A Three-Step Resolution-Reconfigurable Hazardous Multi-Gas Sensor Interface for Wireless Air-Quality Monitoring Applications

Abstract

1. Introduction

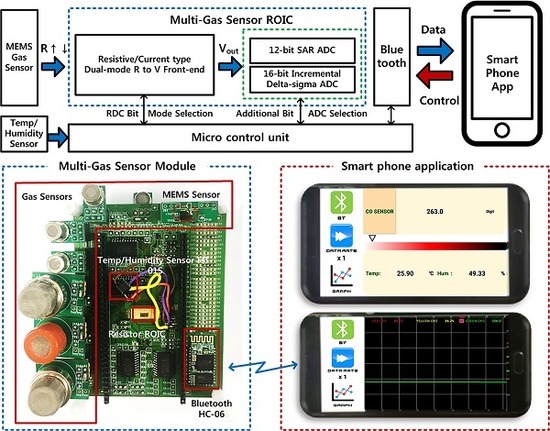

2. Wireless Multi-Gas Sensor Interface

2.1. Multi-Sensor System Architecture

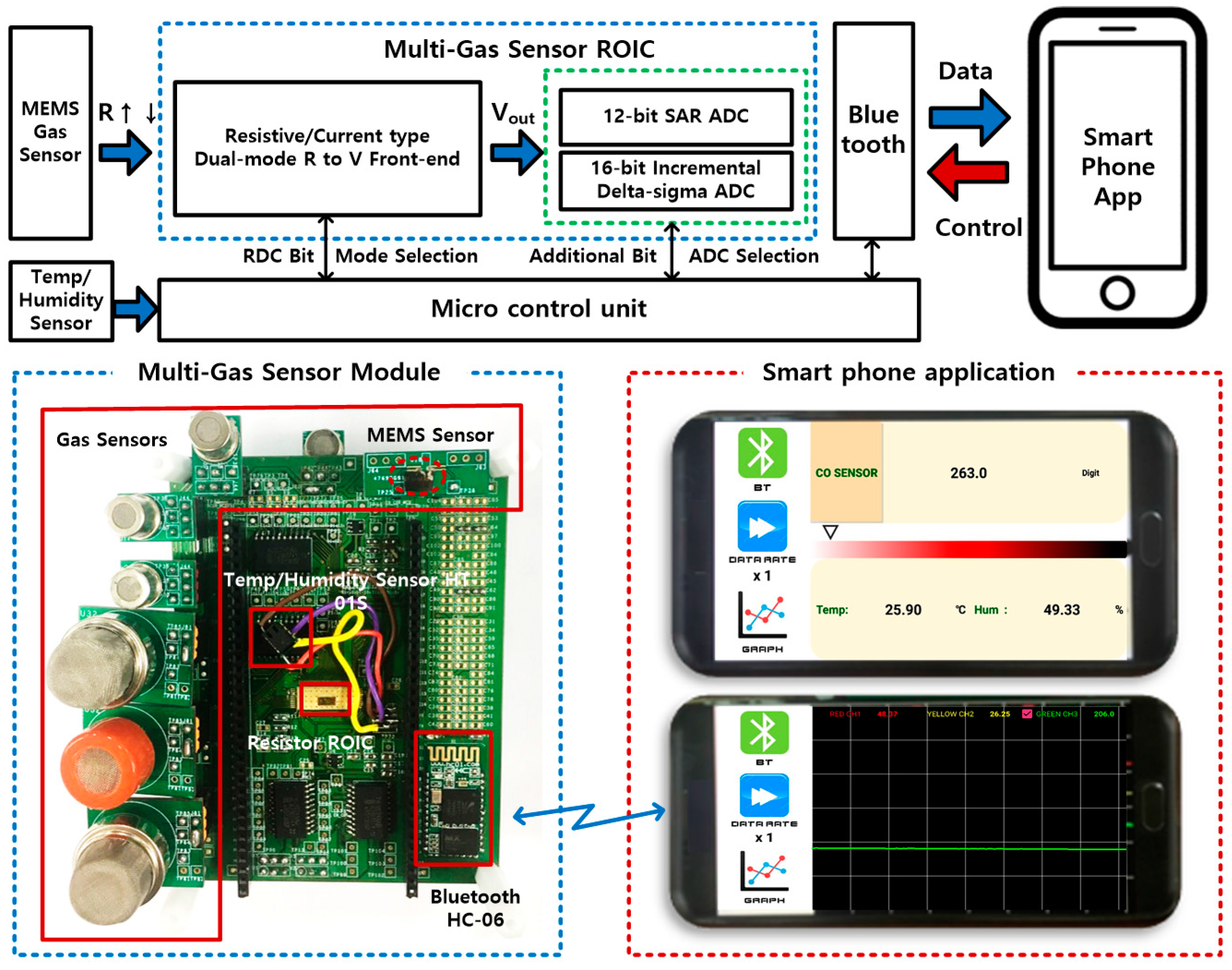

2.2. In-House Mems Sensor Device

