Using a Hexagonal Mirror for Varying Light Intensity in the Measurement of Small-Angle Variation

Abstract

:1. Introduction

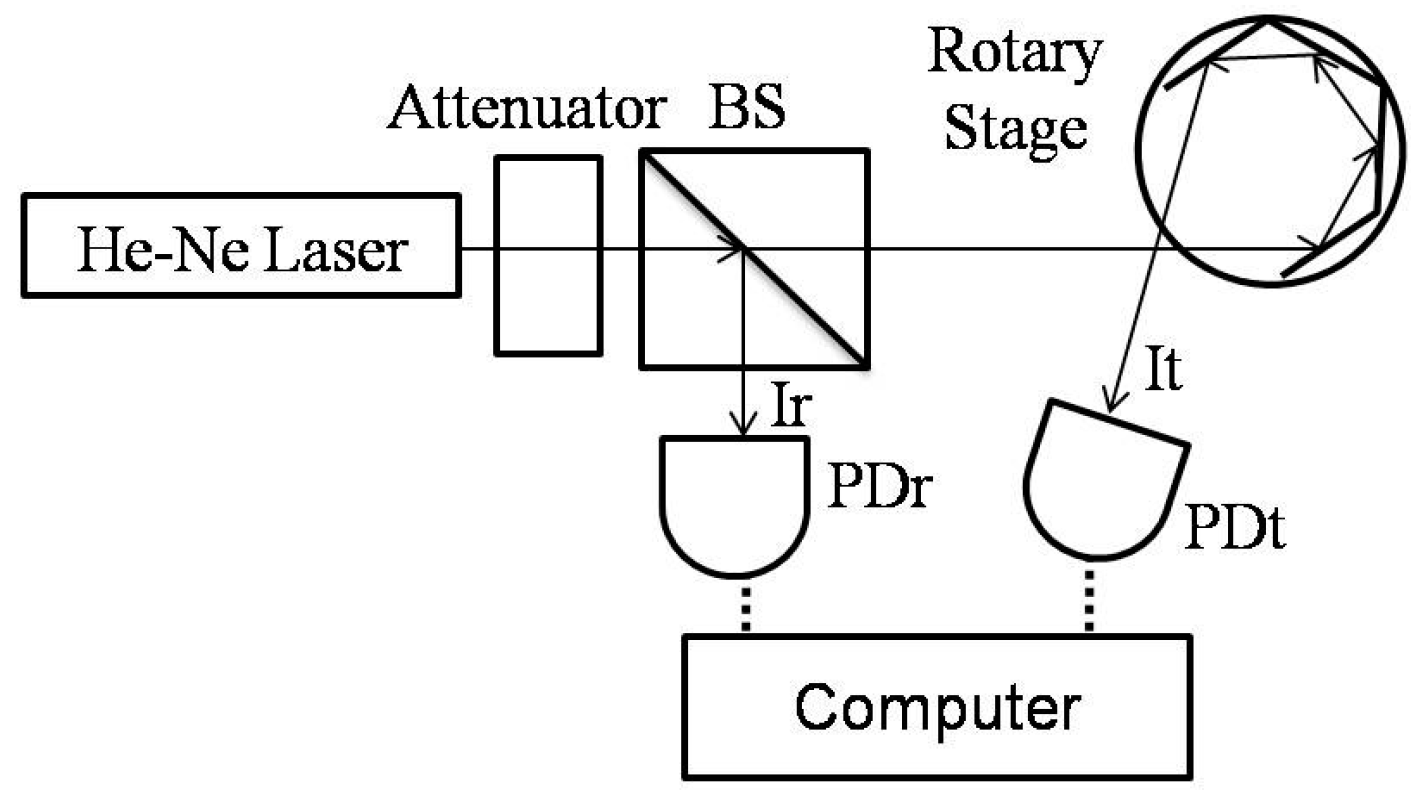

2. Materials and Methods

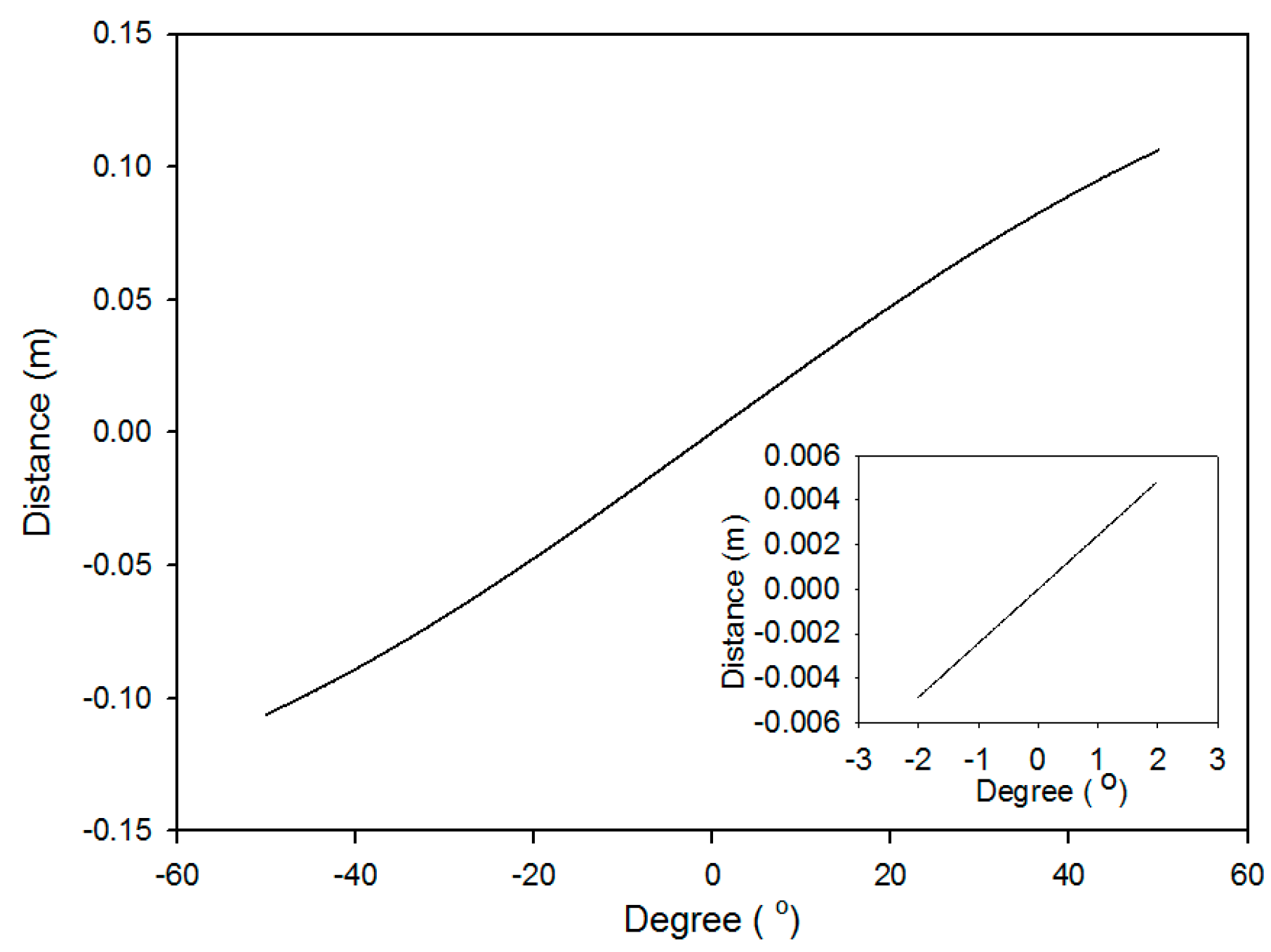

