A Novel Position Compensation Scheme for Cable-Pulley Mechanisms Used in Laparoscopic Surgical Robots

Abstract

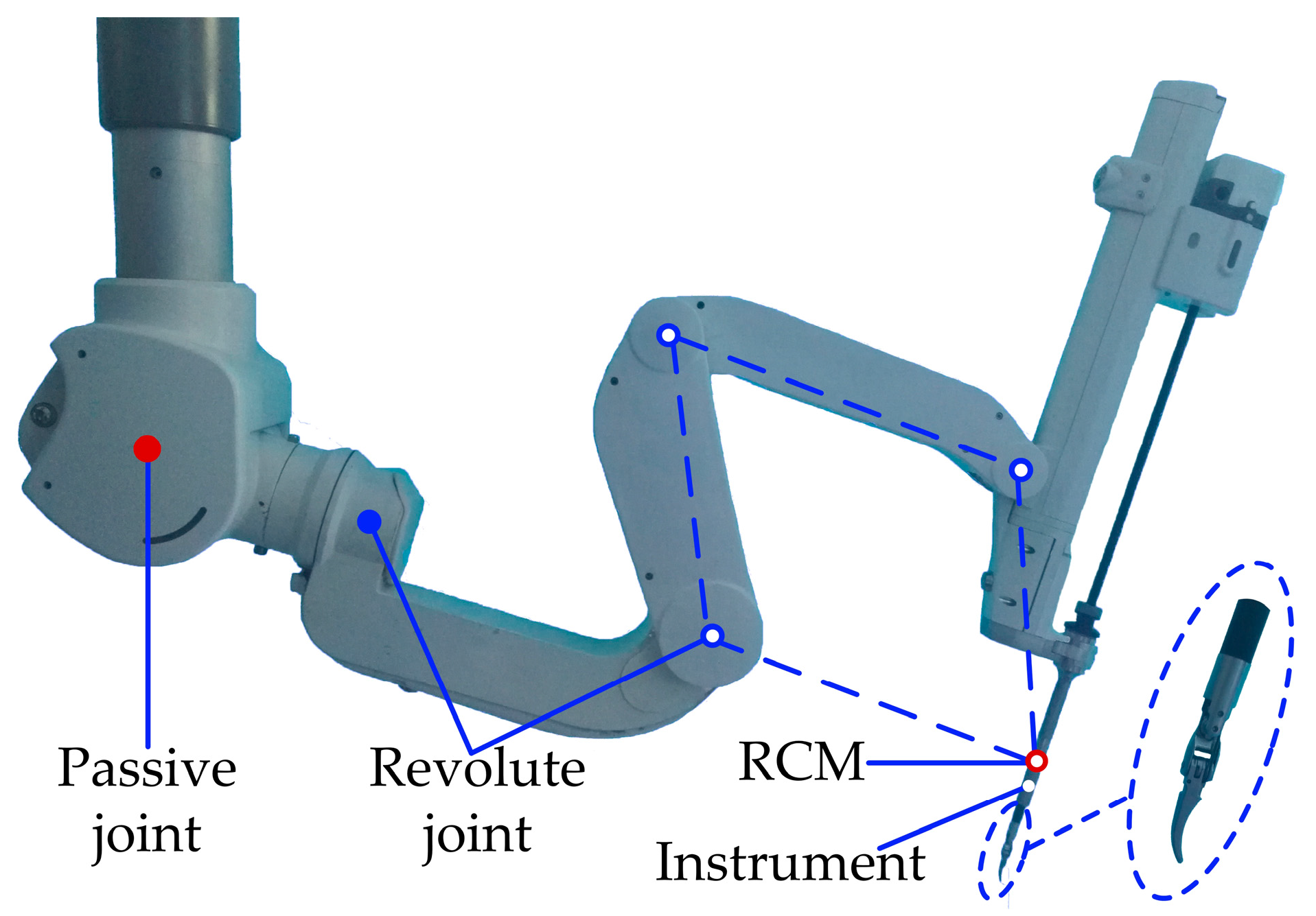

:1. Introduction

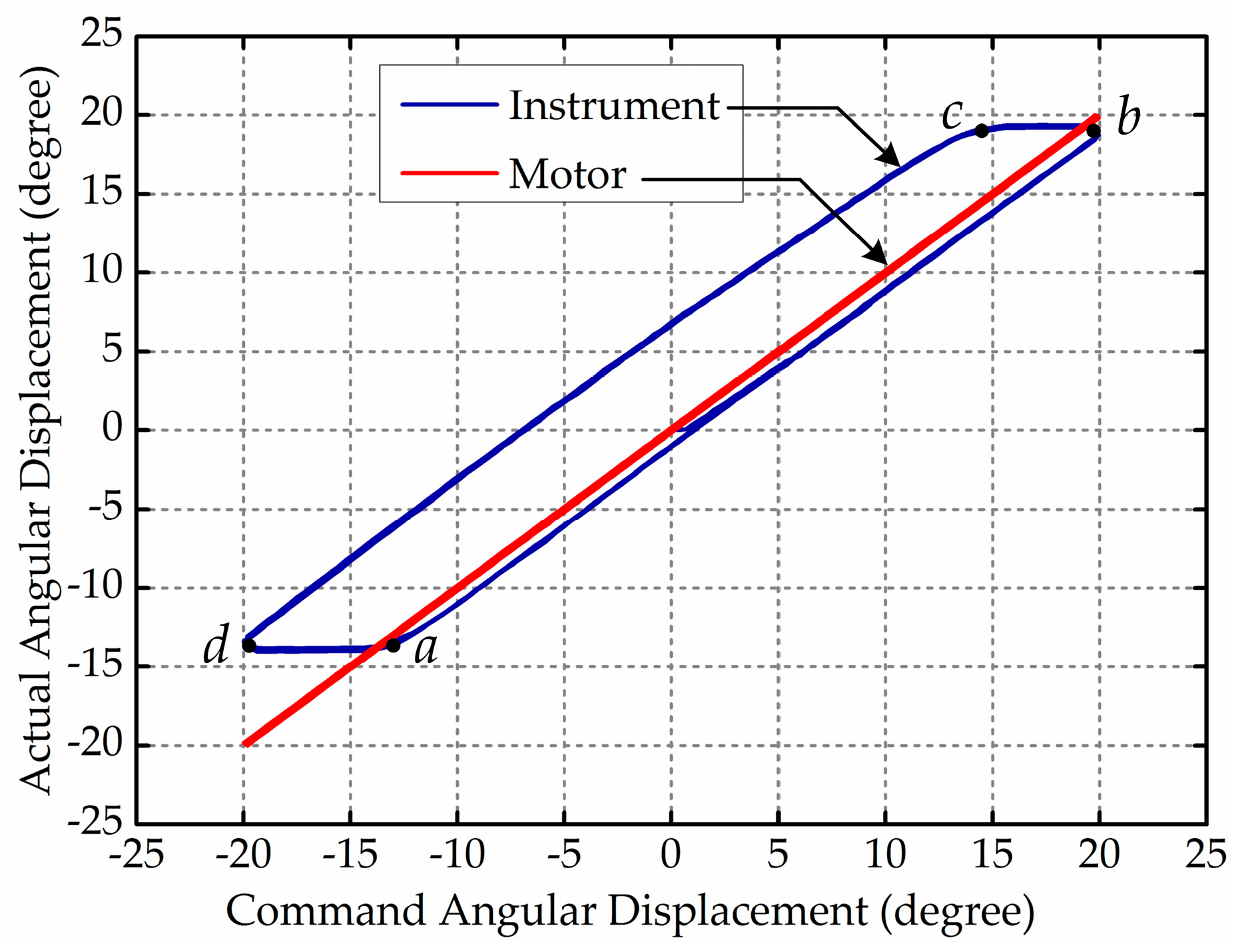

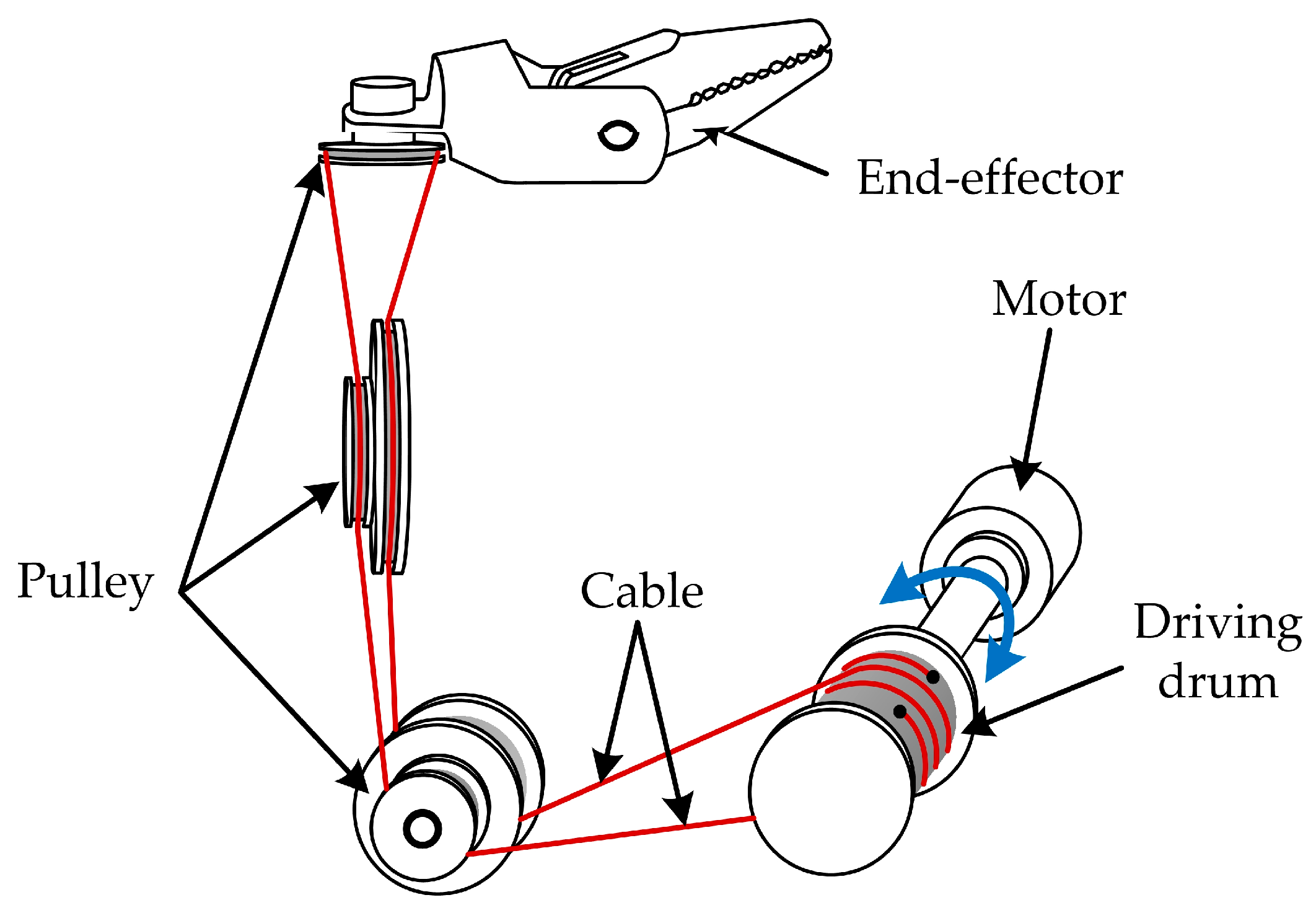

2. The Position Compensation Scheme

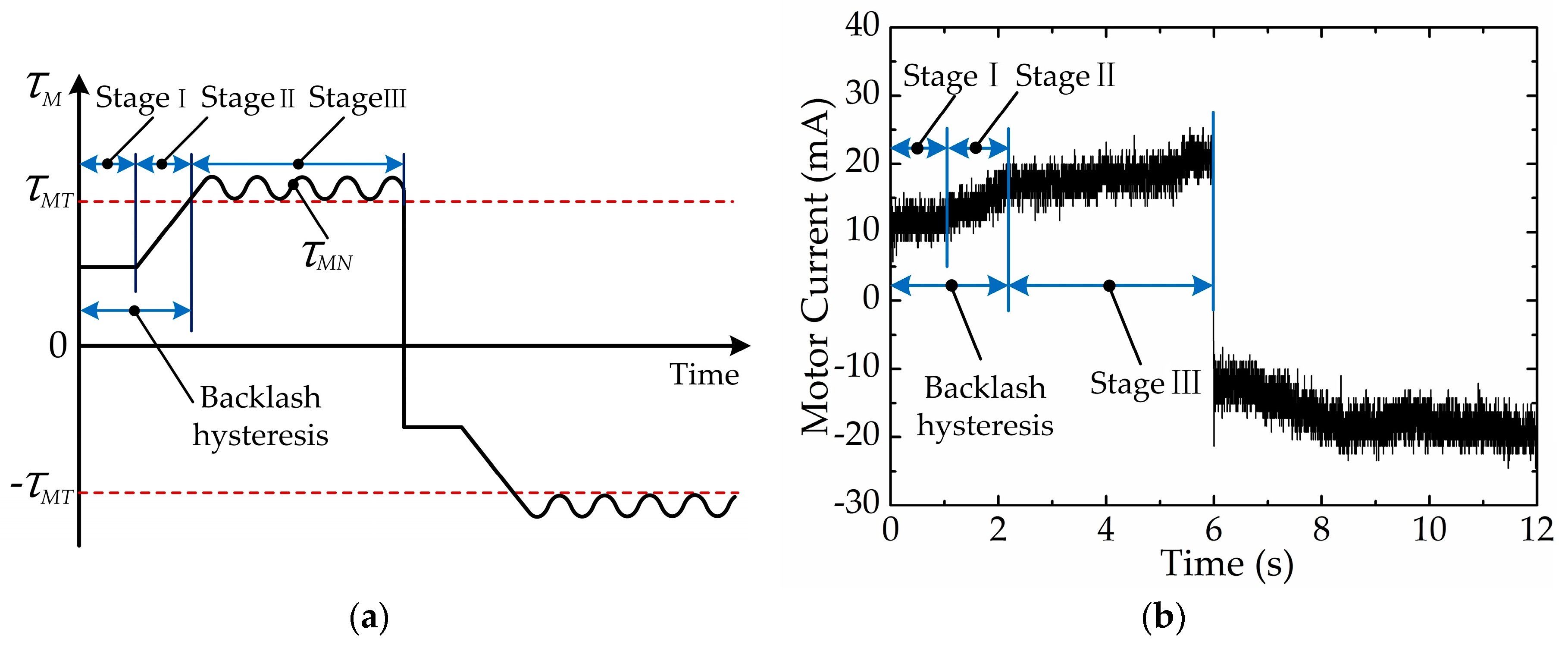

2.1. Kinetic Analysis for the Cable-Pulley Mechanism

2.2. Classification of the End-effector’s Movement Stages

2.3. The Position Compensation Scheme for the Cable-Pulley System Used in the End-effector

3. Experiment and Results

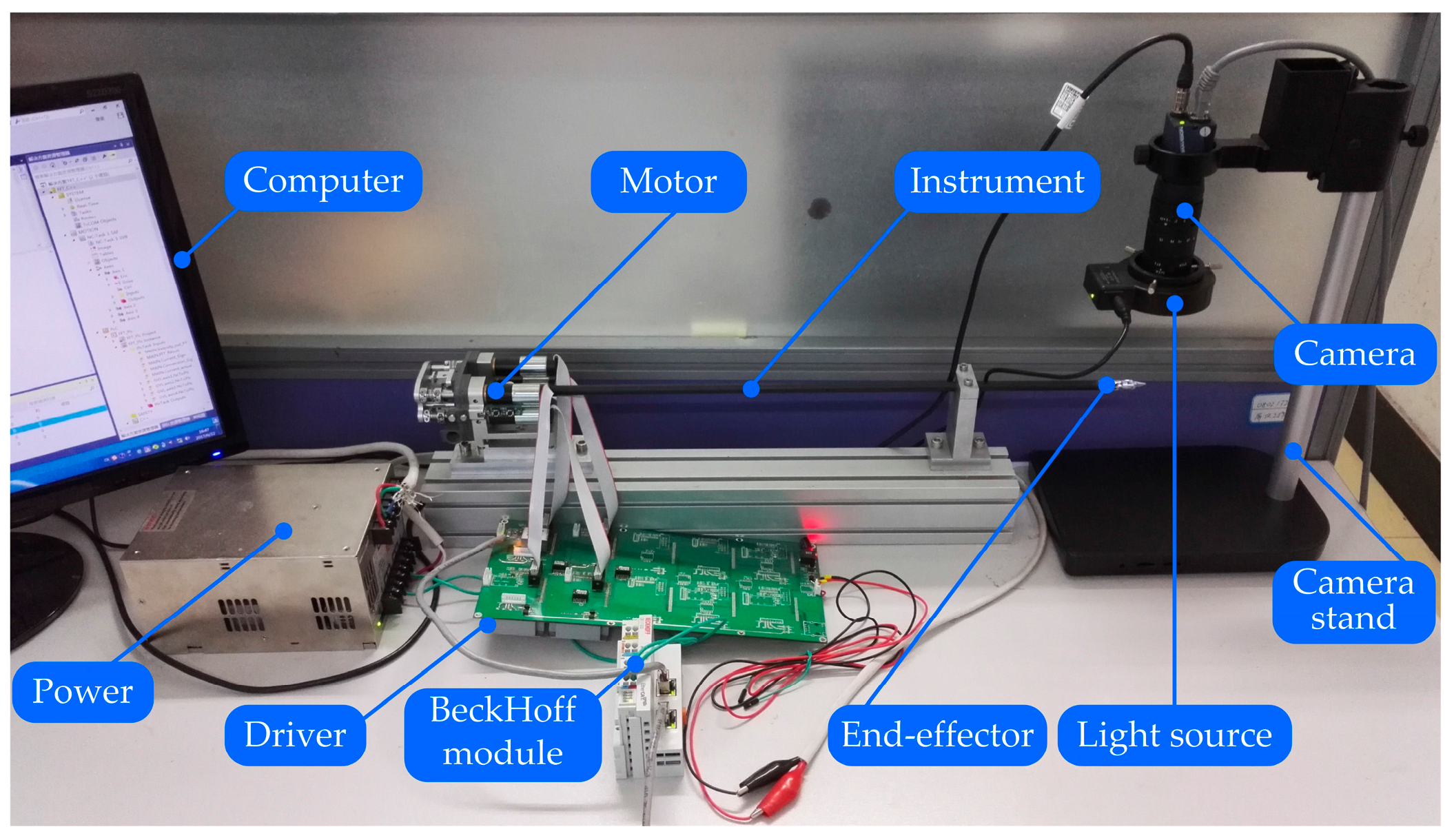

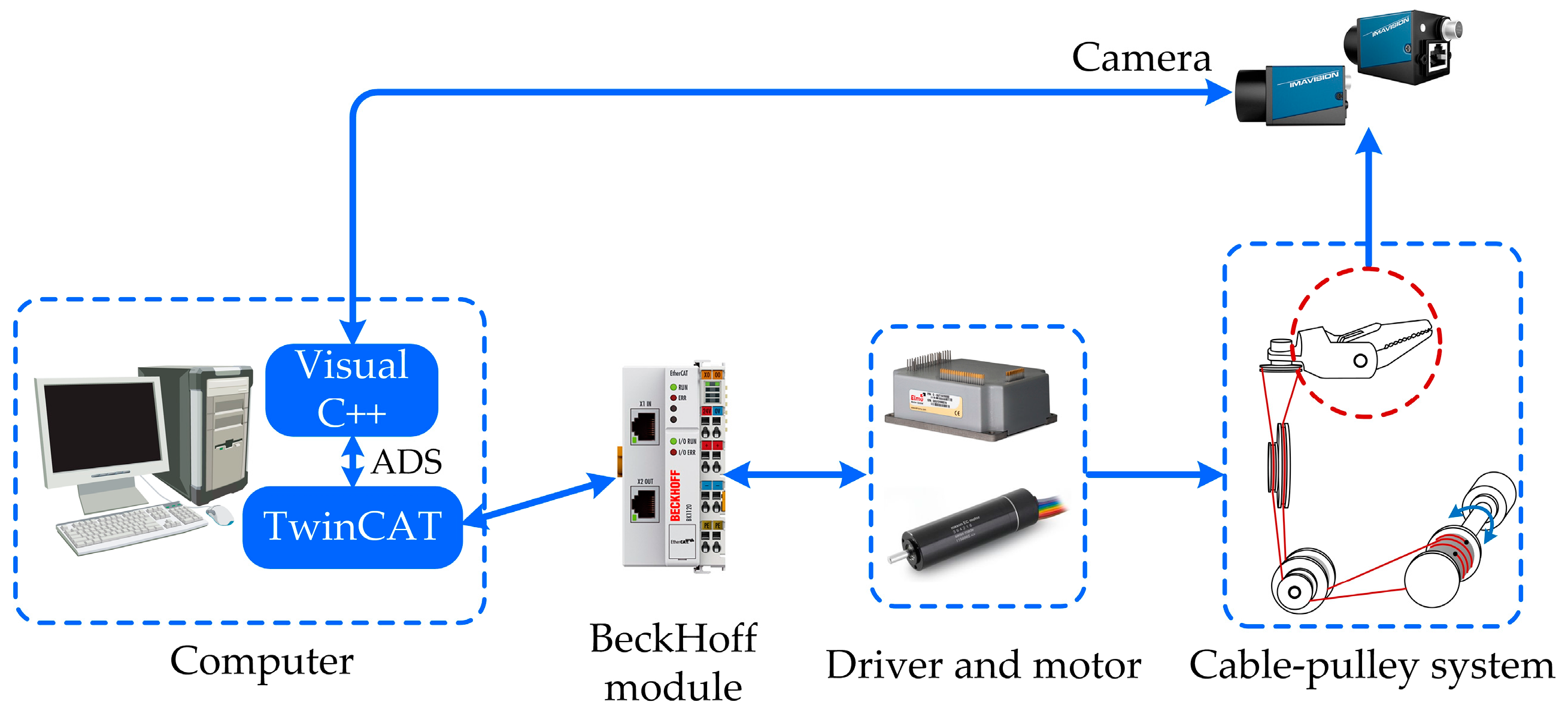

3.1. Experiment Setup

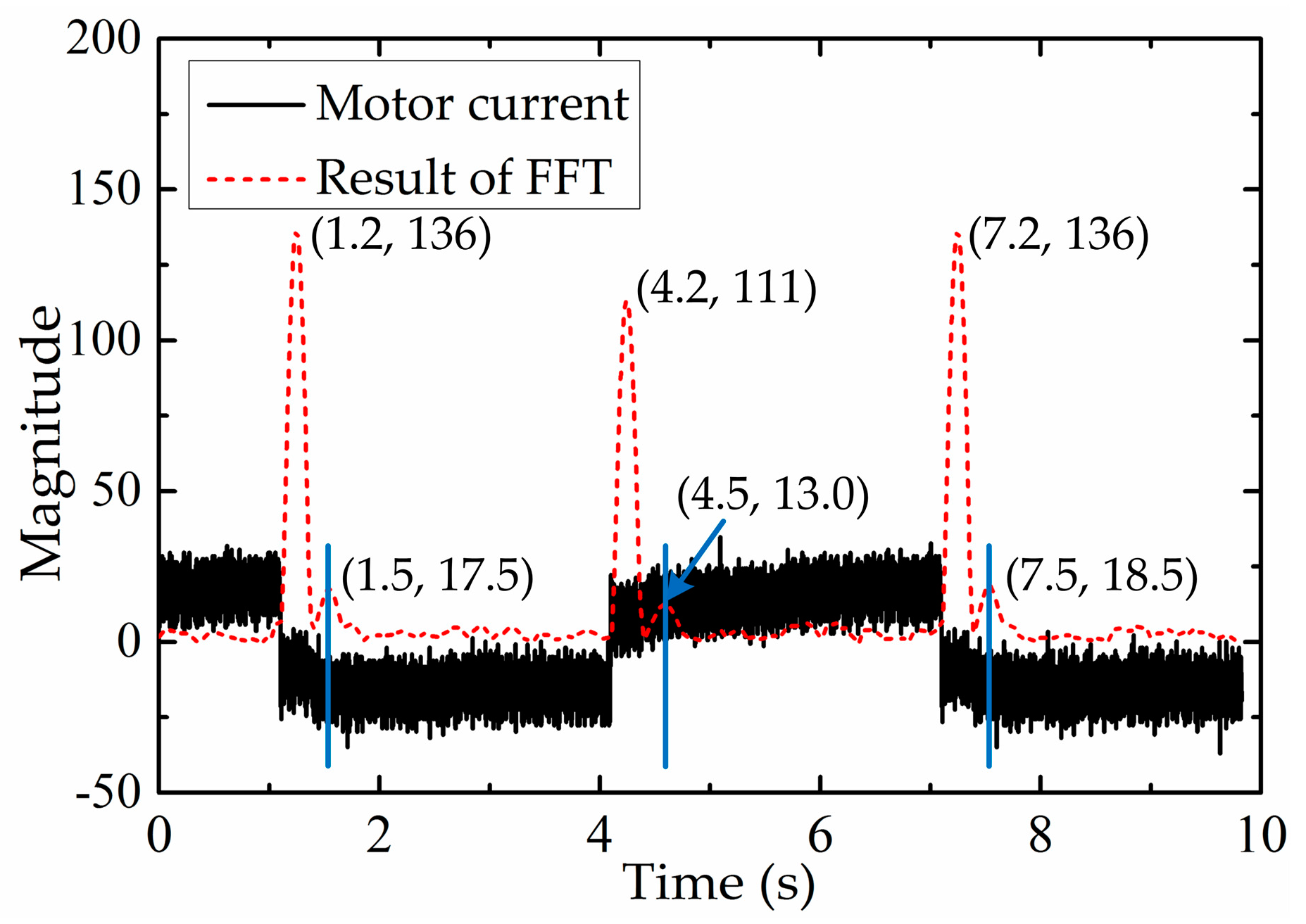

