Online 3D Displacement Measurement Using Speckle Interferometer with a Single Illumination-Detection Path

Abstract

1. Introduction

2. Theory

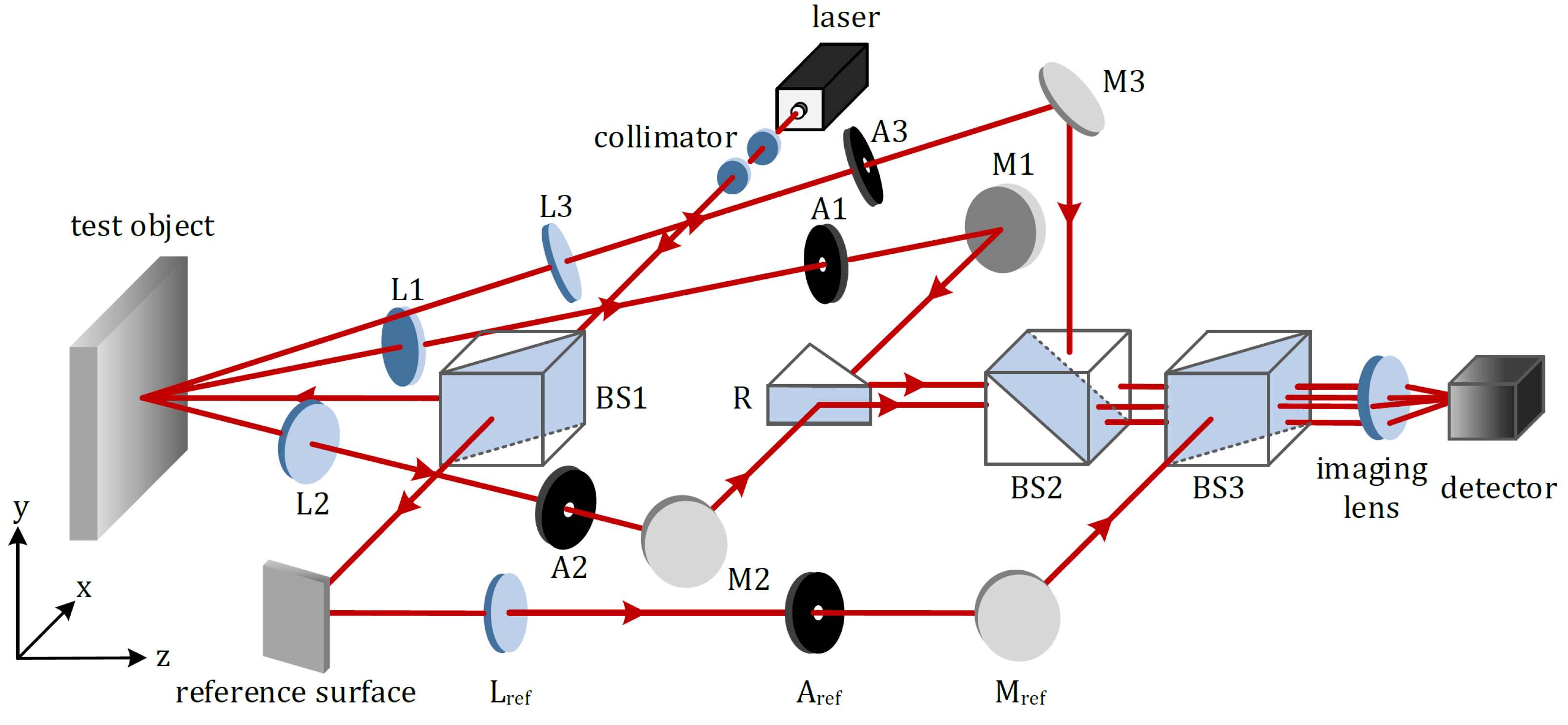

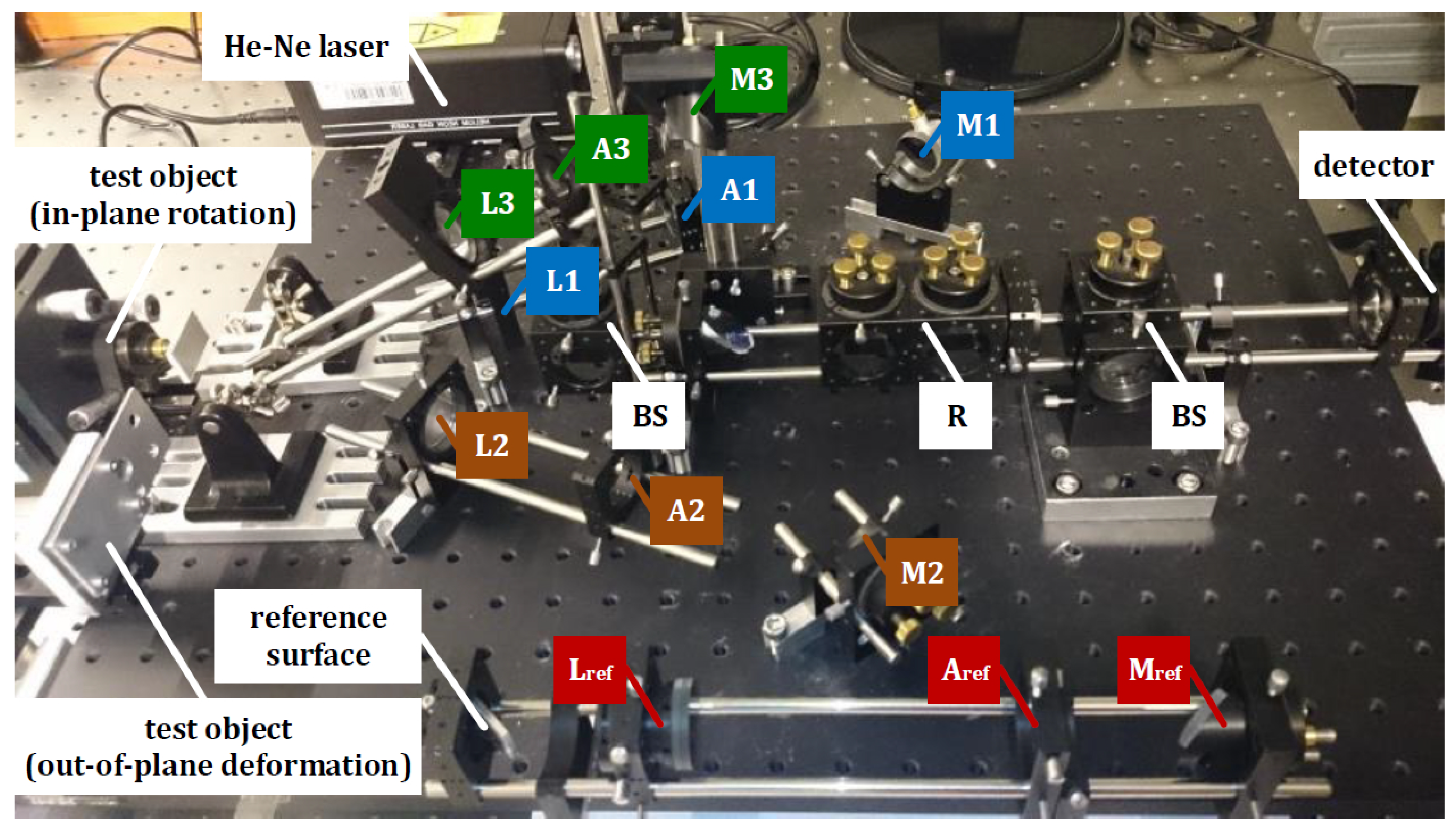

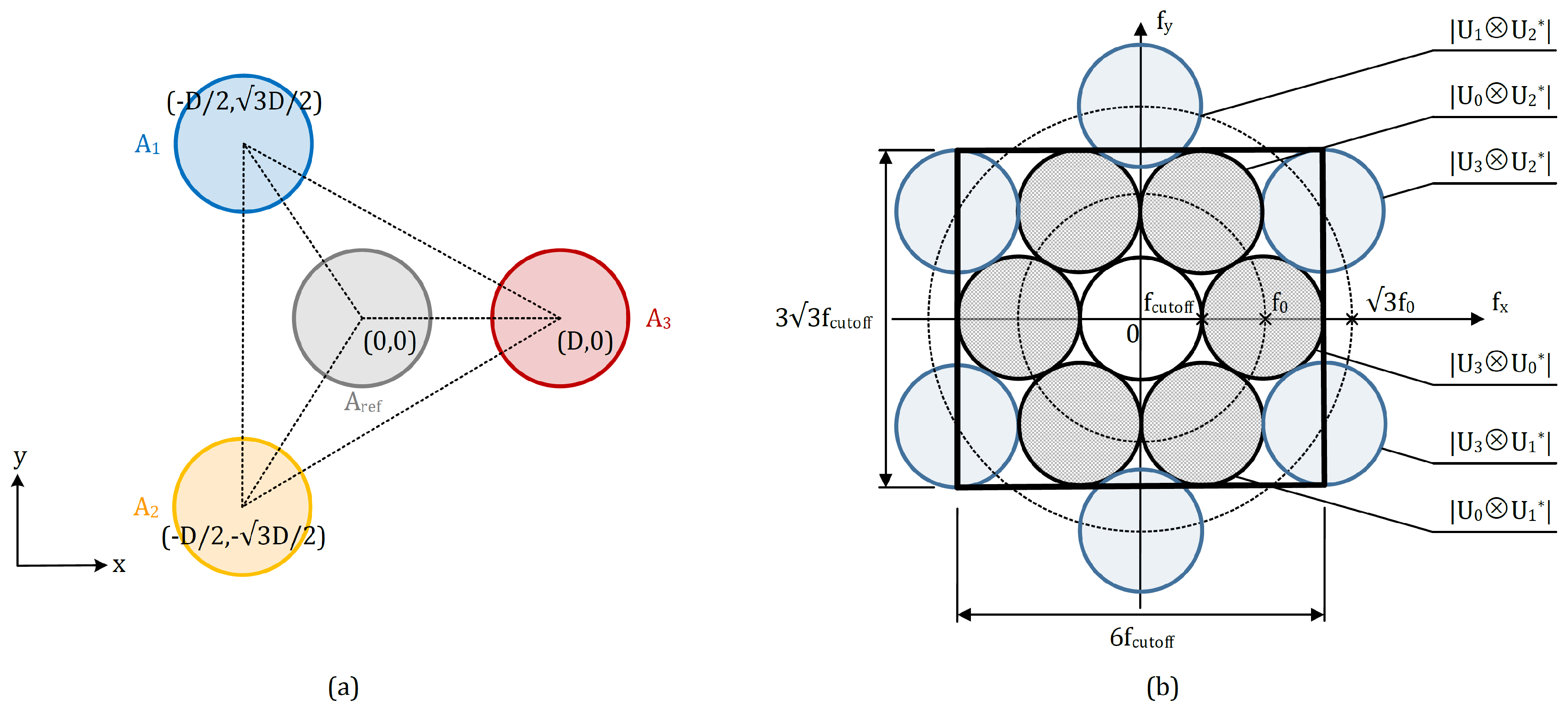

2.1. Optical Arrangement

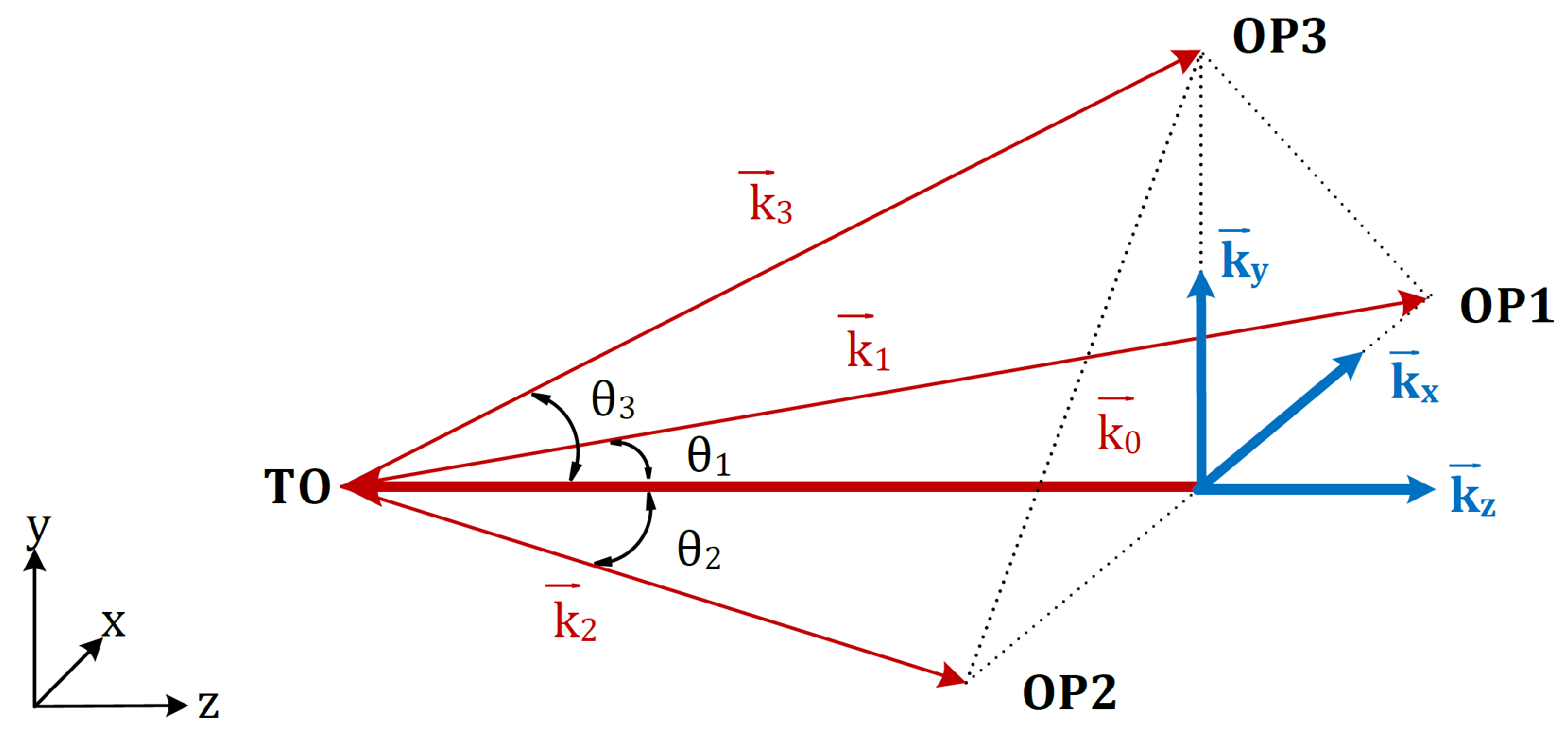

2.2. Working Principle

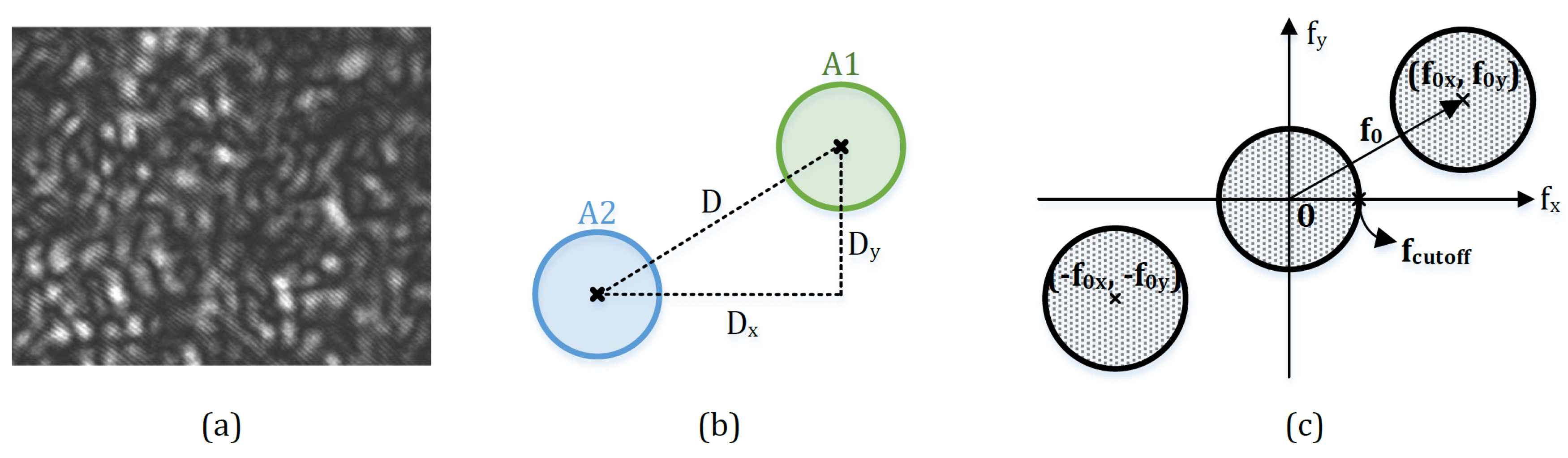

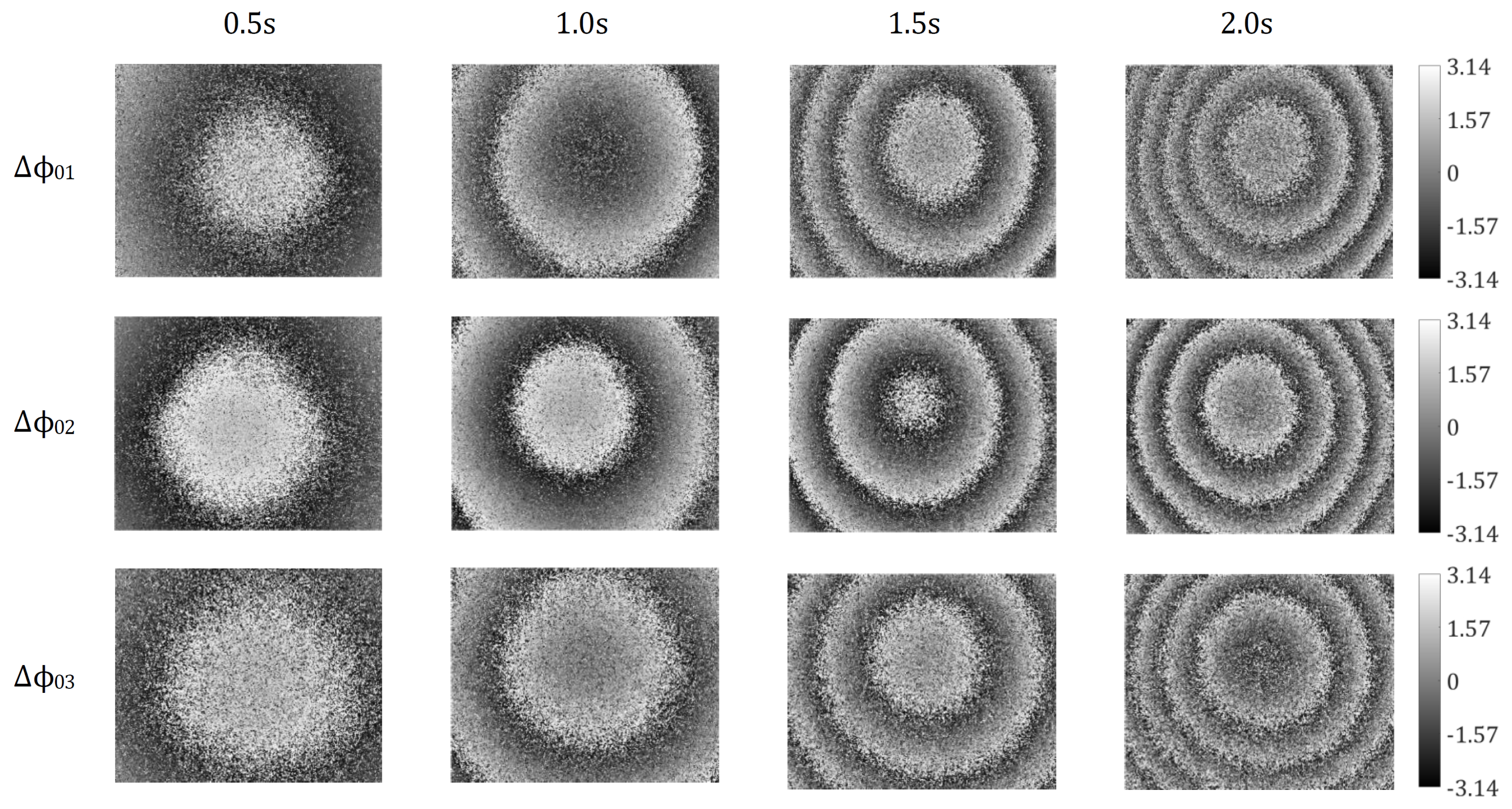

2.3. Phase Retrieval

3. Experimental Results and Disscusion

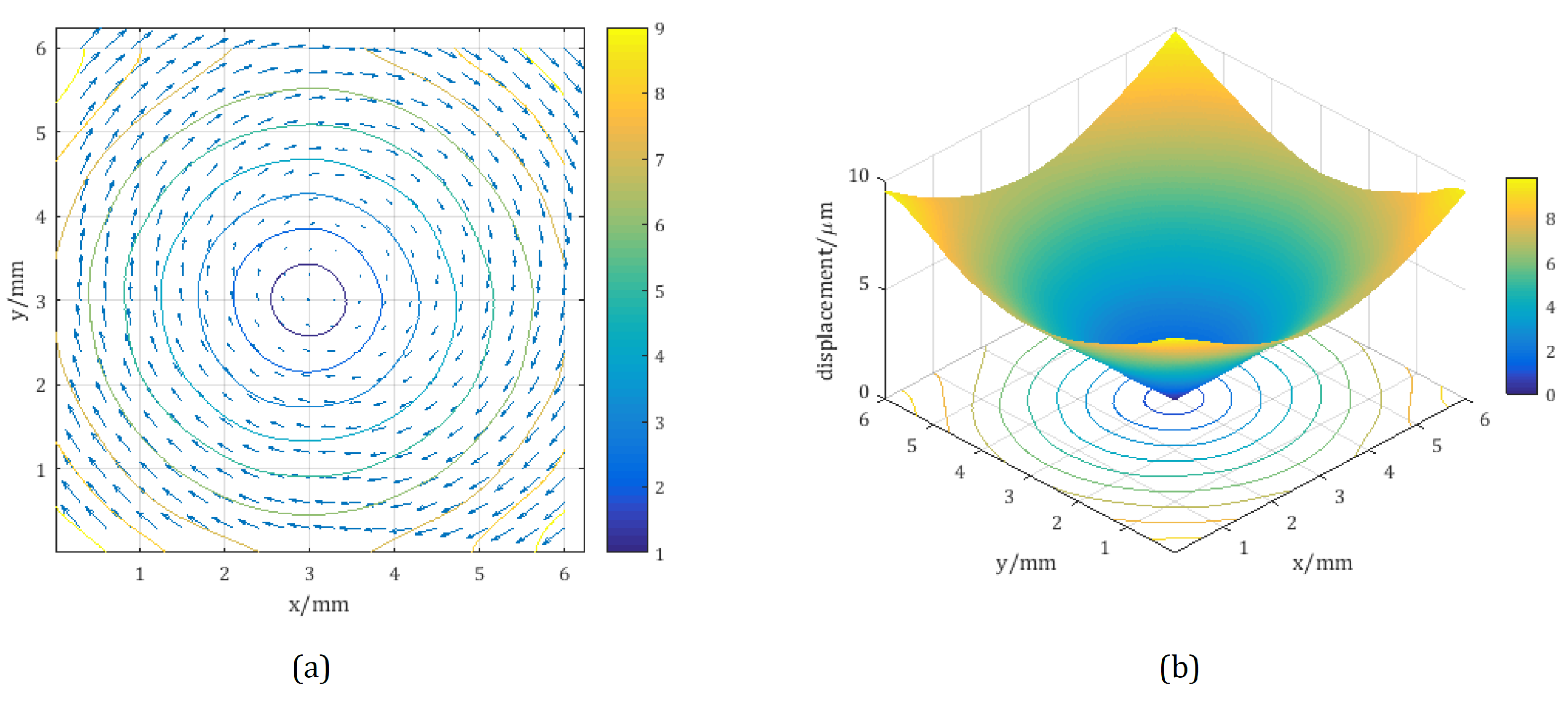

3.1. Rigid-Body Rotation

3.2. Deformation by Central Load