2.1. Laser Beam Parallel Shifter

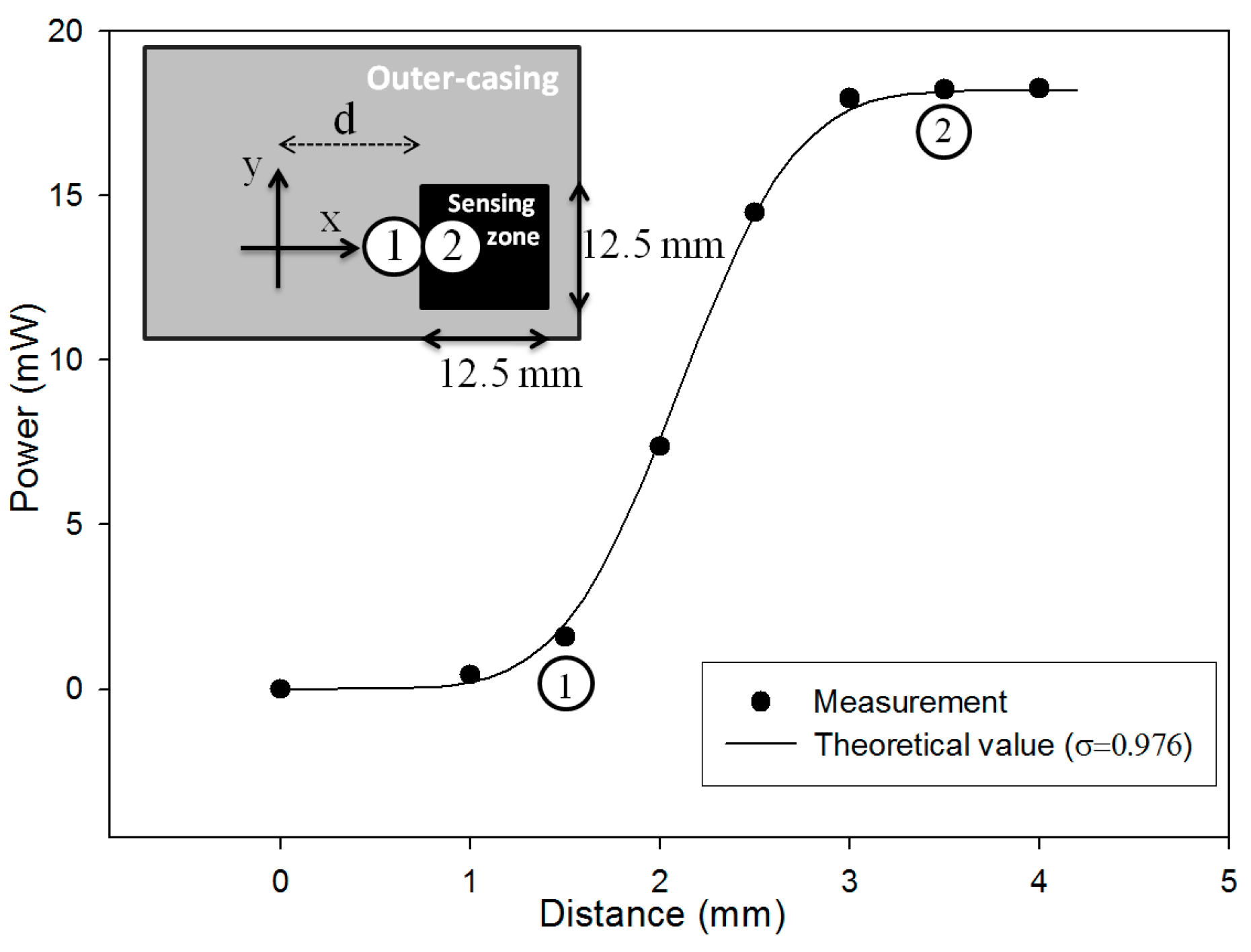

2.2. Laser Parallel Shift and Light Intensity Variation

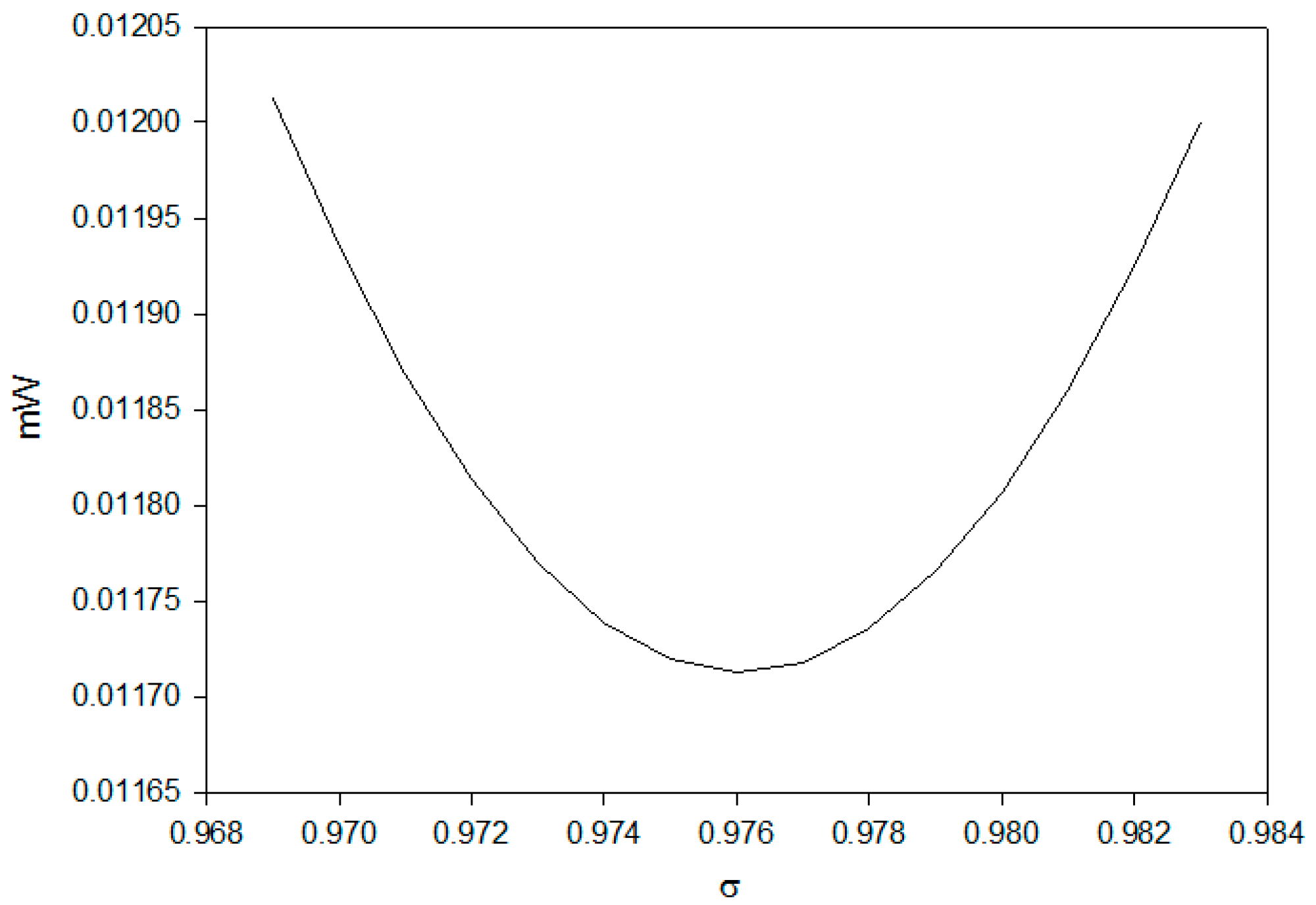

2.3. The Definition of Laser Gaussian Distribution σ Value

