Optimal Control for Aperiodic Dual-Rate Systems With Time-Varying Delays

Abstract

1. Introduction

Preliminaries

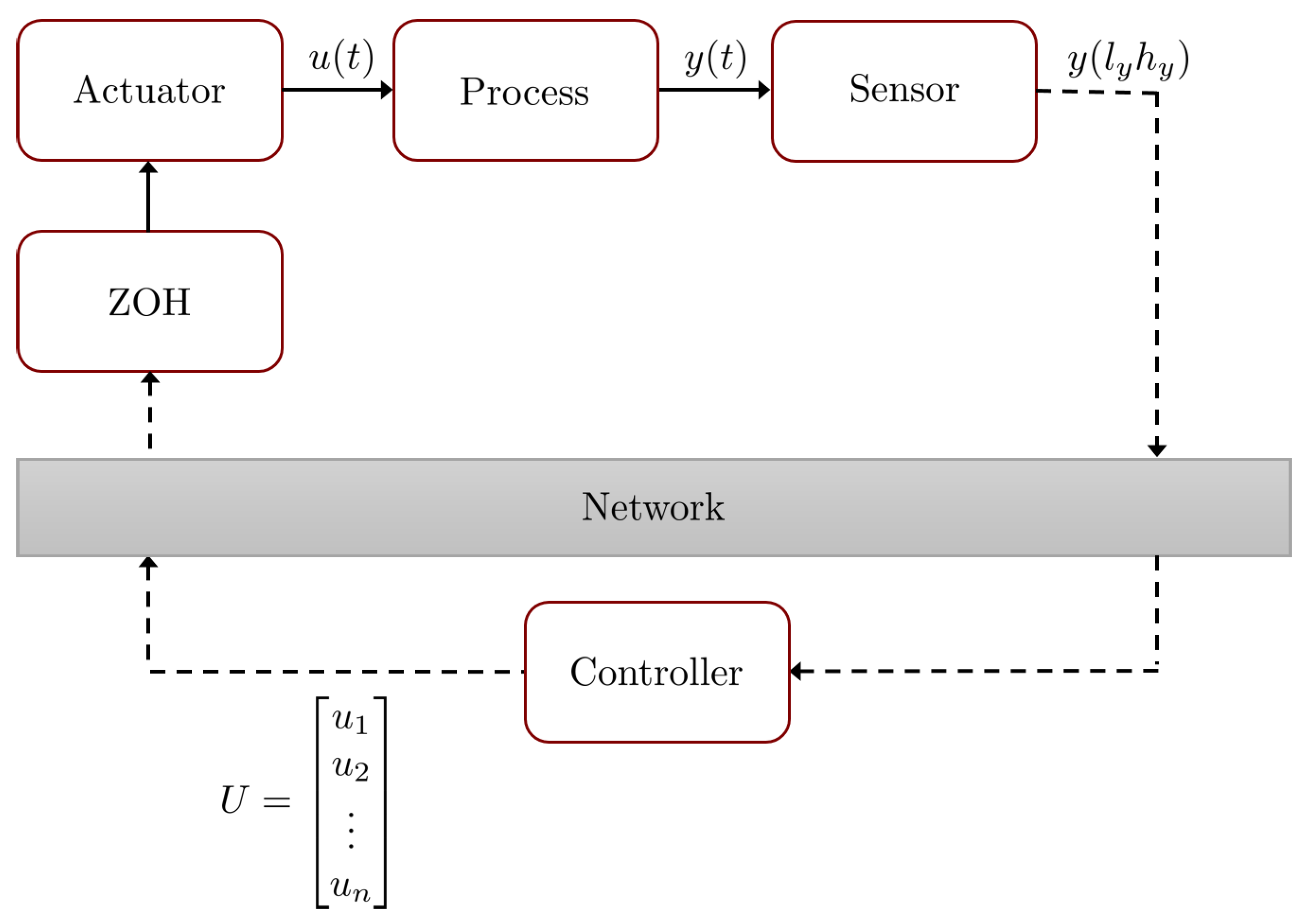

2. Problem Statement

3. Control Algorithm for Decay Rate Optimization