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sansoni, G.; Trebeschi, M.; Docchio, F. State-of-the-art and applications of 3D imaging sensors in industry, cultural heritage, medicine, and criminal investigation. Sensors 2009, 9, 568–601. [Google Scholar] [CrossRef] [PubMed]

- Orteu, J.J.; Bugarin, F.; Harvent, J.; Robert, L.; Velay, V. Multiple-camera instrumentation of a single point incremental forming process pilot for shape and 3D displacement measurements: Methodology and results. Exp. Mech. 2011, 51, 625–639. [Google Scholar] [CrossRef]

- Ren, M.; Liang, J.; Li, L.; Wei, B.; Wang, L.; Tang, Z. Accurate three-dimensional shape and deformation measurement at microscale using digital image correlation. Rev. Sci. Instrum. 2015, 86, 075102. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, I.; Rastogi, P.K.; Hack, E. Digital Holographic Interferometry and Speckle Correlation. In AIP Conference Proceedings; AIP: College Park, MD, USA, 2010; Volume 1236, pp. 46–51. [Google Scholar]

- Prentice, H.; Proud, W.; Furnish, M.D.; Elert, M.; Russell, T.P.; White, C.T. Three-Dimensional Dynamic Deformation Measurements Using Stereoscopic Imaging and Digital Speckle Photography. In AIP Conference Proceedings; AIP: College Park, MD, USA, 2006; Volume 845, pp. 1275–1278. [Google Scholar]

