Mechanism and Characteristics of Humidity Sensing with Polyvinyl Alcohol-Coated Fiber Surface Plasmon Resonance Sensor

Abstract

1. Introduction

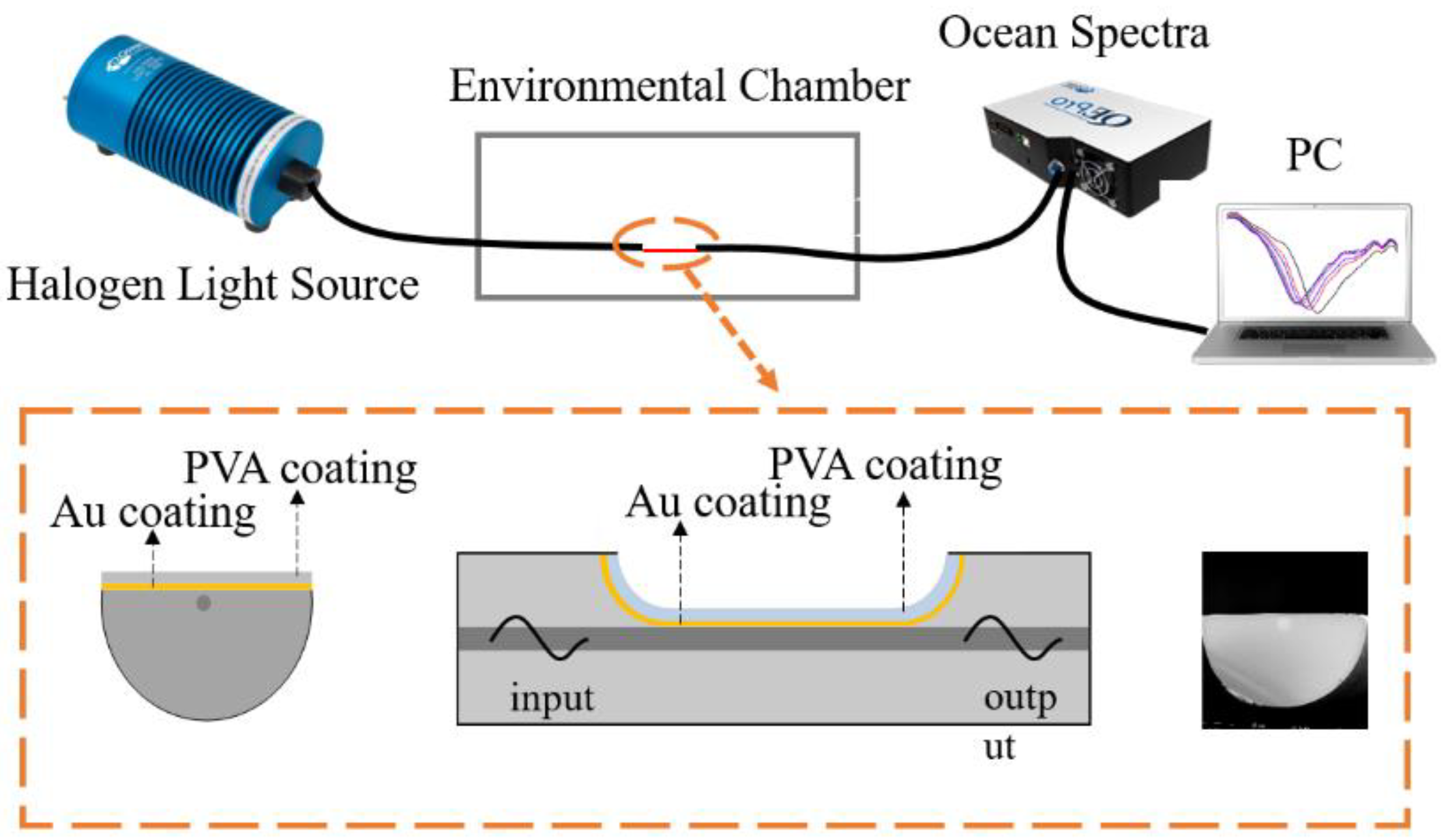

2. Materials and Methods

2.1. SPR Sensor Fabrication

2.2. Polyvinyl Alcohol Coating

2.3. Experimental Setup

3. Results and Discussion

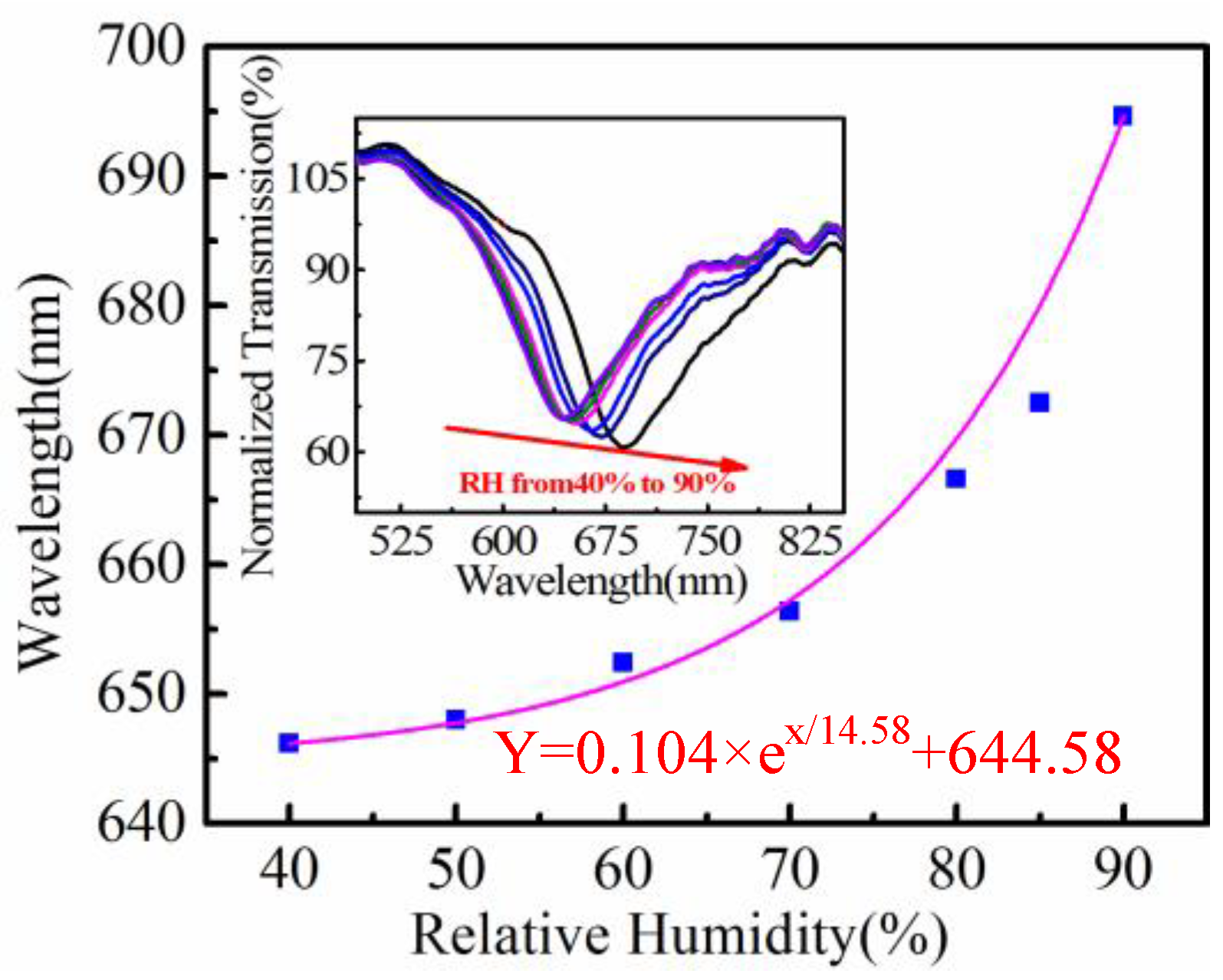

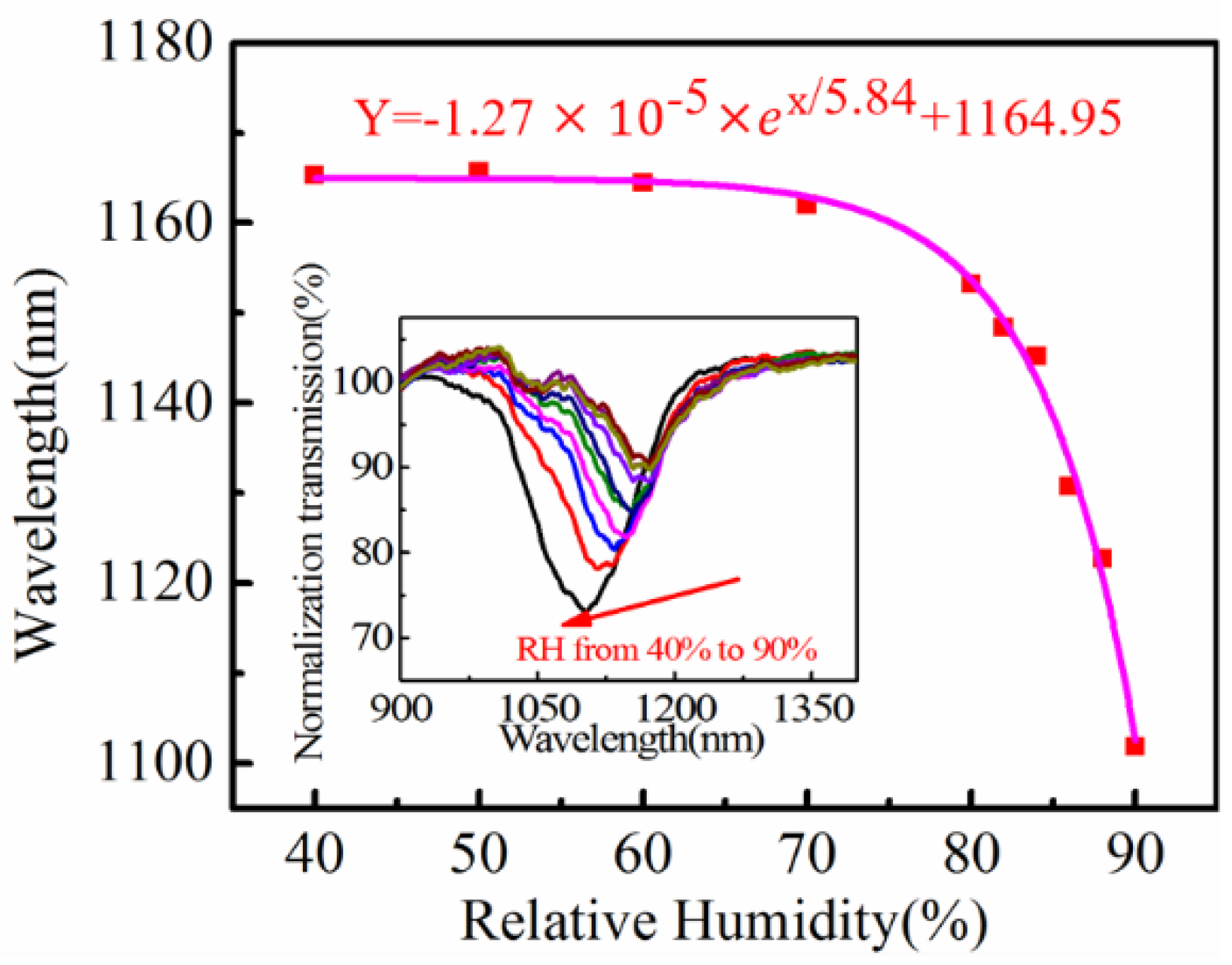

3.1. Relative Humidity Response

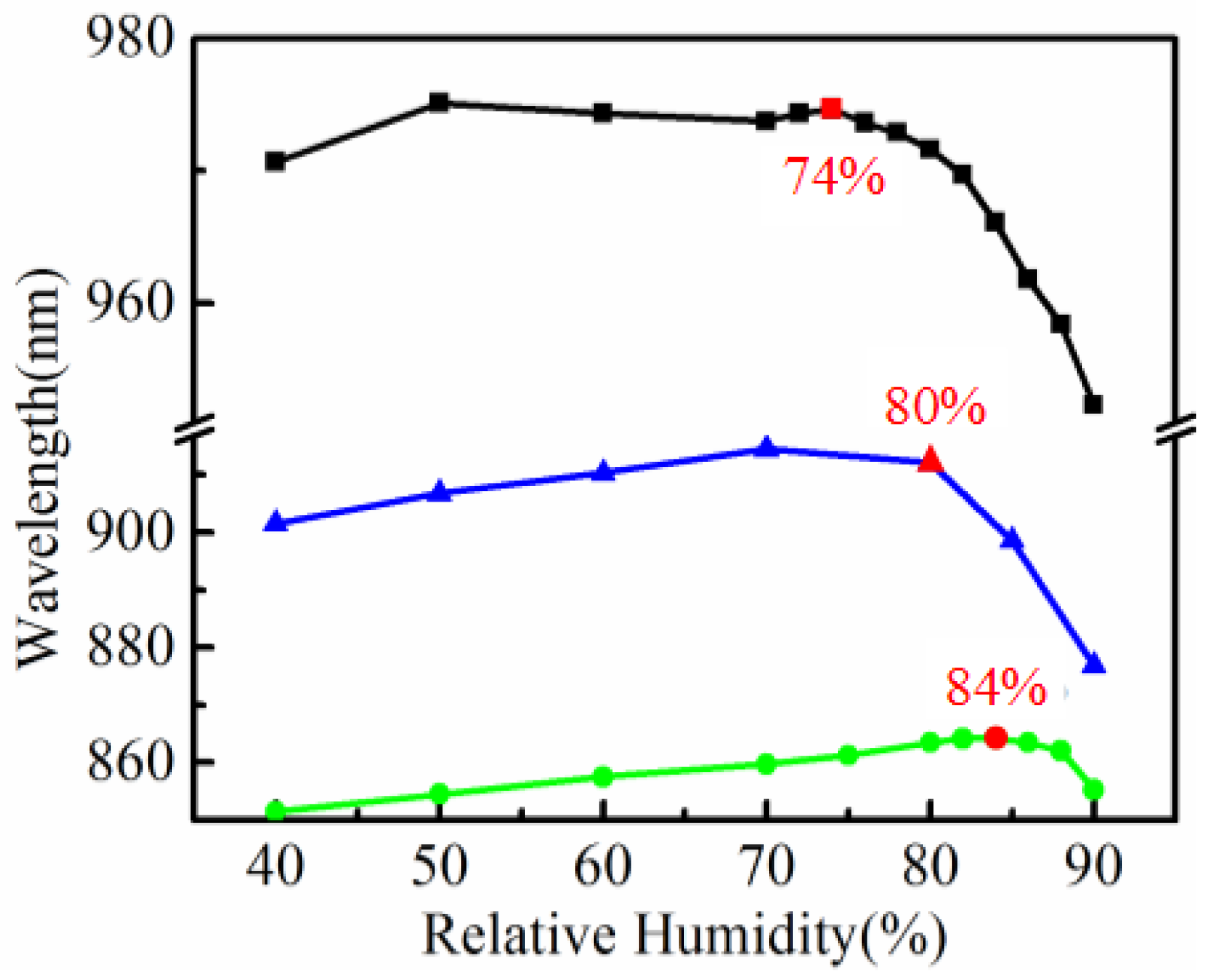

3.2. Sensitivity vs. Thickness of PVA Film

3.3. Stability

3.4. Temperature Cross-Sensitivity