3.1. Extension for Time-Varying Delay Systems

3.2. Implementation of Optimization Algorithm in Real-Time Systems

| Algorithm 1 Optimization algorithm with limited computation resources. |

Offline Computation

Online Computation

|

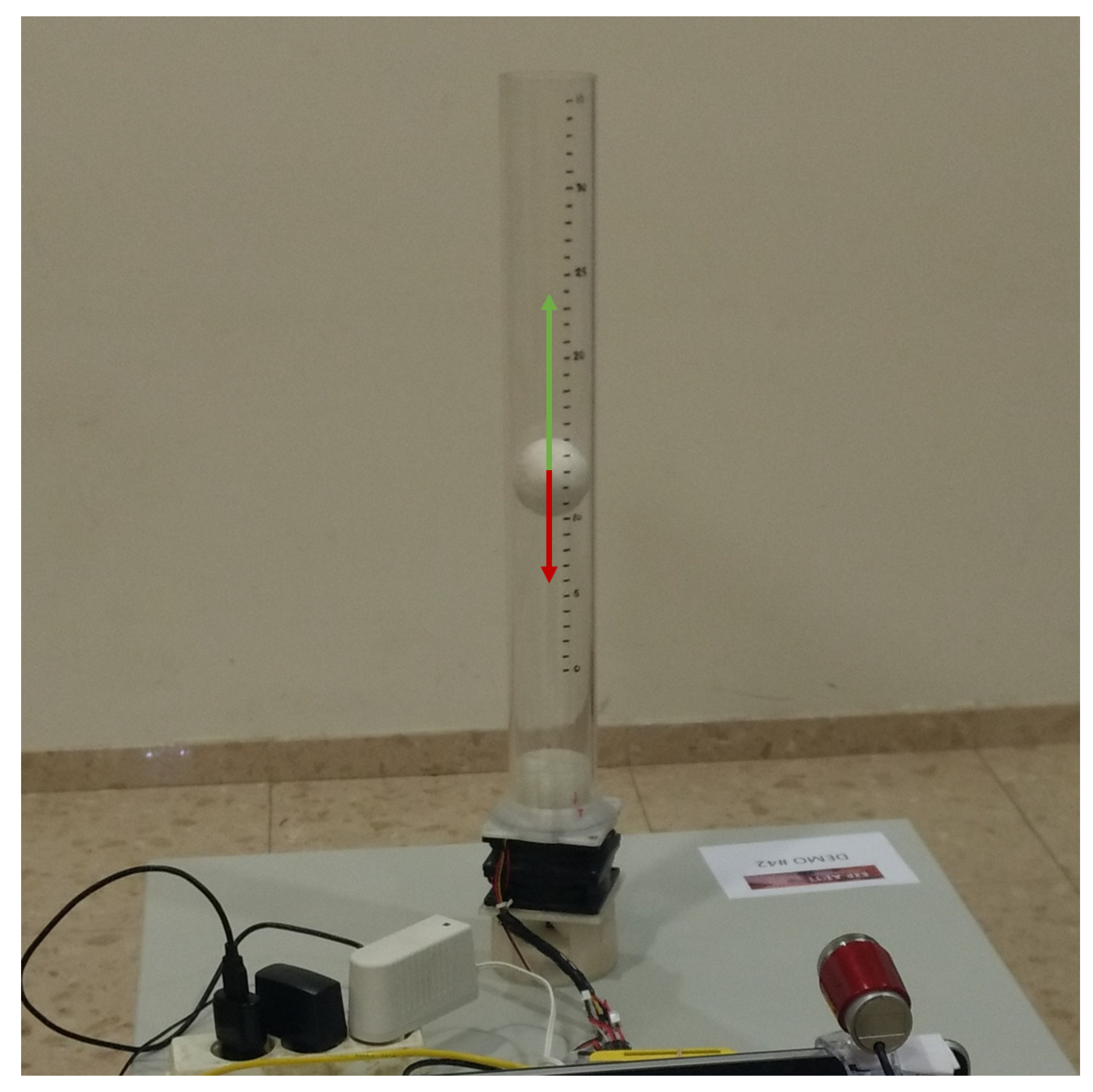

