A Tactile Sensor Network System Using a Multiple Sensor Platform with a Dedicated CMOS-LSI for Robot Applications †

Abstract

:1. Introduction

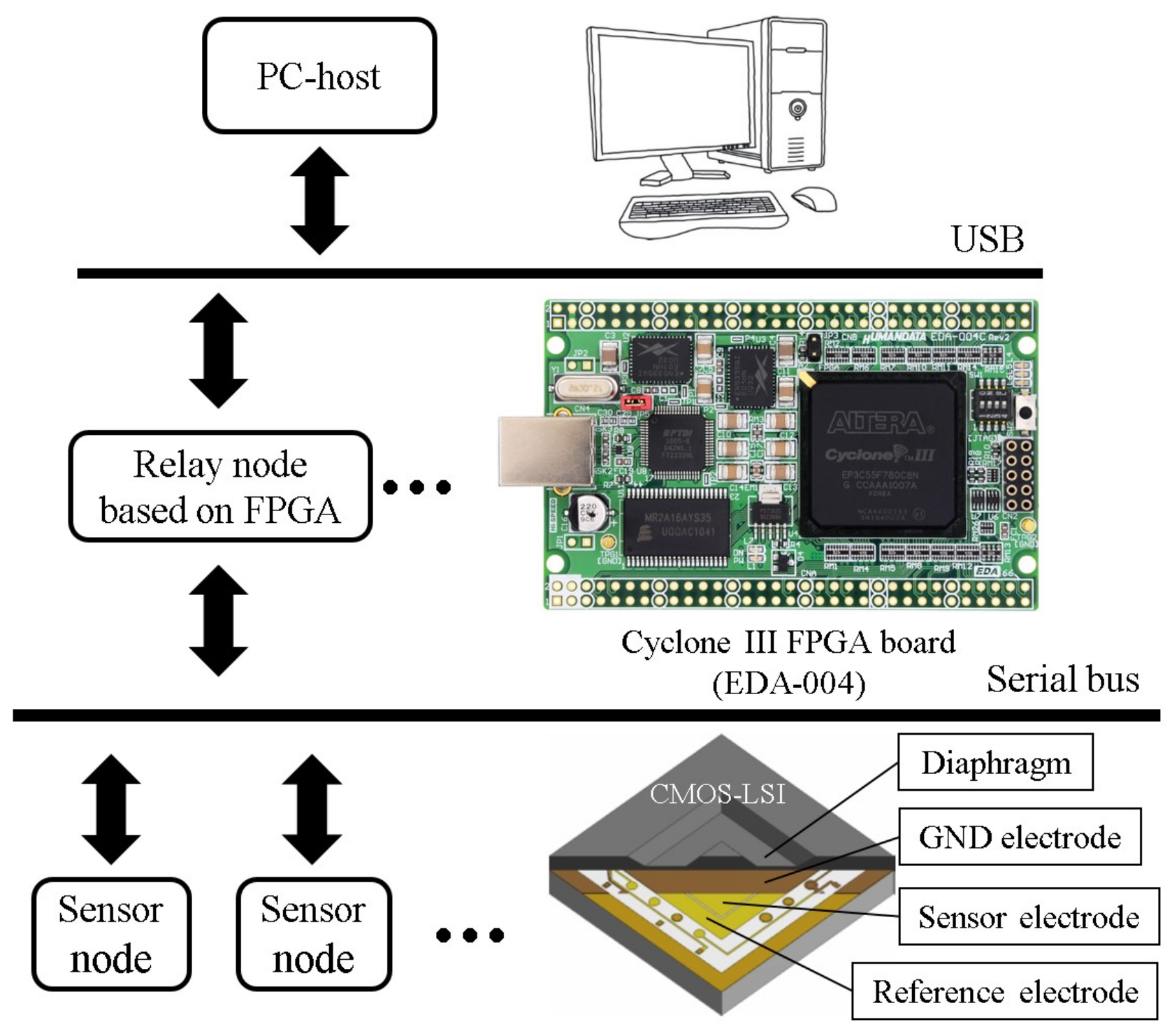

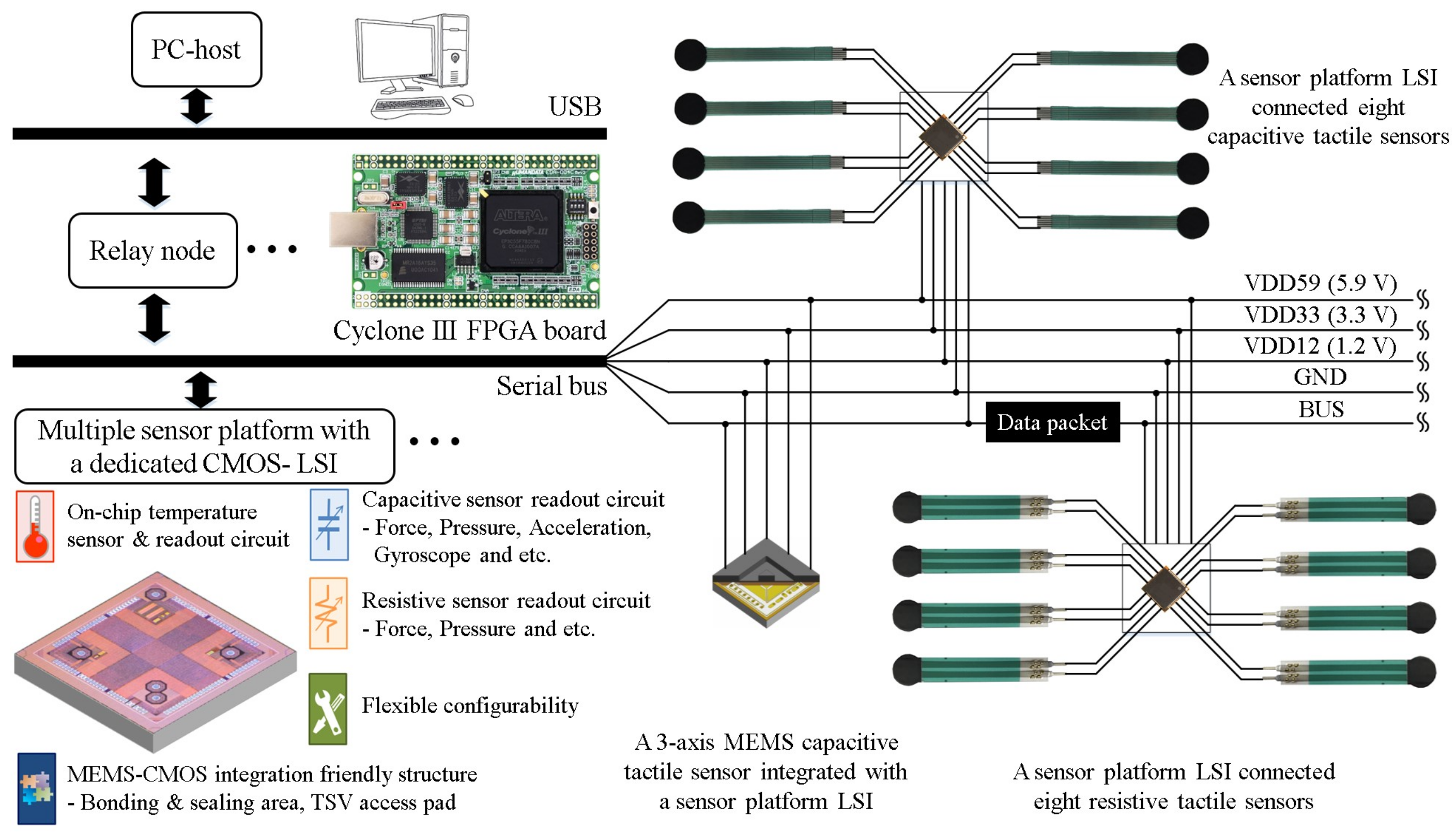

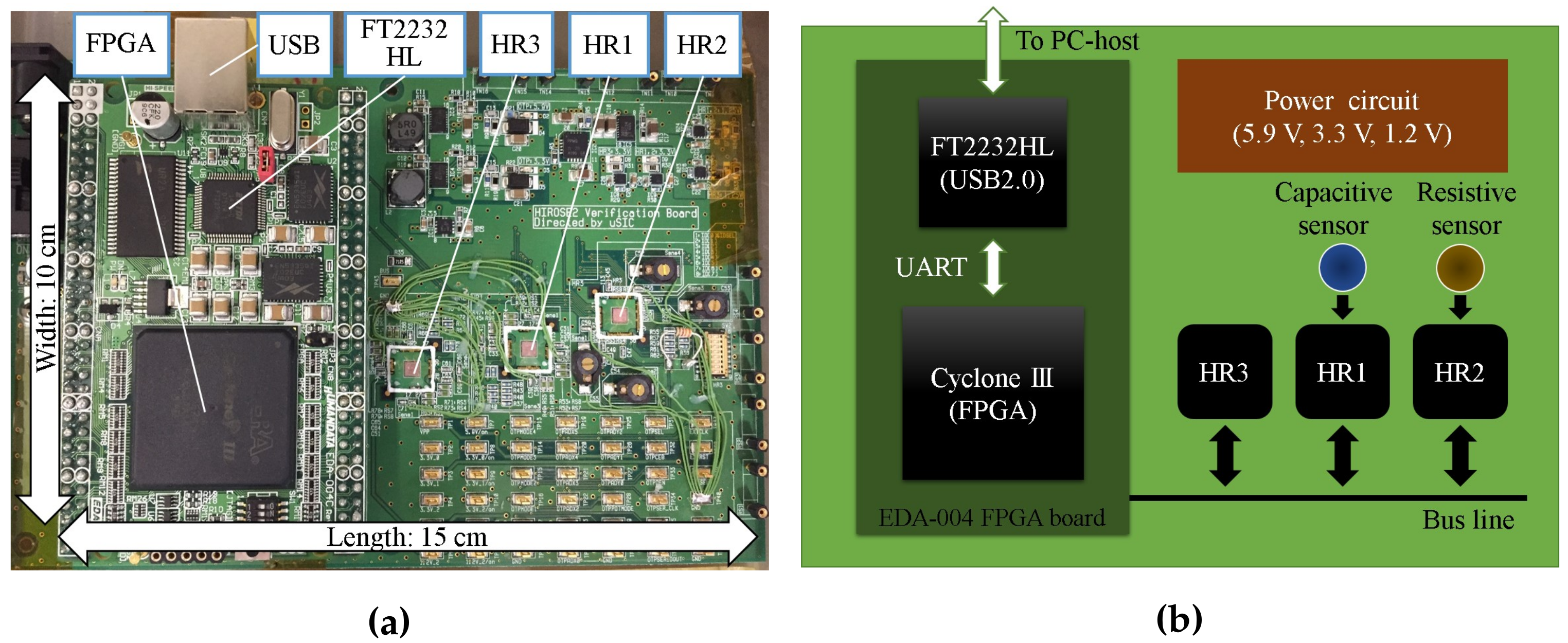

2. Tactile Sensor Network System

2.1. System Overview

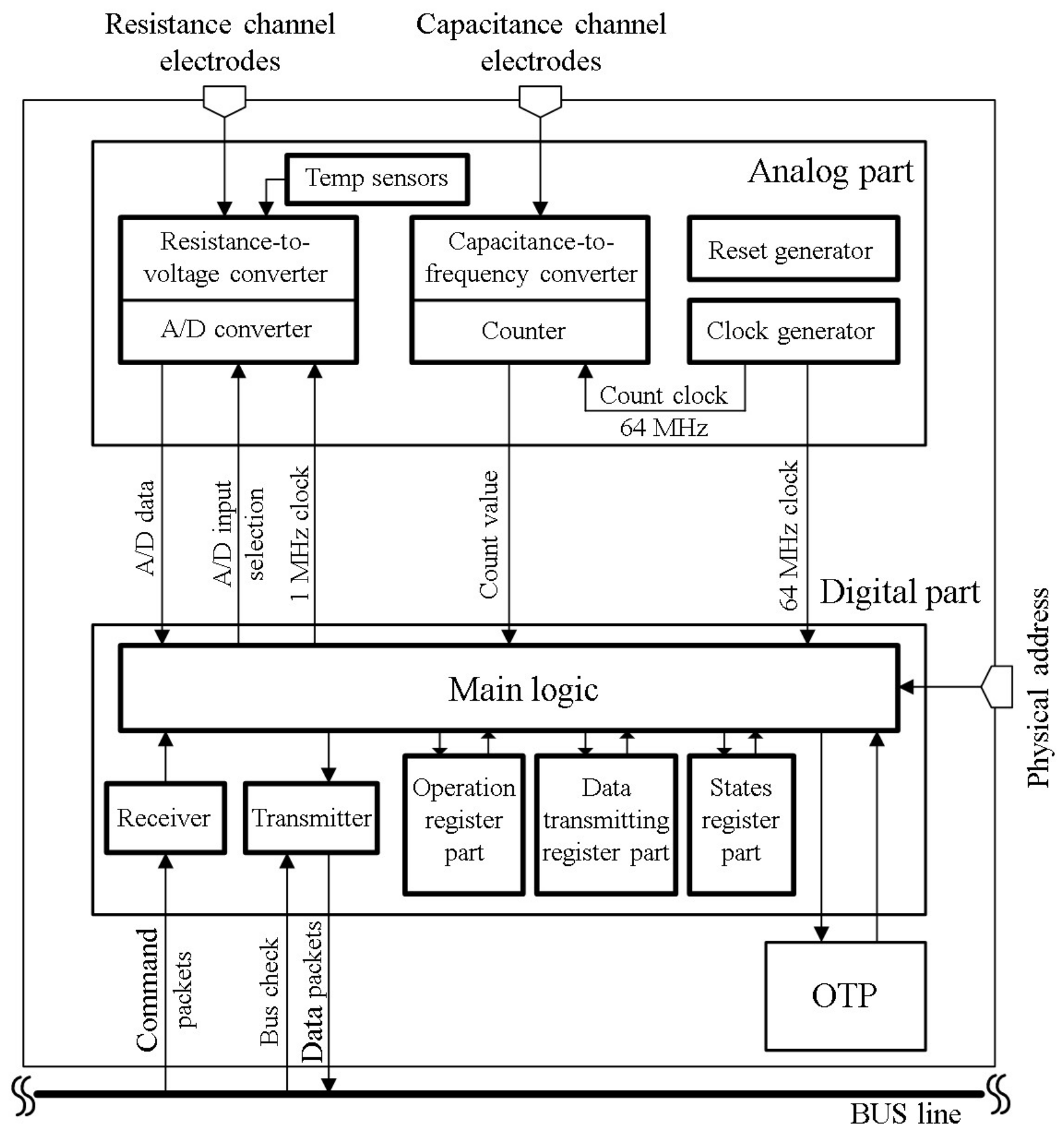

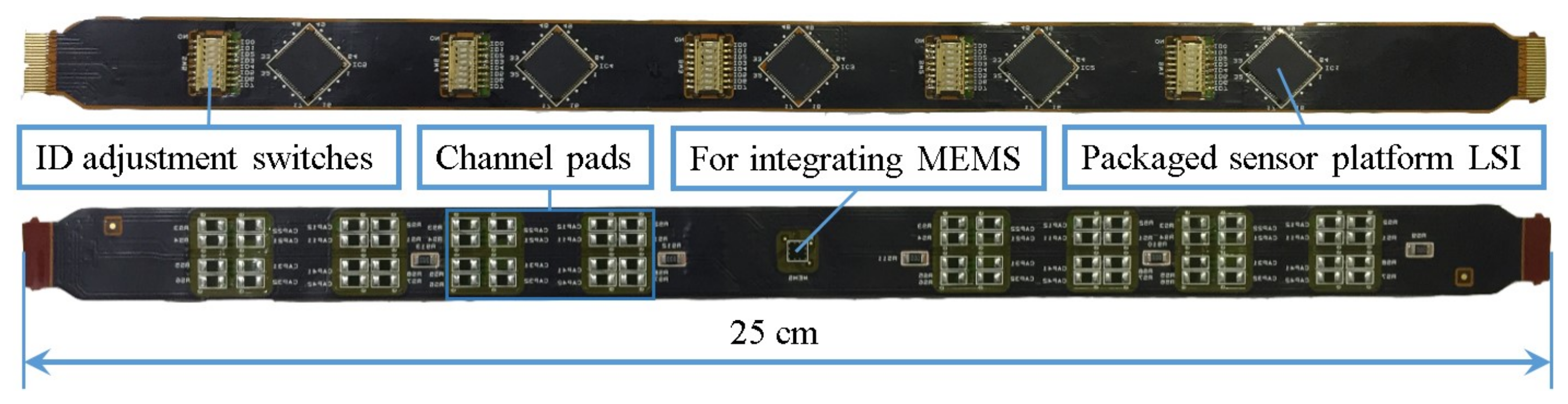

2.2. Multiple Sensor Platform with a Dedicated CMOS-LSI (Sensor Platform LSI)

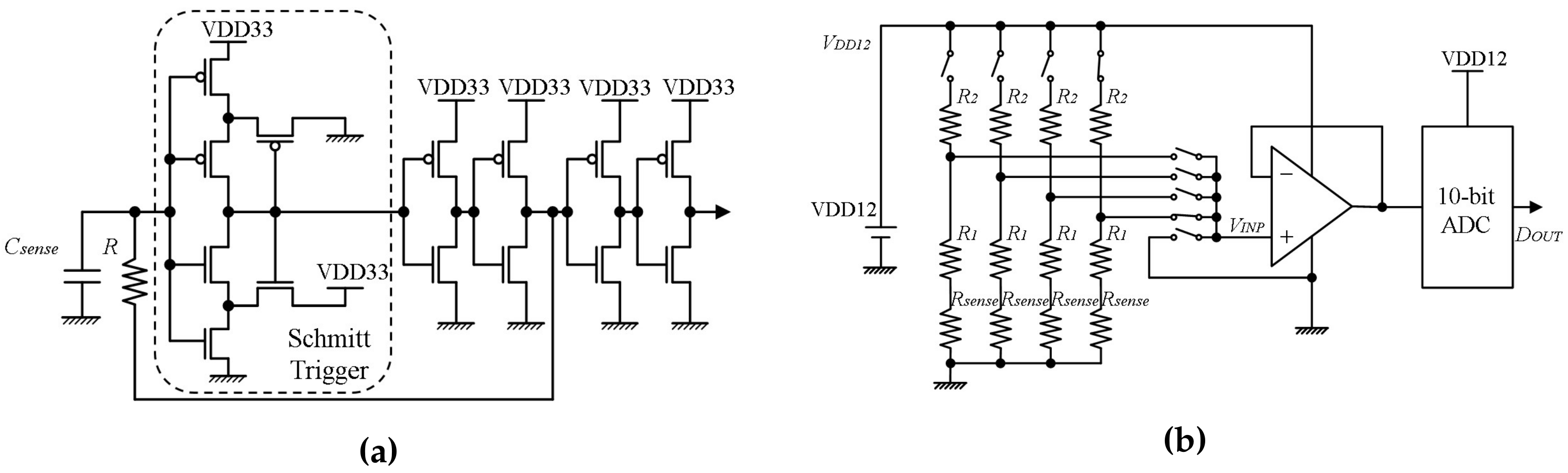

2.2.1. Capacitance-to-Frequency Converter

2.2.2. Resistance-to-Voltage Converter

