An Electricity Price-Aware Open-Source Smart Socket for the Internet of Energy

Abstract

:1. Introduction

- It presents what to our knowledge is the first smart plug that manages in a real-world scenario the price values obtained from a public electricity operator to determine the time intervals with the lowest prices.

- One of the few open-source smart plug systems described in the literature is detailed.

- A novel wireless sensor network communications protocol based on Wi-Fi is presented that allows for creating an easy-to-deploy system that self-organizes and autoconfigures to minimize user intervention.

2. Related Work

2.1. Academic Developments

2.2. Commercial Systems

2.3. Analysis of the State-Of-The-Art

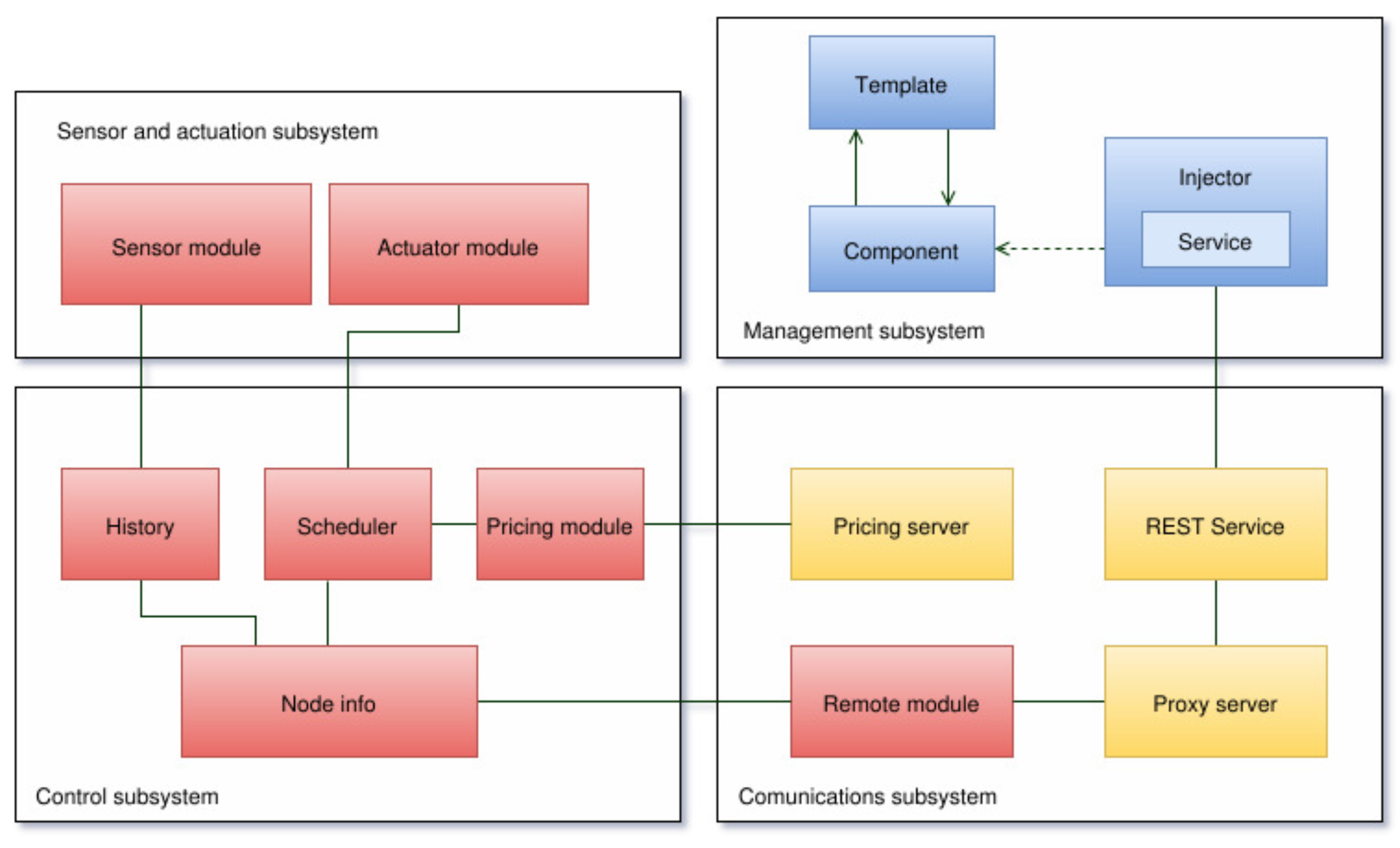

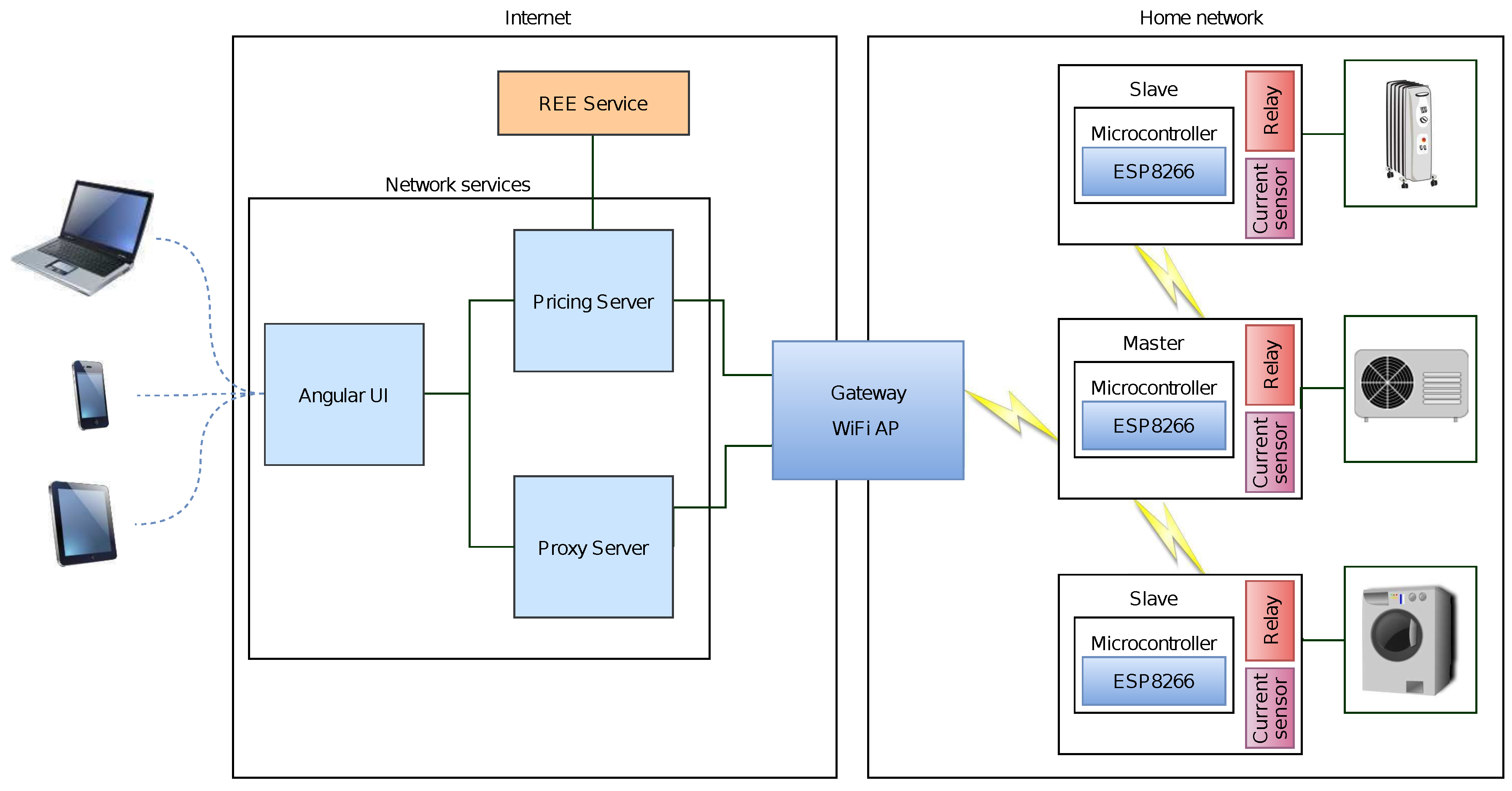

3. Design of the System

- Sensor and actuation subsystem: This controls the sensors and actuators of the system. Such elements consist mainly of a current sensor and a relay. The subsystem is responsible for collecting current data and for activating the power outlet when it receives a request from the control subsystem.

- Communications subsystem: This consists of wireless transceivers that join an auto-configurable star topology.

