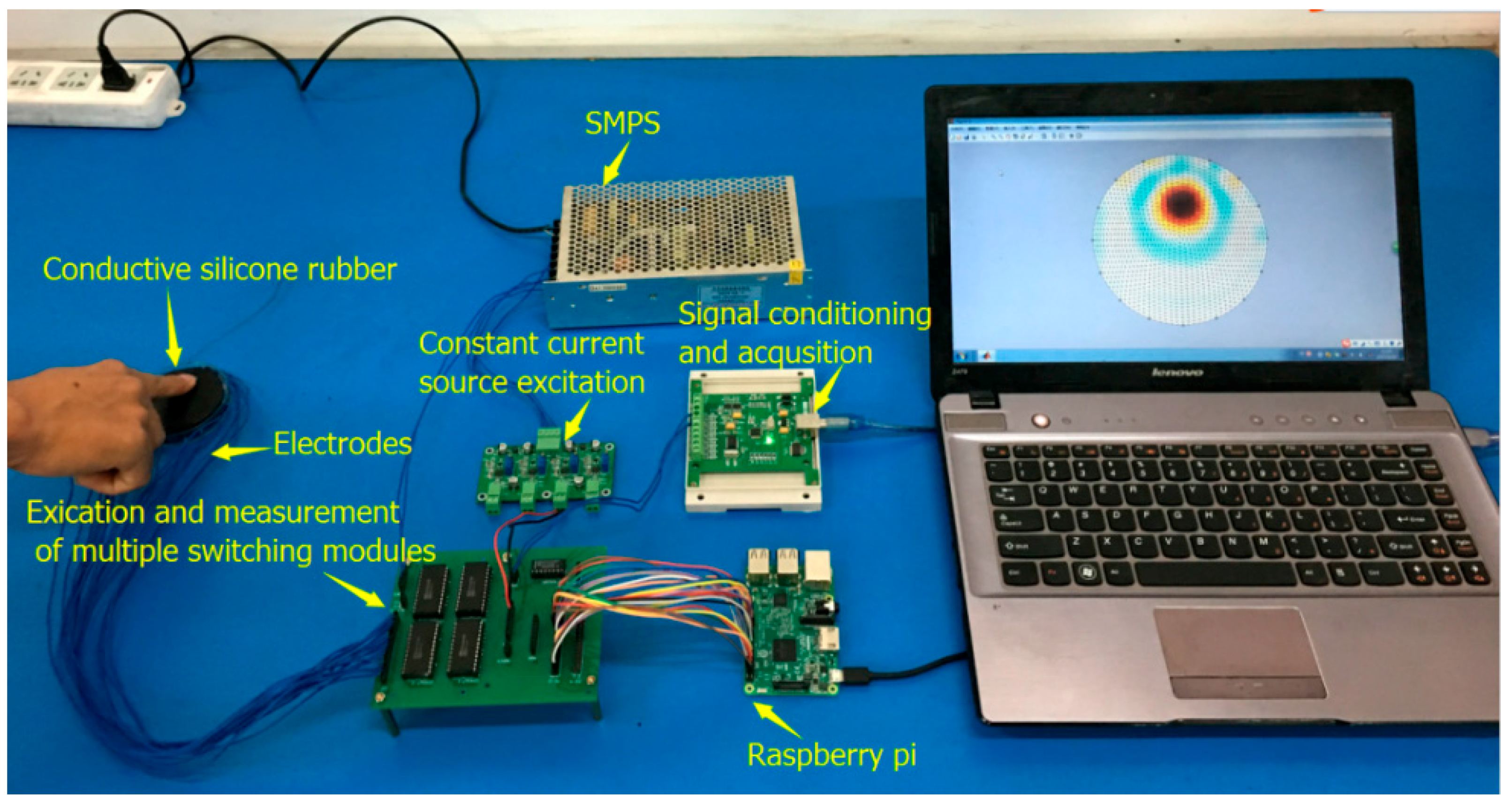

Silicone has a soft touch, which makes it very suitable for human body pressure sensing materials. The conductive silica gel is a composite conductive polymer by adding nano-carbon black in the silica gel. The material has a piezoresistive effect, and the resistivity of the area under pressure will decrease when the conductive silica film is under pressure. The technical principle of the human body pressure distribution system proposed in this paper is to calculate the body pressure distribution by measuring the conductivity of the conductive silica gel under different pressures. The pressure distribution information of the conductive silica gel can be obtained by the conductivity distribution of the sensitive field dielectric. A sensitive field can be established by injecting a constant current into the electrodes on the conductive silica boundary. When the distribution of the conductivity field in the sensitive field changes, the potential distribution in the sensitive field changes, resulting in the corresponding change of the measured voltage on the sensitive field boundary. The change of measurement voltage reflects the change information of electrical conductivity. Using the measurement voltage on the boundary, the electrical conductivity distribution in the sensitive field can be reconstructed by image reconstruction algorithm, so as to realize the visualization measurement of the human pressure distribution.

