1. Introduction

Thrust bearings are an important component in many mechanical systems. They permit rotational motion under axial force while trying to minimize friction. There are several different types of thrust bearings such as cylindrical thrust bearings, magnetic thrust bearings and fluid filled thrust bearings. The tilted pad thrust bearing, developed by Michell and Kingsbury [

1] more than 100 years ago, in its simplest form is comprised of pads at a fixed angle. More sophisticated designs allow the pads to automatically adjust their angle to suit the operating conditions. Regardless of the bearing type, fluid filled bearings all rely on the axial load being supported by a thin layer of oil.

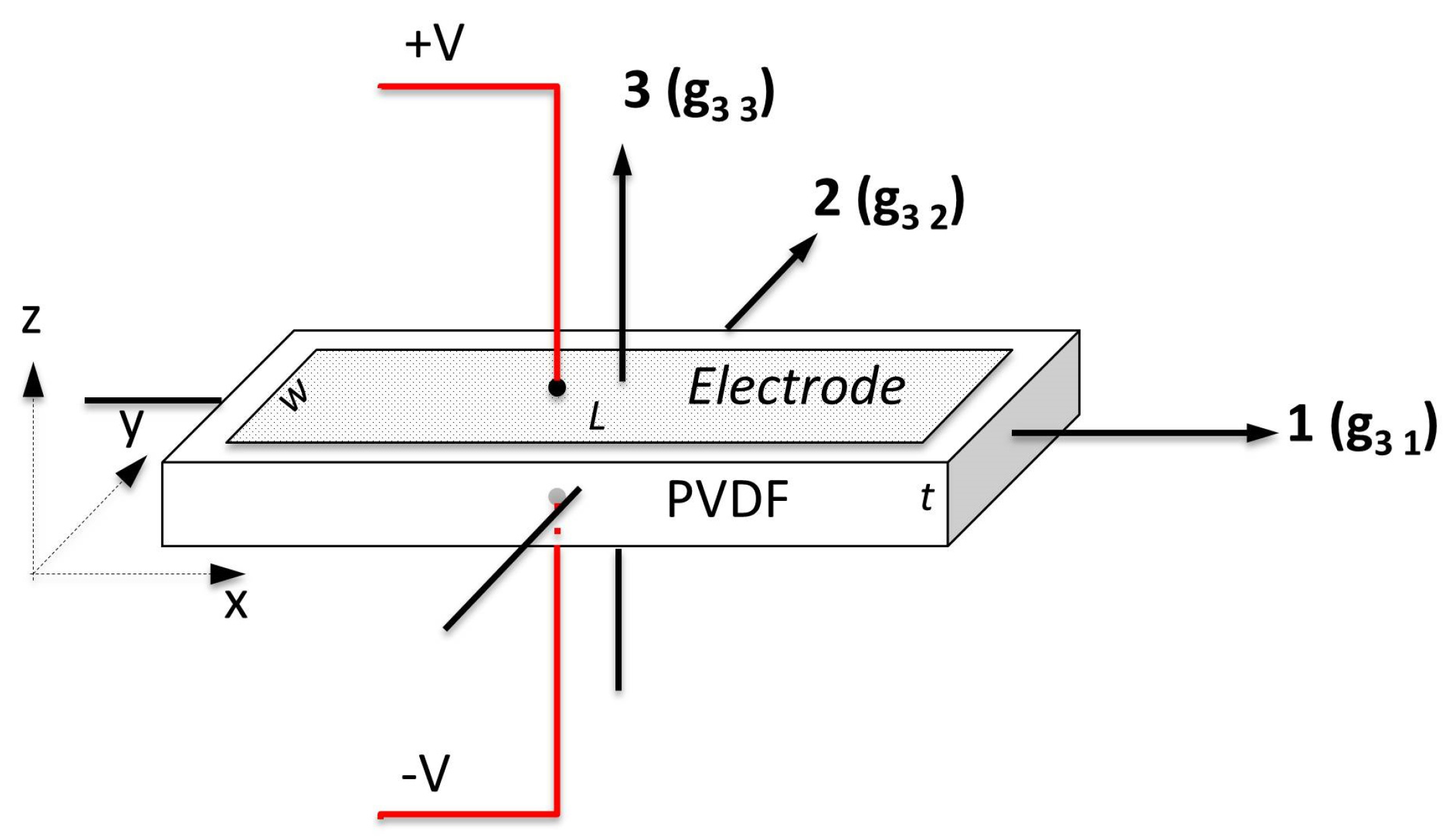

Clearly, deterioration of the bearing can lead to catastrophic results and the ability to accurately monitor the health of the bearing is desirable. Although this can be achieved to some degree using conventional ceramic or Microelectromechanical systems (MEMS) transducers, their physical size and properties make it difficult to install them in confined spaces. As a result, they tend to be attached to the outside of the object of interest and the condition inside inferred. This paper attempts to address this problem by using a polymer piezoelectric film called Polyvinylidene Fluoride (PVDF), which can be installed inside the bearing to directly measure the forces developed in the oil film itself.

Piezoelectricity was discovered in PVDF by Kawai in 1969 [

2] and since then has been used for a number of applications from underwater acoustics [

3], medical imaging [

4], modal analysis [

5] and space applications [

6].

The use of PVDF sensors for sensing capabilities is nothing new [

7,

8,

9,

10]; however, their applications have typically been limited to measuring the pressure of gases, as the strain of the PVDF can be linked with the pressure applied to the sensor. Little literature was found in the measurement of the contact force between the stationary and moving parts of a thrust bearing. Kim et al. [

11] have reported on using PVDF to measure support loads in elastomeric bearings, but these were stationary rubber mounts. A similar application has been discussed by Talbot [

12], who imbedded sensors in a stationary rubber material in order to monitor dynamic loads. Grinspan [

13] was able to achieve the measurement of the contact force of a water droplet with a solid surface and compared this with the droplet of oil. It has also been reported that PVDF film has been embedded inside the insole of a shoe to measure the contact force [

14]; however, these applications only observe a single force that is normal to the plane of the PVDF film.

PVDF has many properties that make it a potential candidate to use in order to directly measure the loads inside an operational thrust bearing [

15]. Apart from condition monitoring, it may also be possible to measure other properties of the bearing such as the hydrodynamic stiffness of the oil film. This, in turn, may lead to a better understanding of the vibrations transmitted through the bearing and result in new methods in reducing the induced structural vibration through the bearing. The authors of this paper have previously published preliminary results of using PVDF sensors in rotating bearings [

16]; however, a detailed analysis and mathematical model of the contact force were missing. This paper addresses this by introducing a mathematical model that describes the interaction between the thrust bearing pads and oil, and this model is also used to characterise some of the features seen in the signature obtained.