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ma, Q.F.; Tou, Z.Q.; Ni, K.; Lim, Y.Y.; Lin, Y.F.; Wang, Y.R.; Zhou, M.H.; Shi, F.F.; Niu, L.; Dong, X.Y.; et al. Carbon-nanotube/Polyvinyl alcohol coated thin core fiber sensor for humidity measurement. Sens. Actuators B Chem. 2018, 257, 800–806. [Google Scholar] [CrossRef]

- Sun, H.; Yang, Z.; Zhou, L.; Liu, N.; Gang, T.; Qiao, X.; Hu, M. A relative humidity sensing probe based on etched thin-core fiber coated with polyvinyl alcohol. Opt. Commun. 2015, 356, 556–559. [Google Scholar] [CrossRef]

- Wong, W.C.; Chan, C.C.; Chen, L.H.; Li, T.; Lee, K.X.; Leong, K.C. Polyvinyl alcohol coated photonic crystal optical fiber sensor for humidity measurement. Sens. Actuators B Chem. 2012, 174, 563–569. [Google Scholar] [CrossRef]

- Wu, S.; Yan, G.; Lian, Z.; Chen, X.; Zhou, B.; He, S. An open-cavity Fabry-Perot interferometer with PVA coating for simultaneous measurement of relative humidity and temperature. Sens. Actuators B Chem. 2016, 225, 50–56. [Google Scholar] [CrossRef]

- Li, T.; Dong, X.Y.; Chan, C.C.; Ni, K.; Zhang, S.Q.; Shum, P.P. Humidity Sensor with a PVA-Coated Photonic Crystal Fiber Interferometer. IEEE Sens. J. 2013, 13, 2214–2216. [Google Scholar] [CrossRef]

- Bian, C.; Hu, M.L.; Wang, R.H.; Gang, T.T.; Tong, R.X.; Zhang, L.S.; Guo, T.; Liu, X.B.; Qiao, X.G. Optical