3.1. Sensing Mechanism of Conductive Silica

The material used in the human body sensor in this paper is conductive silica gel. Silica gel is a kind of biological material, which can simulate the long-term burial of human organs in the body to replace part of the function of a missing organ. For example, long-term indwelling products include hydrocephalus drainage devices, artificial lungs, retinal implants, larynxes, palm joints, artificial tympanic membranes, artificial heart valve accessories, and so on. Conductive silica gel only makes the nano-carbon powder into the silica gel. Nano-carbon powder is a non-toxic additive that is completely harmless to the human body.

The nanoparticles are infiltrated into the silica gel to form a current carrier in a conductive silica gel. The conductive nature of conductive silica is the directional movement of the current carrier in the electric field. The sufficient number of current carriers and the formation of the conductive channel between the two chains are two factors in conductive polymer conduction. The conductive silica gel will produce elastic deformation when it is under pressure, and the resistance decreases with the increase in pressure. This is mainly due to the increase in pressure. The particle spacing decreases, and the probability of particle contact increases. It is easier to form a conductive network and improve the conductive properties of the material. The piezoresistive calculation model of carbon-black-filled conductive silica gel polymer is as follows:

where

φc is the critical percolation threshold, and

τ is the percolation coefficient of composites.

ρh is the resistivity of carbon black particles,

φ0 is the volume fraction of conductive silica without loading force,

E is the elastic modulus of conductive silica gel,

v is the Poisson's ratio, and

P is the pressure.