3. Results and Discussion

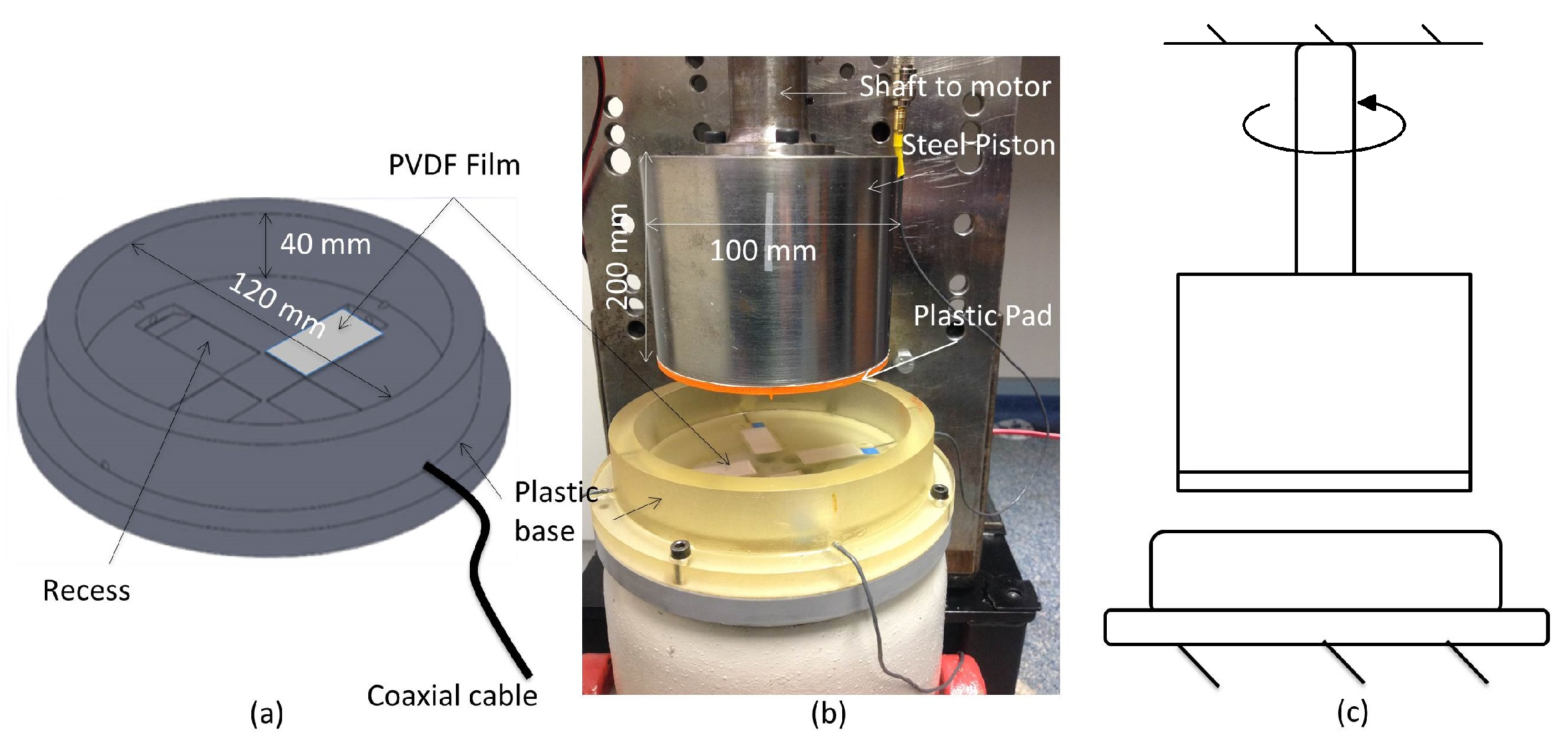

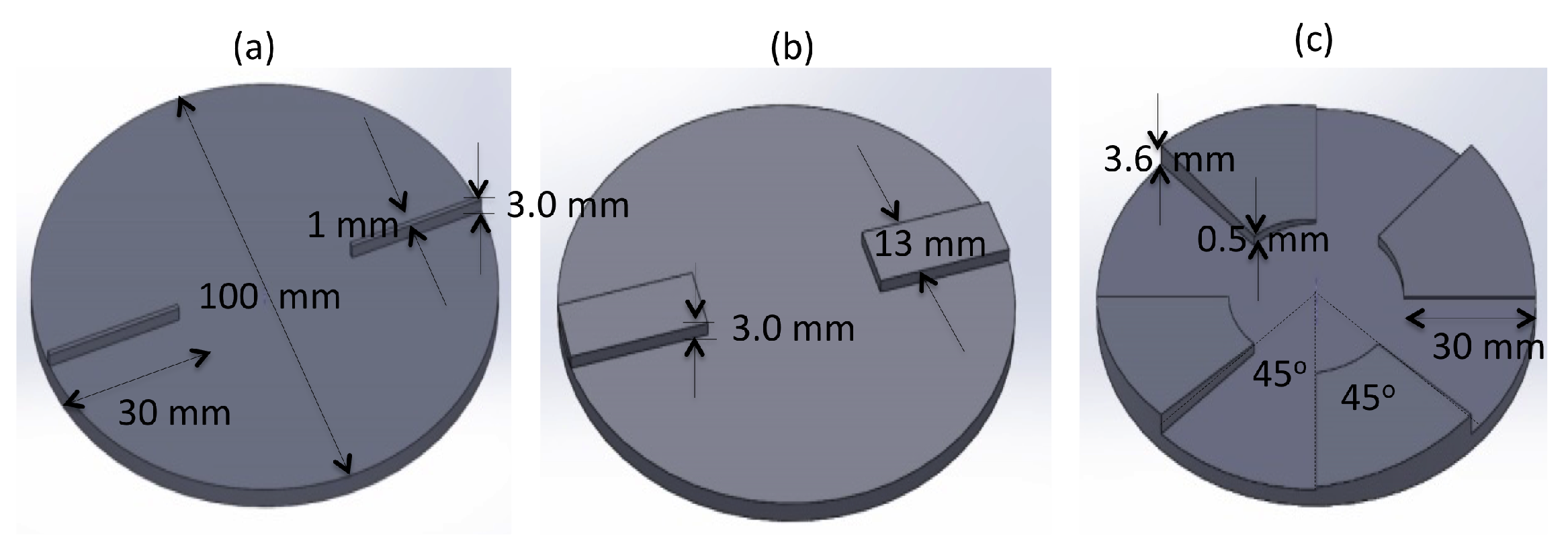

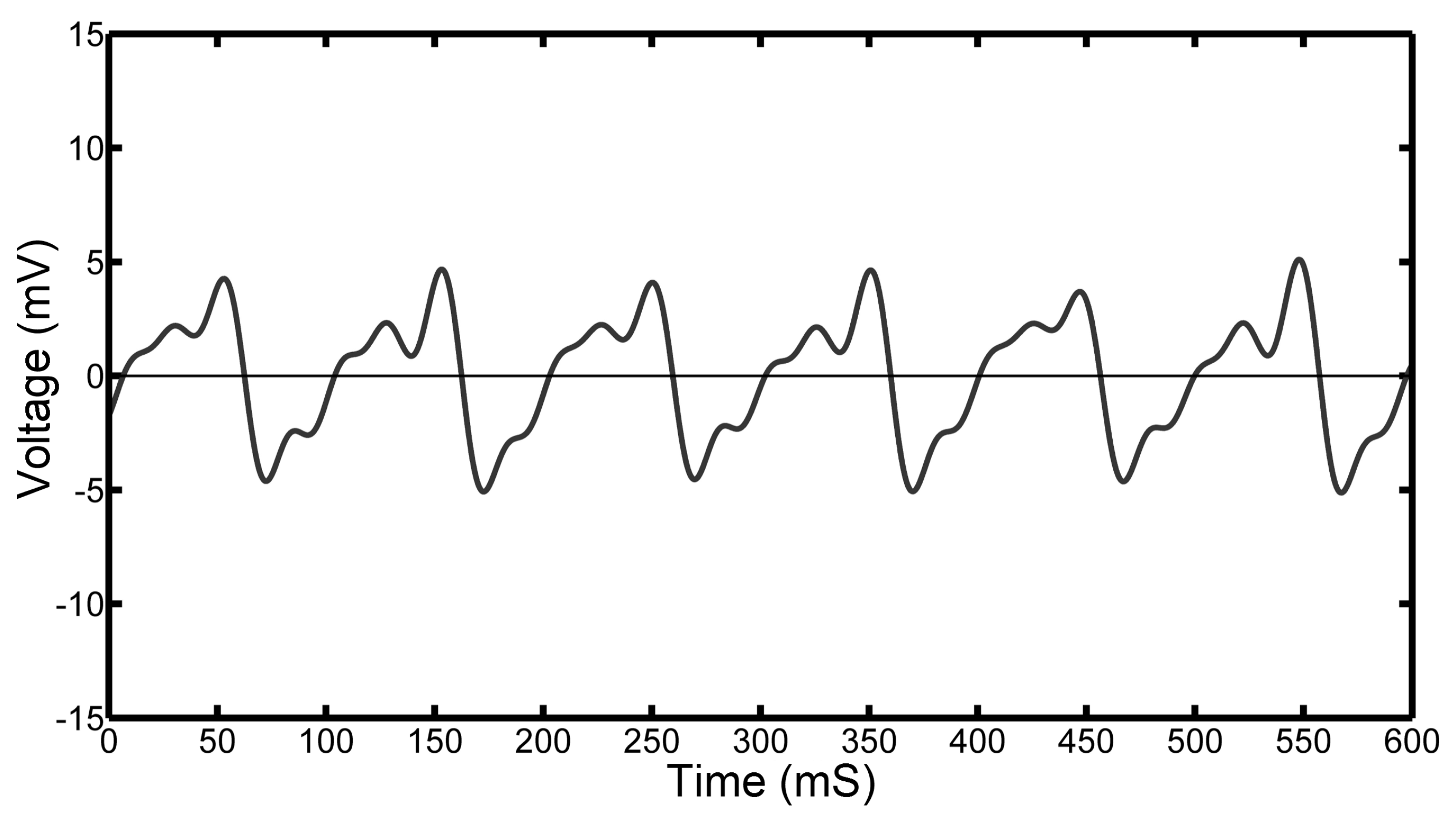

Figure 5 shows a typical time dependent voltage from one PVDF film for several revolutions of the 1 mm pad. Two distinct sets of peaks are observed corresponding to the two individual pads as they pass over one PVDF sensor. The difference in shape and amplitude of the two peaks is due to small misalignments of the pads introduced when setting up the equipment. As can be seen, both positive and negative voltages can be observed corresponding to regions of positive and negative pressures. In