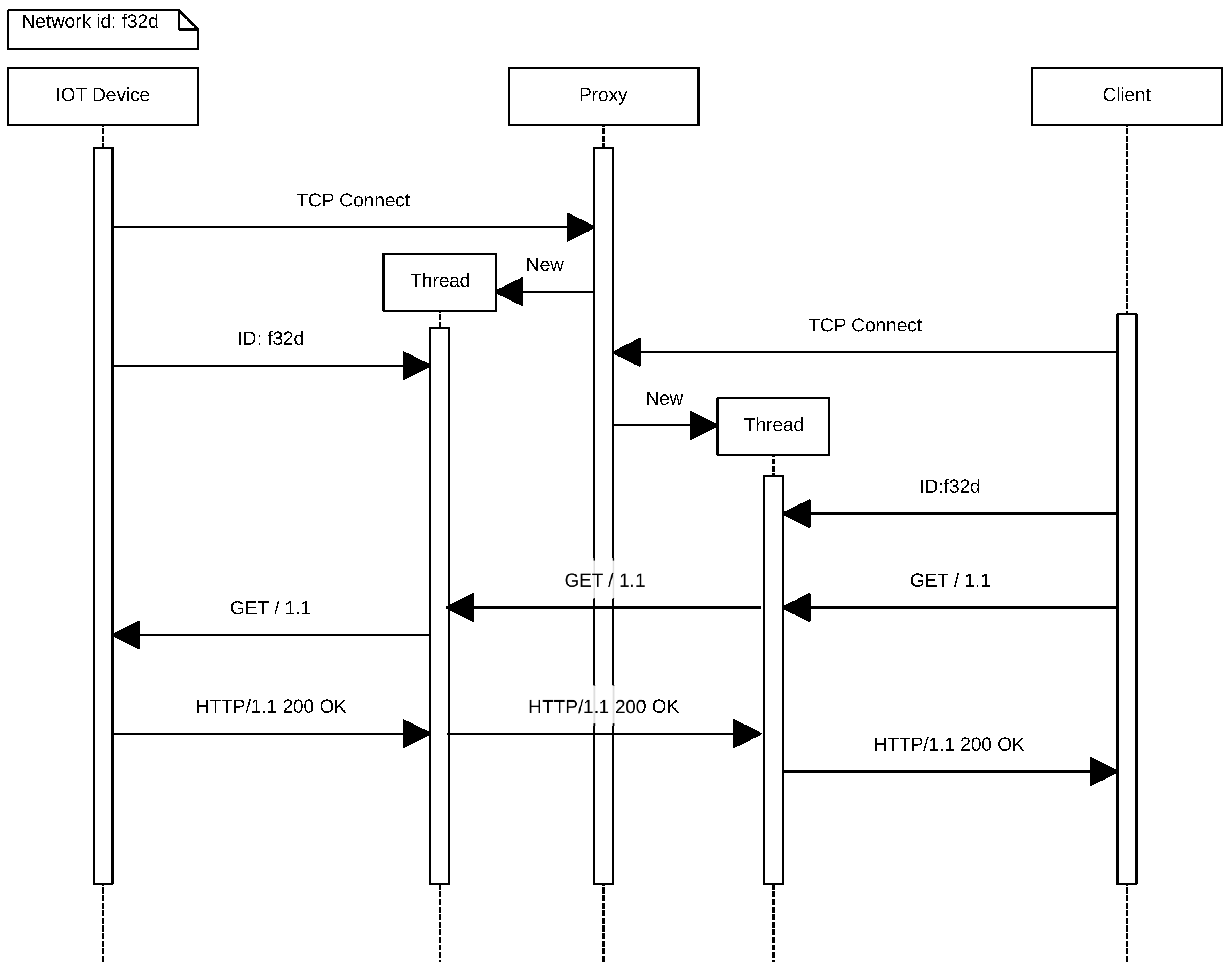

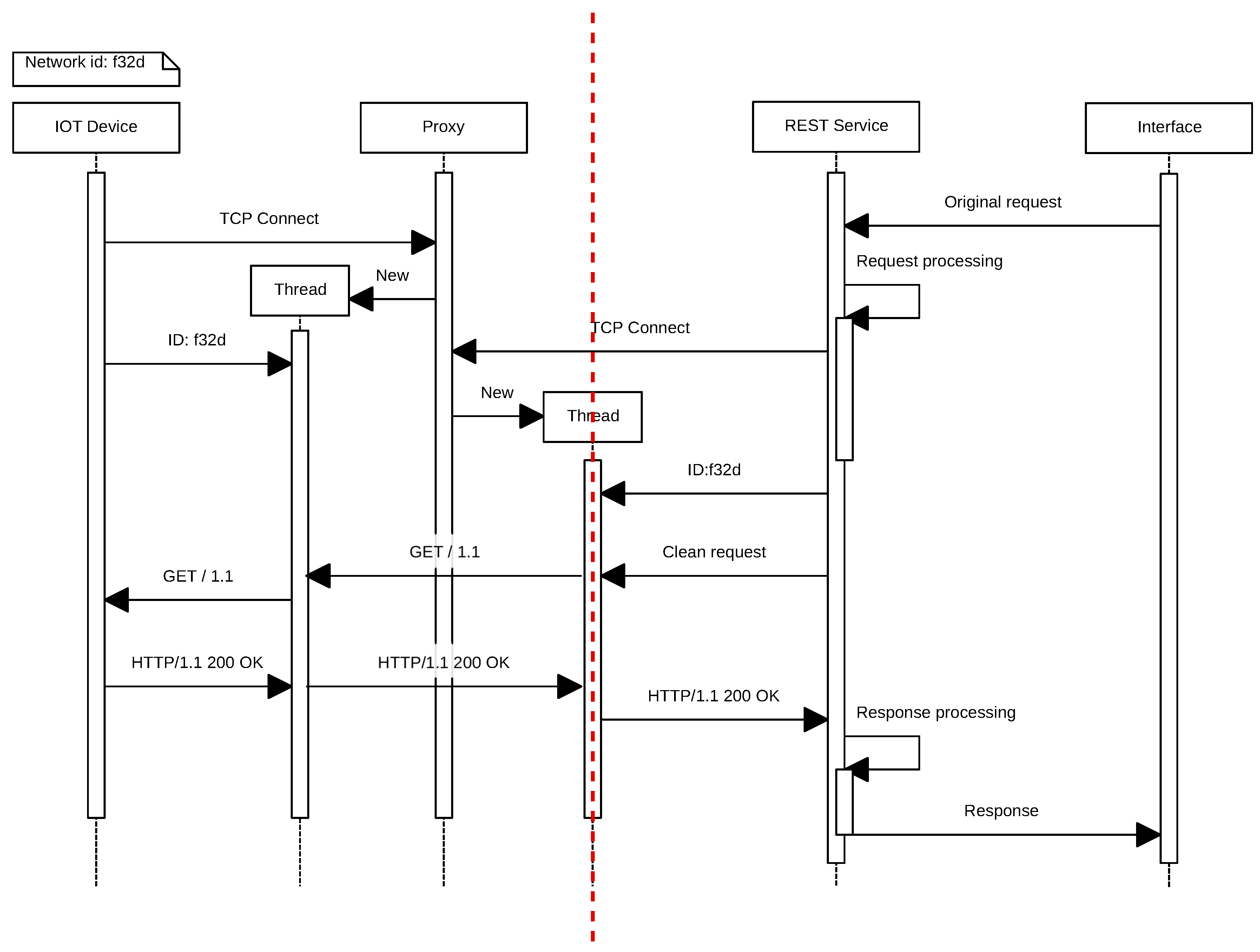

- Management subsystem: This provides the user with the possibility of obtaining the current status of all modules, modifying their configuration and acting directly on them remotely through a web interface. In addition, this subsystem also includes a Representational State Transfer (REST) API that is responsible for transforming and redirecting the requests and responses between the clients and the corresponding device network through a proxy server.

- Control subsystem: This is in charge of controlling and managing the remaining subsystems, registering all existing nodes in the network, processing the data through the appropriate scheduling algorithms in each case and sending the necessary information to each of the modules. In addition, it acts as the gateway of the network to connect to the Internet, and therefore, it is the entry point to the network for the management subsystem.

3.1. Electricity Pricing in Spain

3.2. PVPC Bill Calculation

- The annual power billing FPU is calculated as the product of the power consumed ( expressed in kW) and the price of the power for the PVPC (, expressed in euros/KW and year), according to the following equation:

- The active energy billing term for the corresponding billing period, , is the result of multiplying the energy consumed during the billing period in each tariff period and the price of the corresponding energy term according to the following formulas: In the case of using an smart meter, the formula corresponds to:where:

- –

- is the energy consumed during the billing period p (in kWh).

- –

- is the energy consumed during the hour h of the billing period p (expressed in kWh).

- –

- represents the price of the energy term of the PVPC of the billing period p (in euros/kWh).

- –

- is the term of the hourly cost of energy of PVPC for each hour h (in euros/kWh).

Without a smart meter, the formula corresponds to:where is the hourly coefficient of the adjusted consumption profile. Every week, REE calculates and publishes the coefficients for the following week. - The conditions established for the application of the reactive energy billing term, as well as the obligations related to it, are established in regulation RD 1164/2001 of 26 October 2001 and determine the access tariff for the electricity transmission and for the distribution networks.

