Performance Assessment of a Humidity Measurement System and Its Use to Evaluate Moisture Characteristics of Wheelchair Cushions at the User–Seat Interface

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Acquisition Unit

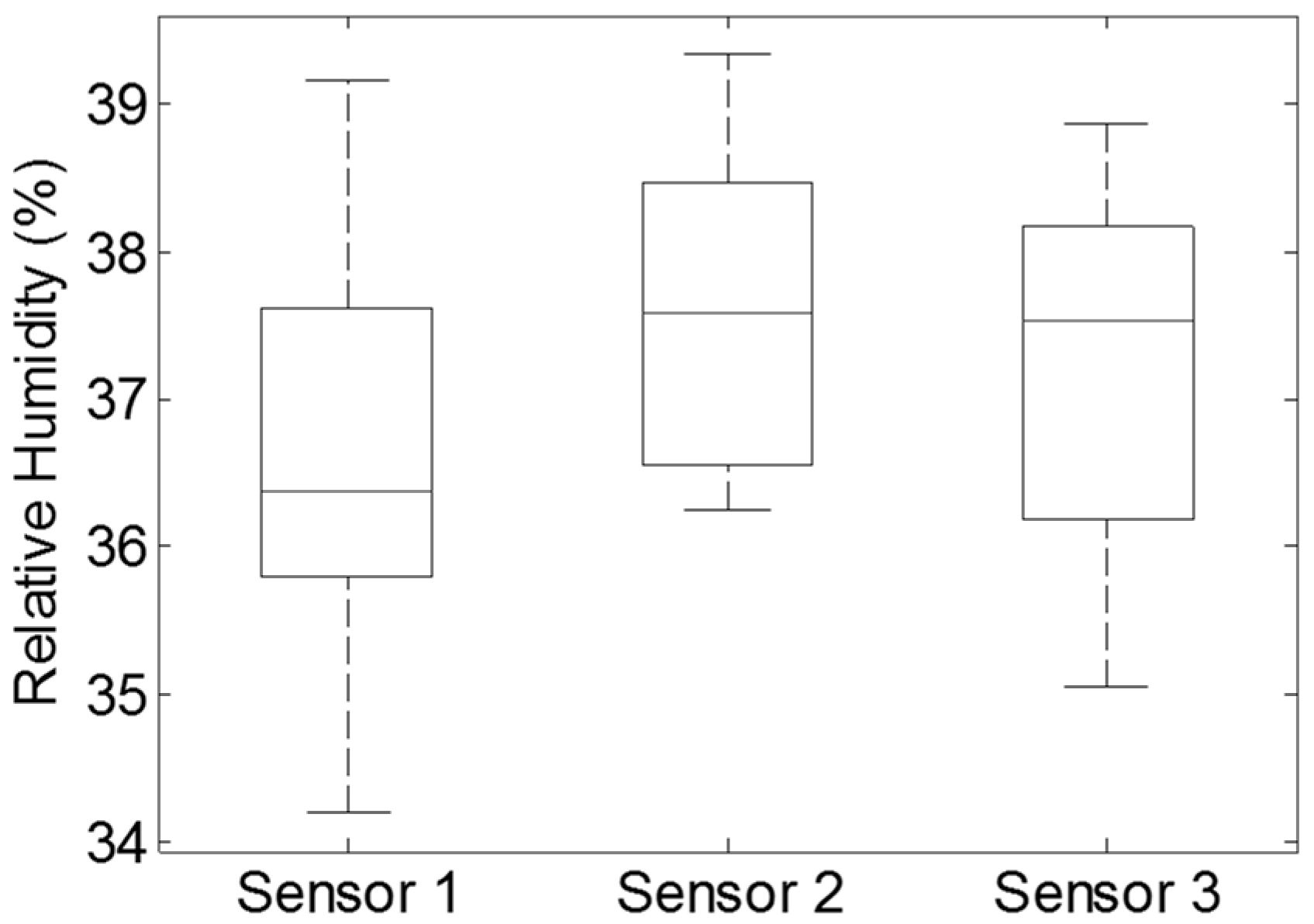

2.2. Sensor Evaluation

2.3. Consistency Test under Sand Bag Loading

2.4. Protocols of Sitting Experiments

2.4.1. Cushions

2.4.2. Participants

2.4.3. Data Smoothing

2.4.4. Data Representation

3. Results

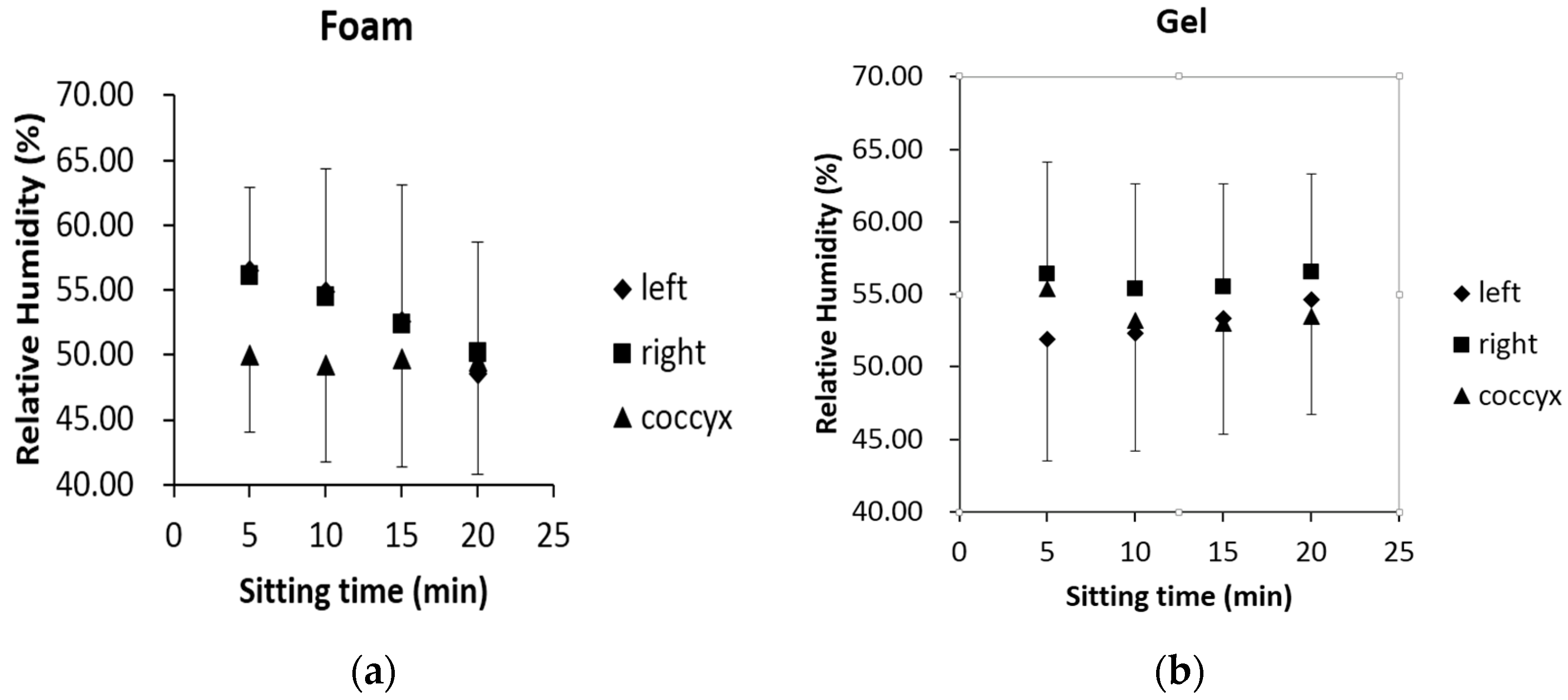

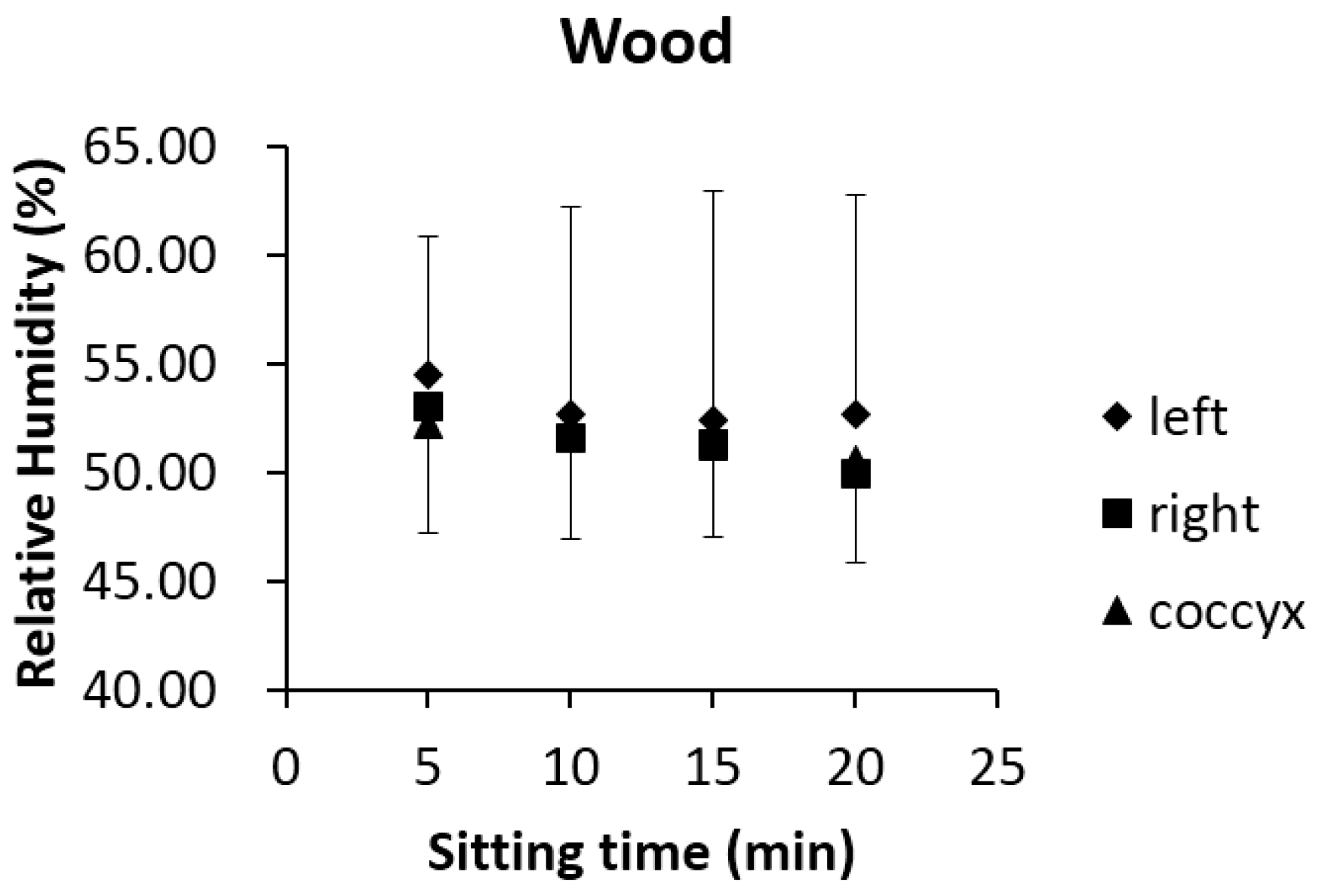

3.1. Comparison among Different Measurement Locations

3.2. Comparison between Different Cushions

4. Discussion

4.1. Humidity Sensor Calibration

4.2. RH Distribution over the Interface

4.3. Sex Influence on RH

4.4. Clinical and Physiological Significance

5. Conclusions

- RH properties at different measurement locations vary (right and left thighs, coccyx). Thus, it is of importance to deploy multiple sensors at the user–seat interface if greater resolution of the RH is needed to determine the highest ‘at risk’ regions. In future research, the optimal number of humidity sensors and their locations will be investigated.

- RH and changes in RH at the three locations are different for the gel and foam cushion (p < 0.05). As cushion composition may have significant impact on moisture at the user–seat interface, it is vital to consider the effects on RH of different materials when selecting cushions for prolonged sitting applications with those in need, such as wheelchair-dependant patients. In addition, this system might help in the future design of materials which can reduce the build-up of moisture at this critical interface zone.

