A Real-Time Weed Mapping and Precision Herbicide Spraying System for Row Crops

Abstract

1. Introduction

- (1)

- To develop a robust grayscale image segmentation algorithm-based weed mapping system.

- (2)

- To integrate a variable-rate herbicide spraying (VRHS) system comprised of a grayscale imaging unit, data processing unit and multi-nozzle variable rate spray controller unit.

- (3)

- To validate the field performance of our VRHS system towards applying chemicals on weeds distributed within a corn field with crop at the seedling growth stage.

2. Materials and Methods

2.1. Imaging System

2.2. Segmentation Algorithm

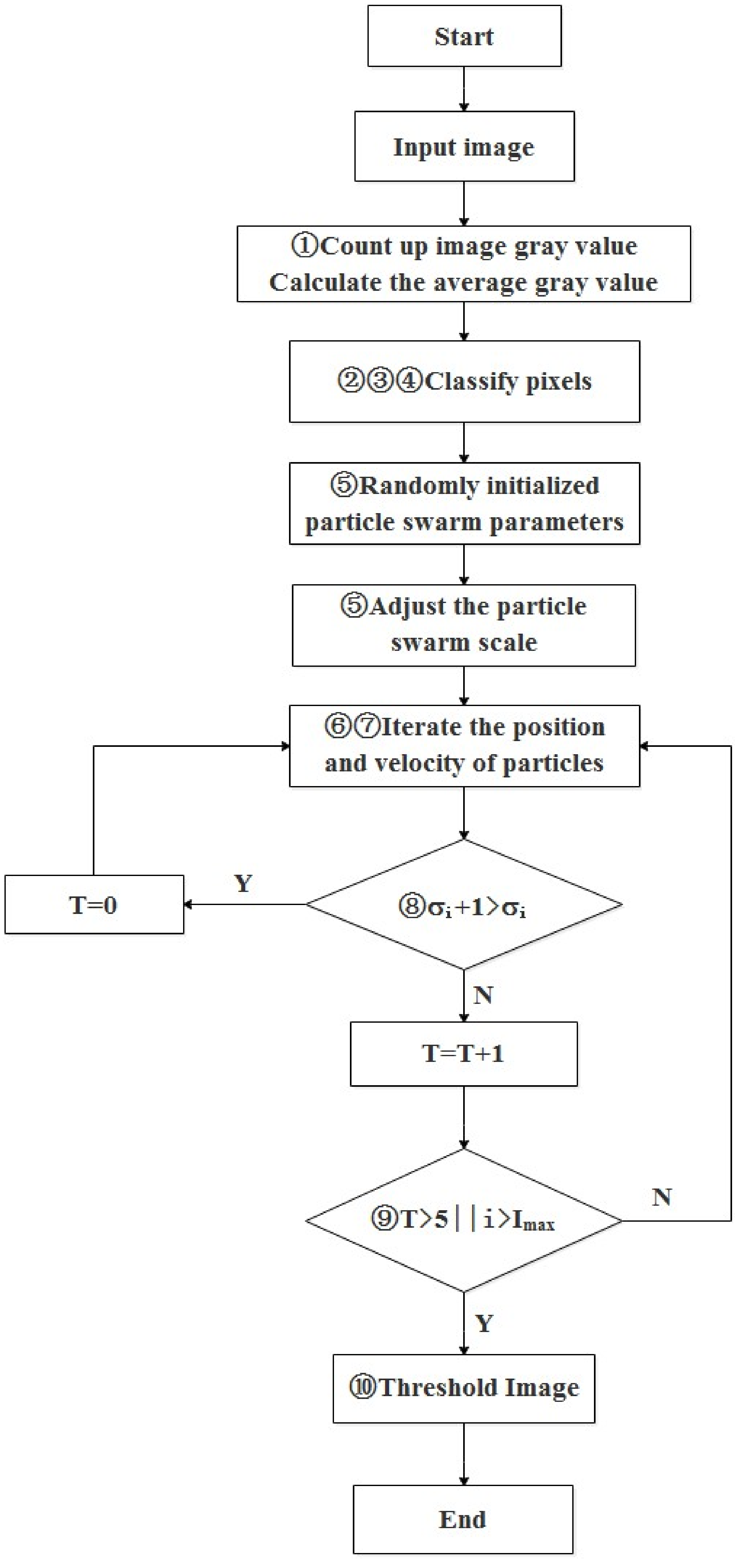

2.2.1. Particle Swarm Optimum Algorithms

2.2.2. Improved of Particle Swarm Optimum Algorithm

- (1)

- Calculate the average gray value of farmland images:where, μL is the average gray value of farmland image, and the range of grayscale is [0, L]. The size of image is M × N and ni represents the number of pixels of grayscale i.

- (2)

- Search the maximum gray value Imax and the minimum gray value of Imin of the farmland image.

- (3)

- Divide the farmland image into two regions called A and B by division value μL. The ranges are A[Imin, μL], B[μL, Imax], respectively. The average gray values μA, μB of A and B are calculated respectively:

- (4)

- Set the search range of particle swarm in the range of [μA, μB].Particle swarm is initialized, and the particle size is set. The number of particle iteration and the random initial position and speed of particle are set as well. The particle swarm scale is updated:where, Gf is the actual particle swarm size, Gs is the initial setting of particle swarm size.

- (6)

- Inter-class variance of OTSU function is used as the fitness of particle swarm, and the maximum variance of particle swarm is updated to obtain the optimal location of local particle swarm:

- (7)

- Particle swarm optimization algorithm can be expressed by Equations (6) and (7). The particle swarm position and speed can be adjusted for the next iteration according to Equations (6) and (7):where, Equations (6) and (7) show that in an N-dimensional space, the space position of the ith particle is Xi = (x1, x2, …, xN) (i is positive integer); Pi = (pi1, pi2, …, piN) is the optimal position that the particles traversed; Pg = (pg1, pg2, …, pgN) is the optimal location of searching the whole particle swarm; the flight velocity of each particle is Vi = (vi1, vi2, …, viN); t stands for current evolutionary algebra; c1 and c2 represent the learning factor (acceleration coefficient); r1 and r2 are a random number distributed in [0, 1]; and W is the inertial weight.