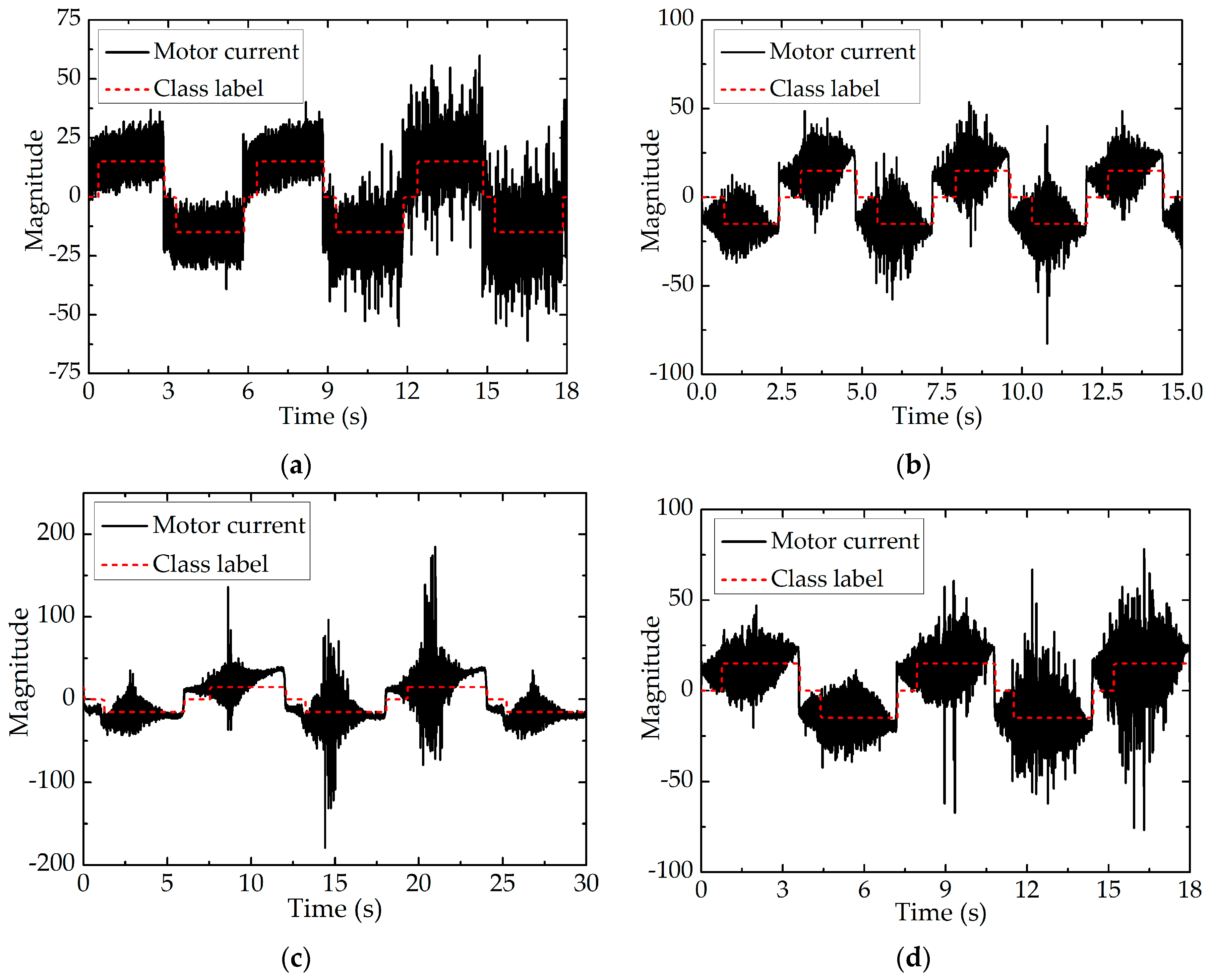

3.2. Training the Classifier and Classifying the Movement Stage in Real-Time

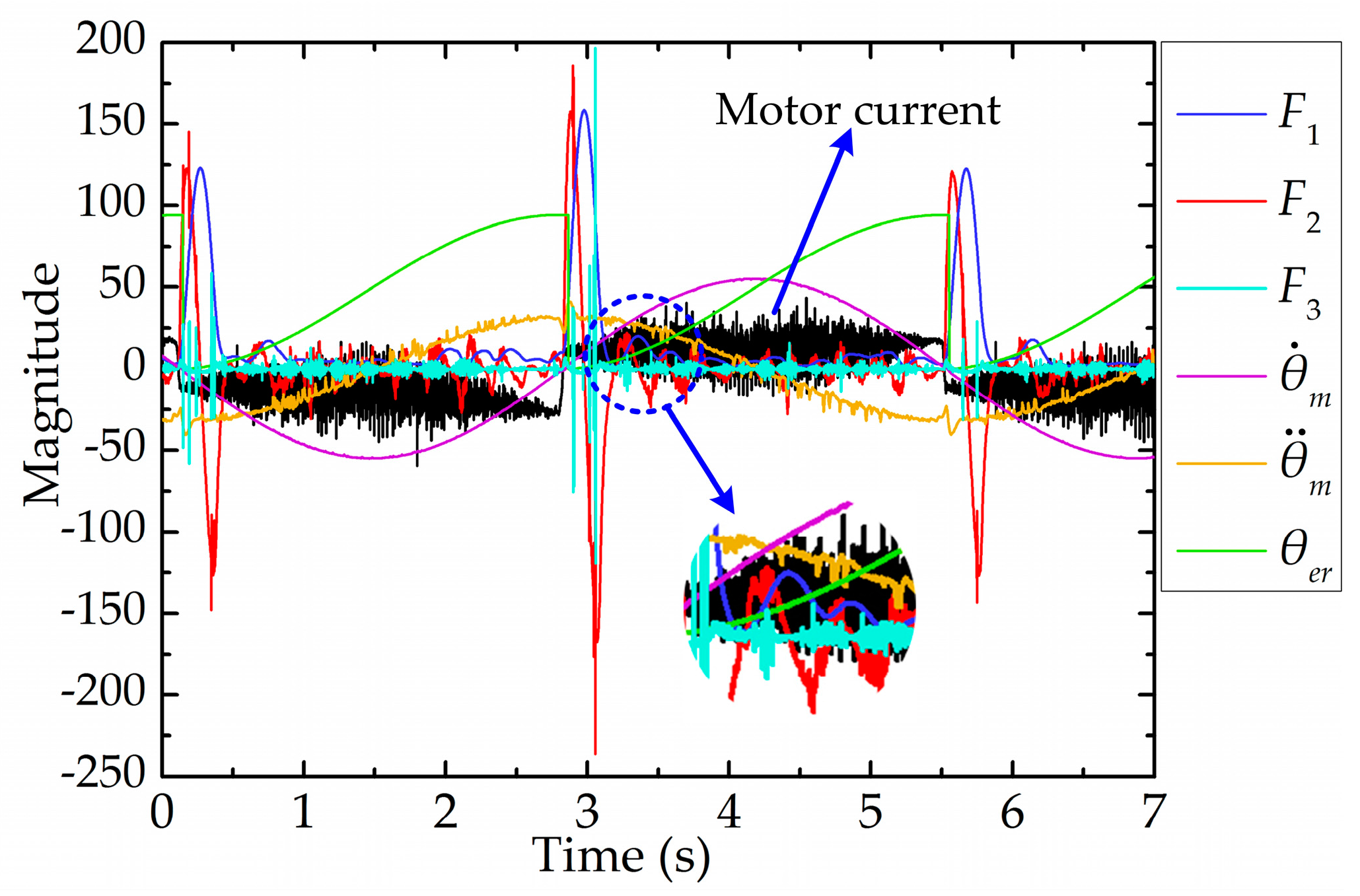

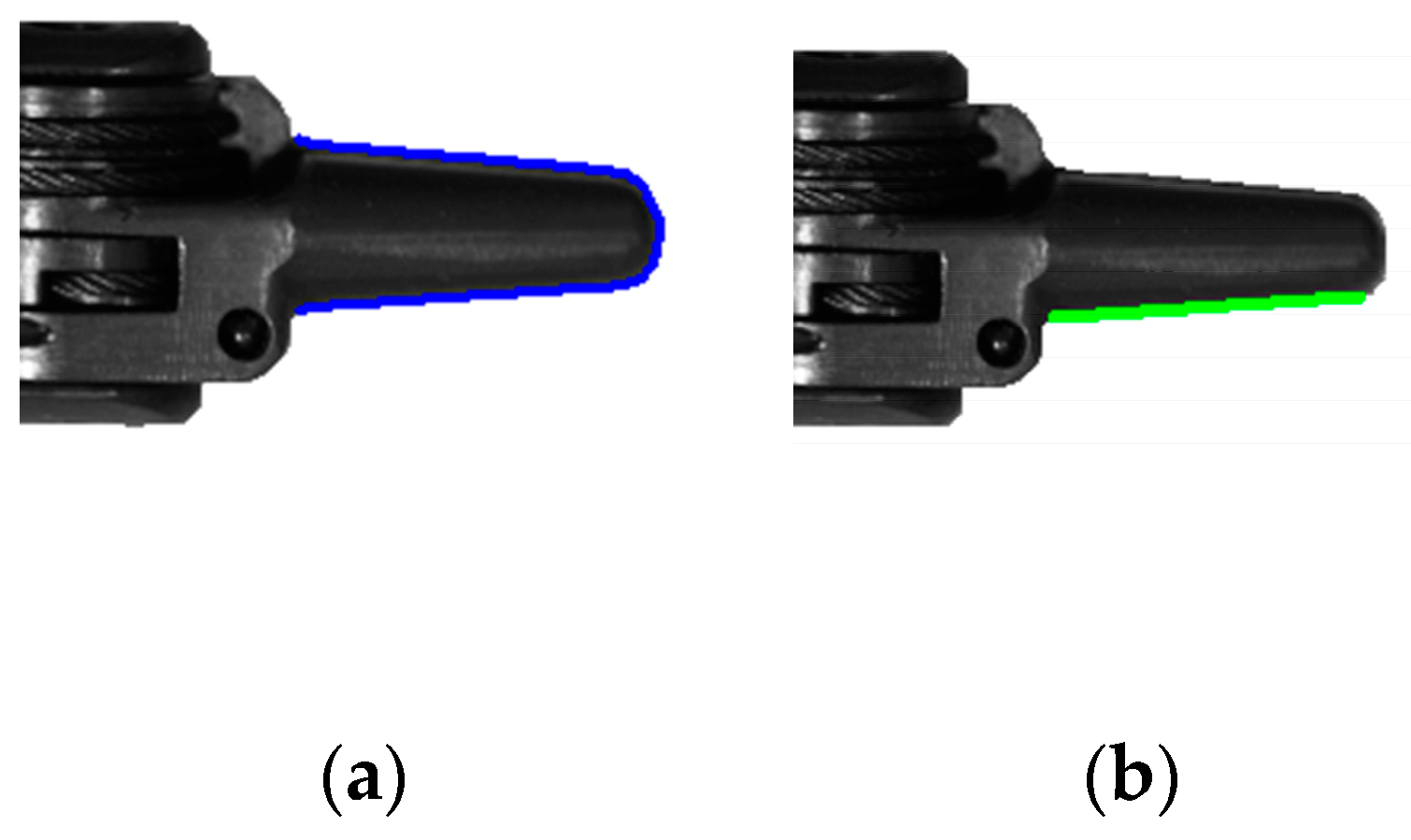

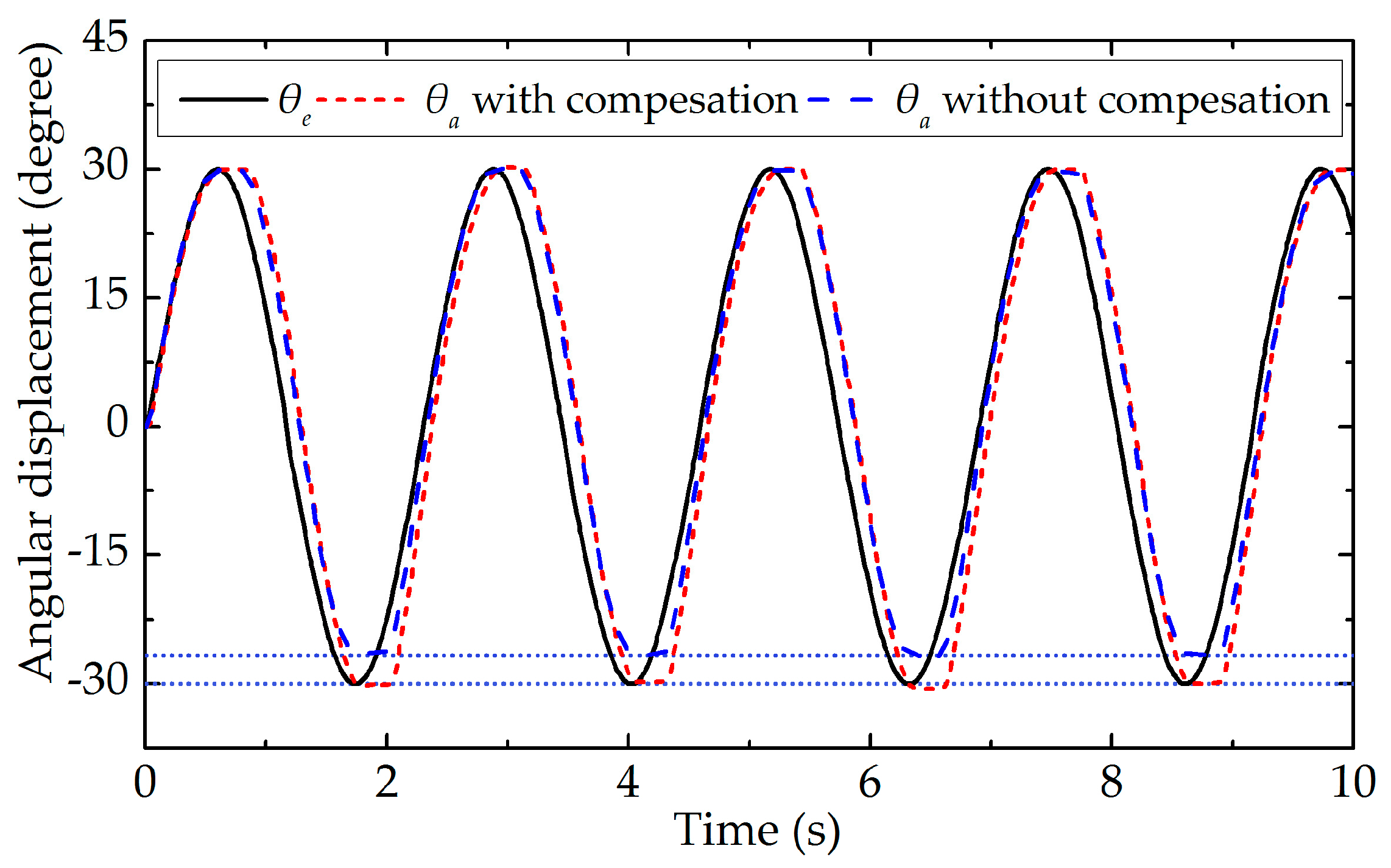

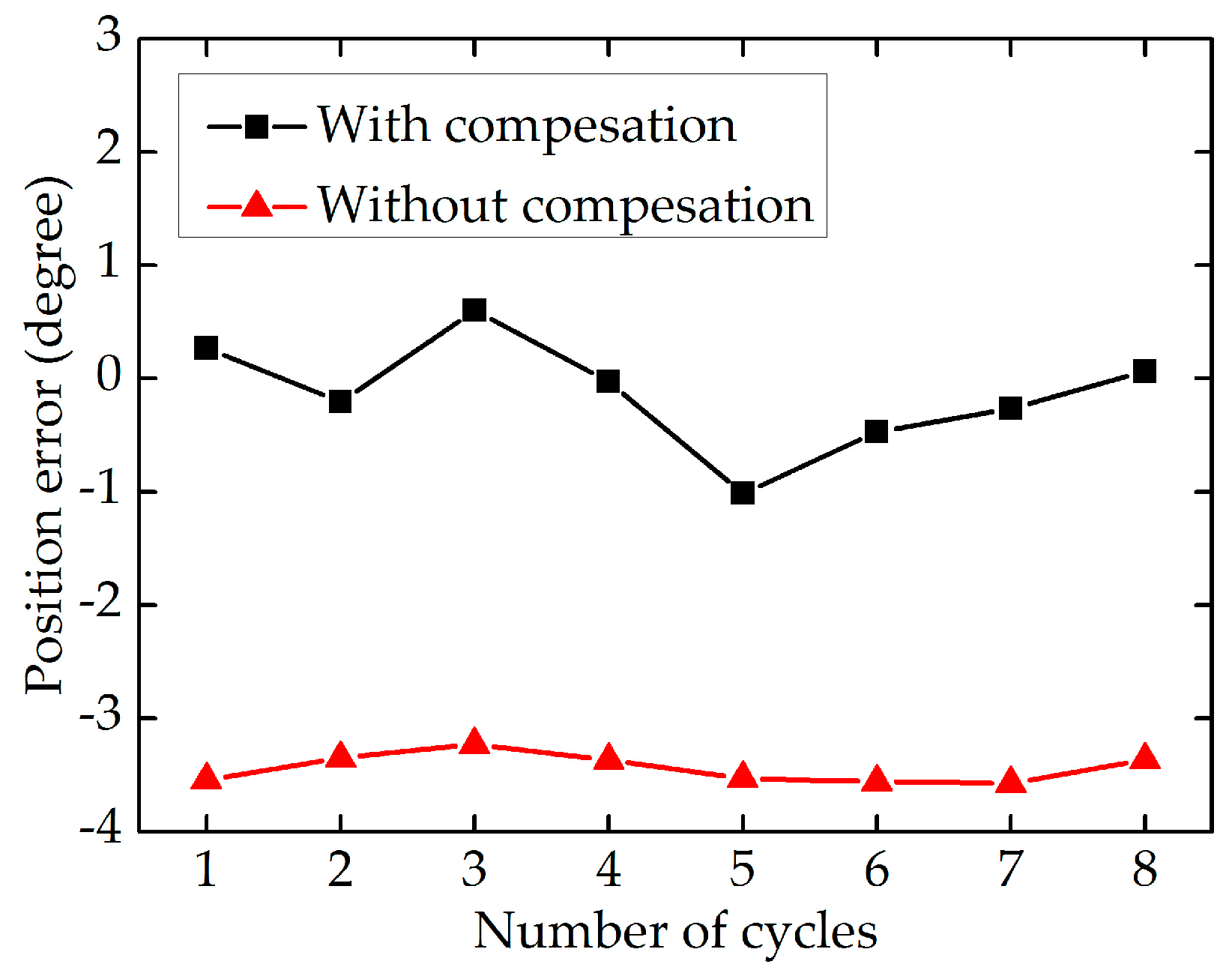

3.3. Actual Angular Displacement Measurement and Position Compensation Control

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Du, Z.; Wang, W.; Yan, Z.; Dong, W.; Wang, W. Variable admittance control based on fuzzy reinforcement learning for minimally invasive surgery manipulator. Sensors 2017, 17, 844. [Google Scholar] [CrossRef] [PubMed]