- For both foam and gel cushions, the time to reach a maximum humidity value during uninterrupted sitting is less than five minutes. This means a shorter testing duration may be possible when evaluating transient humidity properties related to different cushion materials. However, it is important to note that these subjects were not impaired and as a result might have created movements capable of increasing ventilation and reducing interface RH. Therefore, this study should be extended into those populations which are dependent on wheelchairs and may not have the capability of sensing changes at the seat interface.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ostadabbas, S.; Yousefi, R.; Nourani, M.; Faezipour, M.; Tamil, L.; Pompeo, M.Q. A resource-efficient planning for pressure ulcer prevention. IEEE Trans. Inf. Technol. Biomed. 2012, 16, 1265–1273. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Huang, M.C.; Amini, N.; He, L. Ecushion: A textile pressure sensor array design and calibration for sitting posture analysis. IEEE Sens. J. 2013, 13, 3926–3934. [Google Scholar] [CrossRef]

- Demarré, L.; van Lancker, A.; van Hecke, A.; Verhaeghe, S.; Grypdonck, M.; Lemey, J.; Annemans, L.; Beeckman, D. The cost of prevention and treatment of pressure ulcers: A systematic review. Int. J. Nurs. Stud. 2015, 52, 1754–1774. [Google Scholar] [CrossRef] [PubMed]

- Meddings, J.; Reichert, H.; Rogers, M.A.; Hofer, T.P.; McMahon, L.F., Jr.; Grazier, K.L. Under pressure: Financial effect of the hospital-acquired conditions initiative—A statewide analysis of pressure ulcer development and payment. J. Am. Geriatr. Soc. 2015, 63, 1407–1412. [Google Scholar] [CrossRef] [PubMed]

- Thosar, S.S.; Bielko, S.L.; Mather, K.J.; Johnston, J.D.; Wallace, J.P. Effect of prolonged sitting and breaks in sitting time on endothelial function. Med. Sci. Sport Exer. 2015, 47, 843–849. [Google Scholar] [CrossRef] [PubMed]

- Stockton, L.; Rithalia, S. Pressure-reducing cushions: Perceptions of comfort from the wheelchair users’ perspective using interface pressure, temperature and humidity measurements. J. Tissue Viability 2009, 18, 28–35. [Google Scholar] [CrossRef] [PubMed]

- Vlaovi, Z.; Domljan, D.; Grbac, I. Research of temperature and moisture during sitting on office chairs. DRVNA Ind. 2012, 63, 105–112. [Google Scholar] [CrossRef]

- Mccarthy, P.W.; Liu, Z.; Heusch, A.I.; Cascioli, V. Assessment of humidity and temperature sensors and their application to seating. J. Med. Eng. Technol. 2009, 33, 449–453. [Google Scholar] [CrossRef] [PubMed]

- Ferguson-Pell, M.; Hirose, H.; Nicholson, G.; Call, E. Thermodynamic rigid cushion loading indenter: A buttock-shaped temperature and humidity measurement system for cushioning surfaces under anatomical compression conditions. J. Rehabil. Res. Dev. 2009, 46, 945–956. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Cascioli, V.; Heusch, A.I.; Mccarthy, P.W. Studying thermal characteristics of seating materials by recording temperature from 3 positions at the seat-subject interface. J. Tissue Viability 2011, 20, 73–80. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.C.; Chen, S.W. A moving average based filtering system with its application to real-time QRS detection. In Proceedings of the International Conference on Computers in Cardiology, Thessaloniki Chalkidiki, Greece, 21–24 September 2003; pp. 585–588. [Google Scholar]

- Bartels, V.T. Thermal comfort of aeroplane seats: Influence of different seat materials and the use of laboratory test methods. Appl. Ergon. 2003, 34, 393–399. [Google Scholar] [CrossRef]

- Cengiz, T.G.; Babalık, F.C. The effects of ramie blended car seat covers on thermal comfort during road trials. Int. J. Ind. Ergonom. 2009, 39, 287–294. [Google Scholar] [CrossRef]

