Study on Fabrication of ZnO Waveguide Layer for Love Wave Humidity Sensor Based on Magnetron Sputtering

Abstract

1. Introduction

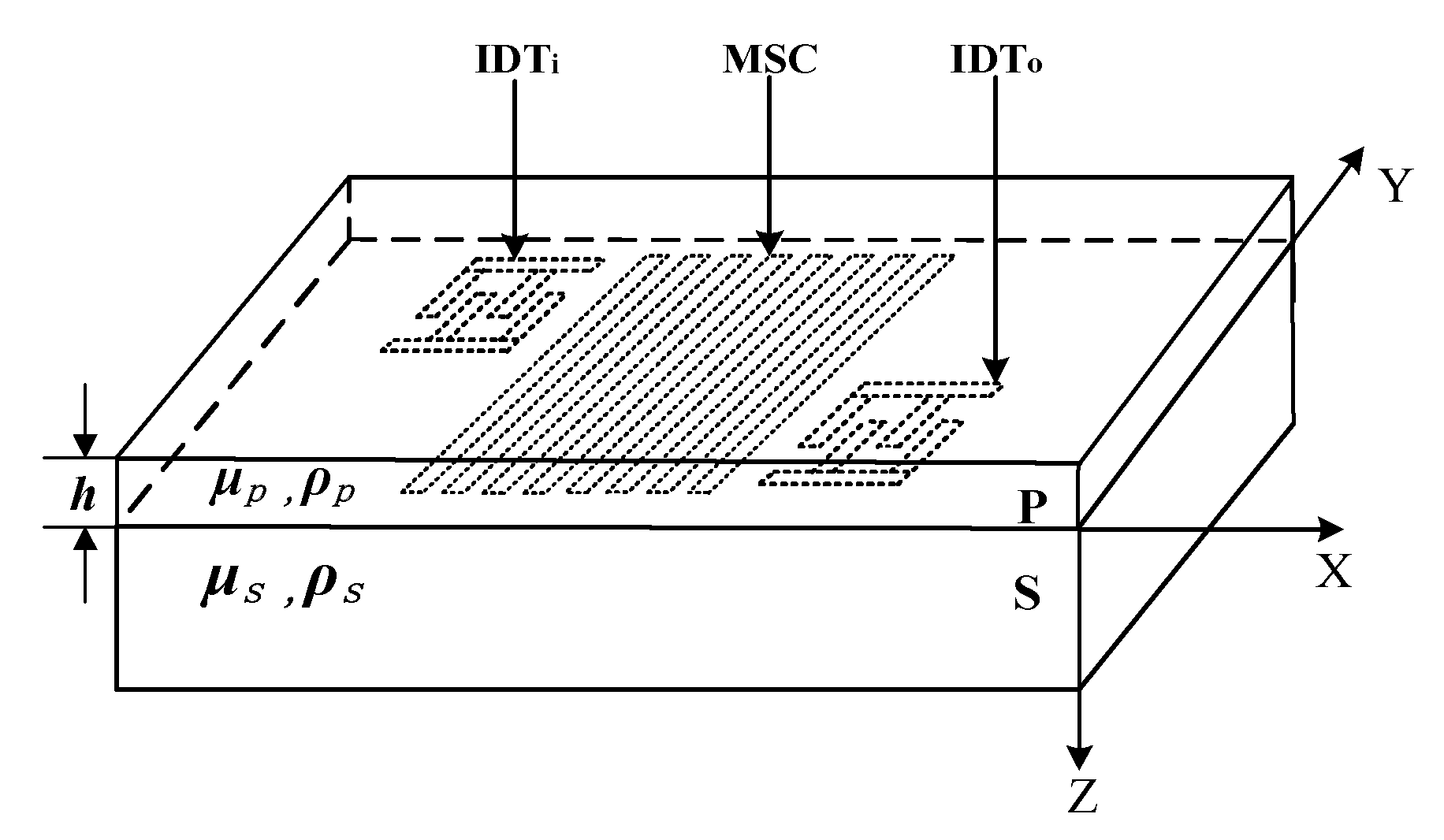

2. Schematic Diagram of Love Wave Humidity Sensor

3. Experiments

3.1. Fabrication of ZnO Waveguide Layer

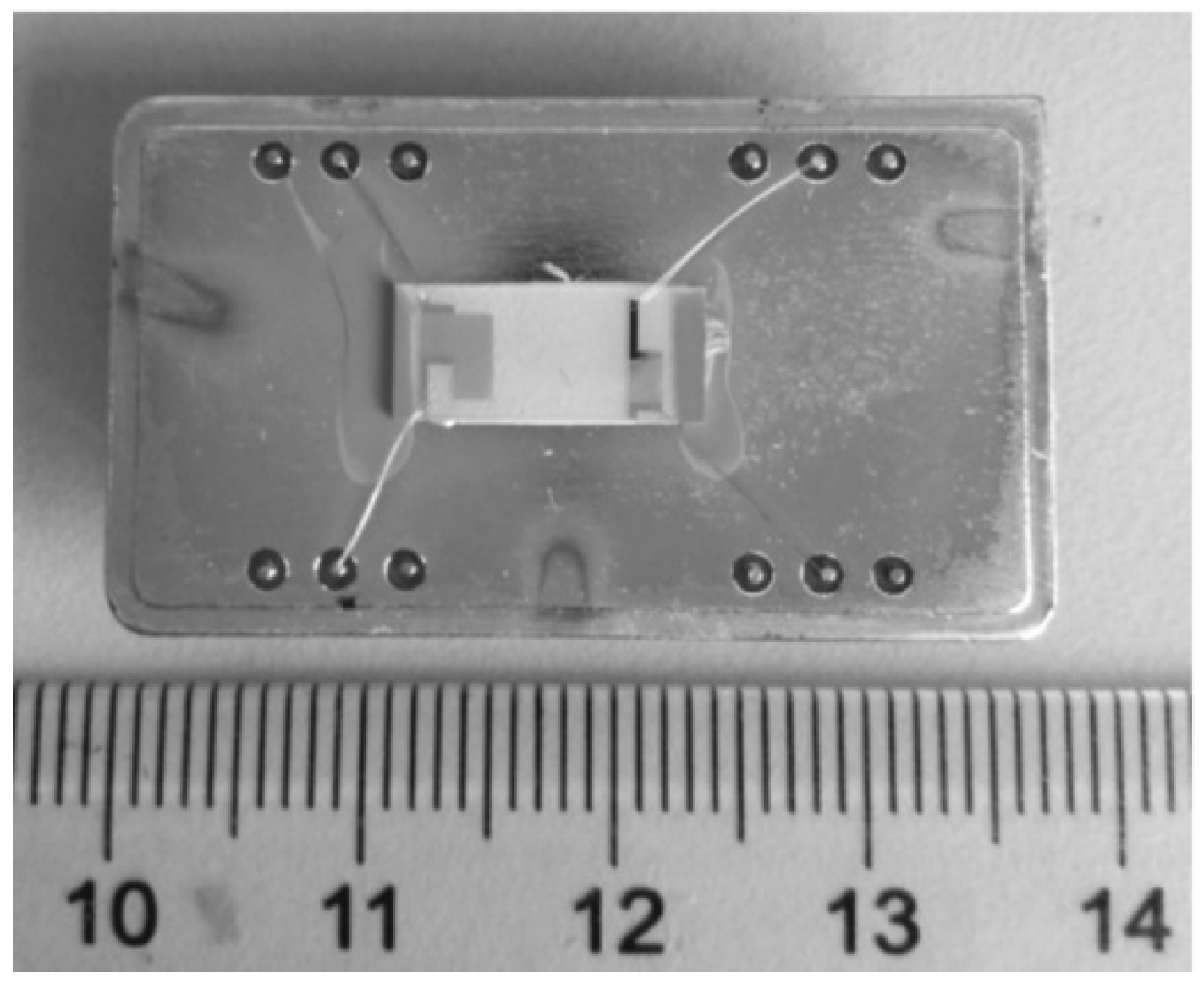

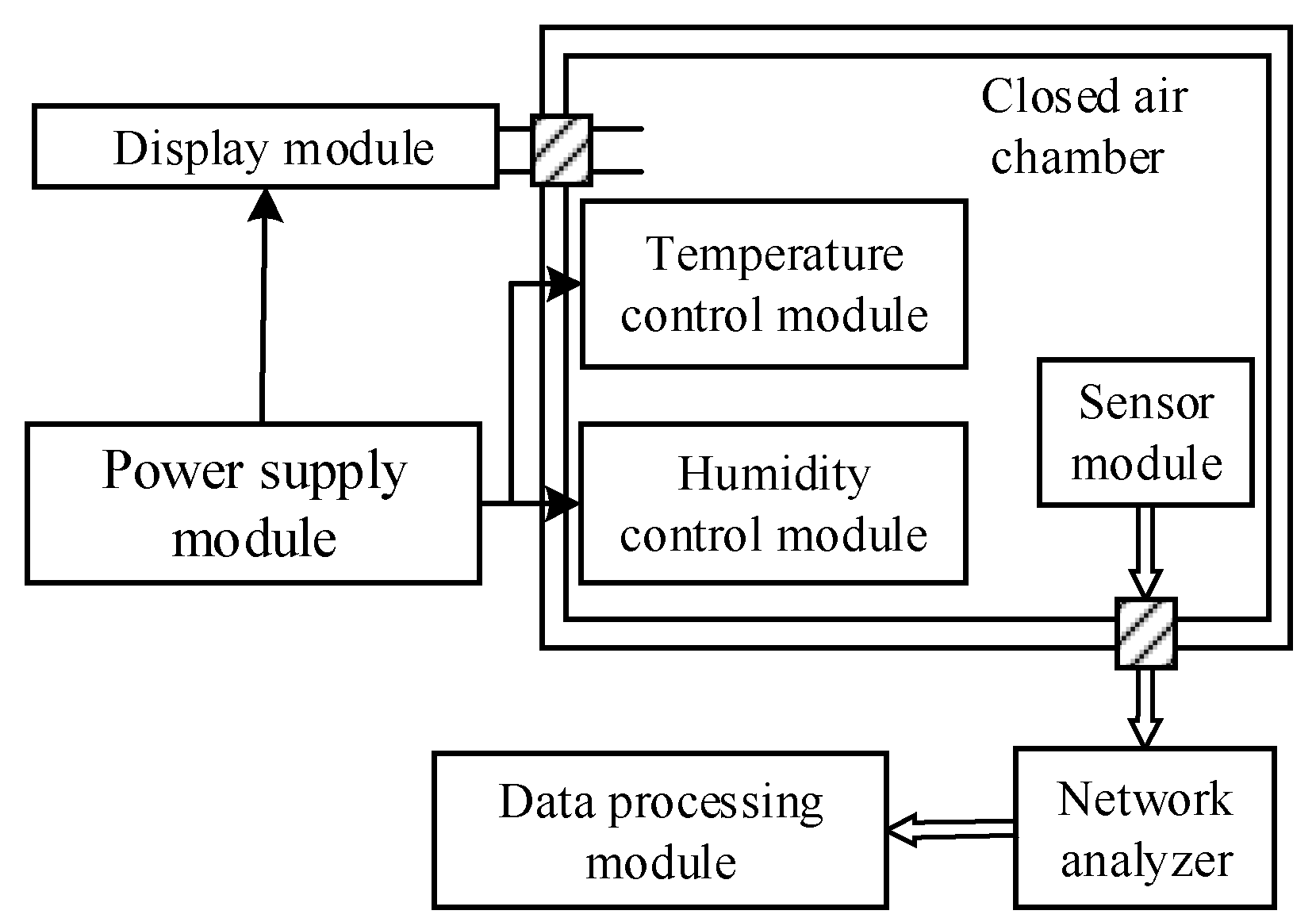

3.2. Design of the Humidity Measurement System

4. Experimental Results and Analysis

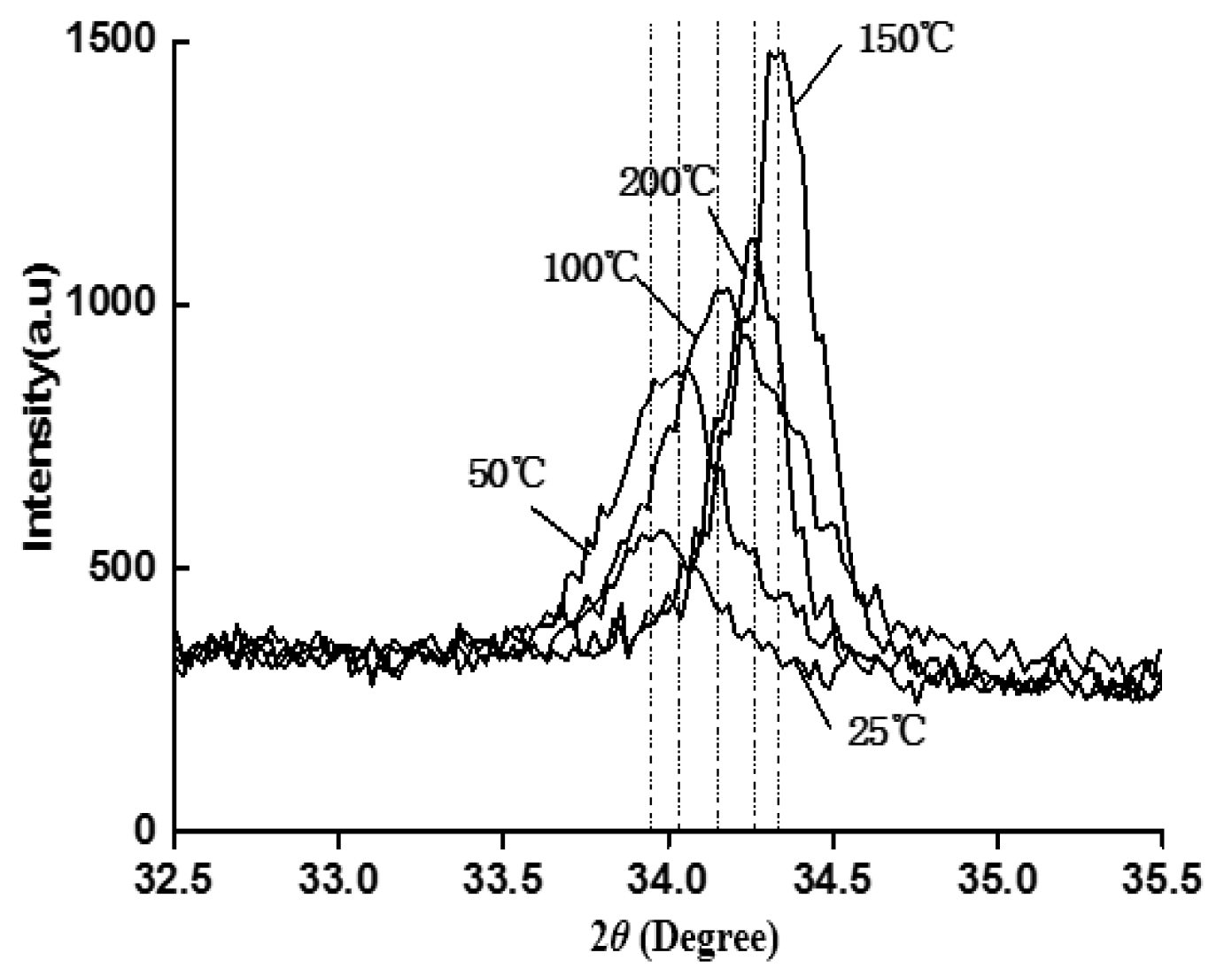

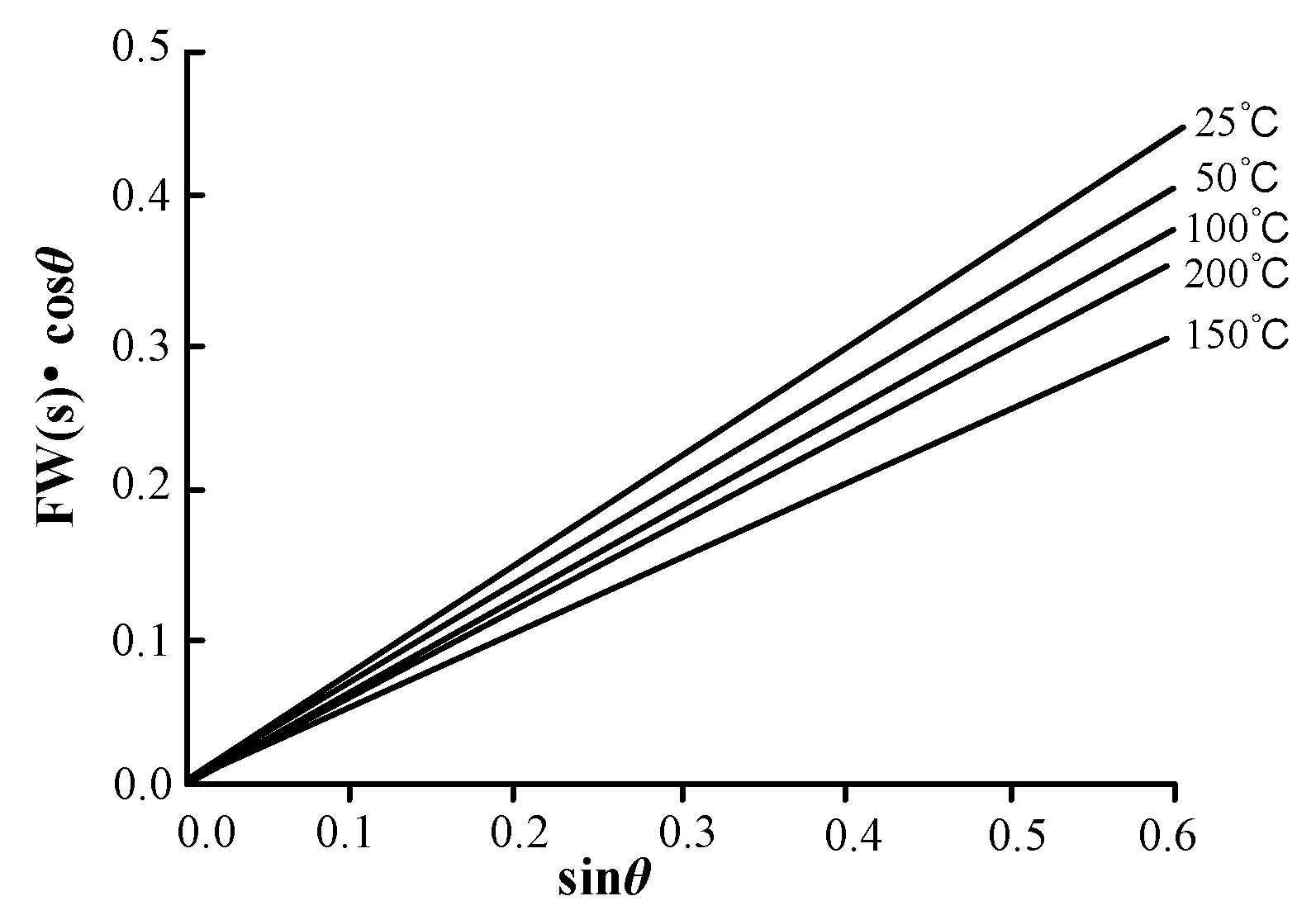

4.1. Crystal Orientation Analysis of the ZnO Waveguide Layer

4.2. Microstructure Analysis of the ZnO Waveguide Layer

