Modeling of Thermal Phase Noise in a Solid Core Photonic Crystal Fiber-Optic Gyroscope

Abstract

:1. Introduction

2. Theory of Thermal Phase Noise

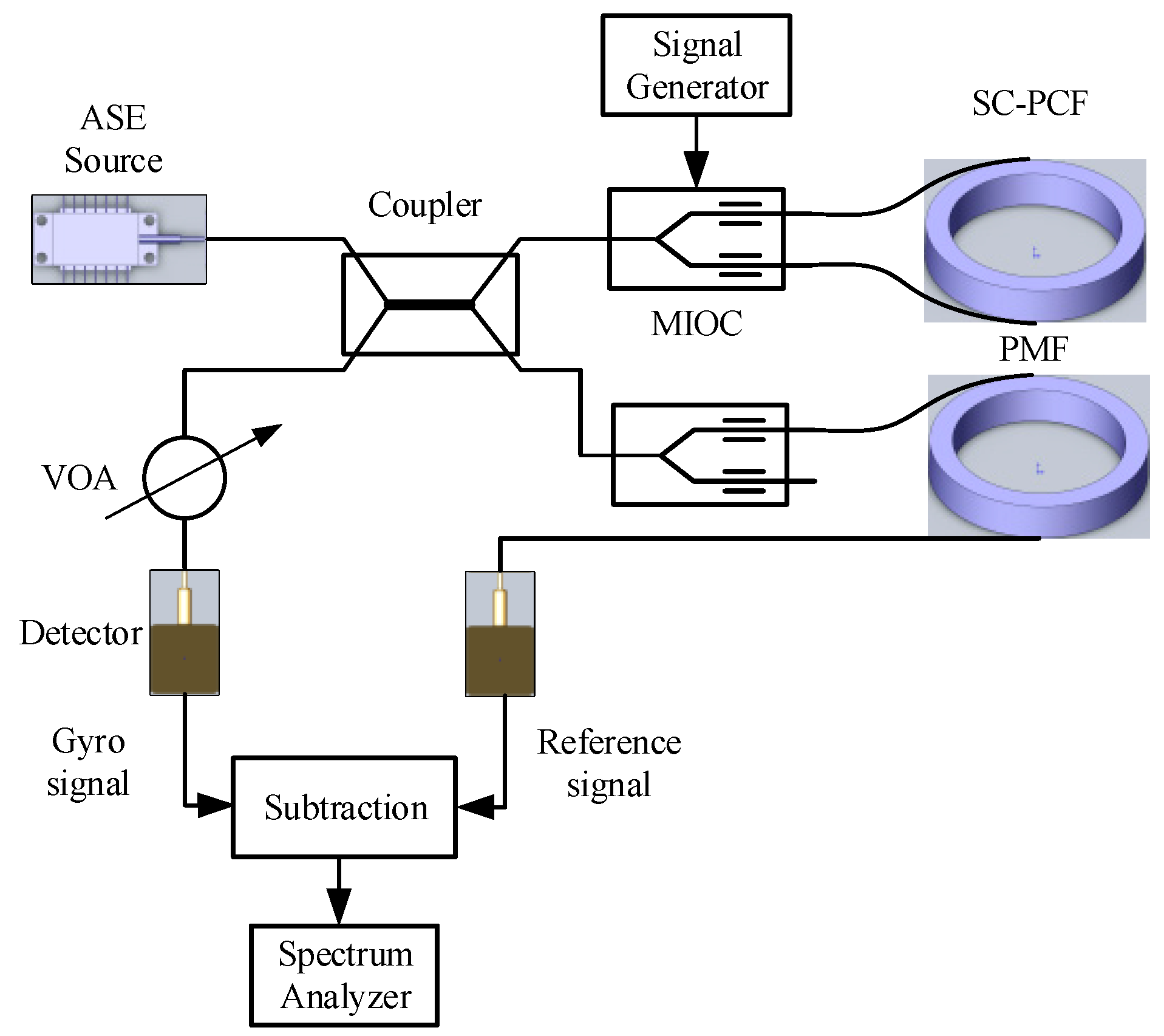

3. Experimental Setup

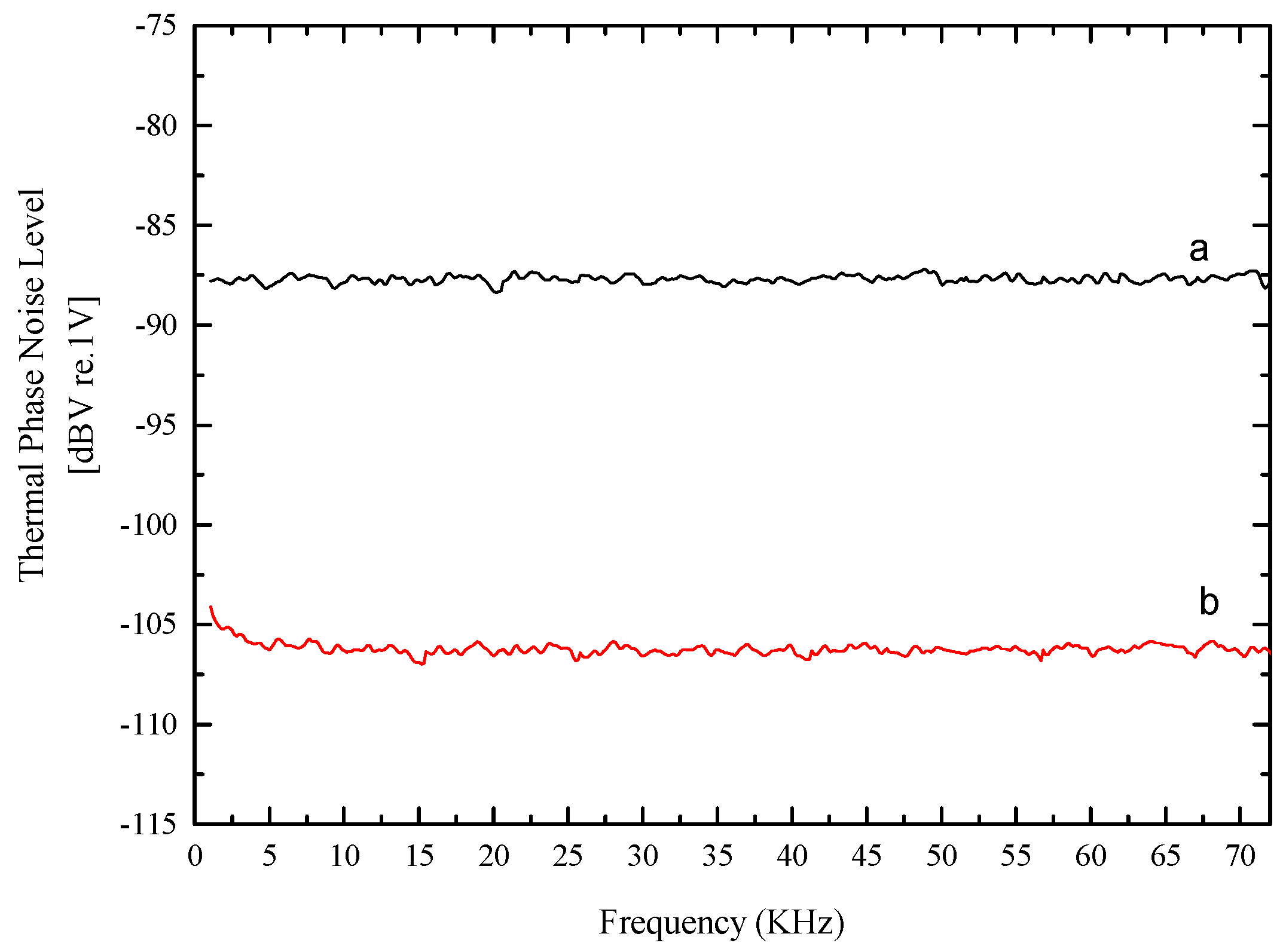

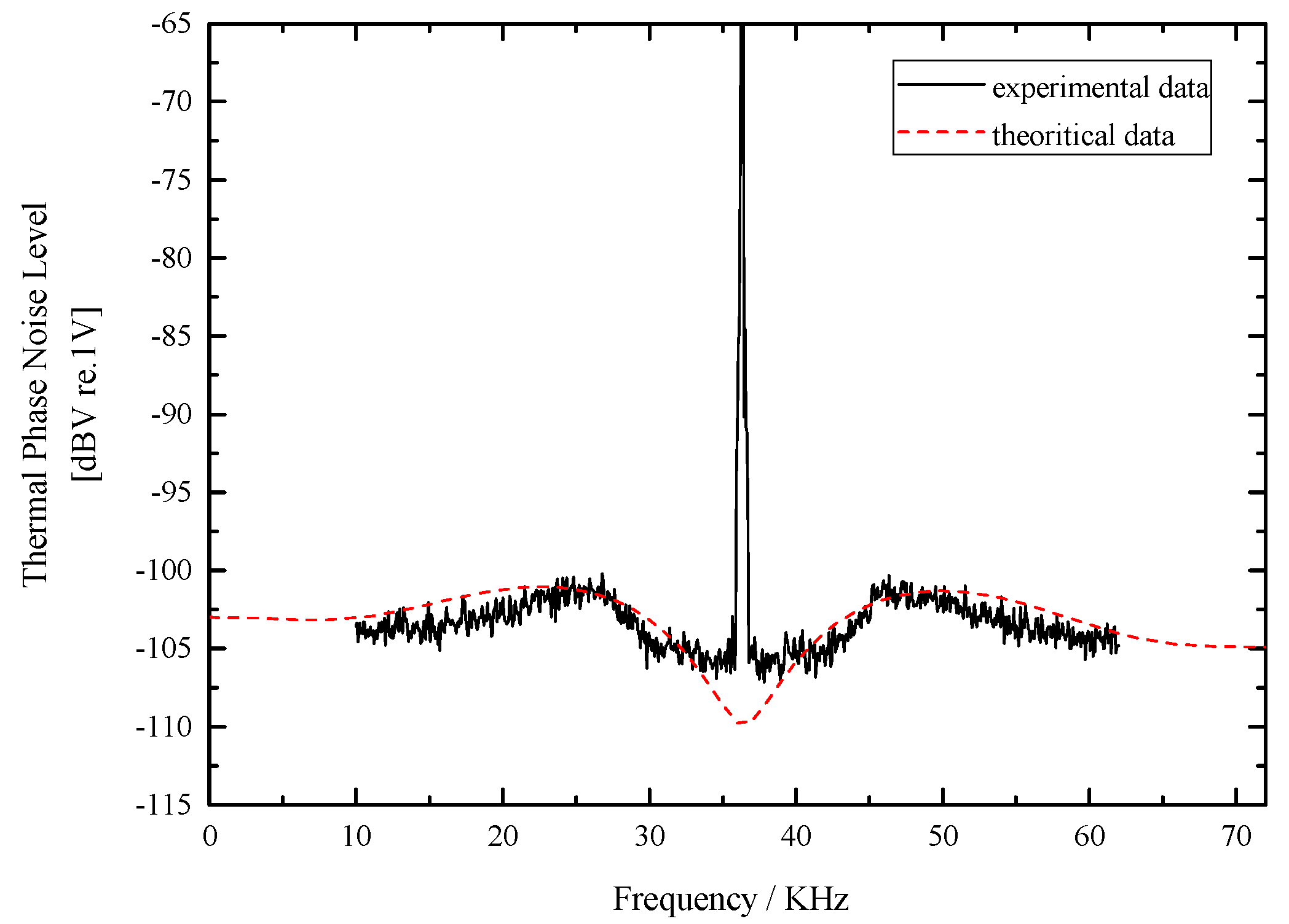

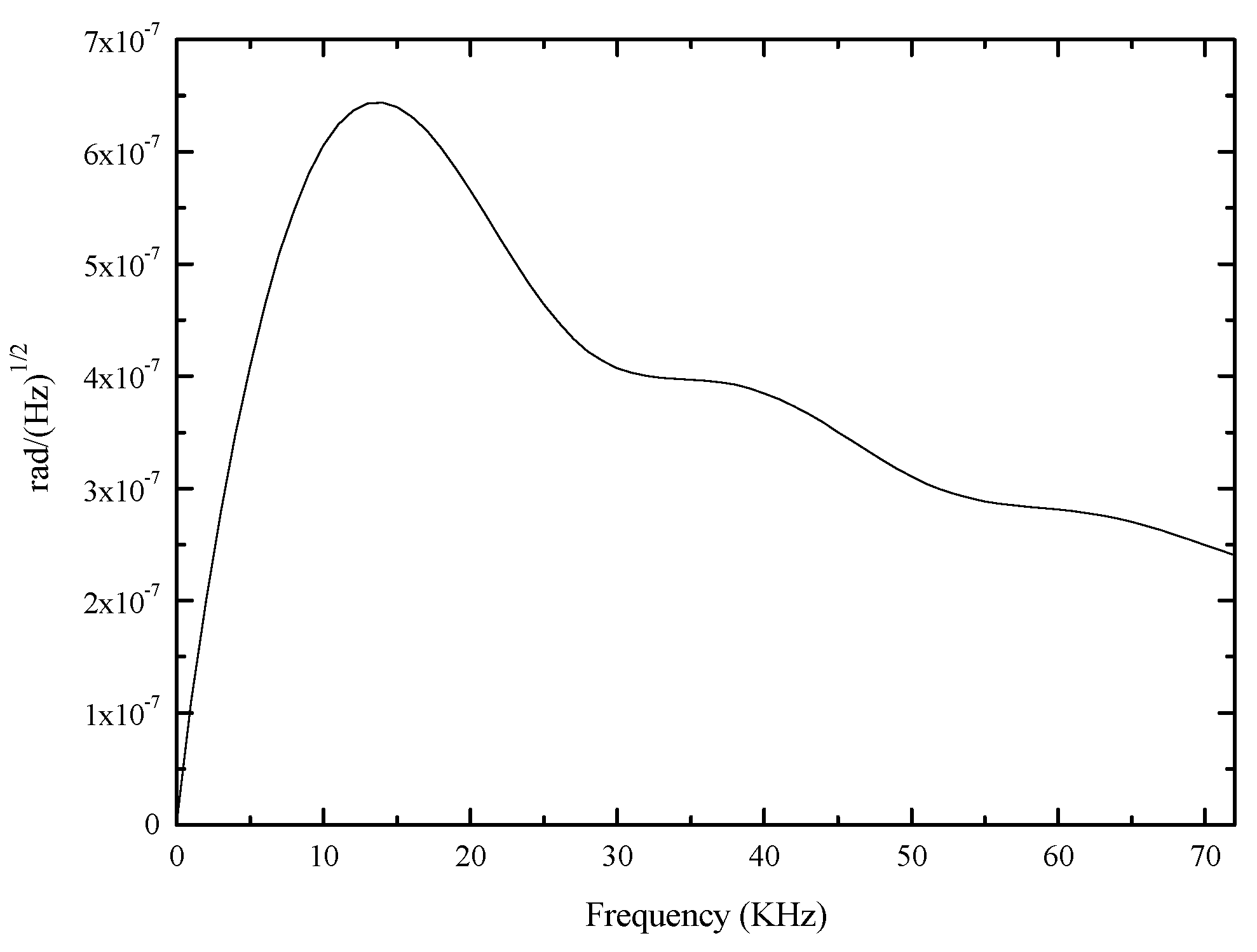

4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lefevre, H.C. The Fiber-Optic Gyroscope, 2nd ed.; Artech House: London, UK, 2014. [Google Scholar]