addition, the resulting shape is quite complex with a number of inflection points observed between the two main peaks. In order to gain better understanding into the mechanism responsible for this shape, the positions of the pads relative to the underlying PVDF film were accurately monitored using a laser tachometer while measuring the voltage output from the film.

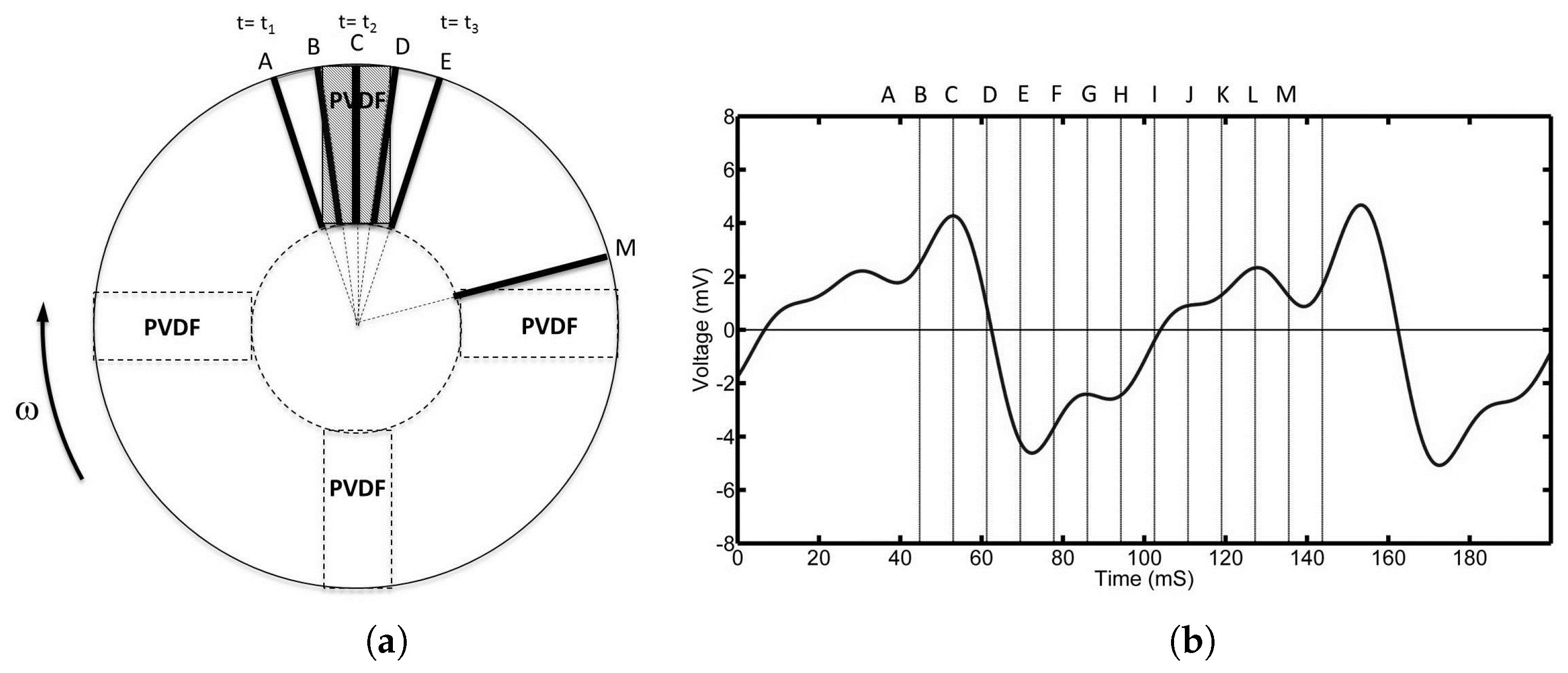

Figure 6b shows the output signal for the 1 mm pad over a time period of 200 ms. This corresponds to half a revolution of the pads at a speed of 300 rpm. The height of the pads above the PVDF film was kept constant at 0.5 mm.