- Abdelhakim, L.; Simos, T.E.; Psihoyios, G.; Tsitouras, C. Displacement Determination by Digital Holographic Interferometry. In AIP Conference Proceedings; AIP: College Park, MD, USA, 2010; Volume 1281, pp. 2089–2094. [Google Scholar]

- Barrientos, B.; Cerca, M.; García-Márquez, J.; Hernández-Bernal, C.; Wetter, N.U.; Frejlich, J. Three-dimensional displacement measurement by fringe projection and speckle photography. In AIP Conference Proceedings; AIP: College Park, MD, USA, 2008; Volume 992, pp. 828–833. [Google Scholar]

- Gao, Z.; Deng, Y.; Duan, Y.; Zhang, Z.; Wei, C.; Chen, S.; Cui, J.; Feng, Q. Continual in-plane displacement measurement with temporal wavelet transform speckle pattern interferometry. Rev. Sci. Instrum. 2012, 83, 015107. [Google Scholar] [CrossRef] [PubMed]

- Aulbach, L.; Salazar Bloise, F.; Lu, M.; Koch, A.W. Non-Contact Surface Roughness Measurement by Implementation of a Spatial Light Modulator. Sensors 2017, 17, 596. [Google Scholar] [CrossRef] [PubMed]

- Preciado, J.S.; Lopez, C.P.; Santoyo, F.M.; Tomasini, E.P. Measurement of dynamic patterns of an elastic membrane at bi-modal vibration using high speed electronic speckle pattern interferometry. In AIP Conference Proceedings; AIP: College Park, MD, USA, 2014; Volume 1600, pp. 196–202. [Google Scholar]

- Synnergren, P.; Sjödahl, M. A stereoscopic digital speckle photography system for 3-D displacement field measurements. Opt. Lasers Eng. 1999, 31, 425–443. [Google Scholar] [CrossRef]

- Sjödahl, M.; Benckert, L. Electronic speckle photography: analysis of an algorithm giving the displacement with subpixel accuracy. Appl. Opt. 1993, 32, 2278–2284. [Google Scholar] [CrossRef] [PubMed]

- Feng, D.; Feng, M.Q.; Ozer, E.; Fukuda, Y. A vision-based sensor for noncontact structural displacement measurement. Sensors 2015, 15, 16557–16575. [Google Scholar] [CrossRef] [PubMed]