- Deppe, O.; Dorner, G.; König, S.; Martin, T.; Voigt, S.; Zimmermann, S. MEMS and FOG Technologies for Tactical and Navigation Grade Inertial Sensors-Recent Improvements and Comparison. Sensors 2017, 17, 567. [Google Scholar] [CrossRef] [PubMed]

- Pan, X.; Liu, P.; Zhang, S.; Jin, J.; Song, N. Novel Compensation Scheme for the Modulation Gain to Suppress the Quantization-Induced Bias in a Fiber Optic Gyroscope. Sensors 2017, 17, 823. [Google Scholar] [CrossRef] [PubMed]

- Paturel, Y.; Honthaas, J.; Lefèvre, H.; Napolitano, F. One nautical mile per month fog-based strapdown inertial navigation system: A dream already within reach? Gyroscopy Navig. 2014, 5, 1–8. [Google Scholar] [CrossRef]

- Krakenes, K.; Bløtekjær, K. Comparison of fiber-optic Sagnac and Mach-Zehnder interferometers with respect to thermal processes in the fiber. J. Lightwave Technol. 1995, 13, 682–686. [Google Scholar] [CrossRef]

- Bartolo, R.E.; Tveten, A.B.; Dandridge, A. Thermal phase noise measurements in optical fiber interferometers. IEEE J. Quantum Electron. 2012, 48, 720–727. [Google Scholar] [CrossRef]

- Knudsen, S.; Tveten, A.B.; Dandridge, A. Measurements of fundamental thermal induced phase fluctuations in the fiber of a Sagnac interferometer. IEEE Photonics Technol. Lett. 1995, 7, 90–92. [Google Scholar] [CrossRef]