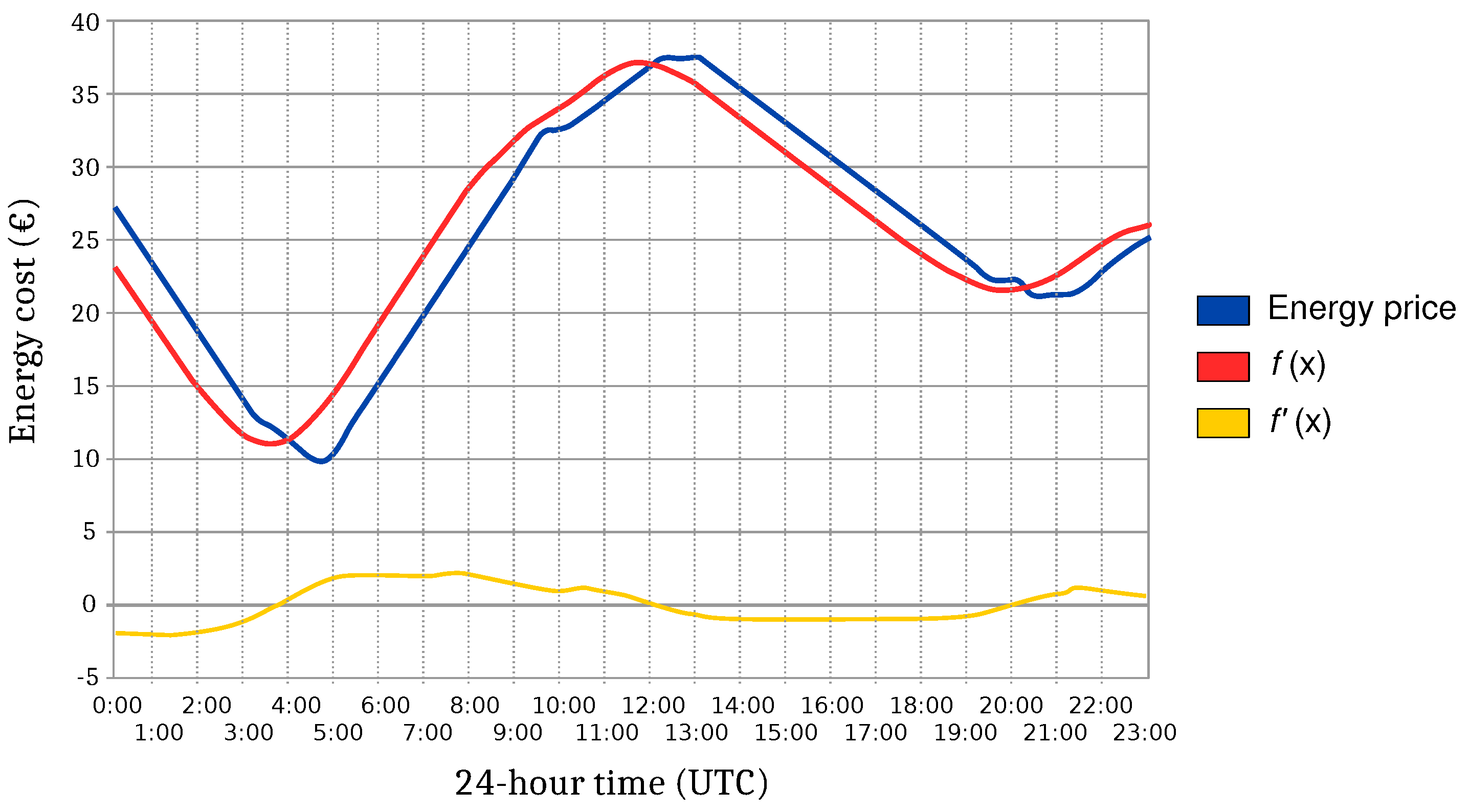

3.3. Minimizing FEU

4. Communications Protocol and Architecture

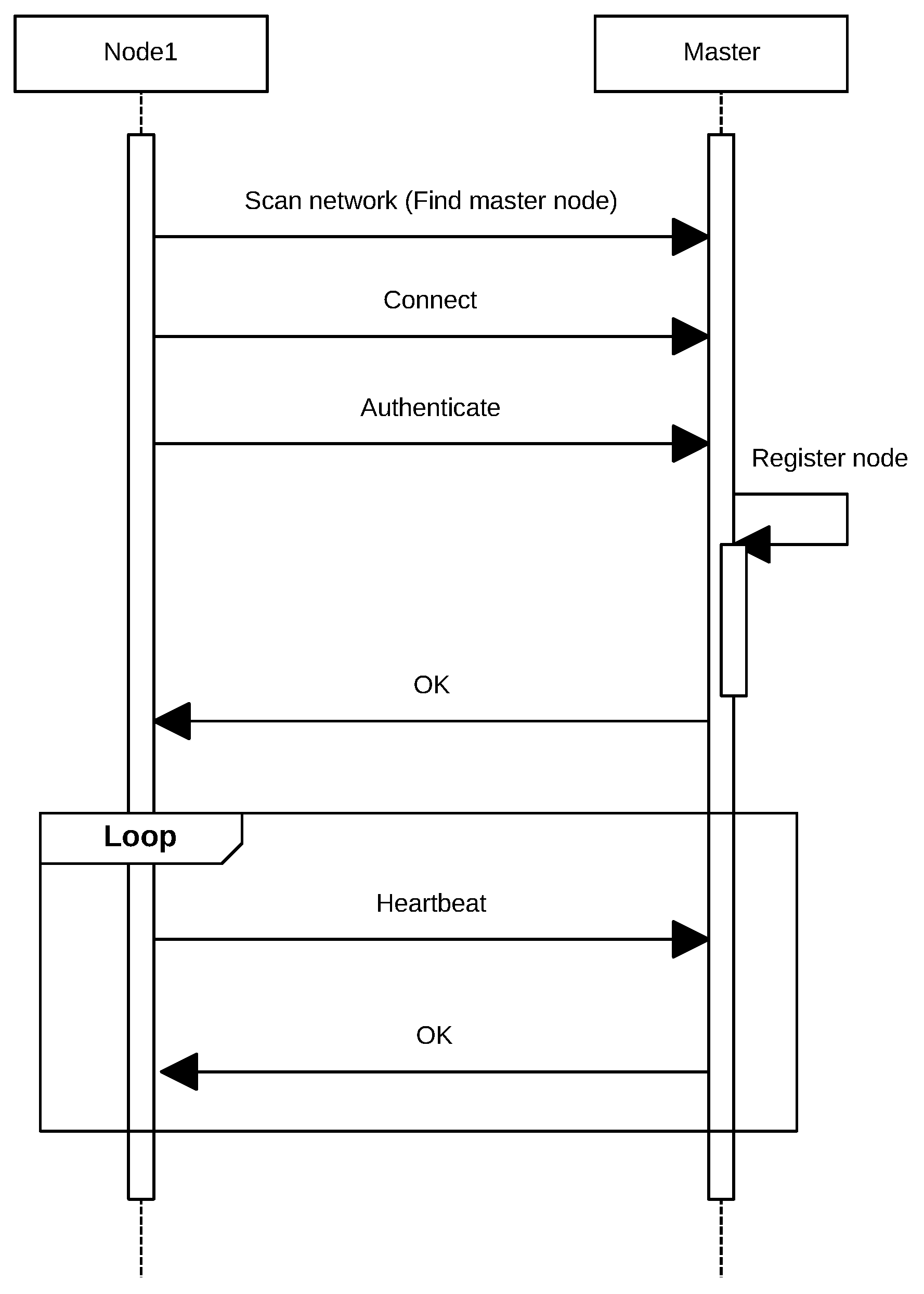

4.1. IoT Network

4.1.1. Keeping the Node List Updated

4.1.2. Clock Synchronization

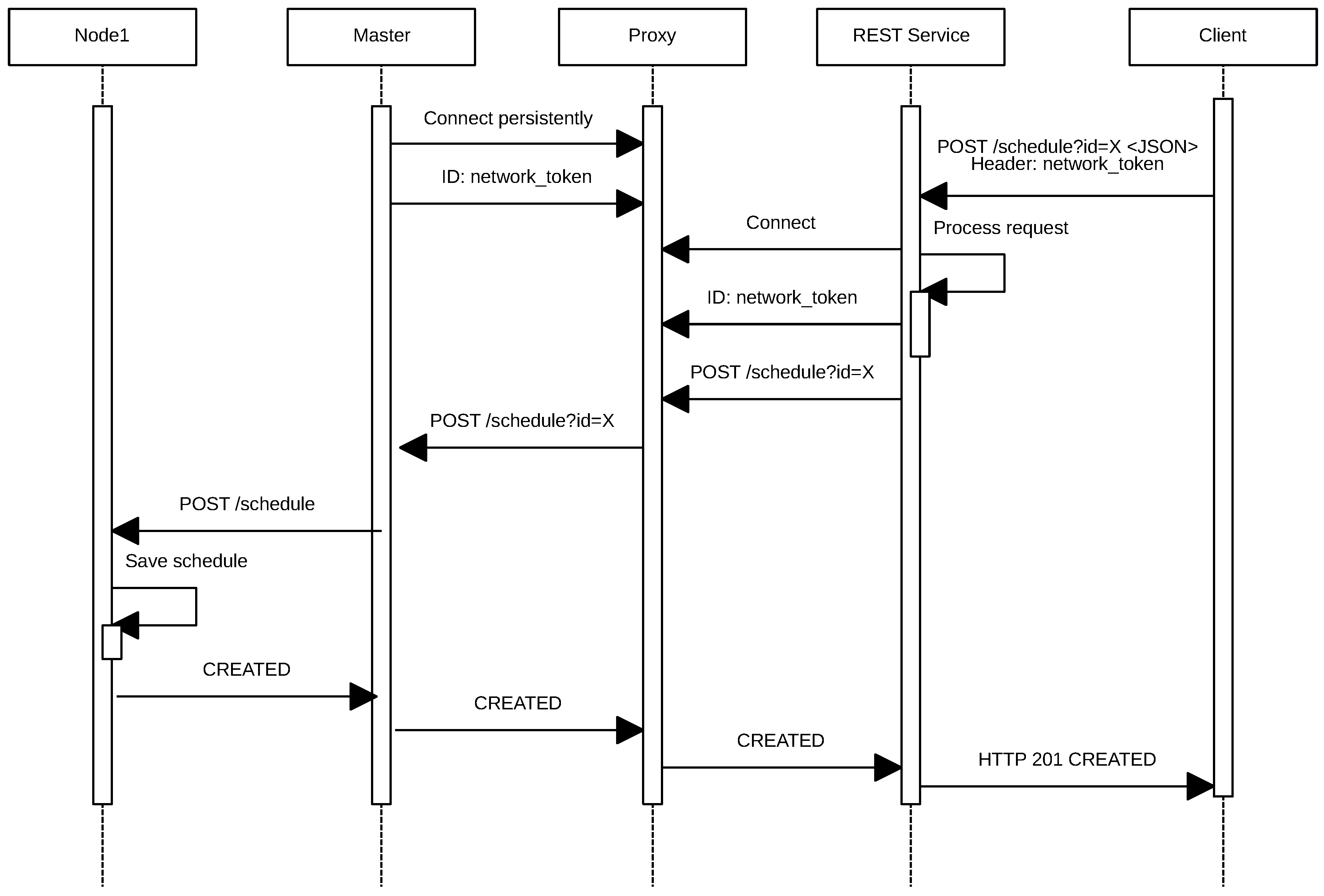

4.2. External Network

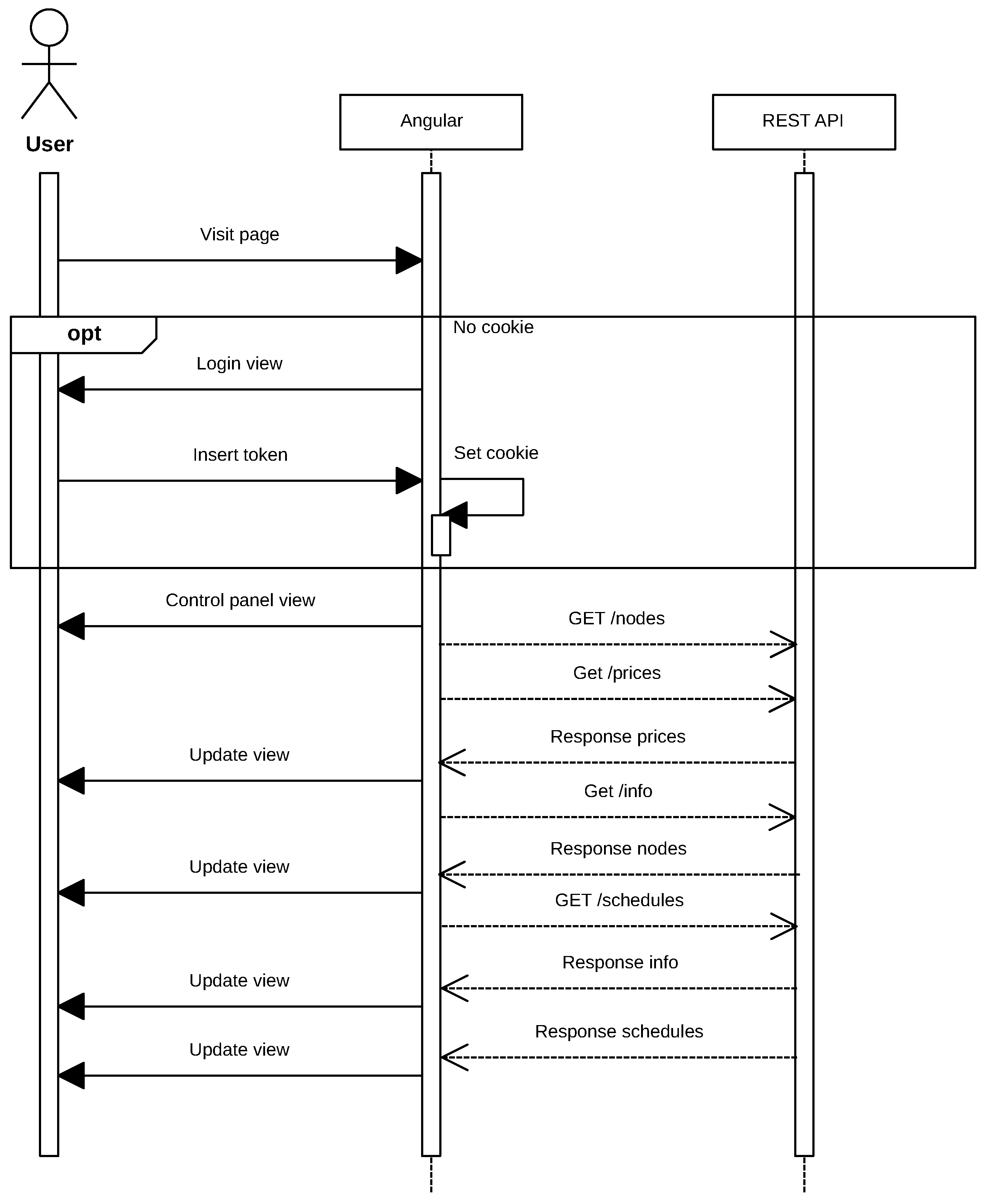

4.3. REST Web Service

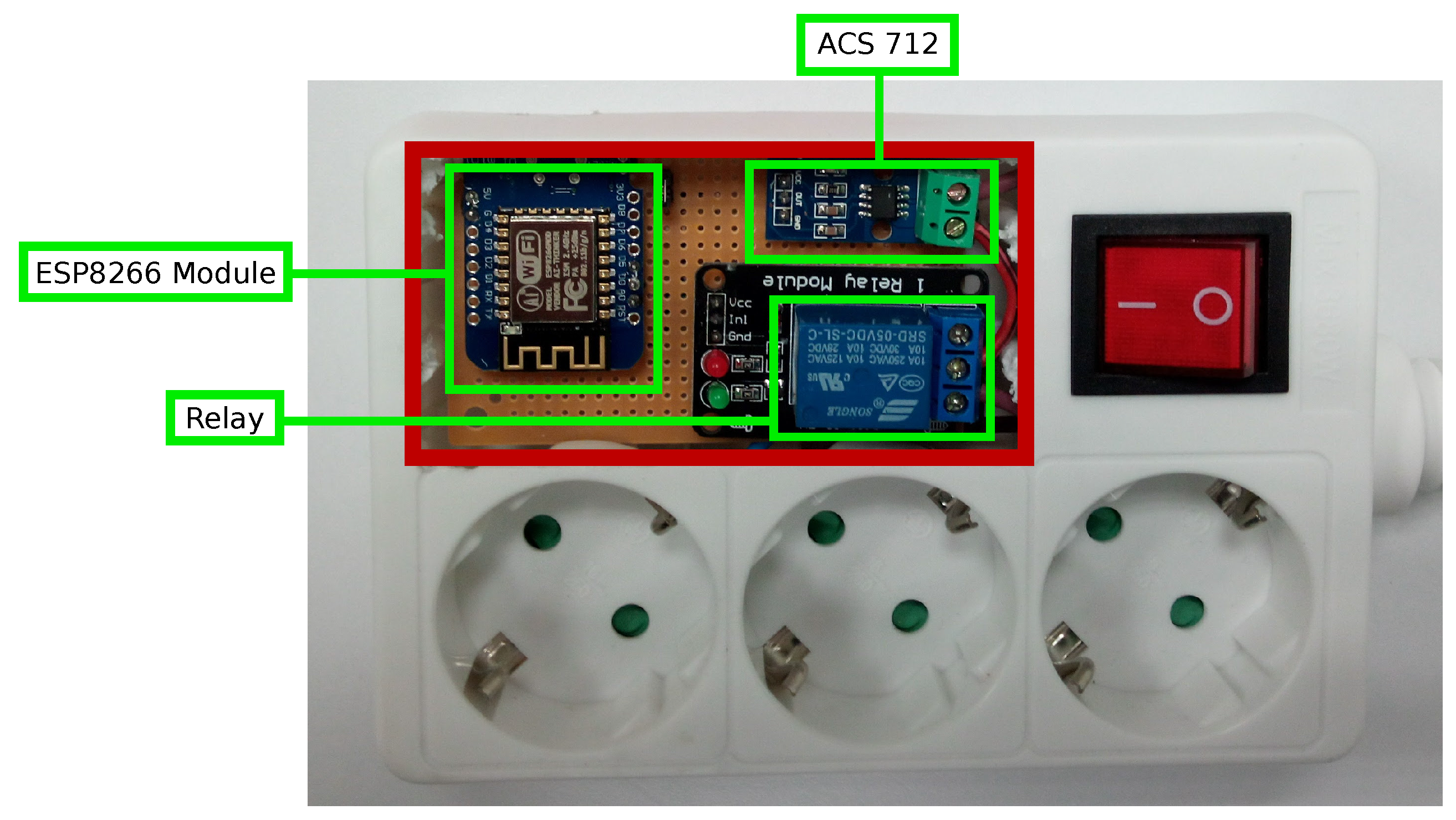

5. Components of the System

5.1. Sensor and Actuation Subsystem

5.1.1. Current Sensor

5.1.2. Relay

5.2. Control and Communications Subsystem

5.3. System Integration

6. Implementation

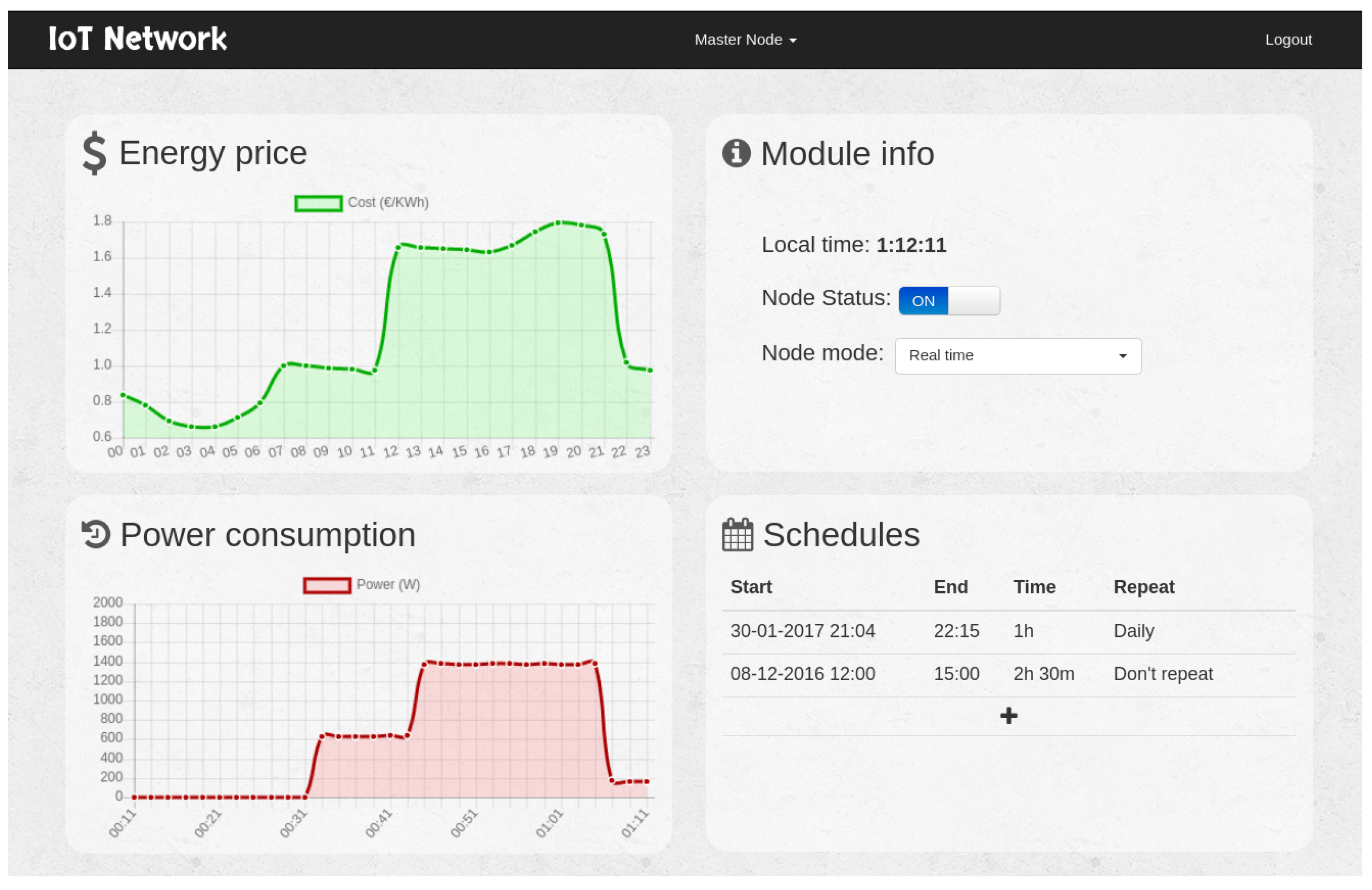

6.1. Implemented Functionality

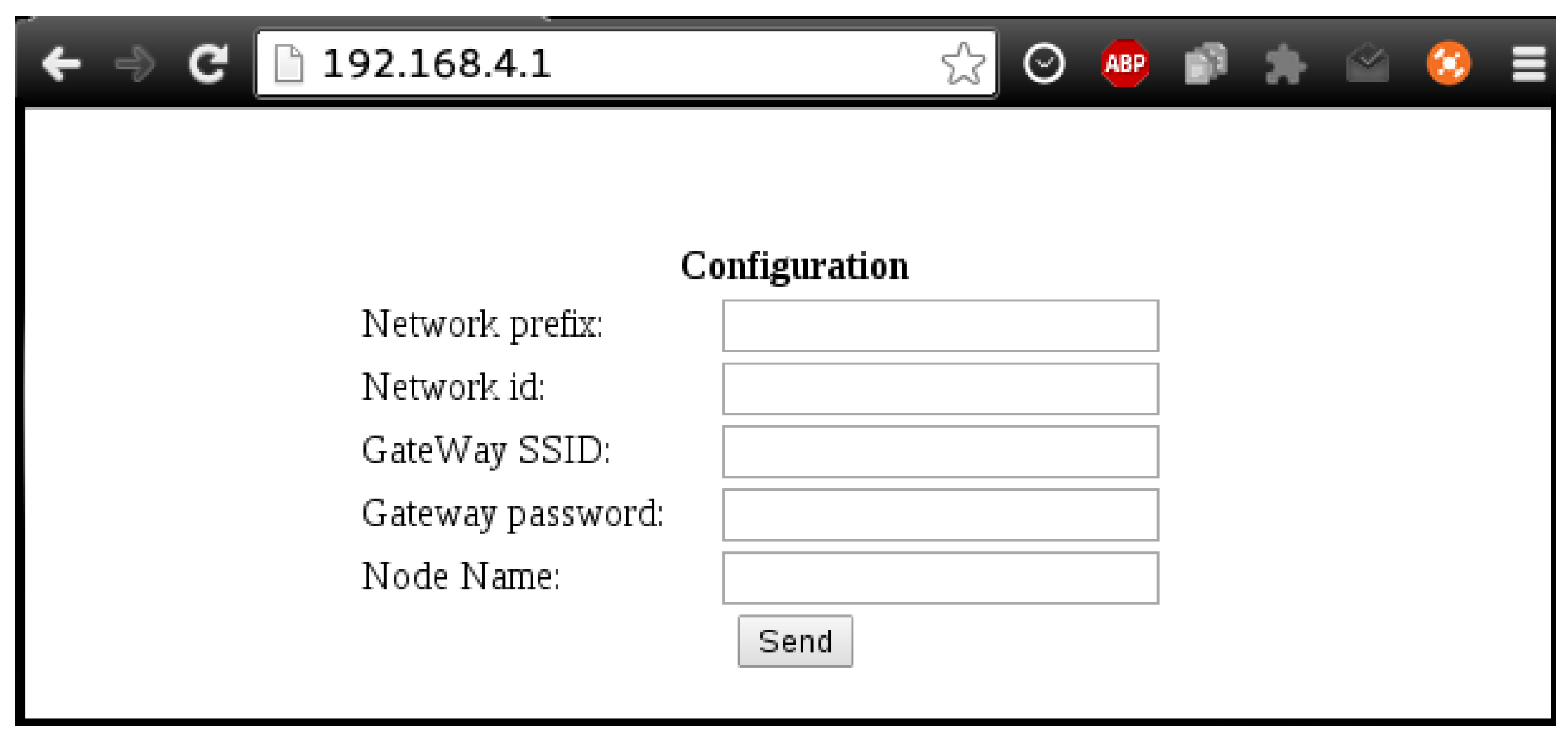

- It allows for the configuration of each individual module in order to modify the network parameters or to add new nodes to an already existing network.

