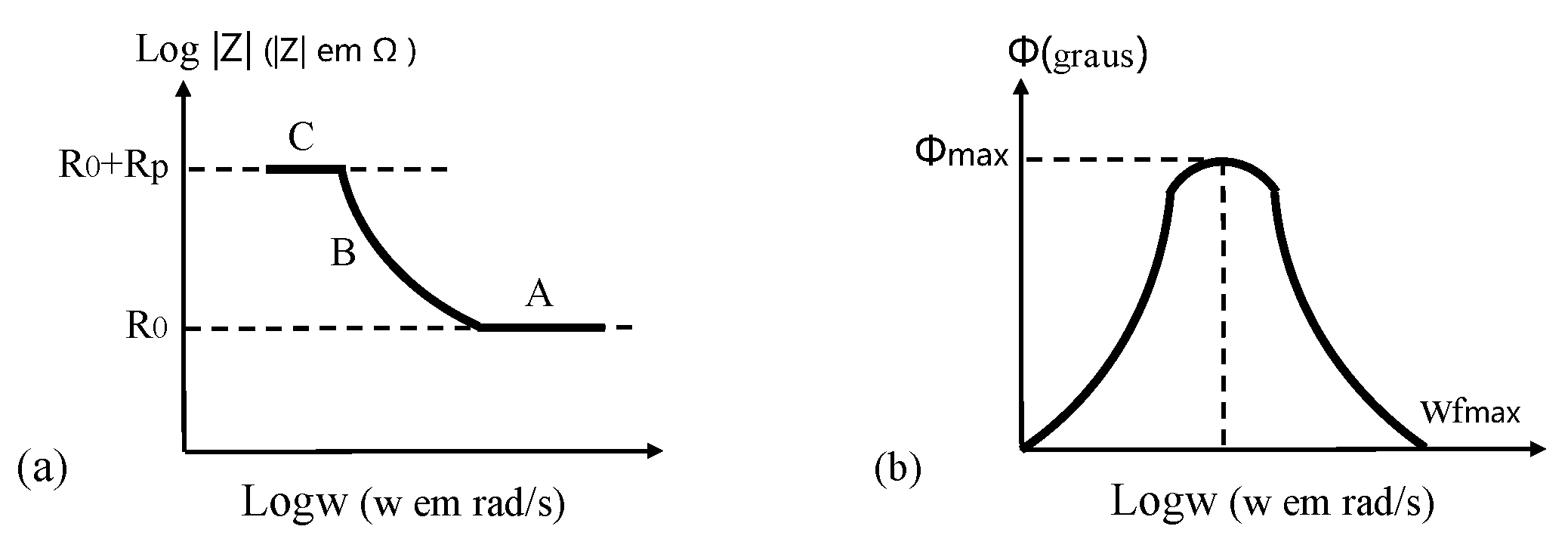

6.6. Electrochemical Impedance Spectroscopy (EIS)

6.7. Harmonic Analysis (HA)

6.8. Electrochemical Noise (EN)

7. Three Electrochemical Factors (TEF)

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviation

| CSB | steel bar embedded in concrete | CSE | copper sulfate electrode |

| RC | reinforced concrete | DC | direct current |

| CCD (icorr) | corrosion current density | AC | alternating current |

| CR () | corrosion rate | concrete resistivity | |

| Icorr | corrosion current | Rp | polarization resistance |

| t | corroding time | Cdl | double layer capacitance of RC interface |

| S | corroded surface area of CSB | RΩ | concrete resistance between reference electrode and CSB |

| D | diameter of CSB | Tafel constants of anode | |

| L | length of CSB | Tafel constants of cathode | |

| initial quality before corrosion | B | Stern–Geary constant | |

| quality after corrosion | λ | compensation coefficient | |

| ϱ | degree of corrosion | Ecorr | corrosion potential |

| molar mass of Fe | E | potential at any time | |

| V | electrons transferred number | I | the current at any time |

| F | Faraday constant | d | density of CSB |

| CS0 | initial cross-section | Iapp | applied constant-current perturbation |

| R0 | initial electrical resistance | Z | impedance in EIS |

| change in electrical resistance | i1 | first harmonic currents | |

| CF | initial circumference of ERPs | i2 | second harmonics currents |

| RCS | cross-section reduction of CSB | i3 | third harmonics currents |

| corroded layer thickness of CSB | Rn | noise resistance | |

| SHM | structure health monitoring | Φ | phase angle |

| RI | reflective index | ω | angular frequency |

| SCE | saturated calomel electrode | f | frequency |

References

- Roqueta, G.; Jofre, L.; Feng, M.Q. Analysis of the Electromagnetic Signature of Reinforced Concrete Structures for Nondestructive Evaluation of Corrosion Damage. IEEE Trans. Instrum. Meas. 2012, 61, 1090–1098. [Google Scholar] [CrossRef]

- Sathiyanarayanan, S.; Natarajan, P.; Saravanan, K. Corrosion monitoring of steel in concrete by galvanostatic pulse technique. Cem. Concr. Compos. 2006, 28, 630–637. [Google Scholar] [CrossRef]

- ASTM Committee G-1 on Corrosion of Metals. Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens; ASTM International: West Conshohocken, PA, USA, 2003; Volume 3, pp. 17–25. [Google Scholar]

- Maaddawy, T.A.E.; Soudki, K.A. Effectiveness of Impressed Current Technique to Simulate Corrosion of Steel Reinforcement in Concrete. J. Mater. Civ. Eng. 2003, 15, 41–47. [Google Scholar] [CrossRef]

- Leifer, J.; Zapp, P.E.; Mickalonis, J.I. Predictive Models for Determination of Pitting Corrosion Versus Inhibitor Concentrations and Temperature for Radioactive Sludge in Carbon Steel Waste Tanks. Corrosion 1999, 55, 31–37. [Google Scholar] [CrossRef]

- Shirazi, A.Z.; Mohammadi, Z. A hybrid intelligent model combining ANN and imperialist competitive algorithm for prediction of corrosion rate in 3C steel under seawater environment. Neural Comput. Appl. 2016, 28, 3455–3464. [Google Scholar] [CrossRef]

- Hodhod, O.A.; Ahmed, H.I. Developing an artificial neural network model to evaluate chloride diffusivity in high performance concrete. HBRC J. 2013, 9, 15–21. [Google Scholar] [CrossRef]

- Sadowski, L. Non-destructive investigation of corrosion current density in steel reinforced concrete by artificial neural networks. Arch. Civ. Mech. Eng. 2013, 13, 104–111. [Google Scholar] [CrossRef]

