Fiber Bragg Grating Measuring System for Simultaneous Monitoring of Temperature and Humidity in Mechanical Ventilation

Abstract

:1. Introduction

2. Working Principle and Fabrication of the Sensors

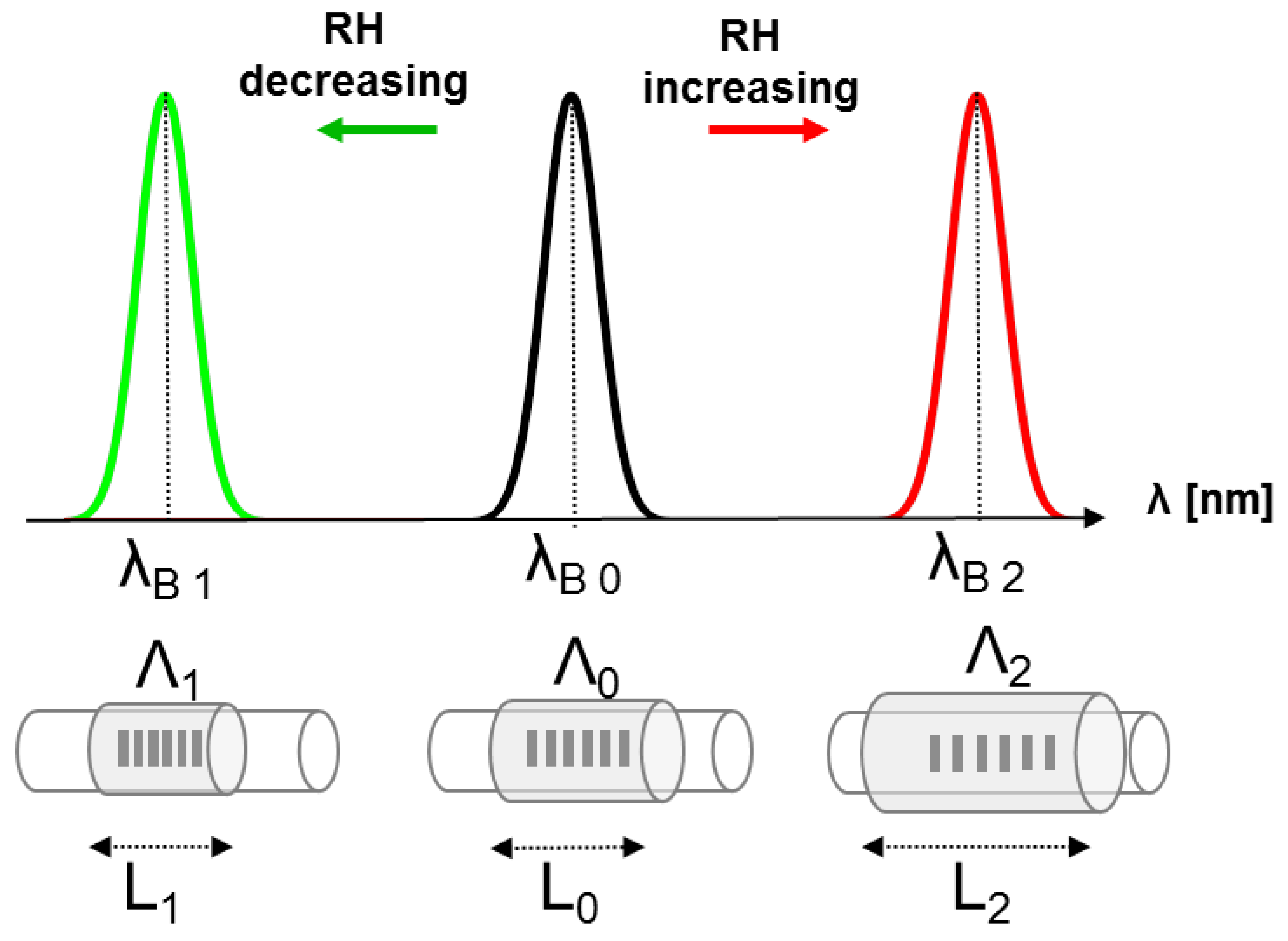

2.1. Working Principle of the Sensors

2.2. Fabrication of the Sensors

3. Experimental Set-up and Results

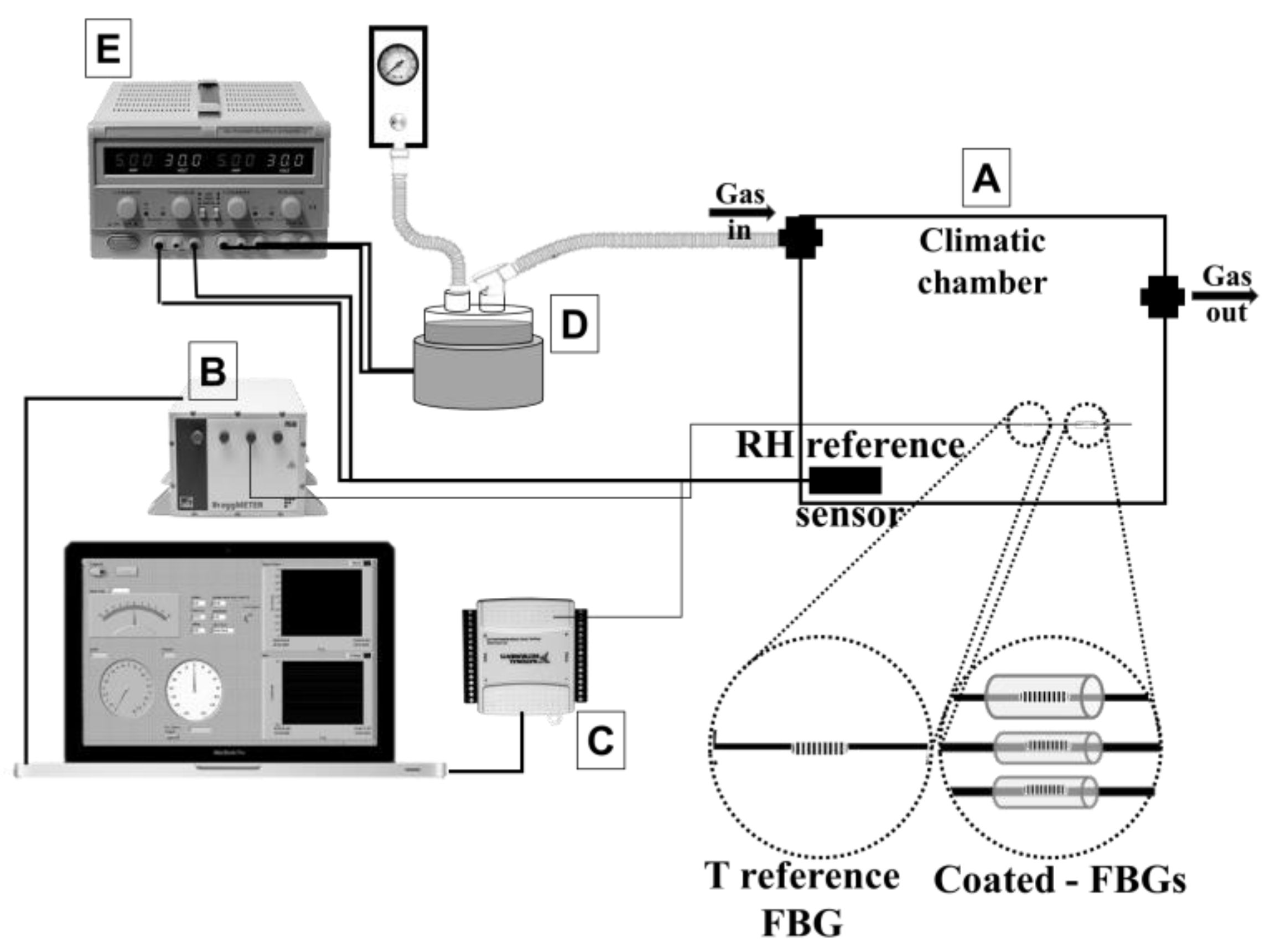

3.1. Description of the Experimental Set-up

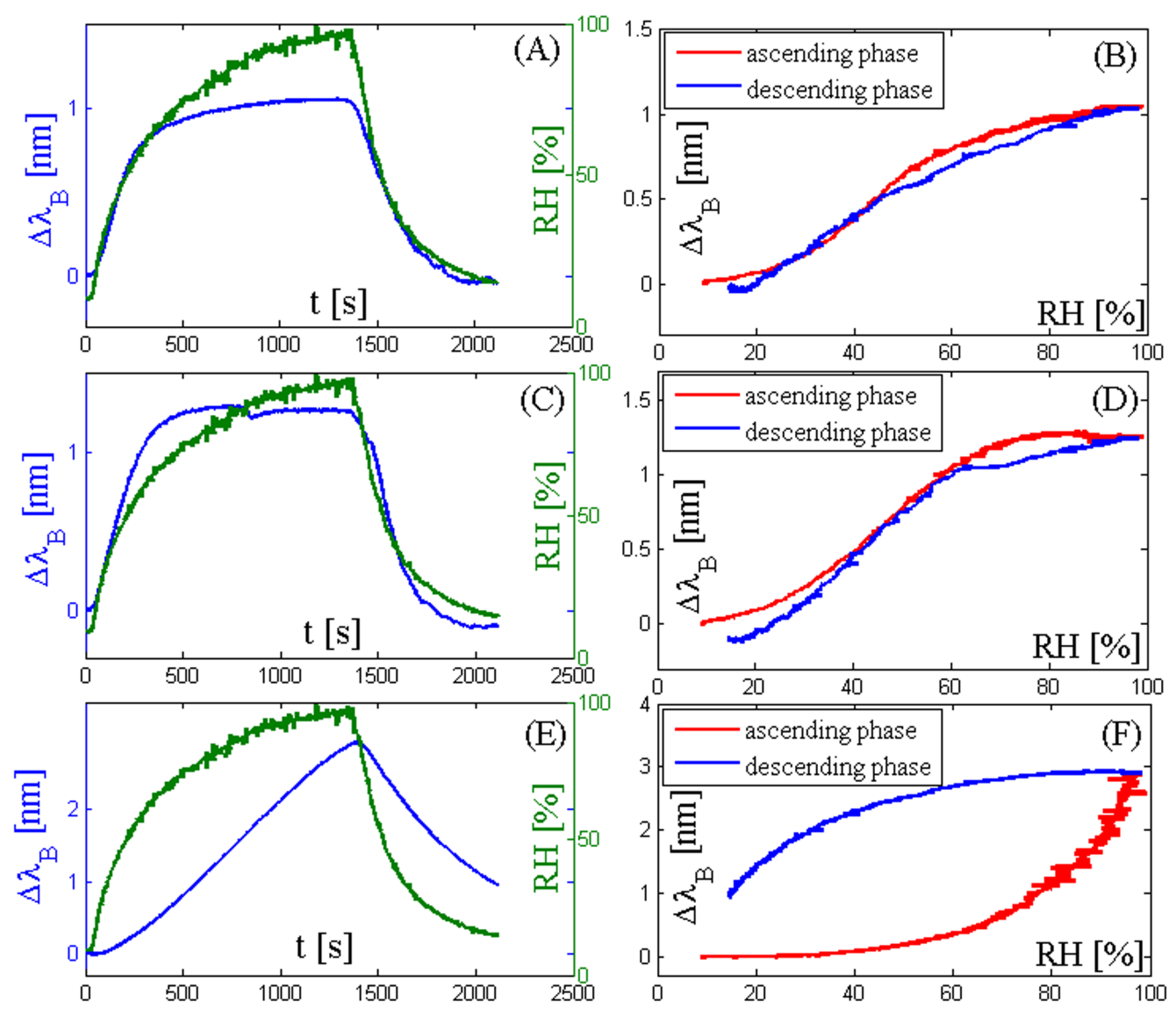

3.2. Results

4. Discussion and Conclusions

Author Contributions