The position of the front edge of the pad (black rectangles) relative to the PVDF film is shown in

Figure 6a. Positions A to E correspond to the region where the pad has direct interaction with the underlying film. As can be seen, once the pad starts to pass over the film (A), the voltage starts to increase. This voltage has a maximum at position B when the top edge of the pad crosses the film. Beyond this point, the voltage gradually decreases to zero at position C, which lies approximately half way across the film. The voltage then continues to decrease to a minimum value between D and E and then starts to increase again until it passes through zero at point H, which is approximately midway between the films. Between E and M, a number of inflection points can be observed until the process is repeated for the second pad.

Similar data was also recorded for the 13 mm step pad and is shown in

Figure 7.

Figure 7b shows the output voltage for half a revolution.

Figure 7a shows the position of the 13 mm pad relative to the top PVDF film. Voltages at times A, B, C and D correspond to the positions A, B, C and D in

Figure 7a. For comparison, the voltage response for the 1 mm step pad has also been shown in black. It is clear that the maximum and minimum voltage occur at the same positions for both pads regardless of length. The voltage produced when the pad is between the PVDF films also has a similar shape. It should be noted that, for the 13 mm pad, the negative voltages are almost double that of the positive, indicating a larger negative pressure behind the pad.

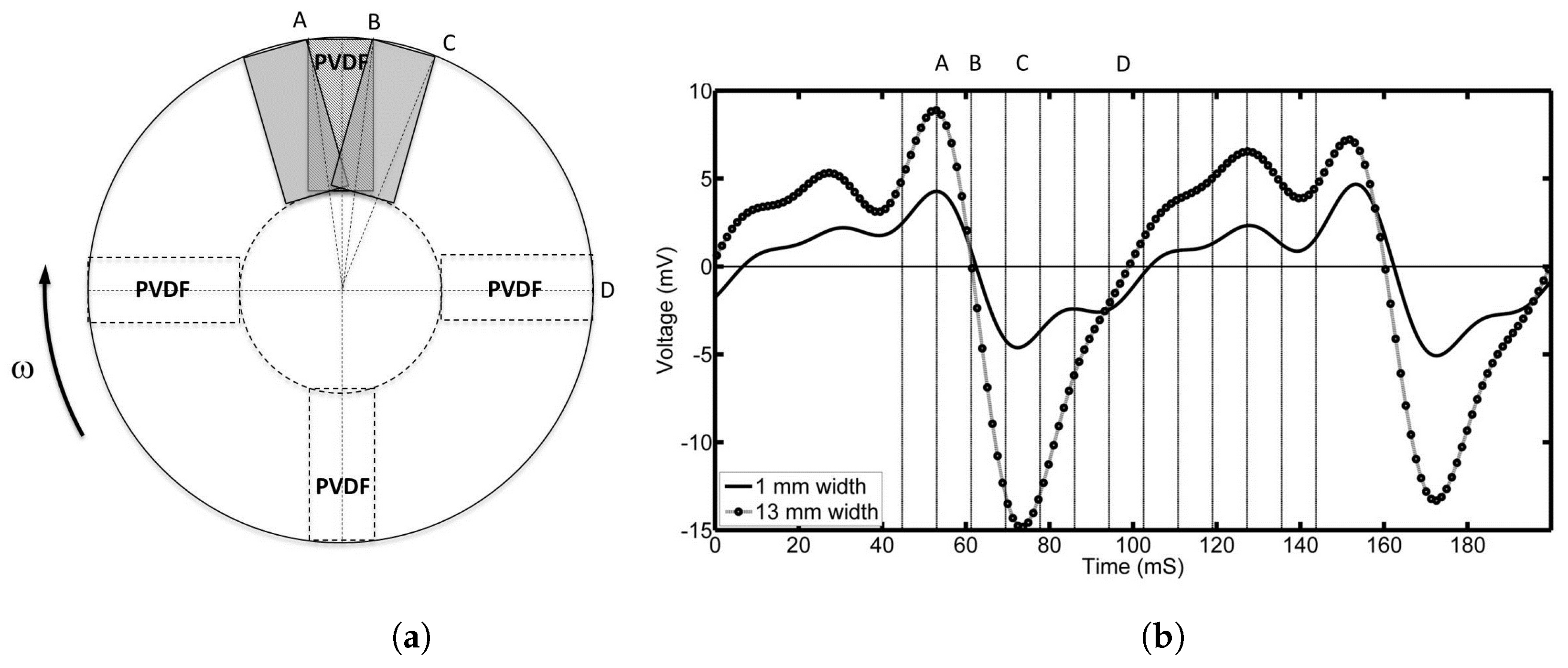

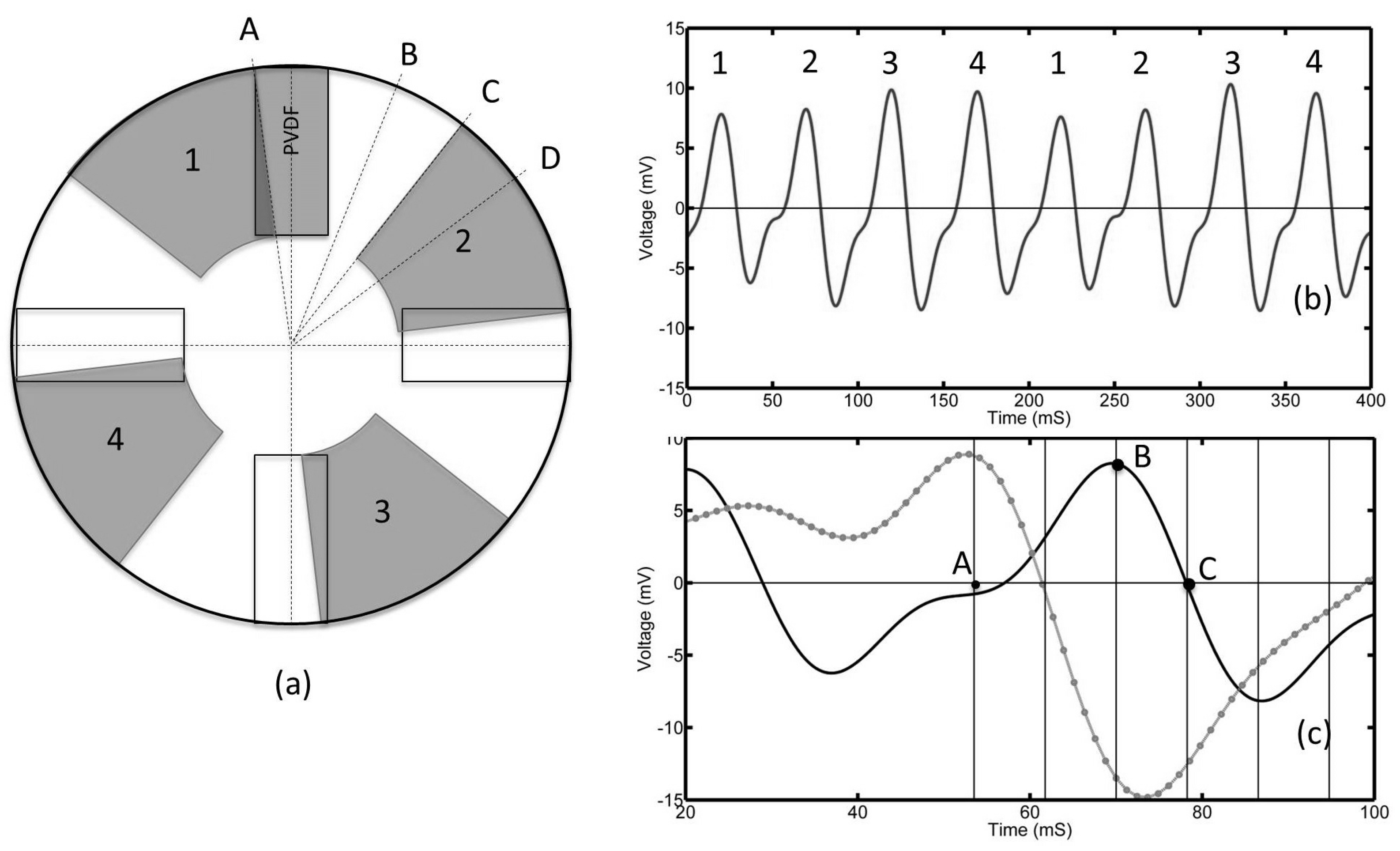

Figure 8 shows the results for the tilted pad. The voltage output from the top PVDF film is shown in

Figure 8b. In addition, 1, 2, 3 and 4 correspond to the four separate pads.

