Plasmonic Optical Fiber Sensor Based on Double Step Growth of Gold Nano-Islands

Abstract

:1. Introduction

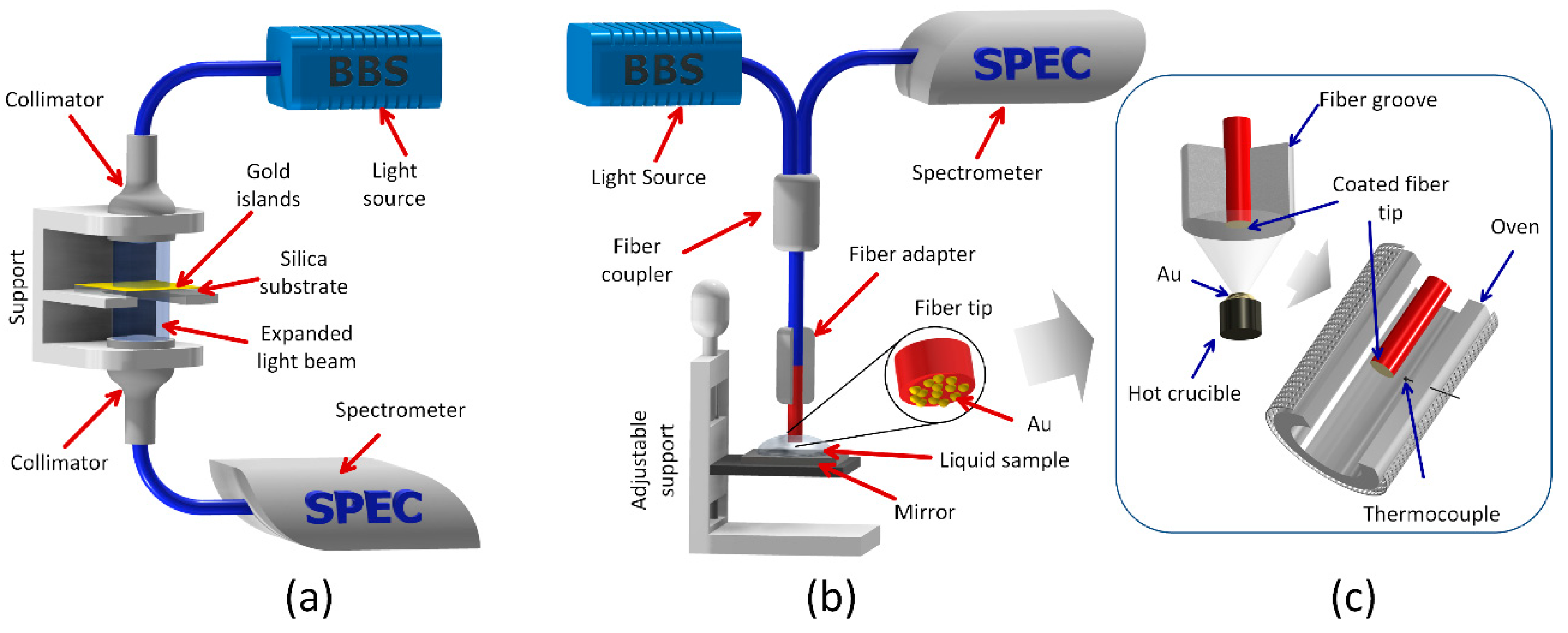

2. Materials and Methods

2.1. Sample Fabrication

2.2. Sample Characterization

3. Experimental Results and Discussion

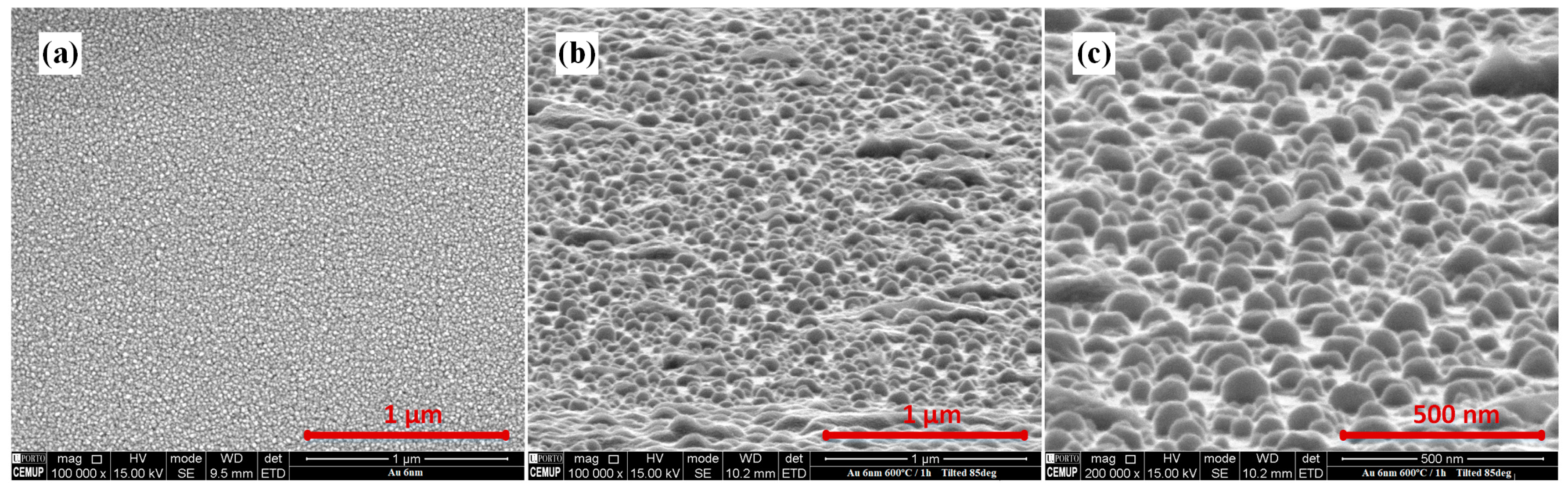

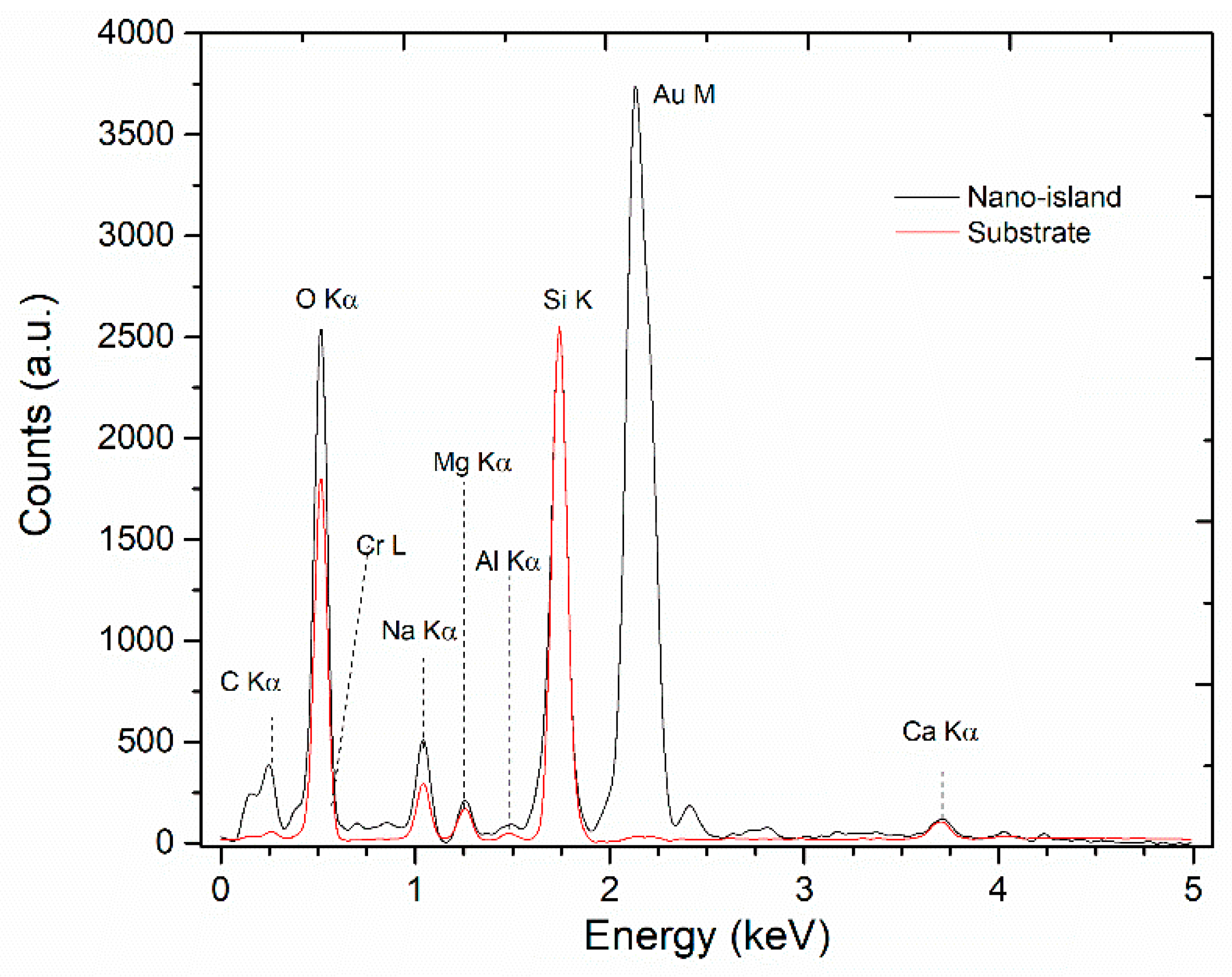

3.1. SEM/EDS Characterization of Planar Samples

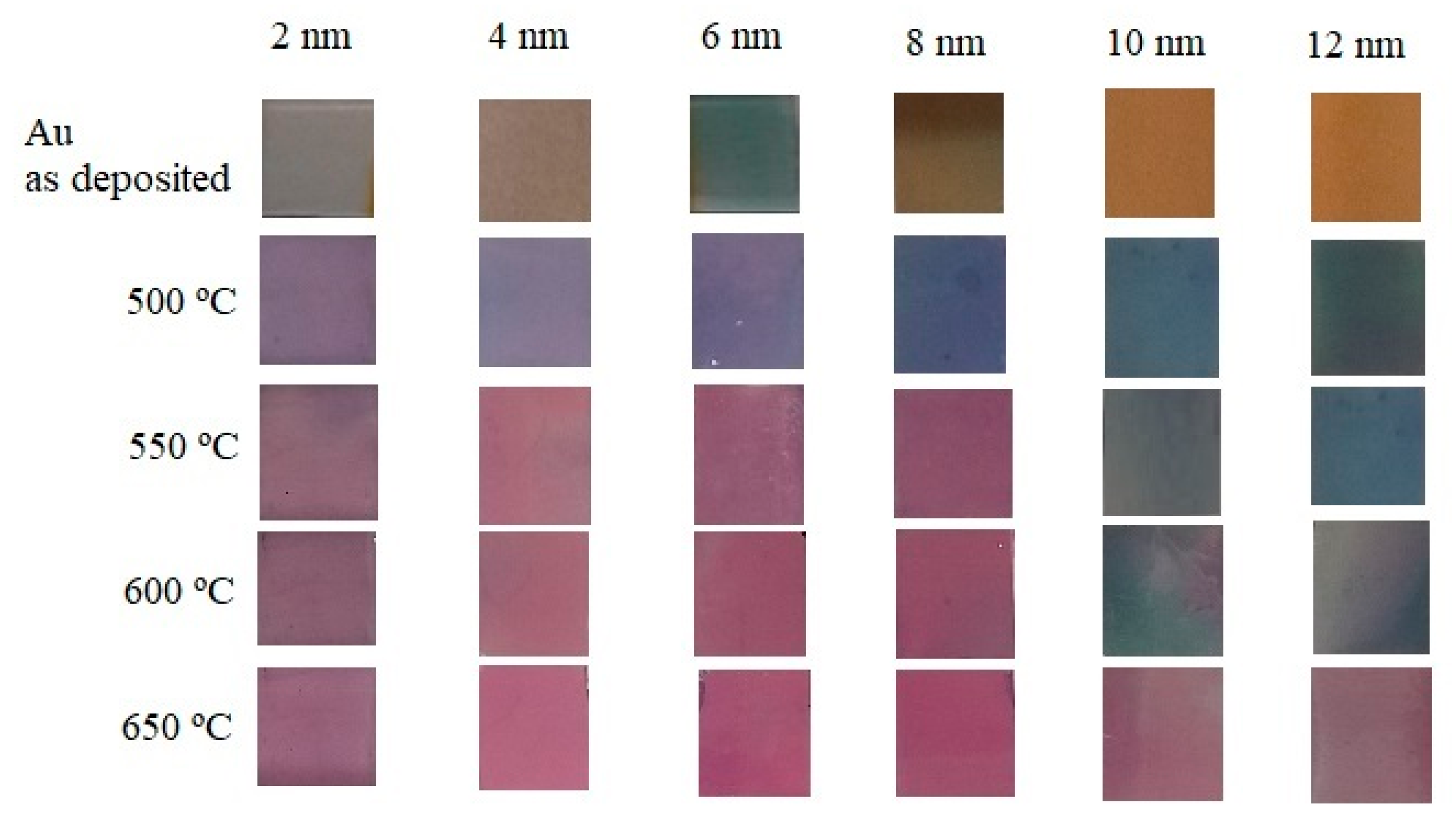

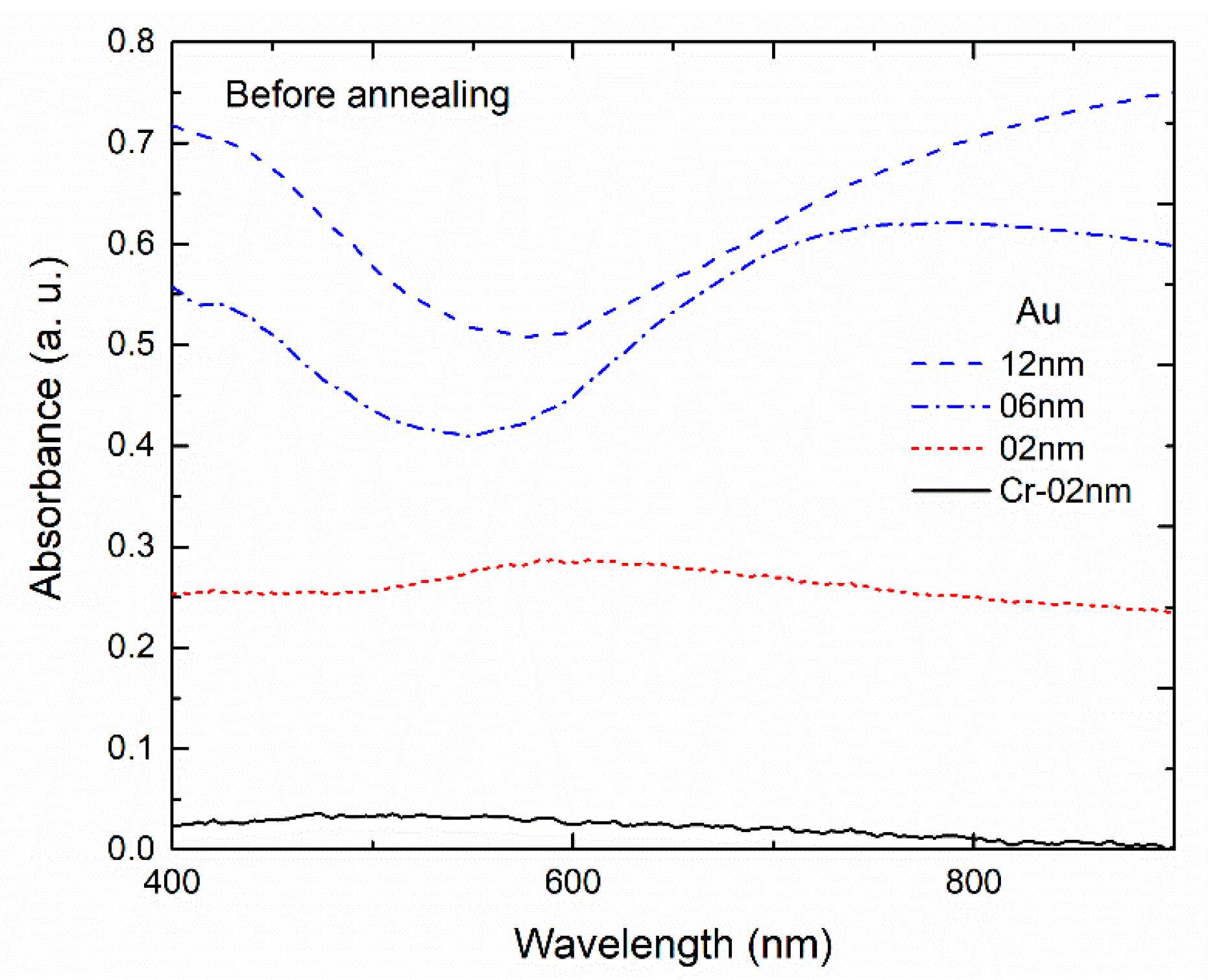

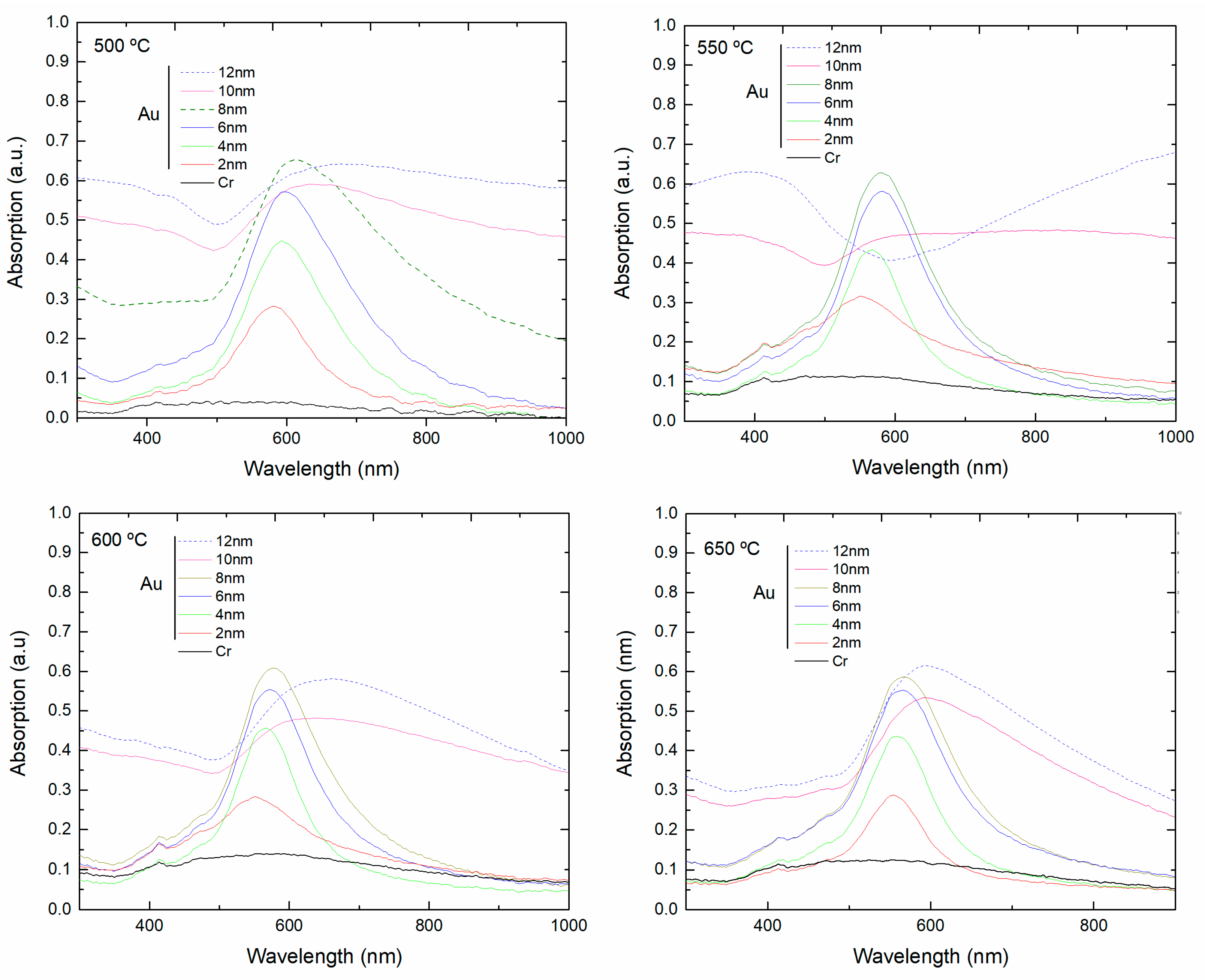