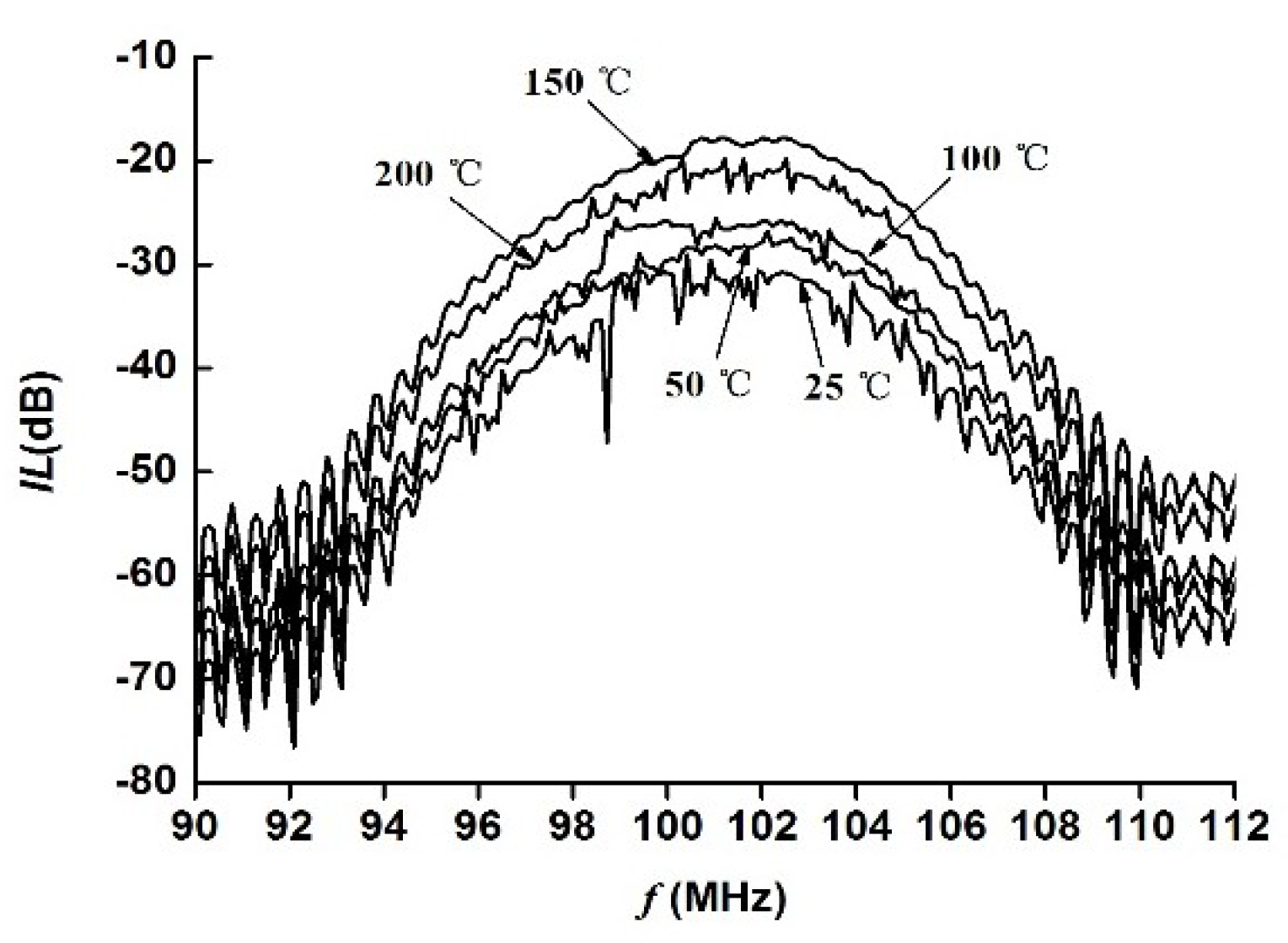

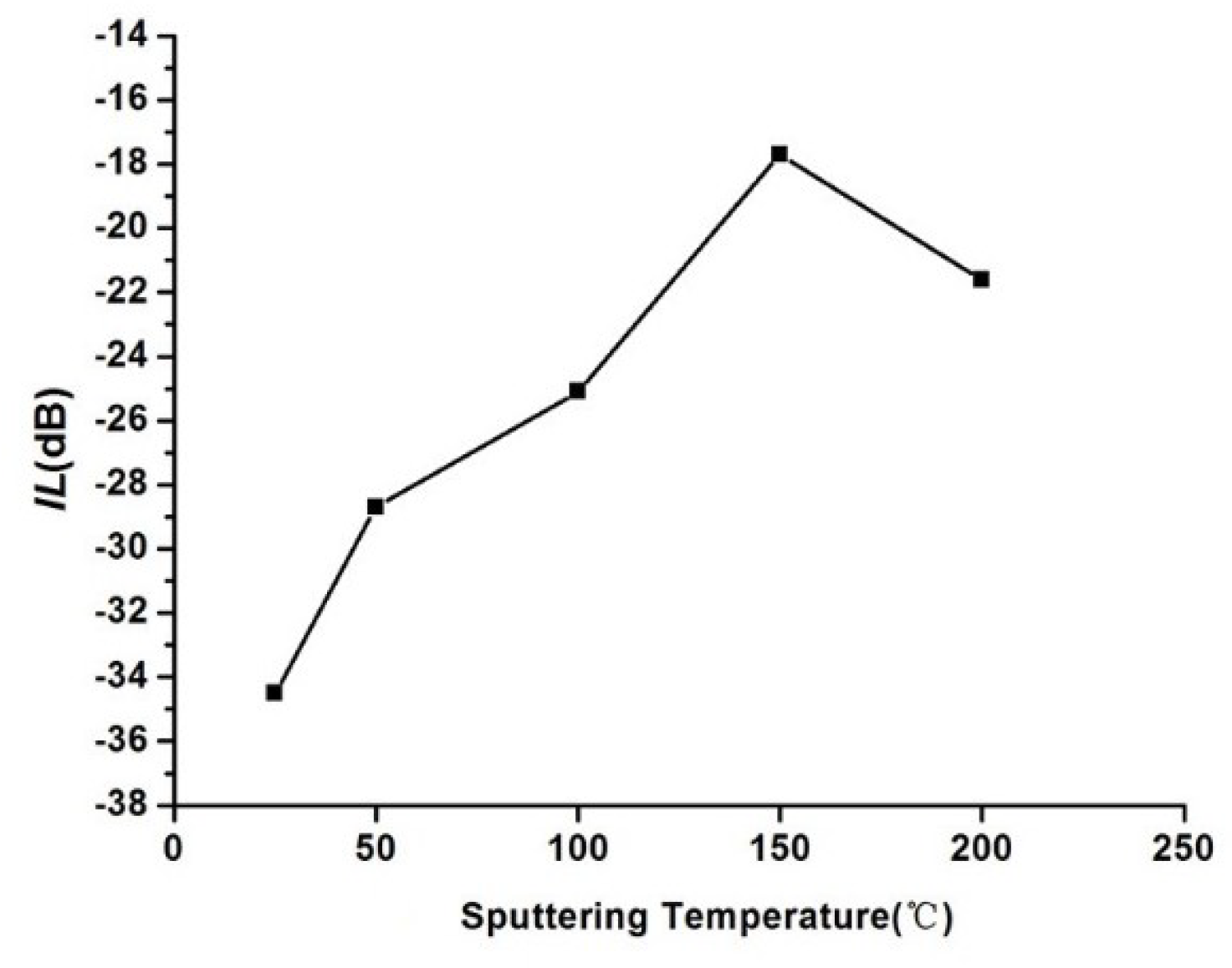

4.3. The Response Characteristics of the Love Wave Device

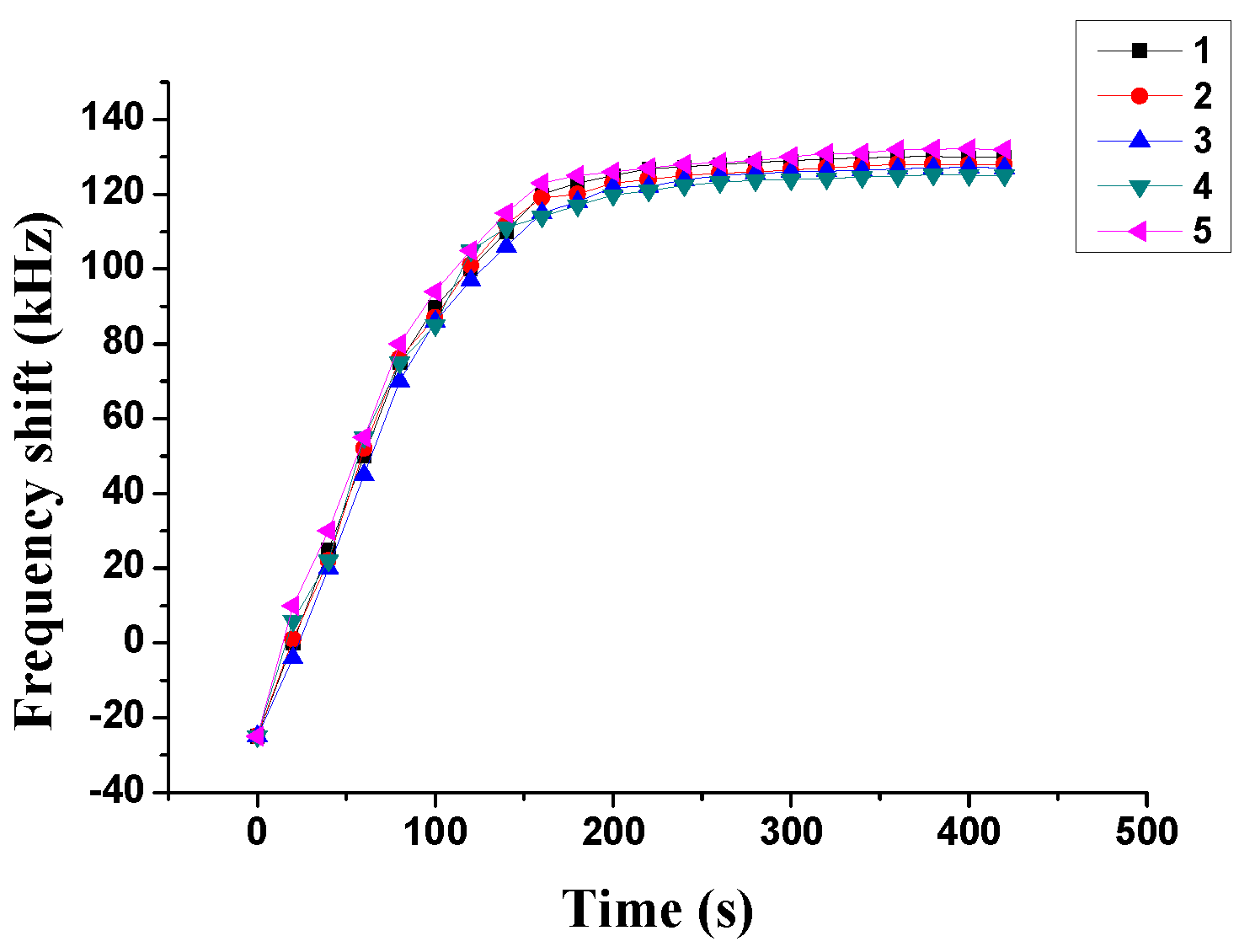

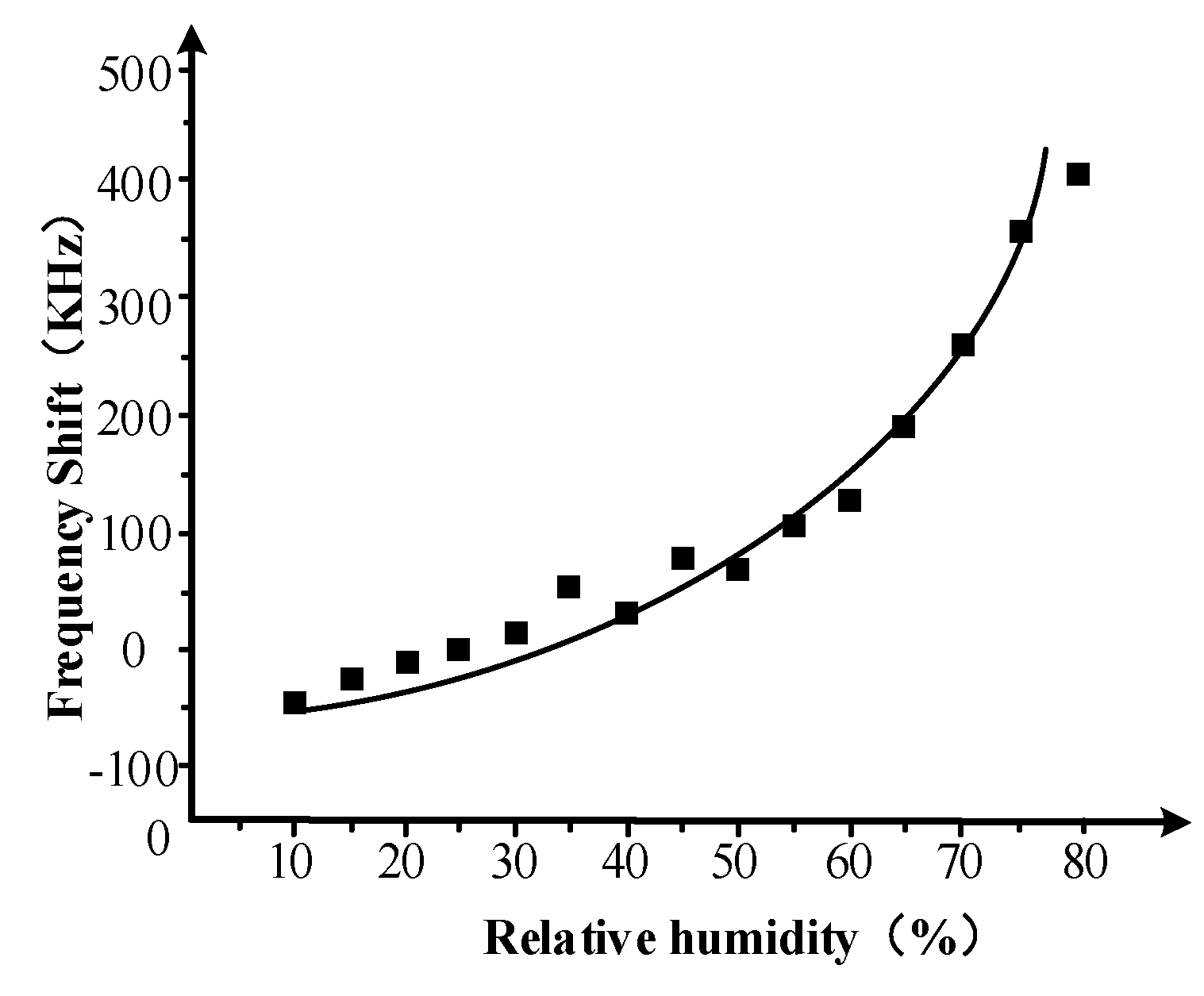

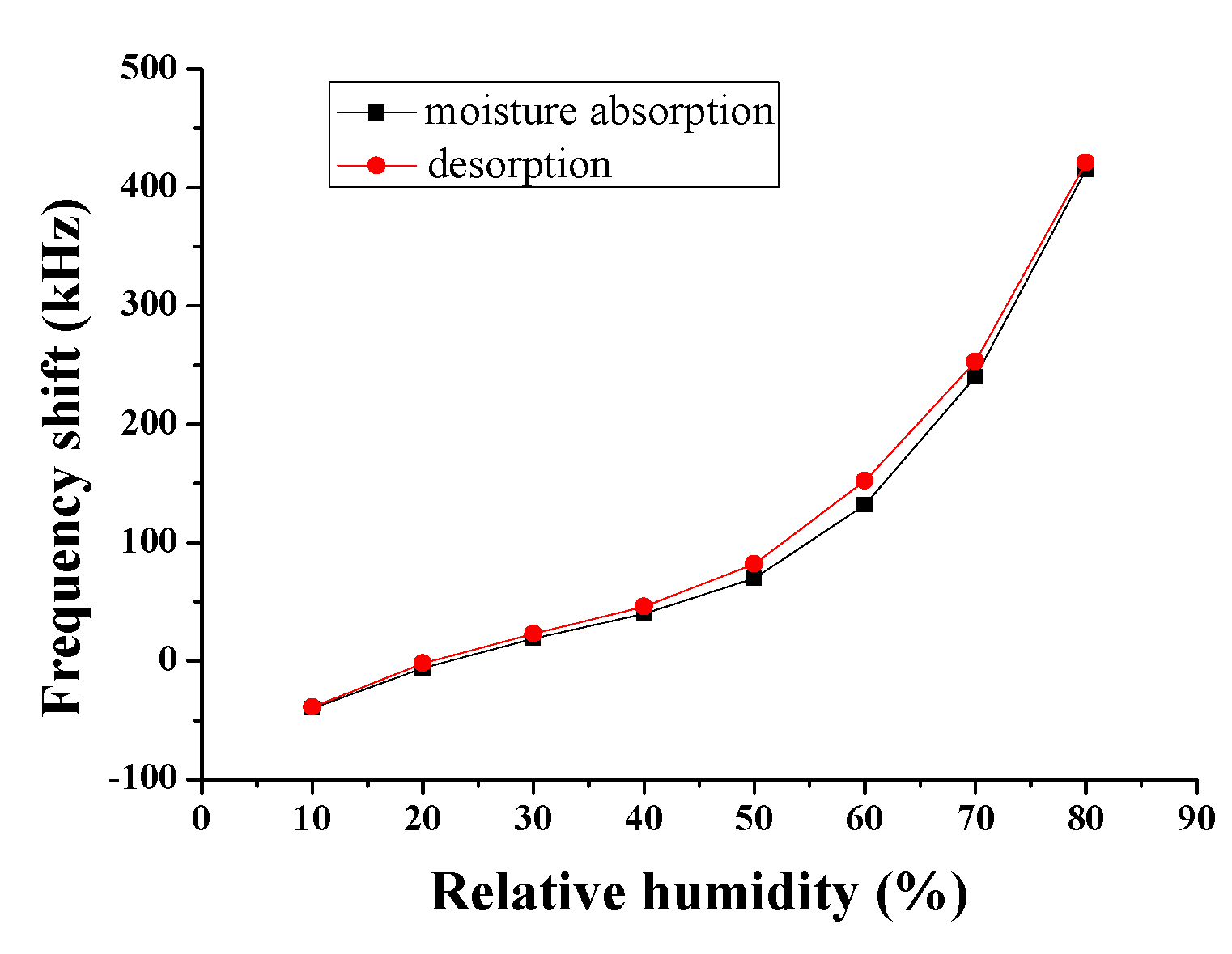

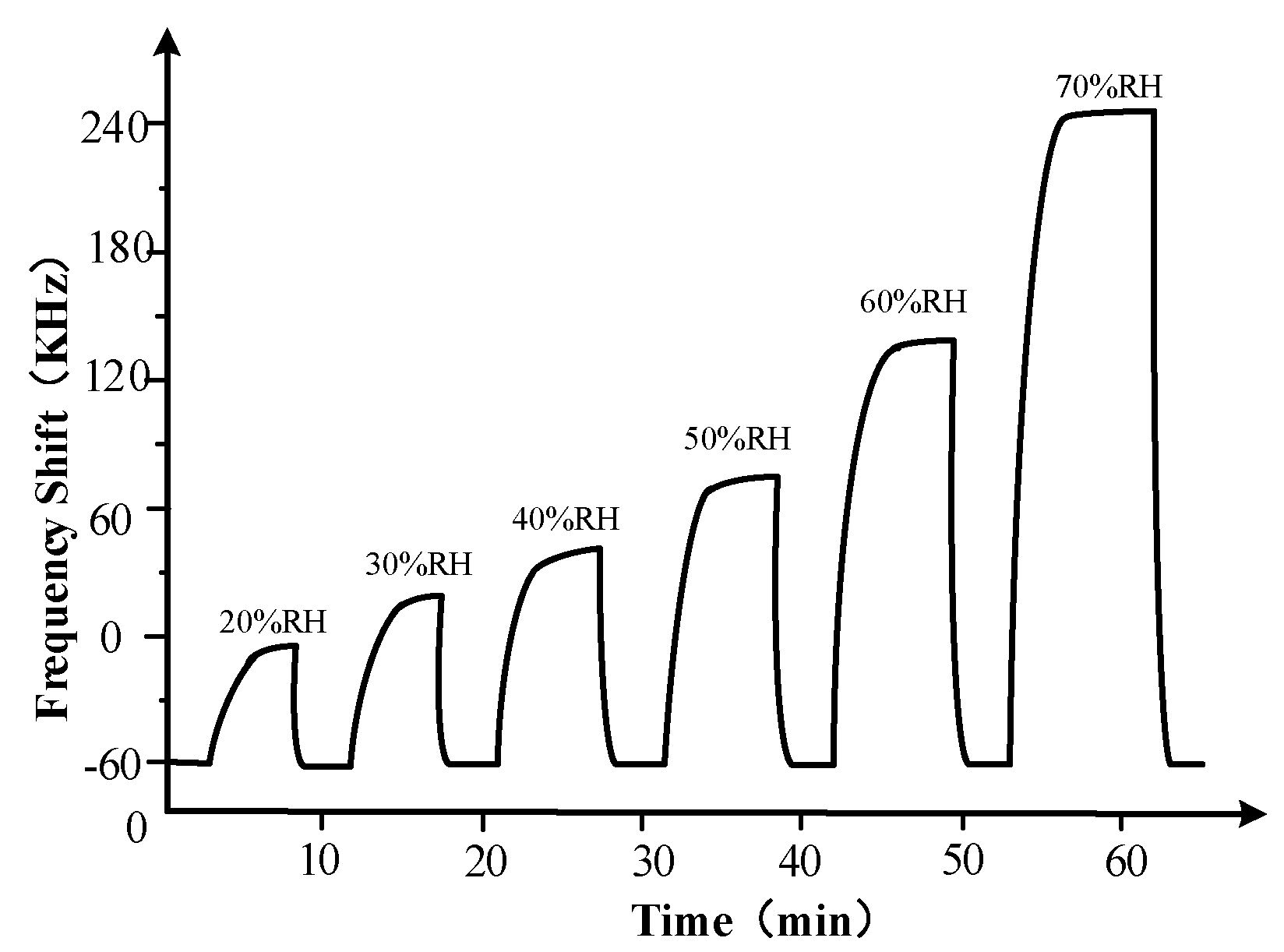

4.4. Characteristic Analysis of the Humidity Sensor

- (1)

- The semiconductor temperature regulator is started to control the temperature of the air chamber at 25 °C, and the temperature of the closed air chamber should be kept at 25 °C throughout the experiment.

- (2)