- DiMaio, S.; Hanuschik, M.; Kreaden, U. The da Vinci surgical system. In Surgical Robotics; Springer: Berlin, Germany, 2011; pp. 199–217. [Google Scholar]

- Guiochet, J.; Tondu, B.; Baron, C. Integration of UML in human factors analysis for aafety of a medical robot for tele-echography. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003), Las Vegas, NV, USA, 27–31 October 2003; pp. 3212–3217. [Google Scholar]

- Giulianotti, P.C.; Coratti, A.; Angelini, M.; Sbrana, F.; Cecconi, S.; Balestracci, T.; Caravaglios, G. Robotics in general surgery: Personal experience in a large community hospital. Arch. Surg. 2003, 138, 777–784. [Google Scholar] [CrossRef] [PubMed]

- Murphy, D.A.; Miller, J.S.; Langford, D.A.; Snyder, A.B. Endoscopic robotic mitral valve surgery. J. Thorac. Cardiovasc. Surg. 2006, 132, 776–781. [Google Scholar] [CrossRef] [PubMed]

- Meireles, O.; Horgan, S. Applications of surgical robotics in general surgery. In Surgical Robotics; Springer: Berlin, Germany, 2011; pp. 791–812. [Google Scholar]

- Biradar, P.G.; Rekha, S.M. Rob-in heart (A surgeon without hand tremor). In Proceedings of the National Conference on Challenges in Research & Technology in the Coming Decades, Ujire, India, 27–28 September 2014; pp. 2–15. [Google Scholar]

- Morley, T.A.; Wallace, D.T. Roll-Pitch-Roll Surgical Tool. U.S. Patent 7,914,522 B2, 29 March 2011. [Google Scholar]

