Wear Degree Quantification of Pin Connections Using Parameter-Based Analyses of Acoustic Emissions

Abstract

1. Introduction

2. Materials and Methods

2.1. b-Value Method

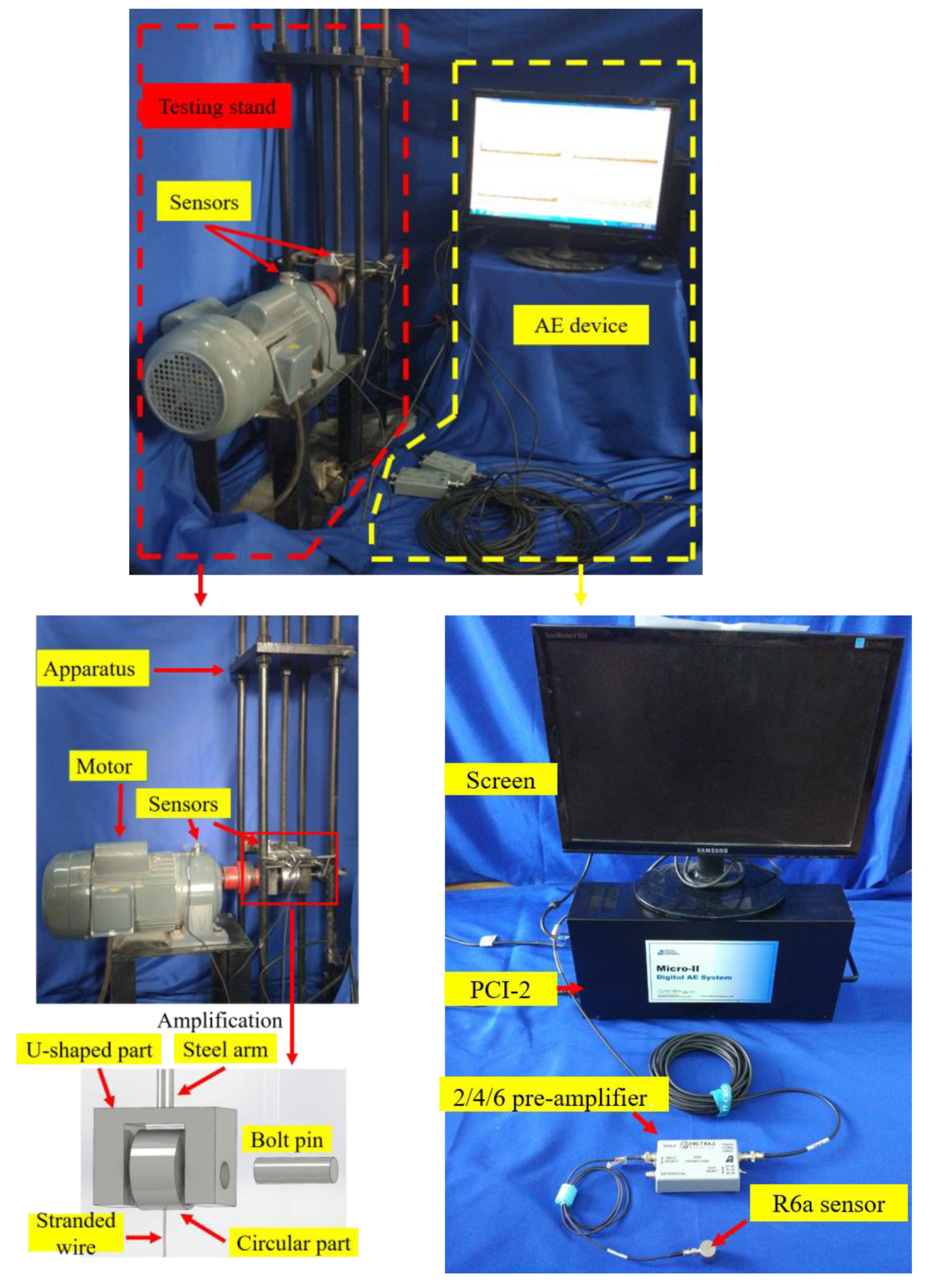

2.2. Test Equipment and Procedures

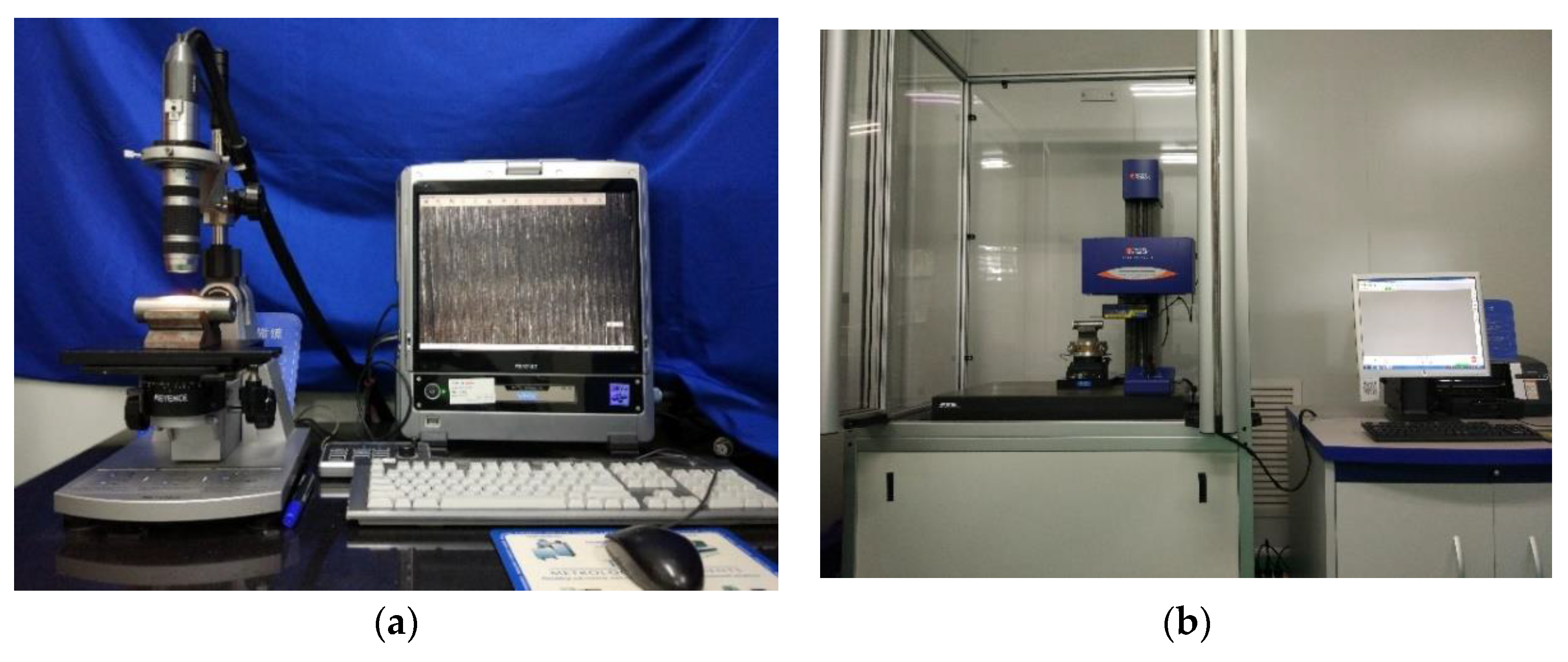

2.3. AE Test Equipment and Measurement Equipment

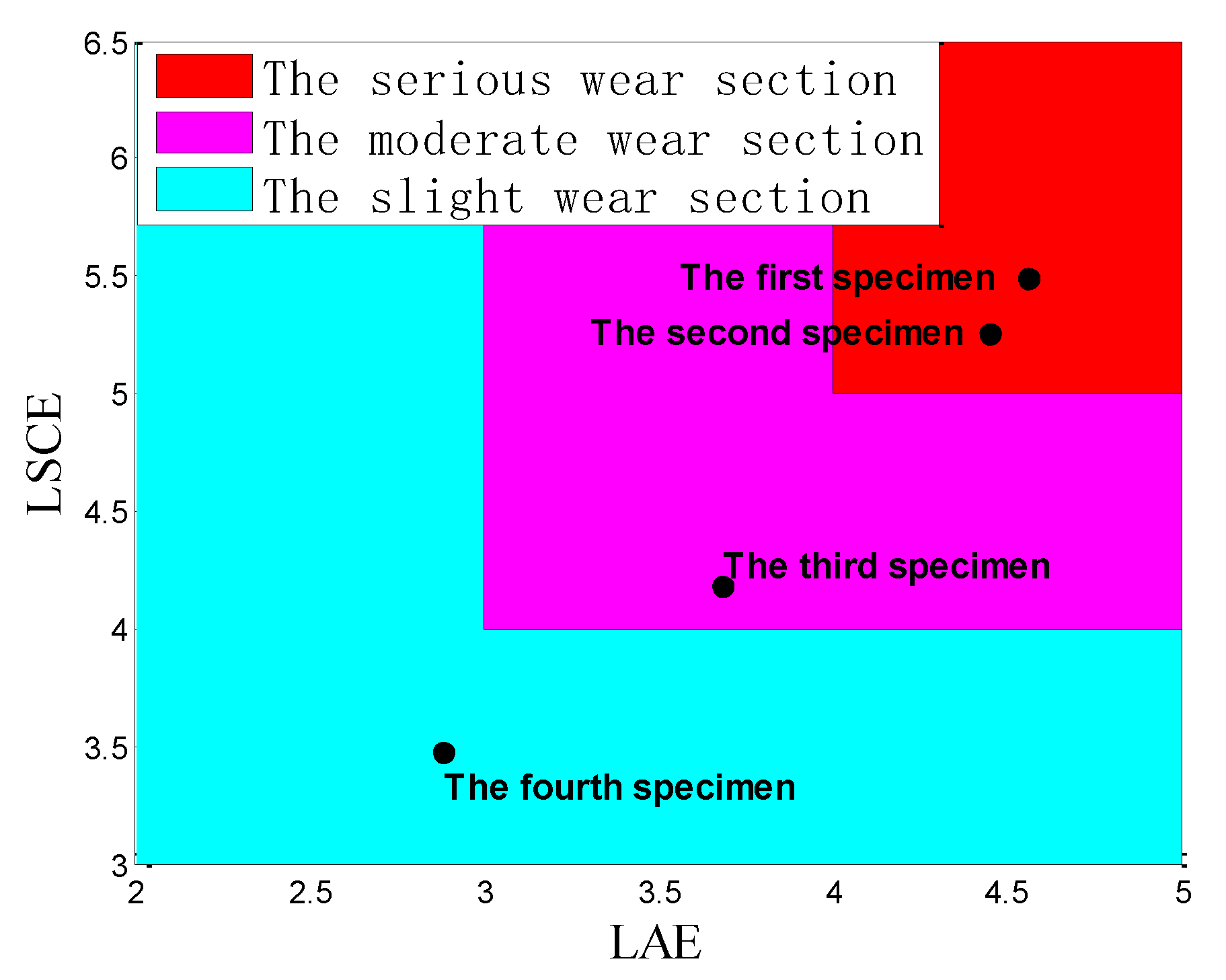

3. Experimental Results and AE Parameter-Based Analyses

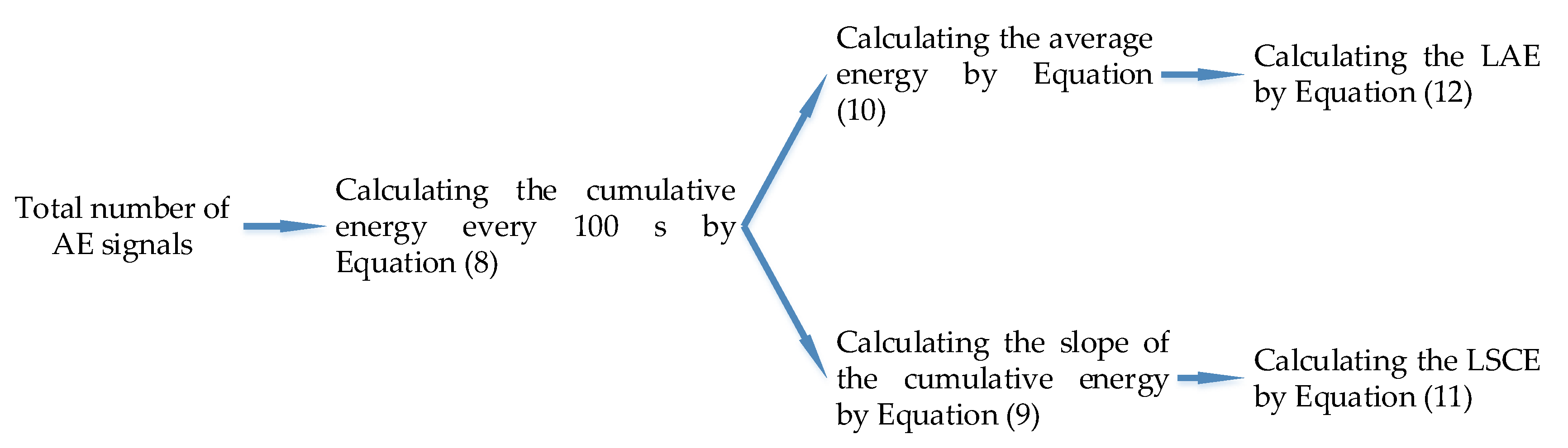

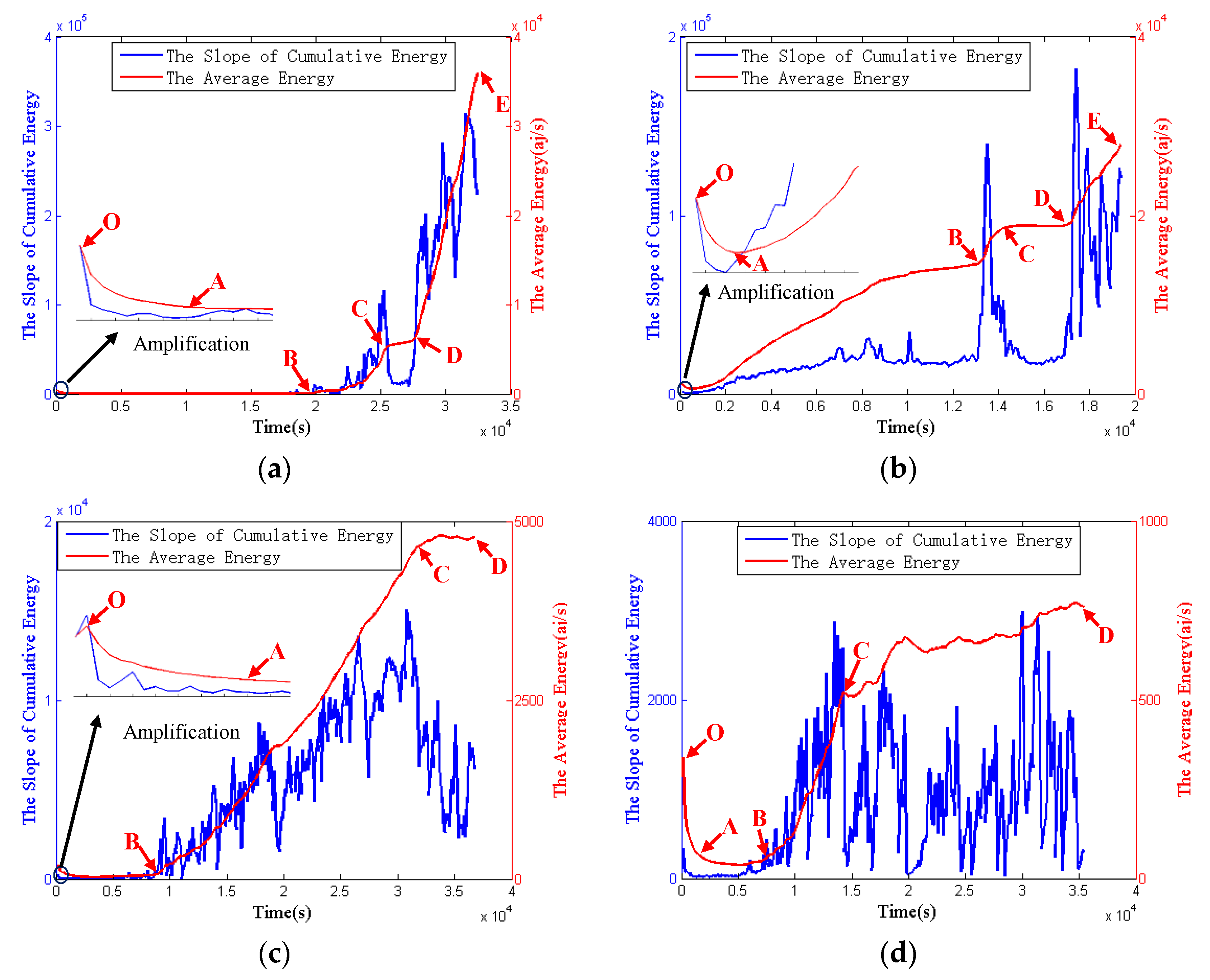

3.1. Features of AE Parameters

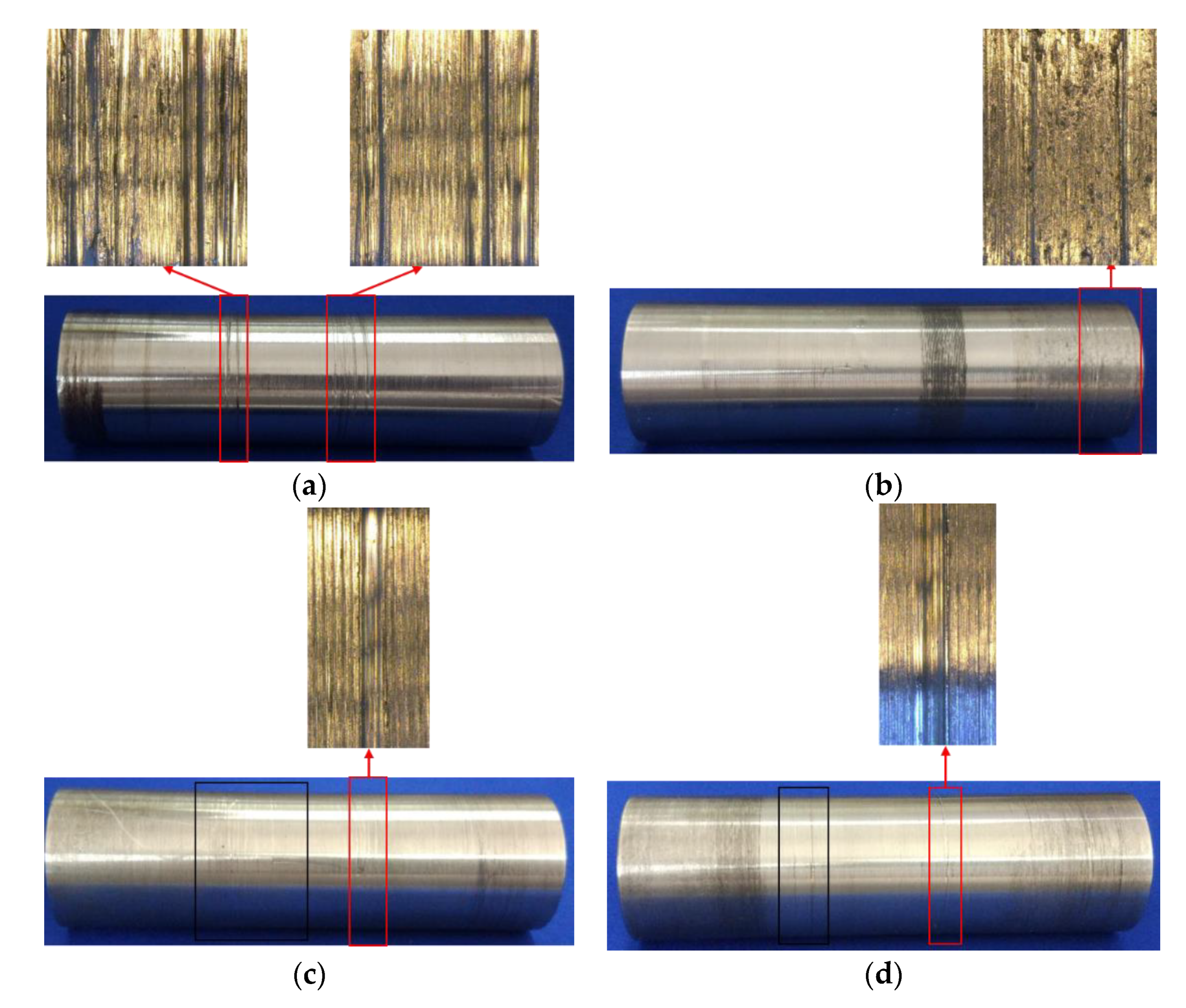

3.2. Analyses Based on Micrographs and Surface Roughness

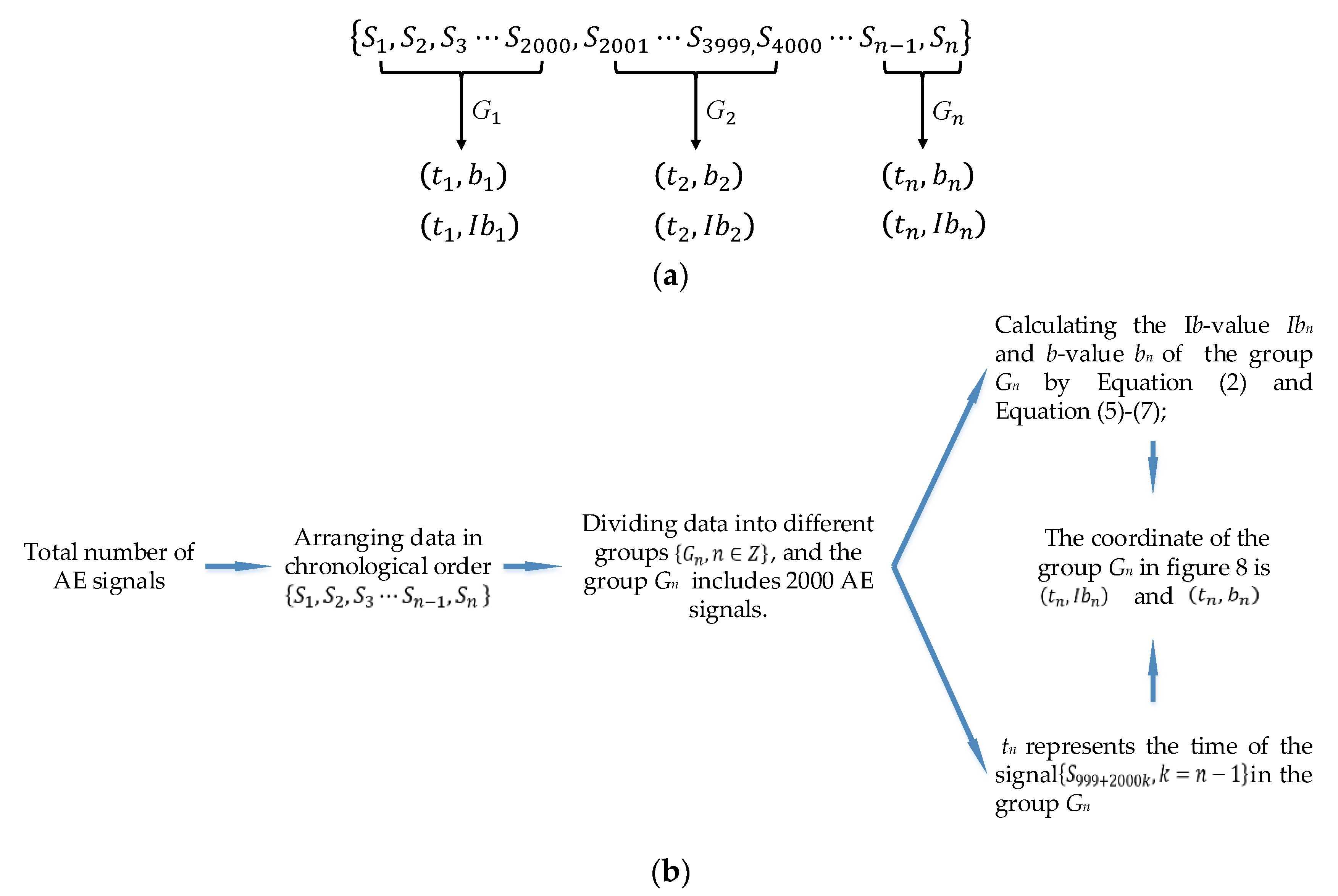

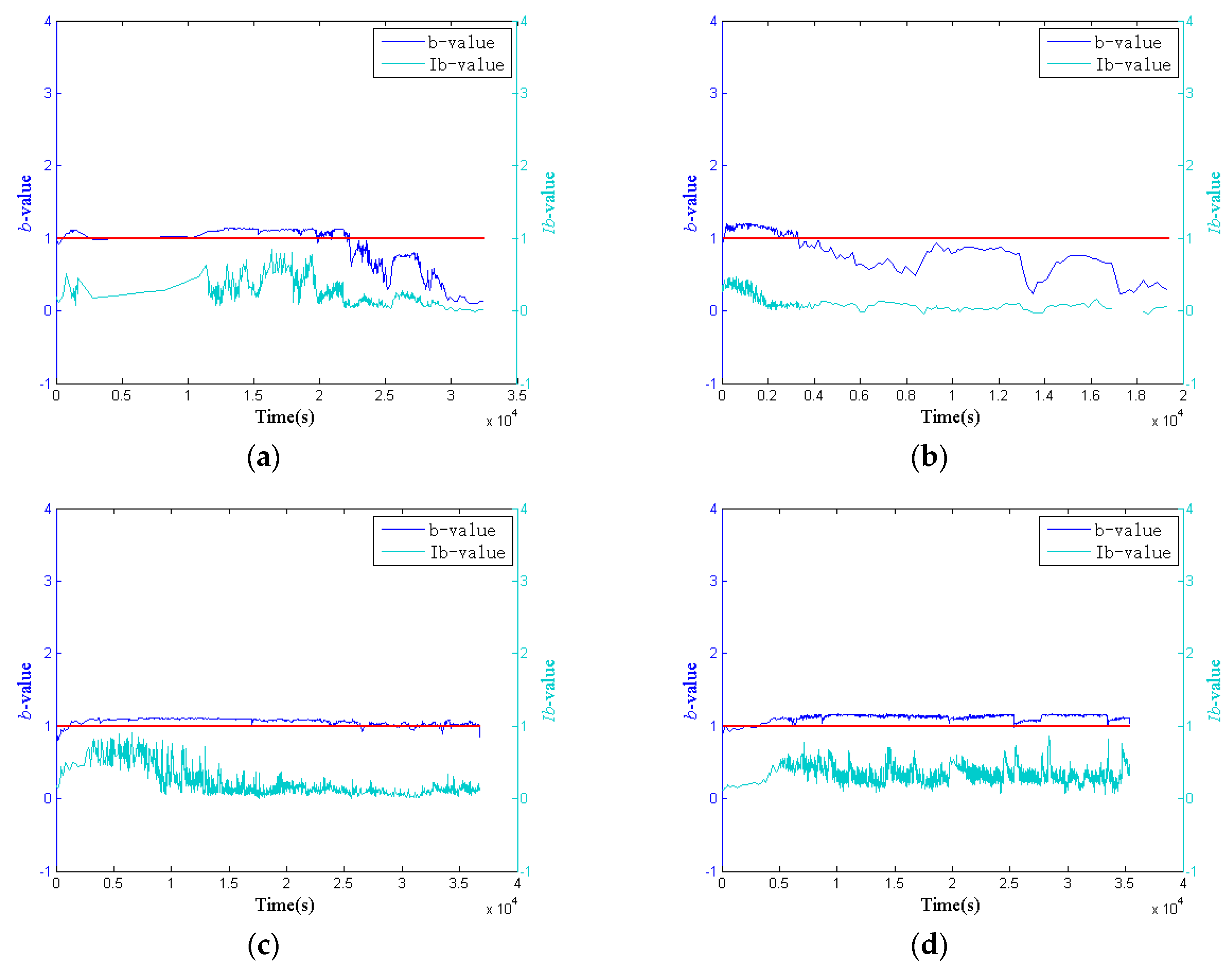

3.3. Features of b-Value Method and Ib-Value Method

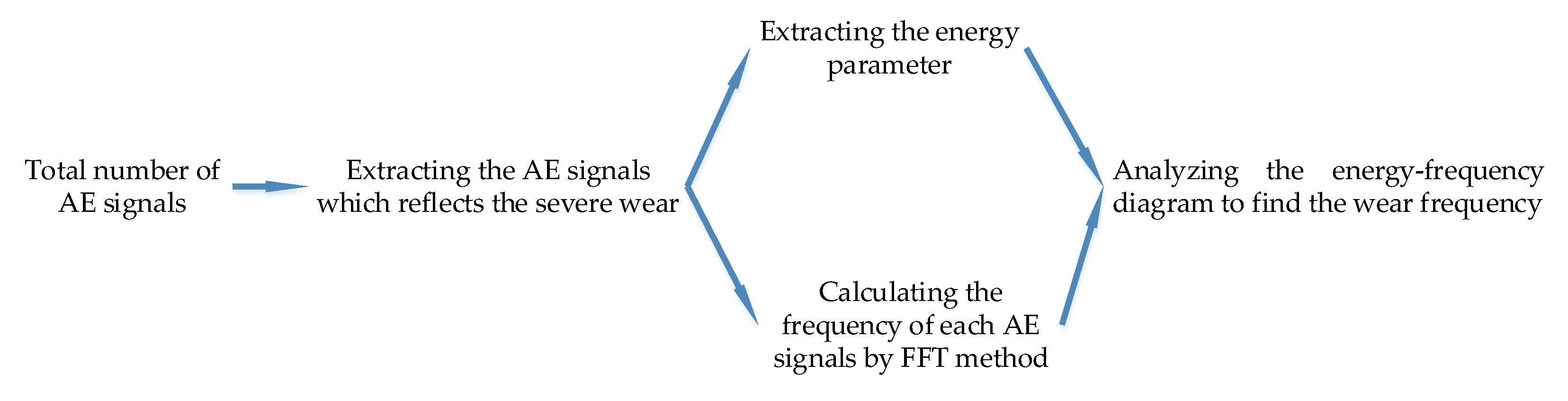

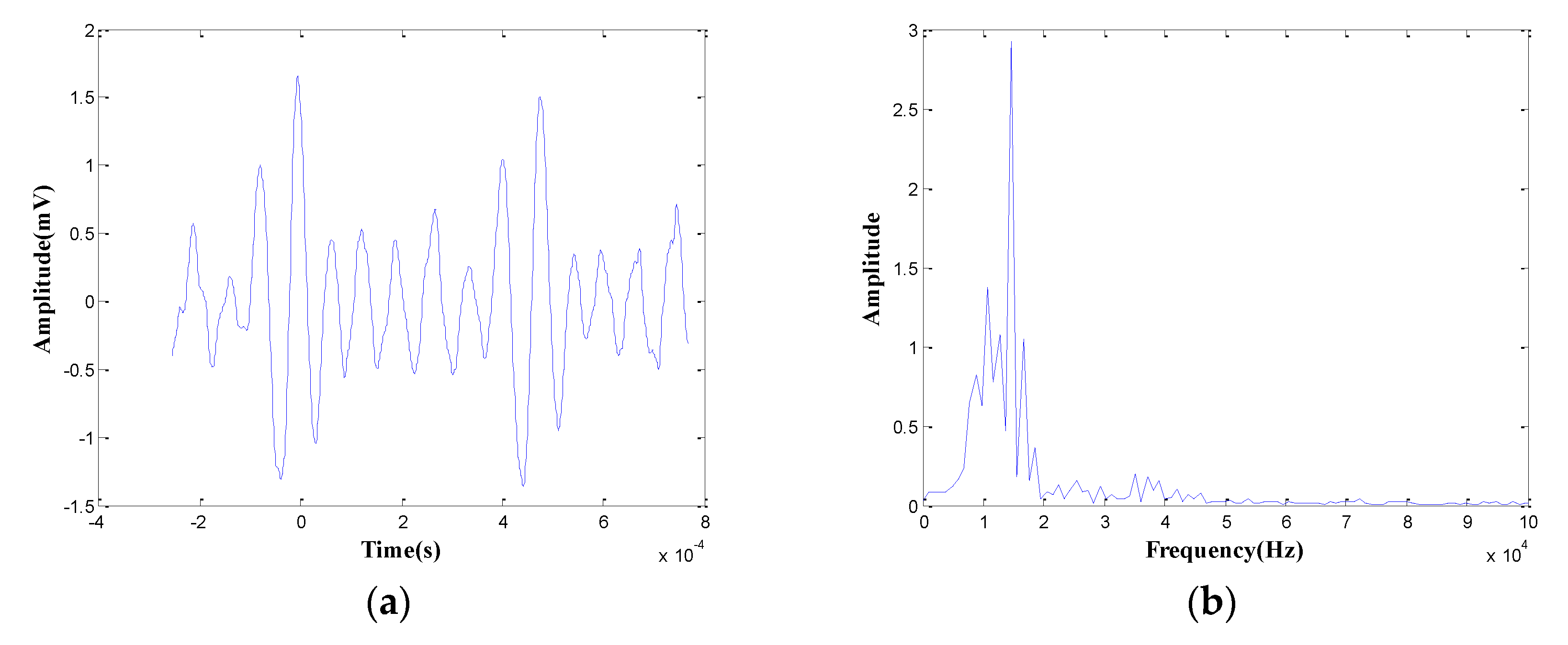

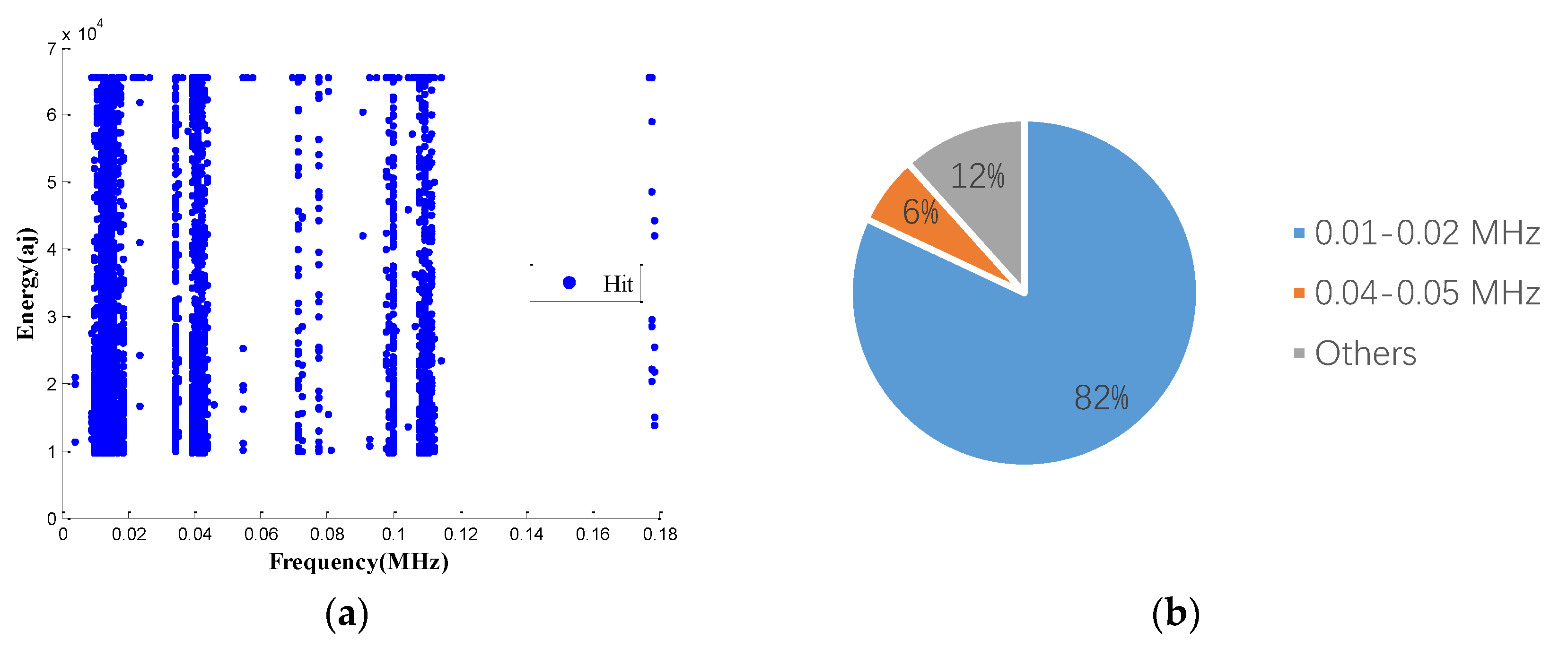

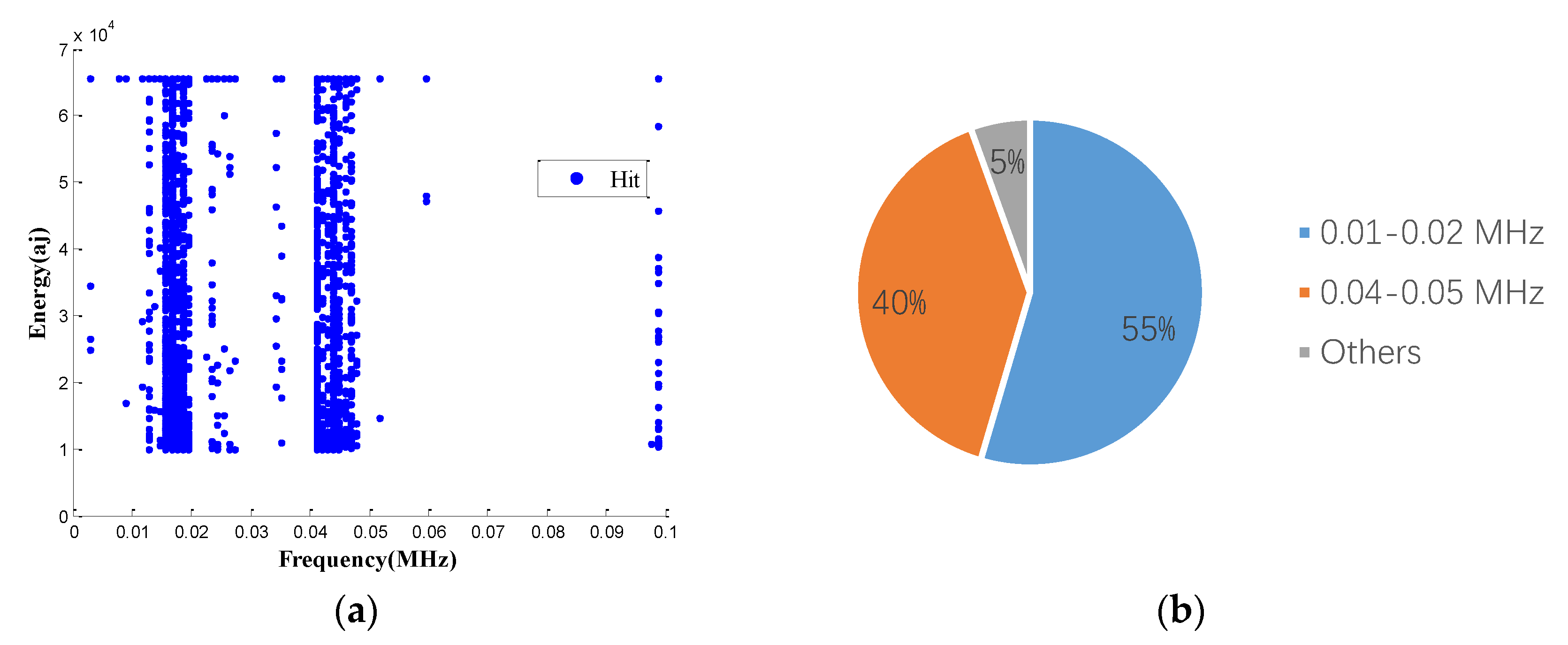

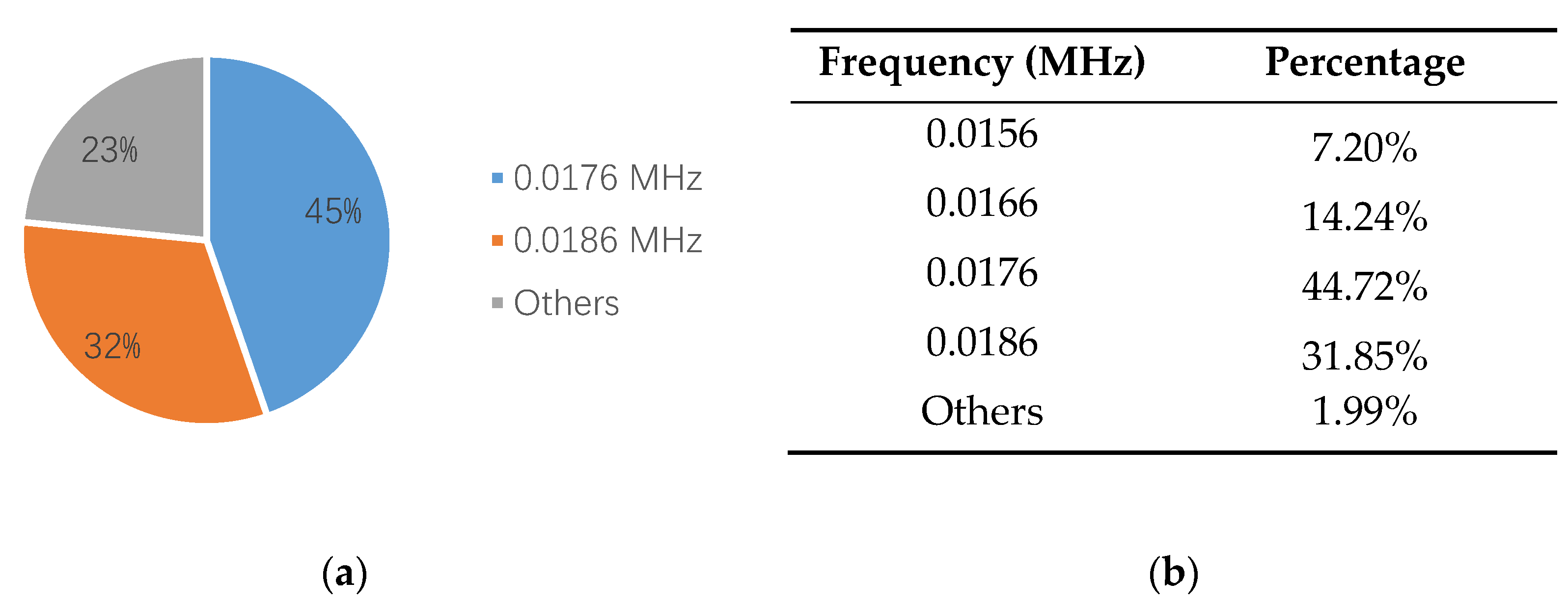