- (8)

- Algorithm iteration terminates when the algorithm reaches the maximum number of iterations or at search of the optimal adaptive value of the particle. Then the optimal global variable of the particle would be obtained. Otherwise it would return to formula (6).

- (9)

- With the optimal particle location as the center, a search area with a range of P is set and scanned. The global optimum is updated when the particle with better fitness exists. Otherwise, the result will remain the same.

- (10)

- Particle location of the optimal segmentation value is used as the optimum threshold to extract the farmland image.

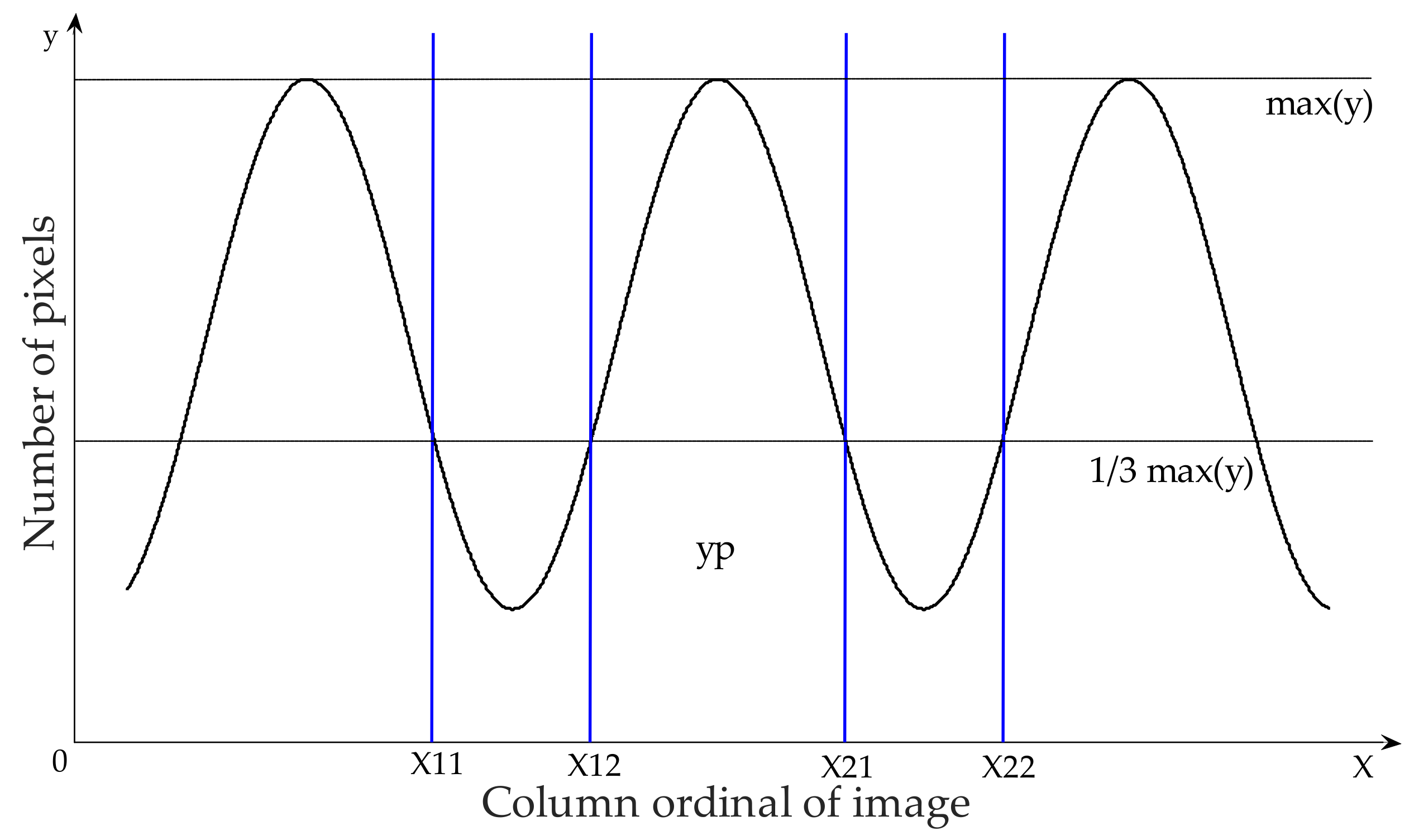

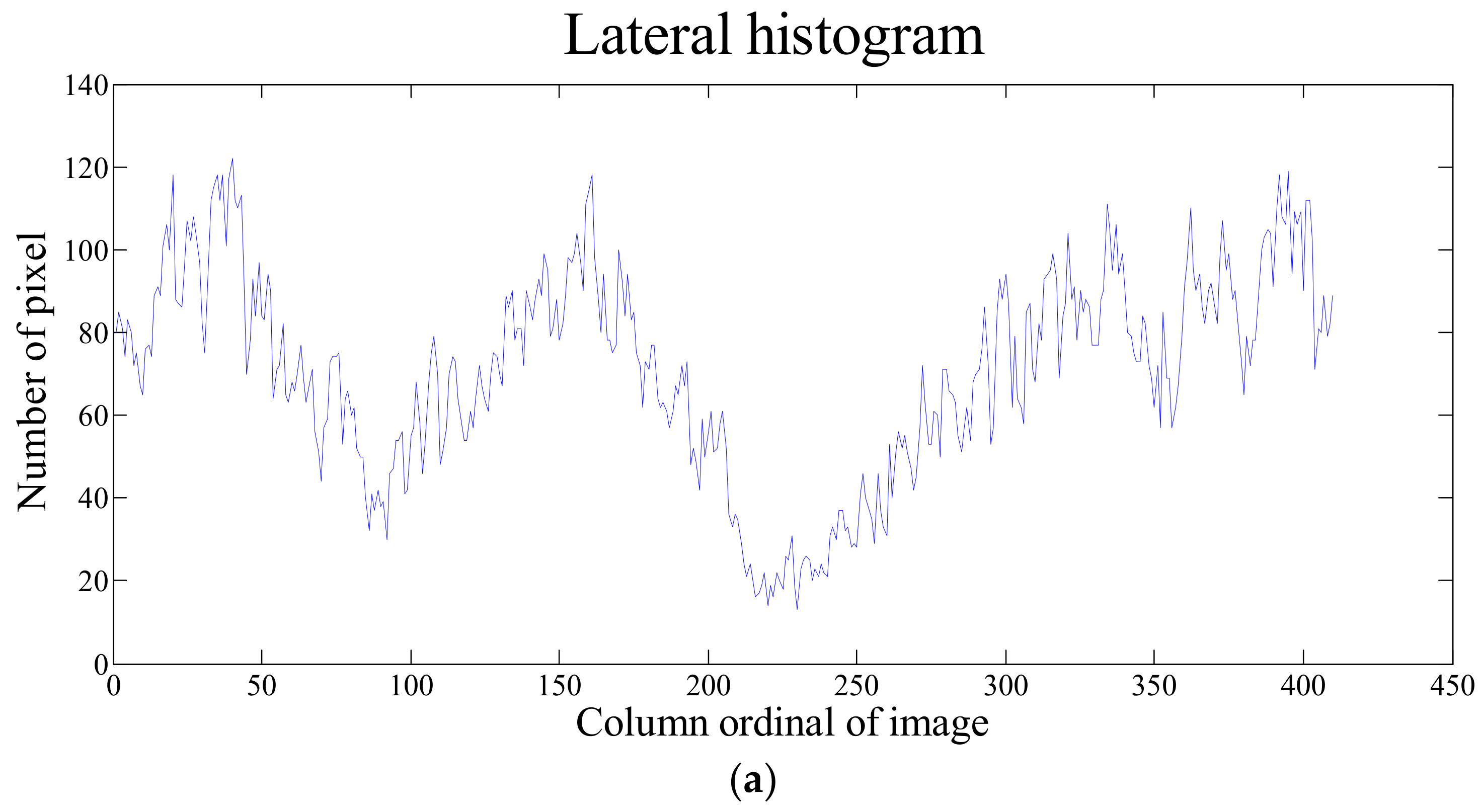

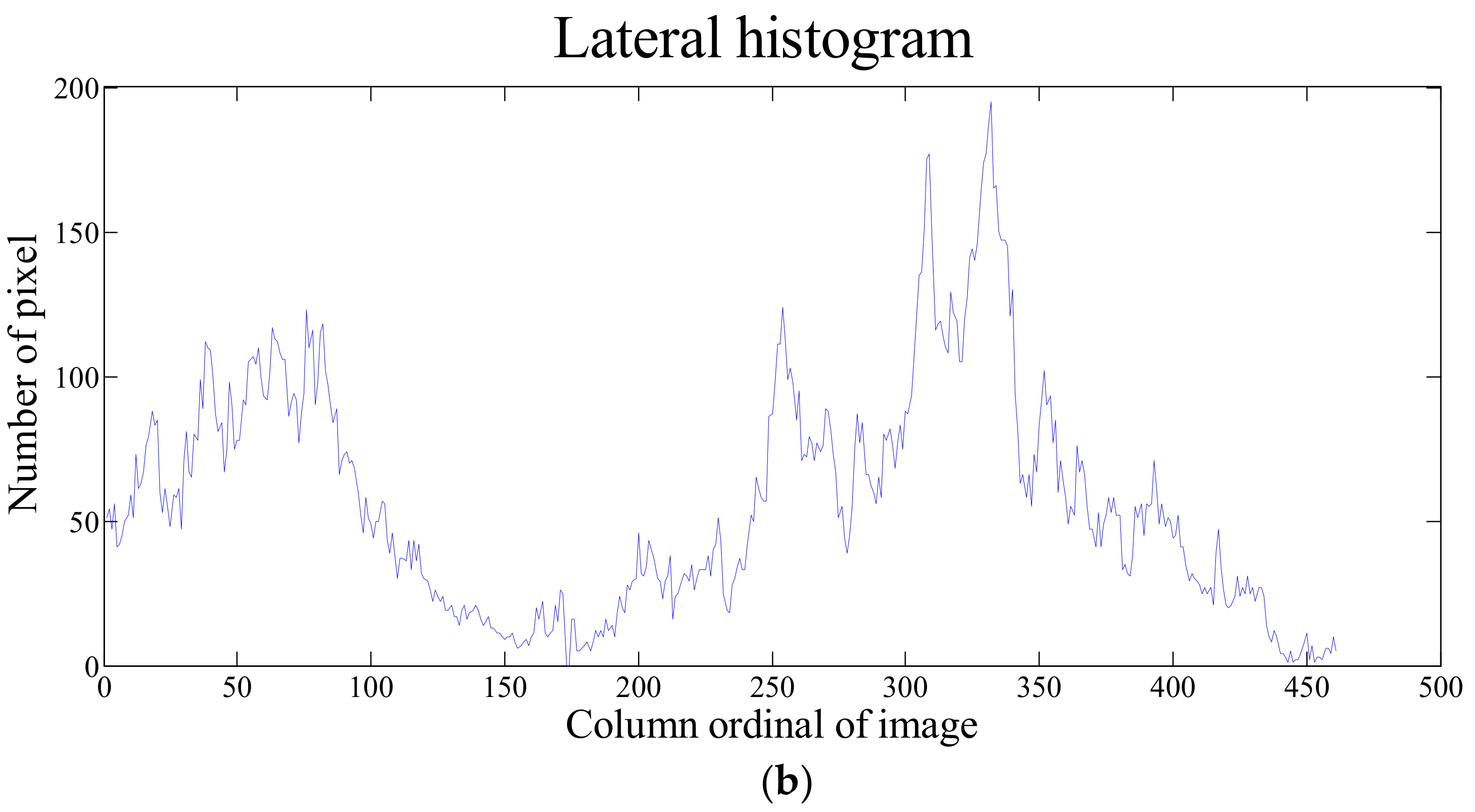

2.3. Weed Distribution Map

2.4. Variable-Rate Herbicide Spraying Control System

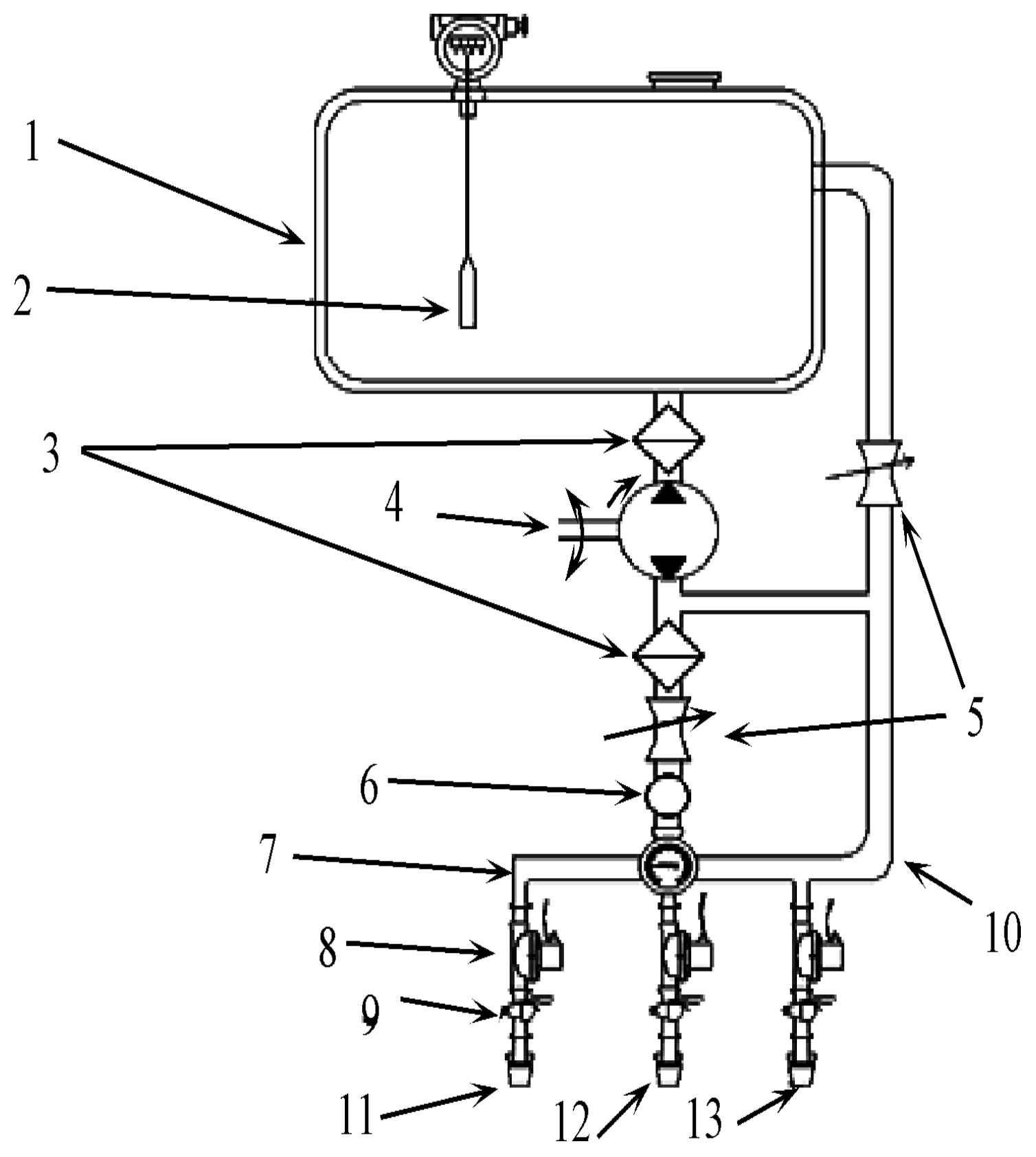

2.4.1. Multi-Nozzle Spraying Sub-System