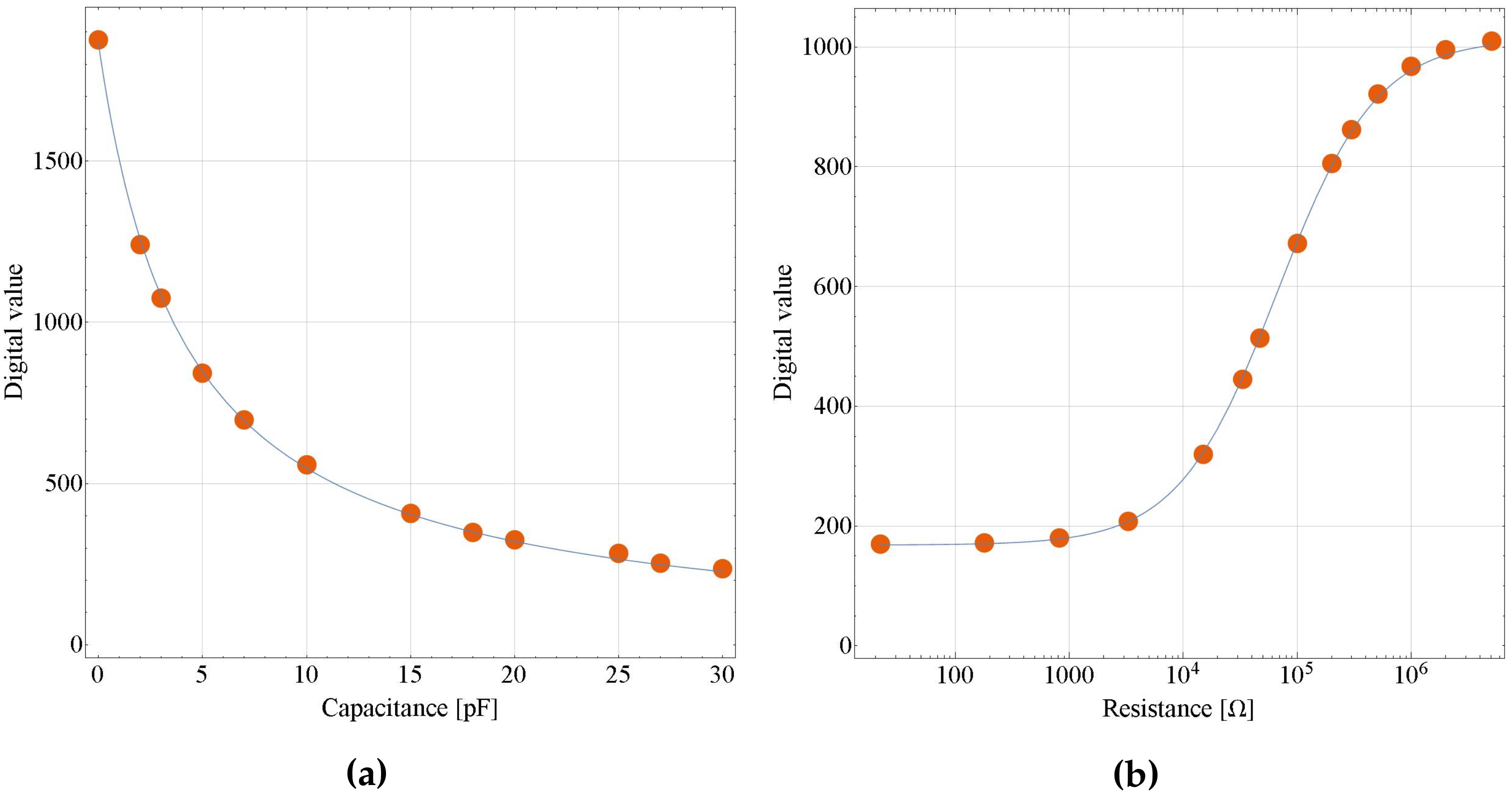

3. Sensor Platform LSI Evaluation Results

3.1. Capacitance-to-Frequency Converter Evaluation with Fixed Capacitors

3.2. Resistance-to-Voltage Converter Evaluation with Fixed Resistors

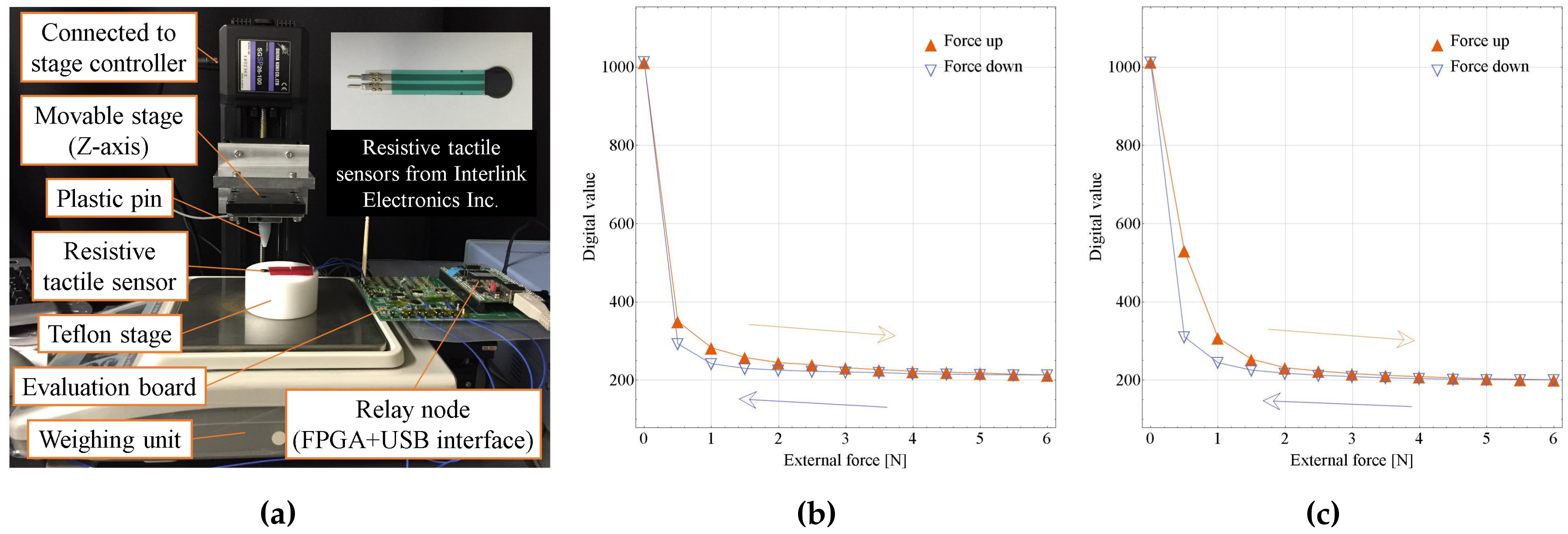

3.3. Sensor Converter Evaluation with Sensors

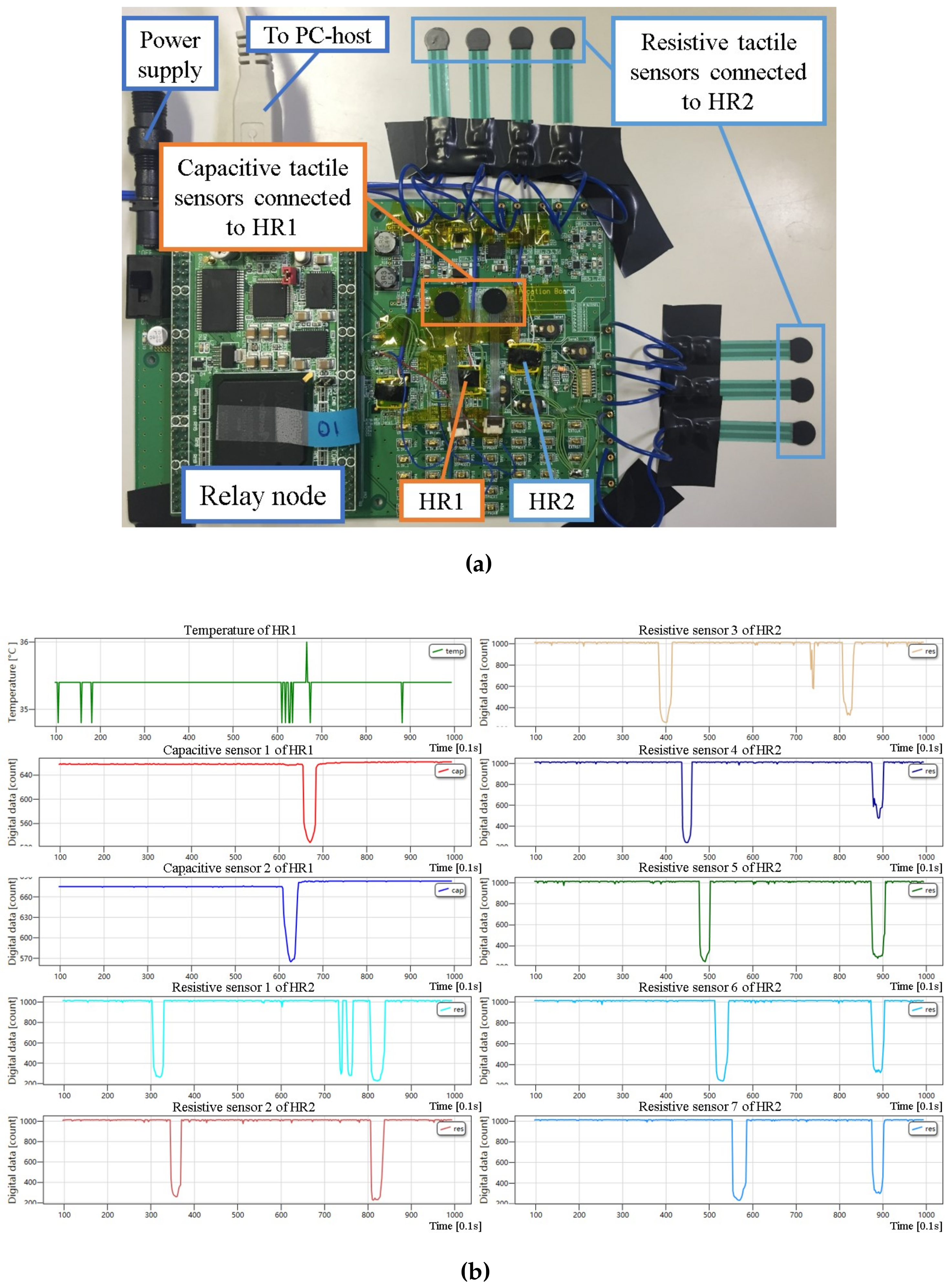

4. Experiments on a Real-Time Data Acquisition System

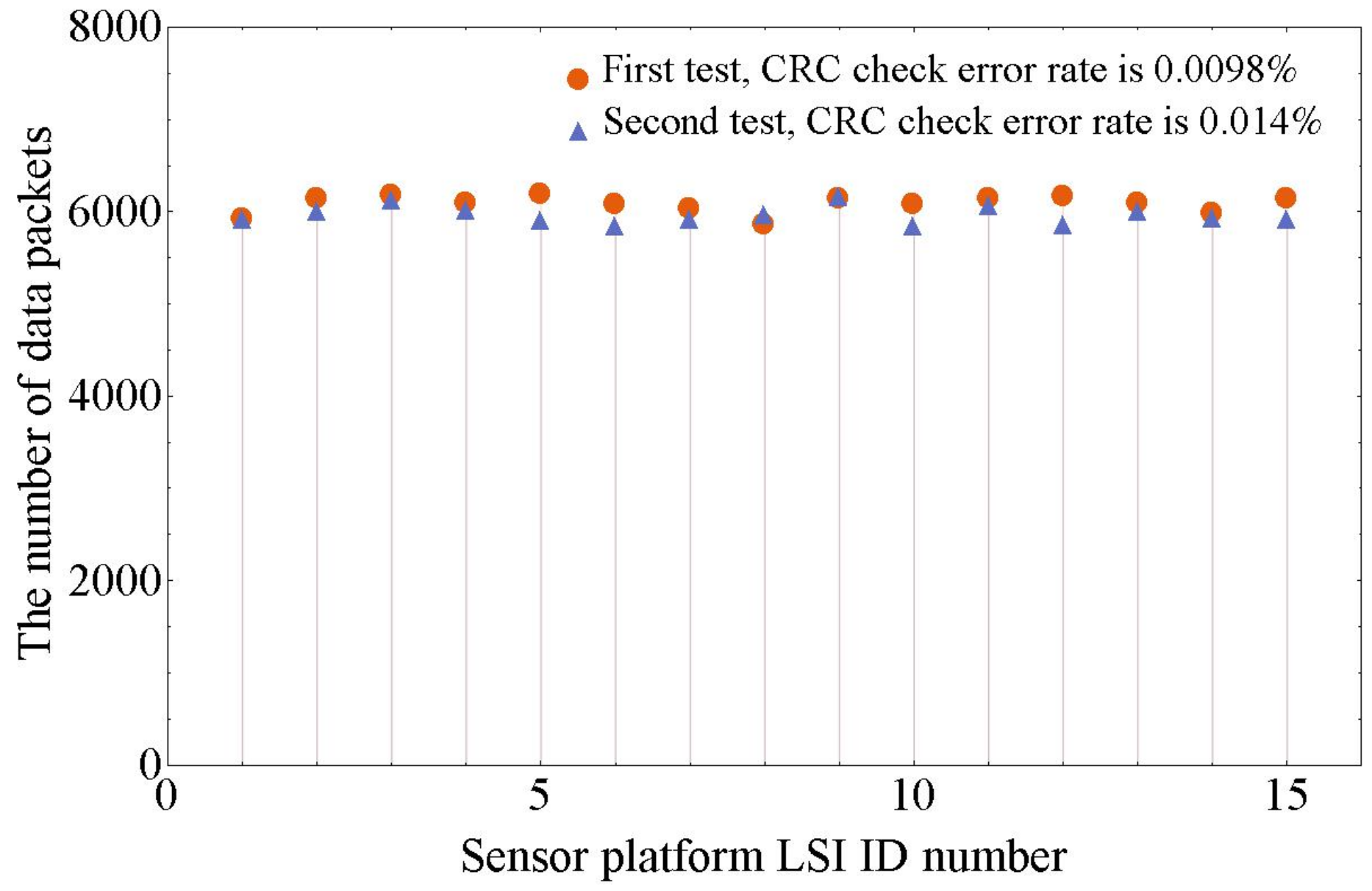

4.1. Evaluation of a System with Multiple Sensors and Rigid Evaluation Board

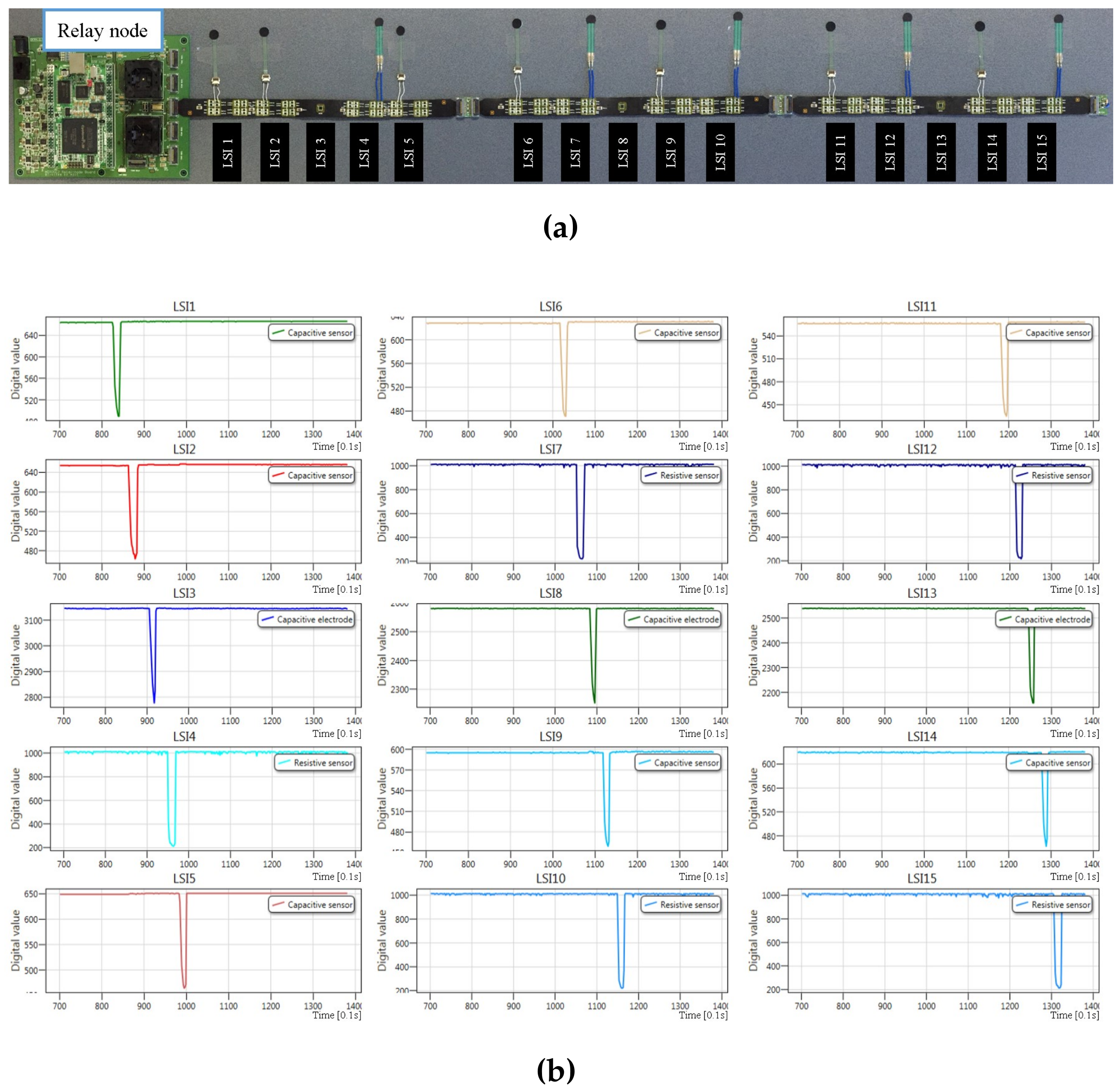

4.2. Evaluation of Multi-Sensor System with Flexible Cable Connection