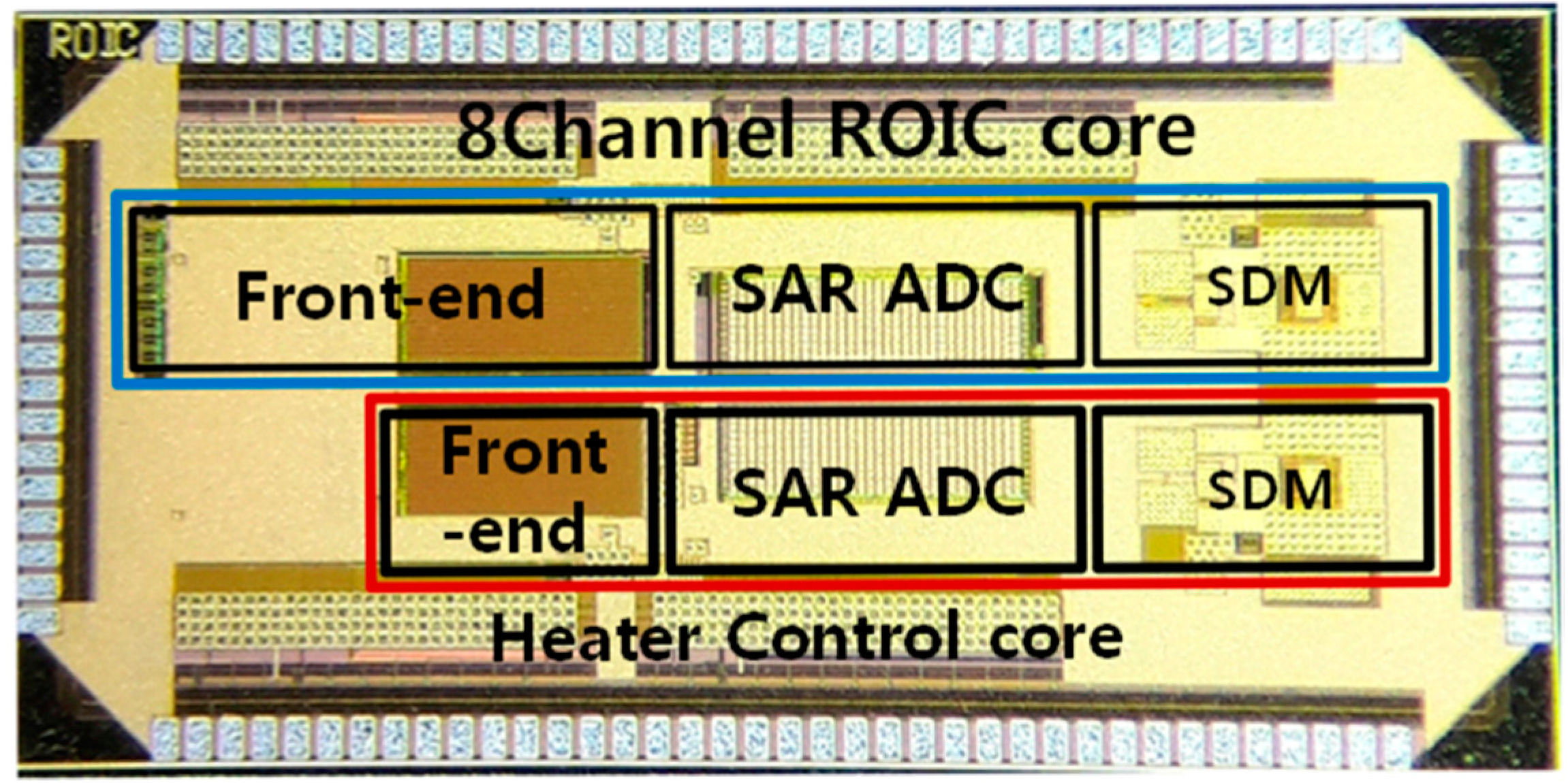

3. Reconfigurable Multi-Gas Sensor ROIC

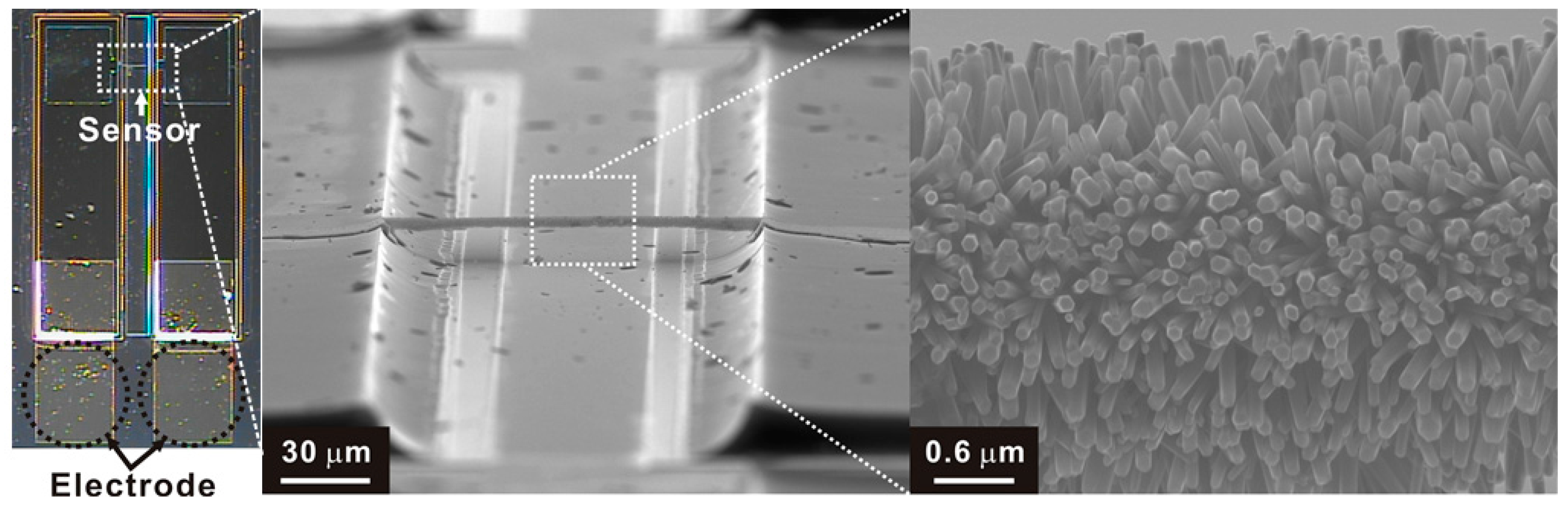

3.1. Dual-Mode Readout Front-End