- Knudsen, S.; Blotekjaer, K. Interferometric fiber-optic gyroscope performance owing to temperature-induced index fluctuations in the fiber: Effect on bias modulation. Opt. Lett. 1995, 20, 1432–1434. [Google Scholar] [CrossRef] [PubMed]

- Moeller, R.P.; Burns, W.K. Observation of thermal noise in a dynamically biased fiber-optic gyro. Opt. Lett. 1996, 21, 171–173. [Google Scholar] [CrossRef] [PubMed]

- Ma, P.; Song, N.; Jin, J.; Song, J.; Xu, X. Birefringence sensitivity to temperature of polarization maintaining photonic crystal fibers. Opt. Laser Technol. 2012, 44, 1829–1833. [Google Scholar] [CrossRef]

- Kim, D.H.; Kang, J.U. Analysis of temperature-dependent birefringence of a polarization-maintaining photonic crystal fiber. Opt. Eng. 2007, 46, 075003. [Google Scholar] [CrossRef]

- Moeller, R.P.; Burns, W.K.; Frigo, N.J. Open-Loop Output and Scale Factor Stability in a Fiber-Optic Gyroscope. J. Lightwave Technol. 1989, 7, 262–269. [Google Scholar] [CrossRef]

- Renato, C.R.; Ricardo, T.C.; James, B. SNR enhancement of intensity noise-limited FOGs. IEEE J. Lightwave Technol. 2000, 18, 2146–2150. [Google Scholar]

- Iwatsuki, K. Excess noise reduction in fiber gyroscope using broader spectrum linewidth Er-doped superfluorescent fiber laser. IEEE Photonics Technol. Lett. 1991, 3, 281–283. [Google Scholar] [CrossRef]

| Parameter | Property | Value |

|---|---|---|

| η (A/W) | Detector responsivity | 0.95 |

| R (kΩ) | Load resistance | 288 |

| λ (nm) | Operational wavelength | 1550 |

| B (Hz) | Reference bandwidth | 30 |

| T (K) | Temperature | 293.15 |

| P0 (μW) | Average optical power | 5.85 |

| L (km) | Length of fiber coil | 2.8 |

| ν (m/s) | Effective speed of light in the fiber | 2.079 × 108 |

| (V) | Modulation phase | 1.4 |

| A (rad) | Modulation depth | 1.8 |

| d (μm) | Fiber cladding diameter | 100 |

| κ (W/(m K)) | Thermal conductivity | 1.02 |

| Di (m2/s) | Thermal diffusity | 0.82 × 10−6 |

| αl (ppm/°C) | Linear thermal expansion coefficient | 1.02 |

| dneff/dT (/°C) | Temperature coefficient of refractive index | 9.9 × 10−6 |

| D (cm) | Diameter of fiber coil | 16 |

| neff | Effective refractive index | 1.435 |

| W0 | Mode field radius | 3.1 |

| Δd (μm) | Diameter of the air holes in the cladding | 3.4 |

| ΔD (μm) | Diameter of the two enlarged air holes in x-direction | 5.8 |

| Λ (μm) | Distance of two adjacent air hole centers | 5.9 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, N.; Ma, K.; Jin, J.; Teng, F.; Cai, W. Modeling of Thermal Phase Noise in a Solid Core Photonic Crystal Fiber-Optic Gyroscope. Sensors 2017, 17, 2456. https://doi.org/10.3390/s17112456

Song N, Ma K, Jin J, Teng F, Cai W. Modeling of Thermal Phase Noise in a Solid Core Photonic Crystal Fiber-Optic Gyroscope. Sensors. 2017; 17(11):2456. https://doi.org/10.3390/s17112456

Chicago/Turabian StyleSong, Ningfang, Kun Ma, Jing Jin, Fei Teng, and Wei Cai. 2017. "Modeling of Thermal Phase Noise in a Solid Core Photonic Crystal Fiber-Optic Gyroscope" Sensors 17, no. 11: 2456. https://doi.org/10.3390/s17112456

APA StyleSong, N., Ma, K., Jin, J., Teng, F., & Cai, W. (2017). Modeling of Thermal Phase Noise in a Solid Core Photonic Crystal Fiber-Optic Gyroscope. Sensors, 17(11), 2456. https://doi.org/10.3390/s17112456