- Feng, D.; Feng, M.Q. Identification of structural stiffness and excitation forces in time domain using noncontact vision-based displacement measurement. J. Sound Vib. 2017, 406, 15–28. [Google Scholar] [CrossRef]

- Lee, J.J.; Shinozuka, M. A vision-based system for remote sensing of bridge displacement. Ndt E Int. 2006, 39, 425–431. [Google Scholar] [CrossRef]

- Oh, B.K.; Hwang, J.W.; Kim, Y.; Cho, T.; Park, H.S. Vision-based system identification technique for building structures using a motion capture system. J. Sound Vib. 2015, 356, 72–85. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Experimental validation of cost-effective vision-based structural health monitoring. Mech. Syst. Signal Process. 2017, 88, 199–211. [Google Scholar] [CrossRef]

- Le Flohic, J.; Parpoil, V.; Bouissou, S.; Poncelet, M.; Leclerc, H. A 3D displacement control by digital image correlation for the multiaxial testing of materials with a Stewart platform. Exp. Mech. 2014, 54, 817–828. [Google Scholar] [CrossRef]

- Schreier, H.; Orteu, J.J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements; Springer: New York, NY, USA, 2009. [Google Scholar]

- Jacquot, P.; Fournier, J.M. Interferometry in Speckle Light: Theory and Applications; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Khodadad, D.; Singh, A.K.; Pedrini, G.; Sjödahl, M. Full-field 3D deformation measurement: comparison between speckle phase and displacement evaluation. Appl. Opt. 2016, 55, 7735–7743. [Google Scholar] [CrossRef] [PubMed]

- Saucedo, A.T.; Santoyo, F.M.; De la Torre-Ibarra, M.; Pedrini, G.; Osten, W. Endoscopic pulsed digital holography for 3D measurements. Opt. Express 2006, 14, 1468–1475. [Google Scholar] [CrossRef] [PubMed]

- Takatsuji, T.; Oreb, B.; Farrant, D.; Tyrer, J. Simultaneous measurement of three orthogonal components of displacement by electronic speckle-pattern interferometry and the Fourier transform method. Appl. Opt. 1997, 36, 1438–1445. [Google Scholar] [CrossRef] [PubMed]

- Flynn, E.B.; Bassman, L.C.; Smith, T.P.; Lalji, Z.; Fullerton, L.H.; Leung, T.C.; Greenfield, S.R.; Koskelo, A.C. Three-wavelength electronic speckle pattern interferometry with the Fourier-transform method for simultaneous measurement of microstructure-scale deformations in three dimensions. Appl. Opt. 2006, 45, 3218–3225. [Google Scholar] [CrossRef] [PubMed]

- Dekiff, M.; Berssenbrügge, P.; Kemper, B.; Denz, C.; Dirksen, D. Simultaneous acquisition of 3D shape and deformation by combination of interferometric and correlation-based laser speckle metrology. Biomed. Opt. Express 2015, 6, 4825–4840. [Google Scholar] [CrossRef] [PubMed]

- Gotoa, D.T.; Grovesa, R.M. A combined experimental with simulation approach to calibrated 3D strain measurement using shearography. Proc. SPIE 2010, 7387, 73871J. [Google Scholar]

- Takeda, M.; Kitoh, M. Spatiotemporal frequency multiplex heterodyne interferometry. JOSA A 1992, 9, 1607–1614. [Google Scholar] [CrossRef]

- Takeda, M.; Gu, Q.; Kinoshita, M.; Takai, H.; Takahashi, Y. Frequency-multiplex Fourier-transform profilometry: A single-shot three-dimensional shape measurement of objects with large height discontinuities and/or surface isolations. Appl. Opt. 1997, 36, 5347–5354. [Google Scholar] [CrossRef] [PubMed]

- Ochoa, N.A.; Huntley, J.M. Convenient method for calibrating nonlinear phase modulators for use in phase shifting interferometry. Opt. Eng. 1998, 37, 2501–2506. [Google Scholar]

- Colomb, T.; Montfort, F.; Kühn, J.; Aspert, N.; Cuche, E.; Marian, A.; Charrière, F.; Bourquin, S.; Marquet, P.; Depeursinge, C. Numerical parametric lens for shifting, magnification, and complete aberration compensation in digital holographic microscopy. JOSA A 2006, 23, 3177–3190. [Google Scholar] [CrossRef] [PubMed]

- Ferraro, P.; Miccio, L.; Grilli, S.; Paturzo, M.; De Nicola, S.; Finizio, A.; Osellame, R.; Laporta, P. Quantitative phase microscopy of microstructures with extended measurement range and correction of chromatic aberrations by multiwavelength digital holography. Opt. Express 2007, 15, 14591–14600. [Google Scholar] [CrossRef] [PubMed]

- Tayebi, B.; Jafarfard, M.R.; Sharif, F.; Bae, Y.S.; Shokuh, S.H.H.; Kim, D.Y. Reduced-phase dual-illumination interferometer for measuring large stepped objects. Opt. Lett. 2014, 39, 5740–5743. [Google Scholar] [CrossRef] [PubMed]

