Design, Fabrication, Simulation and Characterization of a Novel Dual-Sided Microelectrode Array for Deep Brain Recording and Stimulation

Abstract

:1. Introduction

2. Materials and Methods

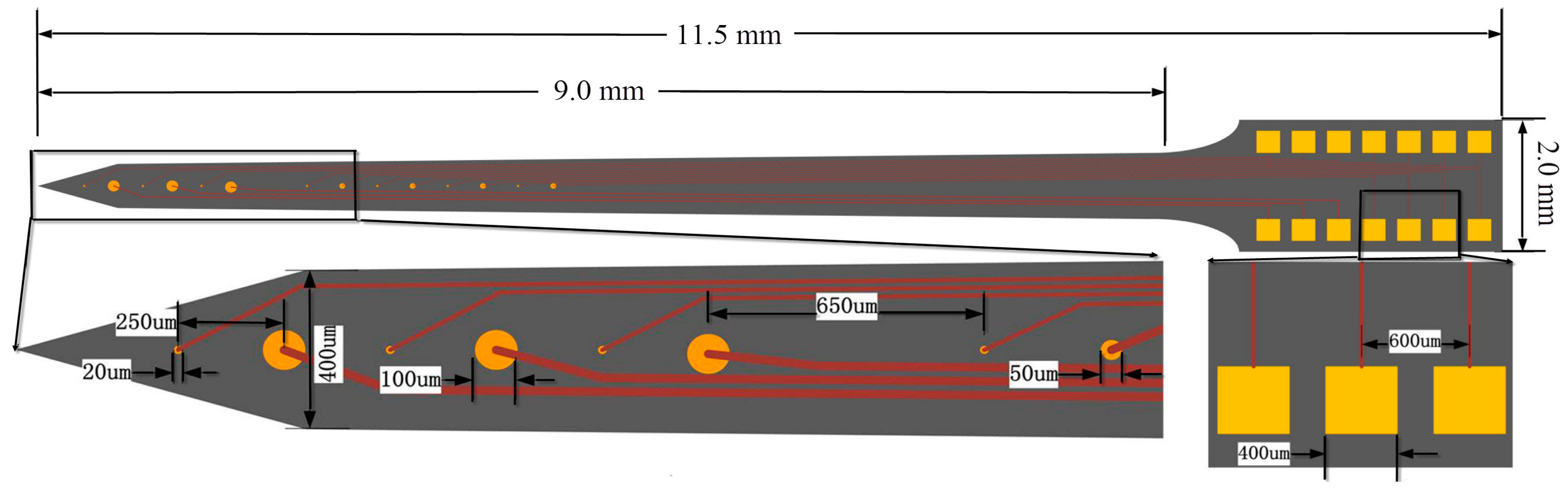