- Sadowski, L.; Nikoo, M. Corrosion current density prediction in reinforced concrete by imperialist competitive algorithm. Neural Comput. Appl. 2014, 25, 1627–1638. [Google Scholar] [CrossRef]

- Song, H.W.; Kwon, S.J. Evaluation of chloride penetration in high performance concrete using neural network algorithm and micro pore structure. Cem. Concr. Res. 2009, 39, 814–824. [Google Scholar] [CrossRef]

- Chen, X.Y.; Yuan, Z.M.; Zheng, Y.P. Prediction of Carbon Steel Corrosion Rate Based on an Alternating Conditional Expectation (Ace) Algorithm. Chem. Technol. Fuels Oils 2016, 51, 728–739. [Google Scholar] [CrossRef]

- Ilker, B.T.; Bog, A.R.; Hocaoglu, F.O. Modeling corrosion currents of reinforced concrete using ANN. Autom. Constr. 2009, 18, 145–152. [Google Scholar]

- Parthiban, T.; Ravi, R.; Parthiban, G.T. Neural network analysis for corrosion of steel in concrete. Corros. Sci. 2005, 47, 1625–1642. [Google Scholar] [CrossRef]

- Liu, T.; Weyers, R.W. Modeling the Dynamic Corrosion Process in Chloride Contaminated Concrete Structures. Cem. Concr. Res. 1998, 28, 365–379. [Google Scholar] [CrossRef]

- Ahmad, S.; Bhattacharjee, B. Empirical modeling of indicators of chloride induced rebar corrosion. Struct. Eng. 2000, 27, 195–207. [Google Scholar]

- Vu, K.A.T.; Stewart, M.G. Structural reliability of concrete bridges including improved chloride-induced corrosion models. Struct. Saf. 2000, 22, 313–333. [Google Scholar] [CrossRef]

- Huet, B.; L’Hostis, V.; Santarini, G. Steel corrosion in concrete: Determinist modeling of cathodic reaction as a function of water saturation degree. Corros. Sci. 2007, 49, 1918–1932. [Google Scholar] [CrossRef]

- Gulikers, J. Theoretical considerations on the supposed linear relationship between concrete resistivity and corrosion rate of steel reinforcement. Mater. Corros. 2015, 56, 393–403. [Google Scholar] [CrossRef]

- Martínez, I.; Andrade, C. Examples of reinforcement corrosion monitoring by embedded sensors in concrete structures. Cem. Concr. Comp. 2009, 31, 545–554. [Google Scholar] [CrossRef]

- Ghods, P.; Isgor, O.B.; Pour-Ghaz, M. A practical method for calculating the corrosion rate of uniformly depassivated reinforcing bars in concrete. Mater. Corros. 2015, 58, 265–272. [Google Scholar] [CrossRef]

- Ghods, P.; Isgor, O.B.; Pour-Ghaz, M. Experimental verification and application of a practical corrosion model for uniformly depassivated steel in concrete. Mater. Struct. 2008, 41, 1211–1223. [Google Scholar] [CrossRef]

- Sahmaran, M. Influence of transverse crack width on reinforcement corrosion in mortar beams. Can. J. Civ. Eng. 2008, 35, 236–245. [Google Scholar] [CrossRef]

- Miyazato, S.; Hasegawa, Y. Proposal of Corrosion Rate Analytical Model of Reinforced Concrete with Crack. Concr. Res. Technol. Jpn. Concr. Inst. 2011, 17, 31–40. [Google Scholar]

- Kranc, S.C.; SagüéS, A.A. Computation of Reinforcing Steel Corrosion Distribution in Concrete Marine Bridge Substructures. Corros. Sci. 1994, 50, 50–61. [Google Scholar] [CrossRef]

- Chang, Z.T.; Cherry, B.; Marosszeky, M. Polarisation behaviour of steel bar samples in concrete in seawater. Part 1: Experimental measurement of polarisation curves of steel in concrete. Corros. Sci. 2008, 50, 357–364. [Google Scholar] [CrossRef]

- Birbilis, N.; Cherry, B.W. Monitoring the corrosion and remediation of reinforced concrete on-site: An alternative approach. Mater. Corros. 2015, 56, 237–243. [Google Scholar] [CrossRef]

- Živica, V. Utilisation of electrical resistance method for the evaluation of the state of steel reinforcement in concrete and the rate of its corrosion. Constr. Build. Mater. 2000, 14, 351–358. [Google Scholar] [CrossRef]

- Marja-Aho, M.; Rajala, P.; Huttunen-Saarivirta, E. Copper corrosion monitoring by electrical resistance probes in anoxic groundwater environment in the presence and absence of sulfate reducing bacteria. Sens. Actuators A Phys. 2018, 274, 252–261. [Google Scholar] [CrossRef]

- Abed, K.; Panchal, P.; Gandhi, A. Evaluation of Impressed Current Cathodically Protected API 650 Tank Bottoms in the Presence of Vapor Phase Corrosion Inhibitor; NACE International: Houston, TX, USA, 2016. [Google Scholar]

- Qiao, X.F.; Mu, P.A.; Dai, S.G. Design and research of corrosion monitor instrument based on a novel coupon-type electrical resistance probe. Electr. Eng. Inf. Sci. 2016, 325–333. [Google Scholar] [CrossRef]

- Vieira, R.E.; Parsi, M.; Zahedi, P. Electrical Resistance probe measurements of solid particle erosion in multiphase annular flow. Wear 2017, 382, 15–28. [Google Scholar] [CrossRef]

- Janousek, L.; Capova, K.; Yusa, N. Multiprobe Inspection for Enhancing Sizing Ability in Eddy Current Nondestructive Testing. IEEE Trans. Magn. 2008, 44, 1618–1621. [Google Scholar] [CrossRef]

- Naasson, D.A. Identification of steel bars immersed in reinforced concrete based on experimental results of eddy current testing and artificial neural network analysis. Nondestr. Test. Eval. 2013, 28, 58–71. [Google Scholar]

- Minesawa, G.V.; Sasaki, E. Eddy current inspection of corrosion defects for concrete embedded steel members. AIP Conf. Proc. 2014, 1581, 781–786. [Google Scholar]

- Bailey, J.; Long, N.; Hunze, A.E. Current Testing with Giant Magnetoresistance (GMR) Sensors and a Pipe-Encircling Excitation for Evaluation of Corrosion under Insulation. Sensors 2017, 17, 2229. [Google Scholar] [CrossRef] [PubMed]