- Freeto, T.; Cypress, A.; Amalraj, S.; Yusufishaq, M.S.; Bogie, K.M. Development of a sitting microenvironment simulator for wheelchair cushion assessment. J. Tissue Viability 2016, 25, 175–179. [Google Scholar] [CrossRef] [PubMed]

- Sonenblum, S.E.; Sprigle, S.H.; Cathcart, M.K.; Winder, R.J. 3D anatomy and deformation of the seated buttocks. J. Tissue Viability 2015, 24, 51–61. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.H.; Chou, T.Y.; Chen, C.H.; Chen, P.; Wang, F.C. Development of a modularized seating system to actively manage interface pressure. Sensors 2014, 14, 14235–14252. [Google Scholar] [CrossRef] [PubMed]

- Kakitsuba, N. Physiological responses to changes in relative humidity under thermally neutral, warm and hot conditions. J. Therm. Biol. 2016, 59, 86–91. [Google Scholar] [CrossRef] [PubMed]

- Cochran, G.V.; Palmieri, V. Development of test methods for evaluation of wheelchair cushions. Bull. Prosthet. Res. 1980, 17, 9–30. [Google Scholar]

- Sumiya, T.; Kawamura, K.; Tokuhiro, A.; Takechi, H.; Ogata, H. A survey of wheelchair use by paraplegic individuals in Japan. Part 1: Characteristics of wheelchair cushions. Spinal Cord. 1997, 35, 590–594. [Google Scholar] [CrossRef] [PubMed]

| Cushion | Sensor Locations | |||

|---|---|---|---|---|

| Left Mid-Thigh | Right Mid-Thigh | Coccyx | ||

| Foam | Average (% RH) | 50.3 ± 5.9 | 50.6 ± 6.4 | 51.4 ± 5.6 |

| Maximum (% RH) | 56.0 ± 6.3 | 53.6 ± 7.0 | 54.7 ± 5.8 | |

| Median (% RH) | 49.6 ± 6.2 | 50.9 ± 6.6 | 52.2 ± 5.8 | |

| Tm (s) | 79.6 ± 6.0 | 119.8 ± 7.1 | 101.7 ± 4.8 | |

| Gel | Average (% RH) | 54.0 ± 9.4 | 56.7 ± 9.2 | 56.4 ± 8.2 |

| Maximum (% RH) | 59.8 ± 11.0 | 60.1 ± 9.7 | 59.9 ± 9.2 | |

| Median (% RH) | 53.2 ± 9.1 | 57.3 ± 9.5 | 57.2 ± 8.2 | |

| Tm (s) | 115.5 ± 4.4 | 139.1 ± 9.2 | 111.8 ± 8.3 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Cheng, H.; Luo, Z.; Cascioli, V.; Heusch, A.I.; Nair, N.R.; McCarthy, P.W. Performance Assessment of a Humidity Measurement System and Its Use to Evaluate Moisture Characteristics of Wheelchair Cushions at the User–Seat Interface. Sensors 2017, 17, 775. https://doi.org/10.3390/s17040775

Liu Z, Cheng H, Luo Z, Cascioli V, Heusch AI, Nair NR, McCarthy PW. Performance Assessment of a Humidity Measurement System and Its Use to Evaluate Moisture Characteristics of Wheelchair Cushions at the User–Seat Interface. Sensors. 2017; 17(4):775. https://doi.org/10.3390/s17040775

Chicago/Turabian StyleLiu, Zhuofu, Haifeng Cheng, Zhongming Luo, Vincenzo Cascioli, Andrew I. Heusch, Nadia R. Nair, and Peter W. McCarthy. 2017. "Performance Assessment of a Humidity Measurement System and Its Use to Evaluate Moisture Characteristics of Wheelchair Cushions at the User–Seat Interface" Sensors 17, no. 4: 775. https://doi.org/10.3390/s17040775

APA StyleLiu, Z., Cheng, H., Luo, Z., Cascioli, V., Heusch, A. I., Nair, N. R., & McCarthy, P. W. (2017). Performance Assessment of a Humidity Measurement System and Its Use to Evaluate Moisture Characteristics of Wheelchair Cushions at the User–Seat Interface. Sensors, 17(4), 775. https://doi.org/10.3390/s17040775