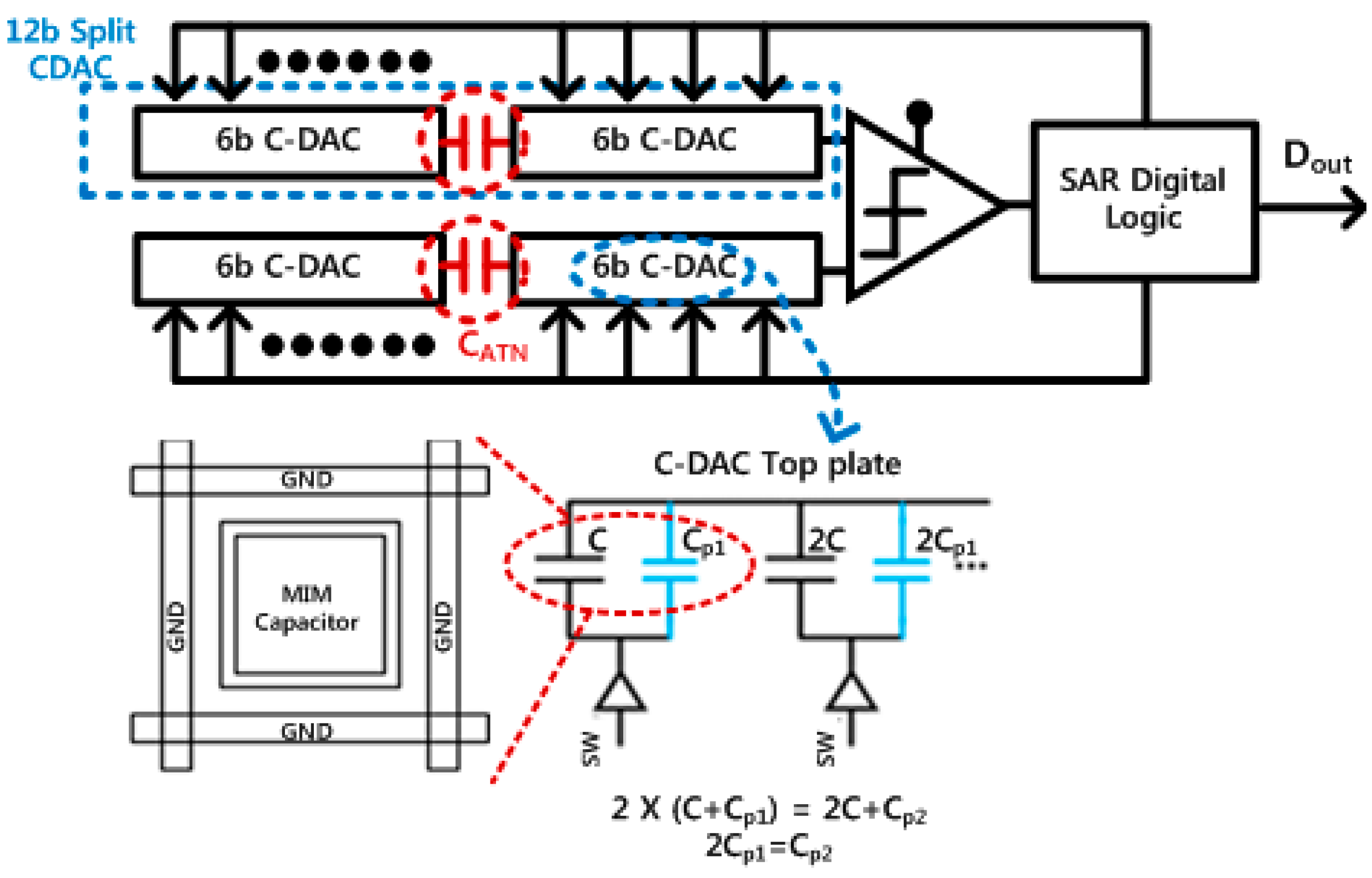

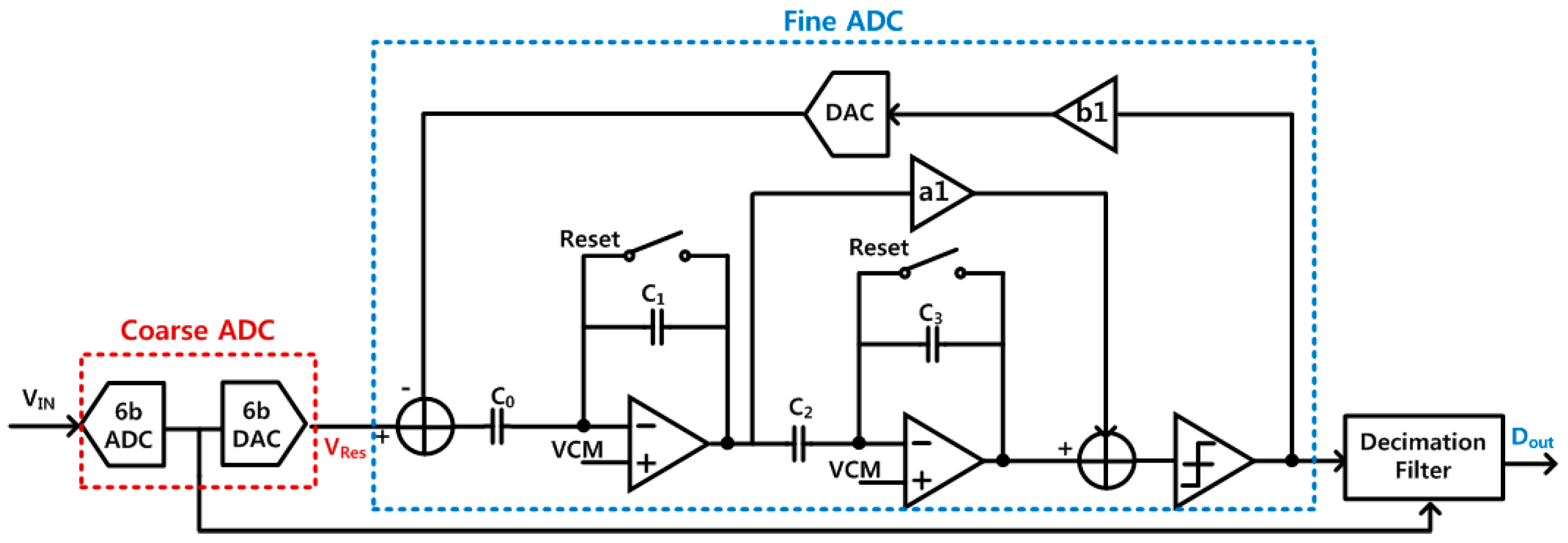

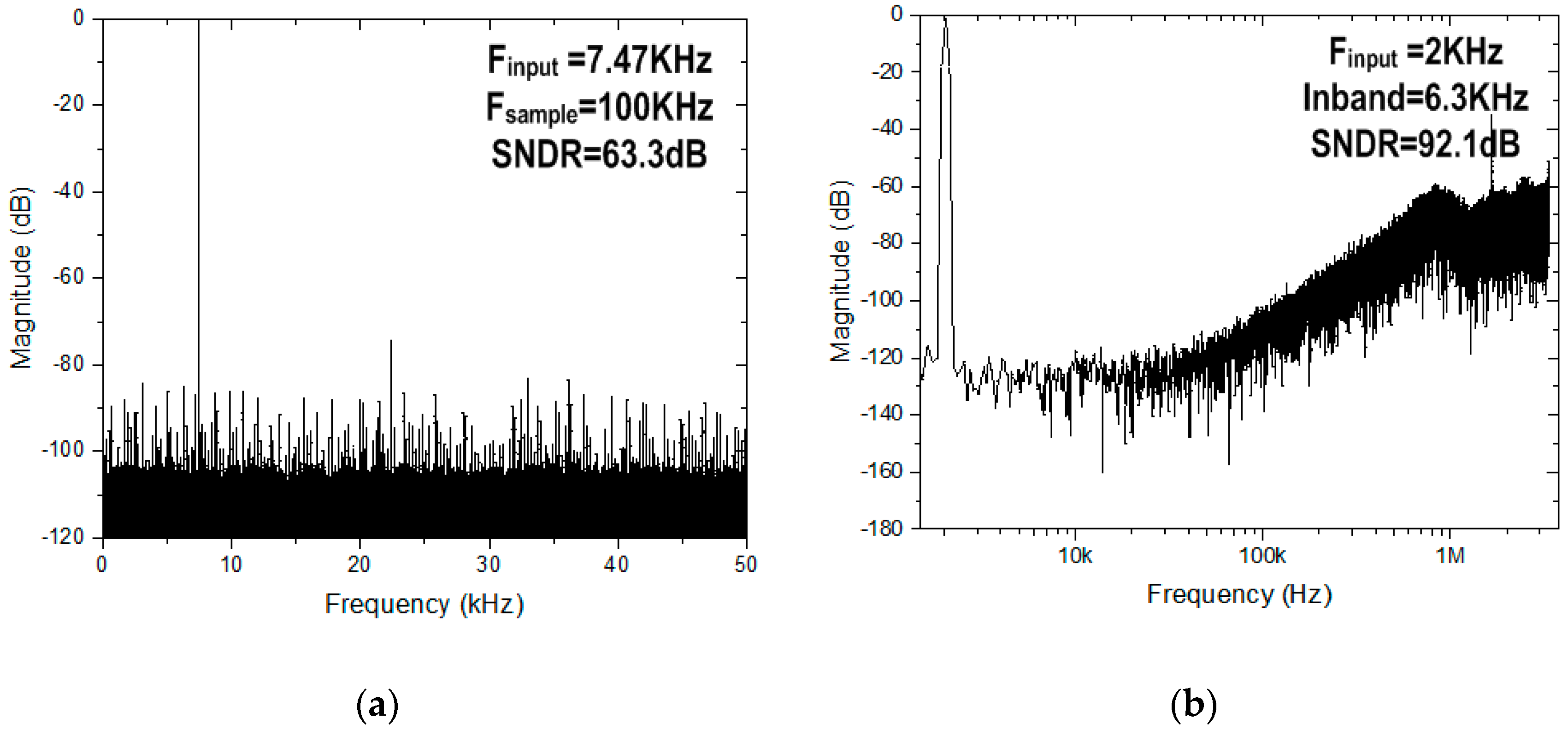

3.2. Three-Step Reconfigurable Digital Conversion