fiber humidity sensor based on the direct response of the polyimide film. Appl. Opt. 2018, 57, 356–361. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Wang, B.W.; Ni, K. Improving the Sensitivity of Humidity Sensor Based on Mach-Zehnder Interferometer Coated with a Methylcellulose. Int. J. Opt. 2018, 2018, 5680128. [Google Scholar] [CrossRef]

- Alwis, L.; Bremer, K.; Sun, T.; Grattan, K.T.V. Analysis of the Characteristics of PVA-Coated LPG-Based Sensors to Coating Thickness and Changes in the External Refractive Index. IEEE Sens. J. 2013, 13, 1117–1124. [Google Scholar] [CrossRef]

- Dissanayake, K.P.W.; Wu, W.P.; Nguyen, H.; Sun, T.; Grattan, K.T.V. Graphene-Oxide-Coated Long-Period Grating-Based Fiber Optic Sensor for Relative Humidity and External Refractive Index. J. Lightwave Technol. 2018, 36, 1145–1151. [Google Scholar] [CrossRef]

- Guan, H.; Xia, K.; Chen, C.; Luo, Y.; Tang, J.; Lu, H.; Yu, J.; Zhang, J.; Zhong, Y.; Chen, Z. Tungsten disulfide wrapped on micro fiber for enhanced humidity sensing. Opt. Mater. Express 2017, 7, 1686. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, C.-L.; Li, J.; Jin, Y.; Ye, M.; Jin, S. Multiplexing of PVA-coated multimode-fiber taper humidity sensors. Opt. Commun. 2013, 308, 11–14. [Google Scholar] [CrossRef]