5. Conclusions

Supplementary Materials

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liang, G.; Wang, Y.; Mei, D.; Xi, K.; Chen, Z. Flexible Capacitive Tactile Sensor Array With Truncated Pyramids as Dielectric Layer for Three-Axis Force Measurement. J. Microelectromech. Syst. 2015, 24, 1510–1519. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Huang, X.H.; Ma, C.W.; Yang, Y.J. A flexible capacitive tactile sensing array with floating electrodes. J. Micromech. Microeng. 2009, 19, 115001. [Google Scholar] [CrossRef]

- Lee, H.K.; Chang, S.I.; Yoon, E. A flexible polymer tactile sensor: Fabrication and modular expandability for large area deployment. J. Microelectromech. Syst. 2006, 15, 1681–1686. [Google Scholar] [CrossRef]

- Canavese, G.; Stassi, S.; Fallauto, C.; Corbellini, S.; Cauda, V.; Camarchia, V.; Pirola, M.; Pirri, C.F. Piezoresistive flexible composite for robotic tactile applications. Sens. Actuators A Phys. 2014, 208, 1–9. [Google Scholar] [CrossRef]

- Hoang, P.T.; Phung, H.; Nguyen, C.T.; Nguyen, T.D.; Choi, H.R. A Highly Flexible, Stretchable and Ultra- Thin Piezoresistive Tactile Sensor Array Using PAM/PEDOT:PSS Hydrogel. In Proceedings of the 2017 