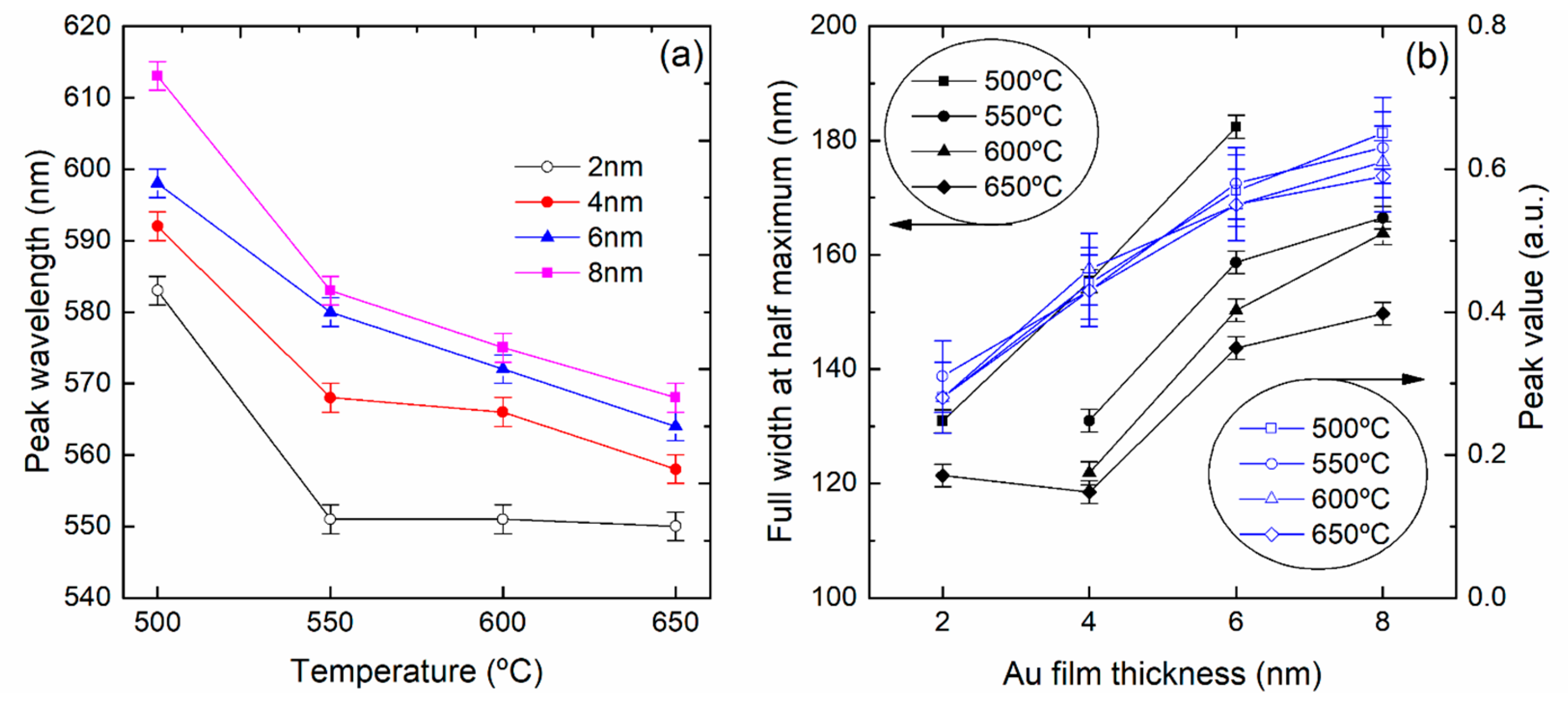

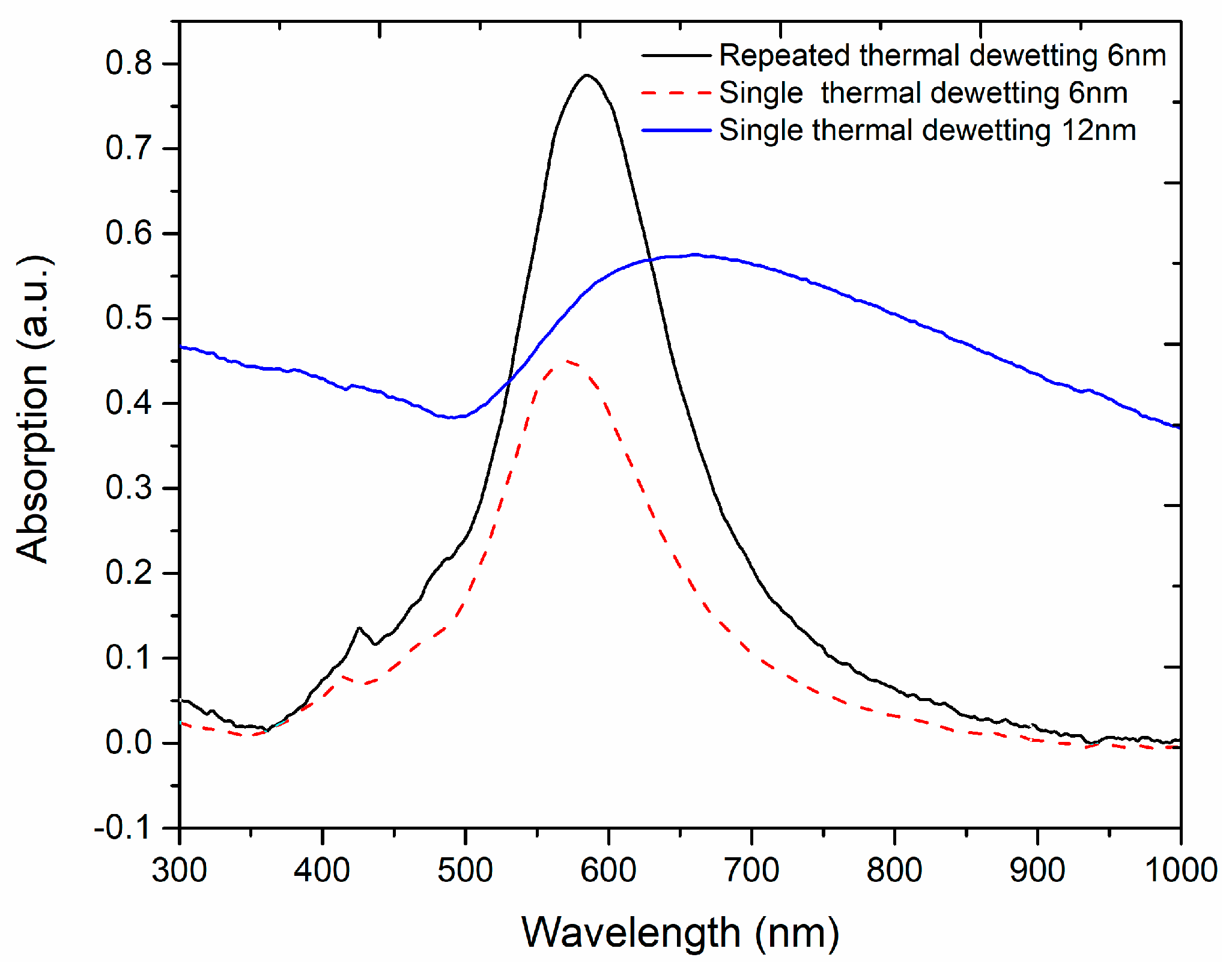

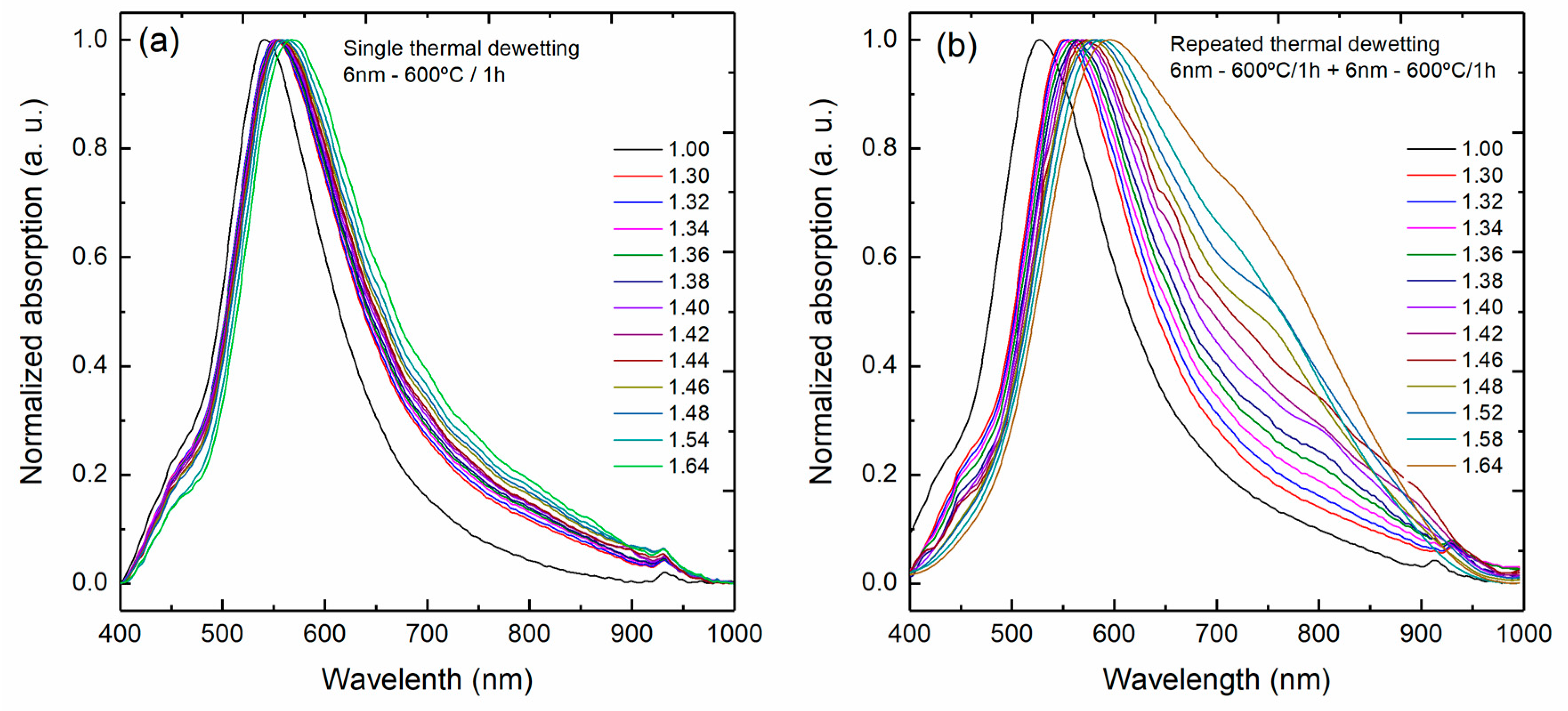

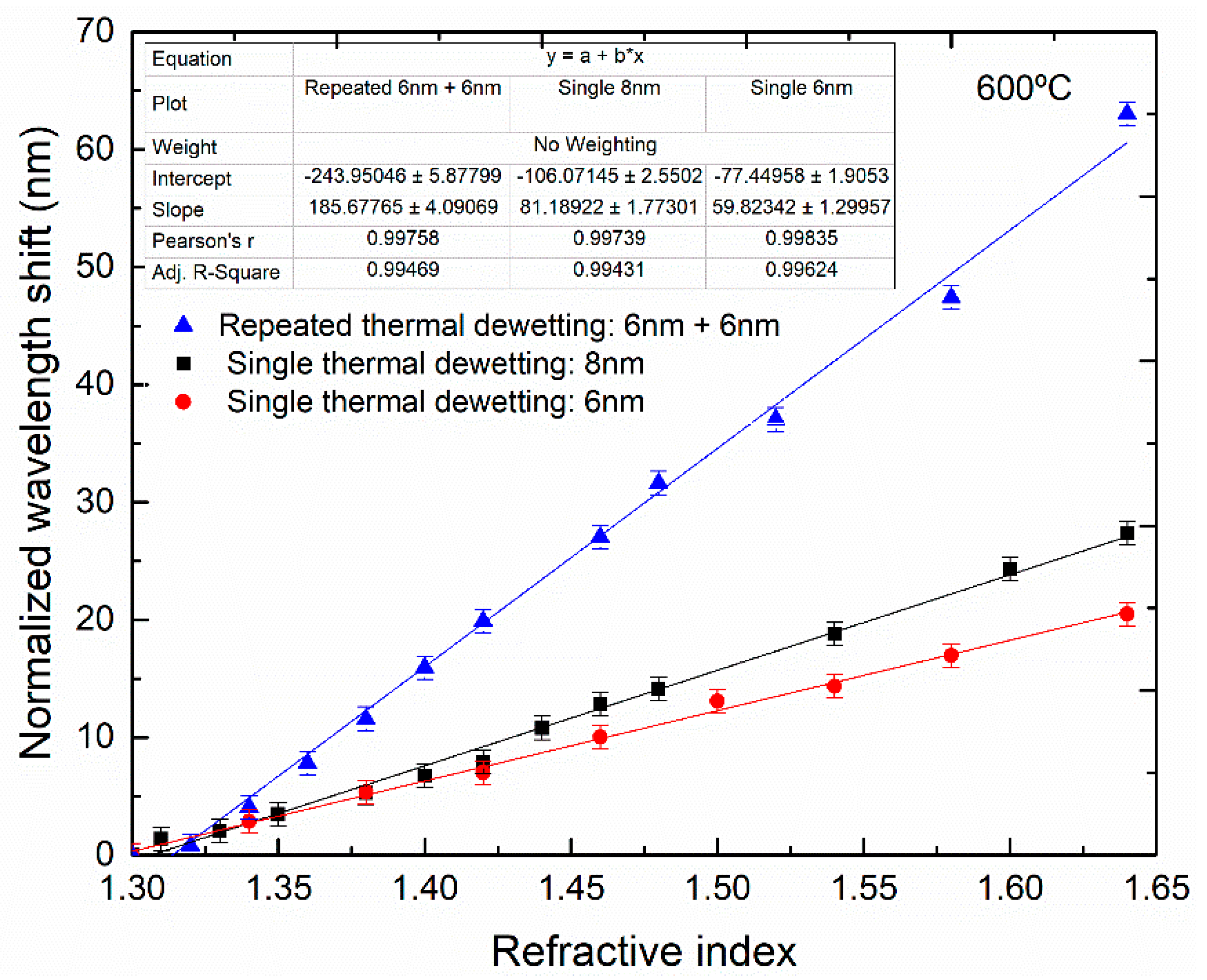

3.2. Optical Characterization of Planar Samples

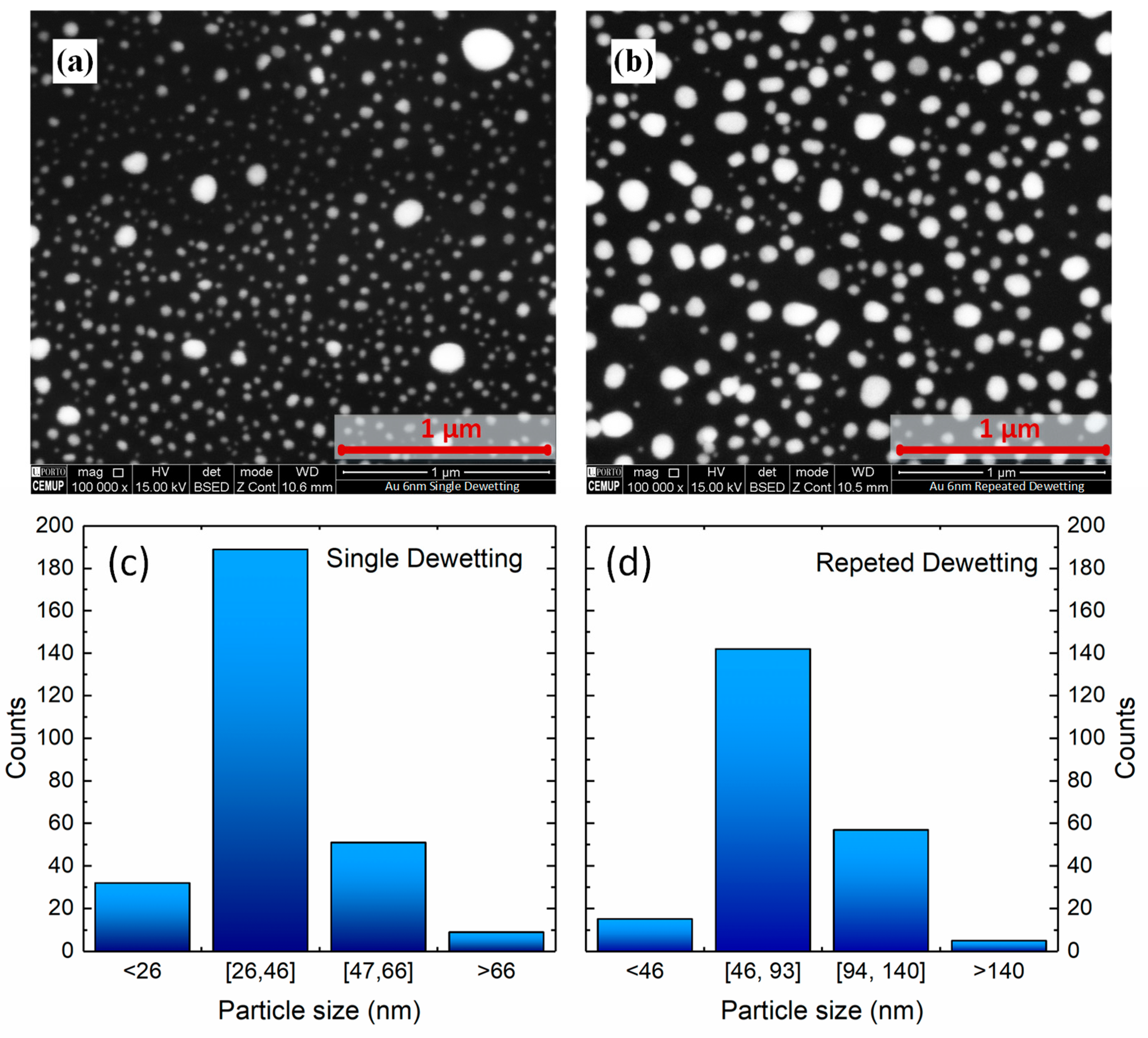

3.3. Repeated Thermal Dewetting of Au Thin Film in Planar Samples

3.4. Optical Characterization of Fiber Sensors

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pospíšilová, M.; Kuncová, G.; Trögl, J. Fiber-optic chemical sensors