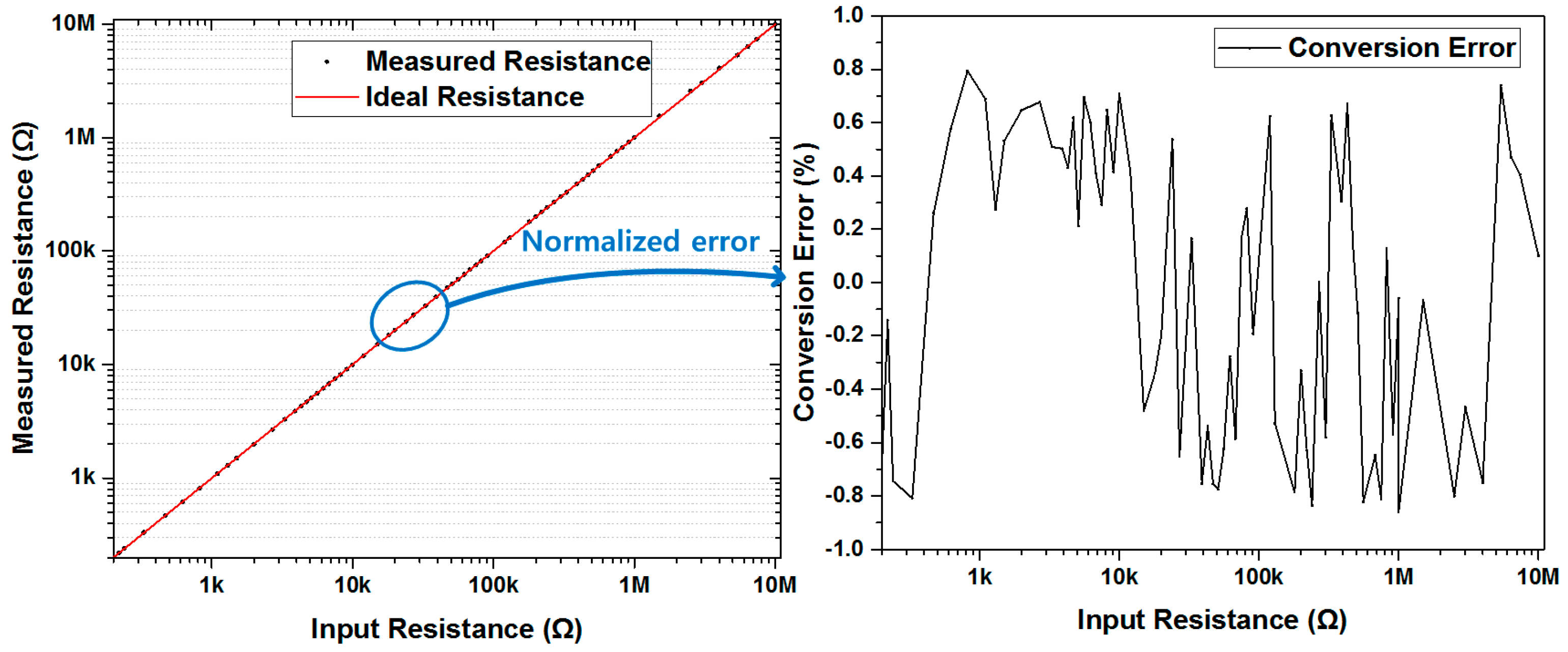

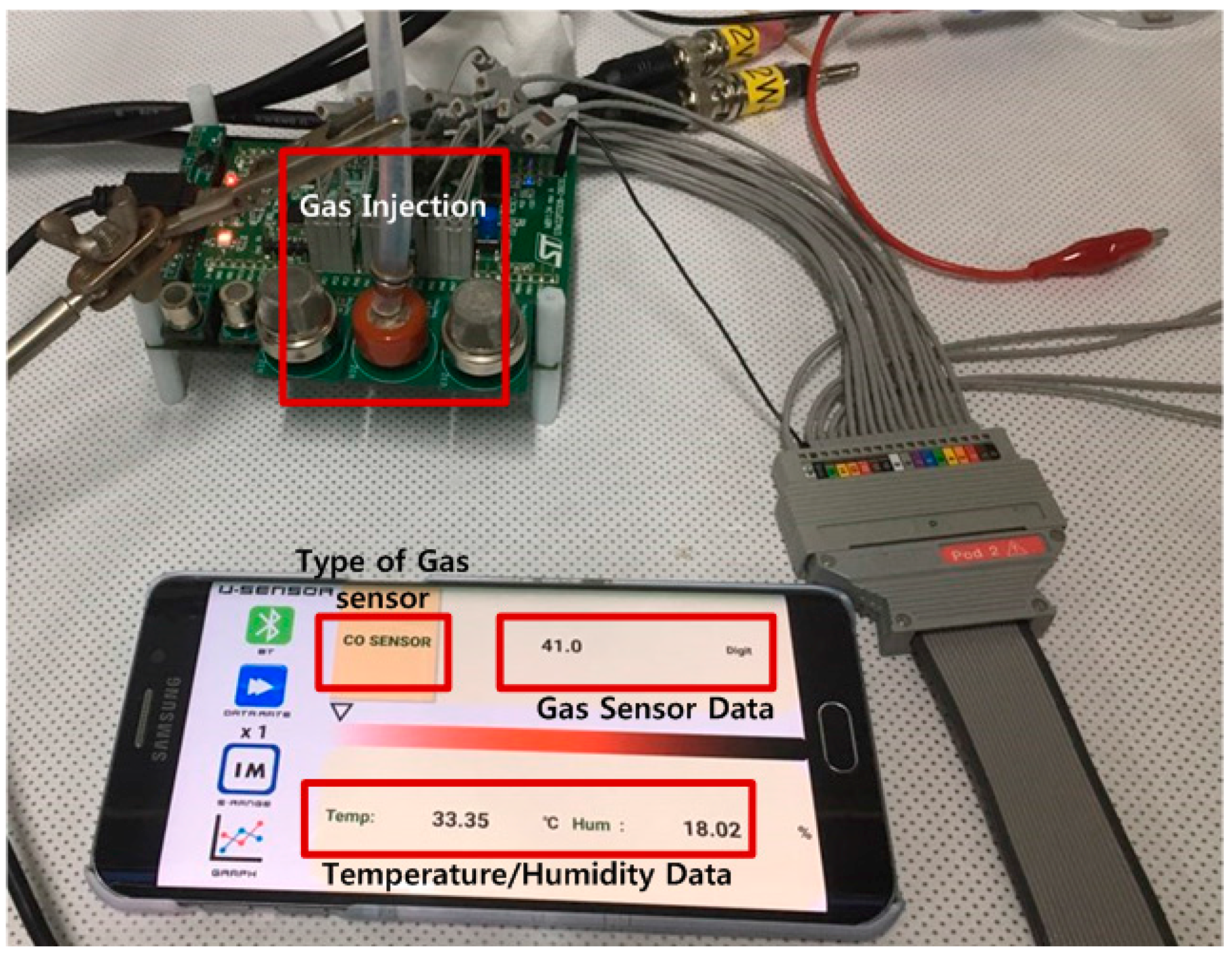

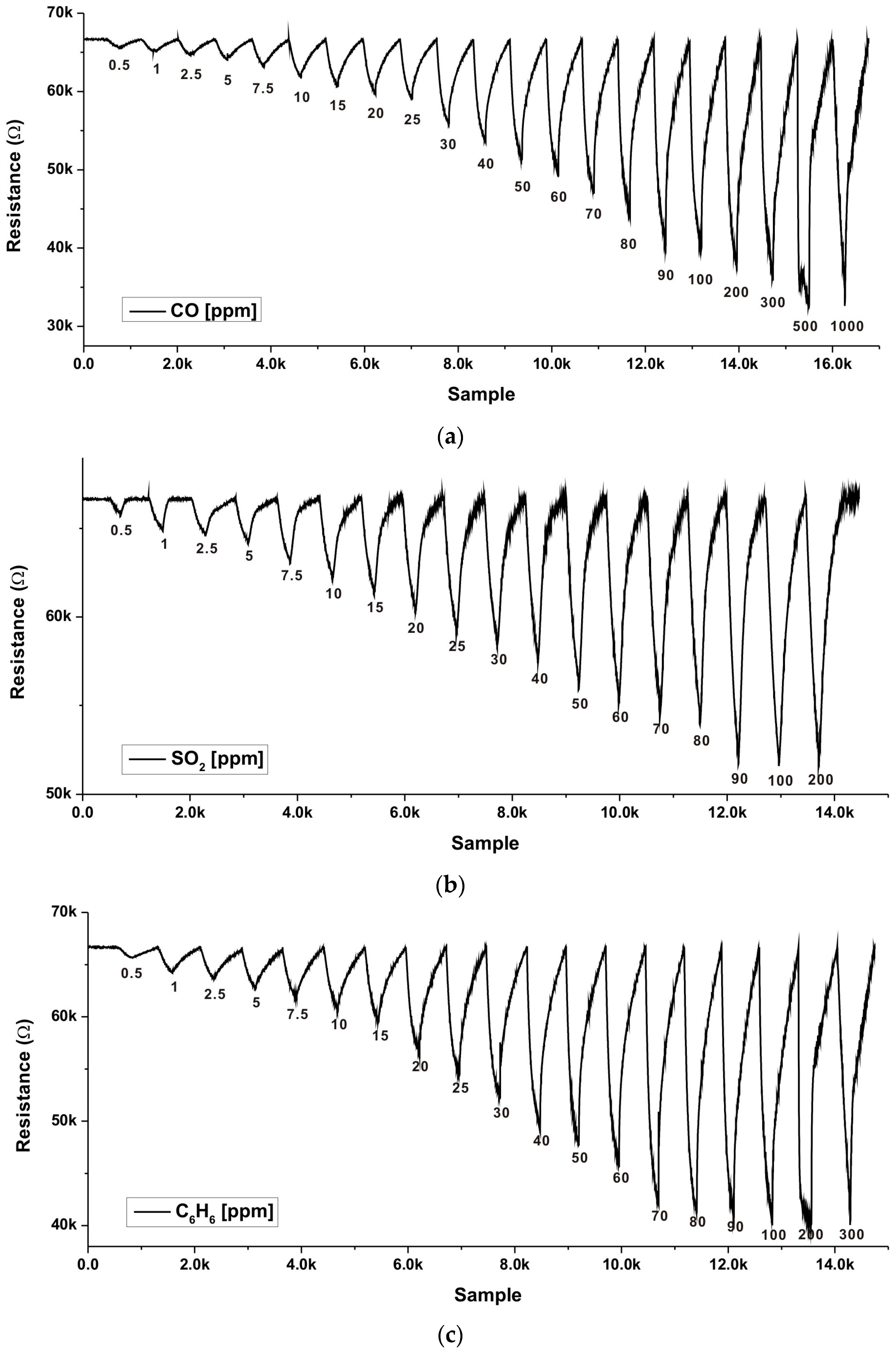

4. Measurement Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yi, W.-Y.; Leung, K.-S.; Leung, Y.; Meng, M.-L.; Mak, T. Modular Sensor System (MSS) for Urban Air Pollution Monitoring. IEEE Sens. 2016, 1–3. [Google Scholar] [CrossRef]