14th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Jeju, Korea, 28 June–1 July 2017; pp. 950–955. [Google Scholar]

- Yang, T.; Xie, D.; Li, Z.; Zhu, H. Recent advances in wearable tactile sensors: Materials, sensing mechanisms, and device performance. Mater. Sci. Eng. R Rep. 2017, 115, 1–37. [Google Scholar] [CrossRef]

- Vidal-Verdú, F.; Barquero, M.J.; Castellanos-Ramos, J.; Navas-González, R.; Sánchez, J.A.; Serón, J.; García-Cerezo, A. A large area tactile sensor patch based on commercial force sensors. Sensors 2011, 11, 5489–5507. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.C.; Cheng, C.L.; Wu, P.H.; Li, S.J. Elastic Capacitive Tactile Array Pressure Sensor System. Sens. Mater. 2017, 29, 885–895. [Google Scholar]

- Silvera-Tawil, D.; Rye, D.; Velonaki, M. Artificial skin and tactile sensing for socially interactive robots: A review. Robot. Auton. Syst. 2015, 63, 230–243. [Google Scholar] [CrossRef]

- Maiolino, P.; Maggiali, M.; Cannata, G.; Metta, G.; Natale, L. A Flexible and Robust Large Scale Capacitive Tactile System for Robots. IEEE Sens. J. 2013, 13, 3910–3917. [Google Scholar] [CrossRef]

- Odhner, L.U.; Jentoft, L.P.; Claffee, M.R.; Corson, N.; Tenzer, Y.; Ma, R.R.; Buehler, M.; Kohout, R.; Howe, R.D.; Dollar, A.M. A compliant, underactuated hand for robust manipulation. Int. J. Robot. Res. 2014, 33, 736–752. [Google Scholar] [CrossRef]

- Tenzer, Y.; Jentoft, L.P.; Howe, R.D. The Feel of MEMS Barometers: Inexpensive and Easily Customized Tactile Array Sensors. IEEE Robot. Autom. Mag. 2014, 21, 89–95. [Google Scholar] [CrossRef]

- Muroyama, M.; Makihata, M.; Nakano, Y.; Matsuzaki, S.; Yamada, H.; Yamaguchi, U.; Nakayama, T.; Nonomura, Y.; Fujiyoshi, M.; Tanaka, S.; et al. Development of an LSI for Tactile Sensor Systems on the Whole-Body of Robots. IEEJ Trans. Sens. Micromach. 2011, 131, 302–309. [Google Scholar] [CrossRef]