and fiber-optic bio-sensors. Sensors 2015, 15, 25208–25259. [Google Scholar] [CrossRef] [PubMed]

- Nath, J.P.; Singh, H.K.; Bezboruah, T. Fiber optic refractometers: A brief qualitative review. Adv. Res. Electr. Electron. Eng. 2016, 3, 400–403. [Google Scholar]

- Bhatia, P.; Gupta, B.D. Surface-plasmon-resonance-based fiber-optic refractive index sensor: Sensitivity enhancement. Appl. Opt. 2011, 50, 2032–2036. [Google Scholar] [CrossRef] [PubMed]

- Jatschka, J.; Dathe, A.; Csáki, A.; Fritzsche, W.; Stranik, O. Propagating and localized surface plasmon resonance sensing—A critical comparison based on measurements and theory. Sens. Bio-Sens. Res. 2016, 7, 62–70. [Google Scholar] [CrossRef]

- Klantsataya, E.; Jia, P.; Ebendorff-Heidepriem, H.; Monro, T.M.; François, A. Plasmonic fiber optic refractometric sensors: From conventional architectures to recent design trends. Sensors 2016, 17, 12. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.K.; Varshney, C.; Gupta, B.D. Surface plasmon resonance based fiber optic refractive index sensor utilizing cu/zno layer. AIP Conf. Proc. 2013, 1536, 1308–1309. [Google Scholar]

- Chung, T.; Lee, S.-Y.; Song, E.Y.; Chun, H.; Lee, B. Plasmonic nanostructures for nano-scale bio-sensing. Sensors 2011, 11, 10907–10929. [Google Scholar] [CrossRef] [PubMed]

- Mayer, K.M.; Hafner, J.H. Localized surface plasmon resonance sensors. Chem. Rev. 2011, 111, 3828–3857. [Google Scholar] [CrossRef] [PubMed]

- Petryayeva, E.; Krull, U.J. Localized surface plasmon resonance: Nanostructures, bioassays