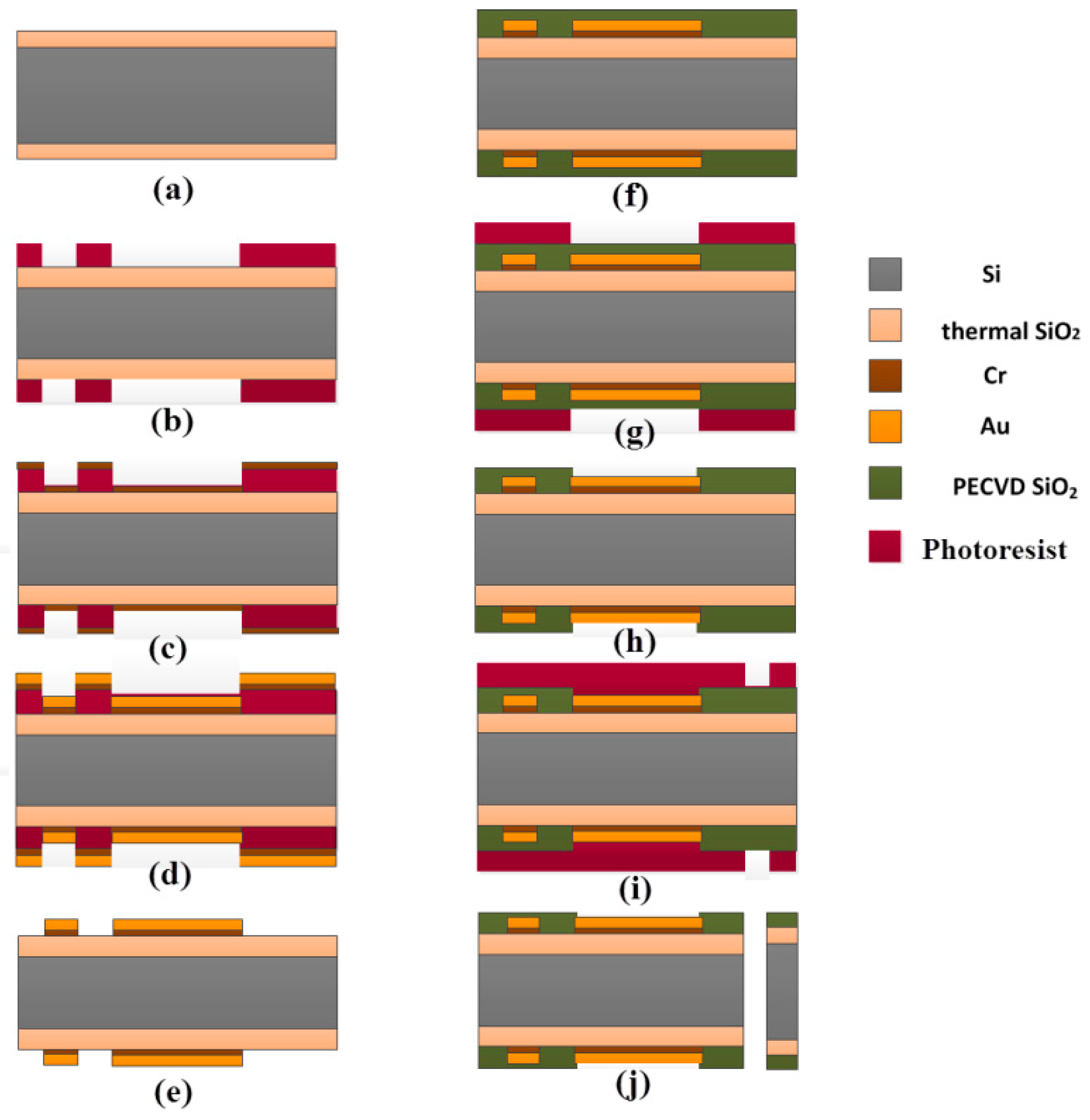

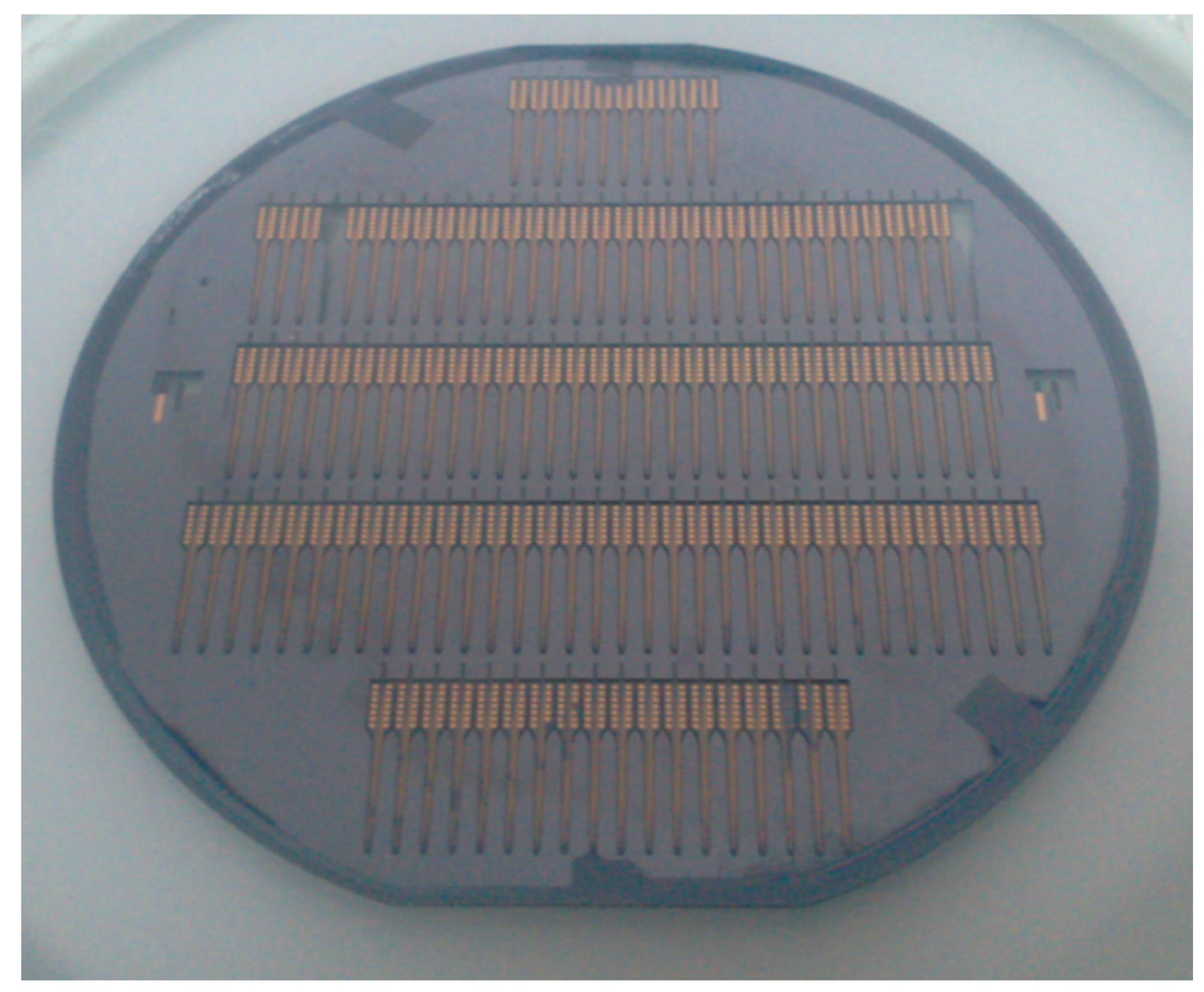

