A Self-Powered, Threshold-Based Wireless Sensor for the Detection of Floor Vibrations

Abstract

1. Introduction

2. Development of a Cantilever-Type Piezoelectric Energy Harvester

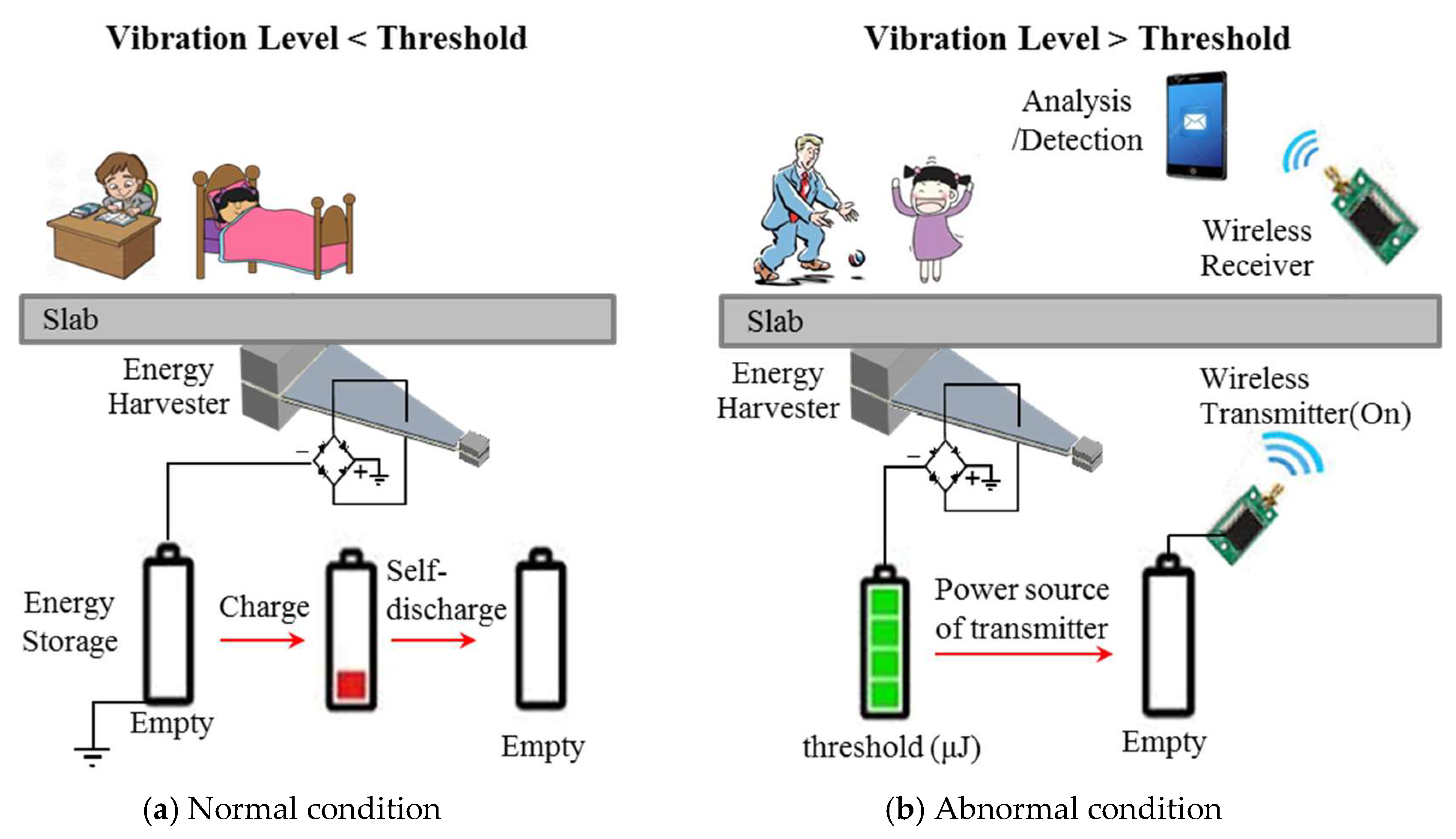