- The relative humidity of the closed air chamber is reduced to 10% by the silica gel desiccant and then keeps for 300 s. The system completes the measurement of the relative humidity when the output signal of the system reaches a stable value.

- (3)

- Each relative humidity was measured by the same method.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liu, T.W.; Lin, Y.C.; Tsai, Y.C.; Ono, T.; Tanaka, S.; Wu, T. Evidence of a Love wave bandgap in a quartz substrate coated with a phononic thin layer. Appl. Phys. Lett. 2014, 104, 181905. [Google Scholar] [CrossRef]

- Li, S.; Wan, Y.; Fan, C.; Su, Y. Theoretical Study of Monolayer and Double-Layer Waveguide Love Wave Sensors for Achieving High Sensitivity. Sensors 2017, 17, 653. [Google Scholar] [CrossRef] [PubMed]

- Han, K.; Yuan, Y.J. Mass sensitivity evaluation and device design of a Love wave device for bond rupture biosensors using the finite element method. IEEE Sens. J. 2014, 14, 2601–2608. [Google Scholar] [CrossRef]

- Sayago, I.; Matatagui, D.; Fernández, M.J.; Fontecha, J.L.; Jurewicz, I.; Garriga, R.; Muñoz, E. Graphene oxide as sensitive layer in Love-wave surface acoustic wave sensors for the detection of chemical warfare agent simulants. Talanta 2016, 148, 393–400. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.S.; Wang, L.J. Dynamics and response of a humidity