2.1. Microelectrode Arrays Design and Fabrication

2.2. Microelectrode Arrays Package

2.3. FEM of STN Stimulation

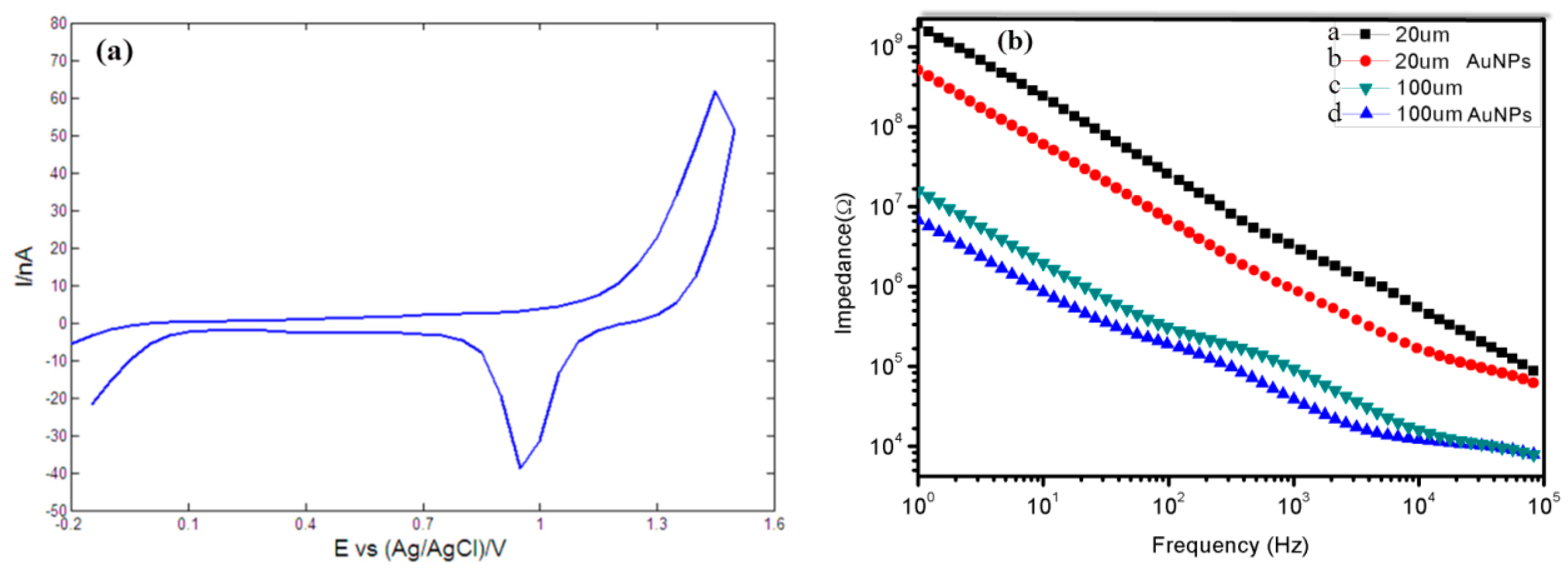

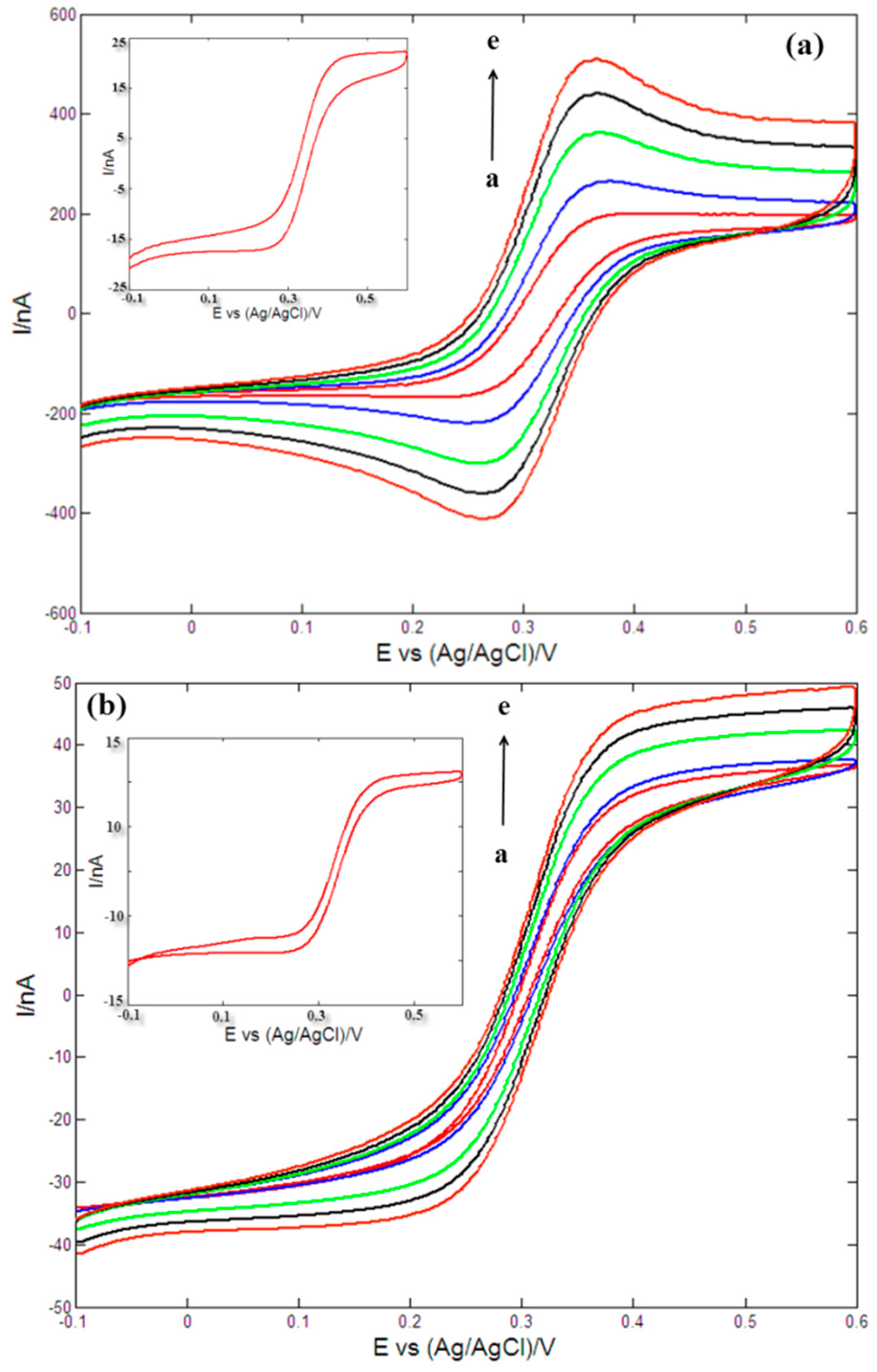

2.4. Electrochemical Characterization