- Deng, C.; Suo, J.; Wang, Y.; Zhang, Z.; Dai, Q. Single-shot thermal ghost imaging using wavelength-division multiplexing. Appl. Phys. Lett. 2018, 112, 051107. [Google Scholar] [CrossRef]

- Hack, E.K.; Riner, M. 3D ESPI and 3D shearography measurements applied to NDT and FEM analysis validation for industrial quality control. In Optical Measurement Systems for Industrial Inspection II: Application in Industrial Design; International Society for Optics and Photonics: Washington, DC, USA, 2001; Volume 4398, pp. 155–168. [Google Scholar]

- Coggrave, C.; Huntley, J. Real-time visualisation of deformation fields using speckle interferometry and temporal phase unwrapping. Opt. Lasers Eng. 2004, 41, 601–620. [Google Scholar] [CrossRef]

- Bergström, P.; Khodadad, D.; Hällstig, E.; Sjödahl, M. Dual-wavelength digital holography: Single-shot shape evaluation using speckle displacements and regularization. Appl. Opt. 2014, 53, 123–131. [Google Scholar] [CrossRef] [PubMed]

- Khodadad, D.; Bergström, P.; Hällstig, E.; Sjödahl, M. Single shot dual-wavelength digital holography: Calibration based on speckle displacements. Int. J. Optomechatron. 2014, 8, 326–339. [Google Scholar] [CrossRef]

- Khodadad, D.; Bergström, P.; Hällstig, E.; Sjödahl, M. Fast and robust automatic calibration for single-shot dual-wavelength digital holography based on speckle displacements. Appl. Opt. 2015, 54, 5003–5010. [Google Scholar] [CrossRef] [PubMed]

- Khaleghi, M.; Furlong, C.; Guignard, J.; Dobrev, I.; Cheng, J.T.; Rosowski, J.J. Multiplexed Holography for Single-Shot Three-Dimensional Shape and Displacement Measurements. In Advancement of Optical Methods in Experimental Mechanics; Springer: New York, NY, USA, 2015; Volume 3, pp. 103–108. [Google Scholar]

- Goodman, J.W. Speckle Phenomena in Optics: Theory and Applications; Roberts and Company Publishers: Englewood, CO, USA, 2007. [Google Scholar]

- Koch, A.; Ruprecht, M.; Toedter, O.; Häusler, G. Optische Messtechnik an Technischen Oberflächen; Expert-Verlag: Renningen-Malmsheim, Germany, 1998. [Google Scholar]

- Lu, M.; Wang, S.; Aulbach, L.; Koch, A.W. Simultaneous displacement and slope measurement in electronic speckle pattern interferometry using adjustable aperture multiplexing. Appl. Opt. 2016, 55, 5868–5875. [Google Scholar] [CrossRef] [PubMed]

- Hung, M.Y.; Shang, H.M.; Yang, L. Unified approach for holography and shearography in surface deformation measurement and nondestructive testing. Opt. Eng. 2003, 42, 1197–1207. [Google Scholar] [CrossRef]

- Pedrini, G.; Zou, Y.; Tiziani, H. Quantitative evaluation of digital shearing interferogram using the spatial carrier method. Pure Appl. Opt. J. Eur. Opt. Soc. Part A 1996, 5, 313. [Google Scholar] [CrossRef]

- Lu, M.; Wang, S.; Aulbach, L.; Jakobi, M.; Koch, A. Non-phase unwrapping interferometric approach for a real-time in-plane rotation measurement. Opt. Lett. 2017, 42, 1984–1989. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, M.; Wang, S.; Bilgeri, L.; Song, X.; Jakobi, M.; Koch, A.W. Online 3D Displacement Measurement Using Speckle Interferometer with a Single Illumination-Detection Path. Sensors 2018, 18, 1923. https://doi.org/10.3390/s18061923

Lu M, Wang S, Bilgeri L, Song X, Jakobi M, Koch AW. Online 3D Displacement Measurement Using Speckle Interferometer with a Single Illumination-Detection Path. Sensors. 2018; 18(6):1923. https://doi.org/10.3390/s18061923

Chicago/Turabian StyleLu, Min, Shengjia Wang, Laura Bilgeri, Xian Song, Martin Jakobi, and Alexander W. Koch. 2018. "Online 3D Displacement Measurement Using Speckle Interferometer with a Single Illumination-Detection Path" Sensors 18, no. 6: 1923. https://doi.org/10.3390/s18061923

APA StyleLu, M., Wang, S., Bilgeri, L., Song, X., Jakobi, M., & Koch, A. W. (2018). Online 3D Displacement Measurement Using Speckle Interferometer with a Single Illumination-Detection Path. Sensors, 18(6), 1923. https://doi.org/10.3390/s18061923