- Alcantara, N.P.D.; Silva, F.M.D.; Guimarães, M.T. Corrosion Assessment of Steel Bars Used in Reinforced Concrete Structures by Means of Eddy Current Testing. Sensors 2015, 16, 15–33. [Google Scholar] [CrossRef] [PubMed]

- Rubinacci, G.; Tamburrino, A.; Ventre, S. Concrete rebars inspection by eddy current testing. Int. J. Appl. Electromagn. 2007, 25, 333–339. [Google Scholar] [CrossRef]

- Suh, D.M.; Jang, K.S.; Jang, J.E. Corrosion Steel Inspection under Steel Plate Using Pulsed Eddy Current Testing. In Proceedings of the 4th International Symposium on NDT in Aerospace, Augsburg, Germany, 13–14 November 2012. [Google Scholar]

- He, Y.; Tian, G.; Zhang, H. Steel Corrosion Characterization Using Pulsed Eddy Current Systems. IEEE Sens. 2012, 12, 2113–2120. [Google Scholar] [CrossRef]

- Fricker, S.; Vogel, T. Site installation and testing of a continuous acoustic monitoring. Constr. Build. Mater. 2007, 21, 501–510. [Google Scholar] [CrossRef]

- Yuyama, S.; Yokoyama, K.; Niitani, K. Detection and evaluation of failures in high-strength tendon of prestressed concrete bridges by acoustic emission. Constr. Build. Mater. 2007, 21, 491–500. [Google Scholar] [CrossRef]

- Sagaidak, A.I.; Elizarov, S.V. Acoustic emission parameters correlated with fracture and deformation processes of concrete members. Constr. Build. Mater. 2007, 21, 477–482. [Google Scholar] [CrossRef]

- Yu, A.P.; Zhao, Y.L.; Wang, L. Experimental study on on-line monitoring of acoustic emission of corroded reinforced concrete. J. Build. Mater. 2014, 17, 291–297. [Google Scholar]

- Benedetti, M.D.; Loreto, G.; Matta, F. Acoustic Emission Historic Index and Frequency Spectrum of Reinforced Concrete under Accelerated Corrosion. J. Mater. Civ. Eng. 2014, 26, 4014059-1–4014059-8. [Google Scholar] [CrossRef]

- Loreto, G. Continuous acoustic emission monitoring of reinforced concrete under accelerated corrosion. J. Mater. Civ. Eng. 2011, 25, 1022–1029. [Google Scholar]

- Mangual, J.; Elbatanouny, M.K.; Ziehl, P. Corrosion Damage Quantification of Prestressing Strands Using Acoustic Emission. J. Mater. Civ. Eng. 2013, 25, 1326–1334. [Google Scholar] [CrossRef]

- Elbatanouny, M.K.; Mangual, J.; Ziehl, P. Early Corrosion Detection in Prestressed Concrete Girders Using Acoustic Emission. J. Mater. Civ. Eng. 2014, 26, 504–511. [Google Scholar] [CrossRef]

- Calabrese, L.; Campanella, G.; Proverbio, E. Noise removal by cluster analysis after long time AE corrosion monitoring of steel reinforcement in concrete. Constr. Build. Mater. 2012, 34, 362–371. [Google Scholar] [CrossRef]

- Qin, L.; Ren, H.; Dong, B. Development of technique capable of identifying different corrosion stages in reinforced concrete. Appl. Acoust. 2015, 94, 53–56. [Google Scholar] [CrossRef]

- Kawasaki, Y.; Wakuda, T.; Kobarai, T. Corrosion mechanisms in reinforced concrete by acoustic emission. Constr. Build. Mater. 2013, 48, 1240–1247. [Google Scholar] [CrossRef]

- Yoon, D.J.; Weiss, W.J.; Shah, S.P. Assessing Damage in Corroded Reinforced Concrete Using Acoustic Emission. J. Eng. Mech. 2016, 126, 273–283. [Google Scholar] [CrossRef]

- Li, W.; Xu, C.; Ho, S.C.M. Monitoring Concrete Deterioration Due to Reinforcement Corrosion by Integrating Acoustic Emission and FBG Strain Measurements. Sensors 2017, 17, 657. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Niccolini, G. Damage analysis of reinforced concrete buildings by the acoustic emission technique. Struct. Control. Health Monit. 2011, 18, 660–673. [Google Scholar] [CrossRef]

- Elfergani, H.A.; Pullin, R.; Holford, K.M. Damage assessment of corrosion in prestressed concrete by acoustic emission. Constr. Build. Mater. 2013, 40, 925–933. [Google Scholar] [CrossRef]

- Ohtsu, M.; Mori, K.; Kawasaki, Y. Corrosion Process and Mechanisms of Corrosion-Induced Cracks in Reinforced Concrete identified by AE Analysis. Strain 2011, 47, 179–186. [Google Scholar] [CrossRef]

- Zaki, A.; Chai, H.K.; Behnia, A. Monitoring fracture of steel corroded reinforced concrete members under flexure by acoustic emission technique. Constr. Build. Mater. 2017, 136, 609–618. [Google Scholar] [CrossRef]

- Ghahari, M.; Krouse, D.; Laycock, N. Synchrotron X-ray radiography studies of pitting corrosion of stainless steel: Extraction of pit propagation parameters. Corros. Sci. 2015, 100, 23–35. [Google Scholar] [CrossRef]

- Outirite, M.; Lagren’ee, M.; Lebrini, M. Ac impedance, Xray photoelectron spectroscopy and density functional theory studies of 3,5-bis(n-pyridyl)-1,2,4-oxadiazoles as efficient corrosion inhibitors for carbon steel surface in hydrochloric acid solution. Electrochim. Acta 2010, 55, 1670–1681. [Google Scholar] [CrossRef]

- Priyada, P.; Margret, M.; Ramar, R. Intercomparison of gamma scattering, gammatography and radiography techniques for mild steel nonuniform corrosion detection. Rev. Sci. Instrum. 2011, 82, 035115. [Google Scholar] [CrossRef] [PubMed]

- Duffó, G.; Gaillard, N.; Mariscotti, M. Application of gamma-ray radiography and gravimetric measurements after accelerated corrosion tests of steel embedded in mortar. Cem. Concr. Res. 2015, 74, 1–9. [Google Scholar] [CrossRef]

- Dong, B.; Fang, G.; Liu, Y. Monitoring reinforcement corrosion and corrosion-induced cracking by X-ray microcomputed tomography method. Cem. Concr. Res. 2017, 100, 311–321. [Google Scholar] [CrossRef]

- Jensen, T.C.; Wendt, S.E.; Gray, J.N. Feasibility Study for Detection and Quantification of Corrosion in Bridge Barrier Rails. Available online: http://publications.iowa.gov/14929/1/IA_DOT_RB11-012_InTrans_bridge_barrier_rails.pdf (accessed on 19 December 2018).