of the Microelectrode Array

3. Results and Discussion

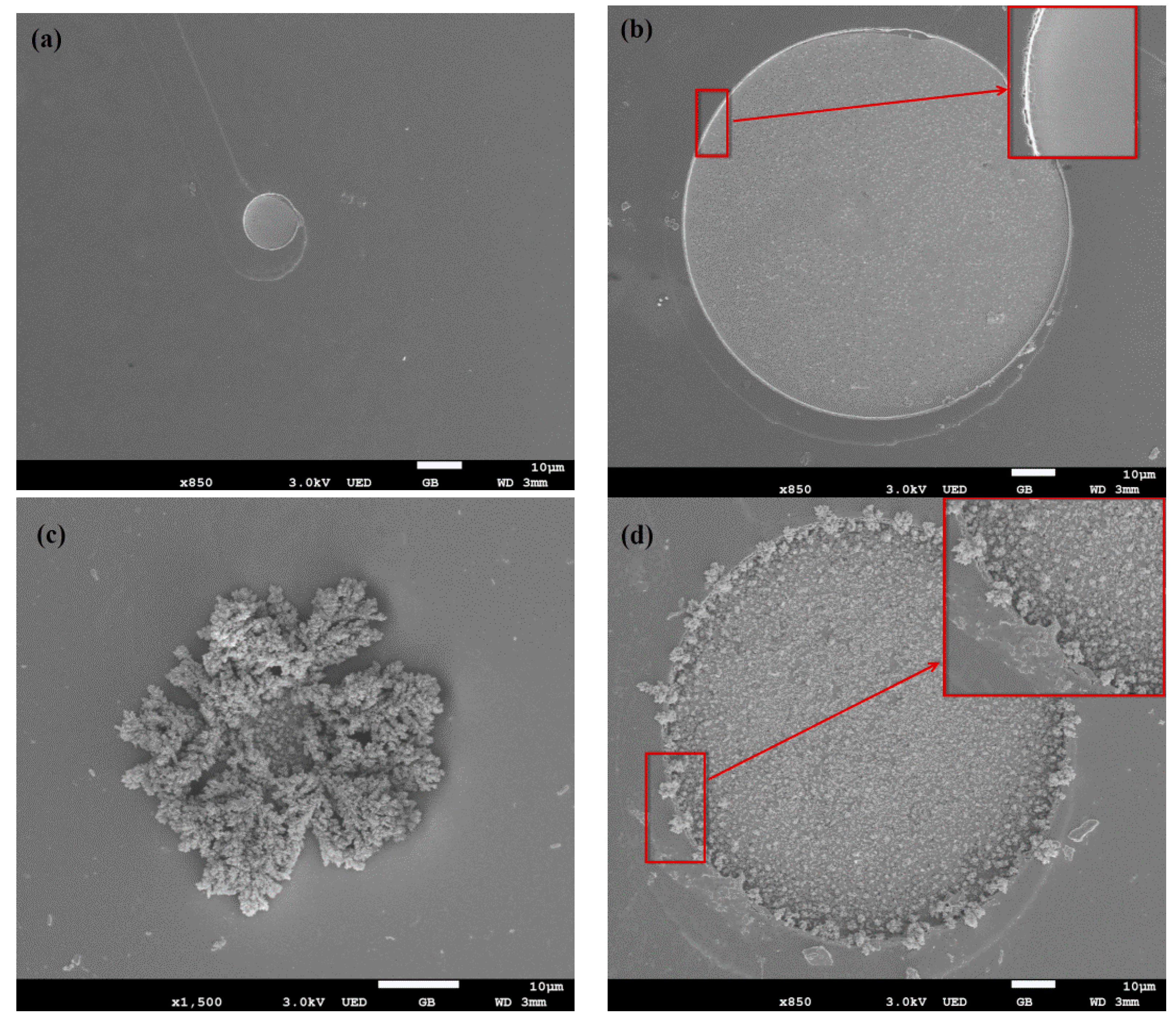