- Once a node is added to a specific network, such a network is able to self-reconfigure and self-manage automatically with the objective of providing network communications to the added node.

- It obtains automatically and on a daily basis the electricity price by using the REE API. The system also shows in real time the cost of the energy.

- The system is able to switch on and off every node of the IoT network in real time. It also shows the state of every power outlet in the network.

- The user can visualize remotely the historical energy consumption values of every IoT node.

- A user can change remotely the operation mode (i.e., manual or intelligent operation) of each power outlet. In intelligent mode, the system automatically switches on and off a node according to the time intervals that minimize the electricity cost.

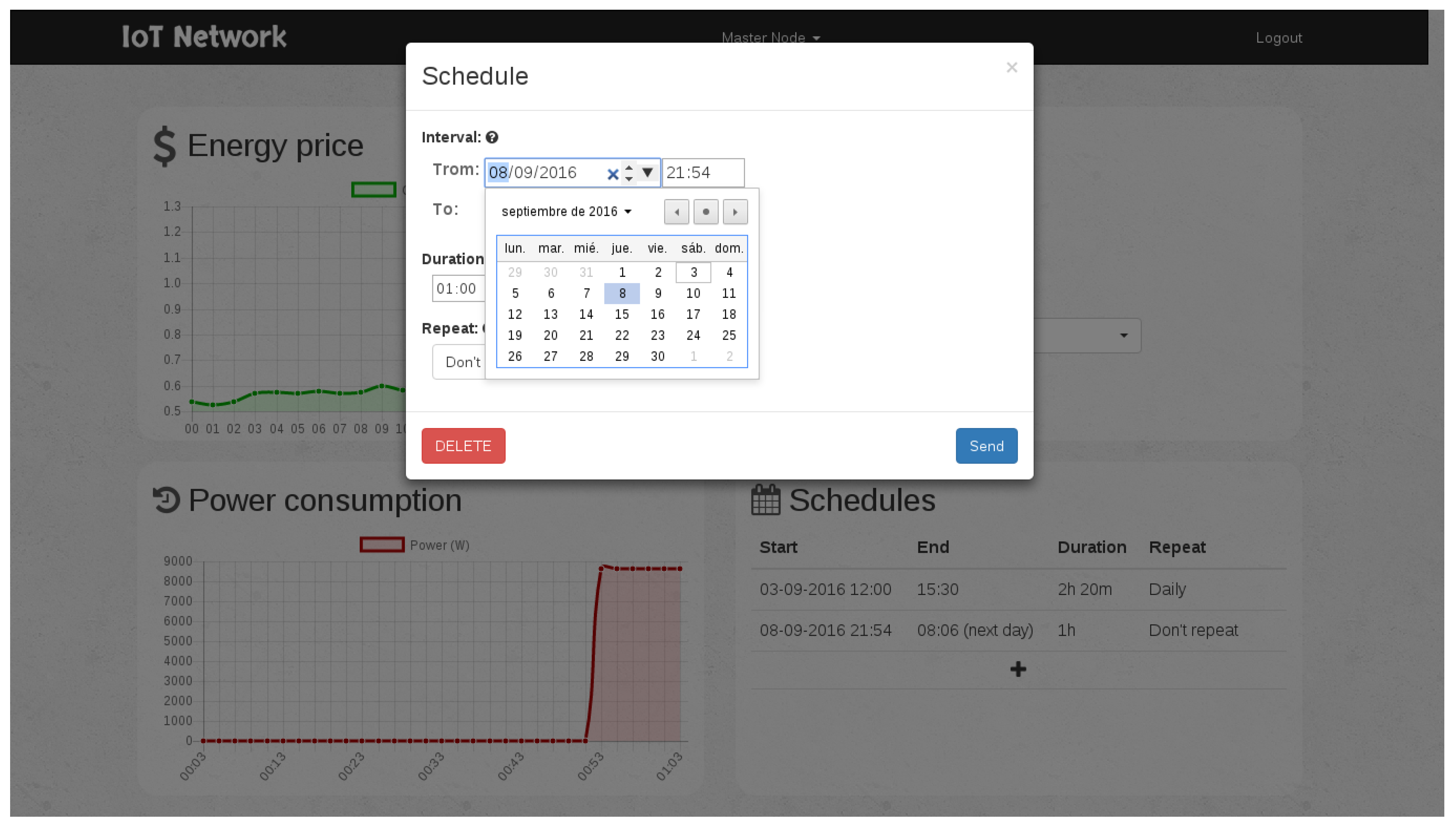

- The user can define, show and modify the operation intervals for every power outlet.