- Thiuthipsakul, P.; Suthakorn, J. Control formulation of a highly complex wire-driven mechanism in a surgical robot based on an extensive assessment of surgical tool-tip position/orientation using optical tracking system. In Proceedings of the 2014 IEEE International Conference on Robotics and Biomimetics (ROBIO), Bali, Indonesia, 5–10 December 2014; pp. 47–52. [Google Scholar]

- Shelton, F.E.; Timm, R.W. Cable Driven Surgical Stapling and Cutting Instrument with Improved Cable Attachment Arrangements. U.S. Patent 20080308603 A1, 18 December 2007. [Google Scholar]

- Phee, S.J.; Low, S.C.; Huynh, V.; Kencana, A.P.; Sun, Z.; Yang, K. Master and slave transluminal endoscopic robot (MASTER) for natural orifice transluminal endoscopic surgery. In Proceedings of the Annual International Conference of the IEEE on Engineering in Medicine and Biology Society (EMBC 2009), Minneapolis, MN, USA, 3–6 September 2009; pp. 1192–1195. [Google Scholar]

- Dachs, G.W.; Peine, W.J. A novel surgical robot design: Minimizing the operating envelope within the sterile field. In Proceedings of the 28th Annual International Conference of the IEEE on Engineering in Medicine and Biology Society (EMBS’06), New York, NY, USA, 30 August–3 September 2006; pp. 1505–1508. [Google Scholar]

- Do, T.; Tjahjowidodo, T.; Lau, M.; Phee, S. Real-time enhancement of tracking performances for cable-conduit mechanisms-driven flexible robots. Robot. Comput.-Integr. Manuf. 2016, 37, 197–207. [Google Scholar] [CrossRef]

- Kaneko, M.; Paetsch, W.; Tolle, H. Input-dependent stability of joint torque control of tendon-driven robot hands. IEEE Trans. Ind. Electron. 1992, 39, 96–104. [Google Scholar] [CrossRef]

- Kaneko, M.; Wada, M.; Maekawa, H.; Tanie, K. A new consideration on tendon-tension control system of robot hands. In Proceedings of the 1991 IEEE International Conference on Robotics and Automation, Sacramento, CA, USA, 9–11 April 1991; pp. 1028–1033. [Google Scholar]

- Agrawal, V.; Peine, W.J.; Yao, B. Modeling of transmission characteristics across a cable-conduit system. IEEE Trans. Robot. 2010, 26, 914–924. [Google Scholar] [CrossRef]