- Meighen, E.A. Characterization of steel corrosion in mortar by various electrochemical and physical techniques. Corros. Sci. 2013, 75, 47–57. [Google Scholar]

- Šavija, B.; Luković, M.; Hosseini, S.A.S. Corrosion induced cover cracking studied by X-ray computed tomography, nanoindentation, and energy dispersive X-ray spectrometry (EDS). Mater. Struct. 2015, 48, 2043–2062. [Google Scholar] [CrossRef]

- Ingham, B.; Ko, M.; Laycock, N. In situ, synchrotron X-ray diffraction study of scale formation during CO2, corrosion of carbon steel in sodium and magnesium chloride solutions. Corros. Sci. 2012, 56, 96–104. [Google Scholar] [CrossRef]

- Michel, A.; Pease, B.J.; Geiker, M.R. Monitoring reinforcement corrosion and corrosion-induced cracking using non-destructive x-ray attenuation measurements. Cem. Concr. Res. 2011, 41, 1085–1094. [Google Scholar] [CrossRef]

- Kobayashi, K.; Banthia, N. Corrosion detection in reinforced concrete using induction heating and infrared thermography. J. Civ. Struct. Health Monit. 2011, 1, 25–35. [Google Scholar] [CrossRef]

- Sato, D. Measurement technique of acquiring sodium chloride concentration by using near-infrared spectrum. Proc. JSCE Annu. Conf. 2001, 56, 844–845. [Google Scholar]

- Kato, Y. Prediction of the resistance performance of the substance movement by using thermograph. Proc. JSCE Annu. Conf. 2003, 58, 825–826. [Google Scholar]

- Showunmi, T. Finite element infrared thermography study on concrete and steel-concrete composite structures. Masters Abstr. Int. 2013, 52, 123p. [Google Scholar]

- Matovu, M.J.; Farhidzadeh, A.; Salamone, S. Damage assessment of steel-plate concrete composite walls by using infrared thermography: A preliminary study. J. Civ. Struct. Health Monit. 2016, 6, 303–313. [Google Scholar] [CrossRef]

- Xu, R.; Jiang, D.; Lu, X. Research on the Application of the Infrared Thermal Image Method in Detection of Concrete Density of Concrete-Filled Steel Tube. Appl. Mech. Mater. 2012, 166–169, 998–1001. [Google Scholar] [CrossRef]

- Laaidi, N. The numerical modeling and the infrared thermography principle applied to the analysis of corrosion defects in oil Conduits. In Proceedings of the 11th International Conference on Quantitative Infrared Thermography, Naples, Italy, 11–14 June 2012. [Google Scholar]

- Jönsson, M.; Rendahl, B.; Annergren, I. The use of infrared thermography in the corrosion science area. Mater. Corros. 2015, 61, 961–965. [Google Scholar] [CrossRef]

- Baek, S.; Xue, W.; Feng, M.Q. Nondestructive Corrosion Detection in RC Through Integrated Heat Induction and IR Thermography. J. Nondestruct. Eval. 2012, 31, 181–190. [Google Scholar] [CrossRef]

- Kwon, S.J.; Sang, S.P. Non Destructive Technique for Steel Corrosion Detection Using Heat Induction and IR Thermography. J. Korea Inst. Struct. Maint. Insp. 2012, 16, 40–48. [Google Scholar]

- Grattan, S.K.T.; Taylor, S.E.; Sun, T. Monitoring of Corrosion in Structural Reinforcing Bars: Performance Comparison Using In Situ Fiber-Optic and Electric Wire Strain Gauge Systems. IEEE Sens. 2009, 9, 1494–1501. [Google Scholar] [CrossRef]

- Majumder, M.; Gangopadhyay, T.K.; Chakraborty, A.K. Fibre Bragg gratings in structural health monitoring-Present status and applications. Sens. Actuators A Phys. 2008, 147, 150–164. [Google Scholar] [CrossRef]

- Tan, C.H.; Adikan, F.R.M.; Shee, Y.G. Non-Destructive Fiber Bragg Grating Based Sensing System: Early Corrosion Detection for Structural Health Monitoring. Sens. Actuators A Phys. 2016, 246, 123–128. [Google Scholar] [CrossRef]

- Nascimento, J.F.; Silva, M.J.; Coêlho, I.J.S. Amplified OTDR Systems for Multipoint Corrosion Monitoring. Sensors 2012, 12, 3438–3448. [Google Scholar] [CrossRef] [PubMed]

- Martins-Filho, J.F.; Fontana, E.; Guimaraes, J. Fiber-optic-based Corrosion Sensor using OTDR. In Proceedings of the 2007 IEEE SENSORS, Atlanta, GA, USA, 28–31 October 2007; pp. 1172–1174. [Google Scholar]

- Kalamkarov, A.L.; Fitzgerald, S.B.; Macdonald, D.O. The use of Fabry Perot fiber optic sensors to monitor residual strains during pultrusion of FRP composites. Compos. Part B Eng. 1999, 30, 167–175. [Google Scholar] [CrossRef]

- Ran, Z.L.; Rao, Y.J.; Liu, W.J. Laser-micromachined Fabry-Perot optical fiber tip sensor for high-resolution temperature-independent measurement of refractive index. Opt. Express 2008, 16, 2252–2263. [Google Scholar] [CrossRef]

- Marques, R.D.S.; Prado, A.R.; Antunes, P.F.D.C. Corrosion Resistant FBG-Based Quasi-Distributed Sensor for Crude Oil Tank Dynamic Temperature Profile Monitoring. Sensors 2015, 15, 30693–30703. [Google Scholar] [CrossRef]

- Cai, L.H.; Li, W.; Fang, H.F. Characterization of Fe-C Alloy Film Optical Fiber Corrosion Sensors by Fractal. Adv. Mater. Res. 2011, 239–242, 976–980. [Google Scholar] [CrossRef]