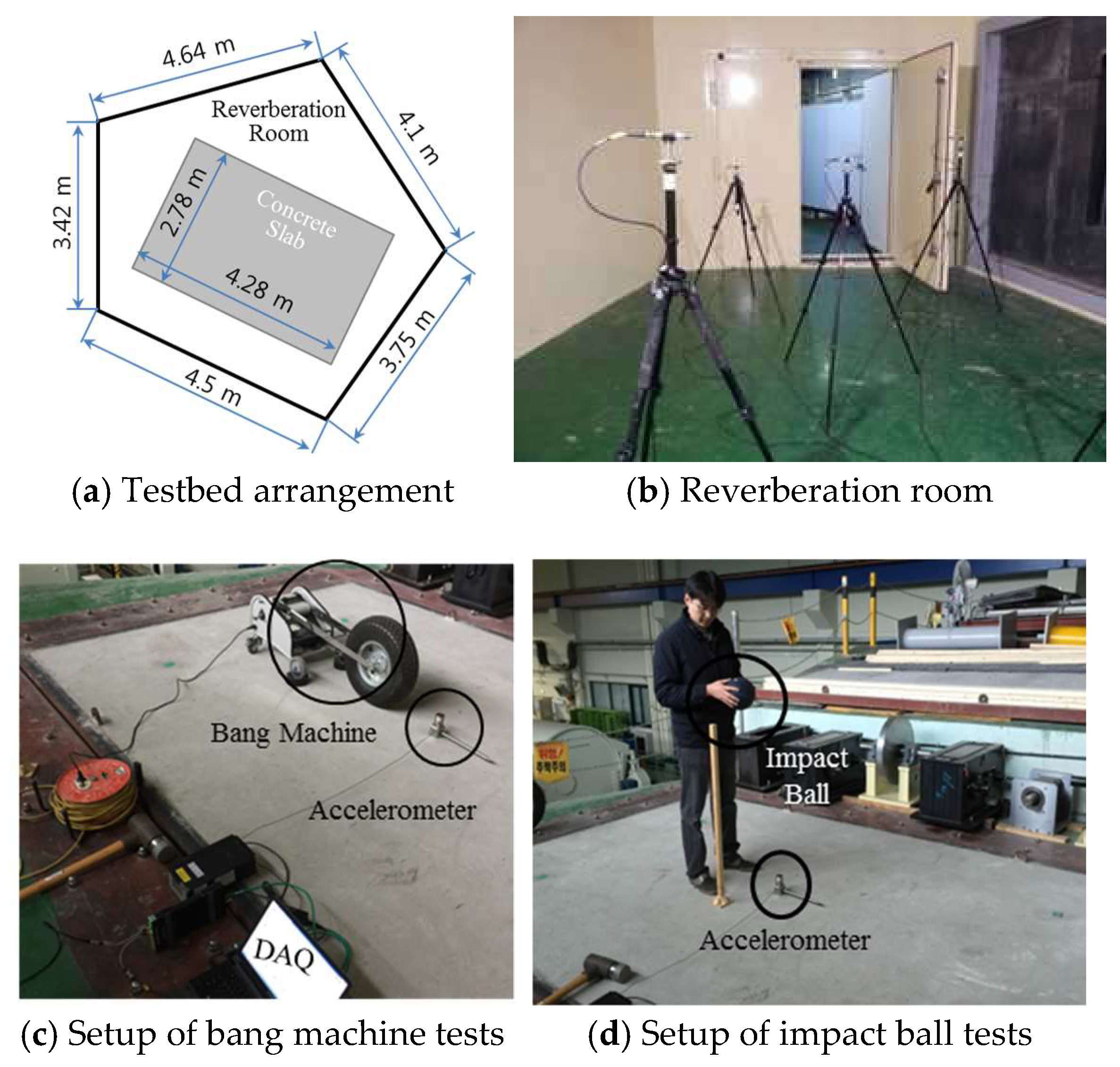

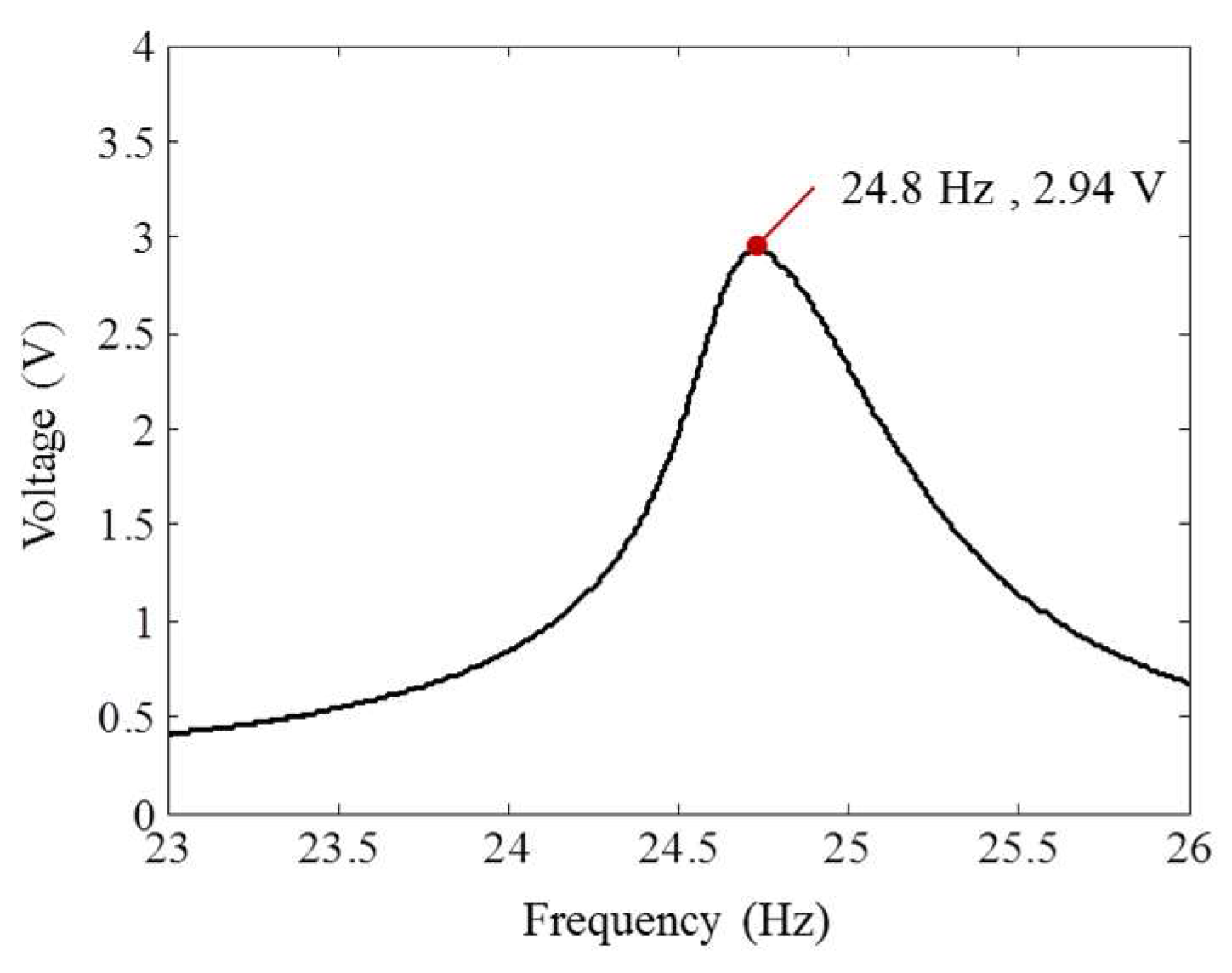

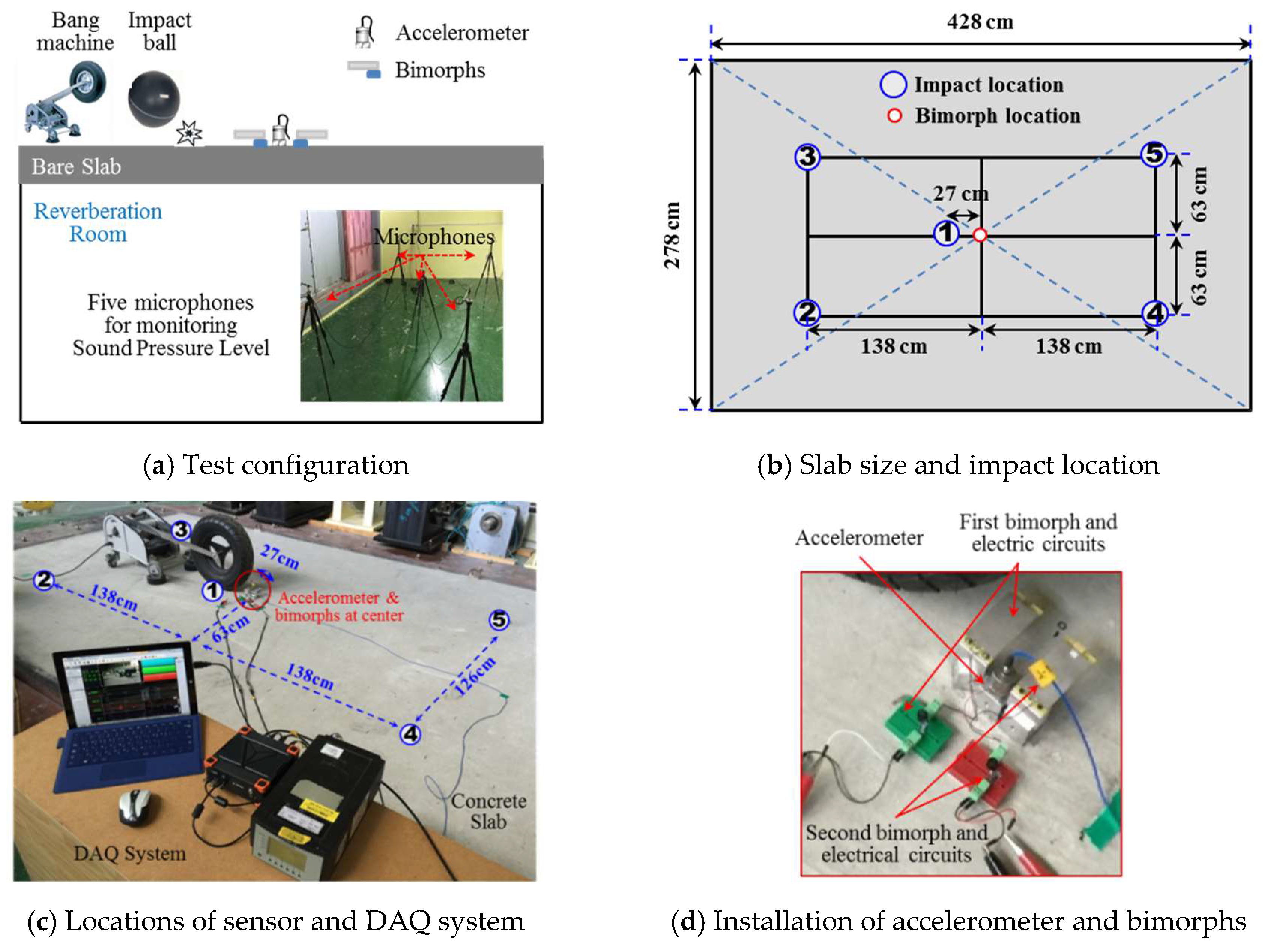

2.1. Testbed and Dynamic Characteristics of the Slab

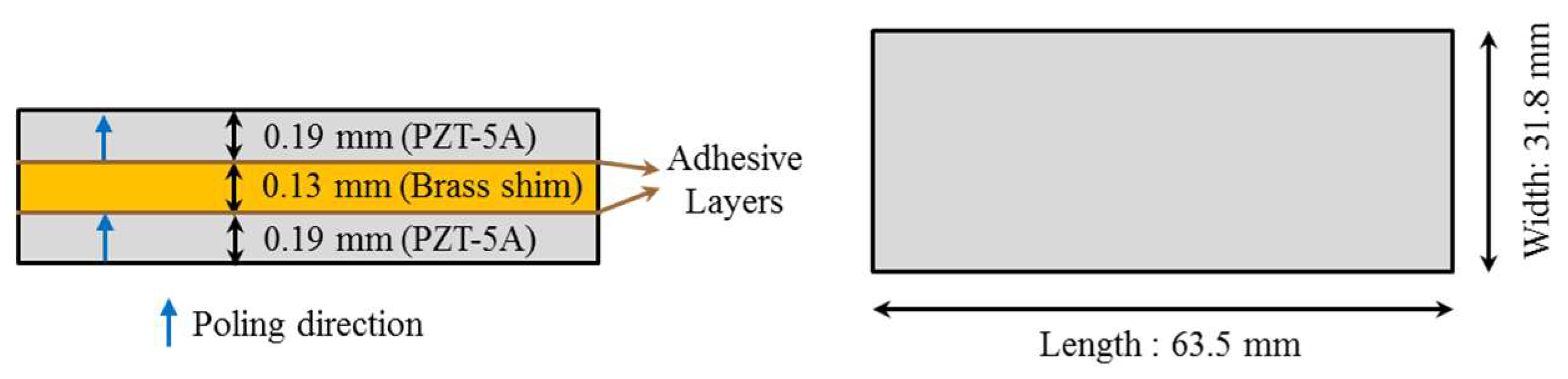