3.2. Human Pressure Distribution Measurement System Based on Electrical Resistance Tomography

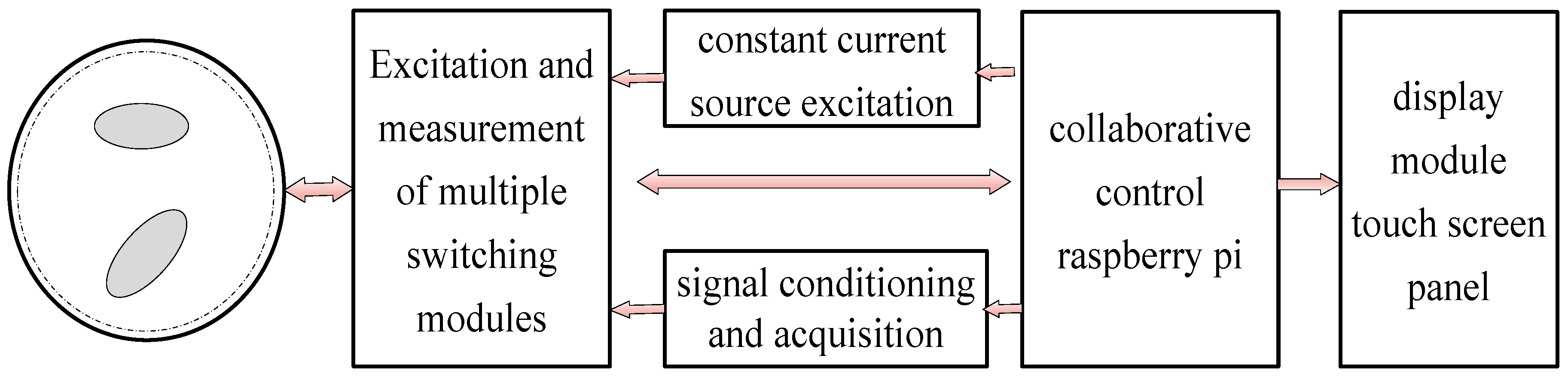

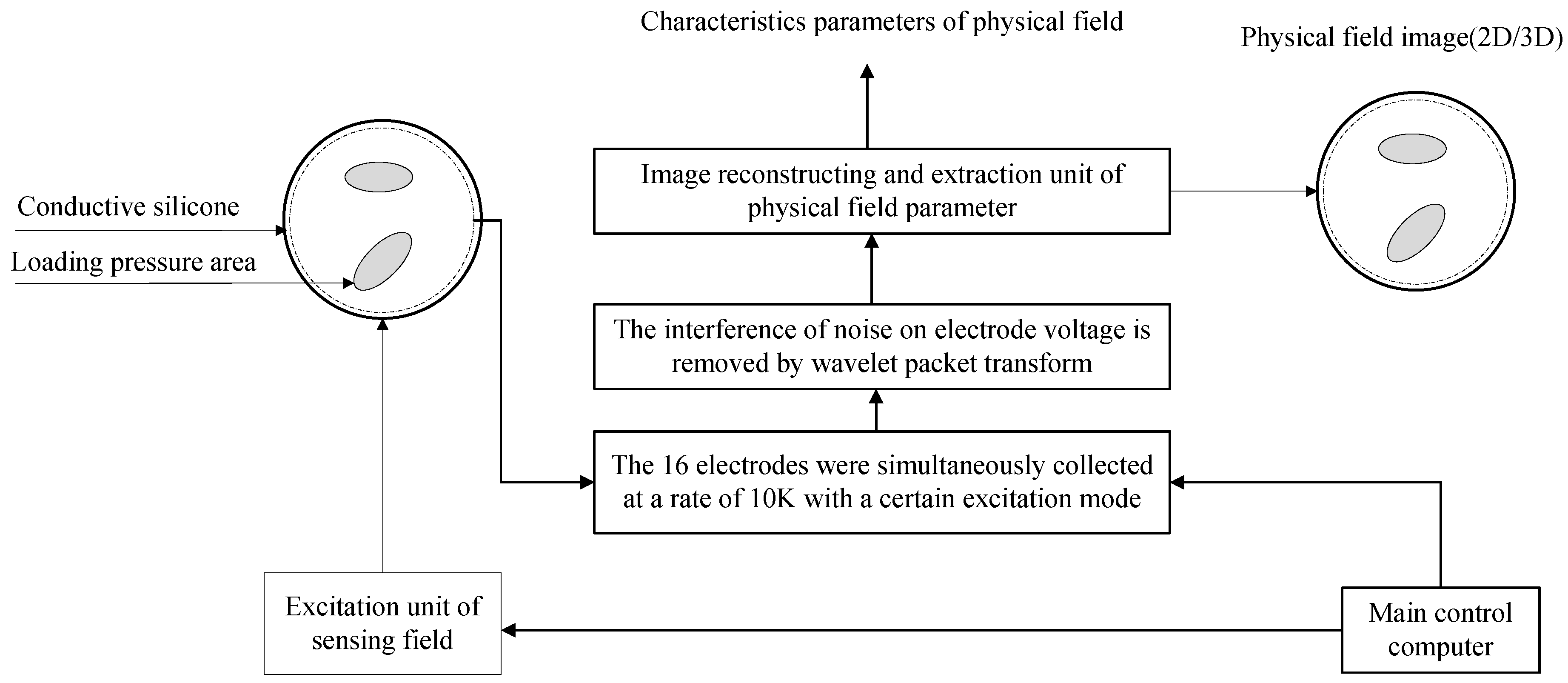

The detailed measurement principle of the human body pressure distribution measurement system is shown in

Figure 2. The material of the human pressure distribution measurement sensing film is conductive silica gel, which can be made into different shapes to meet specific requirements. In this paper, the sensing film is made circular to test its performance. Measurement and excitation electrodes are evenly distributed on the edge of the circular film.

The principle of electrical resistance tomography is to obtain information on medium distribution in the sensitive field by judging the resistivity distribution of the medium in the sensitive field according to the resistivity of different media. That is, when the current excitation is applied at the boundary of the sensitive field, the electric potential distribution in the sensitive field changes with the change in resistivity distribution in the sensitive field, resulting in a corresponding change in measurement voltage on the boundary of the sensitive field. The variation in the measured voltage reflects the change in resistivity. Using the measurement voltage on the boundary, the resistivity distribution in the sensitive field can be reconstructed by a certain image reconstruction algorithm, so as to realize the visualization measurement.

The electrodes arranged on the edge of the conductive silicone are numbered 1 to 16. These electrodes serve both as a measuring electrode and as an excitation electrode, and their functions can be controlled by multiple switches. The excitation electrode mode is selected for the adjacent mode. The adjacent excitation mode applies an excitation current to two adjacent electrodes, measures the voltage on two adjacent electrodes of the non-excitation electrode, and then repeats the above process until all of the adjacent electrode pairs are excited.