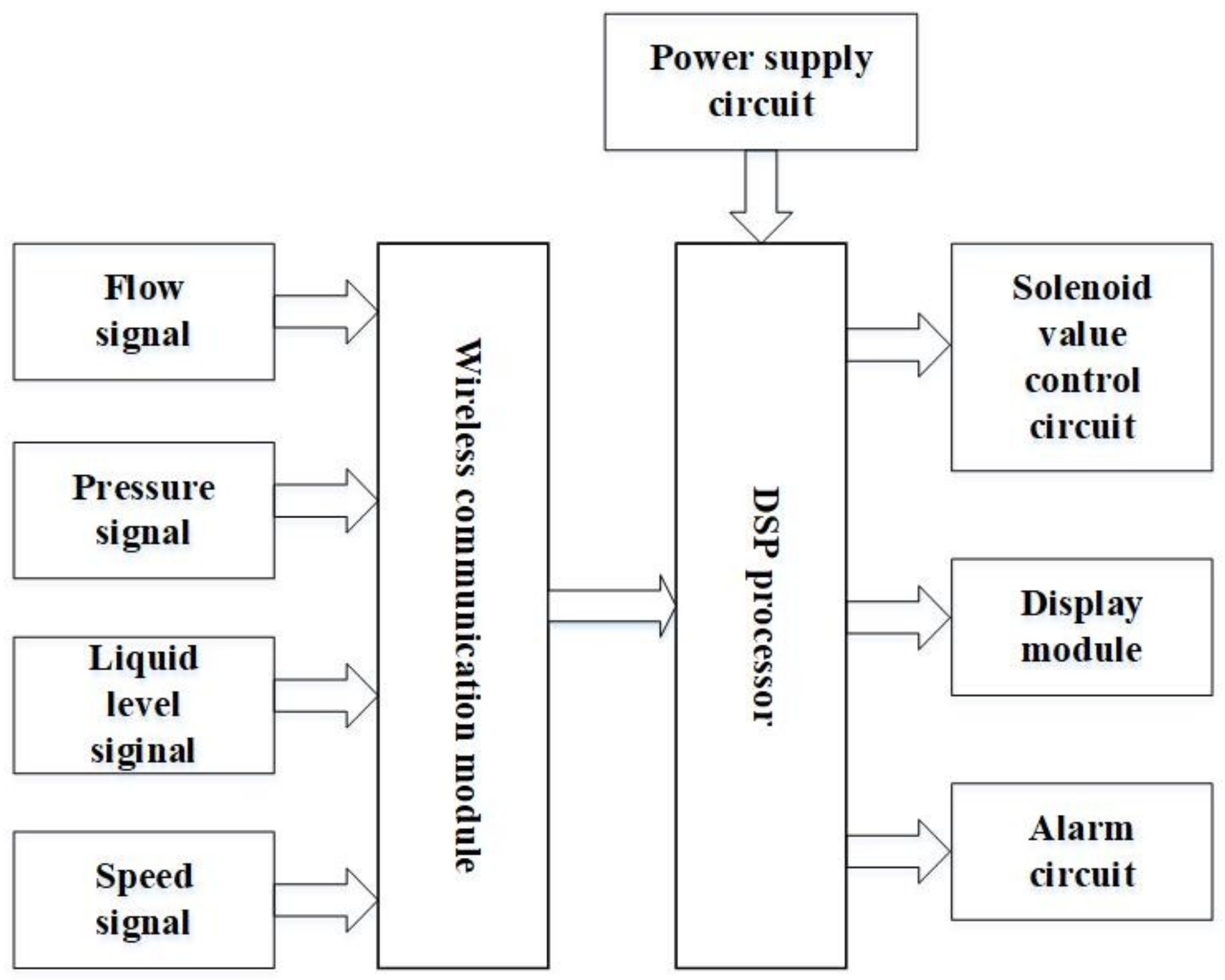

2.4.2. Monitoring Unit

2.4.3. Variable-Rate Herbicide Spraying Control System

2.5. Field Validation Experiment

3. Results and Discussion

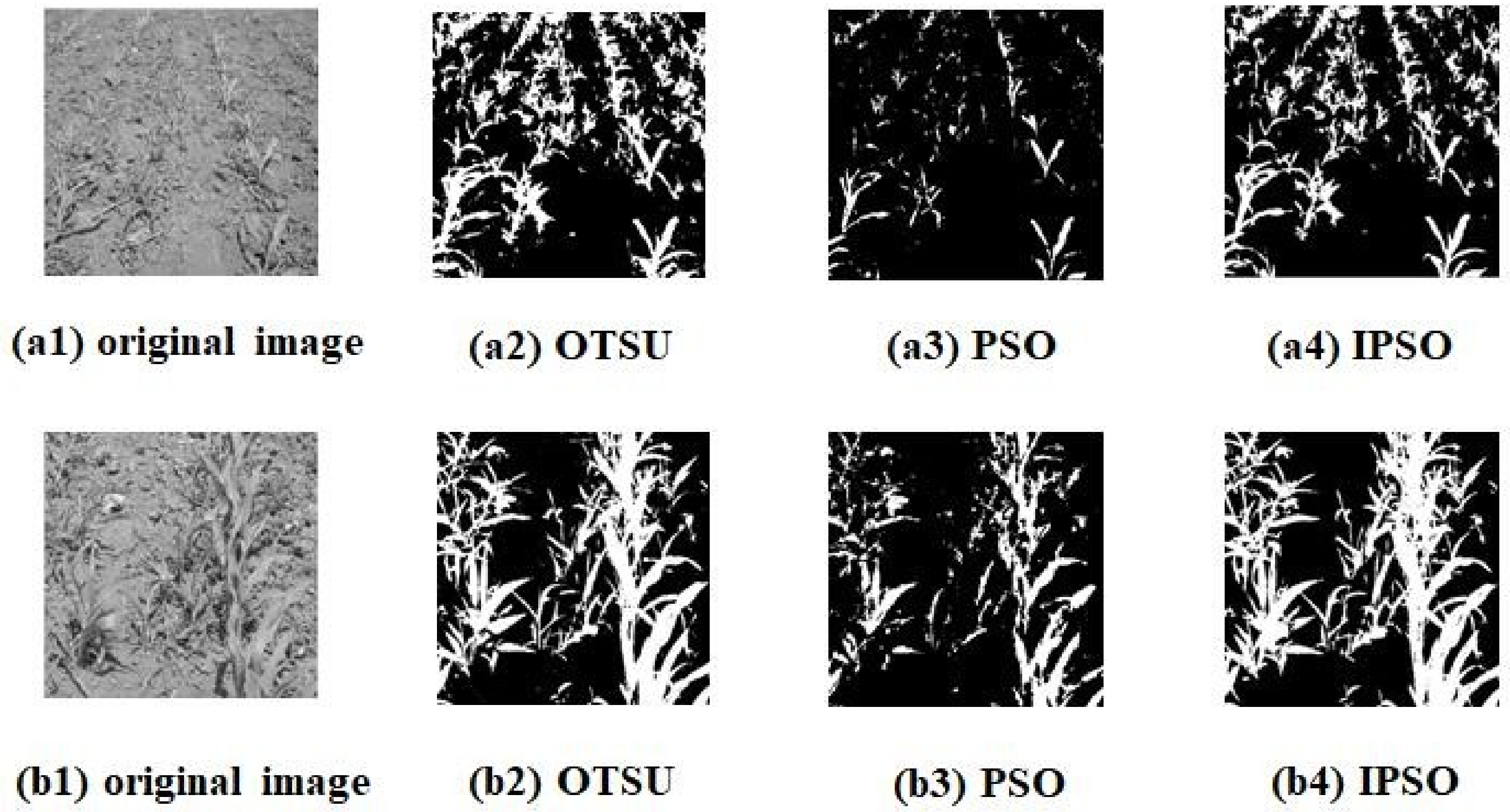

3.1. Image Segmentation

3.2. Weed Distribution Assessment

3.3. Field Validation of Weed Mapping and VRHS System

3.3.1. Real-Time Weed Mapping

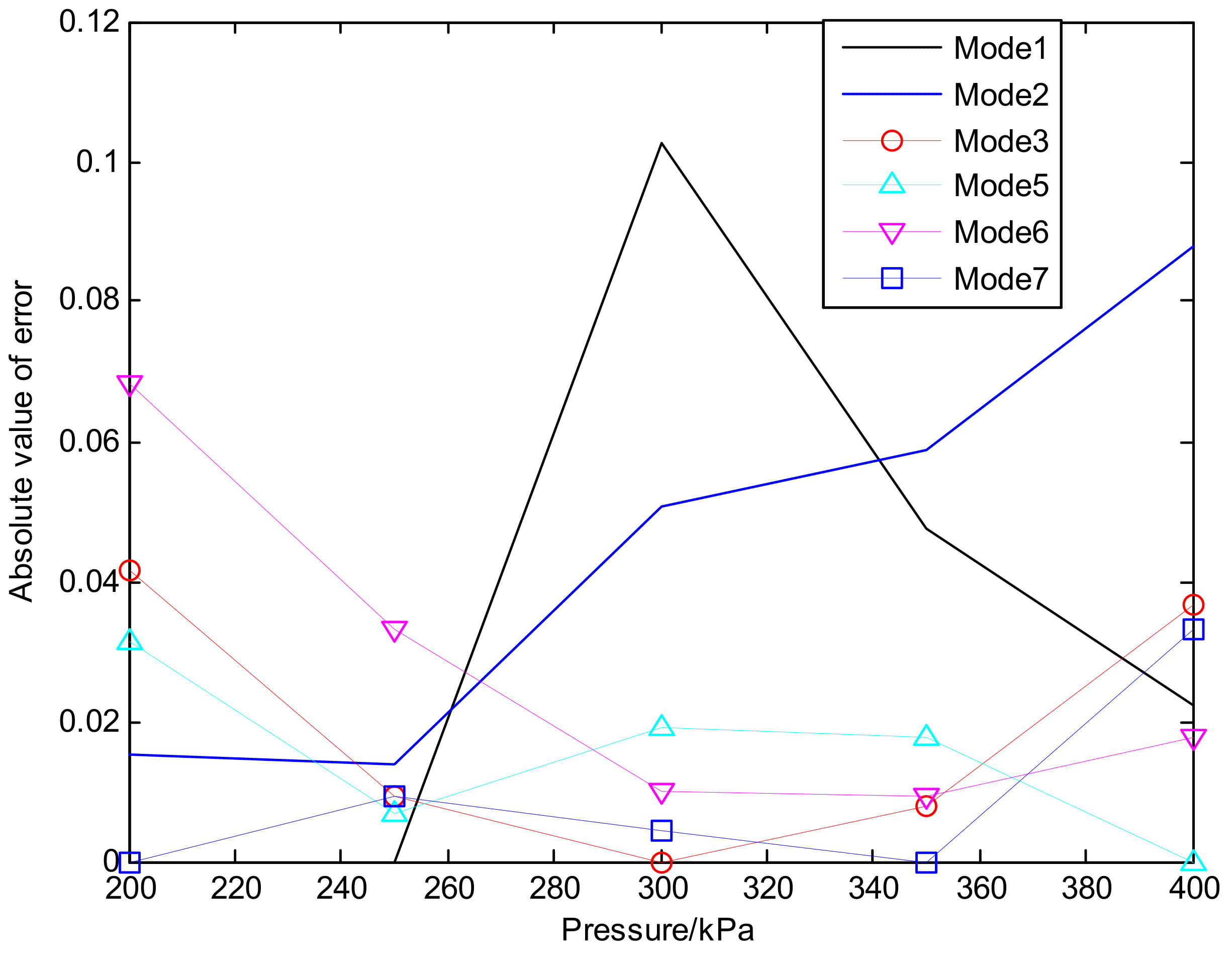

3.3.2. Variable Rate Spraying

4. Conclusions

- (1)

- An improved particle swarm optimum algorithm capable of segmenting field images was developed in this study. The algorithm based on lateral histogram for fast extraction of weed maps could successfully extract the weed distribution information. On this basis, the herbicide application rates were determined and transmitted to a computer via a wireless communication module.

- (2)