- The system can be accessed from remote networks (i.e., from the Internet), being able to work behind a router that uses NAT without requiring additional configuration from the user.

- A REST API was implemented to offer access to the system to third parties, who can interact dynamically with it and develop new applications.

6.2. Initial Network Configuration

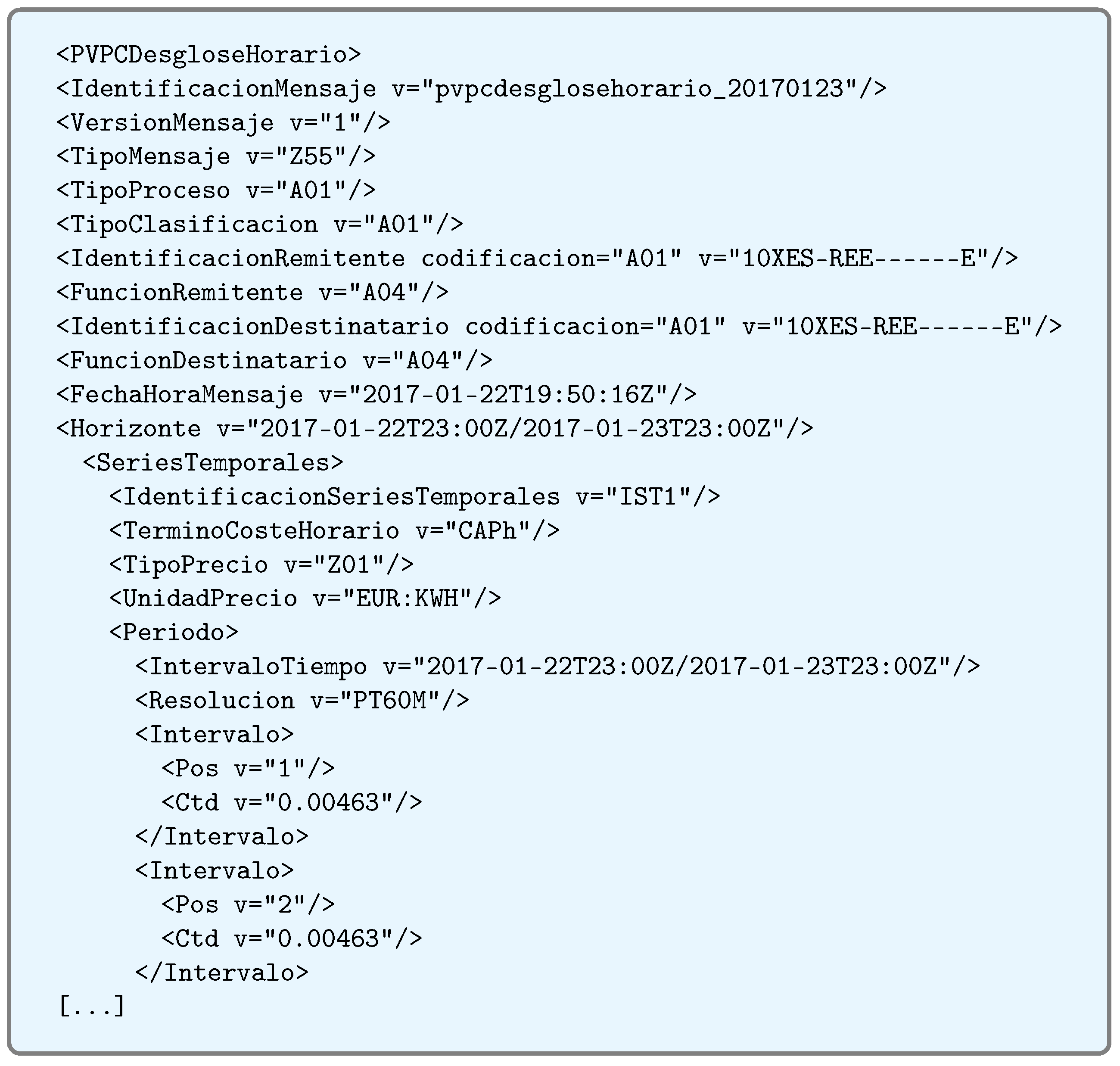

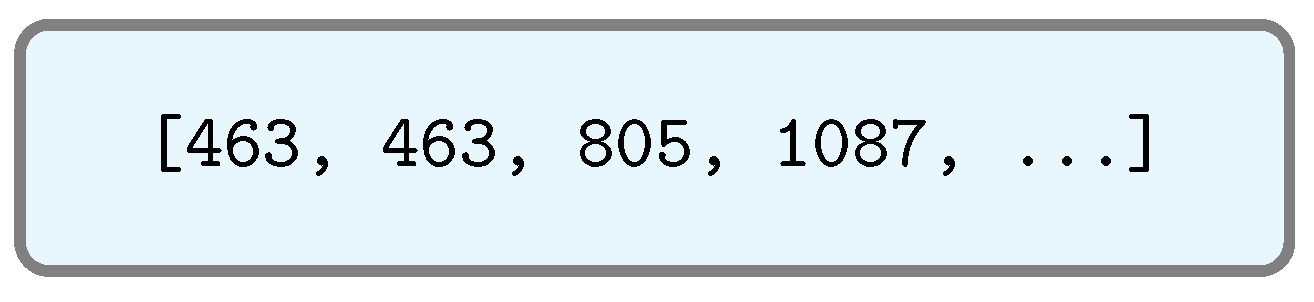

6.3. Obtaining the Electricity Price

- First, prices are supposedly published by law every day at the same time. However, in practice, the publication is delayed systematically. This fact derives having to make periodic requests until the resource becomes available. This is not a problem if a single node makes the requests, but in the case of multiple networks, each master would start polling at the same time, which is not the optimal solution in terms of energy consumption and communications traffic.

- Second, price lists are published in a very verbose XML and with too much information that is not relevant to the system proposed. An example can be seen in Figure 12. Such a large amount of information makes the data file require more than 40 KB, an amount that may seem to be acceptable at first glance, but for an integrated system with only 96 KB of memory (in which more than 50% is used by the network protocols implemented by the manufacturer), it becomes virtually impossible to handle.

