Development of a Telemetric, Miniaturized Electrochemical Amperometric Analyzer

Abstract

:1. Introduction

2. Materials and Methods

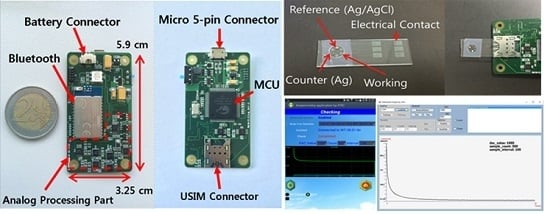

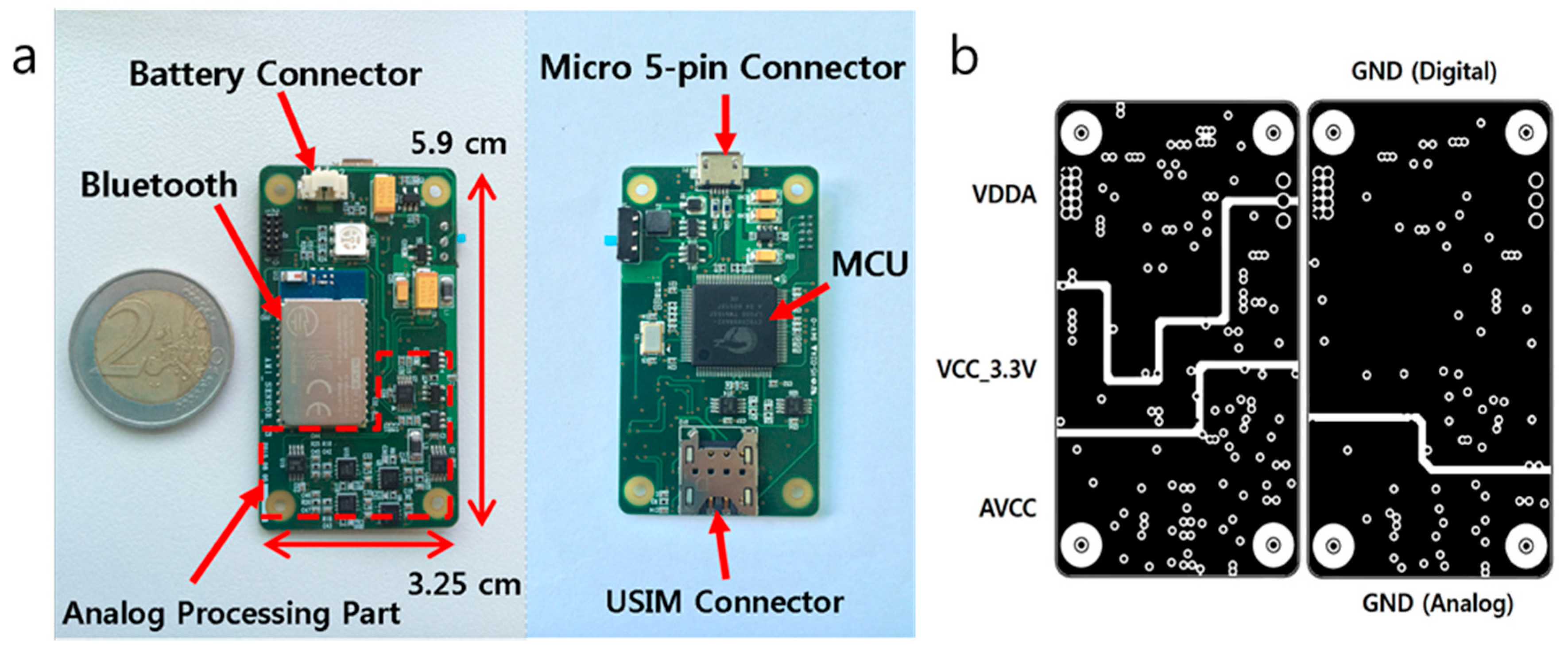

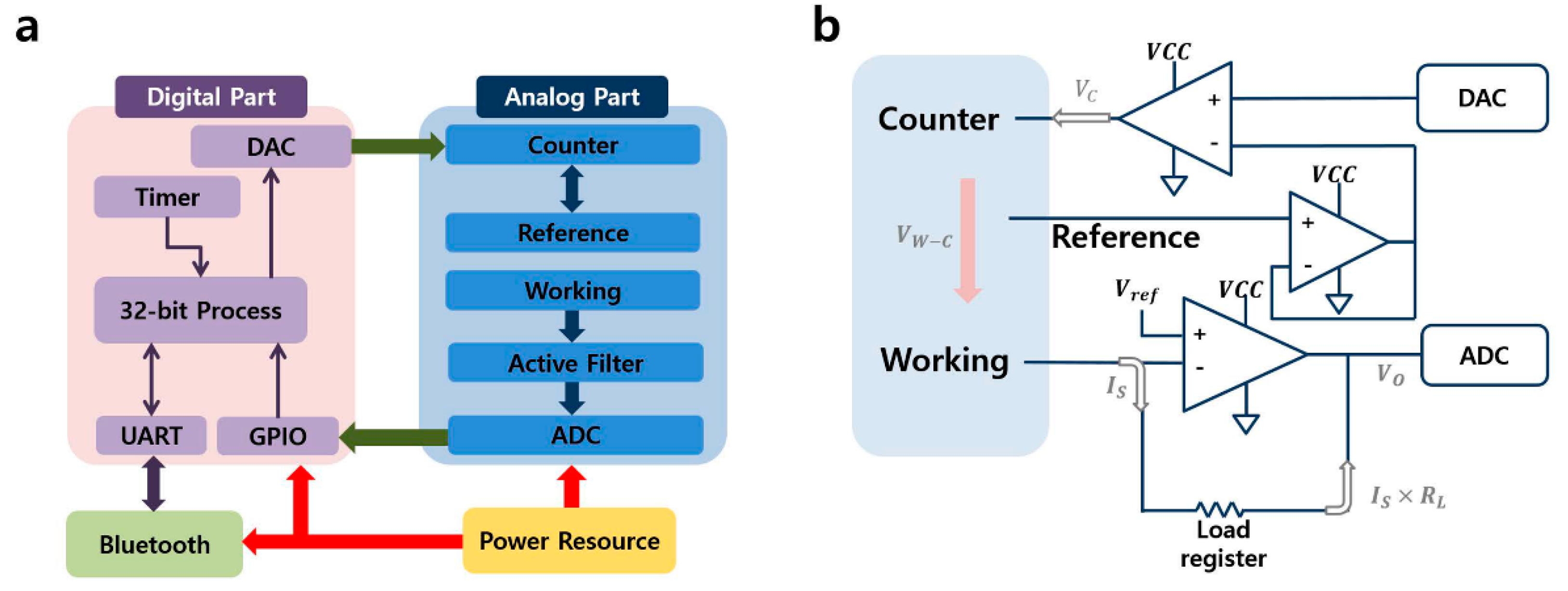

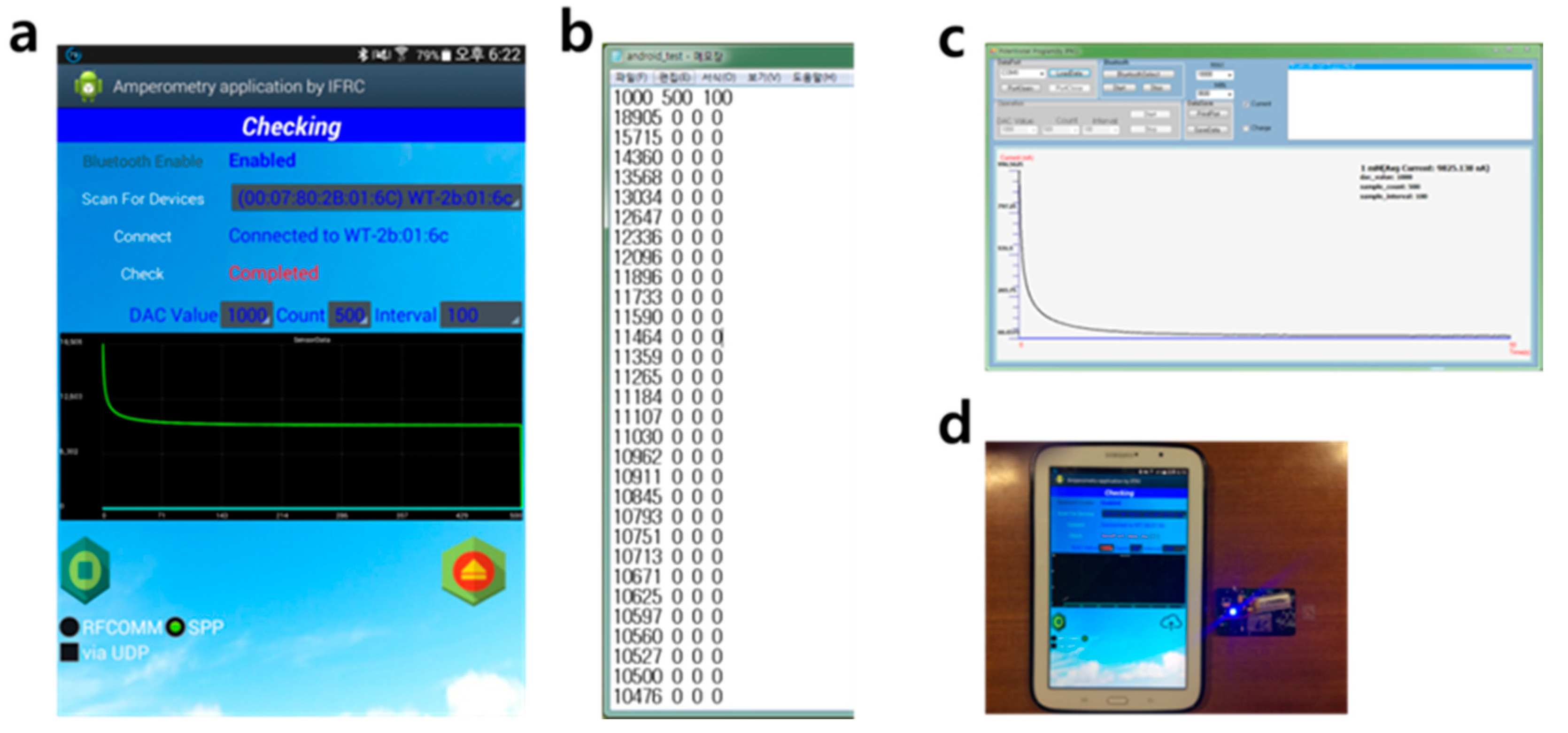

2.1. Design of Amperometric Device

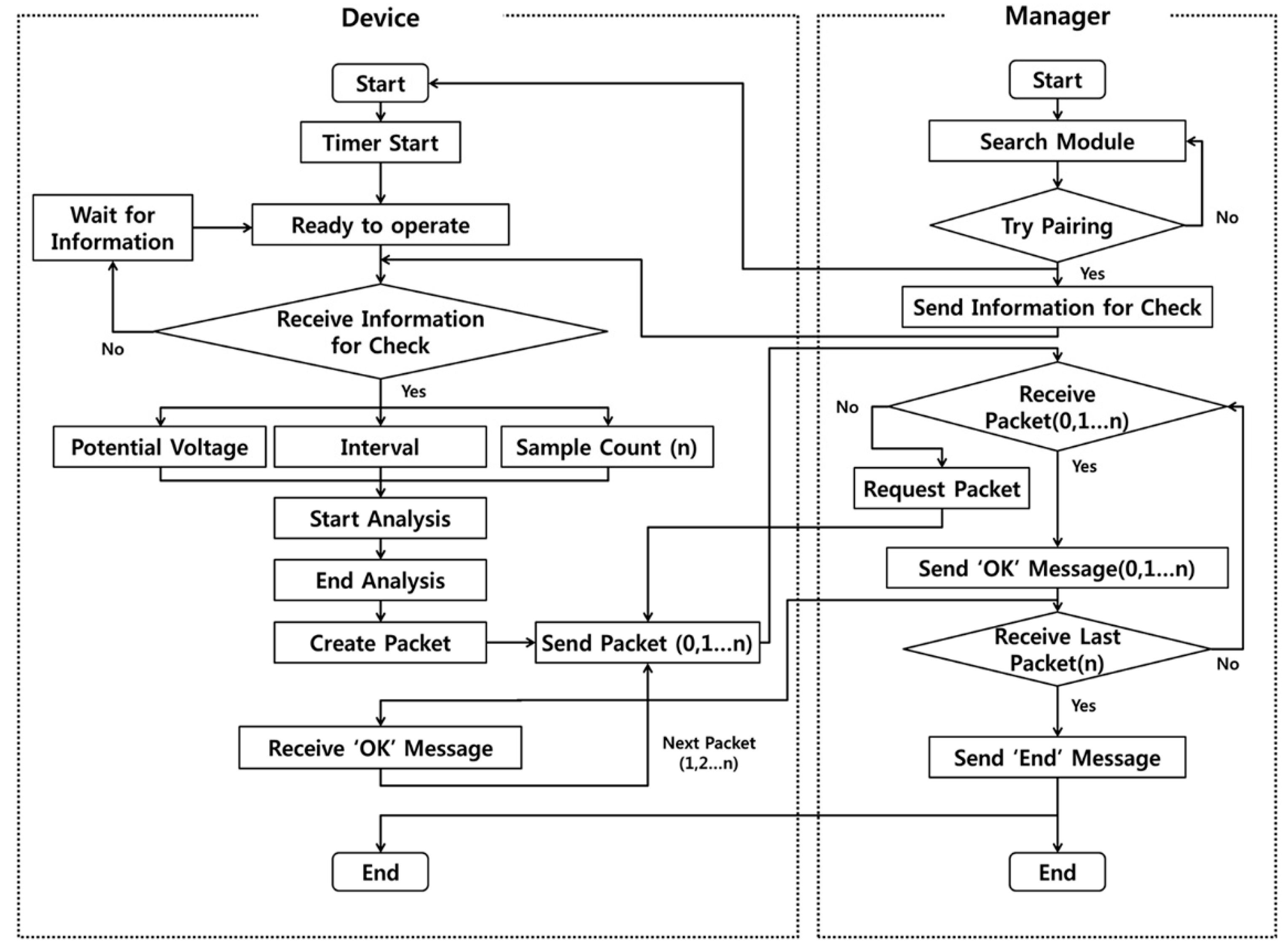