- A VRHS control system based on DSP processor was developed, with enhanced operating performance due to higher logic operation capacity of the central processor. The spraying part, with a 3—nozzle structure was simple, and the adjustable spraying amount ranges were wide, so the defects of conventional controllers were overcome.

- (3)

- The algorithms (segmentation and weed extraction) proposed in this study were validated in the field. The results showed that the IPSO algorithm was accurate, with reduced error rates from 7.1% to 0.1%, and a processing speed of 0.026 s/frame. In addition, the extraction algorithm based on lateral histogram can extract weed map rapidly.

- (4)

- The integrated variable-rate herbicide spraying system was also validated in a corn field. Experimental results showed that the image processing time of the weed mapping system 0.2 s (was good), and the response time of the overall system was 1.562 s, which meet the real-time process requirements. The adjustable flow rate range was wide, and the herbicide utilization rate was improved.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rocha, F.C.; Oliveira Neto, A.M.; Bottega, E.L.; Guerra, N.; Rocha, R.P.; Vilar, C.C. Weed mapping using techniques of precision agriculture. Planta Daninha 2015, 33, 157–164. [Google Scholar] [CrossRef]

- Dammer, K. Real-time variable-rate herbicide application for weed control in carrots. Weed Res. 2016, 56, 237–246. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.; Ma, C.; Xu, Y.; Qi, J.; Wang, W. Design of variable spraying system based on ARM. Trans. Chin. Soc. Agric. Eng. 2010, 26, 113–118. [Google Scholar]

- Zhai, C.; Zhu, R.; Sui, S.; Xue, S.; Shangguan, Z. Design and experiment of control system of variable pesticide application machine hauled by tractor. Trans. Chin. Soc. Agric. Eng. 2009, 25, 105–109. [Google Scholar] [CrossRef]

- Haug, S.; Ostermann, J. A Crop/Weed field image dataset for the evaluation of computer vision based precision agriculture tasks. In Proceedings of the European Conference on Computer Vision, Zurich, Switzerland, 6–12 September 2014; Springer: Cham, Switzerland, 2014; pp. 105–116. [Google Scholar]

- Taghadomi-Saberi, S.; Hemmat, A. Improving field management by machine vision—A review. Agric. Eng. Int. CIGR e-J. 2015, 17, 92–111. [Google Scholar]

- Franco, C.; Pedersen, S.M.; Papaharalampos, H.; Ørum, J.E. The value of precision for image-based decision support in weed management. Precis. Agric. 2017, 18, 366–382. [Google Scholar] [CrossRef]

- Maghsoudi, H.; Minaei, S. A review of applicable methodologies for variable-rate spraying of orchards based on canopy characteristics. J. Crop Prot. 2014, 3, 531–542. [Google Scholar]