6.4. Visualization and Control Software

7. Experiments

7.1. Initial Software Setup

7.2. Initial Configuration of the Nodes

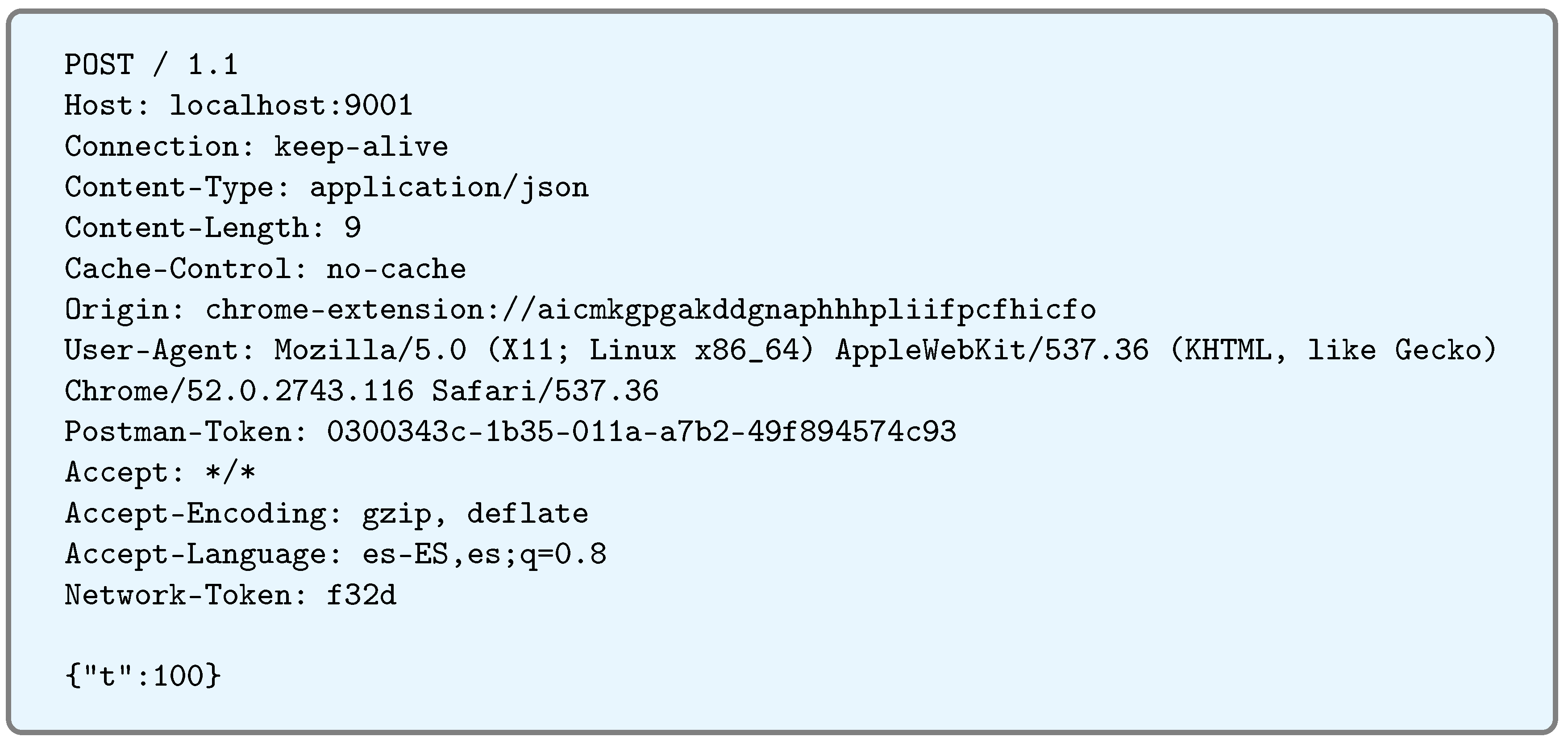

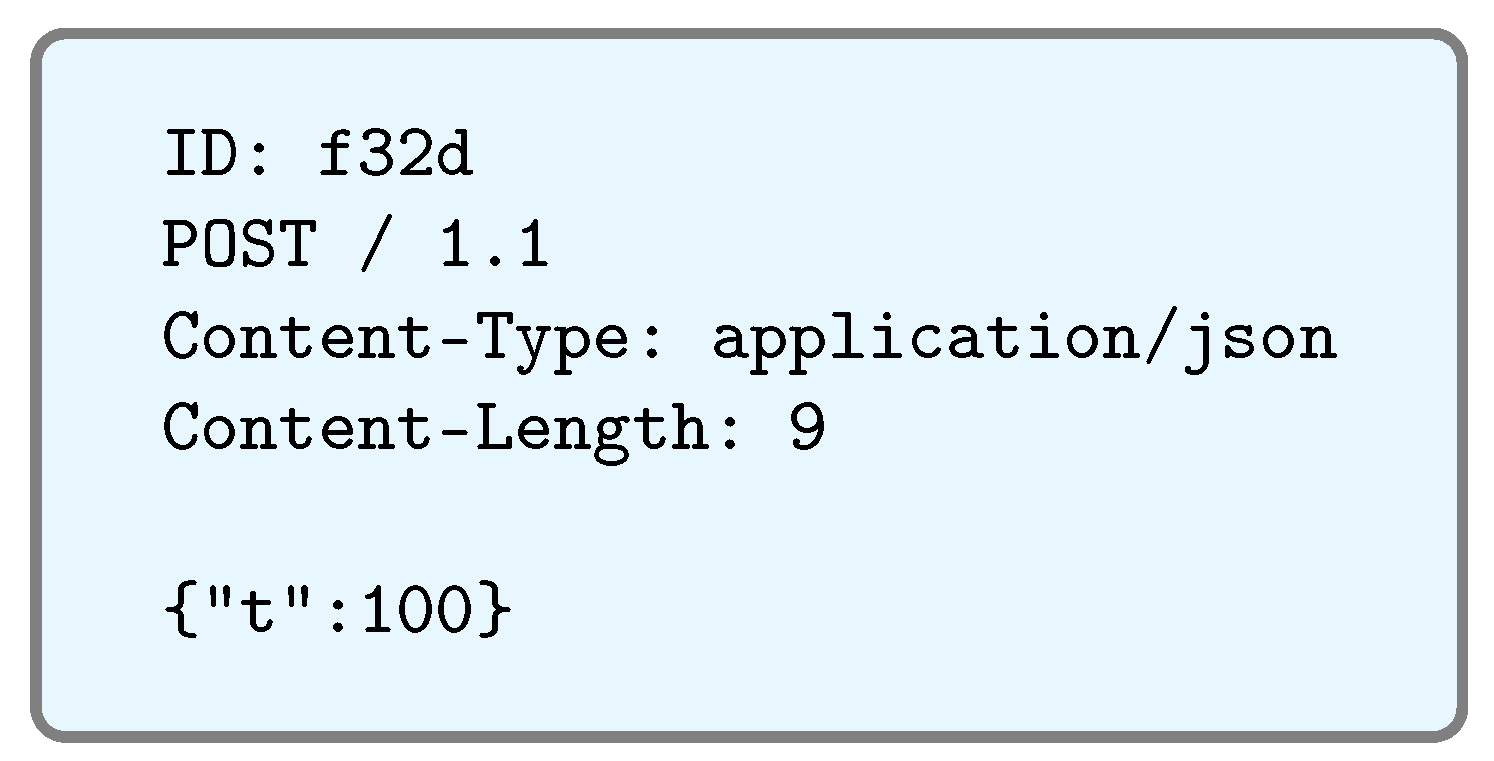

7.3. Accessing the Nodes through the REST API

- “s” stands for the state of the module, and it can be either 0 (off) or 1 (on).

- “t” represents the working mode. If it is equal to 0, the socket is working in intelligent mode, while 1 is for real-time (i.e., manual) mode.

- “l” represents the time when the last scheduling cycle took place. In the previous example, it is equal to 0, which means that it has never been a previous scheduling cycle.

7.4. Testing the Scheduler

7.5. Communications Range

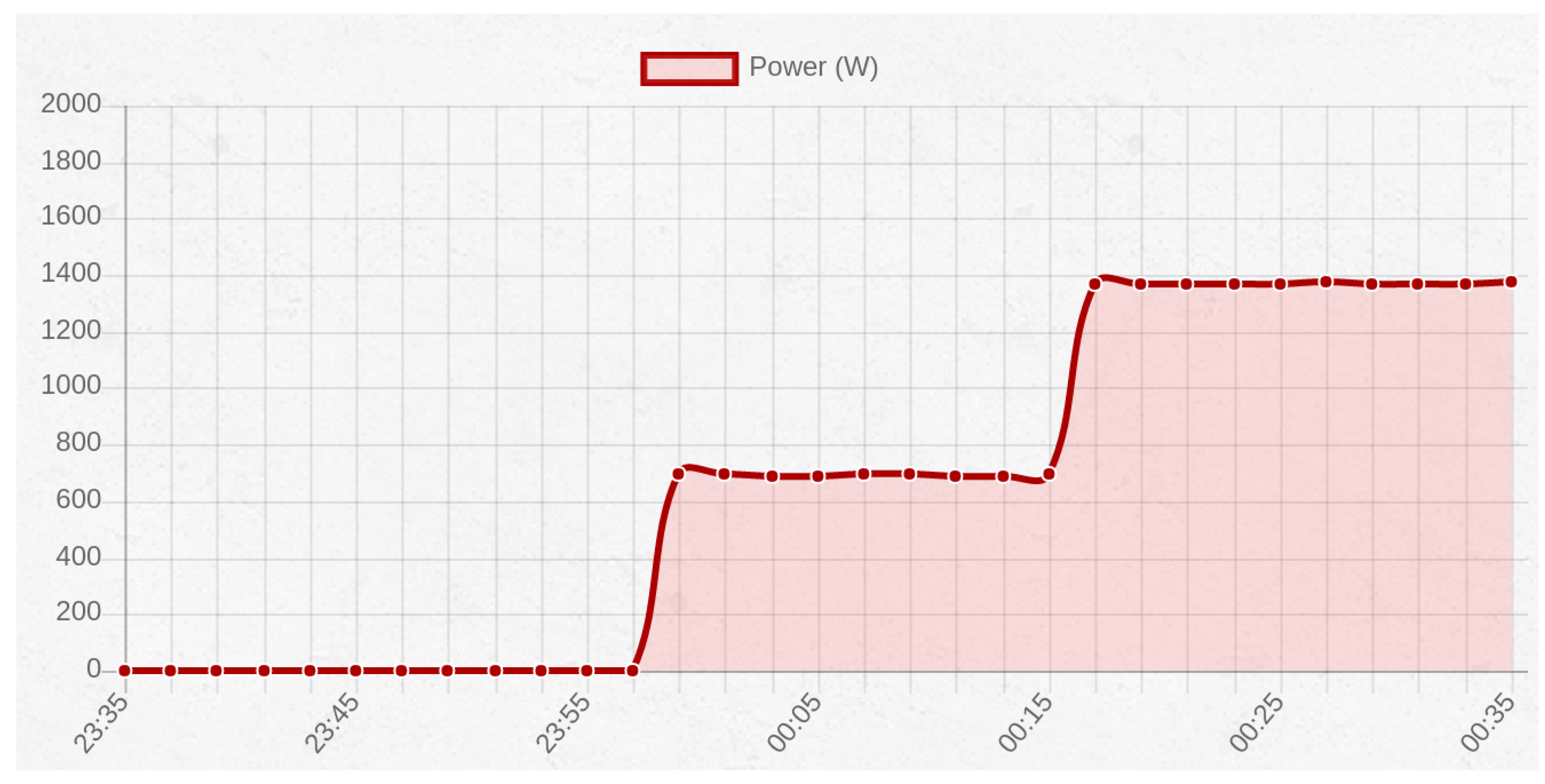

7.6. Current Monitoring

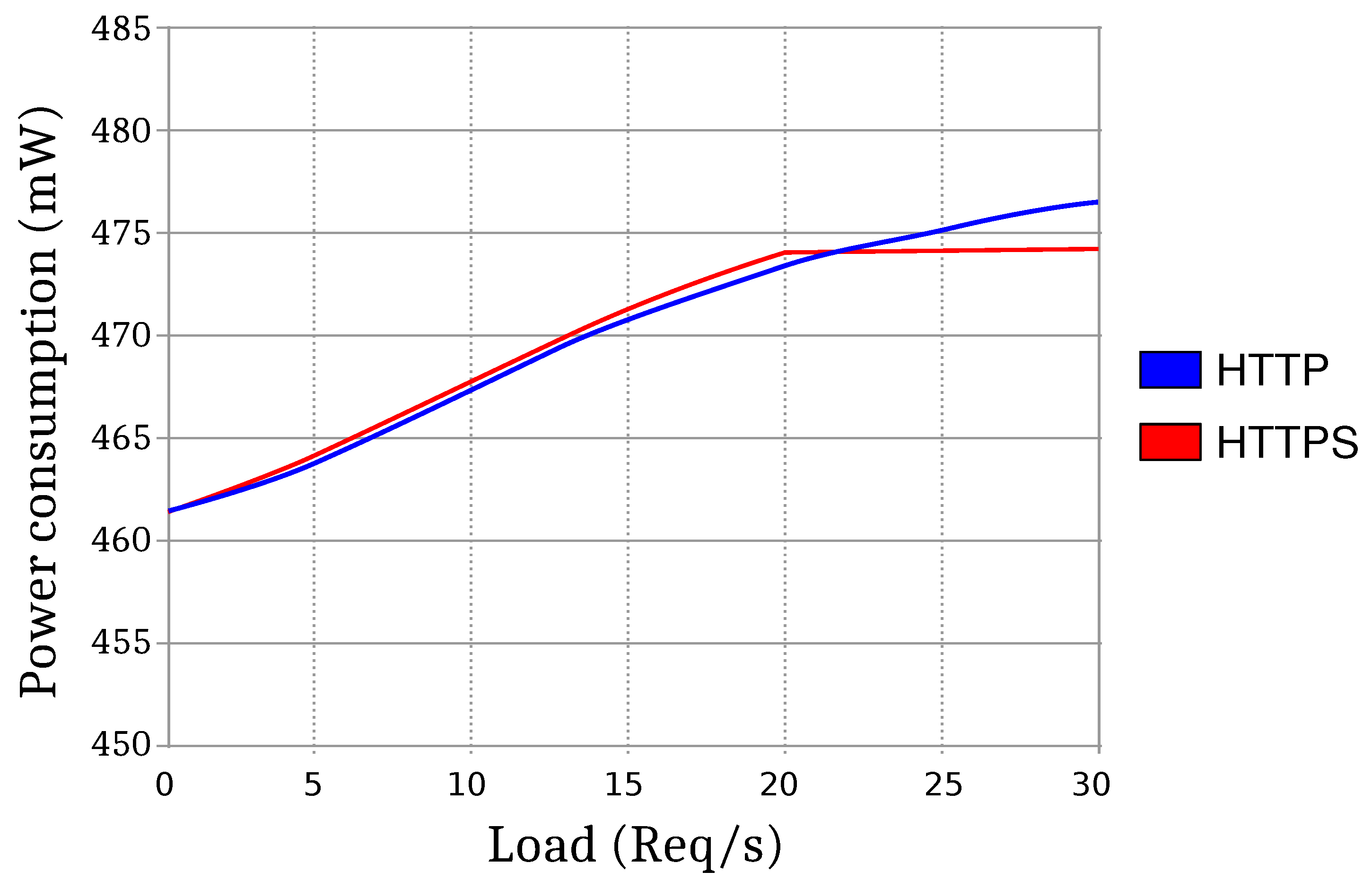

7.7. Socket Performance with and without HTTPS

7.8. Estimated Savings

7.9. Comparison to Other Energy Management Systems

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| API | Application Programming Interface |

| BLE | Bluetooth Low Energy |

| CPS | Cyber-Physical Systems |

| DR | Demand Response |

| Ep | Energía consumida en el período tarifario p |

| FPU | Término de Facturación de Potencia Unitaria |

| HEMS | Home Energy Management System |

| IoE | Internet of Energy |

| IoT | Internet of Things |

| MCF | Margen de Comercialización Fijo |

| NTP | Network Time Protocol |

| PLC | Power Line Communication |

| PVPC | Volunteer Price for the Small Consumer |

| REE | Red Eléctrica de España |

| REST | Representational State Transfer |

| RF | Radio Frequency |

| RFID | Radio Frequency IDentification |

| RTC | Real Time Clock |

| SoC | System-on-Chip |

| TPU | Término de Potencia Unitario |

| UPS | Uninterruptible Power System |

| WSN | Wireless Sensor Network |

References

- 2030 Energy Strategy, European Commission. Available online: https://ec.europa.eu/energy/en/topics/energy-strategy/2030-energy-strategy (accessed on 25 January 2017).

- Intended Nationally Determined Contributions (INDCS) to the Paris Agreement (C2ES, Center for Climate and Energy Solutions). Available online: https://www.c2es.org/international/2015-agreement/indcs (accessed on 25 January 2017).