sensor based on a Love wave device incorporating a polymeric layer. Sens. Actuators B Chem. 2014, 204, 50–56. [Google Scholar] [CrossRef]

- Kovacs, G.; Vellekoop, M.J.; Haueis, R.; Lubking, G.W.; Venema, A. A love wave sensor for (bio)chemical sensing in liquids. Sens. Actuators A Phys. 1994, 43, 38–43. [Google Scholar] [CrossRef]

- Dickert, F.L.; Tortschanoffl, M.; Bulst, W.E.; Fischerauer, G. Molecularly Imprinted Sensor Layers for the Detection of Polycyclic Aromatic Hydrocarbons in Water. Anal. Chem. 1999, 71, 4559–4563. [Google Scholar] [CrossRef]

- Jakoby, B.; Vellekoop, M.J. Properties of Love waves: applications in sensors. Smart Mater. Struct. 1997, 6, 668–679. [Google Scholar] [CrossRef]

- Dejous, C.; Hallil, H.; Raimbault, V.; Lachaud, J.; Plano, B.; Delépée, R.; Favetta, P.; Agrofoglio, L.; Rebière, D. Love Acoustic Wave-Based Devices and Molecularly-Imprinted Polymers as Versatile Sensors for Electronic Nose or Tongue for Cancer Monitoring. Sensors 2016, 16, 915. [Google Scholar] [CrossRef] [PubMed]

- Gammoudi, I.; Tarbague, H.; Othmane, A.; Moynet, D.; Rebière, D.; Kalfat, R.; Dejous, C. Love-wave bacteria-based sensor for the detection of heavy metal toxicity in liquid medium. Biosens. Bioelectron. 2010, 26, 1723–1726. [Google Scholar] [CrossRef] [PubMed]

- Gammoudi, I.; Blanc, L.; Moroté, F.; Grauby-Heywang, C.; Boissière, C.; Kalfat, R.; Rebière, D.; Cohen-Bouhacina, T.; Dejous, C. High sensitive mesoporous TiO2-Coated Love wave device for heavy metal detection. Biosens. Bioelectron. 2013, 57, 162–179. [Google Scholar] [CrossRef] [PubMed]

- Fu, C.; Jung, I.; Yang, S.S.; Lee, K. Towards optimised wireless Love wave biosensor with high sensitivity. Micro Nano Lett. 2012, 7, 1202–1205. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J.; He, S. The Development of Love Wave-Based Humidity Sensors Incorporating Multiple Layers. Sensors 2015, 15, 8615–8623. [Google Scholar] [CrossRef] [PubMed]