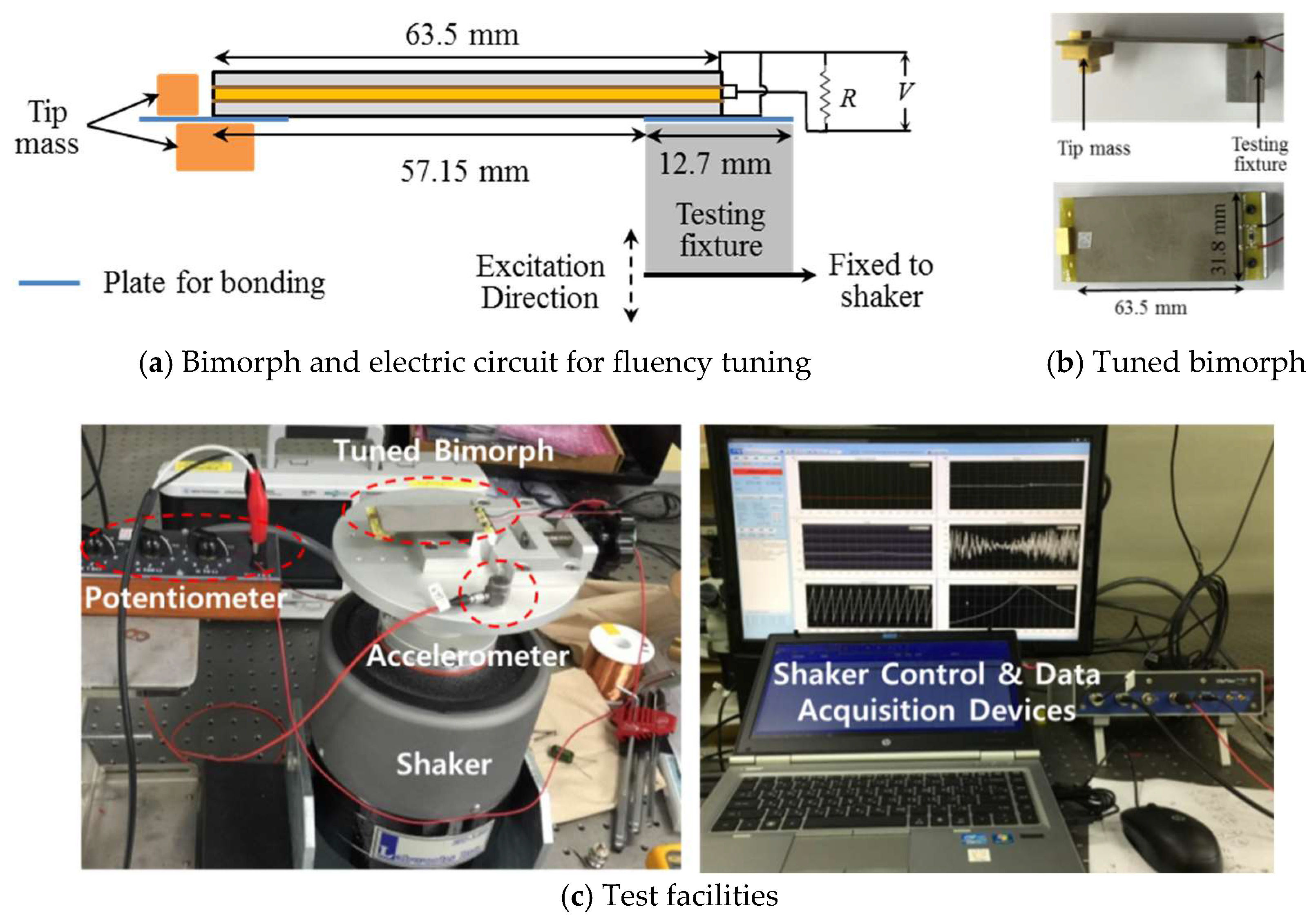

2.2. Design of the Cantilever-Type Piezoelectric Energy Harvester

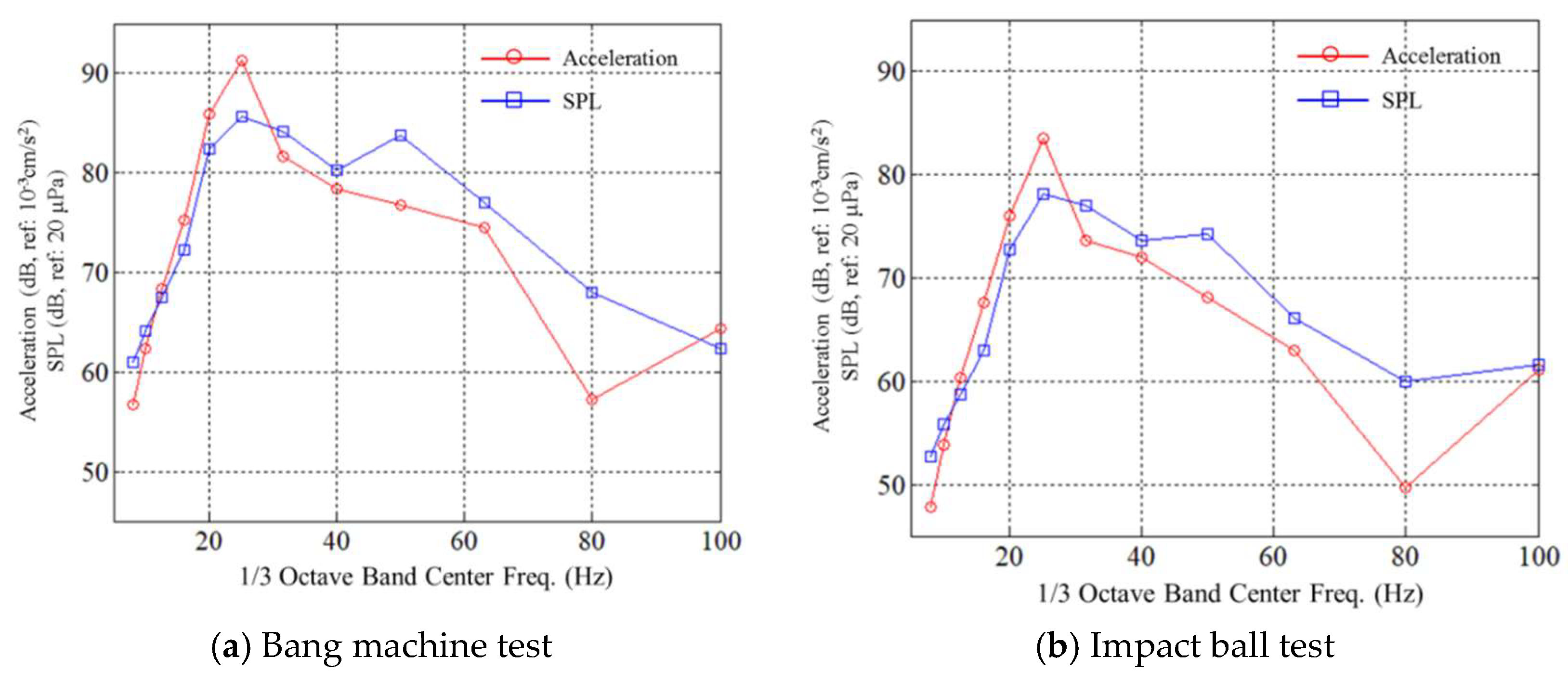

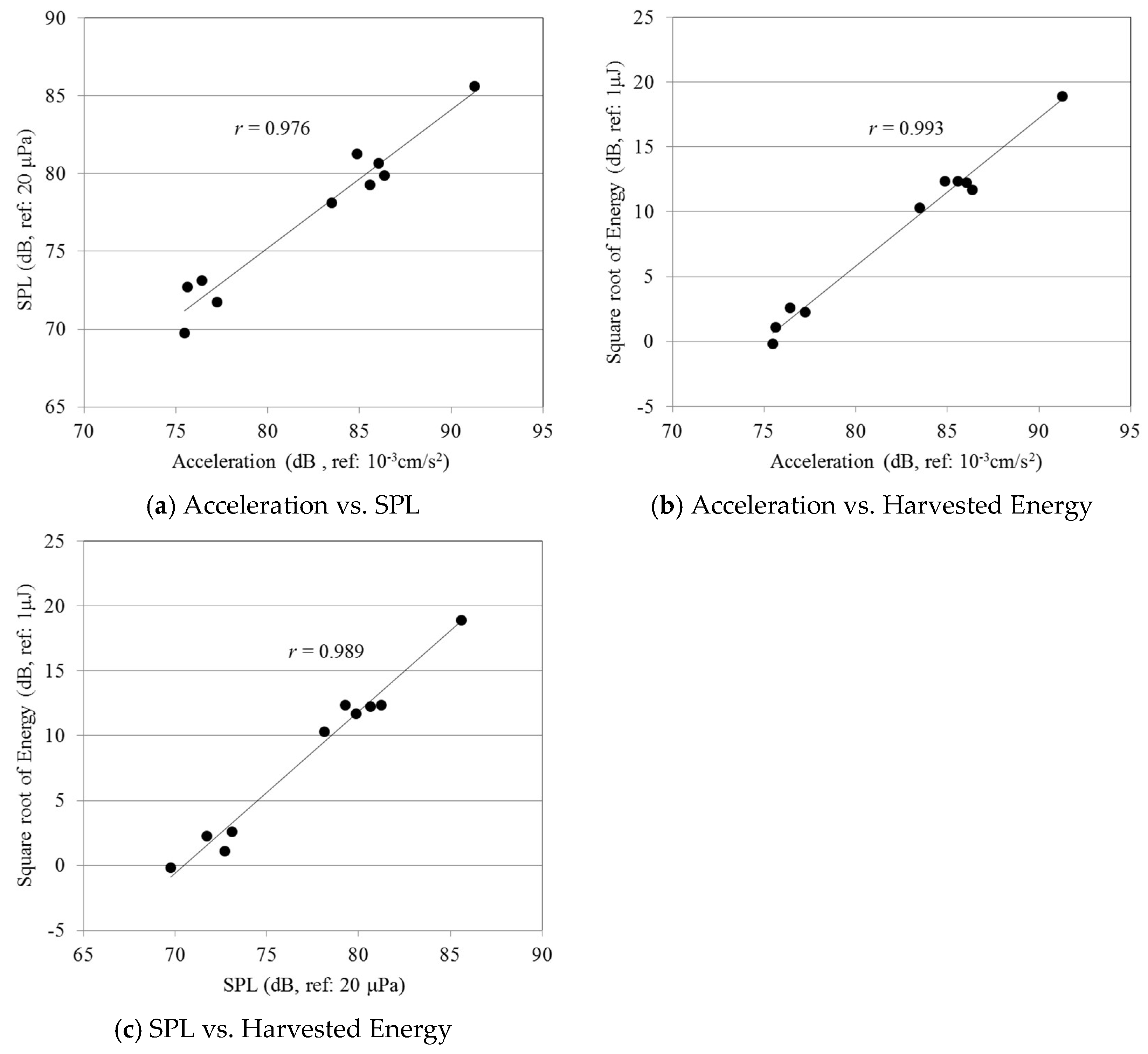

3. Correlation Study

4. Demonstration of the Self-Powered Wireless Sensor for Floor Vibration Detection

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, T.; Ramos, C.; Mohammed, S. Smart City and IoT. Future Gener. Comput. Syst. 2017, 76, 159–162. [Google Scholar] [CrossRef]

- Krishna, R.; Kummitha, R.; Crutzen, N. How do we understand smart cities? An evolutionary perspective. Cities 2017, 67, 43–52. [Google Scholar]