- Zampolli, S.; Elmi, I.; Ahmed, F.; Passini, M.; Cardinali, G.C.; Nicoletti, S.; Dori, L. An electronic nose based on solid state sensor array for low-cost indoor air quality monitoring application. Sens. Actuator B Chem. 2004, 101, 39–46. [Google Scholar] [CrossRef]

- Itoh, T.; Miwai, T.; Tsuruta, A.; Akamatsu, T.; Izu, N.; Shin, W.; Park, J.; Hida, T.; Eda, T.; Setoguchi, Y. Development of an Exhaled Breath Monitoring System with Semiconductive Gas Sensors, a Gas Condenser Unit, and Gas Chromatograph Columns. Sensors 2016, 16, 1891. [Google Scholar] [CrossRef] [PubMed]

- Korotcenkov, G. Metal oxides for solid-state gas sensors: What determines our choice? Mater. Sci. Eng. B. 2007, 139, 1–23. [Google Scholar] [CrossRef]

- Li, C.; Lv, M.; Zuo, J.; Huang, X. SnO2 Highly Sensitive CO Gas Sensors Based on Quasi-Molecular-Imprinting Mechanism Design. Sensors 2015, 15, 3789–3800. [Google Scholar] [CrossRef] [PubMed]

- Xue, N.; Zhang, Q.; Zhang, S.; Zong, P.; Yang, F. Highly Sensitive and Selective Hydrogen Gas Sensor Using the Mesoporous SnO2 Modified Layers. Sensors 2017, 17, 2351. [Google Scholar] [CrossRef] [PubMed]

- Gardner, J.W.; Guha, P.K.; Udrea, F.; Covington, J.A. CMOS Interfacing for Integrated Gas Sensor: A Review. IEEE Sens. J. 2010, 10, 1833–1848. [Google Scholar] [CrossRef]

- Kim, H.; Chung, W.-S.; Kim, H.-J.; Son, S.-H. A Resistance Deviation-to-Pulsewidth Converter for Resistive Sensors. IEEE Trans. Instrum. Meas. 2009, 58, 397–400. [Google Scholar]

- Kim, S.-W.; Eom, W.-J.; Choi, J.; Kim, J.J. Dual-mode wide-range linear CMOS interface circuit for resistive sensors. IEEE. Electron. Lett. 2014, 50, 1575–1577. [Google Scholar] [CrossRef]

- Shu, L.; Tao, X.; Feng, D.D. A New Approach for Readout of Resistive Sensor Arrays for Wearable Electronic Applications. IEEE Sens. J. 2015, 15, 442–452. [Google Scholar]

- Ponnalagu, R.N.; George, B.; Jagadeesh, K.V. A Linearizing Digitizer for Wheatstone Bridge Based Signal Conditioning of Resistive Sensors. IEEE Sens. J. 2017, 17, 1696–1705. [Google Scholar]

- Ha, H.; Suh, Y.; Lee, S.-K.; Park, H.-J.; Sim, J.-Y. A 0.5 V, 11.3-uW, 1-kS/s Resistive Sensor Interface Circuit with Correlated Double Sampling. In Proceedings of the IEEE 2012 Custom Integrated Circuits Conference, San Jose, CA, USA, 9–12 September 2012; pp. 1–4. [Google Scholar]

- Choi, M.; Gu, J.; Blaauw, D.; Sylvester, D. Wide Input Range 1.7 uW 1.2 kS/s Resistive Sensor Interface Circuit with 1 cycle/sample Logarithmic Sub-Ranging. In Proceedings of the 2015 Symposium on VLSI Circuits (VLSI Circuits) Digest of Technical, Kyoto, Japan, 17–19 June 2015; pp. 330–331. [Google Scholar]

- Esch, H.; Huyberechts, G.; Maes, G.; Manca, J.; Ceuninck, W.D.; Schepper, L.D. The stability of Pt heater and temperature sensing elements for silicon integrated tin oxide gas sensors. Sens. Actuator B Chem. 2000, 65, 190–192. [Google Scholar] [CrossRef]

- Wang, M.-H.; Hu, K.-A.; Zhao, B.-Y.; Zhang, N.-F. Degradation phenomena due to humidity in low voltage ZnO varistors. Ceram. Int. 2007, 33, 151–154. [Google Scholar] [CrossRef]

- Sharma, D.K.; Dwara, R.S.V.; Botre, B.A.; Akbar, S.A. Temperature control and readout circuit interface for Mox based NH3 gas sensor. Microsyst. Technol. 2017, 23, 1575–1583. [Google Scholar] [CrossRef]