2.2. System Operation Flow

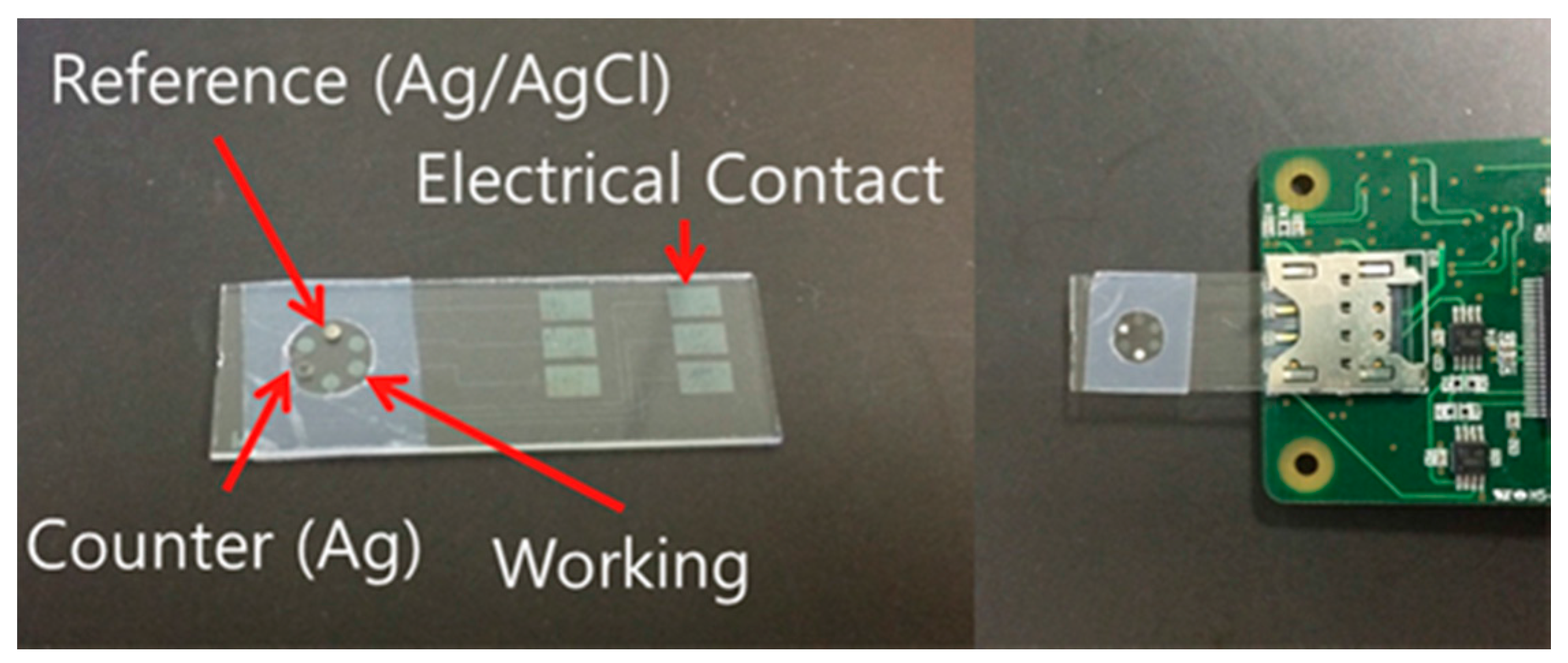

2.3. ITO Glass Sensor

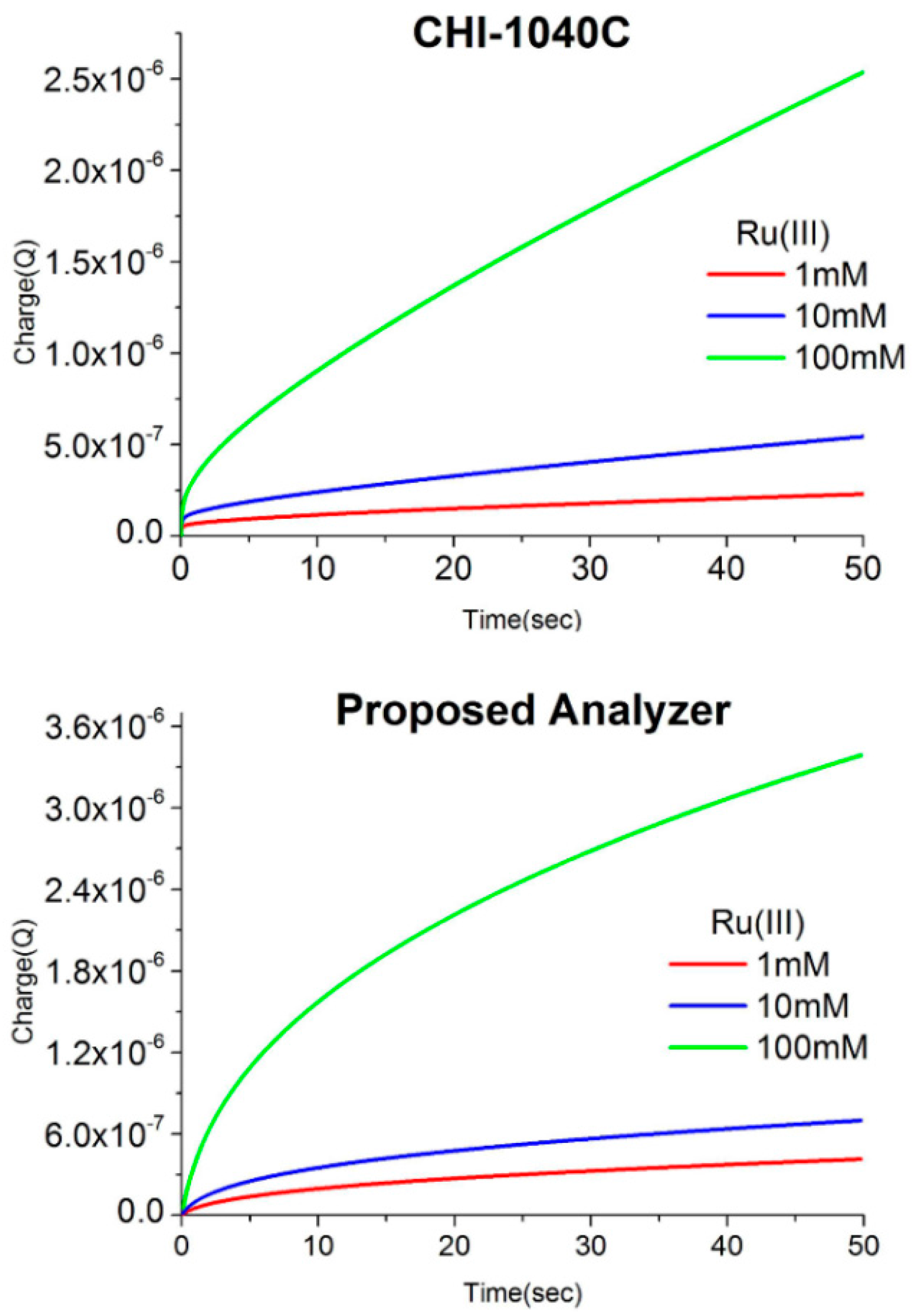

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ahmed, M.U.; Saaem, I.; Wu, P.C.; Brown, A.S. Brown, Personalized diagnostics and biosensors: A review of the biology and technology needed for personalized medicine. Crit. Rev. Biotechnol. 2014, 34, 180–196. [Google Scholar] [CrossRef] [PubMed]