and biosensing—A review. Anal. Chim. Acta 2011, 706, 8–24. [Google Scholar] [CrossRef] [PubMed]

- Saha, K.; Agasti, S.S.; Kim, C.; Li, X.; Rotello, V.M. Gold nanoparticles in chemical and biological sensing. Chem. Rev. 2012, 112, 2739–2779. [Google Scholar] [CrossRef] [PubMed]

- Grzelczak, M.; Pérez-Juste, J.; Mulvaney, P.; Liz-Marzán, L.M. Shape control in gold nanoparticle synthesis. Chem. Soc. Rev. 2008, 37, 1783–1791. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Zeng, Z.; Lin, Y. Localized surface plasmon resonance (lspr)-coupled fiber-optic nanoprobe for the detection of protein biomarkers. In Biosensors and Biodetection: Methods and Protocols Volume 1: Optical-Based Detectors; Rasooly, A., Prickril, B., Eds.; Springer: New York, NY, USA, 2017; pp. 1–14. [Google Scholar]

- Sobhan, M.A.; Withford, M.J.; Goldys, E.M. Enhanced stability of gold colloids produced by femtosecond laser synthesis in aqueous solution of ctab. Langmuir 2009, 26, 3156–3159. [Google Scholar] [CrossRef] [PubMed]