Conflicts of Interest

References

- Restrepo, R.D.; Walsh, B.K. Humidification During Invasive and Noninvasive Mechanical Ventilation: 2012. Respir. Care 2012, 57, 782–788. [Google Scholar] [CrossRef] [PubMed]

- Branson, R.D.; Chatburn, R.L. Humidification of inspired gases during mechanical ventilation. Respir. Care 1993, 38, 461–468. [Google Scholar]

- Todd, D.; Boyd, J.; Lloyd, J.; John, E. Inspired gas humidity during mechanical ventilation: Effects of humidification chamber, airway temperature probe position and environmental conditions. J. Paediatr. Child. Health 2001, 37, 489–494. [Google Scholar] [CrossRef] [PubMed]

- Chiumello, D.; Pelosi, P.; Park, G.; Candiani, A.; Bottini, N.; Storelli, E.; Severgnini, P.; D’Onofrio, D.; Gattinoni, L.; Chiaranda, M. In vitro and in vivo evaluation of a new active heat moisture exchanger. Crit. Care 2004, 8, R281. [Google Scholar] [CrossRef] [PubMed]

- Gross, J.L.; Park, G.R. Humidification of inspired gases during mechanical ventilation. Minerva Anestesiol. 2012, 78, 496–502. [Google Scholar] [PubMed]