- Pasta, M.; La Mantia, F.; Cui, Y. Mechanism of glucose electrochemical oxidation on gold surface. Electochim. Acta 2010, 55, 5561–5568. [Google Scholar] [CrossRef]

- Luppa, P.B.; Müller, C.; Schlichtiger, A.; Schlebusch, H. Point-of-care testing (POCT): Current techniques and future perspectives. TrAC Trends Anal. Chem. 2011, 30, 887–898. [Google Scholar] [CrossRef]

- Ahmadi, M.M.; Jullien, G.A. Current-mirror-based potentiostats for three-electrode amperometric electrochemical sensors. IEEE Trans. Circuits Syst. I Regul. Pap. 2009, 56, 1339–1348. [Google Scholar] [CrossRef]

- Huang, C.Y.; O’Hare, D.; Chao, I.J.; Wei, H.W.; Liang, Y.F.; Liu, B.D.; Lee, M.H.; Lin, H.Y. Integrated potentiostat for electrochemical sensing of urinary 3-hydroxyanthranilic acid with molecularly imprinted poly(ethylene-co-vinyl alcohol). Biosens. Bioelectron. 2015, 67, 208–213. [Google Scholar] [CrossRef] [PubMed]

- Martin, S.M.; Gebara, F.H.; Strong, T.D.; Brown, R.B. A low-voltage, chemical sensor interface for systems-on-chip: The fully-differential potentiostat. In Proceedings of the 2004 International Symposium on Circuits, 2004 (ISCAS’04), Vancouver, BC, Canada, 23–26 May 2004; Volume 4, pp. 892–895. [Google Scholar]

- Blanco, J.R.; Ferrero, F.J.; Campo, J.C.; Anton, J.C.; Pingarron, J.M.; Reviejo, A.J.; Manso, J. Design of a low-cost portable potentiostat for amperometric biosensors. In Proceedings of the Instrumentation and Measurement Technology Conference, 2006 (IMTC 2006), Sorrento, Italy, 24–27 April 2006. [Google Scholar]