3. Experimental Setup

4. Results and Discussions

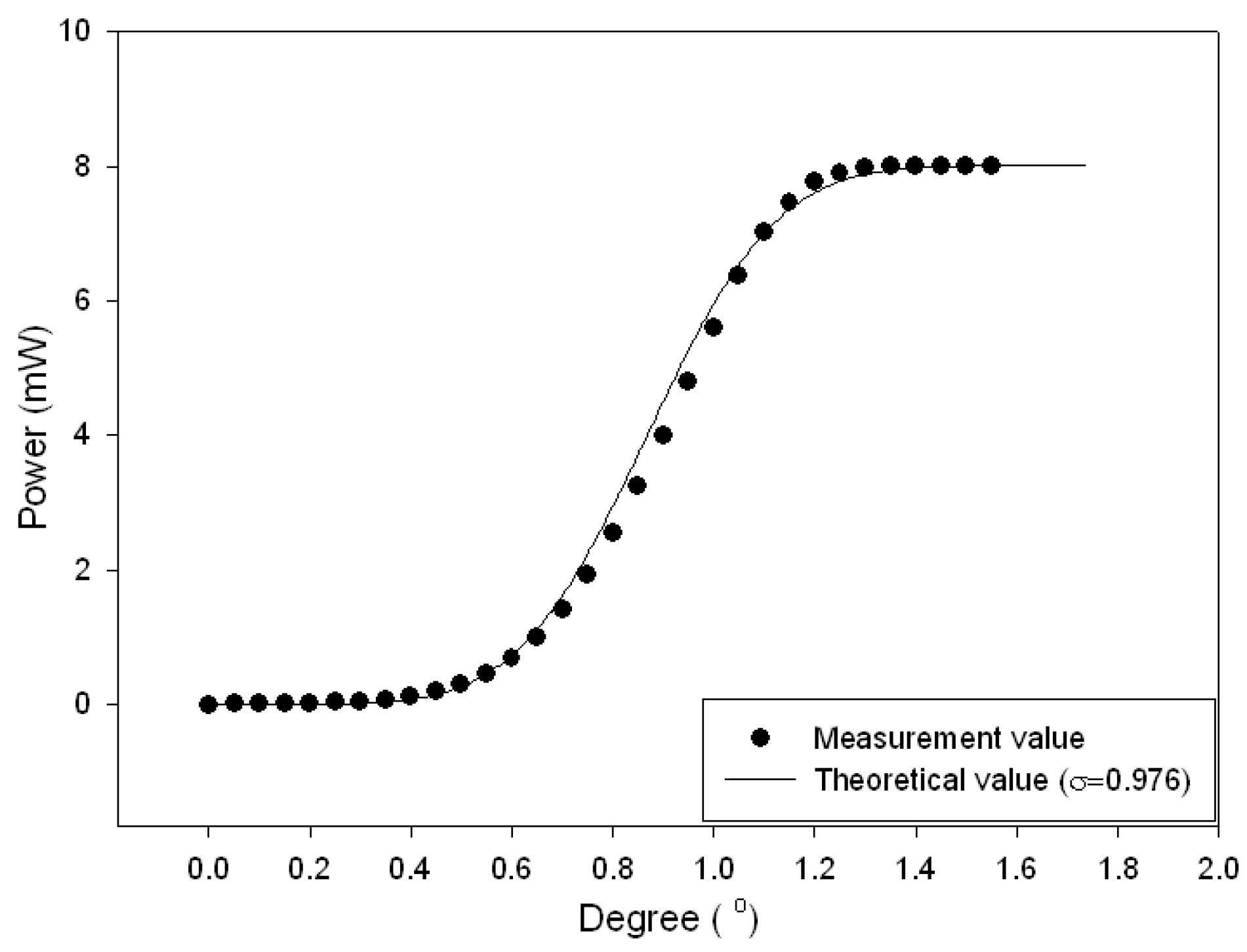

4.1. Experimental Results

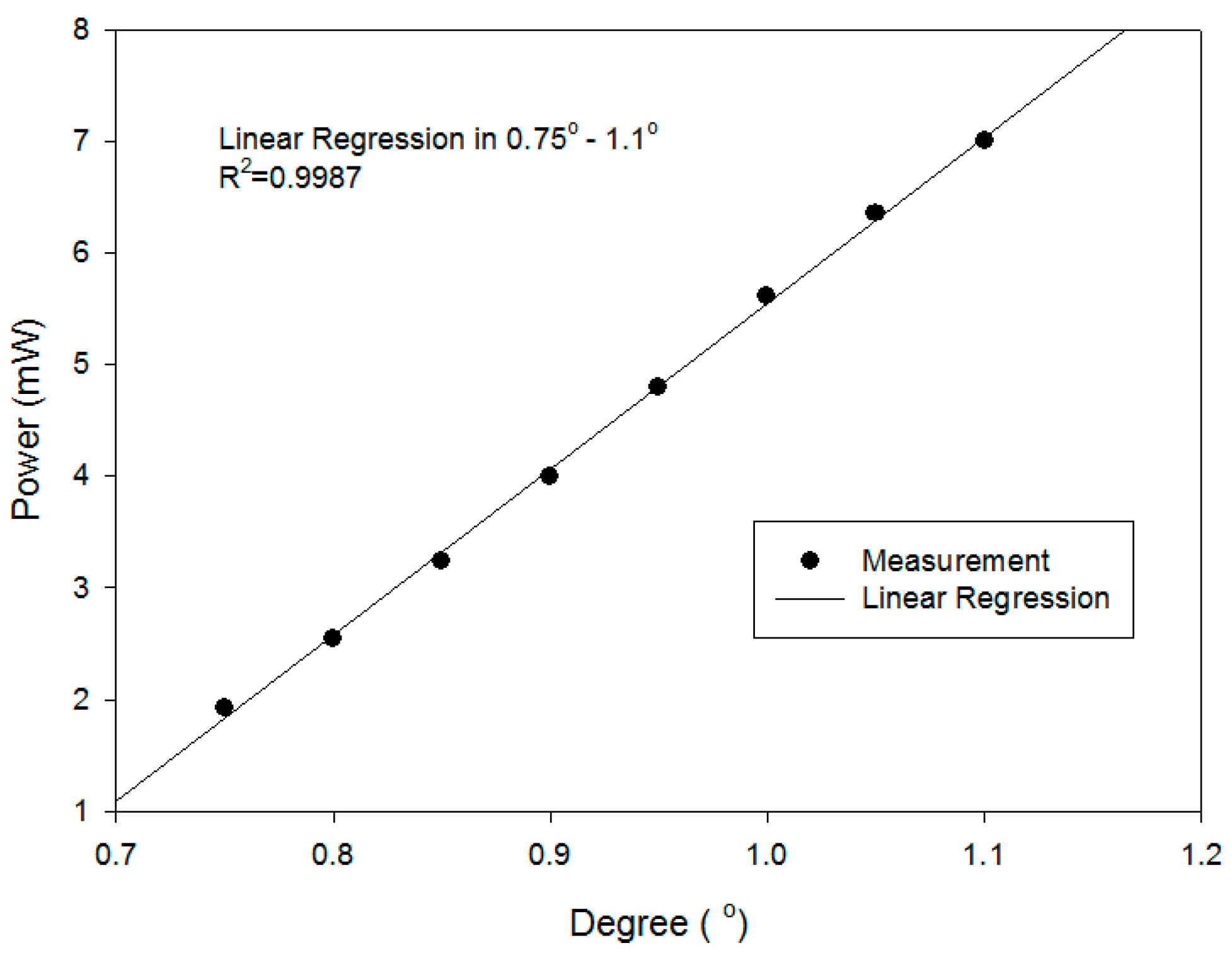

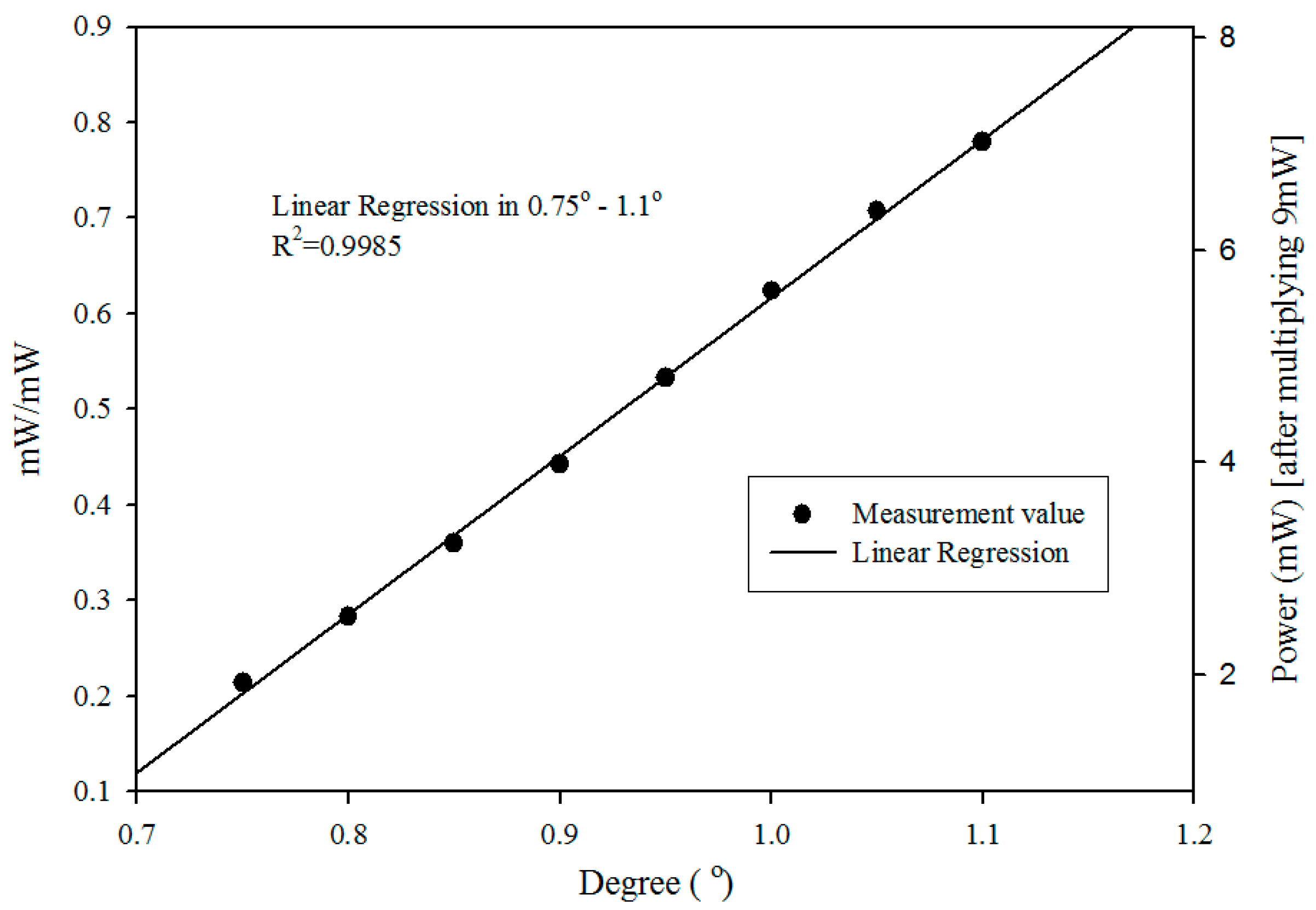