While the voltage output shape appears similar to those obtained for the step pads, closer inspection shows that the maximum and minimum voltages occur at different pad positions than those shown in

Figure 6 and

Figure 7. Zero voltage occurs when the position of the top of the pad has just crossed over the PVDF film. This corresponded to a maximum voltage for both of the step pads. A maximum voltage is generated when the pad is directly over the film in position B. In position C, the pad is just starting to leave the film and zero voltage is observed. A minimum voltage is seen in position D when the pad has left the film. For comparison, the corresponding output of the 13 mm step pad has also been shown in

Figure 8c in grey.

As would be explained and as can be seen from Equation (

4), the pressure under the tilted pad should be directly proportional to the speed of the pad. To verify this, the PVDF output voltage was monitored as a function of speed from 0 to 300 rpm in increments of 20 rpm. It was found that the overall shape of the waveform remained constant; however, the amplitude of the signal increased with increasing speed.

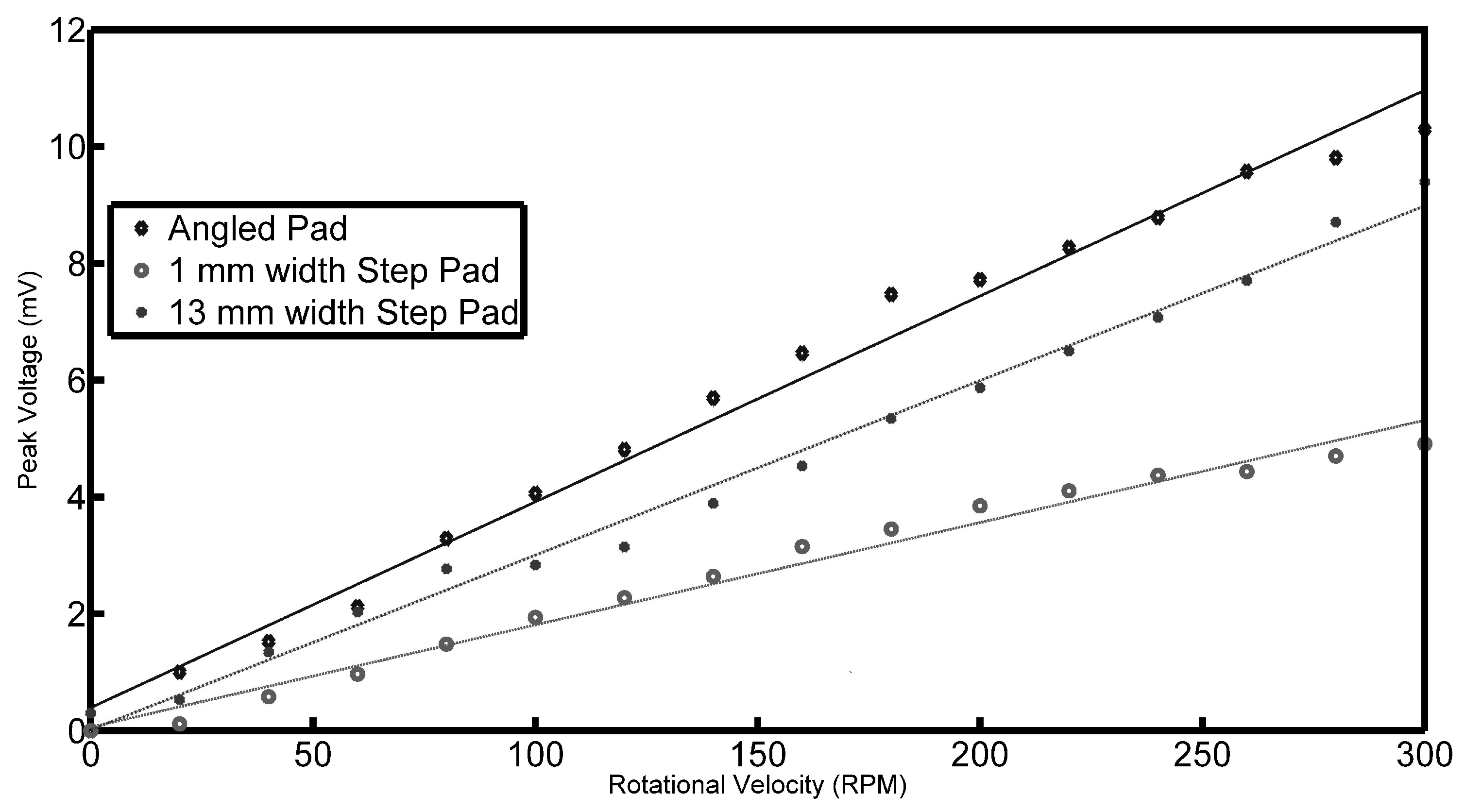

Figure 9 shows the peak voltages observed by the PVDF film against the speed for all three pads. The black line represents the angled pad and clearly shows that the pressures generated by the sliding pads is a linear function of speed as predicted by Equation (

4). Fitting a linear regression line results in a coefficient of determination

of 0.9879 to 0.9977, meaning that a strong linear relationship is present. The two circle markers shows similar results for the two step pads. It is interesting to note that these also show a linear variation with speed except with smaller gradients compared to the tilted pad.

