New Particle Filter Based on GA for Equipment Remaining Useful Life Prediction

Abstract

:1. Introduction

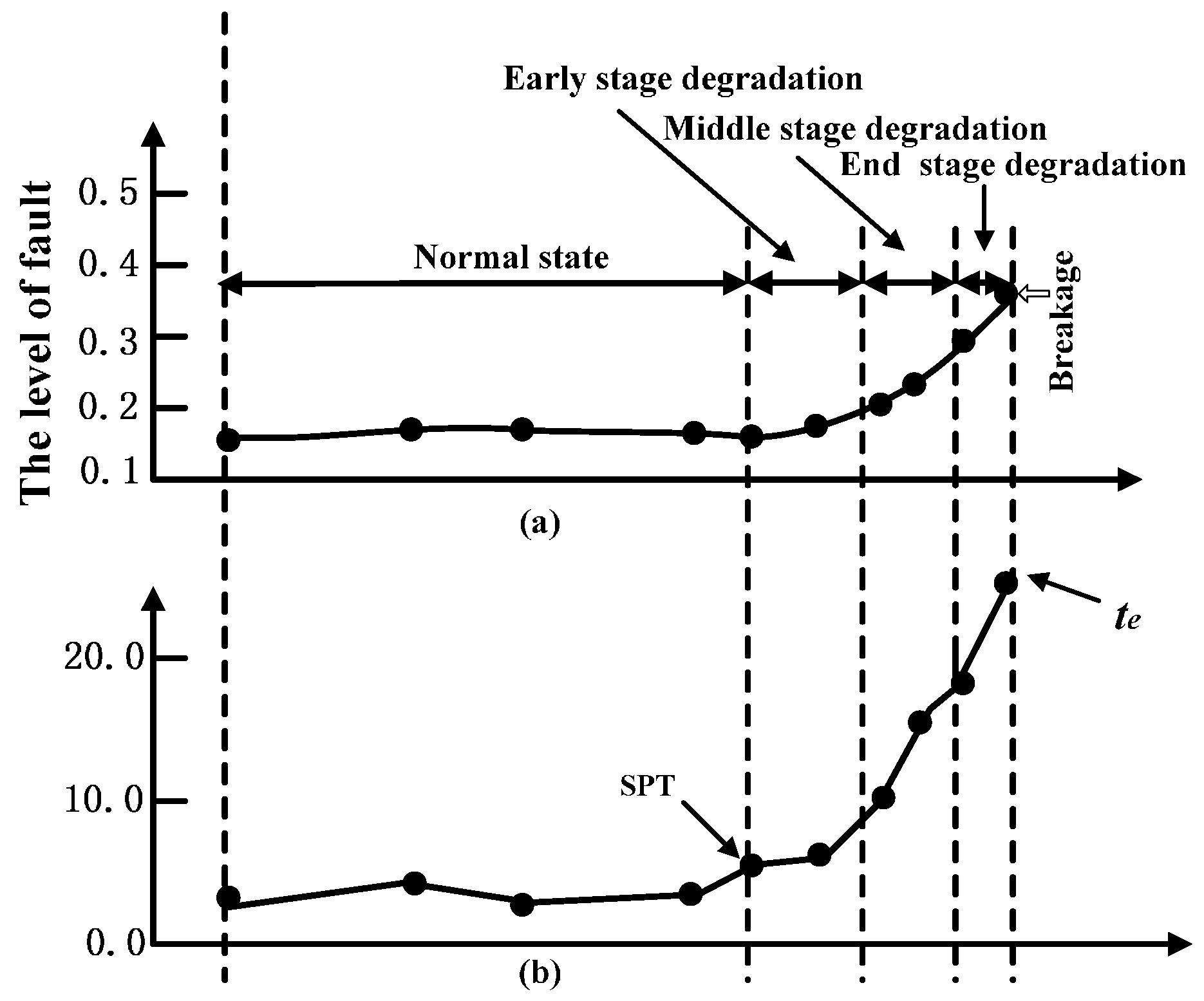

2. Particle Filter

2.1. Basic Theory of PF

2.2. PF Based on GA