- Najafi-Ghalelou, A.; Zare, K.; Nojavan, S. Optimal scheduling of multi-smart buildings energy consumption considering power exchange capability. Sustain. Cities Soc. 2018, 41, 73–85. [Google Scholar] [CrossRef]

- Marinakis, V.; Doukas, H. An advanced IoT-based System for Intelligent Energy Management in Buildings. Sensors 2018, 18, 610. [Google Scholar] [CrossRef] [PubMed]

- Lam, M.; Mirshekari, M.; Pan, S.; Zhang, P.; Noh, H.Y. Robust Occupant Detection through Step-Induced Floor Vibration by Incorporating Structural Characteristics. Dyn. Coupled Struct. 2016, 4, 357–367. [Google Scholar]

- Mun, D.; Park, H.; Hwang, J. Prediction of Concrete Slab Acceleration and Floor Impact Noise Using Frequency Response Function. Trans. Korean Soc. Noise Vib. Eng. 2014, 24, 483–492. [Google Scholar] [CrossRef][Green Version]

- Kim, K.Y.; Chung, J.Y.; Yeon, J.O.; Kim, M.J. Analysis of Floor Impact Sound Propagation around the Adjacent House. Appl. Mech. Mater. 2015, 752–753, 745–748. [Google Scholar] [CrossRef]

- Lee, P.; Jeong, J.; Park, J.; Jeon, J. Comparison of Standard Floor Impact Sources with Human Impact Source. Trans. Korean Soc. Noise Vib. Eng. 2006, 8, 789–796. [Google Scholar]

- Jeon, J.Y.; Ryu, J.K.; Jeong, J.H.; Tachibana, H. Review of the Impact Ball in Evaluating Floor Impact Sound. Acta Acust. United Acust. 2006, 92, 777–786. [Google Scholar]

- Lee, S.; Youn, B.D.; Jung, B.D. Robust segment-type energy harvester and its application to a wireless sensor. Smart Mater. Struct. 2009, 18, 095021. [Google Scholar] [CrossRef]

- Roundy, S.; Wright, P.K.; Rabaey, J.M. Energy Scavenging for Wireless Sensor Networks: With Special Focus on Vibrations; Springer: Berlin, Germany, 2004. [Google Scholar]

- Kim, H.S.; Kim, J.-H.; Kim, J. A review of piezoelectric energy harvesting based on vibration. Int. J. Precis. Eng. Manuf. 2011, 12, 1129–1141. [Google Scholar] [CrossRef]

- Yoon, H.; Youn, B.D.; Kim, H.S. Kirchhoff plate theory based electromechanically-coupled analytical model considering inertia and stiffness effects of a surface-bonded piezoelectric patch. Smart Mater. Struct. 2016, 25, 025017. [Google Scholar] [CrossRef]

- Erturk, A.; Inman, D.J. An experimentally validated bimorph cantilever model for piezoelectric energy harvesting from base excitations. Smart Mater. Struct. 2009, 18, 25009–25018. [Google Scholar] [CrossRef]

- Kim, J.E.; Kim, H.; Yoon, H.; Kim, Y.Y.; Youn, B.D. An Energy conversion model for cantilevered piezoelectric vibration energy harvesters using only measurable parameters. Int. J. Precis. Eng. Manuf.-Green Technol. 2015, 2, 51–57. [Google Scholar] [CrossRef][Green Version]

- Roundy, S.; Kright, P.K. A piezoelectric vibration based generator for wireless electronics. Smart Mater. Struct. 2004, 13, 1131–1142. [Google Scholar] [CrossRef]

- Sodano, H.A.; Park, G.; Inman, D.J. Estimation of Electric Charge Output for Piezoelectric Energy Harvesting. Strain 2004, 40, 49–58. [Google Scholar] [CrossRef]

- Chen, S.N.; Wang, G.J.; Chien, M.C. Analytical modeling of piezoelectric vibration-induced micro power generator. Mechatronics 2006, 16, 379–387. [Google Scholar] [CrossRef]

- Goldschmidtboeing, F.; Woias, P. Characterization of different beam shapes for piezoelectric energy harvesting. J. Micromech. Microeng. 2008, 18, 104013. [Google Scholar] [CrossRef]

- Hehn, T.; Hagedorn, F.; Maurath, D.; Marinkovic, D.; Kuehne, I.; Frey, A.; Manoli, Y. A Fully Autonomous Integrated Interface Circuit for Piezoelectric Harvesters. IEEE J. Solid-State Circuits 2012, 47, 2185–2198. [Google Scholar] [CrossRef]

- Gasnier, P.; Willemin, J.; Boisseau, S.; Despesse, G.; Condemine, C.; Gouvernet, G.; Chaillout, J. An Autonomous Piezoelectric Energy Harvesting IC Based on a Synchronous Multi-Shot Technique. IEEE J. Solid-State Circuits 2014, 49, 1561–1570. [Google Scholar] [CrossRef]

- Quelen, A.; Morel, A.; Gasnier, P.; Grézaud, R.; Monfray, S.; Pillonnet, G. A 30 nA quiescent 80 nW to 14 mW power-range shock-optimized SECE-based piezoelectric harvesting interface with 420% harvested energy improvement. In Proceedings of the IEEE International Solid State Circuits Conference, San Francisco, CA, USA, 11–15 February 2018; pp. 150–152. [Google Scholar]

- Analog Sensor Node. Available online: http://www.ambiosystems.com/ (accessed on 22 July 2018).

- Piezo Systems Product Catalog. Available online: http://piezo.com/ (accessed on 22 July 2018).

- Video of Feasibility Demonstration. Available online: https://youtu.be/fliSTD6A0G8 (accessed on 31 August 2018).