- Chen, W.; Dong, X. Modification of the wavelength-strain coefficient of FBG for the prediction of steel bar corrosion embedded in concrete. Opt. Fiber Technol. 2012, 18, 47–50. [Google Scholar] [CrossRef]

- Handawi, K.A.; Vahdati, N.; Rostron, P. Strain based FBG sensor for real-time corrosion rate monitoring in pre-stressed structures. Sens. Actuators B Chem. 2016, 236, 276–285. [Google Scholar] [CrossRef]

- Islam, M.R.; Bagherifaez, M.; Ali, M.M. Tilted Fiber Bragg Grating Sensors for Reinforcement Corrosion Measurement in Marine Concrete Structure. IEEE Trans. Instrum. Meas. 2015, 64, 3510–3516. [Google Scholar] [CrossRef]

- Gao, J.; Wu, J.; Li, J. Monitoring of corrosion in reinforced concrete structure using Bragg grating sensing. NDT E Int. 2011, 44, 202–205. [Google Scholar] [CrossRef]

- Zheng, Z.; Sun, X.; Lei, Y. Monitoring corrosion of reinforcement in concrete structures via fiber Bragg grating sensors. Front. Mech. Eng. China 2009, 4, 316–319. [Google Scholar] [CrossRef]

- Zhang, N.; Chen, W.; Zheng, X. Optical Sensor for Steel Corrosion Monitoring Based on Etched Fiber Bragg Grating Sputtered with Iron Film. IEEE Sens. J. 2015, 15, 3551–3556. [Google Scholar] [CrossRef]

- Hu, W.; Cai, H.; Yang, M. Fe–C-coated fibre Bragg grating sensor for steel corrosion monitoring. Corros. Sci. 2011, 53, 1933–1938. [Google Scholar] [CrossRef]

- James, S.W.; Tatam, R.P. Optical fibre long-period grating sensors: Characteristics and application. Meas. Sci. Technol. 2003, 14, 49–61. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, F.; Tang, Y. Mechanism and sensitivity of Fe-C coated long period fiber grating sensors for steel corrosion monitoring of RC structures. Corros. Sci. 2017, 127, 70–81. [Google Scholar] [CrossRef]

- Tang, F.; Chen, Y.; Li, Z. Application of Fe-C coated LPFG sensor for early stage corrosion monitoring of steel bar in RC structures. Constr. Build. Mater. 2018, 175, 14–25. [Google Scholar] [CrossRef]

- Coelho, L.; Santos, J.L.; Jorge, P.A.S. Optical fiber sensor for early warning of corrosion of metal structures. In Proceedings of the OCEANS 2017, Aberdeen, UK, 19–22 June 2017. [Google Scholar]

- Huang, Y.; Tang, F.; Liang, X. Steel bar corrosion monitoring with long-period fiber grating sensors coated with nano iron/silica particles and polyurethane. Struct. Health Monit. 2015, 14, 178–189. [Google Scholar] [CrossRef]

- Sun, Y.; Shi, B.; Chen, S.E. Feasibility study on corrosion monitoring of a concrete column with central rebar using BOTDR. Smart Struct. Syst. 2014, 13, 41–53. [Google Scholar] [CrossRef]

- Lv, H.; Zhao, X.; Zhan, Y. Damage evaluation of concrete based on Brillouin corrosion expansion sensor. Constr. Build. Mater. 2017, 143, 387–394. [Google Scholar] [CrossRef]

- Zhao, X.; Gong, P.; Qiao, G. Brillouin Corrosion Expansion Sensors for Steel Reinforced Concrete Structures Using a Fiber Optic Coil Winding Method. Sensors 2011, 11, 10798–10819. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.; Chen, J.; Cui, L. Monitoring the Corrosion Process of Reinforced Concrete Using BOTDA and FBG Sensors. Sensors 2015, 15, 8866–8883. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Zhao, X.; Kong, X. The Performance Analysis of Distributed Brillouin Corrosion Sensors for Steel Reinforced Concrete Structures. Sensors 2014, 14, 431–442. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.H.; Jin, W.L.; He, Y. A novel method of embedding distributed optical fiber sensors for structural health monitoring. Smart Mater. Struct. 2011, 20, 125018. [Google Scholar] [CrossRef]

- Song, H.W.; Saraswathy, V. Corrosion Monitoring of Reinforced Concrete Structures—A Review. Int. J. Electrochem. Sci. 2007, 2, 1–28. [Google Scholar]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Monitoring corrosion of steel bars in reinforced concrete structures. Sci. World J. 2014, 957904. [Google Scholar] [CrossRef]

- ASTM C876-01. Standard Test Method for Half-Cell Potentials of Uncoated Reinforcing Steel in Concrete; ASTM: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Lopez-Calvo, H.Z.; Montes-García, P.; Jiménez-Quero, V.G. Influence of crack width, cover depth and concrete quality on corrosion of steel in HPC containing corrosion inhibiting admixtures and fly ash. Cem. Concr. Compos. 2018, 88, 200–210. [Google Scholar] [CrossRef]

- Schiegg, Y.; Büchler, M.; Brem, M. Potential mapping technique for the detection of corrosion in reinforced concrete structures: Investigation of parameters influencing the measurement and determination of the reliability of the method. Mater. Corros. 2015, 60, 79–86. [Google Scholar] [CrossRef]

- Pour-Ghaz, M.; Isgor, O.B.; Ghods, P. Quantitative Interpretation of Half-Cell Potential Measurements in Concrete Structures. J. Mater. Civ. Eng. 2009, 21, 467–475. [Google Scholar] [CrossRef]

- Elsener, B.; Andrade, C.; Gulikers, J. Half-cell potential measurements—Potential mapping on reinforced concrete structures. Mater. Struct. 2003, 36, 461–471. [Google Scholar] [CrossRef]

- Duong, V.B.; Sahamitmongkol, R.; Tangtermsirikul, S. Effect of leaching on carbonation resistance and steel corrosion of cement-based materials. Constr. Build. Mater. 2013, 40, 1066–1075. [Google Scholar] [CrossRef]

- Jin, M. Research on the Influence of Distance Between the Improved Ag/AgCl RE and the steel on the Corrosion Evaluation in Concrete. Int. J. Electrochem. Sci. 2016, 11, 7890–7908. [Google Scholar] [CrossRef]

- Hope, B.B.; Ip, A.K. Corrosion and electrical impedance in concrete. Cem. Concr. Res. 1985, 15, 525–534. [Google Scholar] [CrossRef]