- Williams, R.; Rankin, N.; Smith, T.; Galler, D.; Seakins, P. Relationship between the humidity and temperature of inspired gas and the function of the airway mucosa. Crit. Care Med. 1996, 24, 1920–1929. [Google Scholar] [CrossRef] [PubMed]

- Nishida, T.; Nishimura, M.; Fujino, Y.; Mashimo, T. Performance of Heated Humidifiers with a Heated Wire According to Ventilatory Settings. J. Aerosol. Med. 2001, 14, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Solomita, M.; Daroowalla, F.; LeBlanc, D.S.; Smaldone, G.C. Y-Piece Temperature and Humidification During Mechanical Ventilation. Respir. Care 2012, 54, 480–486. [Google Scholar]

- Lellouche, F.; Taillé, S.; Maggiore, S.M.; Qader, S.; L’Her, E.; Deye, N.; Brochard, L. Influence of Ambient and Ventilator Output Temperatures on Performance of Heated-Wire Humidifiers. Am. J. Respir. Crit. Care Med. 2004, 170, 1073–1079. [Google Scholar] [CrossRef] [PubMed]

- Verta, A.; Schena, E.; Silvestri, S. Mathematical model and minimal measurement system for optimal control of heated humidifiers in neonatal ventilation. Med. Eng. Phys. 2010, 32, 475–481. [Google Scholar] [CrossRef] [PubMed]

- Schena, E.; Massaroni, C.; Saccomandi, P.; Cecchini, S. Flow measurement in mechanical ventilation: A review. Med. Eng. Phys. 2015, 37, 257–264. [Google Scholar] [CrossRef] [PubMed]

- Sikarwar, S.; Yadav, B.C. Opto-electronic humidity sensor: A review. Sens. Actuators A Phys. 2015, 233, 54–70. [Google Scholar] [CrossRef]

- Mishra, V.; Singh, N.; Tiwari, U.; Kapur, P. Fiber grating sensors in medicine: Current and emerging applications. Sens. Actuators A Phys. 2011, 167, 279–290. [Google Scholar] [CrossRef]

- Lee, B. Review of the present status of optical fiber sensors. Opt. Fiber Technol. 2003, 9, 57–79. [Google Scholar] [CrossRef]

- Zhou, K. Toward a new generation of photonic humidity sensors. Sensors 2014, 14, 3986–4013. [Google Scholar] [CrossRef]

- Yeo, T.L.; Sun, T.; Grattan, K.T.V. Fibre-optic sensor technologies for humidity and moisture measurement. Sens. Actuators A Phys. 2008, 144, 280–295. [Google Scholar] [CrossRef]

- Othonos, A.; Kalli, K.; Kohnke, G.E. Fiber Bragg Gratings: Fundamentals and Applications in Telecommunications and Sensing. Phys. Today 2000, 53, 61. [Google Scholar] [CrossRef]

- James, S.W.; Tatam, R.P. Optical fibre long-period grating sensors: Characteristics and application. Meas. Sci. Technol. 2003, 14, R49–R61. [Google Scholar] [CrossRef]

- Correia, S.F.H.; Antunes, P.; Pecoraro, E.; Lima, P.P.; Varium, H.; Carlos, L.D.; Ferreira, R.A.S.; Andrè, P.S. Optical fiber relative humidity sensor based on a FBG with a di-ureasil coating. Sensors 2012, 12, 8847–8860. [Google Scholar] [CrossRef] [PubMed]

- David, N.A.; Wild, P.M.; Djilali, N. Parametric study of a polymer-coated fibre-optic humidity sensor. Meas. Sci. Technol. 2012, 23, 35103. [Google Scholar] [CrossRef]

- Kronenberg, P.; Rastogi, P.K.; Giaccari, P.; Limberger, H.G. Relative humidity sensor with optical fiber Bragg gratings. Opt. Lett. 2002, 27, 1385–1387. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Gong, Y.; Wu, Y.; Wu, H. Polyimide-coated fiber Bragg grating for relative humidity sensing. Photonic Sens. 2015, 5, 60–66. [Google Scholar] [CrossRef]

- Yeo, T.L.; Sun, T.; Grattan, K.T.V.; Parry, D.; Lade, R.; Powell, B.D. Characterisation of a polymer-coated fibre Bragg grating sensor for relative humidity sensing. Sens. Actuators B Chem. 2005, 110, 148–156. [Google Scholar] [CrossRef]