- Fernández-Caramés, T.M.; Fraga-Lamas, P.; Suárez-Albela, M.; Castedo, L. Reverse Engineering and Security Evaluation of Commercial Tags for RFID-Based IoT Applications. Sensors 2017, 17, 28. [Google Scholar] [CrossRef] [PubMed]

- Fraga-Lamas, P.; Noceda-Davila, D.; Fernández-Caramés, T.M.; Díaz-Bouza, M.A.; Vilar-Montesinos, M. Smart Pipe System for a Shipyard 4.0. Sensors 2016, 16, 2186. [Google Scholar] [CrossRef] [PubMed]

- Bui, N.; Castellani, A.P.; Casari, P.; Zorzi, M. The internet of energy: A web-enabled smart grid system. IEEE Netw. 2012, 26, 39–45. [Google Scholar] [CrossRef]

- Pérez-Expósito, J.P.; Fernández-Caramés, T.M.; Fraga-Lamas, P.; Castedo, L. VineSens: An Eco-Smart Decision-Support Viticulture System. Sensors 2017, 17, 465. [Google Scholar] [CrossRef] [PubMed]

- Suárez-Albela, M.; Fraga-Lamas, P.; Fernández-Caramés, T.M.; Dapena, A.; González-López, M. Home Automation System Based on Intelligent Transducer Enablers. Sensors 2016, 16, 1595. [Google Scholar] [CrossRef] [PubMed]

- Fraga-Lamas, P.; Fernández-Caramés, T.M.; Suárez-Albela, M.; Castedo, L.; González-López, M. A Review on Internet of Things for Defense and Public Safety. Sensors 2016, 16, 1644. [Google Scholar] [CrossRef] [PubMed]

- Fraga-Lamas, P.; Castedo-Ribas, L.; Morales-Méndez, A.; Camas-Albar, J.M. Evolving military broadband wireless communication systems: WiMAX, LTE and WLAN. In Proceedings of the International Conference on Military Communications and Information Systems (ICMCIS), Brussels, Belgium, 23–24 May 2016; pp. 1–8.

- Real Decreto 216/2014 of March 28th, Boletín Oficial del Estado, Number 77, pp. 27397–27428, BOE-A-2014-3376, Ministerio de Industria, Energía y Turismo. Available online: https://www.boe.es/diario_boe/txt.php?id=BOE-A-2014-3376 (accessed on 25 January 2017).

- Precio Voluntario Para el Pequeño Consumidor (PVPC), Red Eléctrica de España. Available online: http://www.ree.es/es/actividades/operacion-del-sistema-electrico/precio-voluntario-pequeno-consumidor-pvpc (accessed on 25 January 2017).

- Lien, C.H.; Bai, Y.W.; Lin, M.B. Remote-Controllable Power Outlet System for Home Power Management. IEEE Trans. Consum. Electron. 2007, 53, 1634. [Google Scholar] [CrossRef]

- Lien, C.H.; Chen, H.C.; Bai, Y.W.; Lin, M.B. Power Monitoring and Control for Electric Home Appliances Based on Power Line Communication. In Proceedings of the 2008 IEEE Instrumentation and Measurement Technology Conference, Vancouver, BC, Canada, 12–15 May 2008; pp. 2179–2184.

- Lien, C.H.; Lin, M.B.; Bai, Y.W. Design and implementation of a remotely controllable UPS outlet system. In Proceedings of the 2008 IEEE International Symposium on Consumer Electronics, Vilamoura, Portugal, 14–16 April 2008; pp. 1–4.

- Lien, C.H.; Bai, Y.W.; Chen, H.C.; Hung, C.H. Home appliance energy monitoring and controlling based on Power Line Communication. In Proceedings of the 2009 IEEE International Symposium on Consumer Electronics, Las Vegas, NV, USA; 2009; pp. 1–2. [Google Scholar]

- Lee, M.; Uhm, Y.; Kim, Y.; Kim, G.; Park, S. Intelligent power management device with middleware based living pattern learning for power reduction. IEEE Trans. Consum. Electron. 2009, 55, 2081–2089. [Google Scholar] [CrossRef]

- Horvat, G.; Vinko, D.; Žagar, D. Household power outlet overload protection and monitoring using cost effective embedded solution. In Proceedings of the 2nd Mediterranean Conference on Embedded Computing (MECO), Budva, Montenegro, 15–20 June 2013; pp. 242–246.

- Garcia, M.R.G.; Chan, H.R.B.; Comendador, B.E.V.; Cornell, G.B.; Celestial, C.D.; Mercolesia, A.E.P. Smart Home Electricity Management System Using Cloud Computing (SHEMS). J. Adv. Comput. Netw. 2013, 1, 44–48. [Google Scholar] [CrossRef]

- Shajahan, A.H.; Anand, A. Data acquisition and control using Arduino-Android platform: Smart plug. In Proceedings of the 2013 International Conference on Energy Efficient Technologies for Sustainability, Nagercoil, India, 10–12 April 2013; pp. 241–244.

- Horvat, I.; Lukac, N.; Pavlovic, R.; Starcevic, D. Smart plug solution based on bluetooth low energy. In Proceedings of the 2015 IEEE 5th International Conference on Consumer Electronics - Berlin (ICCE-Berlin), Berlin, Germany, 6–9 September 2015; pp. 435–437.

- Lentine, A.L.; Ford, J.R.; Finn, J.R.; Furrer, C.T.; Bryan, J.R.; Gonzalez, S.; Spires, S.V.; Goldsmith, S.Y. An intelligent electrical outlet for autonomous load control for electric power grids with a large percentage of renewable resources. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012; pp. 1–8.

- Morsali, H.; Shekarabi, S.M.; Ardekani, K.; Khayami, H.; Fereidunian, A.; Ghassemian, M.; Lesani, H. Smart plugs for building energy management systems. In Proceedings of 2nd Iranian Conference on Smart Grids, Tehran, Iran, 24–25 May 2012; pp. 1–5.

- Bai, Y.W.; Hung, C.H. Remote power On/Off control and current measurement for home electric outlets based on a low-power embedded board and ZigBee communication. In Proceedings of the 2008 IEEE International Symposium on Consumer Electronics, Vilamoura, Portugal, 14–16 April 2008; pp. 1–4.

- Ahmed, M.S.; Mohamed, A.; Homod, R.Z.; Shareef, H.; Sabry, A.H.; Bin Khalid, K. Smart plug prototype for monitoring electrical appliances in Home Energy Management System. In Proceedings of the 2015 IEEE Student Conference on Research and Development (SCOReD), Kuala Lumpur, Malaysia, 13–14 December 2015; pp. 32–36.

- Kau, L.J.; Dai, B.L.; Chen, C.S.; Chen, S.H. A cloud network-based power management technology for smart home systems. In Proceedings of the 2012 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Seoul, Korea, 14–17 October 2012; pp. 2527–2532.

- Han, J.; Lee, H.; Park, K.R. Remote-controllable and energy-saving room architecture based on ZigBee communication. IEEE Trans. Consum. Electron. 2009, 55, 264–268. [Google Scholar] [CrossRef]

- Fernández-Caramés, T.M. An Intelligent Power Outlet System for the Smart Home of the Internet of Things. Int. J. Distrib. Sens. Netw. 2015, 2015, 214805. [Google Scholar] [CrossRef] [PubMed]

- Choi, M.; Park, W.K.; Lee, I. Smart Office Energy-Saving Service Using Bluetooth Low Energy Beacons and Smart Plugs. In Proceedings of 2015 IEEE International Conference on Data Science and Data Intensive Systems, Sydney, Australia, 11–13 December 2015; pp. 247–251.

- Thongkhao, Y.; Pora, W. A low-cost Wi-Fi smart plug with on-off and Energy Metering functions. In Proceedings of 2016 13th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Chiang Mai, Thailand, 28 June–1 July 2016; pp. 1–5.

- Xiong, G.; Chen, C.; Kishore, S.; Yener, A. Smart (in-home) power scheduling for demand response on the smart grid. In Proceedings of the 2011 IEEE PES Innovative Smart Grid Technologies (ISGT), Hilton Anaheim, CA, USA, 17–19 January 2011; pp. 1–7.

- Kim, T.T.; Poor, H.V. Scheduling Power Consumption With Price Uncertainty. IEEE Trans. Smart Grid 2011, 2, 519–527. [Google Scholar] [CrossRef]

- Ridi, A.; Gisler, C.; Hennebert, J. Automatic identification of electrical appliances using smart plugs. In Proceedings of 2013 8th International Workshop on Systems, Signal Processing and their Applications (WoSSPA), Algiers, Algeria, 12–15 May 2013; pp. 301–305.

- Ridi, A.; Gisler, C.; Hennebert, J. Processing smart plug signals using machine learning. In Proceedings of 2015 IEEE Wireless Communications and Networking Conference Workshops (WCNCW), New Orleans, LA, USA, 9–12 March 2015; pp. 75–80.

- Leonardi, A.; Ziekow, H.; Konchalenkov, D.; Rogozina, A. Detecting Smart Plug Configuration Changes in Smart Homes. In Proceedings of Smart SysTech 2014; European Conference on Smart Objects, Systems and Technologies, Dortmund, Germany, 1–2 July 2014; pp. 1–7.

- Santoro, P.; Calderaro, V.; Galdi, V.; Piccolo, A. Active smart socket design to perform local control of power demand in residential units. In Proceedings of 8th IET International Conference on Power Electronics, Machines and Drives (PEMD 2016), Glasgow, UK, 19–21 April 2016; pp. 1–5.

- Elma, O.; Selamoğullari, U.S. A home energy management algorithm with smart plug for maximized customer comfort. In Proceedings of 2015 4th International Conference on Electric Power and Energy Conversion Systems (EPECS), Sharjah, United Arab Emirates, 24–26 November 2015; pp. 1–4.

- Rodney Tan, H.G.; Tan, A.C.; Iriana, M.; Mok, V.H. Power socket programmable circuit breaker system. In Proceedings of the 2nd IEEE International Power and Energy Conference, Johor Bahru, Malaysia, 1–3 December 2008; pp. 574–577.

- Tsunoda, Y.; Tsuchiya, C.; Segawa, Y.; Sawaya, H.; Hasegawa, M.; Ishigaki, S.; Ishibashi, K. A small-size energy-harvesting electric power sensor for implementing existing electrical appliances into HEMS. IEEE Sens. J. 2016, 16, 457–463. [Google Scholar] [CrossRef]

- Rastegar, M.; Fotuhi-Firuzabad, M.; Zareipour, H. Home energy management incorporating operational priority of appliances. Int. J. Electr. Power Energy Syst. 2015, 74, 286–292. [Google Scholar] [CrossRef]

- Siebert, L.C.; Ferreira, L.R.; Yamakawa, E.K.; Custódio, E.S.; Aoki, A.R.; Fernandes, T.S.P. Centralized and decentralized approaches to demand response using smart plugs. In Proceedings of 2014 IEEE PES T&D Conference and Exposition, Chicago, IL, USA, 14–17 April 2014; pp. 1–5.

- Tsai, Y.S.; Chu, C.Y.; Li, M.C.; Lin, Y.H.; Chen, P. Intelligent DC power monitoring system and sensor network based on ZigBee-equipped smart sockets. In Proceedings of 2016 5th International Symposium on Next-Generation Electronics (ISNE), Hsinchu, Taiwan, 4–6 May 2016; pp. 1–4.

- Shie, M.C.; Lin, P.C.; Su, T.M.; Chen, P.; Hutahaean, A. Intelligent energy monitoring system based on ZigBee-equipped smart sockets. In Proceedings of 2014 International Conference on Intelligent Green Building and Smart Grid (IGBSG), Taipei, Taiwan, 23–25 April 2014; pp. 1–5.

- Babu, V.S.; Kumar, U.A.; Priyadharshini, R.; Premkumar, K.; Nithin, S. An intelligent controller for smart home. In Proceedings of 2016 International Conference on Advances in Computing, Communications and Informatics (ICACCI), Jaipur, India, 21–24 September 2016; pp. 2654–2657.