- Schneider, H.G.; Ablitt, P.; Taylor, J. Improved sensitivity of point of care troponin I values using reporting to below 99th percentile of normal. Clin. Biochem. 2013, 46, 979–982. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Yang, H. Sensitive and selective trypsin detection using redox cycling in the presence of l-ascorbic acid. Analyst 2014, 139, 4051–4055. [Google Scholar] [CrossRef] [PubMed]

- Skládal, P. Electrochemical detection for biological identification. In Biological Identification: DNA Amplification and Sequencing, Optical Sensing, Lab-On-Chip and Portable Systems; Schaudies, R.P., Ed.; Woodhead Publishing: Sawston, Cambridge, UK, 2014; pp. 131–152. [Google Scholar]

- Lei, Y.; Luo, N.; Yan, X.; Zhao, Y.; Zhang, G.; Zhang, Y. A highly sensitive electrochemical biosensor based on zinc oxide nanotetrapods for l-lactic acid detection. Nanoscale 2012, 4, 3438–3443. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Feng, H.; Li, J.; Feng, Y.; Zhang, Y.; Jiang, J.; Qian, D. Fabrication of gold nanoparticles-decorated reduced graphene oxide as a high performance electrochemical sensing platform for the detection of toxicant Sudan I. Electrochim. Acta 2015, 167, 226–236. [Google Scholar] [CrossRef]

- Steinberg, M.D.; Lowe, C.R. A micropower amperometric potentiostat. Sens. Actuators B Chem. 2004, 97, 284–289. [Google Scholar] [CrossRef]

- Kaushik, A.; Tiwari, S.; Jayant, R.D.; Vashist, A.; Nikkhah-Moshaie, R.; El-Hage, N.; Nair, M. Electrochemical Biosensors for Early Stage Zika Diagnostics. Trends Biotechnol. 2017, 35, 308–317. [Google Scholar] [CrossRef] [PubMed]

- Vasudev, A.; Kaushik, A.; Tomizawa, Y.; Norena, N.; Bhansali, S. An LTCC-based microfluidic system for label-free, electrochemical detection of cortisol. Sens. Actuators B Chem. 2013, 182, 139–146. [Google Scholar] [CrossRef]

- Kaushik, A.; Jayant, R.D.; Tiwari, S.; Vashist, A.; Nair, M. Nano-biosensors to detect beta-amyloid for Alzheimer’s disease management. Biosens. Bioelectron. 2016, 80, 273–287. [Google Scholar] [CrossRef] [PubMed]

- Cosnier, S. Electrochemical Biosensors; Pan Stanford Publishing: Singapore, 2014; p. 112. [Google Scholar]

- Kaushik, A.; Tiwari, S.; Jayant, R.D.; Marty, A.; Nair, M. Towards detection and diagnosis of Ebola virus disease at point-of-care. Biosens. Bioelectron. 2016, 75, 254–272. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, A.; Yndart, A.; Jayant, R.D.; Sagar, V.; Atluri, V.; Bhansali, S.; Nair, M. Electrochemical sensing method for point-of-care cortisol detection in human immunodeficiency virus-infected patients. Int. J. Nanomed. 2015, 10, 677–685. [Google Scholar]

- Jung, W.; Han, J.; Choi, J.W.; Ahn, C.H. Ahn, Point-of-care testing (POCT) diagnostic systems using microfluidic lab-on-a-chip technologies. Microelectron. Eng. 2015, 132, 46–57. [Google Scholar] [CrossRef]

- Cruz, A.F.D.; Norena, N.; Kaushik, A.; Bhansali, S. A low-cost miniaturized potentiostat for point-of-care diagnosis. Biosens. Bioelectron. 2014, 62, 249–254. [Google Scholar] [CrossRef] [PubMed]

- Pruna, R.; Palacio, F.; Baraket, A.; Bausells, J.; Errachid, A.; López, M. Low-Cost Impedance Measurements for Lab-on-a-Chip Architectures: Towards Potentiostat Miniaturization. Multidiscip. Digit. Publ. Inst. Proc. 2017, 1, 604. [Google Scholar] [CrossRef]