4. Practical Case: Air Levitation System

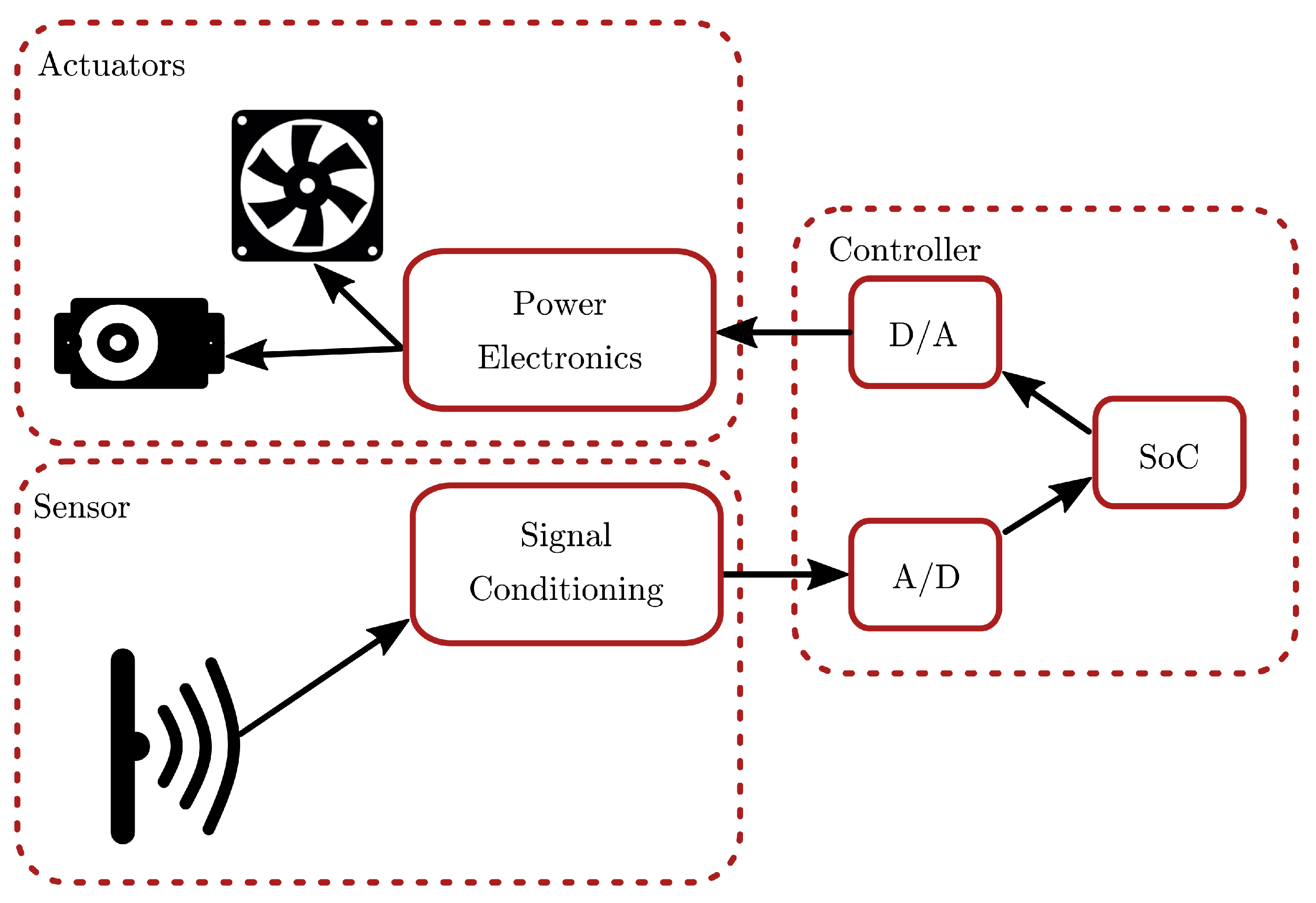

4.1. Hardware Description

4.2. System Model

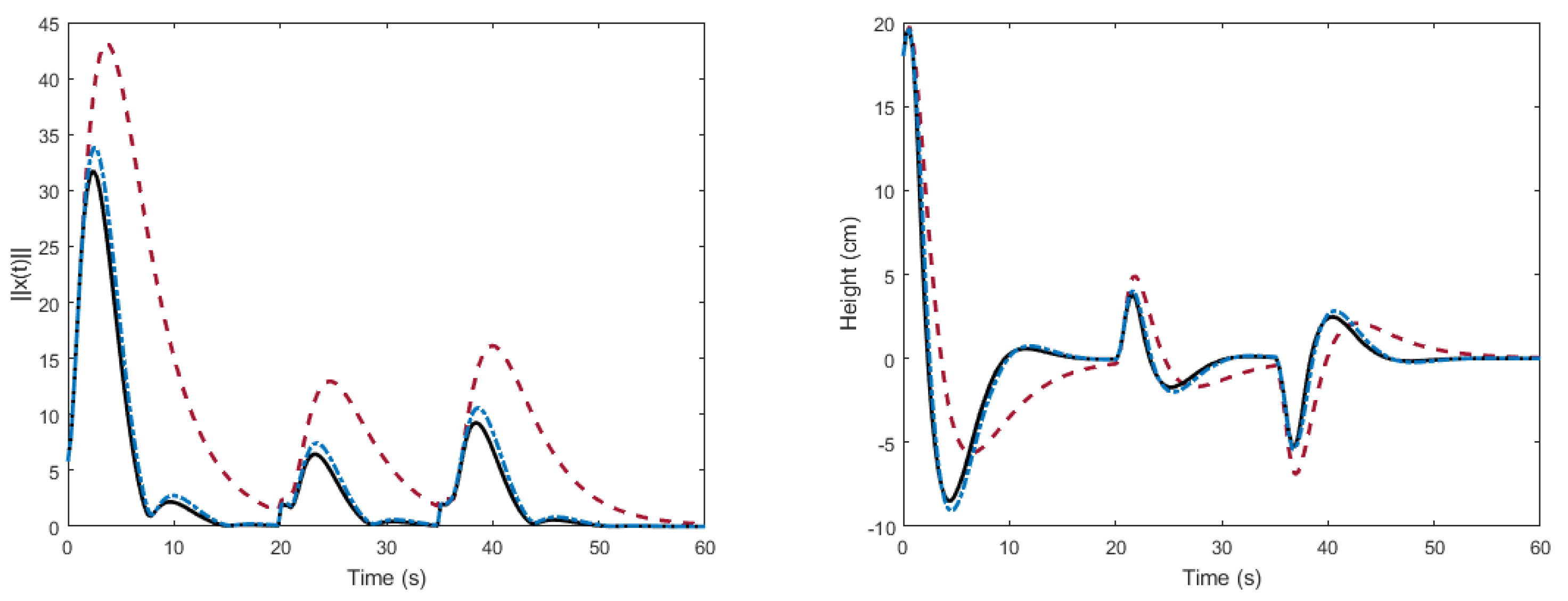

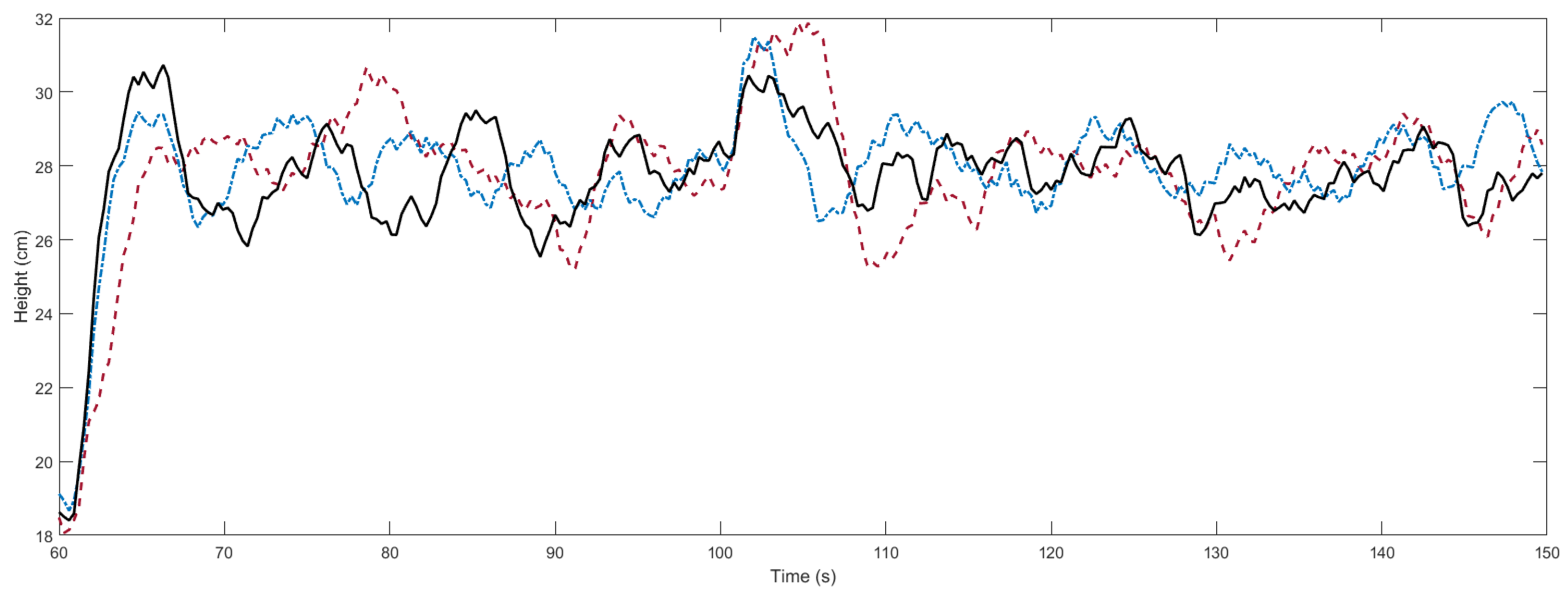

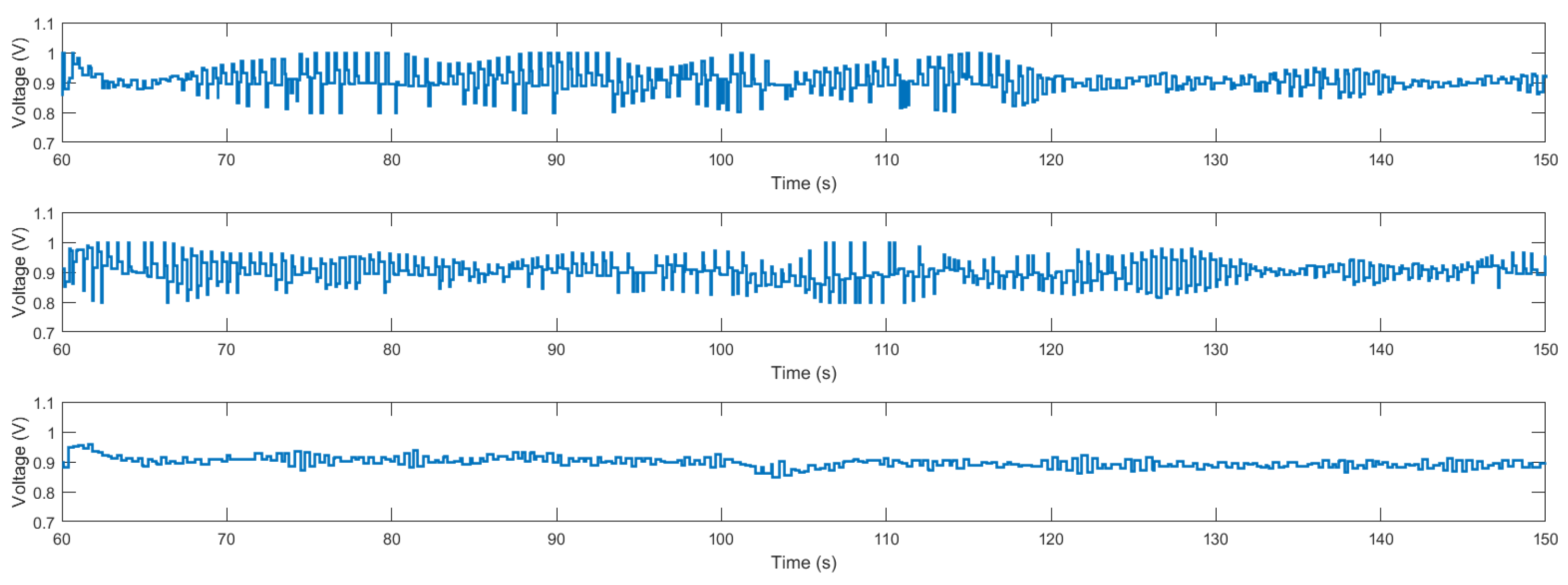