- Woo, S.H.; Choi, Y.Y.; Kim, D.J.; Bien, F.; Kim, J.J. Tissue-Informative Mechanism for Wearable Non-invasive Continuous Blood Pressure Monitoring. Sci. Rep. 2014, 5, 6618. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Kim, D.J.; Choi, Y.Y.; Park, K.; Kim, S.-W.; Woo, S.H.; Kim, J.J. A Multi-Sensor Mobile Interface for Industrial Environment and Healthcare Monitoring. IEEE Trans. Ind. Electron. 2017, 64, 2344–2352. [Google Scholar] [CrossRef]

- Lim, Y.; Heo, J.-I.; Madou, M.; Shin, H. Monolithic carbon structures including suspended single nanowires and nanomeshes as a sensor platform. Nanoscale Res. Lett. 2013, 8, 492. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.; Lim, Y.; Shin, H. Self-heating hydrogen gas sensor based on an array of single suspended carbon nanowires functionalized with palladium nanoparticles. Sens. Actuators B Chem. 2017, 247, 564–572. [Google Scholar] [CrossRef]

- Lim, Y.; Kim, S.; Kwon, Y.M.; Baik, J.M.; Shin, H. Highly sensitive gas sensing platform based on metal-oxide nanowire forest on suspended carbon nanowire fabricated at a wafer level. Sens. Actuators B Chem. 2018, 260, 55–62. [Google Scholar] [CrossRef]

- Park, K.; Kim, S.M.; Eom, W.-J.; Kim, J.J. A Reconfigurable Readout Integrated Circuit for Heterogeneous Display-Based Multi-Sensor System. Sensors 2017, 17, 759. [Google Scholar] [CrossRef] [PubMed]

- Chae, Y.; Souri, K.; Makinwa, K.A.A. A 6.3 μW 20 bit Incremental Zoom-ADC with 6 ppm INL and 1 μV Offset. IEEE J. Solid State Circuits 2013, 48, 3019–3027. [Google Scholar] [CrossRef]

- Eom, W.-J.; Kwon, K.; Lee, K.; Kim, J.J. A Supply-Scalabe Dual-Rate Dual-Mode DAC with an Adaptive Swing Control. IEEE Trans. Circuits Syst. II Express Briefs 2017. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, X.; Tamura, H.; Kibune, M.; Tomita, Y.; Hamada, T.; Yoshioka, M.; Ishikawa, K.; Tsukamoto, S.; Kuroda, T.; et al. Split Capacitor DAC Mismatch Calibration in Successive Approximation ADC. In Proceedings of the 2009 IEEE Custom Integrated Circuit Conference (CICC), Rome, Italy, 13–16 September 2009; pp. 279–281. [Google Scholar]

| Operation mode | Current mode (250 Ω–1 MΩ) | Resistor mode (1 MΩ–10 MΩ) | ||

|---|---|---|---|---|

| Component | Power | Component | Power | |

| Low power mode (Front-end) | Current cell (Current flowing in the sensor) | 1.4 μW–3.1 mW | Resistor DAC (Current flowing in the sensor) | 0.2 μW–12.1 μW |

| Reference current cell | 54.5 μW | Digital logic + Comparator | 1.1 μW | |

| Digital logic + Comparator | 1.1 μW | - | - | |

| Total (Front-end) | 57.1 μW–3.14 mW | Total (Front-end) | 1.3 μW–13.3 μW | |

| Medium resolution mode (Front-end + SAR ADC) | SAR ADC | 73 μW | SAR ADC | 73 μW |

| S/H (Amp + CMFB) | 1.16 mW | S/H (Amp + CMFB) | 1.16 mW | |

| Total (Front-end + SAR ADC + S/H) | 1.29 mW–4.43 mW | Total (Front-end + SAR ADC + S/H) | 1.24 mW–1.25 mW | |

| High resolution mode (Front-end + Incremental ADC) | Incremental ADC + S/H | 1.72 mW | Incremental ADC + S/H | 1.72 mW |

| Total (Front-end + Incremental ADC + S/H) | 1.78 mW–4.87 mW | Total (Front-end + Incremental ADC + S/H) | 1.72 mW–1.73 mW | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.; Park, K.; Lee, S.; Lim, Y.; Oh, B.; Chae, H.Y.; Park, C.S.; Shin, H.; Kim, J.J. A Three-Step Resolution-Reconfigurable Hazardous Multi-Gas Sensor Interface for Wireless Air-Quality Monitoring Applications. Sensors 2018, 18, 761. https://doi.org/10.3390/s18030761

Choi S, Park K, Lee S, Lim Y, Oh B, Chae HY, Park CS, Shin H, Kim JJ. A Three-Step Resolution-Reconfigurable Hazardous Multi-Gas Sensor Interface for Wireless Air-Quality Monitoring Applications. Sensors. 2018; 18(3):761. https://doi.org/10.3390/s18030761

Chicago/Turabian StyleChoi, Subin, Kyeonghwan Park, Seungwook Lee, Yeongjin Lim, Byungjoo Oh, Hee Young Chae, Chan Sam Park, Heungjoo Shin, and Jae Joon Kim. 2018. "A Three-Step Resolution-Reconfigurable Hazardous Multi-Gas Sensor Interface for Wireless Air-Quality Monitoring Applications" Sensors 18, no. 3: 761. https://doi.org/10.3390/s18030761

APA StyleChoi, S., Park, K., Lee, S., Lim, Y., Oh, B., Chae, H. Y., Park, C. S., Shin, H., & Kim, J. J. (2018). A Three-Step Resolution-Reconfigurable Hazardous Multi-Gas Sensor Interface for Wireless Air-Quality Monitoring Applications. Sensors, 18(3), 761. https://doi.org/10.3390/s18030761