- Leonardi, S.G.; Bonyani, M.; Ghosh, K.; Dhara, A.K.; Lombardo, L.; Donato, N.; Neri, G. Development of a Novel Cu (II) Complex Modified Electrode and a Portable Electrochemical Analyzer for the Determination of Dissolved Oxygen (DO) in Water. Chemosensors 2016, 4, 7. [Google Scholar] [CrossRef]

- Richter, E.M.; Tormin, T.F.; Cunha, R.R.; Silva, W.P.; Pérez-Junquera, A.; Fanjul-Bolado, P.; Hernández-Santos, D. A Compact Batch Injection Analysis Cell for Screen Printed Electrodes: A Portable Electrochemical System for On-site Analysis. Electroanalysis 2016, 28, 1856–1859. [Google Scholar] [CrossRef]

- Kotanen, C.N.; Guiseppi-Elie, A. Characterization of a wireless potentiostat for integration with a novel implantable biotransducer. IEEE Sens. J. 2014, 14, 768–776. [Google Scholar] [CrossRef]

- Kadri, N.A.; Hoettges, K.F.; Hughes, M.P. Microelectrode fabrication using Indium Tin Oxide (ITO) for microfluidic devices employing dielectrophoresis. In Proceedings of the 4th Kuala Lumpur International Conference on Biomedical Engineering, Kuala Lumpur, Malaysia, 25–28 June 2008; pp. 719–722. [Google Scholar]

- Jung, J.; Lee, J.; Lee, J.; Kim, Y.T. A smartphone-based U-Healthcare system for real-time monitoring of acute myocardial infarction. Int. J. Commun. Syst. 2015, 28, 2311–2325. [Google Scholar] [CrossRef]

- Hong, C.H.; Shin, J.H.; Ju, B.K.; Kim, K.H.; Park, N.M.; Kim, B.S.; Cheong, W.S. Index-matched indium tin oxide electrodes for capacitive touch screen panel applications. J. Nanosci. Nanotechnol. 2013, 13, 7756–7759. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Goldberg, I.B.; Judy, J.W. Microfabricated electrochemical nitrate sensor using double-potential-step chronocoulometry. Sens. Actuators B Chem. 2009, 135, 618–624. [Google Scholar] [CrossRef]

- Dutta, G.; Park, S.; Singh, A.; Seo, J.; Kim, S.; Yang, H. Low-Interference Washing-Free Electrochemical Immunosensor Using Glycerol-3-phosphate Dehydrogenase as an Enzyme Label. Anal. Chem. 2015, 87, 3574–3578. [Google Scholar] [CrossRef] [PubMed]

| Specification | |

|---|---|

| Electrode | ITO glass (CE: Ag, RE: Ag/AgCl) |

| Technique | Chronoamperometry, Chronocoulometry |

| Channel | 1–4 ch |

| Potential range | ±1.1 V |

| Potential step | 10 mV |

| Sampling interval | 10–1000 msec |

| Sampling count | 100–3000 |

| Current resolution | 0.4 nA |

| Size | 3.25 × 5.9 × 0.9 cm |

| Weight | 35 g |

| Power supply | Li-polyer 120 mAh |

| Display | PC, Tablet PC |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, J.; Lee, J.; Shin, S.; Kim, Y.T. Development of a Telemetric, Miniaturized Electrochemical Amperometric Analyzer. Sensors 2017, 17, 2416. https://doi.org/10.3390/s17102416

Jung J, Lee J, Shin S, Kim YT. Development of a Telemetric, Miniaturized Electrochemical Amperometric Analyzer. Sensors. 2017; 17(10):2416. https://doi.org/10.3390/s17102416

Chicago/Turabian StyleJung, Jaehyo, Jihoon Lee, Siho Shin, and Youn Tae Kim. 2017. "Development of a Telemetric, Miniaturized Electrochemical Amperometric Analyzer" Sensors 17, no. 10: 2416. https://doi.org/10.3390/s17102416

APA StyleJung, J., Lee, J., Shin, S., & Kim, Y. T. (2017). Development of a Telemetric, Miniaturized Electrochemical Amperometric Analyzer. Sensors, 17(10), 2416. https://doi.org/10.3390/s17102416