- Agrawal, V.; Peine, W.J.; Yao, B.; Choi, S. Control of cable actuated devices using smooth backlash inverse. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation (ICRA), Anchorage, AK, USA, 3–7 May 2010; pp. 1074–1079. [Google Scholar]

- Wu, Q.; Wang, X.; Chen, L.; Du, F. Transmission model and compensation control of double-tendon-sheath actuation system. IEEE Trans. Ind. Electron. 2015, 62, 1599–1609. [Google Scholar] [CrossRef]

- Do, T.N.; Tjahjowidodo, T.; Lau, M.; Phee, S.J. In nonlinear modeling and parameter identification of dynamic friction model in tendon sheath for flexible endoscopic systems. In Proceedings of the ICINCO 2013 10th International Conference on Informatics in Control, Automation and Robotic, Reykjavík, Iceland, 29–31 July 2013; pp. 5–10. [Google Scholar]

- Do, T.N.; Tjahjowidodo, T.; Lau, M.W.S.; Phee, S.J. Dynamic friction-based force feedback for tendon-sheath mechanism in notes system. Int. J. Comput. Electr. Eng. 2014, 6, 252. [Google Scholar] [CrossRef]

- Do, T.; Tjahjowidodo, T.; Lau, M.W.S.; Phee, S.J. A new approach of friction model for tendon-sheath actuated surgical systems: Nonlinear modelling and parameter identification. Mech. Mach. Theory 2015, 85, 14–24. [Google Scholar] [CrossRef]

- Do, T.; Tjahjowidodo, T.; Lau, M.W.S.; Phee, S.J. An investigation of friction-based tendon sheath model appropriate for control purposes. Mech. Syst. Signal Proc. 2014, 42, 97–114. [Google Scholar] [CrossRef]

- Do, T.; Tjahjowidodo, T.; Lau, M.; Yamamoto, T.; Phee, S. Hysteresis modeling and position control of tendon-sheath mechanism in flexible endoscopic systems. Mechatronics 2014, 24, 12–22. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, Z.; Phee, S.J. Elongation modeling and compensation for the flexible tendon-sheath system. IEEE/ASME Trans. Mechatron. 2014, 19, 1243–1250. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, Z.; Phee, S.J. Modeling and motion compensation of a bidirectional tendon-sheath actuated system for robotic endoscopic surgery. Comput. Methods Progr. Biomed. 2015, 119, 77–87. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Sun, Z.; Phee, S.J. Modeling tendon-sheath mechanism with flexible configurations for robot control. Robotica 2013, 31, 1131–1142. [Google Scholar] [CrossRef]

- Qi, Z.; Wang, J.; Wang, G. An efficient model for dynamic analysis and simulation of cable-pulley systems with time-varying cable lengths. Mech. Mach. Theory 2017, 116, 383–403. [Google Scholar] [CrossRef]

- Xue, R.; Ren, B.; Yan, Z.; Du, Z. A cable-pulley system modeling based position compensation control for a laparoscope surgical robot. Mech. Mach. Theory 2017, 118, 283–299. [Google Scholar] [CrossRef]

- Ishikawa, T.; Toyota, R.; Matsunami, M.; Kurita, N.; Matsuura, T. Current-based detection of eccentric load coupled to brushless DC motor. In Proceedings of the 2010 International Power Electronics Conference (IPEC), Sapporo, Japan, 21–24 June 2010; pp. 1331–1335. [Google Scholar]

- Iorgulescu, M.; Beloiu, R. Study of DC motor miagnosis based on the vibration spectrum and current analysis. In Proceedings of the 2012 International Conference on Applied and Theoretical Electricity (ICATE), Craiova, Romania, 25–27 October 2012; pp. 1–4. [Google Scholar]

- Du, Z.; Wang, W.; Wang, W.; Dong, W. Preoperative planning for a multi-arm robot-assisted minimally invasive surgery system. Simulation 2017. [Google Scholar] [CrossRef]

- Cavallo, F.; Sinigaglia, S.; Megali, G.; Pietrabissa, A.; Dario, P.; Mosca, F.; Cuschieri, A. Biomechanics-machine learning system for surgical gesture analysis and development of technologies for minimal access surgery. Surg. Innov. 2014, 21, 504–512. [Google Scholar] [CrossRef] [PubMed]

- Megherbi, D.; Soper, B. Effect of feature selection on machine learning algorithms for more accurate predictor of surgical outcomes in Benign Pro Static Hyperplasia cases (BPH). In Proceedings of the 2011 IEEE International Conference on Computational Intelligence for Measurement Systems and Applications (CIMSA), Ottawa, ON, Canada, 19–21 September 2011; pp. 1–7. [Google Scholar]

- Watson, R.A. Use of a machine learning algorithm to classify expertise: Analysis of hand motion patterns during a simulated surgical task. Acad. Med. 2014, 89, 1163–1167. [Google Scholar] [CrossRef] [PubMed]

- Mahler, J.; Krishnan, S.; Laskey, M.; Sen, S.; Murali, A.; Kehoe, B.; Patil, S.; Wang, J.; Franklin, M.; Abbeel, P. Learning accurate kinematic control of cable-driven surgical robots using data cleaning and gaussian process regression. In Proceedings of the 2014 IEEE International Conference on Automation Science and Engineering (CASE), Taipei, Taiwan, 18–22 August 2014; pp. 532–539. [Google Scholar]

- Bouget, D.; Benenson, R.; Omran, M.; Riffaud, L.; Schiele, B.; Jannin, P. Detecting surgical tools by modelling local appearance and global shape. IEEE Trans. Med. Imaging 2015, 34, 2603–2617. [Google Scholar] [CrossRef] [PubMed]

| Motor Direction | ||||||

|---|---|---|---|---|---|---|

| Positive Movement | 0.0290 | 0.0229 | 0.0173 | 0.0067 | 0.0166 | 0.0200 |

| Negative Movement | 0.0210 | 0.0162 | 0.0128 | 0.0055 | 0.0113 | 0.0125 |

| Motor Direction | Train: B→N | Train: N→B | Test: B→N | Test: N→B |

|---|---|---|---|---|

| Positive Movement | 0 | 0 | 0.069% | 0.026% |

| Negative Movement | 0.002% | 0 | 0.039% | 0.003% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Du, Z.; Wang, W.; Sun, L. A Novel Position Compensation Scheme for Cable-Pulley Mechanisms Used in Laparoscopic Surgical Robots. Sensors 2017, 17, 2257. https://doi.org/10.3390/s17102257

Liang Y, Du Z, Wang W, Sun L. A Novel Position Compensation Scheme for Cable-Pulley Mechanisms Used in Laparoscopic Surgical Robots. Sensors. 2017; 17(10):2257. https://doi.org/10.3390/s17102257

Chicago/Turabian StyleLiang, Yunlei, Zhijiang Du, Weidong Wang, and Lining Sun. 2017. "A Novel Position Compensation Scheme for Cable-Pulley Mechanisms Used in Laparoscopic Surgical Robots" Sensors 17, no. 10: 2257. https://doi.org/10.3390/s17102257

APA StyleLiang, Y., Du, Z., Wang, W., & Sun, L. (2017). A Novel Position Compensation Scheme for Cable-Pulley Mechanisms Used in Laparoscopic Surgical Robots. Sensors, 17(10), 2257. https://doi.org/10.3390/s17102257