- Asano, S.; Muroyama, M.; Bartley, T.; Kojima, T.; Nakayama, T.; Yamaguchi, U.; Yamada, H.; Nonomura, Y.; Hata, Y.; Funabashi, H.; et al. Flipped CMOS-Diaphragm Capacitive Tactile Sensor Surface Mountable on Flexible and Stretchable Bus Line. In Proceedings of the 2015 Transducers-2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 97–100. [Google Scholar]

- Muroyama, M.; Makihata, M.; Tanaka, S.; Kojima, T.; Nakayama, T.; Yamaguchi, U.; Yamada, H.; Nonomura, Y.; Funabashi, H.; Hata, Y.; et al. Tactile Sensor Network System with CMOS-MEMS Integration for Social Robot Applications. In Proceedings of the Smart Systems Integration International Conference and Exhibition, Vienna, Austria, 26–27 March 2014; pp. 181–188. [Google Scholar]

- Matsumoto, Y.; Esasi, M. Integrated capacitive absolute pressure sensor. Electron. Commun. Jpn Part II Electron. Engl. Transl. Denshi Tsushin Gakkai Ronbunshi 1993, 76, 93–106. [Google Scholar]

- Dahiya, R.S.; Metta, G.; Valle, M.; Sandini, G. Tactile sensing-from humans to humanoids. IEEE Trans. Robot. 2010, 26, 1–20. [Google Scholar] [CrossRef]

- Bartley, T.; Tanaka, S.; Nonomura, Y.; Nakayama, T.; Muroyama, M. Delay Window Blind Oversampling Clock and Data Recovery Algorithm with Wide Tracking Range. In Proceedings of the IEEE International Symposium on Circuits and Systems, Lisbon, Portugal, 24–27 May 2015; pp. 1598–1601. [Google Scholar]

- Bartley, T.; Tanaka, S.; Nonomura, Y.; Nakayama, T.; Hata, Y.; Muroyama, M. Sensor Network Serial Communication System with High Tolerance to Timing and Topology Variations. In Proceedings of the 2015 IEEE SENSORS, Busan, Korea, 1–4 November 2015; pp. 1–4. [Google Scholar]

- Muroyama, M.; Nakayama, T.; Hata, Y.; Nonomura, Y.; Bartley, T.; Tanaka, S. A CMOS-LSI for a Sensor Network Platform of Social Robot Applications. In Proceedings of the Smart Systems Integration International Conference and Exhibition, Munich, Germany, 9–10 March 2016; pp. 320–327. [Google Scholar]

- Hata, Y.; Nonomura, Y.; Funabashi, H.; Akashi, T.; Fujiyoshi, M.; Omura, Y.; Nakayama, T.; Yamaguchi, U.; Yamada, H.; Tanaka, S.; et al. An SOI Tactile Sensor with a Quad Seesaw Electrode for 3-Axis Complete Differential Detection. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 709–712. [Google Scholar]

- Makihata, M.; Muroyama, M.; Nakano, Y.; Tanaka, S.; Nakayama, T.; Yamaguchi, U.; Yamada, H.; Nonomura, Y.; Funabashi, H.; Hata, Y.; et al. A 1.7 mm3 MEMS-on-CMOS tactile sensor using human-inspired autonomous common bus communication. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems, Barcelona, Spain, 16–20 June 2013; pp. 2729–2732. [Google Scholar]

- Baker, R.J. CMOS Circuit Design, Layout, and Simulation, 3rd ed.; Wiley-IEEE Press: Hoboken, NJ, USA, 2010; pp. 523–527. [Google Scholar]

- Hollinger, A.; Wanderley, M.M. Evaluation of commercial force-sensing resistors. In Proceedings of the International Conference on New Interfaces for Musical Expression, Paris, France, 4–8 June 2006. [Google Scholar]

| System Structure | Sensor Output Digitization Place | Force Sensing Principle | The Number of Capacitors or Resistors | Covering Area | The Number of Analog-to-Digital Converters (ADC) | Sampling Frequency () | Ref. |

|---|---|---|---|---|---|---|---|

| Tactile sensor array with scanning readout circuitry | Off the sensor array | Capacitive | 1 (AD7153) | 3 | [1] | ||

| 1 (ADuC841) | Not mentioned | [2] | |||||

| 1 | 20 | [3] | |||||

| Resistive | 1 (PIC18F2523) | 16 | [4] | ||||

| 1 (dsPIC30F5015) | Not mentioned | [5] | |||||

| Serial bus-based tactile sensor network | At the place of sensation | Capacitive | 16 (AD7147) | 25 | [10] | ||

| 114 | Not mentioned | 114 (MPL115A2) | 50 | [11] | |||

| Capacitive or resistive plus temperature sensing | (Potentially, more than 15 LSIs can be connected.) | 75 (bus line length) | 146 | This work |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, C.; Tanaka, S.; Nakayama, T.; Hata, Y.; Bartley, T.; Nonomura, Y.; Muroyama, M. A Tactile Sensor Network System Using a Multiple Sensor Platform with a Dedicated CMOS-LSI for Robot Applications. Sensors 2017, 17, 1974. https://doi.org/10.3390/s17091974

Shao C, Tanaka S, Nakayama T, Hata Y, Bartley T, Nonomura Y, Muroyama M. A Tactile Sensor Network System Using a Multiple Sensor Platform with a Dedicated CMOS-LSI for Robot Applications. Sensors. 2017; 17(9):1974. https://doi.org/10.3390/s17091974

Chicago/Turabian StyleShao, Chenzhong, Shuji Tanaka, Takahiro Nakayama, Yoshiyuki Hata, Travis Bartley, Yutaka Nonomura, and Masanori Muroyama. 2017. "A Tactile Sensor Network System Using a Multiple Sensor Platform with a Dedicated CMOS-LSI for Robot Applications" Sensors 17, no. 9: 1974. https://doi.org/10.3390/s17091974

APA StyleShao, C., Tanaka, S., Nakayama, T., Hata, Y., Bartley, T., Nonomura, Y., & Muroyama, M. (2017). A Tactile Sensor Network System Using a Multiple Sensor Platform with a Dedicated CMOS-LSI for Robot Applications. Sensors, 17(9), 1974. https://doi.org/10.3390/s17091974