- Bariain, C.; Matias, I.R.; Arregui, F.J.; Lopez-Amo, M. Optical fiber humidity sensor based on a tapered fiber coated with agarose gel. Sens. Actuators B Chem. 2000, 69, 127–131. [Google Scholar] [CrossRef]

- Shin, J.C.; Yoon, M.S.; Han, Y.G. Relative Humidity Sensor Based on an Optical Microfiber Knot Resonator with a Polyvinyl Alcohol Overlay. J. Lightwave Technol. 2016, 34, 4511–4515. [Google Scholar] [CrossRef]

- Alwis, L.; Sun, T.; Grattan, K.T.V. Fibre optic long period grating-based humidity sensor probe using a Michelson interferometric arrangement. Sens. Actuators B Chem. 2013, 178, 694–699. [Google Scholar] [CrossRef]

- Dong, X.; Li, T.; Liu, Y.; Li, Y.; Zhao, C.L.; Chan, C.C. Polyvinyl alcohol-coated hybrid fiber grating for relative humidity sensing. J. Biomed. Opt. 2011, 16, 077001. [Google Scholar] [CrossRef] [PubMed]

- Yan, G.; Liang, Y.; Lee, E.H.; He, S. Novel Knob-integrated fiber Bragg grating sensor with polyvinyl alcohol coating for simultaneous relative humidity and temperature measurement. Opt. Express 2015, 23, 15624–15634. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Dong, X.Y.; Chan, C.C.; Zhao, C.L.; Zu, P. Humidity Sensor Based on a Multimode-Fiber Taper Coated with Polyvinyl Alcohol Interacting with a Fiber Bragg Grating. IEEE Sens. J. 2012, 12, 2205–2208. [Google Scholar] [CrossRef]

- Miao, Y.P.; Liu, B.; Zhang, H.; Li, Y.; Zhou, H.B.; Sun, H.; Zhang, W.H.; Zhao, Q.D. Relative Humidity Sensor Based on Tilted Fiber Bragg Grating with Polyvinyl Alcohol Coating. IEEE Photonics Technol. Lett. 2009, 21, 441–443. [Google Scholar] [CrossRef]

- Zhao, C.; Yuan, Q.; Fang, L.; Gan, X.; Zhao, J. High-performance humidity sensor based on a polyvinyl alcohol-coated photonic crystal cavity. Opt. Lett. 2016, 41, 5515–5518. [Google Scholar] [CrossRef] [PubMed]

- Le, A.D.D.; Han, Y.G. Relative Humidity Sensor Based on a Few-Mode Microfiber Knot Resonator by Mitigating the Group Index Difference of a Few-Mode Microfiber. J. Lightwave Technol. 2018, 36, 904–909. [Google Scholar] [CrossRef]

- Patil, S.; Ramgir, N.; Mukherji, S.; Rao, V.R. PVA modified ZnO nanowire based microsensors platform for relative humidity and soil moisture measurement. Sens. Actuators B Chem. 2017, 253, 1071–1078. [Google Scholar] [CrossRef]

- Jagtap, S.; Rane, S.; Arbuj, S.; Gosavi, S. Optical fiber based humidity sensor using Ag decorated ZnO nanorods. Microelectron. Eng. 2018, 187, 1–5. [Google Scholar] [CrossRef]

- Khijwania, S.K.; Srinivasan, K.L.; Singh, J.P. An evanescent-wave optical fiber relative humidity sensor with enhanced sensitivity. Sens. Actuators B Chem. 2005, 104, 217–222. [Google Scholar] [CrossRef]

- Li, D.; Lu, H.; Qiu, W.; Dong, J.; Guan, H.; Zhu, W.; Yu, J.; Luo, Y.; Zhang, J.; Chen, Z. Molybdenum disulfide nanosheets deposited on polished optical fiber for humidity sensing and human breath monitoring. Opt. Express 2017, 25, 28407. [Google Scholar] [CrossRef]

- Zamarreño, C.R.; Hernaez, M.; Del Villar, I.; Matias, I.R.; Arregui, F.J. Tunable humidity sensor based on ITO-coated optical fiber. Sens. Actuators B Chem. 2010, 146, 414–417. [Google Scholar] [CrossRef]