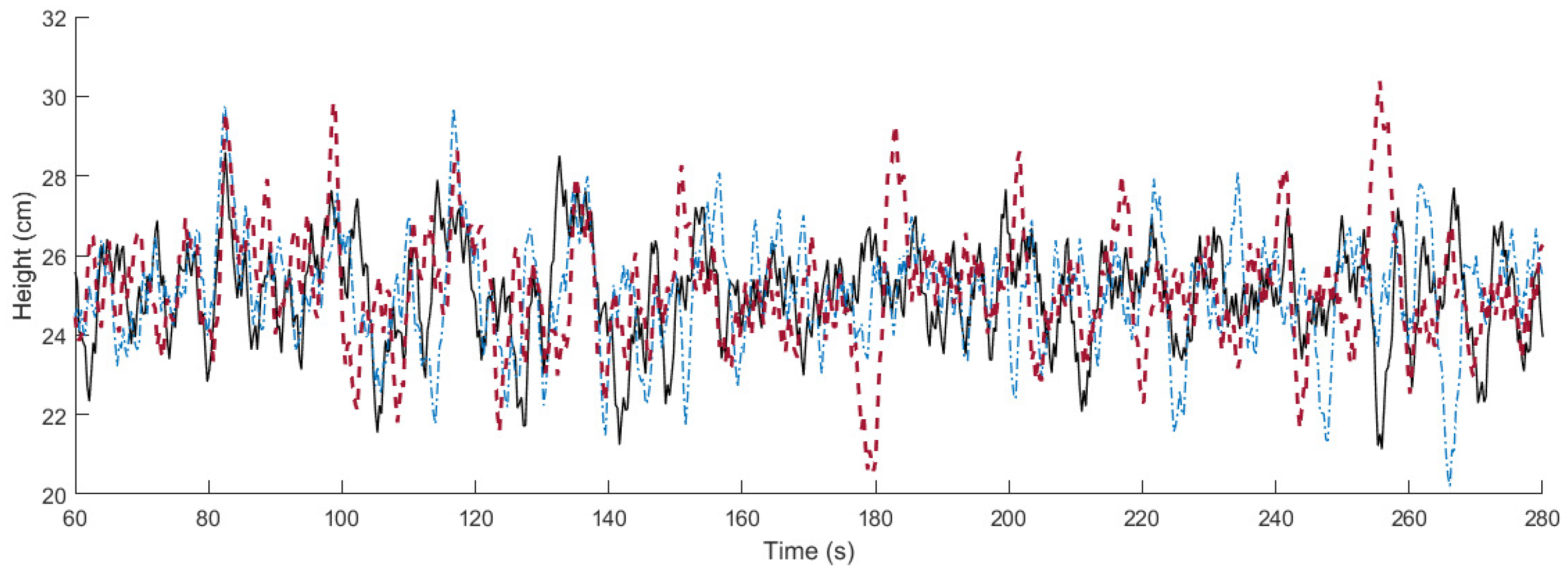

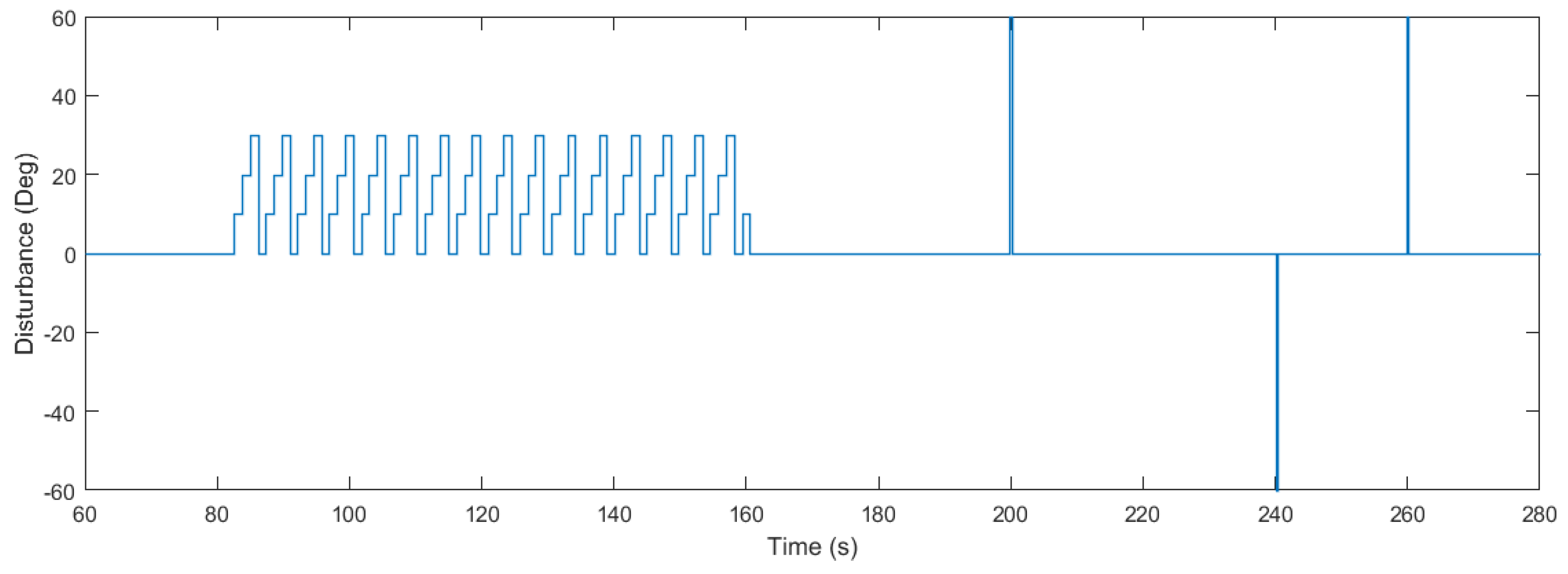

4.3. Experimental Results

5. Discussion

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A

References

- Mansano, R.K.; Godoy, E.P.; Porto, A.J. The Benefits of Soft Sensor and Multi-Rate Control for the Implementation of Wireless Networked Control Systems. Sensors 2014, 14, 24441–24461. [Google Scholar] [CrossRef] [PubMed]

- Shao, Q.M.; Cinar, A. System identification and distributed control for multi-rate sampled systems. J. Process Control 2015, 34, 1–12. [Google Scholar] [CrossRef]

- Albertos, P.; Salt, J. Non-uniform sampled-data control of MIMO systems. Annu. Rev. Control 2011, 35, 65–76. [Google Scholar] [CrossRef]