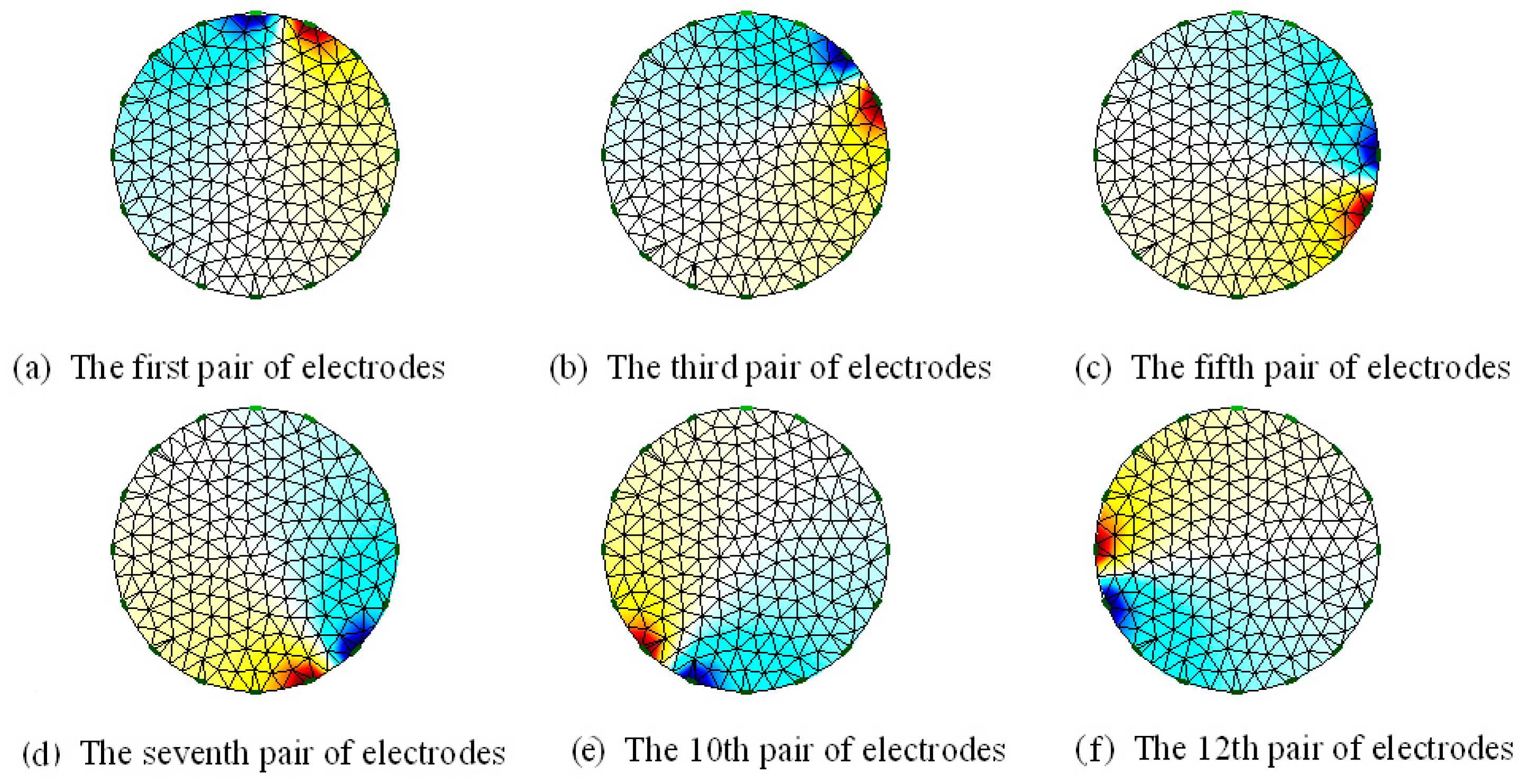

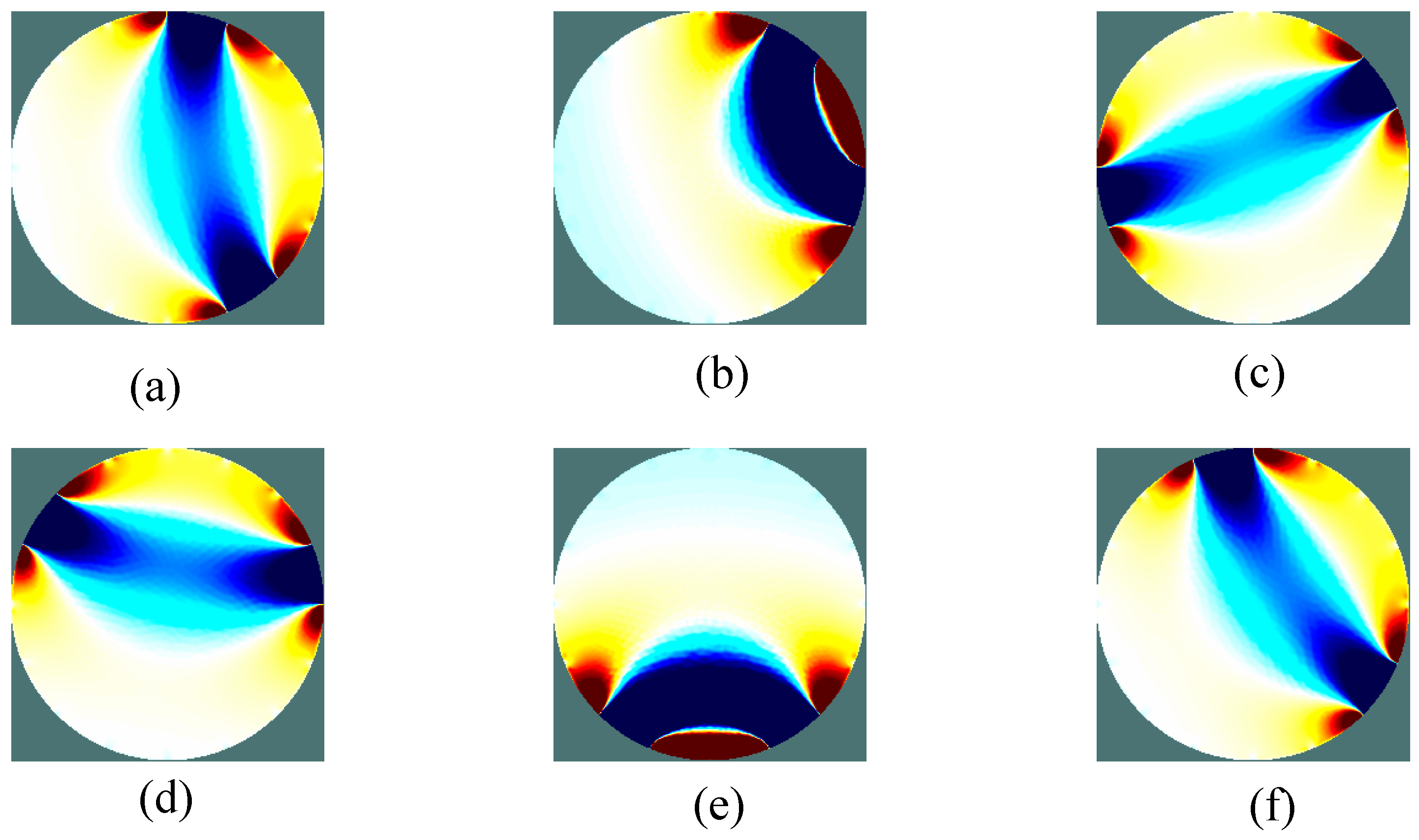

Figure 3 shows the potential distribution at which a different electrode pair is injected with a current of 10 mA when the conductive silica gel is not pressed in the adjacent excitation mode. The solution to the results of

Figure 3 is the forward process of resistance tomography (ERT). Its solution principle is based on the approximate assumption of the following two facts: (1) The sensitive field of the ERT is an approximate steady-state field. When energization is applied at the boundary of the field, the electric field changes at the same time, ignoring the time that the current travels from one point to another in the electric field. (2) The ERT-sensitive field is a constant electric field, and there is no current source or current sink in the excitation field, so the divergence of the current in the sensitive field is zero. According to the above two assumptions and the Maxwell equation of constant electric field, we can obtain a mathematical description of ERT forward problem:

where

is the potential distribution,

is the conductivity distribution,

and

are the surface of the current injected electrode and the current out of the electrode,

is the insulating surface of the conductive silicone. At present, the method of solving Equation (1) is mostly solved by the finite element method, and the software solution technology of the finite element is very mature. OpenFOAM (open field operation and manipulation) is a free tool that can simulate the calculation of electromagnetic fields. OpenFOAM can be used to model

forward problems. A conductive silicone sensor with N electrodes

independent voltage values can be measured using the adjacent excitation mode. We can obtain M equations similar to Equation (1), as well as its discretization and linearization. The ERT positive problem of the observation model is

In Equation (3), is the normalized measurement electrode voltage vector, is the normalized sensitivity matrix, and is the normalized conductivity. The key step in human body pressure distribution image reconstruction is to solve the inverse problem, which is to obtain the conductivity distribution by the measured voltage. In short, how do we get the value of in Equation (3)?

The pressure distribution image inversion process has two main difficulties. One is the problem of obtaining the sensitivity matrix. In the sensitive field, the sensitivity distribution is not uniform, which is easily affected by the distribution of the media, that is, the so-called “soft field” effect; how to obtain the sensitivity matrix effectively and accurately has an important influence on the imaging quality. The other is to reduce the interference of noise to the electrode measurement voltage. Equation (3) is an ill-conditioned systems of equations. Its solution is unstable, and the small perturbation of voltage value will have a great influence on the image gray value .