- Turton, A.; Battacharyya, D.; Wood, D. Love-mode surface acoustic wave liquid sensors using a polyimide waveguide layer. In Proceedings of the 2004 IEEE International Frequency Control Symposium and Exposition, Montreal, QC, Canada, 23–27 August 2004; pp. 250–256. [Google Scholar]

- Wang, W.; Xie, X.; Chen, G.; Liu, J.L.; He, S.T. Temperature-compensated Love wave based gas sensor on waveguide structure of SiO2/36° YX LiTaO3. Smart Mater. Struct. 2015, 24, 065019. [Google Scholar] [CrossRef]

- Harding, G.L.; Du, J. Design and properties of quartz-based Love wave acoustic sensors incorporating silicon dioxide and PMMA guiding layers. Smart Mater. Struct. 1997, 6, 716–720. [Google Scholar] [CrossRef]

- Trivedi, S.; Nemade, H.B. Simulation of a Love wave device with ZnO nanorods for high mass sensitivity. Ultrasonics 2017, 84, 150–161. [Google Scholar] [CrossRef] [PubMed]

- Lan, X.D.; Zhang, S.Y.; Wang, Y.; Li, F.; Shui, X.J. Humidity responses of Love wave sensors based on (1120) ZnO/R-sapphire bilayer structures. Sens. Actuators A Phys. 2015, 230, 136–141. [Google Scholar] [CrossRef]

- Lan, X.D.; Zhang, S.Y.; Fan, L.; Wang, Y. Simulation of SAW Humidity Sensors Based on (1120) ZnO/R-Sapphire Structures. Sensors 2016, 16, 1112. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Fang, J.R.; Zou, L.; Zou, Y.C.; Lang, L.; Gao, F.; Hu, N.; Wang, P. A novel sensitive cell-based Love Wave biosensor for marine toxin detection. Biosens. Bioelectron. 2016, 77, 573–579. [Google Scholar] [CrossRef] [PubMed]

- Escalante, G.; Juárez, H.; Fernández, P. Characterization and sensing properties of ZnO film prepared by single source chemical vapor deposition. Adv. Powder Technol. 2017, 28, 23–29. [Google Scholar] [CrossRef]

- Kamalasanan, M.N.; Chandra, S. Sol–gel synthesis of ZnO thin films. Thin Solid Films. 1996, 288, 112–115. [Google Scholar] [CrossRef]

- Carcia, P.F.; Mclean, R.S.; Reilly, M.H.; Nunes, G.N., Jr. Transparent ZnO thin-film transistor fabricated by rf magnetron sputtering. Appl. Phys. Lett. 2003, 82, 1117–1119. [Google Scholar] [CrossRef]

- Zhu, C.; Li, J.; Yang, Y.; Zhao, X.; Zou, W. Highly moisture and weak-acid resistant Ga-doped ZnO films with titanium dioxide co-doping fabricated by magnetron sputtering. Thin Solid Films 2017, 634, 155–159. [Google Scholar] [CrossRef]

- Liu, W.S.; Chen, W.K.; Wu, S.Y.; Hsueh, K.P. Improved crystal quality of transparent conductive Ga-doped ZnO films by magnesium doping through radio-frequency magnetron sputtering preparation. J. Am. Ceram. Soc. 2014, 97, 473–480. [Google Scholar] [CrossRef]

- Marshall, F.G.; Paige, E.G.S. Novel acoustic-surface-wave directional coupler with diverse applications. Electron. Lett. 1971, 7, 460–462. [Google Scholar] [CrossRef]

- Hoummady, M.; Campitelli, A.; Wlodarski, W. Acoustic wave sensors: design, sensing mechanisms and applications. Smart Mater. Struct. 1997, 6, 647–657. [Google Scholar] [CrossRef]

- Mchale, G.; Newton, M.I.; Martin, F.; Melzak, K.A.; Gizeli, E. Resonant conditions for Love wave guiding layer thickness. Appl. Phys. Lett. 2001, 79, 3542–3543. [Google Scholar] [CrossRef]

- Hu, Y.W.; Shi, J.L.; Jia, H.G.; Wu, Y.H. Love Wave Sensor and the Measurement of Mass Sensitivity. J. Sens. Actuators Chin. 2006, 19, 2126–2129. (In Chinese) [Google Scholar]

- Khan, Z.R.; Khan, M.S.; Zulfequar, M.; Khan, M.S. Optical and structural properties of ZnO thin films fabricated by Sol-Gel method. Mater. Sci. Appl. 2011, 2, 340–345. [Google Scholar] [CrossRef]

| IDTi | Electrode width/μm | 4.888 |

| Electrode gap/μm | 4.888 | |

| Number of electrode pairs | 128 | |

| Maximum acoustic aperture/mm | 1.5212 | |

| Multistrip coupler (MSC) | Electrode width/μm | 7.16 |

| Electrode gap/μm | 7.16 | |

| Number of electrode pairs | 103 | |

| IDTo | Electrode width/μm | 4.888 |

| Electrode gap/μm | 4.888 | |

| Number of electrode pairs | 128 | |

| Maximum acoustic aperture /mm | 1.5212 |

| Sputtering Parameter | Value |

|---|---|

| Power | 120 W |

| Time | 200 min |

| Pressure | 1.2 Pa |

| Temperature | 150 °C |

| Ts/°C | η/rad | D/nm |

|---|---|---|

| 25 | 0.00401 | 37.76 |

| 50 | 0.00370 | 40.93 |

| 100 | 0.00334 | 45.35 |

| 150 | 0.00284 | 53.36 |

| 200 | 0.00313 | 48.41 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, C.; Niu, T.; Ma, Y.; Gao, N.; Ru, F. Study on Fabrication of ZnO Waveguide Layer for Love Wave Humidity Sensor Based on Magnetron Sputtering. Sensors 2018, 18, 3384. https://doi.org/10.3390/s18103384

Wen C, Niu T, Ma Y, Gao N, Ru F. Study on Fabrication of ZnO Waveguide Layer for Love Wave Humidity Sensor Based on Magnetron Sputtering. Sensors. 2018; 18(10):3384. https://doi.org/10.3390/s18103384

Chicago/Turabian StyleWen, Changbao, Taotao Niu, Yue Ma, Nan Gao, and Feng Ru. 2018. "Study on Fabrication of ZnO Waveguide Layer for Love Wave Humidity Sensor Based on Magnetron Sputtering" Sensors 18, no. 10: 3384. https://doi.org/10.3390/s18103384

APA StyleWen, C., Niu, T., Ma, Y., Gao, N., & Ru, F. (2018). Study on Fabrication of ZnO Waveguide Layer for Love Wave Humidity Sensor Based on Magnetron Sputtering. Sensors, 18(10), 3384. https://doi.org/10.3390/s18103384