4.2. The Measurement of Linearity and Reference Light Correction

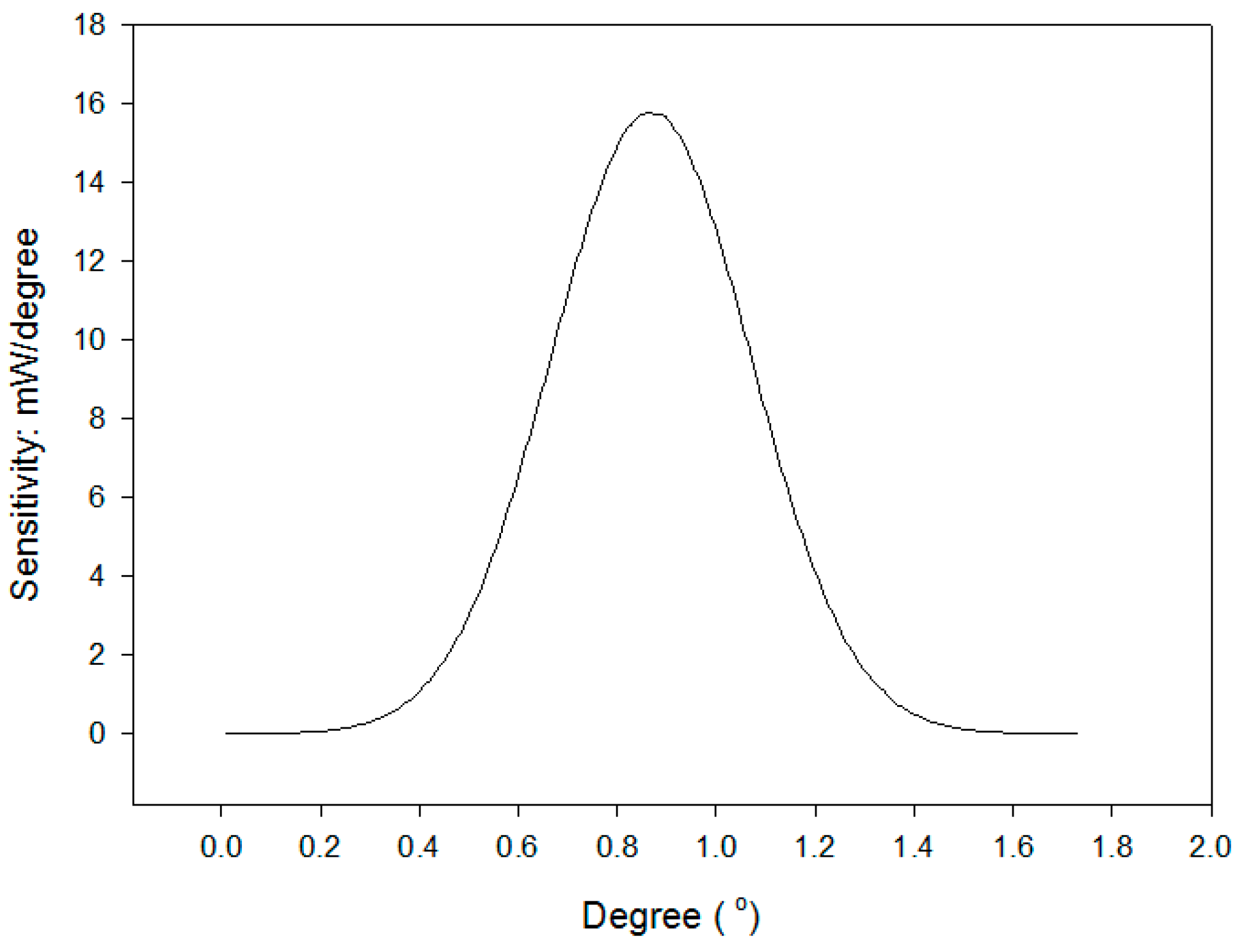

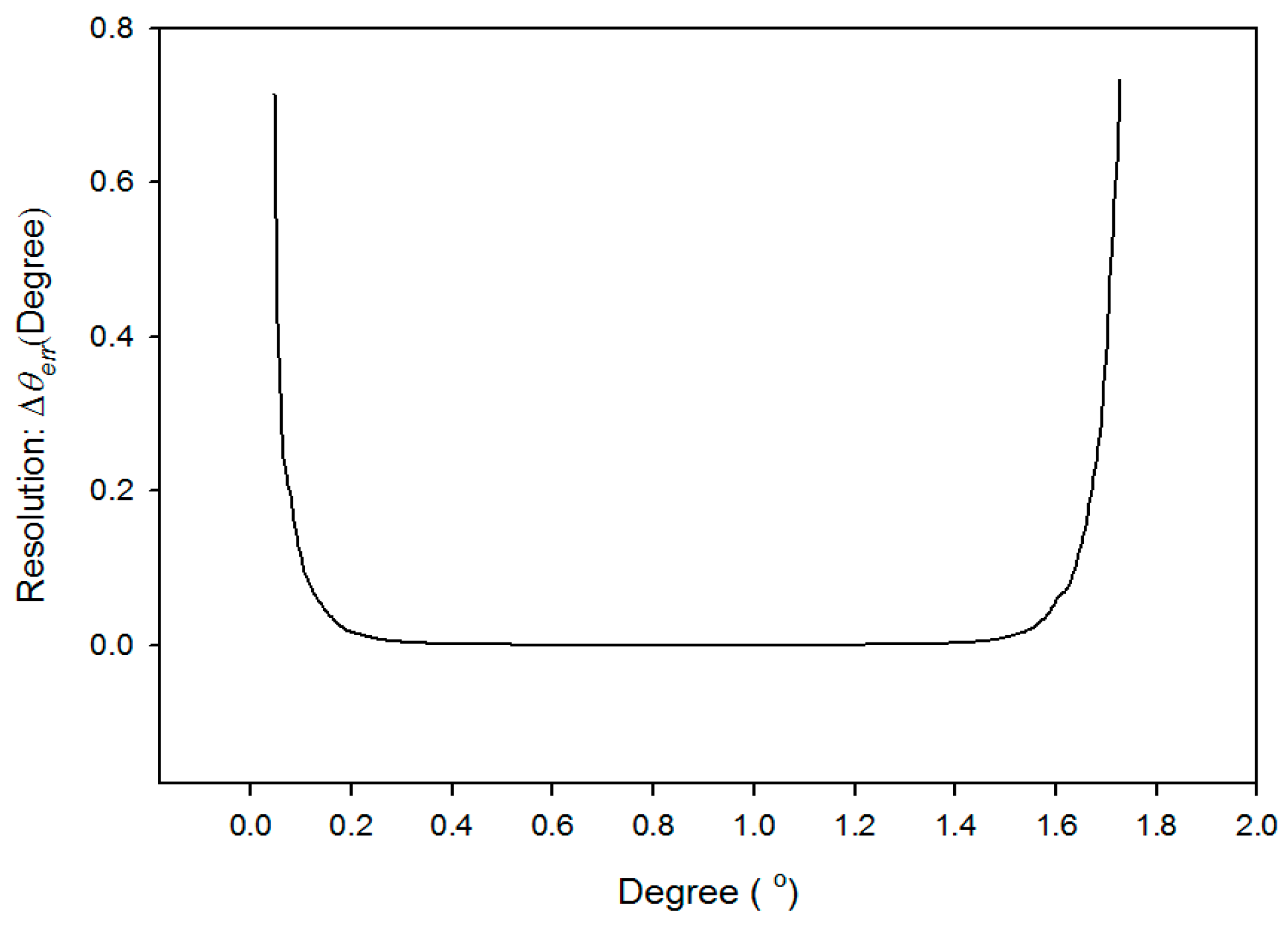

4.3. The Sensitivity and Resolution

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hsieh, M.-C.; Chiu, Y.-H.; Lin, S.-F.; Chang, J.-Y.; Chang, C.-O.; Chiang, H.-K. Amplification of the Signal Intensity of Fluorescence-Based Fiber-Optic Biosensors Using a Fabry-Perot Resonator Structure. Sensors 2015, 15, 3565–3574. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liang, L.; Yuan, Y.; Xu, G.; Liu, F. A two fiber Bragg gratings sensing system to monitor the torque of rotating shaft. Sensors 2016, 16. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, M.-C.; Lin, J.-Y.; Chen, Y.-F.; Chang, C.-O. Measurement of small angle based on a (1 0 0) silicon wafer and heterodyne interferometer. Opt. Rev. 2016, 3, 1–5. [Google Scholar] [CrossRef]