3.4. Frequency Spectrum of Wear

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wu, Z.; He, D.; Xu, E.; Jiao, A.; Chughtai, M.F.J.; Jin, Z. Rapid detection of beta-conglutin with a novel lateral flow aptasensor assisted by immunomagnetic enrichment and enzyme signal amplification. Food Chem. 2018, 269, 375–379. [Google Scholar] [CrossRef]

- Cheng, L.; Huang, K.; Chen, G.; Hu, B.; Jiang, Z.; Knoll, A. Applying periodic thermal management on hard real-time systems to minimize peak temperature. J. Circuits Syst. Comput. 2018, 27. [Google Scholar] [CrossRef]

- Asi, O. Effect of different woven linear densities on the bearing strength behaviour of glass fiber reinforced epoxy composites pinned joints. Compos. Struct. 2009, 90, 43–52. [Google Scholar] [CrossRef]

- Liang, Y.; Li, D.; Parvasi, S.M.; Song, G. Load monitoring of pin-connected structures using piezoelectric impedance measurement. Smart Mater. Struct. 2016, 25, 105011. [Google Scholar] [CrossRef]

- Li, D.; Liang, Y.; Feng, Q.; Song, G. Load monitoring of the pin-connected structure based on wavelet packet analysis using piezoceramic transducers. Measurement 2018, 122, 638–647. [Google Scholar] [CrossRef]

- Fan, S.; Li, W.; Kong, Q.; Feng, Q.; Song, G. Monitoring of pin connection loosening using eletromechanical impedance: Numerical simulation with experimental verification. J. Intell. Mater. Syst. Struct. 2018, 29, 1964–1973. [Google Scholar] [CrossRef]

- Liu, D.S.; Raju, B.B.; You, J.L. Thickness effects on pinned joints for composites. J. Compos. Mater. 1999, 33, 2–21. [Google Scholar] [CrossRef]

- Bridge, R.Q.; Sukkar, T.; Hayward, I.G.; Ommen, M.V. Behaviour and design of structural steel pins. Steel Compos. Struct. Int. J. 2001, 1, 97–110. [Google Scholar] [CrossRef]

- Aktas, A.; Uzun, I. Sea water effect on pinned joint glass fibre composite materials. Compos. Struct. 2008, 85, 59–63. [Google Scholar] [CrossRef]