- Reed, J.A.; Cook, A.; Halaas, D.J.; Parazzoli, P.; Robinson, A.; Matula, T.J.; Grieser, F. The effects of microgravity on nanoparticle size distributions generated by the ultrasonic reduction of an aqueous gold-chloride solution. Ultrason. Sonochem. 2003, 10, 285–289. [Google Scholar] [CrossRef]

- Tesler, A.B.; Maoz, B.M.; Feldman, Y.; Vaskevich, A.; Rubinstein, I. Solid-state thermal dewetting of just-percolated gold films evaporated on glass: Development of the morphology and optical properties. J. Phys. Chem. C 2013, 117, 11337–11346. [Google Scholar] [CrossRef]

- Samavat, F.; Rahman, J.J. Preparation of silver thin films, and the study of the annealing effects on their structures and optical properties. Surf. Topogr. Metrol. Prop. 2015, 3, 045003. [Google Scholar] [CrossRef]

- Kracker, M.; Worsch, C.; Rüssel, C. Optical properties of palladium nanoparticles under exposure of hydrogen and inert gas prepared by dewetting synthesis of thin-sputtered layers. J. Nanopart. Res. 2013, 15, 1594. [Google Scholar] [CrossRef]

- Jia, K.; Bijeon, J.-L.; Adam, P.-M.; Ionescu, R.E. Large scale fabrication of gold nano-structured substrates via high temperature annealing and their direct use for the lspr detection of atrazine. Plasmonics 2013, 8, 143–151. [Google Scholar] [CrossRef]

- Gupta, G.; Tanaka, D.; Ito, Y.; Shibata, D.; Shimojo, M.; Furuya, K.; Mitsui, K.; Kajikawa, K. Absorption spectroscopy of gold nanoisland films: Optical and structural characterization. Nanotechnology 2008, 20, 025703. [Google Scholar] [CrossRef] [PubMed]

- Al-Rubaye, A.G.; Nabok, A.; Tsargorodska, A. Spectroscopic ellipsometry study of gold nanostructures for lspr bio-sensing applications. Sens. Bio-Sens. Res. 2017, 12, 30–35. [Google Scholar] [CrossRef]

- Kang, M.; Park, S.-G.; Jeong, K.-H. Repeated solid-state dewetting of thin gold films for nanogap-rich plasmonic nanoislands. Sci. Rep. 2015, 5, 14790. [Google Scholar] [CrossRef] [PubMed]

- Meriaudeau, F.; Downey, T.; Wig, A.; Passian, A.; Buncick, M.; Ferrell, T.L. Fiber optic sensor based on gold island plasmon resonance. Sens. Actuators B Chem. 1999, 54, 106–117. [Google Scholar] [CrossRef]

- Hosoki, A.; Nishiyama, M.; Watanabe, K. Localized surface plasmon sensor based on gold island films using a hetero-core structured optical fiber. Appl. Opt. 2017, 56, 6673–6679. [Google Scholar] [CrossRef] [PubMed]

- Antohe, I.; Schouteden, K.; Goos, P.; Delport, F.; Spasic, D.; Lammertyn, J. Thermal annealing of gold coated fiber optic surfaces for improved plasmonic biosensing. Sens. Actuators B Chem. 2016, 229, 678–685. [Google Scholar] [CrossRef]

- Dalgaard, P. Introductory Statistics with R; Springer: Berlin, Germany, 2008. [Google Scholar]

- Levine, J.R.; Cohen, J.; Chung, Y. Thin film island growth kinetics: A grazing incidence small angle x-ray scattering study of gold on glass. Surf. Sci. 1991, 248, 215–224. [Google Scholar] [CrossRef]

- Karakouz, T.; Maoz, B.M.; Lando, G.; Vaskevich, A.; Rubinstein, I. Stabilization of gold nanoparticle films on glass by thermal embedding. ACS Appl. Mater. Interfaces 2011, 3, 978–987. [Google Scholar] [CrossRef] [PubMed]

- Treu, J.I. Mie scattering, maxwell garnett theory, and the giaever immunology slide. Appl. Opt. 1976, 15, 2746–2750. [Google Scholar] [CrossRef] [PubMed]

- Rai, V.N.; Srivastava, A.K.; Mukherjee, C.; Deb, S.K. Localized surface plasmon resonance (lspr) and refractive index sensitivity of vacuum evaporated nanostructured gold thin films. arXiv, 2014; arXiv:1406.4605. [Google Scholar]

- Martinsson, E.; Sepulveda, B.; Chen, P.; Elfwing, A.; Liedberg, B.; Aili, D. Optimizing the refractive index sensitivity of plasmonically coupled gold nanoparticles. Plasmonics 2014, 9, 773–780. [Google Scholar] [CrossRef]

| Nano-islands | Thickness of Gold Thin Film (nm) | ||||

|---|---|---|---|---|---|

| 2 | 4 | 6 | 8 | 10 | |

| Diameter ± standard deviation | 24.1 ± 5.1 a | 30.5 ± 5.3 a | 41.9 ± 6.1 b | 61.8 ± 12.3 c | 73.4 ± 15.2 c |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Almeida, J.M.M.M.; Vasconcelos, H.; Jorge, P.A.S.; Coelho, L. Plasmonic Optical Fiber Sensor Based on Double Step Growth of Gold Nano-Islands. Sensors 2018, 18, 1267. https://doi.org/10.3390/s18041267

De Almeida JMMM, Vasconcelos H, Jorge PAS, Coelho L. Plasmonic Optical Fiber Sensor Based on Double Step Growth of Gold Nano-Islands. Sensors. 2018; 18(4):1267. https://doi.org/10.3390/s18041267

Chicago/Turabian StyleDe Almeida, José M. M. M., Helena Vasconcelos, Pedro A. S. Jorge, and Luis Coelho. 2018. "Plasmonic Optical Fiber Sensor Based on Double Step Growth of Gold Nano-Islands" Sensors 18, no. 4: 1267. https://doi.org/10.3390/s18041267

APA StyleDe Almeida, J. M. M. M., Vasconcelos, H., Jorge, P. A. S., & Coelho, L. (2018). Plasmonic Optical Fiber Sensor Based on Double Step Growth of Gold Nano-Islands. Sensors, 18(4), 1267. https://doi.org/10.3390/s18041267