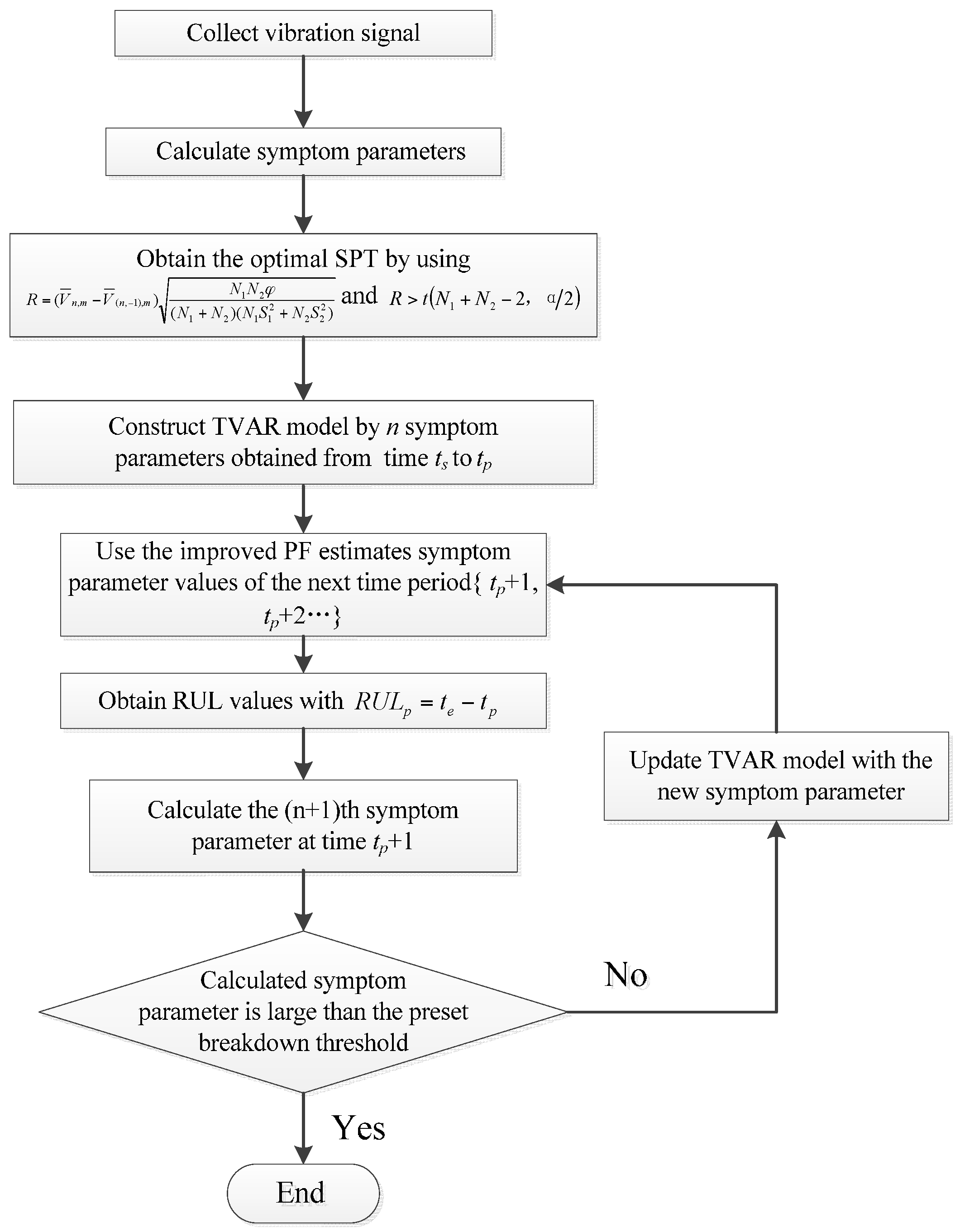

3. RUL Prediction Algorithm

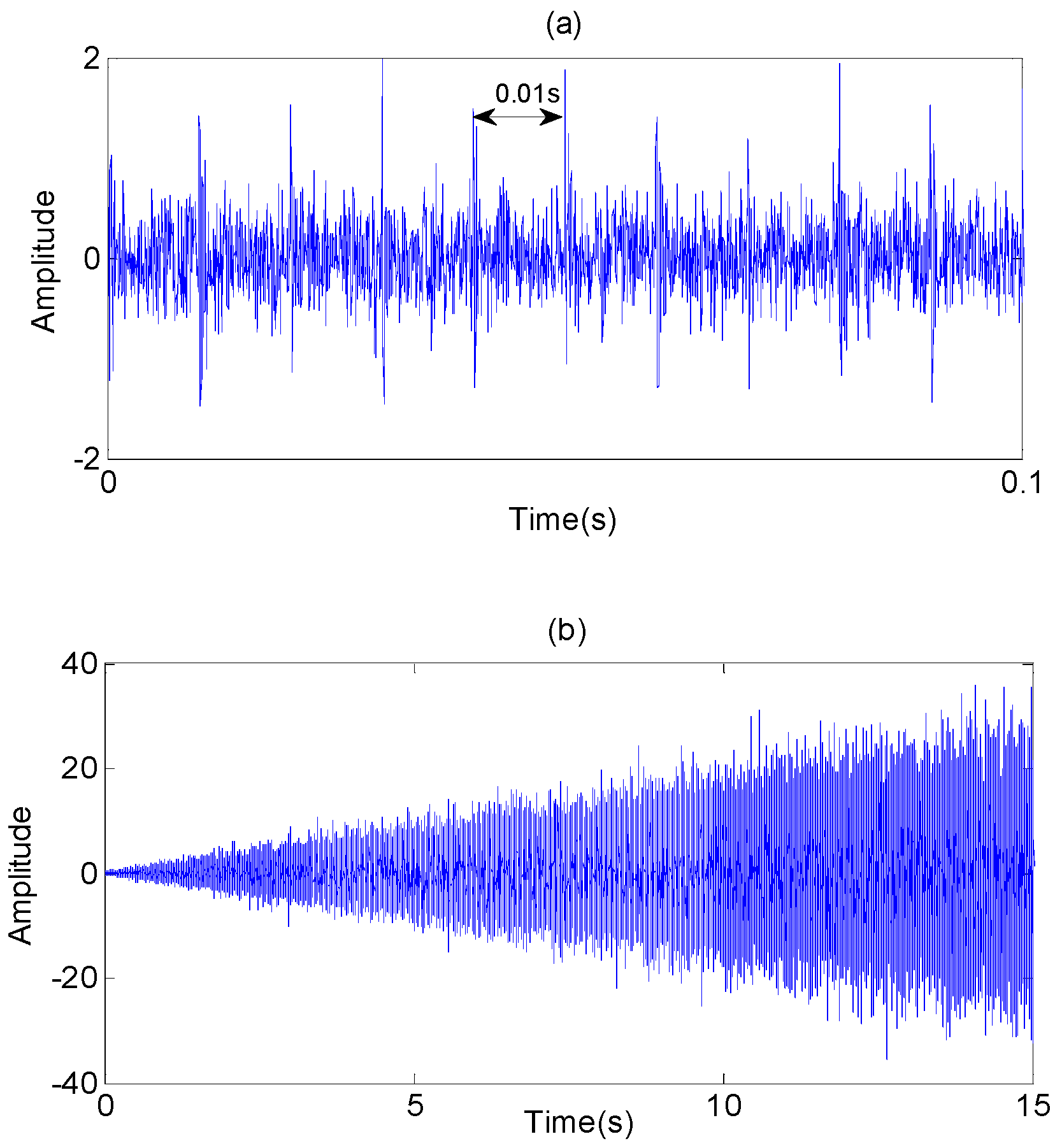

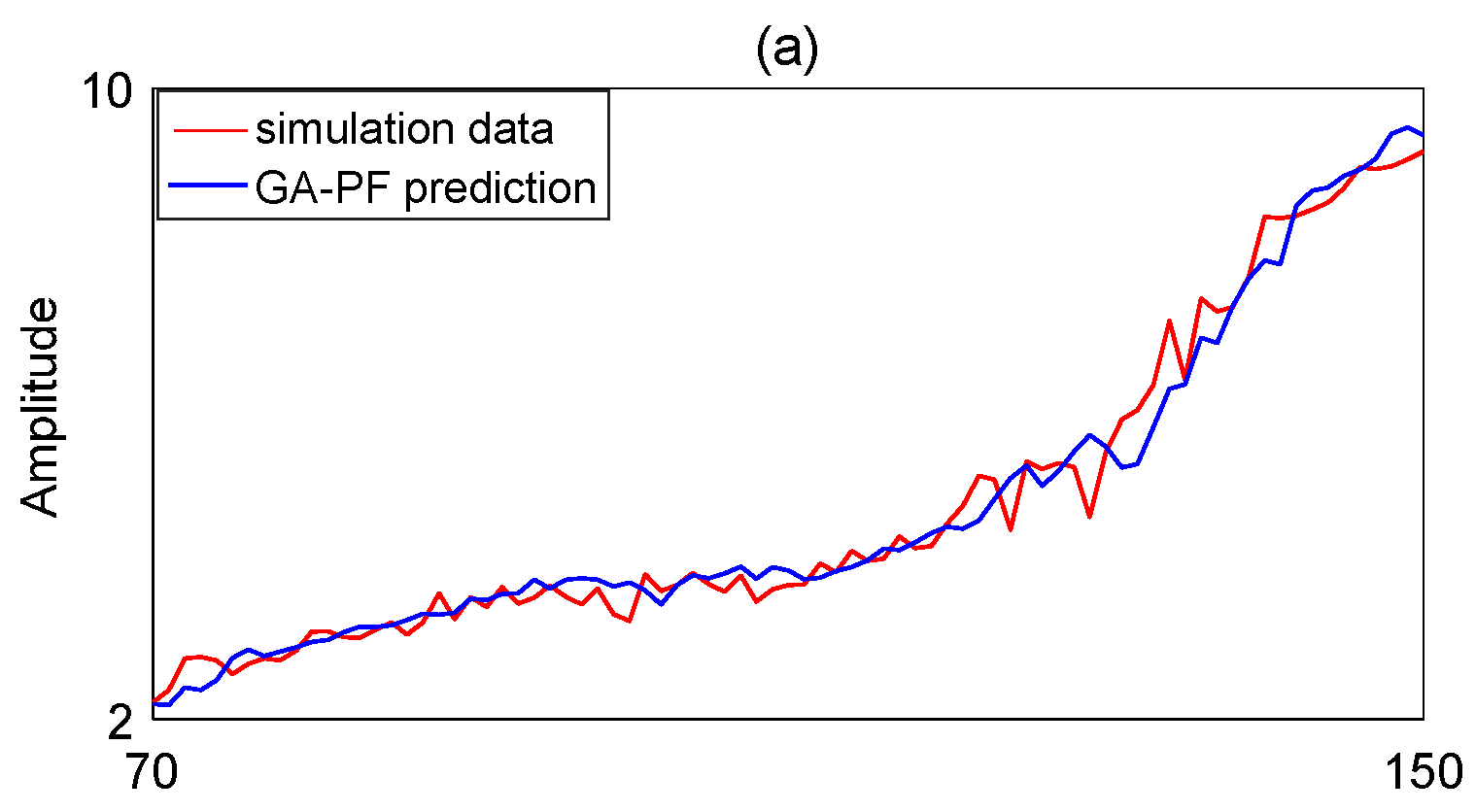

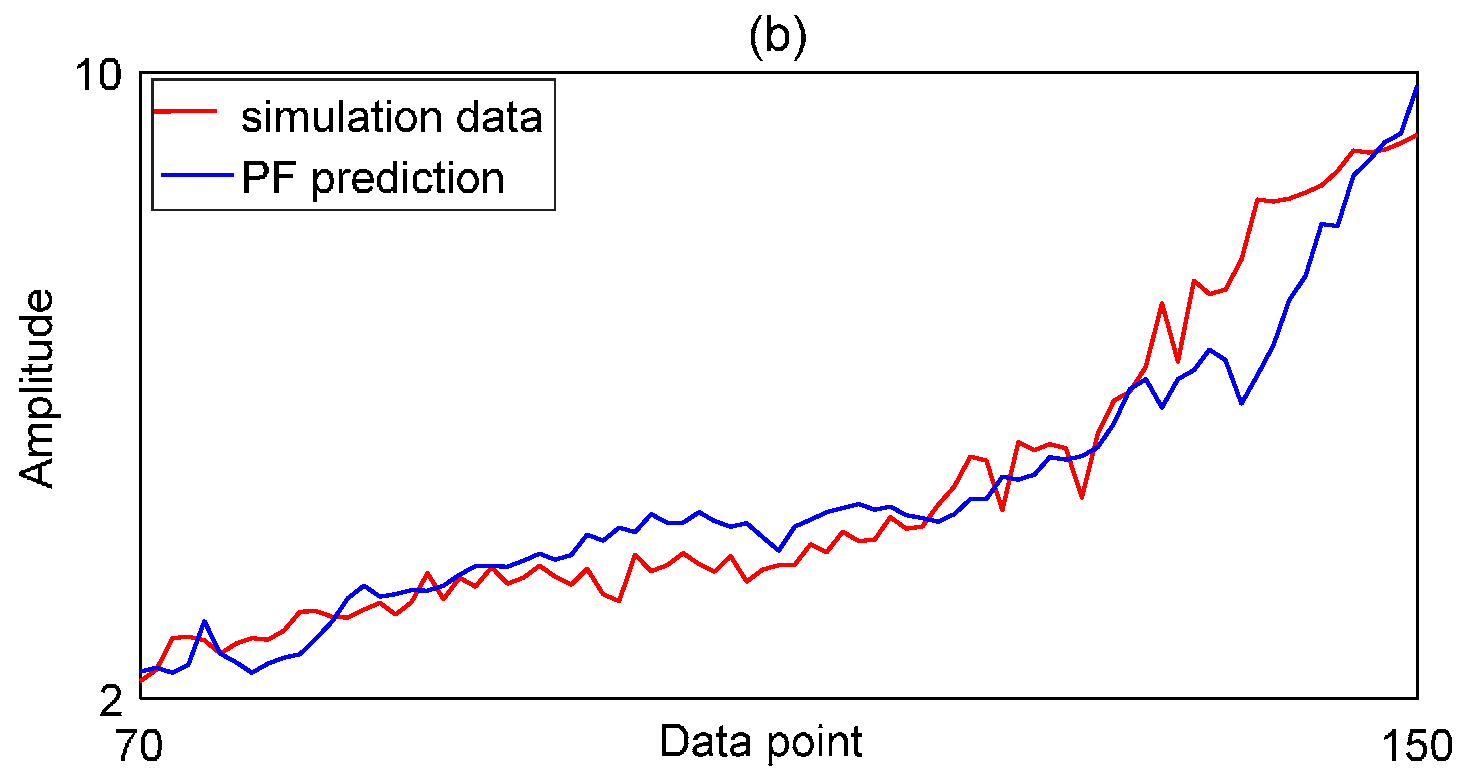

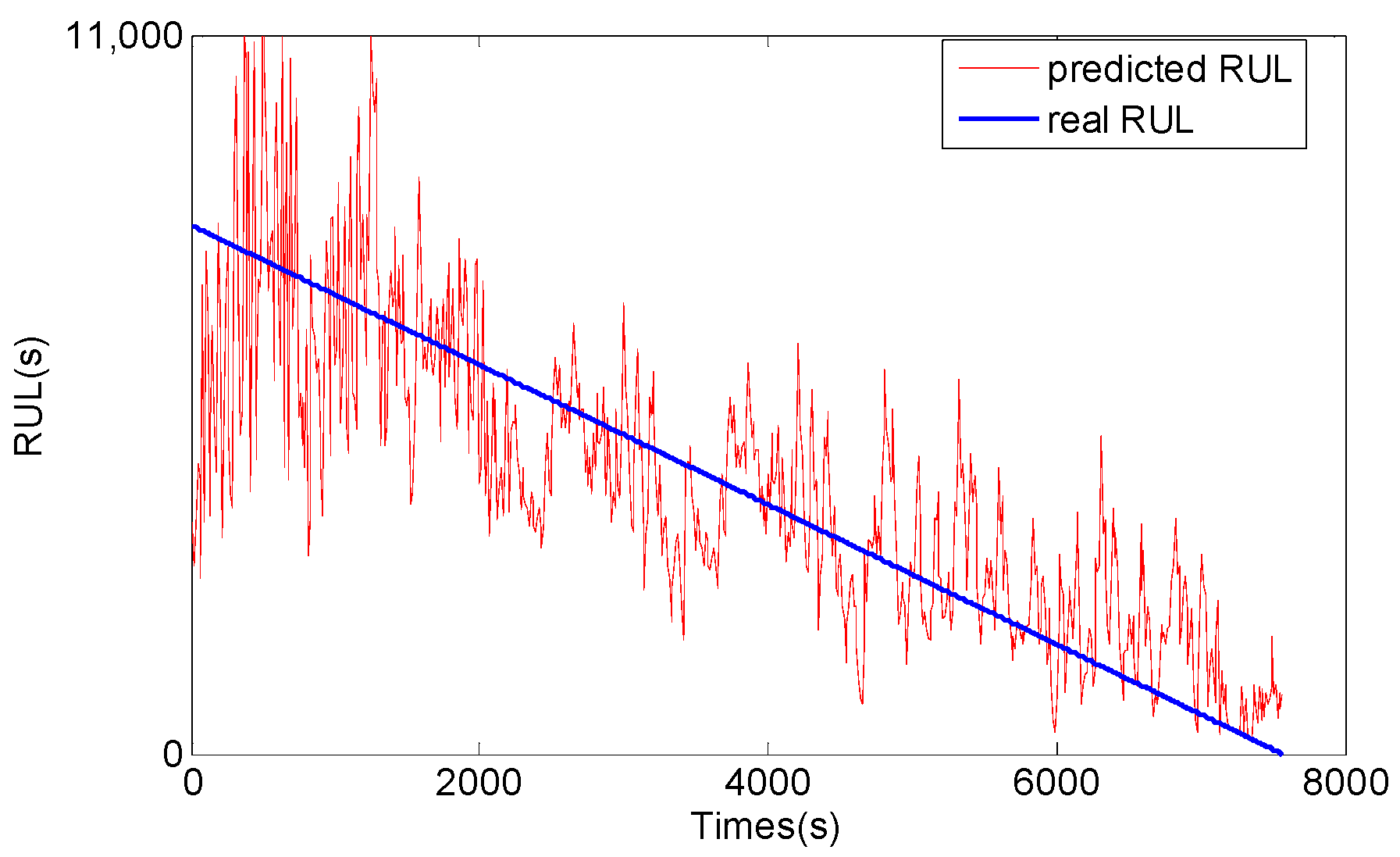

4. Simulation