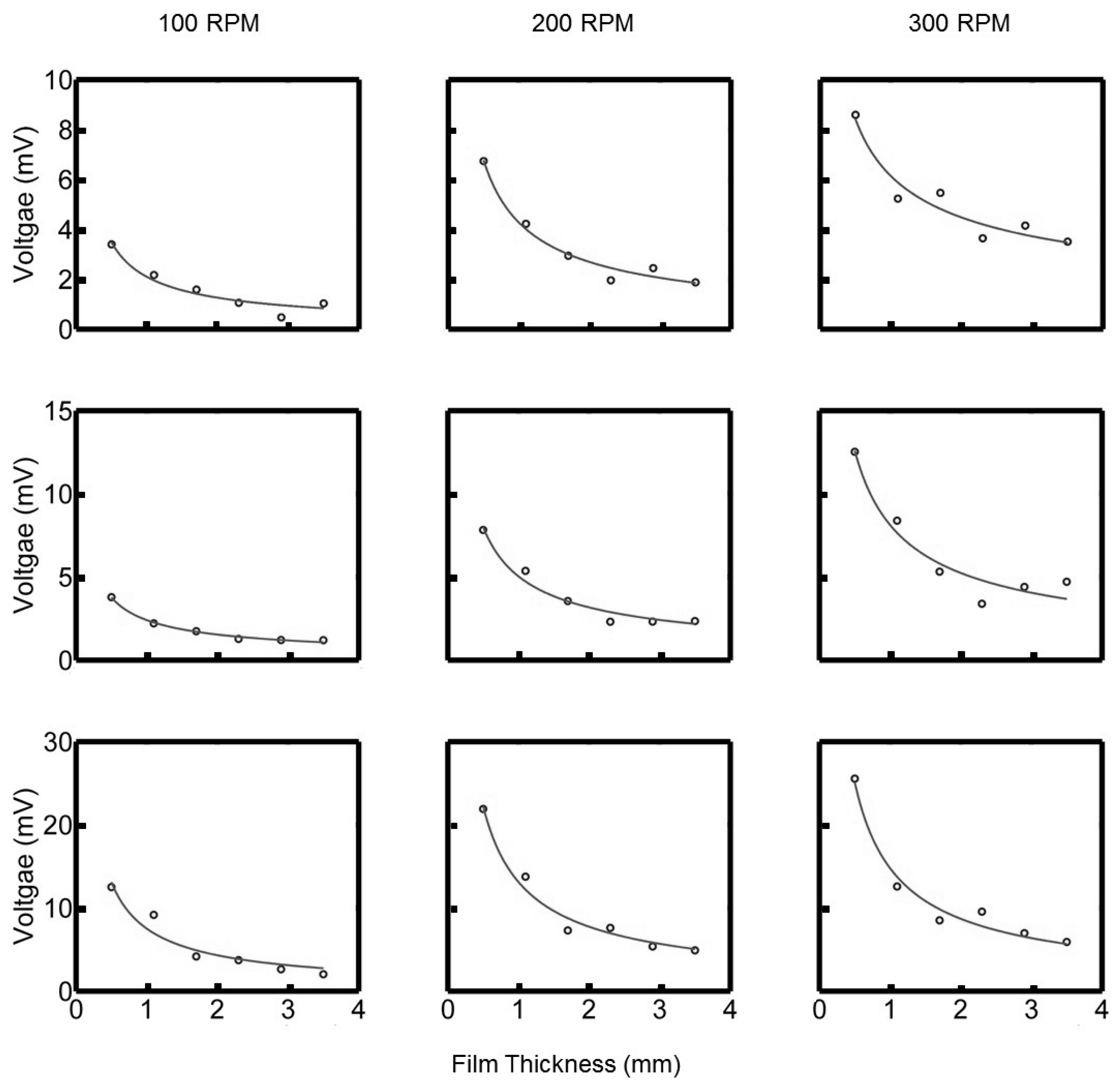

A similar investigation was done for the height variation of the oil film. The thickness of the oil film was increased from 0.6 mm to 3.6 mm in increments of 0.6 mm. These results are shown in

Figure 10 for the three rotational speeds 100, 200 and 300 rpm. The output voltage is inversely proportional to the oil film thickness

h. The lines represent the logistic function that is fitted to the data.

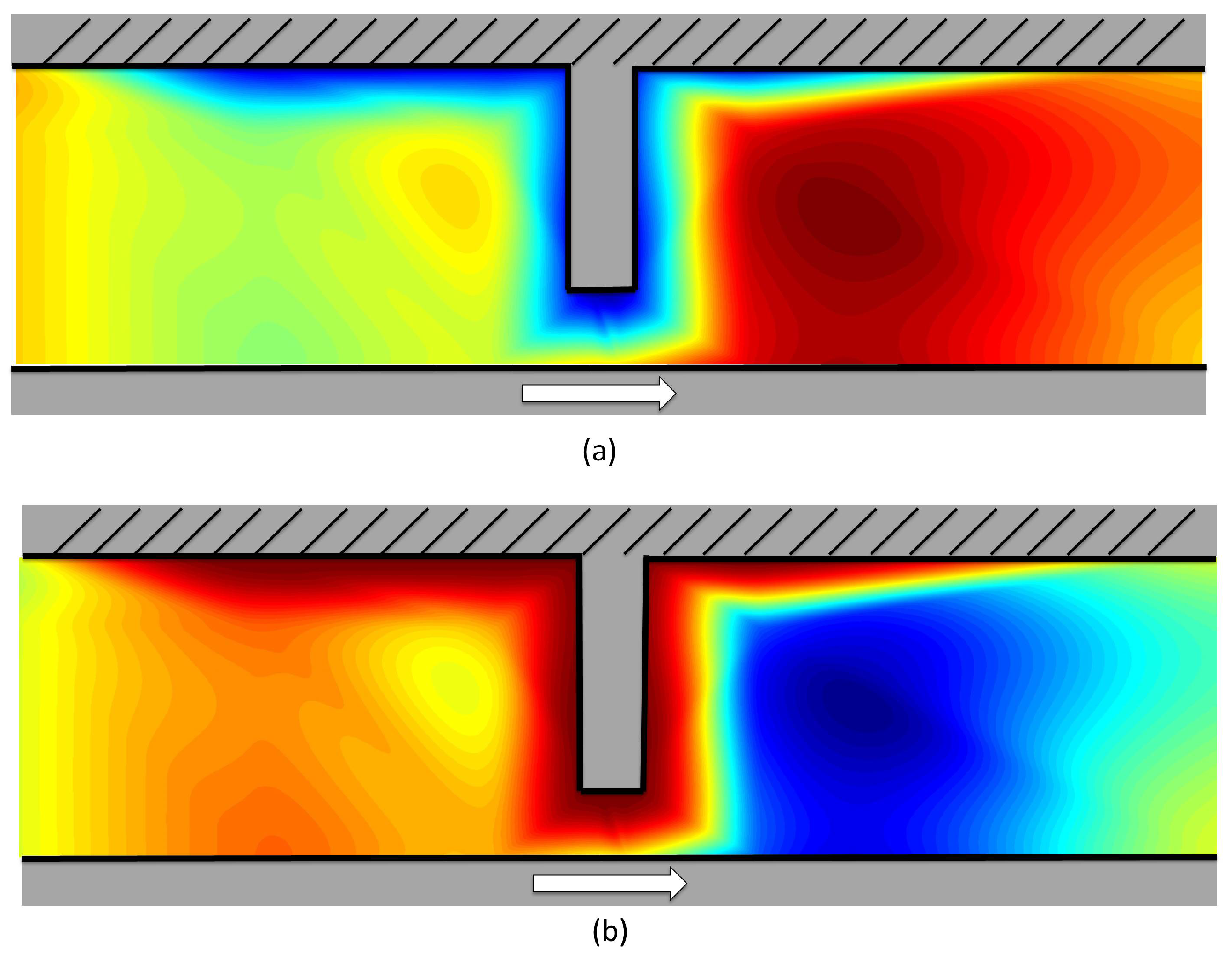

The mathematical models presented in

Section 2.2 were used to predict the force characteristics due to the tilted pad. Comparisons of absolute pressure values were not possible due to the anisotropy issues of the calibration of the PVDF film discussed above. An initial velocity profile was generated using the boundary condition described in