- Jeon, J.Y.; Lee, P.J.; Sato, S. Use of the standard rubber ball as an impact source with heavyweight concrete floors. J. Acoust. Soc. Am. 2009, 126, 167–178. [Google Scholar] [CrossRef] [PubMed]

- Jung, B.C.; Yoon, H.; Oh, H.; Lee, G.; Yoo, M.; Youn, B.D.; Huh, Y.C. Hierarchical model calibration for designing piezoelectric energy harvester in the presence of variability in material properties and geometry. Struct. Multidiscip. Optim. 2016, 53, 161–173. [Google Scholar] [CrossRef]

| Impact Source | Natural Frequency of Slab | Acceleration (Peak to Peak) | Time Duration of Slab Vibration | |

|---|---|---|---|---|

| Bang machine | 24.8 Hz | −3.0 m/s2 ~4.0 m/s2 | ≈0.8 s | |

| Drop height | 0.85 m | |||

| Tire pressure | 240 kPa | |||

| Impact force (peak) | ≈4000 N | |||

| Time duration | ≈20 ms | |||

| Impact ball | 24.8 Hz | −1.17 m/s2 ~1.55 m/s2 | ≈0.6 s | |

| Drop height | 1 m | |||

| Impact force (peak) | ≈1500 N | |||

| Time duration | ≈20 ms | |||

| Specification | Value |

|---|---|

| Model number | D220-A4-503YB |

| Piezo material | PZT-5A |

| Size of a base specimen | 63.5 × 31.8 mm |

| Active length of the bimorph (Figure 5a) | 57.15 mm |

| Weight | 10.4 gram |

| PZT thickness | 0.019 mm |

| Brass thickness | 0.013 mm |

| Capacitance | 232 μF |

| Natural frequency (without mass) | 52 Hz |

| Impact Machine | Impact Location | Distance from Accelerometer & Bimorph | Harvested Energy (Average of Two Bimorphs) (μJ) | Square Root of Harvested Energy (dB, Ref.:1 μJ)) | Acceleration at 25 Hz (dB, Ref.: 10−3 cm/s2) | SPL at 25 Hz (dB, Ref.: 20 μPa) |