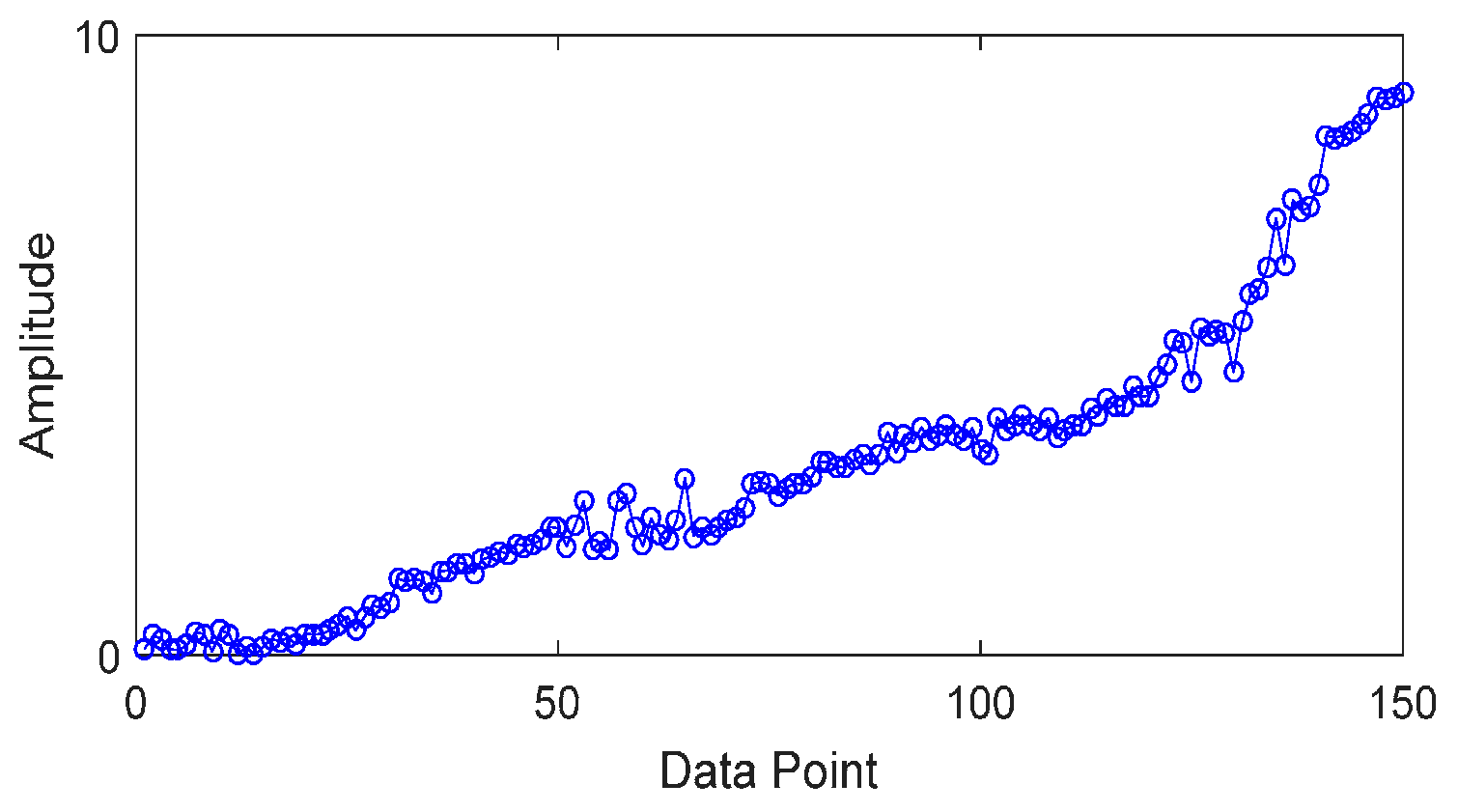

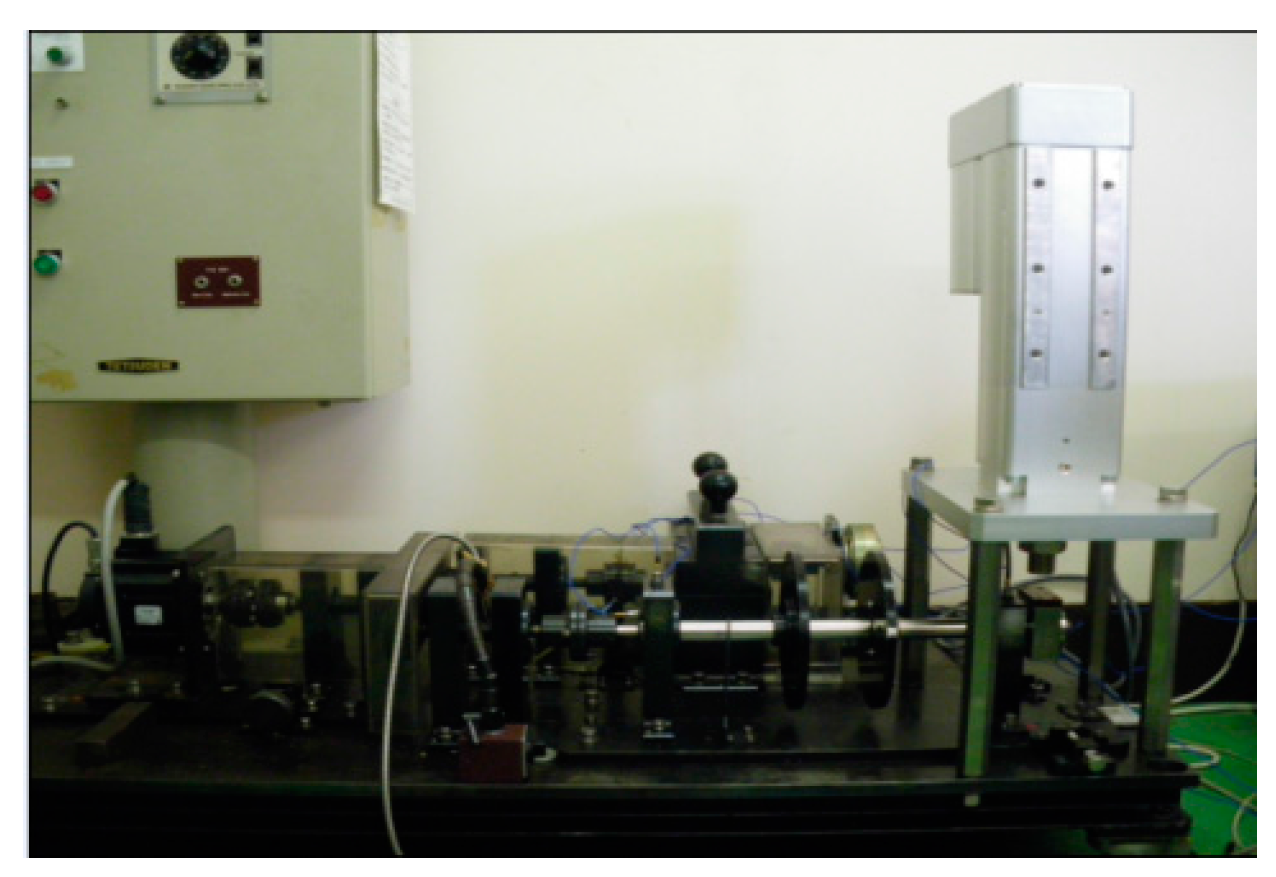

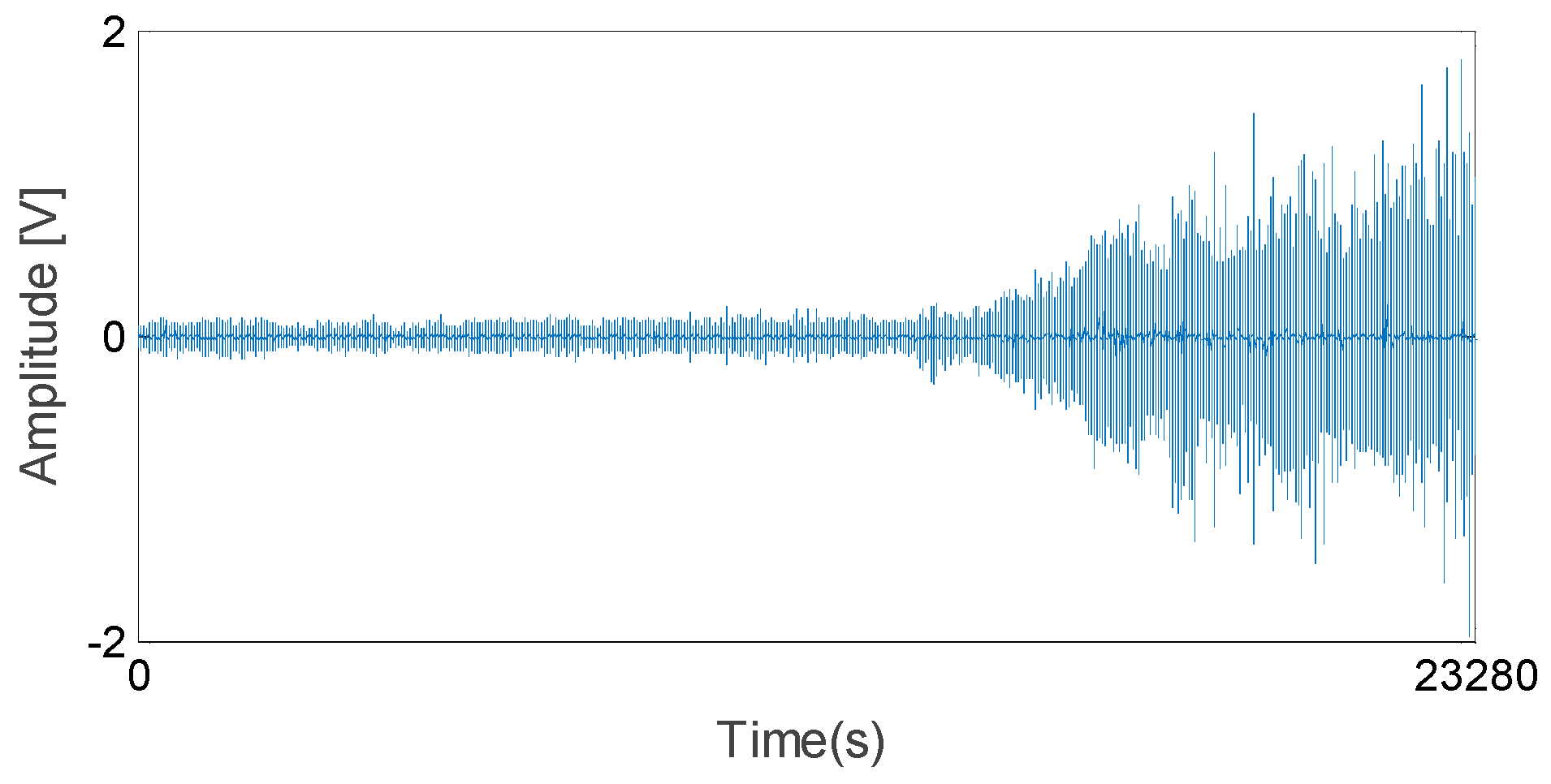

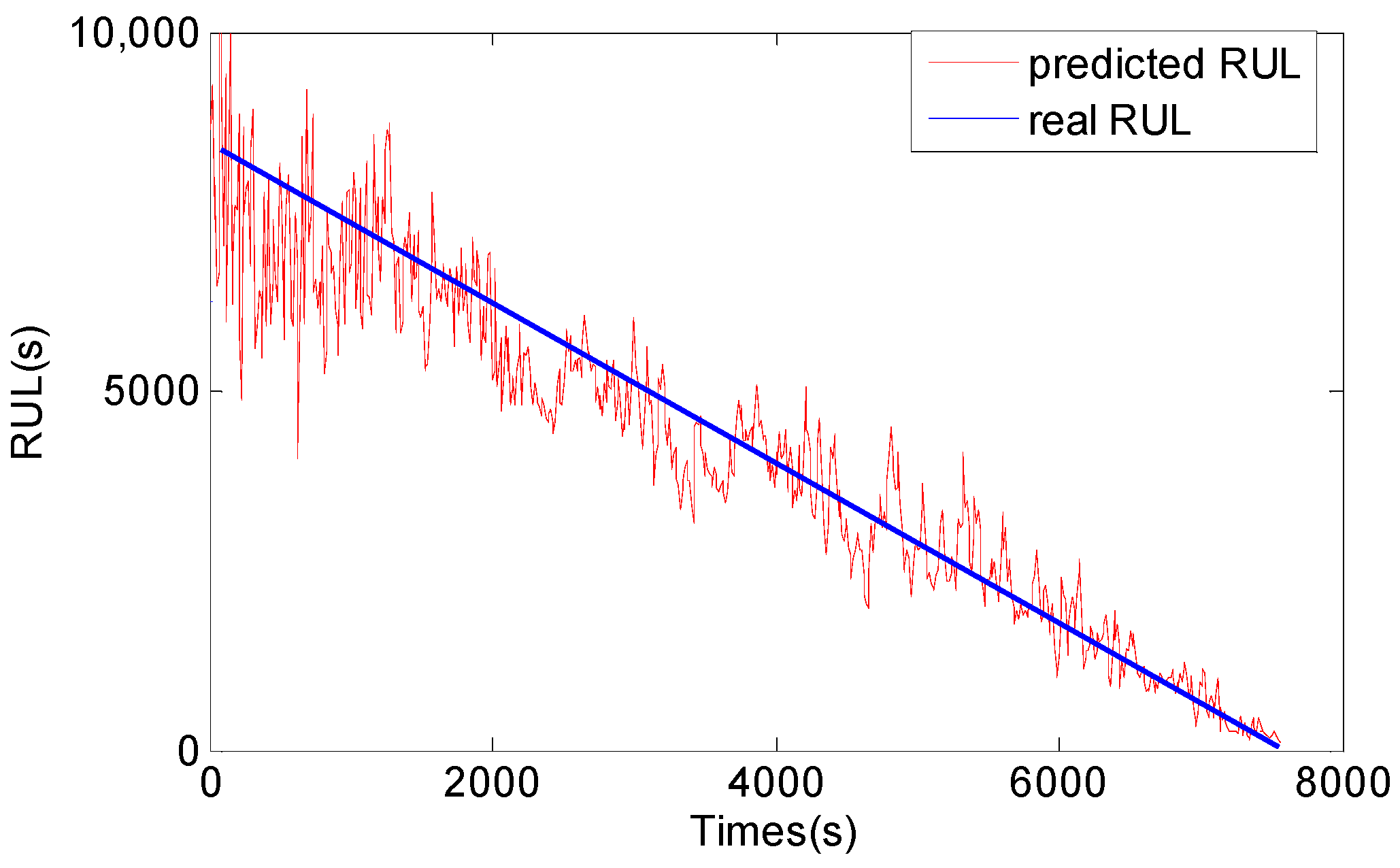

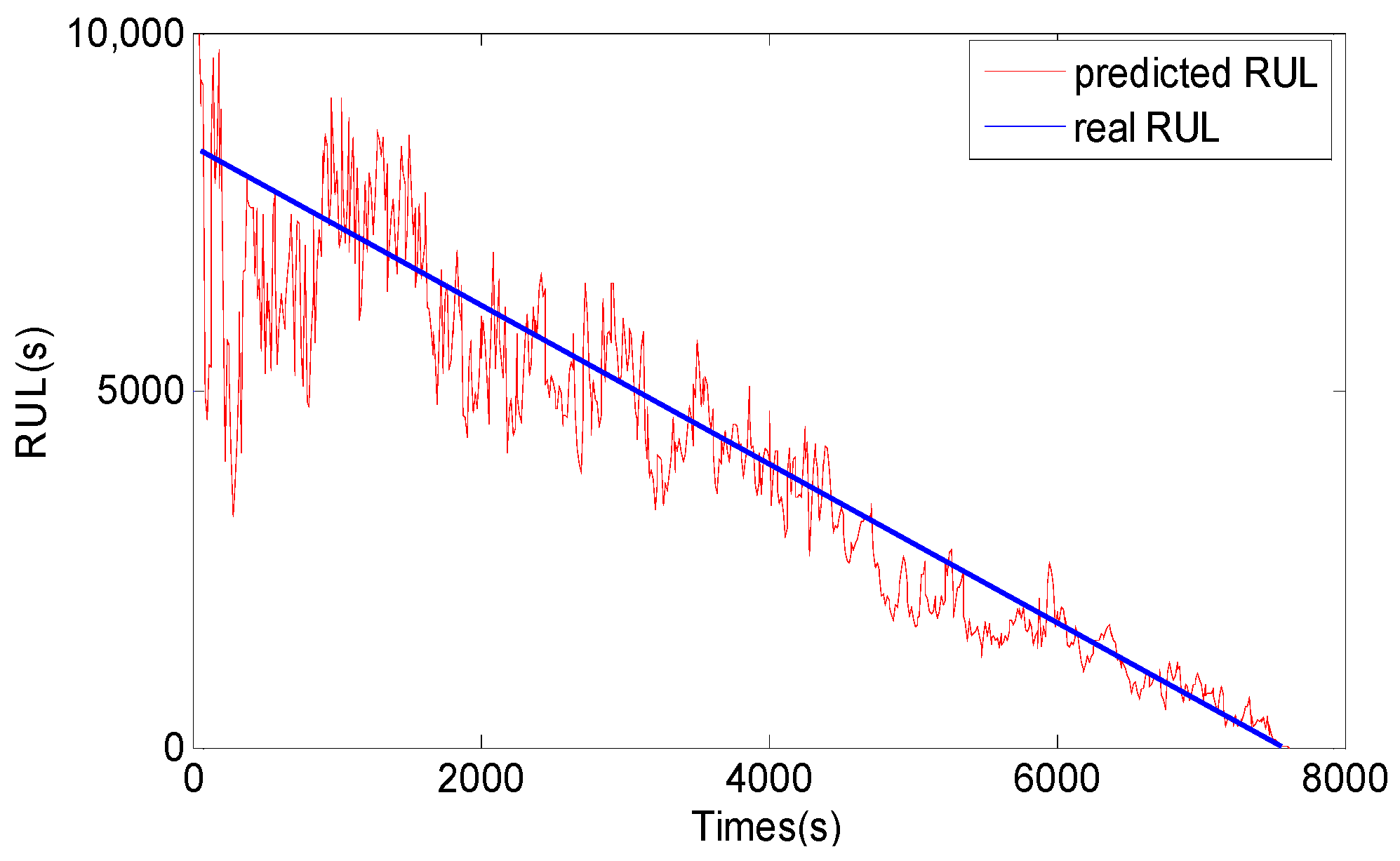