Section 2.2 and is shown in

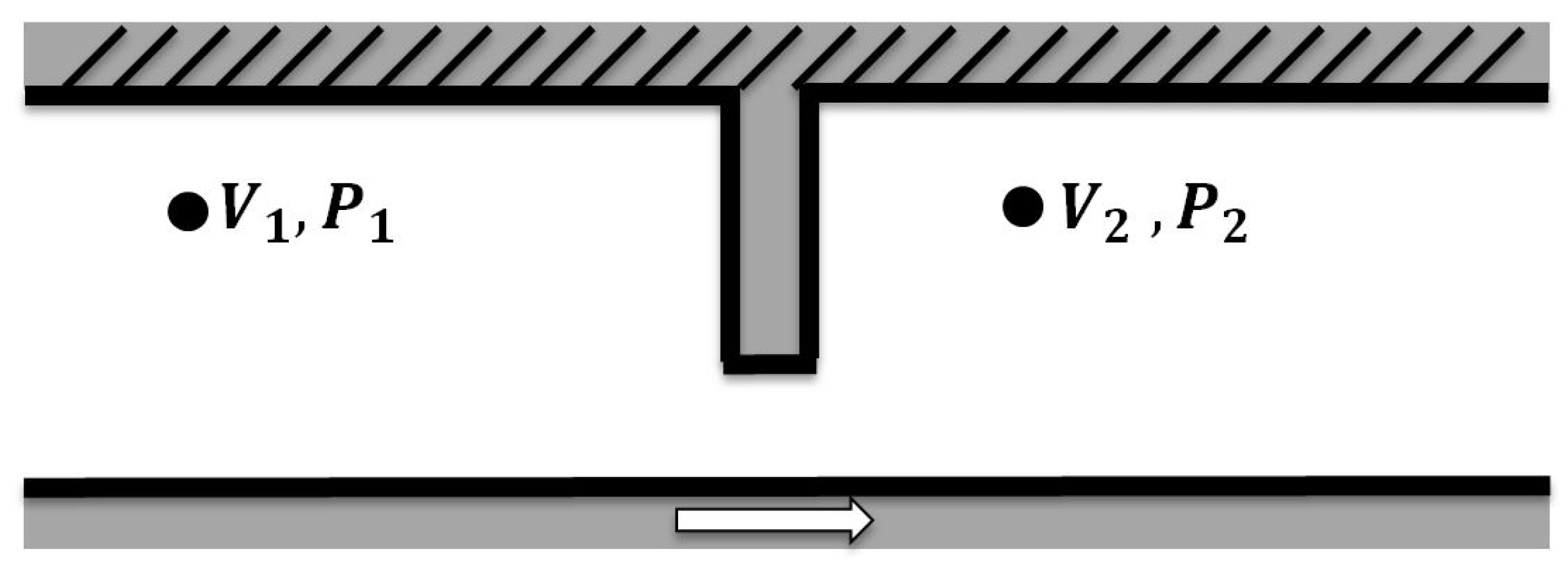

Figure 11a. Red represents high velocity and blue zero velocity. The orange region on the left-hand side corresponds to the inflow, while the red region is the outflow.

Using this velocity profile, the pressure at different locations was calculated using Bernoulli’s equations, assuming that the inflow pressure is zero. The result is shown in

Figure 11b. Green, red and blue indicate zero pressure, positive pressures and negative pressures, respectively.

Figure 11 clearly shows that, when the velocity of the oil is accelerated (+ve and −ve) by the step, it generates pockets of positive and negative pressures in front and behind the pad, respectively. The sensors’ response, however, is the sum of applied pressure across the entire film, and, as a result, the film output can be obtained by integrating over the length of the sensor. The result for the 1 mm pad is shown in

Figure 12 in red. The black curve is the experimental data. Both data sets have been normalised to help comparison. As can be seen, there is good agreement, especially in the region when the pad interacts with the film. The small inflection points observed on either side of the main peak in the experimental data may be due to oil movement in the radial direction. In the model, it is assumed that the surfaces have infinite width in the direction perpendicular to the motion, and, as a result, no flow is possible in this radial direction.

A feature to note is that the maximum force observed is just before the leading edge of the step, as shown in

Figure 12. This is where the oil comes to a complete stop. Past this point, the oil accelerates to the max velocity, resulting in a negative pressure. After this, the oil begins to slow down, equalizing the pressure.

Similar analysis can be done for the tilted pad. However, in order to do this, it is necessary to couple the Reynold and Bernoulli models to give an approximate prediction of the pressure wave in front, under and behind the pad. It is necessary to couple the two models at the leading and trailing edge of the pads because zero pressures are expected at the inlet and outlet of the bearing.