- Ionescu, B.; Müller, H.; Villegas, M.; Arenas, H.; Boato, G.; Dang-Nguyen, D.T.; Islam, B. Overview of imageCLEF 2017: Information extraction from images. In Proceedings of the International Conference of the Cross-Language Evaluation Forum for European Languages, Dublin, Ireland, 11–14 September 2017; Springer: Cham, Switzerland, 2017; pp. 315–337. [Google Scholar]

- Rad, C.R.; Hancu, O.; Takacs, I.A.; Olteanu, G. Smart monitoring of potato crop: A cyber-physical system architecture model in the field of precision agriculture. Agric. Agric. Sci. Procedia 2015, 6, 73–79. [Google Scholar] [CrossRef]

- Singh, K.; Agrawal, K.N.; Bora, G.C. RETRACTED: Advanced techniques for weed and crop identification for site specific weed management. Biosyst. Eng. 2011, 109, 52–64. [Google Scholar] [CrossRef]

- Paulus, S.; Schumann, H.; Kuhlmann, H.; Léon, J. High-precision laser scanning system for capturing 3D plant architecture and analysing growth of cereal plants. Biosyst. Eng. 2014, 121, 1–11. [Google Scholar] [CrossRef]

- Mathanker, S.K.; Weckler, P.R.; Taylor, R.K.; Fan, G. Adaboost and support vector machine classifiers for automatic weed control: Canola and Wheat. In Proceedings of the American Society of Agricultural and Biological Engineers, Pittsburgh, PA, USA, 20–23 June 2010. [Google Scholar]

- Bai, J.; Xu, Y.; Wei, X.; Zhang, J.; Shen, B. Weed identification from winter rape at seedling stage based on spectrum characteristics analysis. Trans. Chin. Soc. Agric. Eng. 2013, 29, 136–142. [Google Scholar]

- Hassanein, M.; Lari, Z.; Elsheimy, N. A New Vegetation Segmentation Approach for Cropped Fields Based on Threshold Detection from Hue Histograms. Sensors 2018, 18, 1253. [Google Scholar] [CrossRef] [PubMed]

- He, P.; Qiao, D.; Li, Y.; Gao, Z.; Li, H.; Tang, J. Weed recognition based on SVM-DS multiple feature fusion. Trans. Chin. Soc. Agric. Mach. 2013, 2, 188–193. [Google Scholar]

- Bai, X.D.; Cao, Z.G.; Wang, Y.; Yu, Z.H.; Zhang, X.F.; Li, C.N. Crop segmentation from images by morphology modeling in the CIE Lab color space. Comput. Electron. Agric. 2013, 99, 21–34. [Google Scholar] [CrossRef]

- Hernández-Hernández, J.L.; García-Mateos, G.; González-Esquiva, J.M.; Escarabajal-Henarejos, D.; Ruiz-Canales, A.; Molina-Martínez, J.M. Optimal color space selection method for plant/soil segmentation in agriculture. Comput. Electron. Agric. 2016, 122, 124–132. [Google Scholar] [CrossRef]

- Zhai, R.; Fang, Y.; Lin, C.; Peng, H.; Liu, S.; Luo, J. Segmentation of field rapeseed plant image based on Gaussian HI color algorithm. Trans. Chin. Soc. Agric. Eng. 2016, 32, 150–155. [Google Scholar]

- Chen, X.; Tang, J.; Wang, D. Research on farmland image segmentation based on SLIC method under strong light. Comput. Eng. Appl. 2017, 11, 1–8. [Google Scholar]

- Rosell-Polo, J.R.; Planas, S.; Gil, E.; Pomar, J.; Camp, F.; Llorens, J.; Solanelles, F. Variable rate sprayer. Part 1—Orchard prototype: Design, implementation and validation. Comput. Electron. Agric. 2013, 95, 122–135. [Google Scholar] [CrossRef]

- Qu, F.; Zhang, J.; Xiong, B.; Li, X.; Ma, Q.; Li, N.; Li, W. Precision target spraying in greenhouse based on internet remote control. In Proceedings of the 2016 American Society of Agricultural and Biological Engineers Annual International Meeting, Orlando, FL, USA, 17–20 July 2016. [Google Scholar]

- Huanyu, J.; Mingchuan, Z.; Junhua, T.; Yan, L. PWM variable spray control based on Kalman filter. Trans. Chin. Soc. Agric. Mach. 2014, 45, 60–65. [Google Scholar]

- Wang, H.; Chen, S. The design and experimental research of variable spraying system based on PWM. J. Agric. Mech. Res. 2012, 12, 159–161. [Google Scholar]

- Xu, Y.; Bao, J.; Fu, D.; Zhu, C. Design and experiment of variable spraying system based on multiple combined nozzles. Trans. Chin. Soc. Agric. Eng. 2016, 32, 47–54. [Google Scholar]

- Guo, N.; Hu, J. Design and experiment of variable rate spaying system on Smith-Fuzzy PID control. Trans. Chin. Soc. Agric. Eng. 2014, 30, 56–64. [Google Scholar]

- Tamouridou, A.A.; Alexandridis, T.K.; Pantazi, X.E. Application of multilayer perceptron with automatic relevance determination on weed mapping using UAV multispectral imagery. Sensors 2017, 17, 2307. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Nuyttens, D.; Lootens, P.; He, Y.; Pieters, J.G. Recognising weeds in a maize crop using a random forest machine-learning algorithm and near-infrared snapshot mosaic hyperspectral imagery. Biosyst. Eng. 2018, 170, 39–50. [Google Scholar] [CrossRef]

- Dubbini, M.; Pezzuolo, A.; De Giglio, M.; Gattelli, M.; Curzio, L.; Covi, D.; Yezekyan, T.; Marinello, F. Last generation instrument for agriculture multispectral data collection. Agric. Eng. Int. CIGR J. 2017, 19, 87–93. [Google Scholar]

- Prey, L.; Bloh, M.; Schmidhalter, U. Evaluating RGB imaging and multispectral active and hyperspectral passive sensing for assessing early plant vigor in winter wheat. Sensors 2018, 18, 2931. [Google Scholar] [CrossRef] [PubMed]