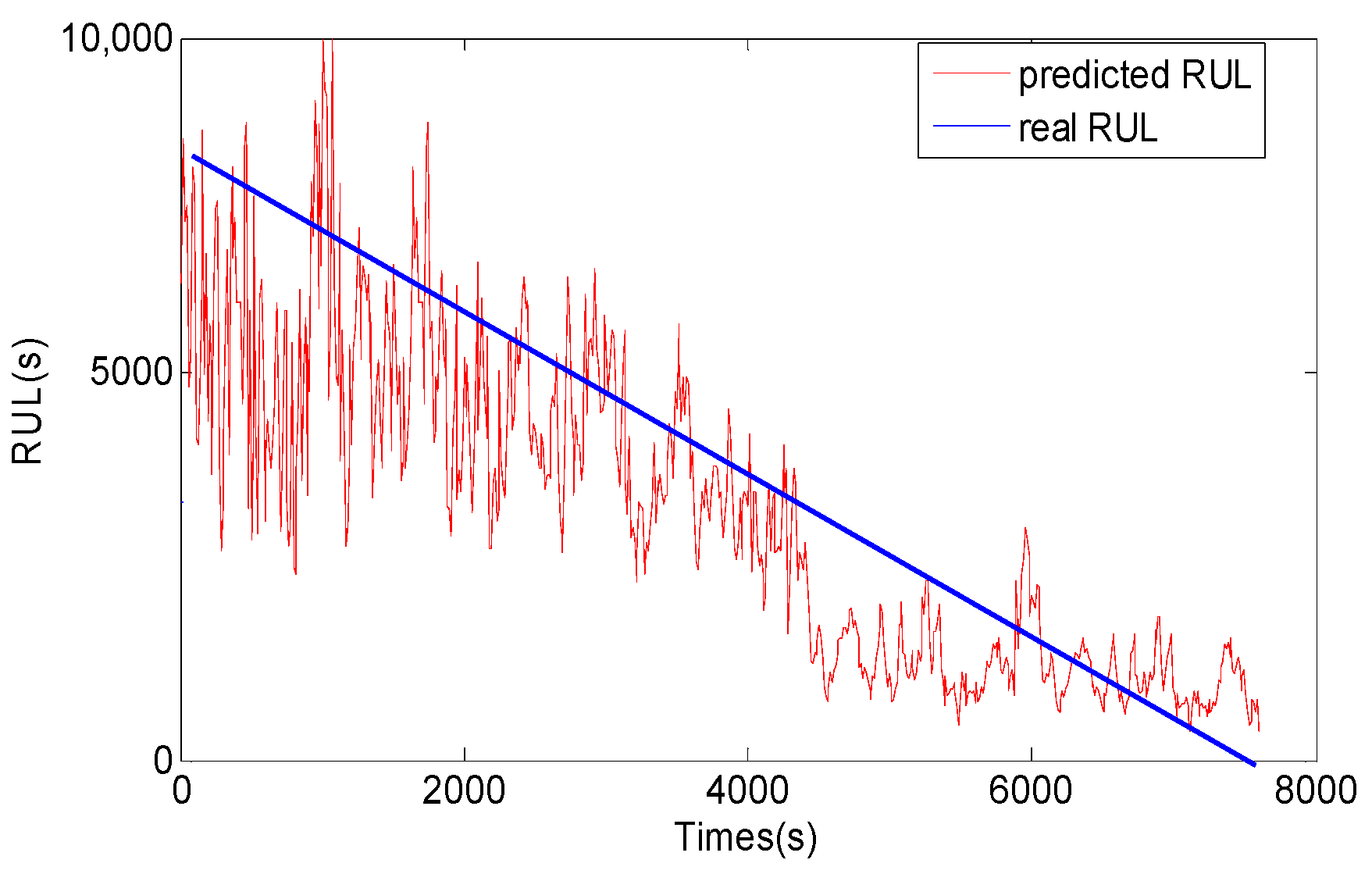

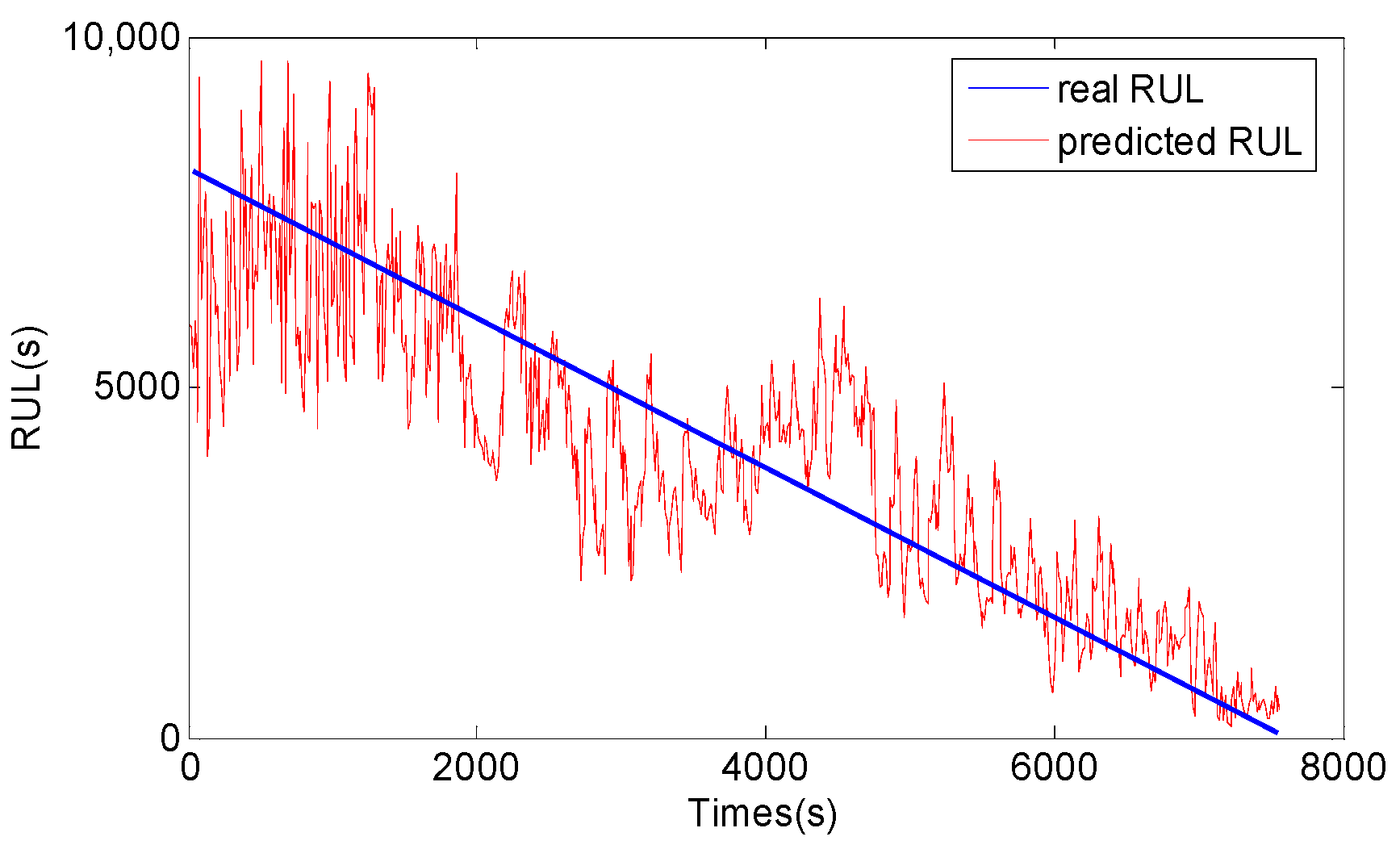

5. Application to RUL of Rolling Element Bearing

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Malhi, A.; Yan, R.; Gao, R.X. Prognosis of defect propagation based on recurrent neural networks. IEEE Trans. Instrum. Meas. 2011, 60, 703–711. [Google Scholar] [CrossRef]

- Qian, Y.; Yan, R.; Hu, S. Bearing degradation evaluation using recurrence quantification analysis and Kalman filter. IEEE Trans. Instrum. Meas. 2014, 63, 2599–2610. [Google Scholar] [CrossRef]

- Li, K.; Chen, P.; Wang, S.M. An Intelligent Diagnosis Method for Rotating Machinery Using Least Squares Mapping and a Fuzzy Neural Network. Sensors 2012, 12, 5919–5939. [Google Scholar] [CrossRef] [PubMed]

- Liao, L.X. Discovering prognostic features using genetic programmingin remaining useful life prediction. IEEE Trans. Ind. Electron. 2014, 61, 2464–2472. [Google Scholar] [CrossRef]