- Liu, Y.; Kuang, C.; Ku, Y. Small angle measurement method based on the total internal multi-reflection. Opt. Laser Technol. 2012, 44, 1346–1350. [Google Scholar] [CrossRef]

- Iwasaki, T.; Takeshita, T.; Arinaga, Y.; Sawada, R. Torque measurement device using an integrated micro displacement sensor. Sens. Mater. 2013, 25, 601–608. [Google Scholar]

- Xiao, X.; Gao, Y.; Xiang, J.; Zhou, F. Laser-induced thermal effect in surface plasmon resonance. Anal. Chim. Acta 2010, 676, 75–80. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.-Y.; Liao, Y.-C. Small-angle measurement with highly sensitive total-internal-reflection heterodyne interferometer. Appl. Opt. 2014, 53, 1903–1908. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Kiyono, S.; Uda, Y. Nanoradian angle sensor and in situ self calibration. Appl. Opt. 1998, 37, 4154–4159. [Google Scholar] [CrossRef] [PubMed]

- García-Valenzuela, A.; Sandoval-Romero, G.-E.; Sánchez-Pérez, C. High-resolution optical angle sensors: Approaching the diffraction limit to the sensitivity. Appl. Opt. 2004, 43, 4311–4321. [Google Scholar] [CrossRef] [PubMed]

- Hogan, J.-M.; Hammer, J.; Chiow, S.-W.; Dickerson, S.-D.; Johnson, M.-S.; Kovachy, T.; Sugarbaker, A.; Kasevich, M.A. Precision angle sensor using an optical lever inside a Sagnac interferometer. Opt. Lett. 2011, 36, 1698–1700. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Vitard, J.; Haliyo, S.; Régnier, S. Optical lever calibration in atomic force microscope with a mechanical lever. Rev. Sci. Instrum. 2008, 79. [Google Scholar] [CrossRef] [PubMed]

- Dixon, P.-B.; Starling, D.-J.; Jordan, A.-N.; Howell, J.-C. Ultrasensitive beam deflection measurement via interferometer weak value amplification. Phys. Rev. Lett. 2009, 102. [Google Scholar] [CrossRef] [PubMed]

- Yukita, S.; Shiokawa, N.; Kanemaru, H.; Namiki, H.; Kobayashi, T.; Tokunaga, E. Deflection switching of a laser beam by the Pockels effect of water. Appl. Phys. Lett. 2012, 100. [Google Scholar] [CrossRef]

- Chiu, M.-H.; Lee, J.-Y.; Su, D.-C. Complex refractive-index measurement based on Fresnel’s equations and the uses of heterodyne interferometry. Appl. Opt. 1999, 38, 4047–4052. [Google Scholar] [CrossRef] [PubMed]

- Shiokawa, N.; Tokunaga, E. Quasi first-order Hermite Gaussian beam for enhanced sensitivity in Sagnac interferometer photothermal deflection spectroscopy. Opt. Express 2016, 24, 11961–11974. [Google Scholar] [CrossRef] [PubMed]

- Ok, G.; Choi, S.-W.; Park, K.H.; Chun, H.S. Foreign object detection by sub-Terahertz quasi-Bessel beam imaging. Sensors 2013, 13, 71–85. [Google Scholar] [CrossRef] [PubMed]

- Alda, J. Laser and Gaussian beam propagation and transformation. Encycl. Opt. Eng. 2013, 2013, 999–1013. [Google Scholar]

- Wang, S.-F. A Small-displacement sensor using total internal reflection theory and surface plasmon resonance technology for heterodyne interferometry. Sensors 2009, 9, 2498–2510. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.-Y.; Chen, K.-H.; Chen, J.-H. Measurement of small displacement based on surface plasmon resonance heterodyne interferometry. Opt. Lasers Eng. 2011, 49, 811–815. [Google Scholar]

- Hsieh, M.-C.; Lin, J.-Y.; Chang, C.-O. Measurement of small wavelength shifts based on total internal reflection heterodyne interferometry. Chin. Opt. Lett. 2016, 14. Available online: https://www.osapublishing.org/col/abstract.cfm?uri=col-14-8-081202 (accessed on 15 August 2016). [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsieh, M.-C.; Lin, J.-Y.; Chang, C.-O. Using a Hexagonal Mirror for Varying Light Intensity in the Measurement of Small-Angle Variation. Sensors 2016, 16, 1301. https://doi.org/10.3390/s16081301

Hsieh M-C, Lin J-Y, Chang C-O. Using a Hexagonal Mirror for Varying Light Intensity in the Measurement of Small-Angle Variation. Sensors. 2016; 16(8):1301. https://doi.org/10.3390/s16081301

Chicago/Turabian StyleHsieh, Meng-Chang, Jiun-You Lin, and Chia-Ou Chang. 2016. "Using a Hexagonal Mirror for Varying Light Intensity in the Measurement of Small-Angle Variation" Sensors 16, no. 8: 1301. https://doi.org/10.3390/s16081301

APA StyleHsieh, M.-C., Lin, J.-Y., & Chang, C.-O. (2016). Using a Hexagonal Mirror for Varying Light Intensity in the Measurement of Small-Angle Variation. Sensors, 16(8), 1301. https://doi.org/10.3390/s16081301