- Yeo, T.L.; Grattan, K.T.V.; Parry, D.; Lade, R.; Powell, B.D. Polymer-coated fiber Bragg grating for relative humidity sensing. IEEE Sens. J. 2005, 5, 1082–1089. [Google Scholar] [CrossRef]

- Dong, X.; Li, T.; Liu, Y.; Li, Y.; Zhao, C.-L.; Chan, C.C. Polyvinyl alcohol-coated hybrid fiber grating for relative humidity sensing. J. Biomed. Opt. 2011, 16, 77001. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Dong, X.; Chan, C.C.; Zhao, C.L.; Zu, P. Humidity sensor based on a multimode-fiber taper coated with polyvinyl alcohol interacting with a fiber bragg grating. IEEE Sens. J. 2012, 12, 2205–2208. [Google Scholar] [CrossRef]

- Miao, Y.M.Y.; Liu, B.L.B.; Zhang, H.Z.H.; Li, Y.; Zhou, H.; Sun, H.; Zhang, W.; Zhao, Q. Relative Humidity Sensor Based on Tilted Fiber Bragg Grating With Polyvinyl Alcohol Coating. IEEE Photonics Technol. Lett. 2009, 21, 441–443. [Google Scholar] [CrossRef]

- Huang, X.F.; Sheng, D.R.; Cen, K.F.; Zhou, H. Low-cost relative humidity sensor based on thermoplastic polyimide-coated fiber Bragg grating. Sens. Actuators B Chem. 2007, 127, 518–524. [Google Scholar] [CrossRef]

- Bariáin, C.; Matías, I.R.; Arregui, F.J.; López-Amo, M. Optical fiber humidity sensor based on a tapered fiber coated with agarose gel. Sens. Actuators B Chem. 2000, 69, 127–131. [Google Scholar] [CrossRef]

- Batumalay, M.; Harun, S.W.; Ahmad, F.; Nor, R.M.; Zulkepely, N.R.; Ahmad, H. Study of a fiber optic humidity sensor based on agarose gel. J. Mod. Opt. 2014, 61, 244–248. [Google Scholar] [CrossRef]

- Miao, Y.; Zhang, K.; Yuam, Y.; Liu, B.; Zhang, H.; Liu, Y.; Yao, J. Agarose gel-coated LPG based on two sensing mechanisms for relative humidity measurement. Appl. Opt. 2013, 52, 90–95. [Google Scholar] [CrossRef] [PubMed]

- Mathew, J.; Semenova, Y.; Farrell, G. A miniature optical humidity sensor. Proceedings of IEEE Sensors, Limerick, Ireland, 28–31 October 2011; pp. 2030–2033. [Google Scholar]

- Hernandez, F.U.; Correia, R.; Morgan, S.P.; Hayes-Gill, B.; Evans, D.; Sinha, R.; Norris, A.; Harvey, D.; Hardman, J.G.; Korposh, S. Simultaneous temperature and humidity measurements in a mechanical ventilator using an optical fibre sensor. Proc. SPIE 2016, 9916. [Google Scholar] [CrossRef]

- Viegas, D.; Hernaez, M.; Goicoechea, J.; Santos, J.L.; Araujo, F.M.; Arregui, F.; Matias, I.R. Simultaneous measurement of humidity and temperature based on an SiO2-nanospheres film deposited on a long-period grating in-line with a fiber Bragg grating. IEEE Sens. J. 2011, 11, 162–166. [Google Scholar] [CrossRef]

- Alwis, L.; Sun, T.; Grattan, K.V. Analysis of Polyimide-Coated Optical Fiber Long-Period Grating-Based Relative Humidity Sensor. IEEE Sens. J. 2013, 13, 767–771. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Zhang, M.; Tu, D.; Mao, X.; Liao, Y. A relative humidity sensor using a hydrogel-coated long period grating. Meas. Sci. Technol. 2007, 18, 3131–3134. [Google Scholar] [CrossRef]

- Duckworth, M.; Yaphe, W. The structure of agar. Carbohydr. Res. 1971, 16, 189–197. [Google Scholar] [CrossRef]

- Armisén, R. Agar and agarose biotechnological applications. Hydrobiologia 1991, 221, 157–166. [Google Scholar] [CrossRef]

- Erdogan, T. Fiber grating spectra. J. Lightwave Technol. 1997, 15, 1277–1294. [Google Scholar] [CrossRef]

- Branson, R.D. The effects of inadequate humidity. Respir. Care Clin. N. Am. 1998, 4, 199–214. [Google Scholar] [PubMed]