|---|---|---|---|---|---|---|

| Impact Ball | ① | 27 cm | 10.75 | 10.31 | 83.50 | 78.13 |

| Bang Machine | ① | 27 cm | 78.11 | 18.93 | 91.29 | 85.62 |

| Impact Ball | ① | 151.7 cm | 0.95 | −0.22 | 75.46 | 69.77 |

| Bang Machine | ① | 151.7 cm | 17.29 | 12.38 | 85.59 | 79.30 |

| Impact Ball | ① | 151.7 cm | 1.69 | 2.27 | 77.23 | 71.73 |

| Bang Machine | ① | 151.7 cm | 14.83 | 11.71 | 86.36 | 79.88 |

| Impact Ball | ① | 151.7 cm | 1.28 | 1.09 | 75.65 | 72.70 |

| Bang Machine | ① | 151.7 cm | 17.20 | 12.36 | 84.87 | 81.25 |

| Impact Ball | ① | 151.7 cm | 1.82 | 2.60 | 76.43 | 73.12 |

| Bang Machine | ① | 151.7 cm | 16.77 | 12.25 | 86.05 | 80.65 |

| Factors | Correlation Coefficient |

|---|---|

| Acceleration vs. Sound Pressure Level | 0.976 |

| Acceleration vs. Harvested Energy | 0.993 |

| Sound Pressure Level vs. Harvested Energy | 0.989 |

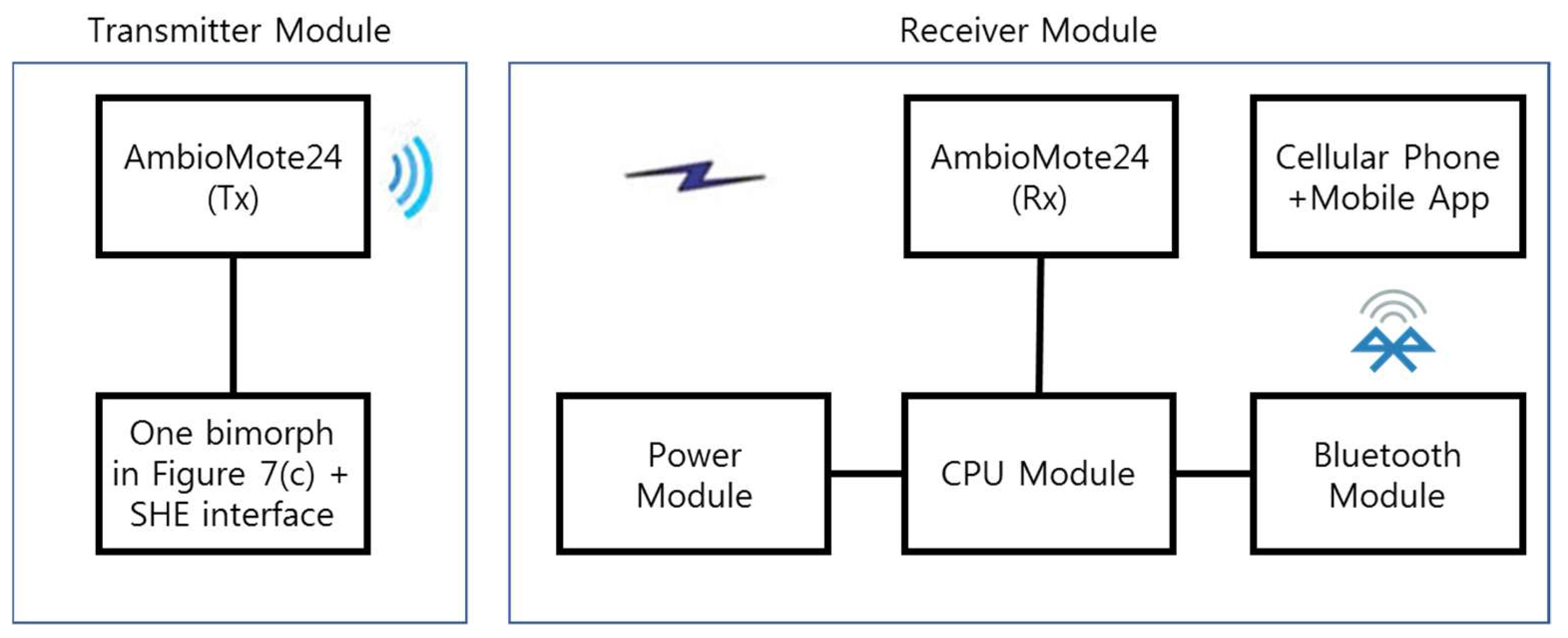

| Module | Main Specifications |

|---|---|

| AmbioMote24 | AmbioSYSTEMS AmbioMote24-A |

| Frequency band: 2.4 GHz | |

| ADC Convert resolution: 10 bit | |

| Capacitance: 0.5 μ | |

| Communication distance: up to 80 m | |

| Data transmission rate(Tx): 10 Hz | |

| CPU Module | STMicroelectronics STM32L152RCT6 |

| Clock speed: max. 32 MHz | |

| Data bus width: 32 bit | |

| Memory: 256 KB, 32 KB RAM, 8 KB ROM | |

| Bluetooth Module | Firmtech FB155BC(SPP + HID) |

| Bluetooth Version: 2.1 (2.4 GHz ISM Band) | |

| Communication distance: 10 m |

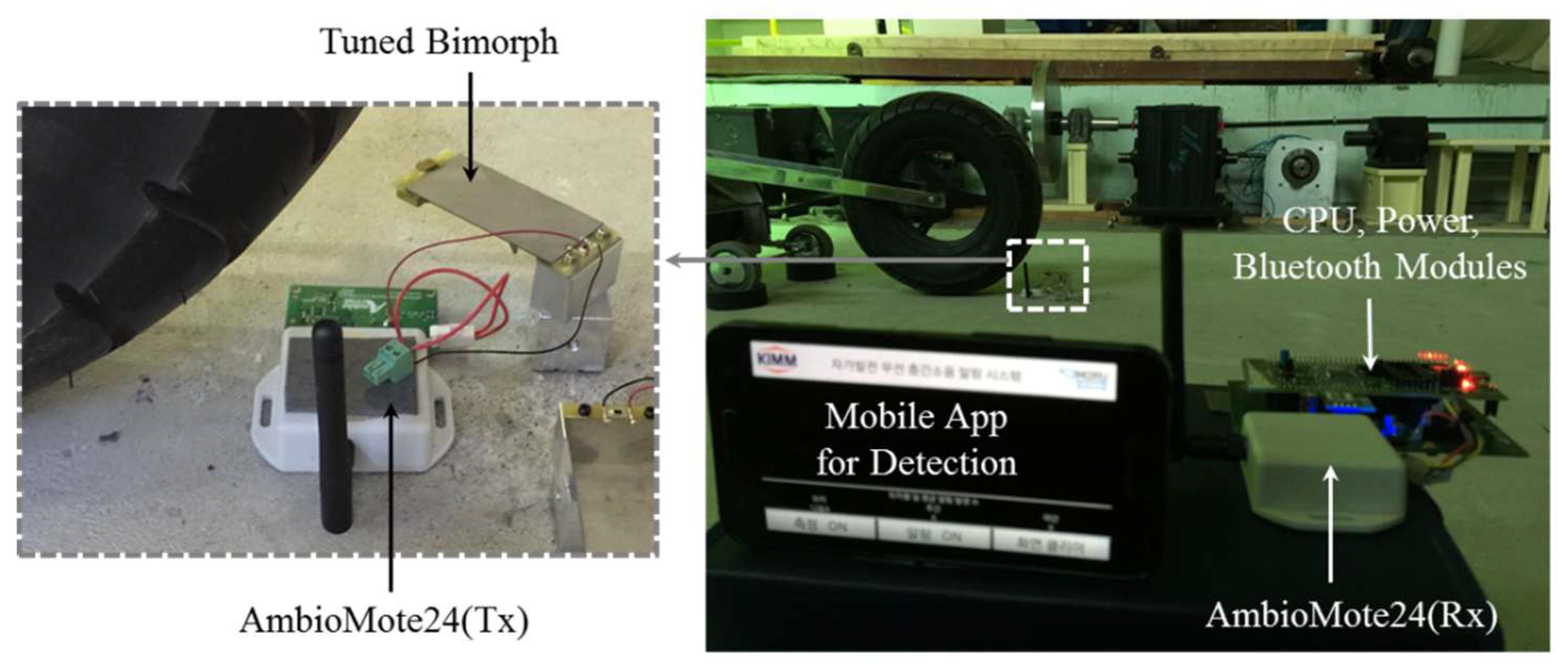

| Impact Source | Impact Location | Number of Impacts | Number of Signals Transmitted |

|---|---|---|---|

| Bang machine | ① | 1 | 7 |

| Impact ball | ① | 3 | 4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, B.C.; Huh, Y.C.; Park, J.-W. A Self-Powered, Threshold-Based Wireless Sensor for the Detection of Floor Vibrations. Sensors 2018, 18, 4276. https://doi.org/10.3390/s18124276

Jung BC, Huh YC, Park J-W. A Self-Powered, Threshold-Based Wireless Sensor for the Detection of Floor Vibrations. Sensors. 2018; 18(12):4276. https://doi.org/10.3390/s18124276

Chicago/Turabian StyleJung, Byung C., Young Cheol Huh, and Jin-Woo Park. 2018. "A Self-Powered, Threshold-Based Wireless Sensor for the Detection of Floor Vibrations" Sensors 18, no. 12: 4276. https://doi.org/10.3390/s18124276

APA StyleJung, B. C., Huh, Y. C., & Park, J.-W. (2018). A Self-Powered, Threshold-Based Wireless Sensor for the Detection of Floor Vibrations. Sensors, 18(12), 4276. https://doi.org/10.3390/s18124276