- Liang, Y.; Li, D.; Kong, Q.; Song, G. Load monitoring of the pin-connected structure using time reversal technique and piezoceramic transducers-a feasibility study. IEEE Sens. J. 2016, 16, 7958–7966. [Google Scholar] [CrossRef]

- Jiang, T.; Kong, Q.; Patil, D.; Luo, Z.; Huo, L.; Song, G. Detection of debonding between fiber reinforced polymer bar and concrete structure using piezoceramic transducers and wavelet packet analysis. IEEE Sens. J. 2017, 17, 1992–1998. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.; Song, G. Health status monitoring of cuplock scaffold joint connection based on wavelet packet analysis. Shock Vib. 2015, 2015, 695845. [Google Scholar] [CrossRef]

- Jiang, T.; Kong, Q.; Wang, W.; Huo, L.; Song, G. Monitoring of grouting compactness in a post-tensioning tendon duct using piezoceramic transducers. Sensors 2016, 16, 1343. [Google Scholar] [CrossRef] [PubMed]

- Cheung, W.-F.; Lin, T.-H.; Lin, Y.-C. A real-time construction safety monitoring system for hazardous gas integrating wireless sensor network and building information modeling technologies. Sensors 2018, 18, 436. [Google Scholar] [CrossRef]

- Yin, H.; Wang, T.; Yang, D.; Liu, S.; Shao, J.; Li, Y. A smart washer for bolt looseness monitoring based on piezoelectric active sensing method. Appl. Sci. 2016, 6, 320. [Google Scholar] [CrossRef]

- Shao, J.; Wang, T.; Yin, H.; Yang, D.; Li, Y. Bolt looseness detection based on piezoelectric impedance frequency shift. Appl. Sci. 2016, 6, 298. [Google Scholar] [CrossRef]

- Kong, Q.; Robert, R.H.; Silva, P.; Mo, Y.L. Cyclic crack monitoring of a reinforced concrete column under simulated pseudo-dynamic loading using piezoceramic-based smart aggregates. Appl. Sci. 2016, 6, 341. [Google Scholar] [CrossRef]

- Na, W.S.; Baek, J. A review of the piezoelectric electromechanical impedance based structural health monitoring technique for engineering structures. Sensors 2018, 18, 1307. [Google Scholar] [CrossRef] [PubMed]

- Song, G.; Wang, C.; Wang, B. Structural health monitoring (SHM) of civil structures. Appl. Sci. 2017, 7, 789. [Google Scholar] [CrossRef]

- Laffont, G.; Cotillard, R.; Roussel, N.; Desmarchelier, R.; Rougeault, S. Temperature resistant fiber bragg gratings for on-line and structural health monitoring of the next-generation of nuclear reactors. Sensors 2018, 18, 1791. [Google Scholar] [CrossRef] [PubMed]

- Dziendzikowski, M.; Niedbala, P.; Kurnyta, A.; Kowalczyk, K.; Dragan, K. Structural health monitoring of a composite panel based on pzt sensors and a transfer impedance framework. Sensors 2018, 18, 1521. [Google Scholar] [CrossRef] [PubMed]

- Lan, C.; Zhou, W.; Xie, Y. Detection of ultrasonic stress waves in structures using 3D shaped optic fiber based on a mach-zehnder interferometer. Sensors 2018, 18, 1218. [Google Scholar] [CrossRef] [PubMed]

- Venugopal, V.P.; Wang, G. Modeling and analysis of lamb wave propagation in a beam under lead zirconate titanate actuation and sensing. J. Intell. Mater. Syst. Struct. 2015, 26, 1679–1698. [Google Scholar] [CrossRef]