- Cuenca, Á.; Salt, J. RST controller design for a non-uniform multi-rate control system. J. Process Control 2012, 22, 1865–1877. [Google Scholar] [CrossRef]

- Cuenca, Á.; Ojha, U.; Salt, J.; Chow, M.Y. A non-uniform multi-rate control strategy for a Markov chain-driven Networked Control System. Inf. Sci. 2015, 321, 31–47. [Google Scholar] [CrossRef][Green Version]

- Kalman, R.E.; Bertram, J.E. General synthesis procedure for computer control of single-loop and multiloop linear systems (An optimal sampling system). Trans. Am. Inst. Electr. Eng. Part II Appl. Ind. 1959, 77, 602–609. [Google Scholar] [CrossRef]

- Khargonekar, P.P.; Poolla, K.; Tannenbaum, A. Robust control of linear time-invariant plants using periodic compensation. IEEE Trans. Autom. Control 1985, 30, 1088–1096. [Google Scholar] [CrossRef]

- Bamieh, B.; Pearson, J.B.; Francis, B.A.; Tannenbaum, A. A lifting technique for linear periodic systems with applications to sampled-data control. Syst. Control Lett. 1991, 17, 79–88. [Google Scholar] [CrossRef]

- Li, D.; Shah, S.L.; Chen, T.; Qi, K.Z. Application of dual-rate modeling to CCR octane quality inferential control. IEEE Trans. Control Syst. Technol. 2003, 11, 43–51. [Google Scholar] [CrossRef]

- Salt, J.; Albertos, P. Model-based multirate controllers design. IEEE Trans. Control Syst. Technol. 2005, 13, 988–997. [Google Scholar] [CrossRef]

- Nemani, M.; Tsao, T.C.; Hutchinson, S. Multi-rate analysis and design of visual feedback digital servo-control system. J. Dyn. Syst. Meas. Control 1994, 116, 45–55. [Google Scholar] [CrossRef]

- Sim, T.P.; Hong, G.S.; Lim, K.B. Multirate predictor control scheme for visual servo control. IEE Proc.-Control Theory Appl. 2002, 149, 117–124. [Google Scholar] [CrossRef]

- Huang, X.; Nagamune, R.; Horowitz, R. A comparison of multirate robust track-following control synthesis techniques for dual-stage and multisensing servo systems in hard disk drives. IEEE Trans. Magn. 2006, 42, 1896–1904. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Y.; Zhang, W. A discrete-time chattering free sliding mode control with multirate sampling method for flight simulator. Math. Probl. Eng. 2013, 2013, 865493. [Google Scholar] [CrossRef]

- Salt, J.; Tomizuka, M. Hard disk drive control by model based dual-rate controller. Computation saving by interlacing. Mechatronics 2014, 24, 691–700. [Google Scholar] [CrossRef]

- Salt, J.; Casanova, V.; Cuenca, A.; Pizá, R. Multirate control with incomplete information over Profibus-DP network. Int. J. Syst. Sci. 2014, 45, 1589–1605. [Google Scholar] [CrossRef]

- Liu, F.; Gao, H.; Qiu, J.; Yin, S.; Fan, J.; Chai, T. Networked multirate output feedback control for setpoints compensation and its application to rougher flotation process. IEEE Trans. Ind. Electron. 2014, 61, 460–468. [Google Scholar] [CrossRef]

- Khargonekar, P.P.; Sivashankar, N. H2 optimal control for sampled-data systems. Syst. Control Lett. 1991, 17, 425–436. [Google Scholar] [CrossRef]

- Tornero, J.; Albertos, P.; Salt, J. Periodic optimal control of multirate sampled data systems. IFAC Proc. Vol. 2001, 34, 195–200. [Google Scholar] [CrossRef]

- Kim, C.H.; Park, H.J.; Lee, J.; Lee, H.W.; Lee, K.D. Multi-rate optimal controller design for electromagnetic suspension systems via linear matrix inequality optimization. J. Appl. Phys. 2015, 117, 17B506. [Google Scholar] [CrossRef]

- Lee, J.H.; Gelormino, M.S.; Morarih, M. Model predictive control of multi-rate sampled-data systems: A state-space approach. Int. J. Control 1992, 55, 153–191. [Google Scholar] [CrossRef]

- Mizumoto, I.; Ikejiri, M.; Takagi, T. Stable Adaptive Predictive Control System Design via Adaptive Output Predictor for Multi-rate Sampled Systems. IFAC-PapersOnLine 2015, 48, 1039–1044. [Google Scholar] [CrossRef]

- Geng, Y.; Liu, B. Guaranteed cost control for the multi-rate networked control systems with output prediction. In Proceedings of the IEEE International Conference on Information and Automation, Lijiang, China, 8–10 August 2015; pp. 3020–3025. [Google Scholar]