- Chen, Q.; Lu, P. Fiber bragg gratings and their applications as temperature and humidity sensors. In Atomic, Molecular and Optical Physics; Nova Science Publisher, Inc.: New York, NY, USA, 2008. [Google Scholar]

- Zhang, C.; Zhang, W.; Webb, D.J.; Peng, G.-D. Optical fibre temperature and humidity sensor. Electron. Lett. 2010, 46, 643. [Google Scholar] [CrossRef]

- Schena, E.; Saccomandi, P.; Ramandi, C.; Silvestri, S. A novel control strategy to improve the performances of heated wire humidifiers in artificial neonatal ventilation. Physiol. Meas. 2012, 33, 1199–1211. [Google Scholar] [CrossRef] [PubMed]

- Schena, E.; Saccomandi, P.; Cappelli, S.; Silvestri, S. Mechanical ventilation with heated humidifiers: Measurements of condensed water mass within the breathing circuit according to ventilatory settings. Physiol. Meas. 2013, 34, 813–821. [Google Scholar] [CrossRef] [PubMed]

- Losquadro, C.; Saccomandi, P.; Massaroni, C.; Schena, E. Performances of heated wire humidifiers during adult mechanical ventilation: Estimation of the amount of condensation. In Proceedings of the 2016 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Benevento, Italy, 15–18 May 2016. [Google Scholar]

- Hromadka, J.; Korposh, S.; Partridge, M.C.; James, S.W.; Davis, F.; Crump, D.; Tatam, R.P. Multi-parameter measurements using optical fibre long period gratings for indoor air quality monitoring. Sens. Actuators B Chem. 2017, 244, 217–225. [Google Scholar] [CrossRef]

- Urrutia, A.; Goicoechea, J.; Ricchiuti, A.L.; Barrera, D.; Sales, S.; Arregui, F.J. Simultaneous measurement of humidity and temperature based on a partially coated optical fiber long period grating. Sens. Actuators B Chem. 2016, 227, 135–141. [Google Scholar] [CrossRef]

- Liu, H.; Liang, H.; Sun, M.; Ni, K.; Jin, Y. Simultaneous Measurement of Humidity and Temperature Based on a Long-Period Fiber Grating Inscribed in Fiber Loop Mirror. IEEE Sens. J. 2014, 14, 893–896. [Google Scholar] [CrossRef]

- Wu, S.; Yan, G.; Lian, Z.; Chen, X.; Zhou, B.; He, S. An open-cavity Fabry-Perot interferometer with PVA coating for simultaneous measurement of relative humidity and temperature. Sens. Actuators B Chem. 2016, 225, 50–56. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, X.; Yuan, L.; Zhou, L.; Qiao, X.; Hu, M. An Optical Fiber Fabry-Perot Interferometer Sensor for Simultaneous Measurement of Relative Humidity and Temperature. IEEE Sens. J. 2014. [Google Scholar] [CrossRef]

- Arregui, F.J.; Matias, I.R.; Cooper, K.L.; Claus, R.O. Simultaneous measurement of humidity and temperature by combining a reflective intensity-based optical fiber sensor and a fiber Bragg grating. IEEE Sens. J. 2002, 2, 482–487. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Massaroni, C.; Caponero, M.A.; D’Amato, R.; Lo Presti, D.; Schena, E. Fiber Bragg Grating Measuring System for Simultaneous Monitoring of Temperature and Humidity in Mechanical Ventilation. Sensors 2017, 17, 749. https://doi.org/10.3390/s17040749

Massaroni C, Caponero MA, D’Amato R, Lo Presti D, Schena E. Fiber Bragg Grating Measuring System for Simultaneous Monitoring of Temperature and Humidity in Mechanical Ventilation. Sensors. 2017; 17(4):749. https://doi.org/10.3390/s17040749

Chicago/Turabian StyleMassaroni, Carlo, Michele A. Caponero, Rosaria D’Amato, Daniela Lo Presti, and Emiliano Schena. 2017. "Fiber Bragg Grating Measuring System for Simultaneous Monitoring of Temperature and Humidity in Mechanical Ventilation" Sensors 17, no. 4: 749. https://doi.org/10.3390/s17040749

APA StyleMassaroni, C., Caponero, M. A., D’Amato, R., Lo Presti, D., & Schena, E. (2017). Fiber Bragg Grating Measuring System for Simultaneous Monitoring of Temperature and Humidity in Mechanical Ventilation. Sensors, 17(4), 749. https://doi.org/10.3390/s17040749