- Enevoldsen, J.N.; Hansson, C.M.; Hope, B.B. The influence of internal relative humidity on the rate of corrosion of steel embedded in concrete and mortar. Cem. Concr. Res. 1994, 24, 1373–1382. [Google Scholar] [CrossRef]

- Glass, G.K.; Page, C.L.; Short, N.R. Factors affecting the corrosion rate of steel in carbonated mortars. Corros. Sci. 1991, 32, 1283–1294. [Google Scholar] [CrossRef]

- Osterminski, K.; Schießl, P.; Volkwein, A. Modelling reinforcement corrosion-usability of a factorial approach for modelling resistivity of concrete. Mater. Corros. 2006, 57, 926–931. [Google Scholar] [CrossRef]

- Almutlaq, F.M. The influence of EAF dust on resistivity of concrete and corrosion of steel bars embedded in concrete. Adv. Concr. Constr. 2014, 2, 163–176. [Google Scholar] [CrossRef]

- Polder, R.B. Test methods for onsite measurement of resistivity of concrete-a RILEM TC-154 technical recommendation. Constr. Build. Mater. 2001, 15, 125–131. [Google Scholar] [CrossRef]

- Angst, U.M.; Elsener, B. On the Applicability of the Wenner Method for Resistivity Measurements of Concrete. ACI Mater. J. 2013, 111, 661–671. [Google Scholar] [CrossRef]

- Sadowski, L. Methodology for assessing the probability of corrosion in concrete structures on the basis of half-cell potential and concrete resistivity measurements. Sci. World J. 2013, 2, 714501. [Google Scholar] [CrossRef] [PubMed]

- Salehi, M.; Ghods, P.; Isgor, O.B. Numerical investigation of the role of embedded reinforcement mesh on electrical resistivity measurements of concrete using the Wenner probe technique. Mater. Struct. 2016, 49, 301–316. [Google Scholar] [CrossRef]

- Yu, B.; Liu, J.; Chen, Z. Probabilistic evaluation method for corrosion risk of steel reinforcement based on concrete resistivity. Constr. Build. Mater. 2017, 138, 101–113. [Google Scholar] [CrossRef]

- Huang, Z.H.; Yu, B.; Yang, L.F. Influences of Concrete Resistivity on Corrosion Rate of Steel Bar in Concrete. Appl. Mech. Mater. 2013, 438–439, 349–352. [Google Scholar] [CrossRef]

- Presuelmoreno, F.; Suares, A.; Liu, Y. Characterization of New and Old Concrete Structures Using Surface Resistivity Measurements. Available online: http://www.fdot.gov/research/completed_proj/summary_smo/fdot_bd546-08_rpt.pdf (accessed on 19 December 2018).

- Lim, Y.C.; Noguchi, T.; Cho, C.G. A quantitative analysis of the geometric effects of reinforcement in concrete resistivity measurement above reinforcement. Constr. Build. Mater. 2015, 83, 189–193. [Google Scholar] [CrossRef]

- Castillo, F.B.; Aperador, W.; Roa-Rodríguez, G. Remote Measurement of Linear Polarization Resistance in Concrete Structures. MRS Online Proc. Libr. Arch. 2016, 1815. [Google Scholar] [CrossRef]

- Gowers, K.R.; Millard, S.G. Electrochemical techniques for corrosion assessment of reinforced concrete structures. Proc. Inst. Civ. Eng. Struct. B 1999, 134, 129–137. [Google Scholar] [CrossRef]

- Carino, N.J. Nondestructive Techniques to Investigate Corrosion Status in Concrete Structures. J. Perform. Constr. Facil. 1999, 13, 96–106. [Google Scholar] [CrossRef]

- Millard, S.G.; Law, D.; Bungey, J.H. Environmental influences on linear polarization corrosion rate measurement in reinforced concrete. NDT E Int. 2001, 34, 409–417. [Google Scholar] [CrossRef]

- FeliÚ, S.; GonzÁ, J.A. Electrochemical Methods for On-Site Determinations of Corrosion Rates of Rebars. ASTM Int. 1996, 1276, 12. [Google Scholar] [CrossRef]

- Dong, Z.; Luo, Y.; Yi, Y. Smart of guard ring electrode technique for online monitoring of corrosion of reinforced concrete. Corros. Sci. Prot. Technol. 2009, 21, 247–249. [Google Scholar]

- Xu, J.X.; Cao, Y.L. Error Estimation of Linear Polarization Resistance Measurement Caused by IR Drop for Reinforcement Corrosion in Concrete. Mater. Sci. Forum 2016, 866, 14–19. [Google Scholar] [CrossRef]

- Alghamdi, S.A.; Ahmad, S. Service life prediction of RC structures based on correlation between electrochemical and gravimetric reinforcement corrosion rates. Cem. Concr. Compos. 2014, 47, 64–68. [Google Scholar] [CrossRef]

- Faritov, A.T.; Rozhdestvenskii, Y.G.; Yamshchikova, S.A. Improvement of the linear polarization resistance method for testing steel corrosion inhibitors. Russ. Metall. 2016, 11, 1035–1041. [Google Scholar] [CrossRef]

- Rovshan, H.; Selen, B.; Semra, B. Experimental and theoretical calculations on corrosion inhibition of steel in 1 M HSO by crown type polyethers. Corros. Sci. 2010, 52, 984–990. [Google Scholar]

- Abd El-Maksoud, S.A. Electrochemical studies on the effect of pyrazolo-containing compounds on the corrosion of carbon steel in 1 M sulphuric acid. Mater. Corros. 2015, 54, 106–112. [Google Scholar] [CrossRef]

- Amin, M.A.; Mersal, G.A.M.; Mohsen, Q. Monitoring corrosion and corrosion control of low alloy ASTM A213 grade T22 boiler steel in HCl solutions. Arab. J. Chem. 2011, 4, 223–229. [Google Scholar] [CrossRef]

- Glass, G.K.; Page, C.L.; Short, N.R. An investigation of galvanostatic transient methods used to monitor the corrosion rate of steel in concrete. Corros. Sci. 1993, 35, 1585–1592. [Google Scholar] [CrossRef]

- So, H.S.; Millard, S.G. Assessment of Corrosion Rate of Reinforcing Steel in Concrete Using Galvanostatic Pulse Transient Technique. Int. J. Concr. Struct. Mater. 2007, 1, 31–36. [Google Scholar]

- Birbilis, N.; Nairn, K.M.; Forsyth, M. Transient response analysis of steel in concrete. Corros. Sci. 2003, 45, 1895–1902. [Google Scholar] [CrossRef]