- Carpiuc, S.C.; Lazar, C. Real-time multi-rate predictive cascade speed control of synchronous machines in automotive electrical traction drives. IEEE Trans. Ind. Electron. 2016, 63, 5133–5142. [Google Scholar] [CrossRef]

- Roshany-Yamchi, S.; Cychowski, M.; Negenborn, R.R.; De Schutter, B.; Delaney, K.; Connell, J. Kalman filter-based distributed predictive control of large-scale multi-rate systems: Application to power networks. IEEE Trans. Control Syst. Technol. 2013, 21, 27–39. [Google Scholar] [CrossRef]

- Anta, A.; Tabuada, P. On the minimum attention and anytime attention problems for nonlinear systems. In Proceedings of the 49th IEEE Conference on Decision and Control (CDC), Atlanta, GA, USA, 15–17 December 2010; pp. 3234–3239. [Google Scholar]

- Donkers, M.C.F.; Tabuada, P.; Heemels, W.P.M.H. Minimum attention control for linear systems. Discret. Event Dyn. Syst. 2014, 24, 199–218. [Google Scholar] [CrossRef]

- Gupta, V. On an anytime algorithm for control. In Proceedings of the 48th IEEE Conference Decision and Control (CDC), Shanghai, China, 16–18 December 2009; pp. 6218–6223. [Google Scholar]

- Quevedo, D.E.; Ma, W.J.; Gupta, V. Anytime control using input sequences with Markovian processor availability. IEEE Trans. Autom. Control 2015, 60, 515–521. [Google Scholar] [CrossRef]

- Aranda-Escolástico, E.; Guinaldo, M.; Cuenca, Á.; Salt, J.; Dormido, S. Anytime Optimal Control Strategy for Multi-Rate Systems. IEEE Access 2017, 5, 2790–2797. [Google Scholar] [CrossRef]

- Guinaldo, M.; Sánchez, J.; Dormido, S. Event-based Control for Networked Systems: From Centralized to Distributed Approaches. RIAI-Rev. Iberoam. Autom. Inform. Ind. 2017, 14, 16–30. [Google Scholar] [CrossRef]

- Loan, C.V. The sensitivity of the matrix exponential. SIAM J. Numer. Anal. 1977, 14, 971–981. [Google Scholar] [CrossRef]

- Khalil, H. Nonlinear Systems, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Hazan, E. Introduction to Online Convex Optimization. Found. Trends Optim. 2016, 2, 157–325. [Google Scholar] [CrossRef]

- Sala, A.; Cuenca, Á.; Salt, J. A retunable PID multi-rate controller for a networked control system. Inf. Sci. 2009, 179, 2390–2402. [Google Scholar] [CrossRef]

- Upton, E.; Halfacree, G. Raspberry Pi User Guide; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Coley, G. Beaglebone Black System Reference Manual; Texas Instruments: Dallas, TX, USA, 2013. [Google Scholar]

- Chacon, J.; Saenz, J.; Torre, L.D.L.; Diaz, J.M.; Esquembre, F. Design of a Low-Cost Air Levitation System for Teaching Control Engineering. Sensors 2017, 17, 2321. [Google Scholar] [CrossRef] [PubMed]

| Controller | Settling Time | ISE (Stabilization) | ISE (Sawtooth Wave) | ISE (Impulse) |

|---|---|---|---|---|

| Auxiliary PI controller | s | |||

| Algorithm in [30] | s | |||

| Proposed algorithm | s |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aranda-Escolástico, E.; Salt, J.; Guinaldo, M.; Chacón, J.; Dormido, S. Optimal Control for Aperiodic Dual-Rate Systems With Time-Varying Delays. Sensors 2018, 18, 1491. https://doi.org/10.3390/s18051491

Aranda-Escolástico E, Salt J, Guinaldo M, Chacón J, Dormido S. Optimal Control for Aperiodic Dual-Rate Systems With Time-Varying Delays. Sensors. 2018; 18(5):1491. https://doi.org/10.3390/s18051491

Chicago/Turabian StyleAranda-Escolástico, Ernesto, Julián Salt, María Guinaldo, Jesús Chacón, and Sebastián Dormido. 2018. "Optimal Control for Aperiodic Dual-Rate Systems With Time-Varying Delays" Sensors 18, no. 5: 1491. https://doi.org/10.3390/s18051491

APA StyleAranda-Escolástico, E., Salt, J., Guinaldo, M., Chacón, J., & Dormido, S. (2018). Optimal Control for Aperiodic Dual-Rate Systems With Time-Varying Delays. Sensors, 18(5), 1491. https://doi.org/10.3390/s18051491