- Oppenheimer, C.H.; Loparo, K.A. Physically based diagnosis and prognosis of cracked rotor shafts. Proc. SPIE 2002, 4733, 122–132. [Google Scholar]

- Choi, Y.; Liu, C.R. Spall progression life model for rolling contact verified by finish hard machined surfaces. Wear 2007, 262, 24–35. [Google Scholar] [CrossRef]

- Chen, B.; Chen, X.; Li, B.; Cai, G. Reliability estimation for cutting tool based on Logistic Regression Model. Chin. J. Mech. Eng. 2011, 47, 158–164. [Google Scholar] [CrossRef]

- Nakai, M.E.; Aguiar, P.R.; Junior, H.G.; Bianchi, E.C.; Spatti, D.; D’Addona, D.M. Evaluation of Neural Models Applied to the Estimation of Tool Wear in the Grinding of Advanced Ceramics. Expert Syst. Appl. 2015, 42, 7026–7035. [Google Scholar] [CrossRef]

- D’Addona, D.M.; Matarazzo, D.; Ullah, A.M.M.S.; Teti, R. Tool wear control through cognitive paradigms. Procedia CIRP 2015, 33, 221–226. [Google Scholar] [CrossRef]

- Dong, M.; He, D. A segmental hidden semi-Markov model (HSMM)-based diagnostics and prognostics framework and methodology. Mech. Syst. Signal Process. 2007, 21, 2248–2266. [Google Scholar] [CrossRef]

- Chen, C.C.; Zhang, B.; Vachtsevanos, G.; Orchard, M.E. Machine condition prediction based on adaptive neuro-fuzzy and high-order particle filtering. IEEE Trans. Ind. Electron. 2011, 58, 4353–4364. [Google Scholar] [CrossRef]

- Maio, F.D.; Tsui, K.L.; Zio, E. Combining relevance vector machines and exponential regression for bearing residual life estimation. Mech. Syst. Signal Process. 2012, 31, 405–427. [Google Scholar] [CrossRef]

- Chen, X.; Shen, Z.; He, Z.; Sun, C.; Liu, Z. Remaining life prognostics of rolling bearing based on relative features and multivariable support vector machine. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2013, 227, 2849–2860. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, B.; Vachtsevanos, G. Prediction of machine health condition using Neuro-fuzzy and Bayesian algorithms. IEEE Trans. Instrum. Meas. 2012, 61, 297–306. [Google Scholar] [CrossRef]

- Orchard, M.E.; Vachtsevanos, G.J. A particle-filtering approach foron-line fault diagnosis and failure prognosis. Trans. Inst. Meas. Control 2009, 31, 221–246. [Google Scholar] [CrossRef]

- Orchard, M.E.; Hevia-Koch, P.; Zhang, B.; Tang, L. Risk measures for particle-filtering-based state-of-charge prognosis in lithium-ion batteries. IEEE Trans. Ind. Electron. 2013, 60, 5260–5269. [Google Scholar] [CrossRef]

- Abbas, M.; Ferri, A.; Orchard, M.E.; Vachtsevanos, G. An intelligent diagnostic/prognostic framework for automotive electrical systems. In Proceedings of the IEEE Intelligent Vehicle Symposium, Istanbul, Turkey, 13–15 June 2007; pp. 352–357. [Google Scholar]

- Zhang, H.B. Dynamic Auto-regression Prediction Model Based on Particle Filter. Electr. Sci. Technol. 2016, 15–18. [Google Scholar]

- Liu, Y.; Sun, D.Q.; Kong, L. Rao-blackwellized particle filtering for fault detection and diagnosis. In Proceedings of the 29th Chinese Control Conference, Beijing, China, 29–31 July 2010; pp. 29–31. [Google Scholar]

- Doucet, A.; de Freitas, N.; Neil, G. Sequential Monte-Carlo Methods in Practice; Springer: New York, NY, USA, 2001. [Google Scholar]

- Douc, R.; Cappé, O. Comparison of resampling schemes for particle filtering. In Proceedings of the 4th Intelligence Symposium on Image Signal Processing and Analysis, Zagreb, Croatia, 15–17 September 2005; pp. 64–69. [Google Scholar]

- Arulampalam, M.S.; Maskell, S.; Gordon, N.; Clapp, T. A tutorial on particle filters for online nonlinear/non-Gaussian Bayesian tracking. IEEE Trans. Signal Process. 2002, 50, 174–188. [Google Scholar] [CrossRef]

- Yoon, Y.; Kim, Y. An efficient genetic algorithm for maximum coverage deployment in wireless sensor networks. IEEE Trans. Cybern. 2013, 43, 1473–1483. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Koide, Y.; Li, K.; Satonaga, N. Life Prediction of Rolling Bearing Using Genetic Algorithm. Appl. Mech. Mater. 2011, 58–60, 2423–2427. [Google Scholar] [CrossRef]

- Fei, W.C.; Bai, L. Time-varying parameter auto-regressive models for autocovariance nonstationary time series. Sci. China Ser. A Math. 2009, 52, 577–584. [Google Scholar] [CrossRef]

- Liu, Y.; He, B.; Liu, F.; Lu, S.; Zhao, Y. Feature fusion using kernel joint approximate diagonalization of eigen-matrices for rolling bearing fault identification. J. Sound Vib. 2016, 385, 389–401. [Google Scholar] [CrossRef]

| Particle Number | RMSE | Available Particle | Time | |

|---|---|---|---|---|

| General PF | 500 | 0.7852 | 127 | 0.456 |

| 1000 | 0.3126 | 205 | 1.139 | |

| 2000 | 0.2816 | 276 | 3.013 | |

| 500 | 0.3092 | 215 | 0.541 | |

| GA-PF | 1000 | 0.1865 | 413 | 1.232 |

| 2000 | 0.1772 | 501 | 3.251 |

| SP | Method | RMSE | MRE | VRE | Available Particle |

|---|---|---|---|---|---|

| RMS | SVM | 4.78 | 0.63 | 4.75 | |

| RMS | General PF | 4.57 | 0.58 | 1.75 | 233 |

| RMS | GA-PF | 2.21 | 0.18 | 0.13 | 452 |

| Peak value | SVM | 7.15 | 1.07 | 9.86 | |

| Peak value | General PF | 6.58 | 0.92 | 3.11 | 216 |

| Peak value | GA-PF | 3.19 | 0.25 | 0.05 | 437 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Wu, J.; Zhang, Q.; Su, L.; Chen, P. New Particle Filter Based on GA for Equipment Remaining Useful Life Prediction. Sensors 2017, 17, 696. https://doi.org/10.3390/s17040696

Li K, Wu J, Zhang Q, Su L, Chen P. New Particle Filter Based on GA for Equipment Remaining Useful Life Prediction. Sensors. 2017; 17(4):696. https://doi.org/10.3390/s17040696

Chicago/Turabian StyleLi, Ke, Jingjing Wu, Qiuju Zhang, Lei Su, and Peng Chen. 2017. "New Particle Filter Based on GA for Equipment Remaining Useful Life Prediction" Sensors 17, no. 4: 696. https://doi.org/10.3390/s17040696

APA StyleLi, K., Wu, J., Zhang, Q., Su, L., & Chen, P. (2017). New Particle Filter Based on GA for Equipment Remaining Useful Life Prediction. Sensors, 17(4), 696. https://doi.org/10.3390/s17040696