- Shinbo, K.; Ohdaira, Y.; Baba, A.; Kato, K.; Kaneko, F. Vapor sorption to polyvinyl alcohol thin film observed using a hybrid sensor of quartz-crystal-microbalance and surface-plasmon-resonance. Mol. Cryst. Liq. Cryst. 2015, 622, 67–73. [Google Scholar] [CrossRef]

- Zhao, J.; Cao, S.; Liao, C.; Wang, Y.; Wang, G.; Xu, X.; Fu, C.; Xu, G.; Lian, J.; Wang, Y. Surface plasmon resonance refractive sensor based on silver-coated side-polished fiber. Sens. Actuators B Chem. 2016, 230, 206–211. [Google Scholar] [CrossRef]

- Cao, S.; Shao, Y.; Wang, Y.; Wu, T.; Zhang, L.; Huang, Y.; Zhang, F.; Liao, C.; He, J.; Wang, Y. Highly sensitive surface plasmon resonance biosensor based on a low-index polymer optical fiber. Opt. Express 2018, 26, 3988–3994. [Google Scholar] [CrossRef] [PubMed]

- Alwis, L.; Sun, T.; Grattan, K.T.V. Design and performance evaluation of polyvinyl alcohol/polyimide coated optical fibre grating-based humidity sensors. Rev. Sci. Instrum. 2013, 84, 025002. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Zhao, W.-M. A comprehensive review of lossy mode resonance-based fiber optic sensors. Opt. Lasers Eng. 2018, 100, 47–60. [Google Scholar] [CrossRef]

| Configuration | Sensitivity | Dynamic Range (%RH) | |

|---|---|---|---|

| W.C. Wong [3] | Michelson interferometer | 0.60 nm/%RH | 30% to 90% RH |

| S. Wu [4] | F-P interferometer | −23.1 pm/%RH | 30% to 90% RH |

| T. Li [5] | PCF-mode interferometer | 40.9 pm/%RH | 20% to 95% RH |

| C. Zhao [19] | PVA coated photonic crystal cavity | 129 pm/%RH | 40% to 90% RH |

| C.R. Zamarreno [25] | ITO coated optical fiber | 0.83 nm/%RH | 20% to 90% RH |

| This article | PVA coated SPR fiber | 1.01 nm/%RH | 40% to 90% RH |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, Y.; Wang, Y.; Cao, S.; Huang, Y.; Zhang, L.; Zhang, F.; Liao, C.; Wang, Y. Mechanism and Characteristics of Humidity Sensing with Polyvinyl Alcohol-Coated Fiber Surface Plasmon Resonance Sensor. Sensors 2018, 18, 2029. https://doi.org/10.3390/s18072029

Shao Y, Wang Y, Cao S, Huang Y, Zhang L, Zhang F, Liao C, Wang Y. Mechanism and Characteristics of Humidity Sensing with Polyvinyl Alcohol-Coated Fiber Surface Plasmon Resonance Sensor. Sensors. 2018; 18(7):2029. https://doi.org/10.3390/s18072029

Chicago/Turabian StyleShao, Yu, Ying Wang, Shaoqing Cao, Yijian Huang, Longfei Zhang, Feng Zhang, Changrui Liao, and Yiping Wang. 2018. "Mechanism and Characteristics of Humidity Sensing with Polyvinyl Alcohol-Coated Fiber Surface Plasmon Resonance Sensor" Sensors 18, no. 7: 2029. https://doi.org/10.3390/s18072029

APA StyleShao, Y., Wang, Y., Cao, S., Huang, Y., Zhang, L., Zhang, F., Liao, C., & Wang, Y. (2018). Mechanism and Characteristics of Humidity Sensing with Polyvinyl Alcohol-Coated Fiber Surface Plasmon Resonance Sensor. Sensors, 18(7), 2029. https://doi.org/10.3390/s18072029