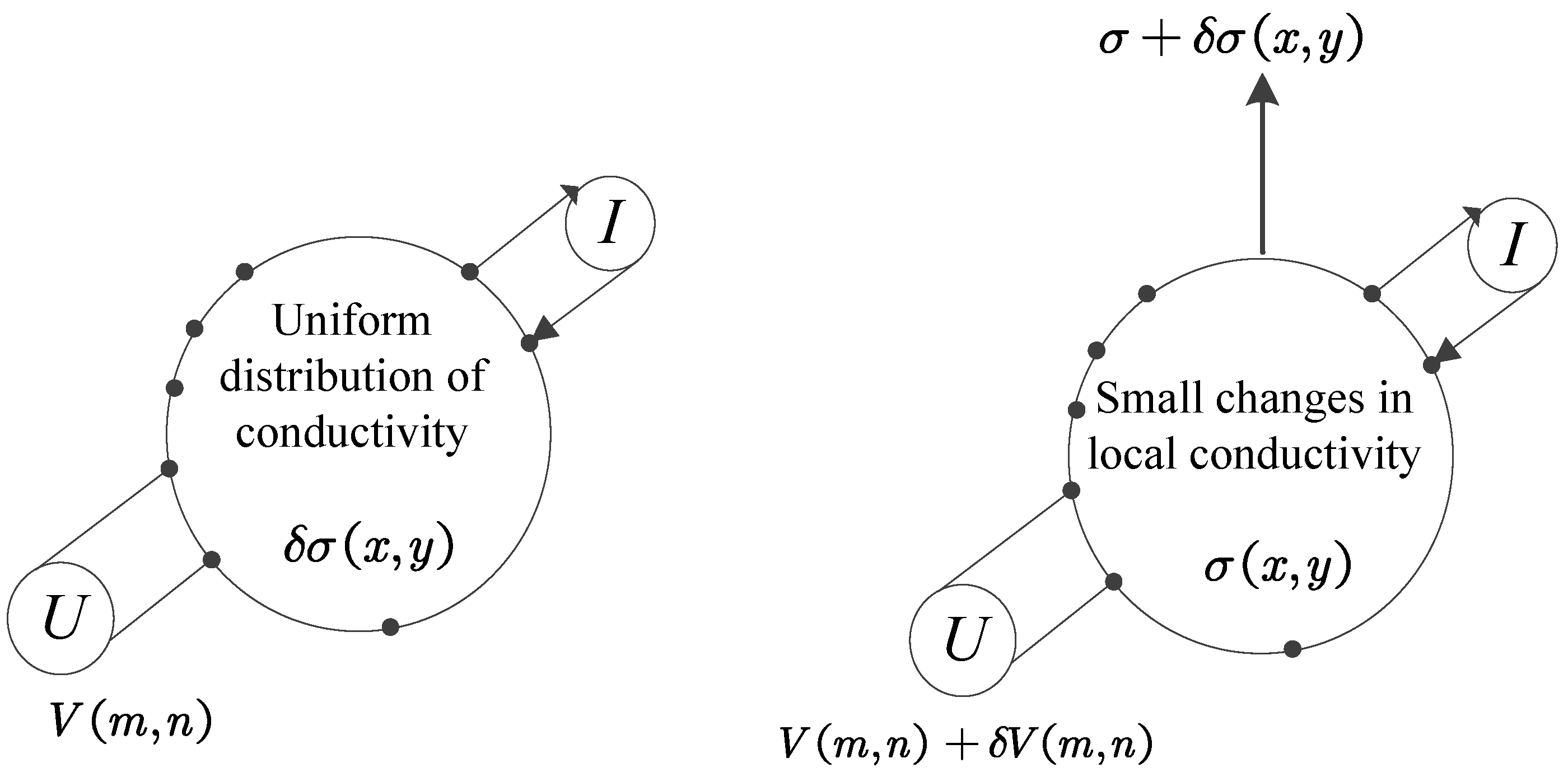

The sensitivity coefficient is related to the shape and conductivity of the conductive silica gel, which can be calculated via finite element analysis. The physical significance of sensitivity is illustrated by typical four-electrode current excitation voltage measurement, as shown in

Figure 4.

Assuming that the conductivity in the field,

, is uniformly distributed, the excitation current

I is injected into the

mth pair of electrodes, and the voltage measured

on the

nth pair of electrodes. When the conductivity of a certain region changes slightly

, the measured voltage on the corresponding

nth electrode changes to

. If

is small enough, it can be assumed that the distribution of the equipotential line in the sensitive field is unchanged before and after the change of the conductivity, and the variation of the measurement voltage is proportional to the change in conductivity. The proportionality constant is defined as the sensitivity coefficient

:

According to Gese–Lowitz compensation [

16] and the finite element principle, Equation (4) can be converted to

where

is the serial number of the excitation electrode pair, and

n is the serial number of the measurement electrode pair. The subscript

i represents the

ith independent measurement,

denotes the

unit,

are the potential distributions of the nodes in the field, respectively, when the excitation current

is injected into the

mth and

pairs of electrodes.

is the area of the

jth unit.

is the potential of

nodes on the corresponding unit

.

is the finite element coefficient matrix of element

.