- Talab, A.M.A.; Huang, Z.; Fan, X.; Liu, H. Detection crack in image using Otsu method and multiple filtering in image processing techniques. Optik-Int. J. Light Electron Opt. 2016, 127, 1030–1033. [Google Scholar] [CrossRef]

- Bangare, S.L.; Bangare, P.S.; Patl, S.T. Reviewing Otsu’s Method for Image Thresholding. Int. J. Appl. Eng. Res. 2015, 10, 21777–21783. [Google Scholar]

- Lavania, S.; Matey, P.S. Novel method for weed classification in maize field using Otsu and PCA implementation. In Proceedings of the 2015 IEEE International Conference on Computational Intelligence & Communication Technology, Ghaziabad, India, 13–14 February 2015; pp. 534–537. [Google Scholar]

- Marini, F.; Walczak, B. Particle swarm optimization (PSO). A tutorial. Chemom. Intell. Lab. Syst. 2015, 149, 153–165. [Google Scholar] [CrossRef]

- Ghamisi, P.; Benediktsson, J.A. Feature selection based on hybridization of genetic algorithm and particle swarm optimization. IEEE Geosci. Remote Sens. Lett. 2015, 12, 309–313. [Google Scholar] [CrossRef]

- Du, W.B.; Gao, Y.; Liu, C.; Zheng, Z.; Wang, Z. Adequate is better: Particle swarm optimization with limited-information. Appl. Math. Comput. 2015, 268, 832–838. [Google Scholar] [CrossRef]

- Li, H.; He, H.; Wen, Y. Dynamic particle swarm optimization and K-means clustering algorithm for image segmentation. Optik-Int. J. Light Electron Opt. 2015, 126, 4817–4822. [Google Scholar] [CrossRef]

| Algorithm | Image Size (Pixels × Pixels) | Threshold Value | Optimization Number | Running Time (s) | Optimization Rate (%) | Error Rate |

|---|---|---|---|---|---|---|

| OTSU | 1280 × 1060 | 38.9 | 30 | 0.145 | 100.0 | 0.0 |

| PSO | 1280 × 1060 | 36.1 | 13 | 0.032 | 43.3 | 7.1 |

| IPSO | 1280 × 1060 | 38.6 | 28 | 0.026 | 93.3 | 0.1 |

| Treatment | Response Time (s) | Mean Response Time (s) | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 1 | 1.530 | 1.510 | 1.550 | 1.590 | 1.600 | 1.556 |

| 2 | 1.560 | 1.540 | 1.530 | 1.570 | 1.610 | 1.562 |

| 3 | 1.540 | 1.550 | 1.570 | 1.590 | 1.580 | 1.566 |

| 4 | 1.500 | 1.550 | 1.600 | 1.570 | 1.590 | 1.562 |

| 5 | 1.590 | 1.580 | 1.570 | 1.540 | 1.540 | 1.564 |

| Pressure (kpa) | Mode 1 | Mode 2 | Mode 3 | Mode 4 | Mode 5 | Mode 6 | Mode 7 |

|---|---|---|---|---|---|---|---|

| Flow Rate (L/min) | |||||||

| 200 | 0.32 | 0.65 | 0.96 | 0.97 | 1.28 | 1.61 | 1.93 |

| 250 | 0.36 | 0.73 | 1.08 | 1.09 | 1.44 | 1.81 | 2.17 |

| 300 | 0.39 | 0.79 | 1.18 | 1.18 | 1.57 | 1.97 | 2.36 |

| 350 | 0.42 | 0.85 | 1.28 | 1.27 | 1.70 | 2.13 | 2.55 |

| 400 | 0.45 | 0.91 | 1.36 | 1.36 | 1.81 | 2.27 | 2.72 |

| Pressure (kpa) | Mode 1 | Mode 2 | Mode 3 | Mode 5 | Mode 6 | Mode 7 |

|---|---|---|---|---|---|---|

| Flow Rate (L/min) | ||||||

| 200 | 0.00 | 0.64 | 0.92 | 1.24 | 1.50 | 1.93 |

| 250 | 0.36 | 0.72 | 1.09 | 1.43 | 1.87 | 2.15 |

| 300 | 0.35 | 0.83 | 1.18 | 1.54 | 1.99 | 2.35 |

| 350 | 0.40 | 0.90 | 1.27 | 1.73 | 2.15 | 2.55 |

| 400 | 0.44 | 0.99 | 1.41 | 1.81 | 2.31 | 2.81 |

| Pressure (kpa) | Mode 1 | Mode 2 | Mode 3 | Mode 5 | Mode 6 | Mode 7 |

|---|---|---|---|---|---|---|

| Total Flow Rate (L/hm2) | ||||||

| 200 | 0.0 | 153.6 | 220.8 | 297.6 | 360.0 | 463.2 |

| 250 | 86.4 | 172.8 | 261.6 | 343.2 | 448.8 | 516.0 |

| 300 | 84.0 | 199.2 | 283.2 | 369.6 | 477.6 | 564.0 |

| 350 | 96.0 | 216.0 | 304.8 | 415.2 | 516.0 | 612.0 |

| 400 | 105.6 | 237.6 | 338.4 | 434.4 | 554.4 | 674.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Gao, Z.; Khot, L.; Meng, X.; Zhang, Q. A Real-Time Weed Mapping and Precision Herbicide Spraying System for Row Crops. Sensors 2018, 18, 4245. https://doi.org/10.3390/s18124245

Xu Y, Gao Z, Khot L, Meng X, Zhang Q. A Real-Time Weed Mapping and Precision Herbicide Spraying System for Row Crops. Sensors. 2018; 18(12):4245. https://doi.org/10.3390/s18124245

Chicago/Turabian StyleXu, Yanlei, Zongmei Gao, Lav Khot, Xiaotian Meng, and Qin Zhang. 2018. "A Real-Time Weed Mapping and Precision Herbicide Spraying System for Row Crops" Sensors 18, no. 12: 4245. https://doi.org/10.3390/s18124245

APA StyleXu, Y., Gao, Z., Khot, L., Meng, X., & Zhang, Q. (2018). A Real-Time Weed Mapping and Precision Herbicide Spraying System for Row Crops. Sensors, 18(12), 4245. https://doi.org/10.3390/s18124245