- Karfopoulos, E.; Tena, L.; Torres, A.; Salas, P.; Jorda, J.G.; Dimeas, A.; Hatziargyriou, N. A multi-agent system providing demand response services from residential consumers. Electr. Power Syst. Res. 2015, 120, 163–176. [Google Scholar] [CrossRef]

- Pilloni, V.; Floris, A.; Meloni, A.; Atzori, L. Smart Home Energy Management Including Renewable Sources: A QoE-driven Approach. IEEE Trans. Smart Grid 2016. [Google Scholar] [CrossRef]

- Du, P.; Lu, N. Appliance Commitment for Household Load Scheduling. IEEE Trans. Smart Grid 2011, 2, 411–419. [Google Scholar] [CrossRef]

- Jo, H.C.; Kim, S.; Joo, S.K. Smart heating and air conditioning scheduling method incorporating customer convenience for home energy management system. IEEE Trans. Consum. Electron. 2013, 59, 316–322. [Google Scholar] [CrossRef]

- Zhang, D.; Li, S.; Sun, M.; O’Neill, Z. An Optimal and Learning-Based Demand Response and Home Energy Management System. IEEE Trans. Smart Grid 2016, 7, 1790–1801. [Google Scholar] [CrossRef]

- Chen, S.; Liu, T.; Gao, F.; Ji, J.; Xu, Z.; Qian, B.; Guan, X. Butler, Not Servant: A Human-Centric Smart Home Energy Management System. IEEE Commun. Mag. 2017, 55, 27–33. [Google Scholar] [CrossRef]

- Belkin’s WeMo Official Website. Available online: http://www.belkin.com/us/Products/home-automation/c/wemo-home-automation/ (accessed on 25 January 2017).

- Orvibo Official Website. Available online: http://www.orvibo.com.es/ (accessed on 25 January 2017).

- D-link’s Smart Plug Official Website. Available online: http://us.dlink.com/products/connected-home/wi-fi-smart-plug/ (accessed on 25 January 2017).

- MeterPlug on Sticknfind. Available online: https://www.sticknfind.com/MeterPlug/ (accessed on 25 January 2017).

- SafePlug Official Website. Available online: http://www.safeplug.com/ (accessed on 25 January 2017).

- Edimax Smart Plug Switch Official Website. Available online: http://www.edimax.com/edimax/merchandise/merchandisedetail/data/edimax/global/homeautomationsmartplug/sp-2101w/ (accessed on 25 January 2017).

- MyPlug 2 Official Website. Available online: http://www.my-plug.fr/decouvrir/myplug2 (accessed on 25 January 2017).

- Plugwise Official Website. Available online: https://www.plugwise.com/ (accessed on 25 January 2017).

- SwannOne Smart Plug Official Website. Available online: http://www.swannone.com/gb/swannone-smart-plug (accessed on 25 January 2017).

- Thinkeco’s MyModlet Official Website. Available online: https://mymodlet.com (accessed on 25 January 2017).

- Ankuoo Official Website. Available online: http://www.ankuoo.com/ (accessed on 25 January 2017).

- Kampianakis, E.; Kimionis, J.; Tountas, K.; Konstantopoulos, C.; Koutroulis, E.; Bletsas, A. Wireless Environmental Sensor Networking With Analog Scatter Radio and Timer Principles. IEEE Sens. J. 2014, 14, 3365–3376. [Google Scholar] [CrossRef]

- Barro-Torres, S.; Fernández-Caramés, T.M.; Escudero, C.J. Enabling Collaborative Musical Activities through Wireless Sensor Networks (WSN). Int. J. Distrib. Sens. Netw. 2012, 8, 1–13. [Google Scholar]

- Barro-Torres, S.J.; Fernández-Caramés, T.M.; Pérez-Iglesias, H.J.; Escudero, C.J. Real-Time Personal Protective Equipment Monitoring System. Comput. Commun. 2012, 36, 42–50. [Google Scholar] [CrossRef]

- ZigBee Alliance Webpage on ZigBee IP. Available online: http://www.zigbee.org/zigbee-for-developers/network-specifications/zigbeeip/ (accessed on 25 January 2017).

- IETF 6LoWPANWorking Group. RFC 4919: IPv6 over Low-Power Wireless Personal Area Networks (6LoWPANs): Overview, Assumptions, Problem Statement, and Goals; IETF: Reston, VA, USA, 2008. [Google Scholar]

- Red Eléctrica de España (REE). Available online: http://www.ree.es/en/ (accessed on 25 January 2017).

- PostMan Official Website. Available online: https://www.getpostman.com (accessed on 25 January 2017).

- Iniewski, K. Smart Sensors for Industrial Applications, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- ACS712 Datasheet. Available online: http://www.allegromicro.com/~/media/Files/Datasheets/ACS712-Datasheet.ashx?la=en (accessed on 25 January 2017).

- Songle’s SRD Relay Datasheet. Available online: http://www.songle.com/en/pdf/20084141716341001.pdf (accessed on 25 January 2017).

- Espressif’s ESP8266 Overview. Available online: https://espressif.com/en/products/hardware/esp8266ex/overview (accessed on 25 January 2017).

- NodeMCU Official Website. Available online: http://www.nodemcu.com (accessed on 25 January 2017).

- WeMos D1 Mini Board Official Website. Available online: https://www.wemos.cc/product/d1-mini.html (accessed on 25 January 2017).

- Espressif Official Website. Available online: http://espressif.com/ (accessed on 25 January 2017).

- Ivan Grokhotkov’s ESP8266 Arduino Repository. Available online: https://github.com/esp8266/Arduino (accessed on 25 January 2017).

- Red Eléctrica de España (REE) API Website. Available online: https://api.esios.ree.es/ (accessed on 25 January 2017).

- Fink, G.; Flatow, I. Pro Single Page Application Development: Using Backbone.Js and ASP.Net, 1st ed.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Angular2 Framework Official Website. Available online: https://angular.io/ (accessed on 25 January 2017).

- Smart Socket’s GitHub Repository for the IoT Server. Available online: https://github.com/4m1g0/IOT_server (accessed on 25 January 2017).

- Docker Official Website. Available online: https://www.docker.com/ (accessed on 25 January 2017).

| Model | Manufacturer | Communications Technology | Remote Control | Scheduling | Power Meter | Real-Time Pricing | Other Functionality | Price |

|---|---|---|---|---|---|---|---|---|

| MeterPlug | StickNFind | Bluetooth 4.0 | Within 30 m | No | Yes | No | Stand-by detection Bluetooth proximity detection | In Pre-Order |

| DSP-W215 | DLink | Wi-Fi | Yes | Yes | Yes | No | Overheat protection | $ 39.99 |

| MyModlet | ThinkEco | Wi-Fi | Yes | Yes | Yes | No | - | $ 50 (Starter Kit) |

| MyPlug 2 | Orange | GSM/GPRS | Yes | No | Yes | No | Blackout detection | €79 |

| Energy Safety Outlet | SafePlug | ZigBee | No | No | Yes | No | Electrical shock and fire prevention, stand-by detection | $ 66 |

| Neo | Ankuoo | Wi-Fi | Yes | No | No | No | Amazon Echo support | $ 19.99 |

| SP-1101W | Edimax | Wi-Fi | Yes | Yes | No | No | - | €40 |

| SWO-SMP1PA | SwannOne | ZigBee, Wi-Fi | Yes | Yes | Yes | No | - | $ 64.99 |

| Circle | PlugWise | ZigBee | Yes | Yes | Yes | No | - | €360 (Home Basic Kit) |

| WeMo | Belkin | Wi-Fi | Yes | Yes | No | No | - | €49.99 |

| S20 | Orvibo | Wi-Fi, RF 433 MHz | Yes | Yes | No | No | - | $ 19.99 |

| Appliance | Average Power (KW) | Duration (h) | Max. Cost (€/day) | Min. Cost (€/day) | Annual Savings (€) |

|---|---|---|---|---|---|

| Dishwasher | 1.3 | 1 | 0.212979 | 0.161174 | 18.9088 |

| Washing machine | 0.5 | 1 | 0.081915 | 0.06199 | 7.2726 |

| Dryer | 2 | 0.5 | 0.16383 | 0.12398 | 14.5452 |

| Air conditioning/heating | 2.5 | 2 | 0.80955 | 0.62485 | 67.4155 |

| System | Scenario | Objective | Architecture | Price source | Cost savings |

|---|---|---|---|---|---|

| Shajahan et al. [19] | Plug | Monitoring remote devices | Not defined | Price unawareness | When unwanted loads are turned off, authors claim an energy saving of 15% |

| Choi et al. [28] | Smart office | Control the power state of a user’s PC and the switching of the lights | Location-aware approach based on BLE beacons, smart plugs and a mobile app | Price unawareness | Experimental results over a three-month period showed average energy savings of 31.9% for the PCs and 15.3% for the lights |

| Rastegar et al. [39] | Washing machine, dryer and dishwasher | Incorporate priorities of on/off controllable appliances | HEMS | Three-level Time-of-Use (TOU) tariffs and Inclining Block Rate (IBR) pricing | Savings of 7.5% while respecting user preferences |

| Siebert et al. [40] | Two offices, multimedia set and washing machine | Compare centralized and decentralized smart plug networks | Different approaches to smart plug scheduling in HEMS | Brazilian opt-in TOU tariff for weekdays with three levels: off-peak, intermediate-peak and peak | The system is able to detect devices in stand-by mode, saving almost 13 h of stand-by consumption per day and device |

| Tsai et al. [41] | Home | DC power monitoring system and sensor network | ZigBee-based smart socket network | Re-scheduling between peak and off-peak hours | Savings between 10%–15% are achieved for a single demo room with proper setting and scheduling |

| Shie et al. [42] | Home | Smart energy monitoring system | ZigBee-based smart socket network | Price unawareness | Not specified |

| Babu et al. [43] | Intelligent home controller | Remote interface controller that includes customer preferences for loads. Its decisions are based on dynamic tariff rates using fuzzy logic | HEMS | Three-level TOU tariffs: off-peak, intermediate-peak and peak | Not specified |

| Karfopoulos et al. [44] | Home | Distributed demand management mechanism with QoE | HEMS with a coordination mechanism that evaluates in real-time the stochastic behavior of the customer and the intermittency of the distributed RES production | Not specified | Not specified |

| Pilloni et al. [45] | Washing machine, dishwasher, dryer, electric oven, HVAC and water heater | Optimize user profile preferences and consumption in off-peak periods | QoE-aware SHEM (Smart HEM) system | Scheduling appliances using TOU electricity prices of ENEL or maximizing renewable energy use | QoE case achieves up to 22% without Renewable Energy Sources (RES) and 30% with RES. QoE-unaware case, 33% without RES and 46% with RES |

| Du et al. [46] | Water heater | Create an appliance commitment algorithm that schedules thermostatically controlled household loads based on price and consumption forecasts considering QoE | Two-step linear sequential multi-loop algorithm | Forecasted, one day-ahead from the market clearing price | Savings of up to 21% when respecting users preferences, and up to 75% without respecting them |

| Jo et al. [47] | HVAC | Schedule considering QoE as well as the characteristics of thermal appliances | HVAC scheduling method for HEMS | Hybrid-power: electricity price and natural gas price based on the TOU and natural gas rates | Savings of up to 36% when setting a temperature range between 19 °C in 21 °C |

| Chen et al. [49] | Smart home | Minimize the electricity cost while satisfying user preferences | CPS (GPS, sensors, bio-sensors) | Real-time pricing published by PJMin the United States | Electricity cost can be reduced 14% on average |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanco-Novoa, Ó.; Fernández-Caramés, T.M.; Fraga-Lamas, P.; Castedo, L. An Electricity Price-Aware Open-Source Smart Socket for the Internet of Energy. Sensors 2017, 17, 643. https://doi.org/10.3390/s17030643

Blanco-Novoa Ó, Fernández-Caramés TM, Fraga-Lamas P, Castedo L. An Electricity Price-Aware Open-Source Smart Socket for the Internet of Energy. Sensors. 2017; 17(3):643. https://doi.org/10.3390/s17030643

Chicago/Turabian StyleBlanco-Novoa, Óscar, Tiago M. Fernández-Caramés, Paula Fraga-Lamas, and Luis Castedo. 2017. "An Electricity Price-Aware Open-Source Smart Socket for the Internet of Energy" Sensors 17, no. 3: 643. https://doi.org/10.3390/s17030643

APA StyleBlanco-Novoa, Ó., Fernández-Caramés, T. M., Fraga-Lamas, P., & Castedo, L. (2017). An Electricity Price-Aware Open-Source Smart Socket for the Internet of Energy. Sensors, 17(3), 643. https://doi.org/10.3390/s17030643