Figure 5 is a sensitive field distribution of conductive silicone as a sensor for human pressure distribution. For the convenience of image inversion, the shape of the sensor of the conductive silicone pressure distribution test system is circular. Sixteen electrodes are evenly arranged around the outer periphery of the circular conductive silica gel. There are a total of

measurement models. The size of the sensitivity matrix is

.

In principle, after obtaining the sensitivity matrix, the distribution of electrical conductivity can be distributed by measuring the electrode voltage in various excitation modes. However, Equation (3) is an ill-conditioned systems and very sensitive to voltage measurements, which must be accurate so as to remove measuring voltage signals containing noise, so that a good conductivity distribution image can be obtained.

3.3. Wavelet Transform and Noise Removal

Wavelet transform is the expansion and approximation of a function on wavelet basis in a specific space. It is the perfect crystallization of functional analysis, Fourier analysis, spline analysis, harmonic analysis, and numerical analysis. From an engineering point of view, wavelet analysis is a signal and information processing tool, is another effective time–frequency method in addition to Fourier analysis, can be used in time domain and frequency domain analysis, and has time–frequency localization and multi-resolution characteristics. Therefore, it is known as the “digital microscope” of the analysis signal, especially suitable for dealing with non-stationary signals.

Definition: If and , then

This is a continuous wavelet, where

is the basic wavelet or generating wavelet in function space

,

is the variable in real number field

,

a is the scale or location coefficient, and

b is the translation factor, and satisfies the admissible condition

where

is the Fourier transform of

at frequency

.

If a signal

is deconstructed into the function set, the continuous wavelet transform

is defined as

where “< >” indicates the inner product,

are the coefficients of wavelet transform corresponding to scale and location

, and

represents the conjugations of

. This transform is known as a continuous wavelet transform (CWT) when

a and

b are continuously changing, and as a discrete wavelet transform (DWT) when

a and

b are discrete points.

Typically,

a and

b are taken as a power series:

when

, the scale and translation are dyadic discrete and the dyadic wavelet is obtained:

Hereafter, the DWT is represented as this dyadic wavelet transform, and the DWT coefficients are

is the

th largest value of the coefficients in the

jth deconstruction level.