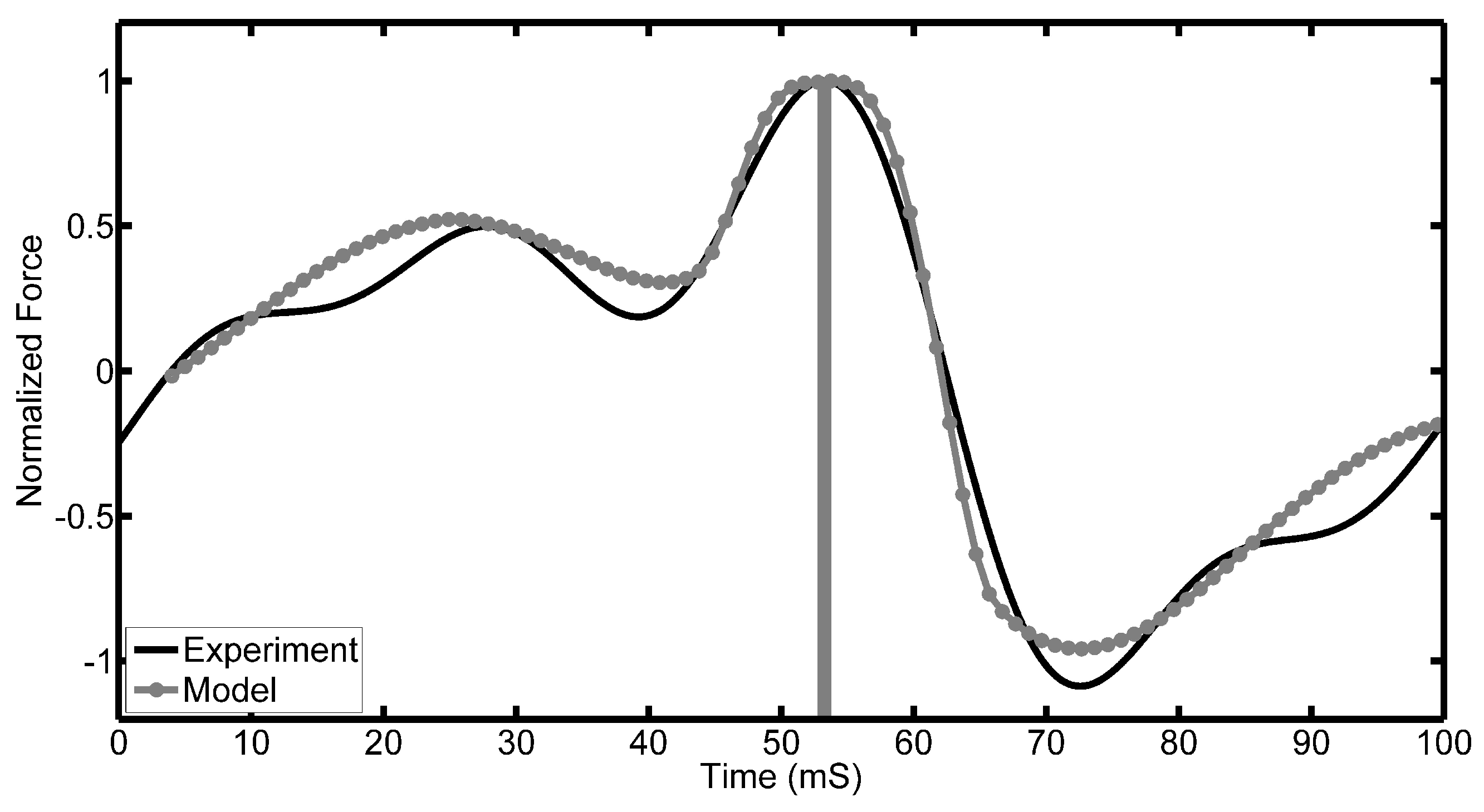

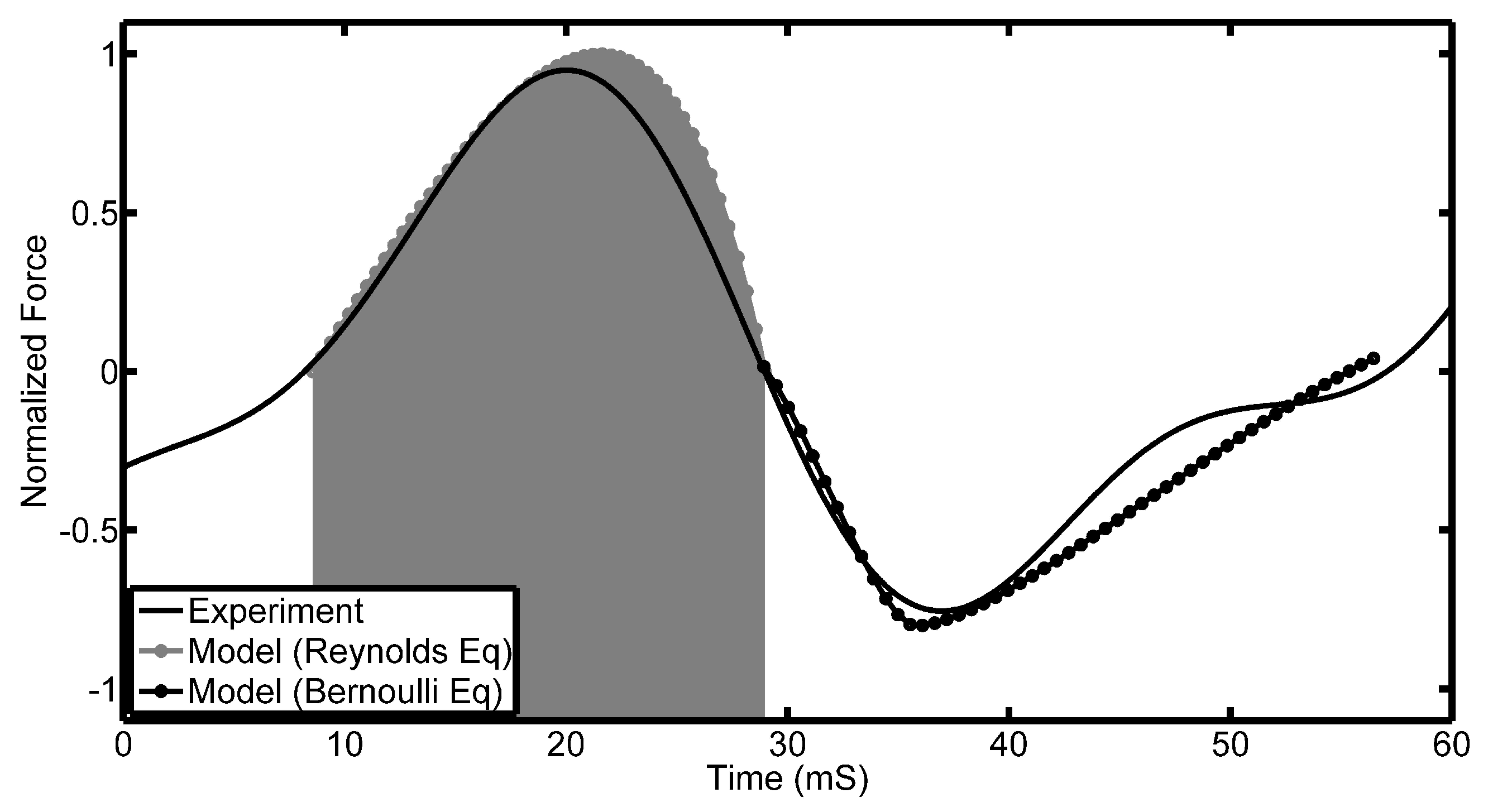

Figure 13 shows the normalised force as a function of time for the tilted pad. The grey curves show the theoretical results using the Reynolds and Bernoulli equations over their respective domains. The black curve is the experimental result. From the results, it can be seen that:

At the inlet of the pad entering and after the outlet leaving the PVDF, the measured force is zero. This agrees with the assumptions made above.

A maximum force is observed by the PVDF directly underneath the bearing. The position of this maximum force lies closer to the outlet of the bearing. This is more prominent in the theoretical result that assumes a pad of infinite width. This observation is also explained by the assumption made earlier when describing Reynolds equation.

The inflection point observed experimentally after the main peak is not present theoretically. As mentioned above, this is most probably due to infinite pad approximation.

The mechanism of the oil force observed under the tilted pad is through the generation of a viscous liquid film between the moving surfaces. Since the top surface is inclined at a certain angle to the bottom surface, a pressure field is generated; otherwise, there would be more lubricant entering the wedge than leaving it due to the smaller cross-sectional area. In addition to further describing the waveforms of the signatures, the model can also assist in explaining the speed and height variations. In

Figure 9, it was shown that there is a linear relationship between the observed voltage peaks and the speed of rotation. This observation is in line with what is expected, and Equation (

4) describes the pressure field that exists underneath a tilted pad, and it is clear that the pressure field is directly proportional to speed. Concerning the height variation of the oil film, this is not as easy as describing using the presented equation. In

Figure 13, it is clear that the relationship between the oil film height and the pressures observed are not directly proportional, but rather inversely proportional.