- Dou, Y.T.; Hao, B.H.; Meng, B. The Study to the Corrosion of Reinforcing Steel in Concrete by Using Galvanostatic Pulse Technique. Appl. Mech. Mater. 2014, 4, 501–504. [Google Scholar] [CrossRef]

- Vedalakshmi, R.; Balamurugan, L.; Saraswathy, V. Reliability of Galvanostatic Pulse Technique in assessing the corrosion rate of rebar in concrete structures: Laboratory vs. field studies. KSCE J. Civ. Eng. 2010, 146, 867–877. [Google Scholar] [CrossRef]

- Abbas, Y.; Nutma, J.S.; Olthuis, W. Corrosion Monitoring of Reinforcement Steel Using Galvanostatically Induced Potential Transients. IEEE Sens. 2016, 16, 693–698. [Google Scholar] [CrossRef]

- Xu, Y.Y.; Lin, B.L. Corrosion Behavior of HRB400 Reinforcing Steel Based on Electrochemical Impedance Spectroscopy. Appl. Mech. Mater. 2012, 105, 1797–1800. [Google Scholar] [CrossRef]

- Ko, Y.; Singh, I.B.; Park, S.M. A Novel Method for Corrosion Reaction Analysis by Fourier Transform Electrochemical Impedance Spectroscopy: Corrosion of 9Cr-1 Mo Ferritic Steel in 0.050 M H2SO4. Electroanaly 2013, 25, 1035–1043. [Google Scholar] [CrossRef]

- Ribeiro, D.V.; Souza, C.A.C.; Abrantes, J.C.C. Use of Electrochemical Impedance Spectroscopy (EIS) to monitoring the corrosion of reinforced concrete. Rev. Ibracon Estrut. Mater. 2015, 8, 529–546. [Google Scholar] [CrossRef]

- Lopes, I.M.F.; Loureiro, C.R.O.; Junqueira, R.M.R. Corrosion monitoring of galvanized steel in soil extract solutions by electrochemical impedance spectroscopy. Mater. Werkst. 2014, 45, 619–627. [Google Scholar] [CrossRef]

- Wei, J.; Fu, X.X.; Dong, J.H. Corrosion Evolution of Reinforcing Steel in Concrete under Dry/Wet Cyclic Conditions Contaminated with Chloride. J. Mater. Sci. Technol. 2012, 28, 905–912. [Google Scholar] [CrossRef]

- Lebrini, M.; Traisnel, M.; Gengembre, L. Electrochemical impedance spectroscopy and X-ray photoelectron spectroscopy study of the corrosion behaviour of galvanized steel and electroplating steel. Appl. Surf. Sci. 2011, 257, 3383–3387. [Google Scholar] [CrossRef]

- Dong, B.; Wang, Y.; Ding, W. Electrochemical impedance study on steel corrosion in the simulated concrete system with a novel self-healing microcapsule. Constr. Build. Mater. 2014, 56, 1–6. [Google Scholar] [CrossRef]

- Montemor, M.F.; Simões, A.M.P.; Ferreira, M.G.S. Chloride-induced corrosion on reinforcing steel: From the fundamentals to the monitoring techniques. Cem. Concr. Compos. 2003, 25, 491–502. [Google Scholar] [CrossRef]

- Shi, J.; Sun, W.; Ming, J. Characterization of corrosion behaviors of steel in concrete by time and frequency domain electrochemical methods. Procedia Eng. 2012, 27, 412–422. [Google Scholar] [CrossRef]

- Jankowski, J.; Harmonic, S. A Novel Electrochemical Method for Corrosion Rate Monitoring. J. Electrochem. Soc. 2003, 150, B181–B191. [Google Scholar] [CrossRef]

- Gill, J.S.; Callow, L.M.; Scantlebury, J.D. Corrosion Measurements Derived from Small Perturbation Non-Linearity—Part 1: Harmonic Analysis. Corrosion 1983, 39, 61–66. [Google Scholar] [CrossRef]

- Łukasz, B.; Darowicki, K. Determination of Local Corrosion Current from Individual Harmonic Components. J. Electrochem. Soc. 2017, 164, C796–C800. [Google Scholar]

- SathyaNarayanan, S.; Balakrishnan, K. Critique of harmonic analysis for corrosion rate measurements Brit. Corros. J. 1994, 29, 152–155. [Google Scholar] [CrossRef]

- Vedalakshmi, R.; Manoharan, S.; Song, H.W. Application of harmonic analysis in measuring the corrosion rate of rebar in concrete. Corros. Sci. 2009, 51, 2777–2789. [Google Scholar] [CrossRef]

- Lawson, K.; Scantlebury, J.D. The use of harmonic analysis to monitor steel rebar corrosion in concrete. Mater. Sci. 1989, 44–45, 387–392. [Google Scholar] [CrossRef]

- Rios, E.C.; Zimer, A.M.; Pereira, E.C. Analysis of AISI 1020 steel corrosion in seawater by coupling electrochemical noise and optical microscopy. Electrochim. Acta 2014, 124, 211–217. [Google Scholar] [CrossRef]

- Wu, P.Q.; Quan, Z.L.; Celis, J.P. On-line corrosion and corrosion-wear monitoring using a modified electrochemical noise technique. Mater. Corros. 2015, 56, 379–383. [Google Scholar] [CrossRef]

- Rios, E.C.; Zimer, A.M.; Mendes, P.C.D. Corrosion of AISI 1020 steel in crude oil studied by the electrochemical noise measurements. Fuel 2015, 150, 325–333. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, W. Electrochemical noise analysis of pitting corrosion of J55 steel in NaCl + NaHCO3 electrolytes. Surf. Interface Anal. 2011, 43, 1018–1021. [Google Scholar] [CrossRef]

- Moshrefi, R.; Mahjani, M.G.; Ehsani, A. A study of the galvanic corrosion of titanium/L 316 stainless steel in artificial seawater using electrochemical noise (EN) measurements and electrochemical impedance spectroscopy (EIS). Anti-Corros. Method Mater. 2011, 58, 250–257. [Google Scholar] [CrossRef]

- Mehdipour, M.; Ramezanzadeh, B.; Arman, S.Y. Electrochemical noise investigation of Aloe plant extract as green inhibitor on the corrosion of stainless steel in 1 M H2SO4. J. Ind. Eng. Chem. 2015, 21, 318–327. [Google Scholar] [CrossRef]