- Zhao, X.; Li, W.; Song, G.; Zhu, Z.; Du, J. Scour monitoring system for subsea pipeline based on active thermometry: Numerical and experimental studies. Sensors 2013, 13, 1490–1509. [Google Scholar] [CrossRef]

- Zhao, X.; Li, W.; Zhou, L.; Song, G.-B.; Ba, Q.; Ou, J. Active thermometry based ds18b20 temperature sensor network for offshore pipeline scour monitoring using k-means clustering algorithm. Int. J. Distrib. Sens. Netw. 2013, 9, 852090. [Google Scholar] [CrossRef]

- Tsukamoto, A.; Hato, T.; Adachi, S.; Oshikubo, Y.; Tsukada, K.; Tanabe, K. Development of eddy current testing system using HTS-SQUID on a hand cart for detection of fatigue cracks of steel plate used in expressways. IEEE Trans. Appl. Supercond. 2018, 28. [Google Scholar] [CrossRef]

- Ahmed, S.; Miorelli, R.; Calmon, P.; Anselmi, N.; Salucci, M. Real time flaw detection and characterization in tube through partial least squares and svr: Application to eddy current testing. In AIP Conference Proceedings of the 44th Annual Review of Progress in Quantitative Nondestructive Evaluation, Provo, UT, USA, 15–16 July 2017; Chimenti, D.E., Bond, L.J., Eds.; AIP Publishing: College Park, MD, USA, 2018; Volume 1949. [Google Scholar]

- Hu, X.; Zhu, H.; Wang, D. A study of concrete slab damage detection based on the electromechanical impedance method. Sensors 2014, 14, 19897–19909. [Google Scholar] [CrossRef]

- Annamdas, K.K.K.; Annamdas, V.G.M. Piezo impedance sensors to monitor degradation of biological structure. In Advanced Environmental, Chemical, and Biological Sensing Technologies VII; VoDinh, T., Lieberman, R.A., Gauglitz, G., Eds.; SPIE: Orlando, FL, USA, 2010; Volume 7673. [Google Scholar]

- Annamdas, V.G.M.; Annamdas, K.K.K. Impedance based sensor technology to monitor stiffness of biological structures. In Advanced Environmental, Chemical, and Biological Sensing Technologies VII; VoDinh, T., Lieberman, R.A., Gauglitz, G., Eds.; SPIE: Orlando, FL, USA, 2010; Volume 7673. [Google Scholar]

- Xu, C.; Xie, J.; Zhang, W.; Kong, Q.; Chen, G.; Song, G. Experimental investigation on the detection of multiple surface cracks using vibrothermography with a low-power piezoceramic actuator. Sensors 2017, 17, 2705. [Google Scholar] [CrossRef] [PubMed]

- Parvasi, S.M.; Xu, C.; Kong, Q.; Song, G. Detection of multiple thin surface cracks using vibrothermography with low-power piezoceramic-based ultrasonic actuator-a numerical study with experimental verification. Smart Mater. Struct. 2016, 25, 055042. [Google Scholar] [CrossRef]

- Alhashan, T.; Elforjani, M.; Addali, A.; Teixeira, J. Monitoring of bubble formation during the boiling process using acoustic emission signals. Int. J. Eng. Res. Sci. 2016, 2, 66–72. [Google Scholar]

- Li, W.; Ho, S.C.M.; Patil, D.; Song, G. Acoustic emission monitoring and finite element analysis of debonding in fiber-reinforced polymer rebar reinforced concrete. Struct. Health Monit. Int. J. 2017, 16, 674–681. [Google Scholar] [CrossRef]

- Li, W.; Xu, C.; Ho, S.C.M.; Wang, B.; Song, G. Monitoring concrete deterioration due to reinforcement corrosion by integrating acoustic emission and fbg strain measurements. Sensors 2017, 17, 657. [Google Scholar] [CrossRef]

- Chen, B.; Wang, Y.; Yan, Z. Use of acoustic emission and pattern recognition for crack detection of a large carbide anvil. Sensors 2018, 18, 386. [Google Scholar] [CrossRef]

- Liu, P.F.; Chu, J.K.; Liu, Y.L.; Zheng, J.Y. A study on the failure mechanisms of carbon fiber/epoxy composite laminates using acoustic emission. Mater. Des. 2012, 37, 228–235. [Google Scholar] [CrossRef]

- Choi, W.-C.; Yun, H.-D. Acoustic emission activity of cfrp-strengthened reinforced concrete beams after freeze-thaw cycling. Cold Reg. Sci. Technol. 2015, 110, 47–58. [Google Scholar] [CrossRef]

- Bunnori, N.M.; Lark, R.J.; Holford, K.M. The use of acoustic emission for the early detection of cracking in concrete structures. Mag. Concr. Res. 2011, 63, 683–688. [Google Scholar] [CrossRef]

- Schumacher, T.; Higgins, C.C.; Lovejoy, S.C. Estimating operating load conditions on reinforced concrete highway bridges with b-value analysis from acoustic emission monitoring. Struct. Health Monit. Int. J. 2011, 10, 17–32. [Google Scholar] [CrossRef]

- Nair, A.; Cai, C.S. Acoustic emission monitoring of bridges: Review and case studies. Eng. Struct. 2010, 32, 1704–1714. [Google Scholar] [CrossRef]

- Behrens, B.-A.; Huebner, S.; Woelki, K. Acoustic emission a promising and challenging technique for process monitoring in sheet metal forming. J. Manuf. Process. 2017, 29, 281–288. [Google Scholar] [CrossRef]

- Chai, M.; Zhang, Z.; Duan, Q.; Song, Y. Assessment of fatigue crack growth in 316ln stainless steel based on acoustic emission entropy. Int. J. Fatigue 2018, 109, 145–156. [Google Scholar] [CrossRef]

- Li, X.L. A brief review: Acoustic emission method for tool wear monitoring during turning. Int. J. Mach. Tools Manuf. 2002, 42, 157–165. [Google Scholar] [CrossRef]

- Moradian, Z.A.; Ballivy, G.; Rivard, P.; Gravel, C.; Rousseau, B. Evaluating damage during shear tests of rock joints using acoustic emissions. Int. J. Rock Mech. Min. Sci. 2010, 47, 590–598. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Z.; Zhang, X.; Wang, Y.; Zhang, X.; Li, D. Experimental investigation on the mechanical and acoustic emission characteristics of shale softened by water absorption. J. Nat. Gas Sci. Eng. 2018, 50, 301–308. [Google Scholar] [CrossRef]

- Koerner, R.M.; McCabe, W.M.; Lord, A.E. Overview of acoustic-emission monitoring of rock structures. Rock Mech. 1981, 14, 27–35. [Google Scholar] [CrossRef]

- Abouhussien, A.A.; Hassan, A.A.A. Acoustic emission-based analysis of bond behavior of corroded reinforcement in existing concrete structures. Struct. Control Health Monit. 2017, 24, e1893. [Google Scholar] [CrossRef]

- Aldandooh, M.A.A.; Bunnori, N.M. Crack classification in reinforced concrete beams with varying thicknesses by mean of acoustic emission signal features. Constr. Build. Mater. 2013, 45, 282–288. [Google Scholar] [CrossRef]

- Kulandaivelu, P.; Kumar, P.S.; Sundaram, S. Wear monitoring of single point cutting tool using acoustic emission techniques. Sadhana-Acad. Proc. Eng. Sci. 2013, 38, 211–234. [Google Scholar] [CrossRef]

- Benabdallah, H.S.; Aguilar, D.A. Acoustic emission and its relationship with friction and wear for sliding contact. Tribol. Trans. 2008, 51, 738–747. [Google Scholar] [CrossRef]

- Hase, A.; Wada, M.; Mishina, H. Scanning electron microscope observation study for identification of wear mechanism using acoustic emission technique. Tribol. Int. 2014, 72, 51–57. [Google Scholar] [CrossRef]

- Alhashan, T.; Addali, A.; Teixeira, J.A.; Elhashan, S. Identifying bubble occurrence during pool boiling employing acoustic emission technique. Appl. Acoust. 2018, 132, 191–201. [Google Scholar] [CrossRef]

- Bianchi, D.; Mayrhofer, E.; Groeschl, M.; Betz, G.; Vernes, A. Wavelet packet transform for detection of single events in acoustic emission signals. Mech. Syst. Signal Process. 2015, 64–65, 441–451. [Google Scholar] [CrossRef]