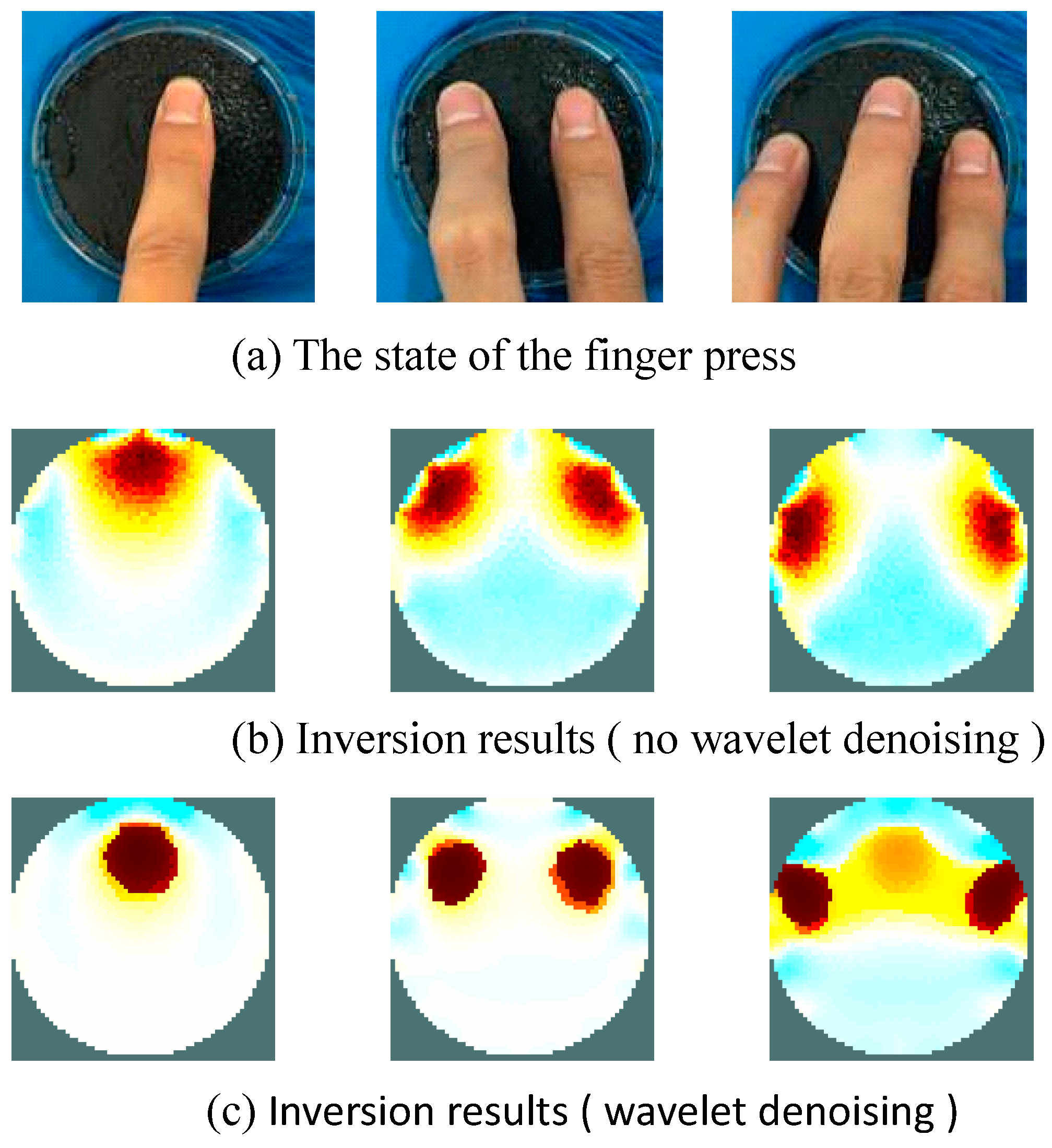

The reconstruction formula is

The basic idea of wavelet transform de-noising can be summarized as follows: the noise signal of the electrode voltage signal is decomposed into multi-scale by wavelet transform. The wavelet transform is used to divide the wavelet coefficients, and the wavelet coefficients are then removed at each scale. The wavelet coefficients belonging to the signal are enhanced, and the signal after wavelet de-noising is finally reconstructed. The question to answer is, by what criterion can the wavelet coefficients of the noise be removed, and what part of the measurement electrode voltage signal be enhanced? In this method, the median filter based on the wavelet is used to de-noise. Median filtering is a commonly used non-linear method to suppress noise and can overcome the problem of signal mutation caused by linear filtering, such as least mean square filtering and mean filtering, so as to obtain a more satisfactory de-noising effect. The principle is very simple: A window with a length of is moved in the time axis of the voltage signal. In each position, the voltage value in the window is arranged from so small to large, and the intermediate value is used as the output value of the window. One of the biggest advantages of wavelet transform is that the wavelet function family is very rich and can have many choices. Wavelets generated by different wavelet coefficients have different effects in removing noise. Noise is often manifested as a sudden change in electrode voltage amplitude, with high frequency characteristics and time irrelevance. The electrode voltage signal is decomposed by the wavelet to obtain the low frequency part and the high frequency part. The low frequency part reflects the outline of the signal. The high frequency part is reflected in the details of the signal and the noise is mixed. Therefore, the de-noising of the electrode voltage signal only needs to deal with its high frequency coefficients. The specific noise removal steps are as follows:

Step 1: A set of wavelet coefficients is obtained by making wavelet transform of electrode signal with noise

Step 2: Given a default wavelet decomposition level j, and coefficients of and higher, all coefficients are retained.

Step 3: For the wavelet decomposition coefficient of the layer

, the

coefficient of the maximum absolute value is kept, and the value of

is determined by the following formula:

In this formula, and are empirical coefficient, where the default is , which is the length of the coefficient. satisfies the inequality , and the value of general condition is 3.

Step 4: According to the threshold of the wavelet decomposition coefficients determined in Step 3, the wavelet coefficients greater than the threshold value are set to zero.

Step5: Using to reconstruct the wavelet, we obtain the estimated signal , that is, the electrode voltage signal to remove the noise.

After obtaining accurate measurement of the sensitive field coefficient and the electrode voltage, the resistance tomography technique can be used to solve the distribution of the sensitive field conductivity. The implementation steps of the algorithm are as follows:

Step 1: The sensitive field is divided and the solution domain is discretized.

Step 2: The coverage matrix of the equipotential of the projection area is generated, the sensitive field is divided into several equipotential regions, and the equipotential regions corresponding to each cell are determined.

Step 3: The boundary measurement voltage is solved by the system or the finite element method.

Step 4: The back projection algorithm is used to perform back projection imaging and display imaging results.