- Nagiub, A.M. Comparative Electrochemical Noise Study of the Corrosion of Different Alloys Exposed to Chloride Media. Engineering 2014, 6, 1007–1016. [Google Scholar] [CrossRef]

- Tan, Y. Experimental methods designed for measuring corrosion in highlyresistive and inhomo-geneous media. Corros. Sci. 2011, 53, 1145–1155. [Google Scholar] [CrossRef]

- Hardon, R.G.; Lambert, P.; Page, C.L. Relationship between electrochemical noise and corrosion rate of steel in salt contaminated concrete. Br. Corros. J. 2013, 23, 225–228. [Google Scholar] [CrossRef]

- Yang, Z.; Jiquan, H.E.; Chenhua, L.I. Corrosion Severity Assessment of Reinforcing Steel in Concrete by Using Three Electrochemical Factors. J. Univ. Sci. Technol. Beijing 2003, 25, 193–194. [Google Scholar]

| Model Classification | Characteristics | |

|---|---|---|

| Empirical model [14,15] | 1) Their model-building by regression analysis based on experimental and field data; 2) Easy operation, but limited application. | |

| Reaction-control model | Oxygen diffusion [16,17] | 1) Its theoretical principle mainly considers two important factors controlling corrosion reaction; 2) The corrosion analysis without considering of electrochemistry principles; 3) The application of important parameters affecting corrosion propagation in model-building process, such as external loads and cracks [22,23]. |

| Resistivity [18,19] | ||

| Coupling of oxygen and resistivity [20,21] | ||

| Electrochemical model | Based on Butler–Volmer dynamics [24,25] | 1) Based on corrosion reaction dynamics, the relationship between current density of two electrodes and other electrochemical parameters is well established; 2) The requirement of complex corrosion electrochemistry theory makes it difficult to popularize in practical engineering. |

| Model based on other theories [26] | ||

| Methods | Visual Inspection | Empirical Analysis | ERP | ECT | AE | |

| Non-perturbing | No | No | Yes | Yes | Yes | |

| Sensitivity | Low | Low | Medium | Medium | Medium | |

| Measurement speed | Slow | Slow | Fast | Medium | Medium | |

| Applicability | Both (field and experiment) | Experiment | Both | Experiment | Both | |

| Obtained information | Qualitative | Qualitative (based on empirical data) | Quantitative | Semi-quantitative | Qualitative | |

| Measurement parameter or data type | Average CR | Predicted CR | Mass loss of CSB | Corrosion probability | Corrosion probability | |

| Types of corrosion assessed | General and local corrosion | General corrosion | General corrosion | General and local corrosion | Early stages of corrosion and different crack types | |

| Data interpretation | Simple, but superficial | Simple, but inaccurate | Simple and accurate | Visual and accurate | Relatively inaccurate | |

| Advanced instruments or special requirements | Convenient instrument and experience needed | Convenient instrument and experience needed | Convenient instrument, easy and safe operation | Convenient instrument, easy and safe operation | Convenient instrument, easy and safe operation | |

| Methods | Radiography | IT | FOCS | HCP | CRM | |

| Non-perturbing | Yes | Yes | Yes | Yes | Yes | |

| Sensitivity | Low | Medium | High | Medium | Medium | |

| Measurement speed | Slow | Medium | Fast | Fast | Fast | |

| Applicability | Experiment | Experiment | Both | Both | Both | |

| Obtained information | Qualitative | Qualitative | Quantitative | Qualitative | Qualitative | |

| Measurement parameter or data type | Images and ray value | Corrosion probability | CR | Corrosion probability | Corrosion probability | |

| Types of corrosion assessed | General and local corrosion | General and local corrosion | General corrosion | General corrosion | General corrosion | |

| Difficulty level of data interpretation | Visual, but superficial | Visual and intuitive | Simple and accurate | Simple and intuitive | Simple, but relative inaccurate | |

| Advanced instruments or special requirements | Bulky and costly equipment, highly technical and hazardous | Convenient instrument, easy and safe operation | Convenient instrument, easy and safe operation | Convenient instrument, easy and safe operation | Convenient instrument, easy and safe operation | |

| Methods | LPR | TE | GPT | EIS | HA | EN |

| Non-perturbing | No | No | No | No | No | Yes |

| Sensitivity | High | High | High | High | High | High |

| Measurement speed | Fast | Fast | Fast | Medium | Medium | Medium |

| Applicability | Both | Experiment | Both | Experiment | Experiment | Experiment |

| Obtained information | Quantitative | Quantitative | Quantitative | Quantitative | Quantitative | Quantitative |

| Measurement parameter or data type | CR | CR | CR | CR and corrosion mechanism | CR | CR |

| Types of corrosion assessed | General and galvanic corrosion. | General and local corrosion | Active/passive corrosion | General corrosion | General corrosion | General, local and pitting corrosion |

| Difficulty level of data interpretation | Relatively difficult (IR drop) | Simple and accurate | Simple and accurate | Relatively difficult (Equivalent circuits) | Simple and accurate | Difficult (sophisticated mathematics) |

| Advanced instruments or special requirements | Convenient instrument, easy and safe operation | Convenient instrument, easy and safe operation | Convenient instrument, easy and safe operation | Costly equipment, easy and safe operation | Convenient instrument, easy and safe operation | Convenient instrument, easy and safe operation |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, D.; Li, Y.; Li, J.; Lim, K.-S.; Nazal, N.A.M.; Ahmad, H. A Recent Progress of Steel Bar Corrosion Diagnostic Techniques in RC Structures. Sensors 2019, 19, 34. https://doi.org/10.3390/s19010034

Luo D, Li Y, Li J, Lim K-S, Nazal NAM, Ahmad H. A Recent Progress of Steel Bar Corrosion Diagnostic Techniques in RC Structures. Sensors. 2019; 19(1):34. https://doi.org/10.3390/s19010034

Chicago/Turabian StyleLuo, Dong, Yuanyuan Li, Junnan Li, Kok-Sing Lim, Nurul Asha Mohd Nazal, and Harith Ahmad. 2019. "A Recent Progress of Steel Bar Corrosion Diagnostic Techniques in RC Structures" Sensors 19, no. 1: 34. https://doi.org/10.3390/s19010034

APA StyleLuo, D., Li, Y., Li, J., Lim, K.-S., Nazal, N. A. M., & Ahmad, H. (2019). A Recent Progress of Steel Bar Corrosion Diagnostic Techniques in RC Structures. Sensors, 19(1), 34. https://doi.org/10.3390/s19010034