- Dong, S.; Yuan, M.; Wang, Q.; Liang, Z. A modified empirical wavelet transform for acoustic emission signal decomposition in structural health monitoring. Sensors 2018, 18, 1645. [Google Scholar] [CrossRef] [PubMed]

- Mao, K.; Lu, D.; Dazhi, E.; Tan, Z. A case study on attribute recognition of heated metal mark image using deep convolutional neural networks. Sensors 2018, 18, 1871. [Google Scholar] [CrossRef]

- Chen, X.; Wang, D.; Yin, J.; Wu, Y. A direct position-determination approach for multiple sources based on neural network computation. Sensors 2018, 18, 1925. [Google Scholar] [CrossRef] [PubMed]

- Pashmforoush, F.; Fotouhi, M.; Ahmadi, M. Damage characterization of glass/epoxy composite under three-point bending test using acoustic emission technique. J. Mater. Eng. Perform. 2012, 21, 1380–1390. [Google Scholar] [CrossRef]

- Yin, C.; Zhu, Y.; Fei, J.; He, X. A deep learning approach for intrusion detection using recurrent neural networks. IEEE Access 2017, 5, 21954–21961. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, M.; Zhai, G. Application of deep learning architectures for accurate and rapid detection of internal mechanical damage of blueberry using hyperspectral transmittance data. Sensors 2018, 18, 1126. [Google Scholar] [CrossRef] [PubMed]

- Psuj, G. Multi-sensor data integration using deep learning for characterization of defects in steel elements. Sensors 2018, 18, 292. [Google Scholar] [CrossRef]

- Mao, Y.; Zhong, H.; Qi, H.; Ping, P.; Li, X. An adaptive trajectory clustering method based on grid and density in mobile pattern analysis. Sensors 2017, 17, 2013. [Google Scholar] [CrossRef]

- Zhao, S.; Li, W.; Cao, J. A user-adaptive algorithm for activity recognition based on k-means clustering, local outlier factor, and multivariate gaussian distribution. Sensors 2018, 18, 1850. [Google Scholar] [CrossRef] [PubMed]

- Kurz, J.H.; Grosse, C.U.; Reinhardt, H.W. Strategies for reliable automatic onset time picking of acoustic emissions and of ultrasound signals in concrete. Ultrasonics 2005, 43, 538–546. [Google Scholar] [CrossRef]

- Schechinger, B.; Vogel, T. Acoustic emission for monitoring a reinforced concrete beam subject to four-point-bending. Constr. Build. Mater. 2007, 21, 483–490. [Google Scholar] [CrossRef]

- Gutenberg, B.; Richter, C.F. Frequency of earthquakes in california. Bull. Seism. Am. 1944, 34, 185–188. [Google Scholar]

- Colombo, I.S.; Main, I.G.; Forde, M.C. Assessing damage of reinforced concrete beam using “b-value” analysis of acoustic emission signals. J. Mater. Civ. Eng. 2003, 15, 280–286. [Google Scholar] [CrossRef]

- Shiotani, T.; Fujii, K.; Aoki, T.; Amou, K. Evaluation of Progressive Failure Using AE Sources and Improved b-Value on Slope Model Tests. In Proceedings of the 12th International Acoustic Emission Symposium, Sapporo, Japan, 17–20 October 1994; Volume 7, pp. 529–534. [Google Scholar]

- Shiotani, T.; Yuyama, S.; Li, Z.W.; Ohtsu, M. Application of AE Improved b-Value to Quantitative Evaluation of Fracture Process in Concrete Materials. J. Acoust. Emiss. 2001, 19, 118–133. [Google Scholar]

- Lockner, D.A. Brittle fracture as an analog to earthquakes: Can acoustic emission be used to develop a viable prediction strategy? J. Acoust. Emiss. 1996, 14, S88–S101. [Google Scholar]

- Smith, W.D. The b-value as an earthquake precursor. Nature 1981, 289, 136–139. [Google Scholar] [CrossRef]

- Rao, M.; Lakshmi, K.J.P. Analysis of b-value and improved b-value of acoustic emissions accompanying rock fracture. Curr. Sci. 2005, 89, 1577–1582. [Google Scholar]

- Hase, A.; Mishina, H.; Wada, M. Correlation between features of acoustic emission signals and mechanical wear mechanisms. Wear 2012, 292, 144–150. [Google Scholar] [CrossRef]

- Shabalinskaya, L.A.; Golovanov, V.V.; Bubnova, E.S.; Melnikov, A.O.; Grigorev, A.V.; Prodanov, E.S. Tribodiagnostics of aviation reduction gears according to the stages of the surface fatigue wear for its units. J. Frict. Wear 2017, 38, 297–301. [Google Scholar] [CrossRef]

- Ono, K. Application of acoustic emission for structure diagnosis. Konf. Nauk. 2010, 317–341. [Google Scholar]

- ElBatanouny, M.K.; Ziehl, P.H.; Larosche, A.; Mangual, J.; Matta, F.; Nanni, A. Acoustic emission monitoring for assessment of prestressed concrete beams. Constr. Build. Mater. 2014, 58, 46–53. [Google Scholar] [CrossRef]

- Wang, F.; Ho, S.C.M.; Huo, L.; Song, G. A Novel Fractal Contact-Electromechanical Impedance Model for Quantitative Monitoring of Bolted Joint Looseness. IEEE Access 2018, 6, 40212–40220. [Google Scholar] [CrossRef]

- Wang, F.; Huo, L.; Song, G. A piezoelectric active sensing method for quantitative monitoring of bolt loosening using energy dissipation caused by tangential damping based on the fractal contact theory. Smart Mater. Struct. 2017, 27, 015023. [Google Scholar] [CrossRef]

| Elements | Proportion |

|---|---|

| C | ≤0.07 |

| Mn | ≤2.00 |

| P | ≤0.035 |

| S | ≤0.030 |

| Si | ≤1.00 |

| Cr | 17.00~19.00 |

| Ni | 8.00~11.00 |

| Parameters | Range |

|---|---|

| Magnification | 20× to 200× |

| Observation range | 19.05–1.14 mm |

| Repeat position precision | ±0.5 µm |

| Parameters | Range |

|---|---|

| Measurement length | 120 mm |

| Movement speed | 0.1/0.25/0.5/1.0/10.0 mm/s |

| Measurement speed | 0.1/0.25/0.5 mm/s |

| Sampling interval in horizontal | 0.15 /0.1–15 mm 0.25 /15–30 mm 1 /30–200 mm |

| Accuracy of main spindle |

| Specimens | The Average Surface Roughness (μm) | The Maximum Surface Roughness (μm) |

|---|---|---|

| The control specimen | 0.8473 | 1.1247 |

| The first specimen | 6.5552 | 8.4731 |

| The second specimen | 5.1232 | 6.9239 |

| The third specimen | 4.6801 | 5.6099 |

| The fourth specimen | 4.7704 | 5.2681 |

| Specimens | The Number of Data Whose b-Value Is Lower than 1 | Total Number of Data | Proportion |

| The first specimen | 307 | 863 | 35.57% |

| The second specimen | 415 | 415 | 26.98% |

| The third specimen | 53 | 2176 | 2.44% |

| The fourth specimen | 18 | 2943 | 0.61% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Huo, L.; Liu, C.; Song, G. Wear Degree Quantification of Pin Connections Using Parameter-Based Analyses of Acoustic Emissions. Sensors 2018, 18, 3503. https://doi.org/10.3390/s18103503

Wang J, Huo L, Liu C, Song G. Wear Degree Quantification of Pin Connections Using Parameter-Based Analyses of Acoustic Emissions. Sensors. 2018; 18(10):3503. https://doi.org/10.3390/s18103503

Chicago/Turabian StyleWang, Jingkai, Linsheng Huo, Chunguang Liu, and Gangbing Song. 2018. "Wear Degree Quantification of Pin Connections Using Parameter-Based Analyses of Acoustic Emissions" Sensors 18, no. 10: 3503. https://doi.org/10.3390/s18103503

APA StyleWang, J., Huo, L., Liu, C., & Song, G. (2018). Wear Degree Quantification of Pin Connections Using Parameter-Based Analyses of Acoustic Emissions. Sensors, 18(10), 3503. https://doi.org/10.3390/s18103503