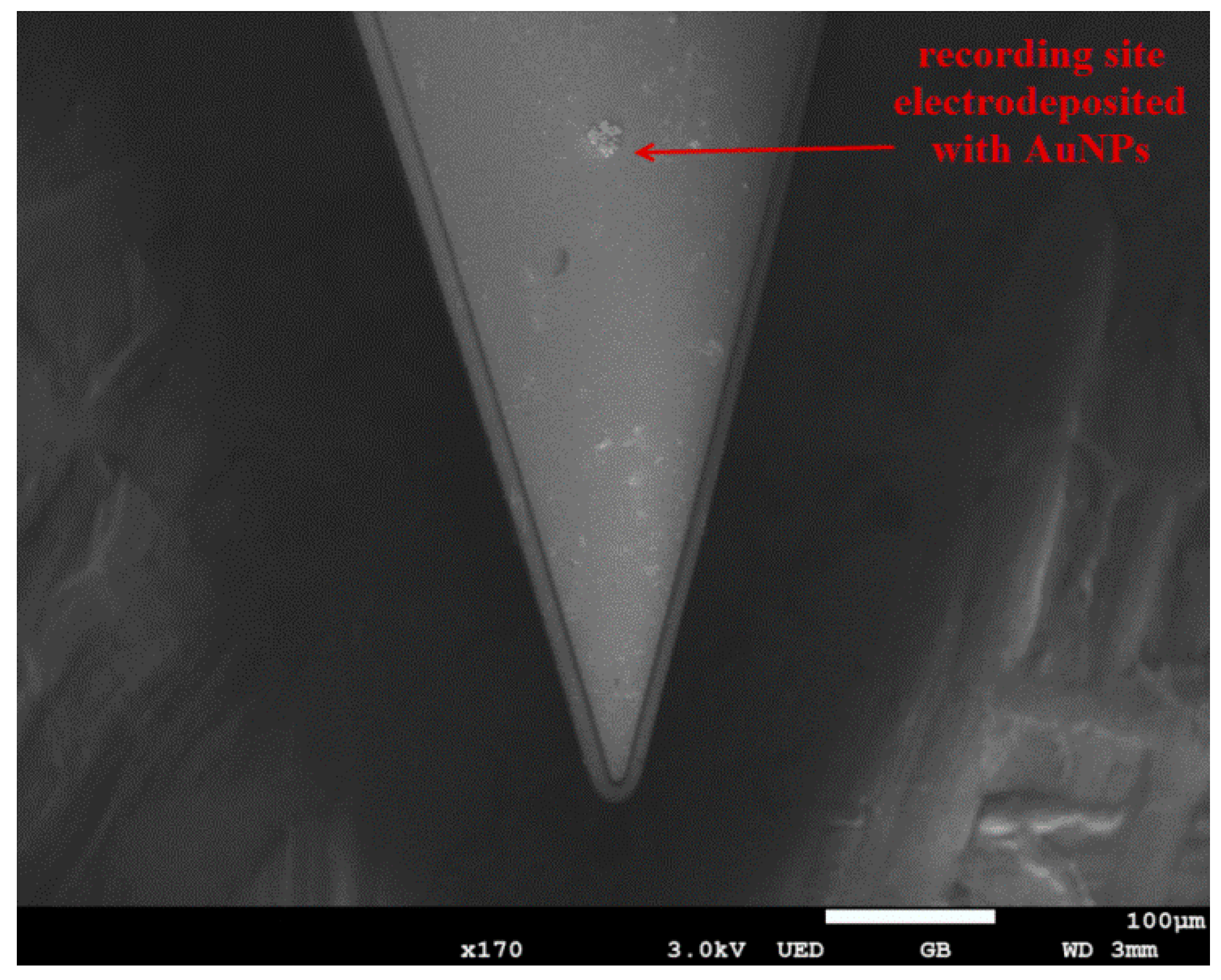

3.1. Morphological Characterization

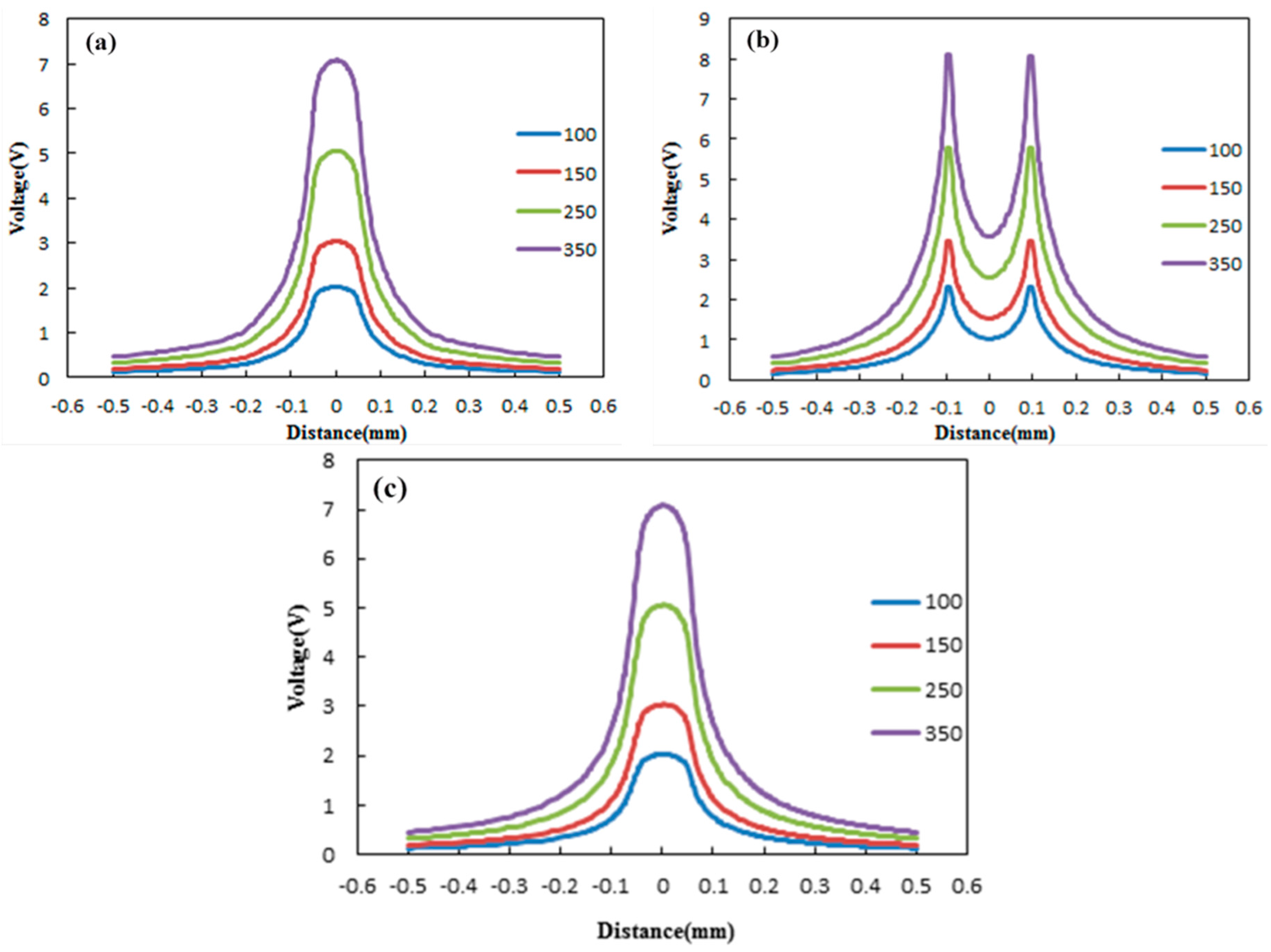

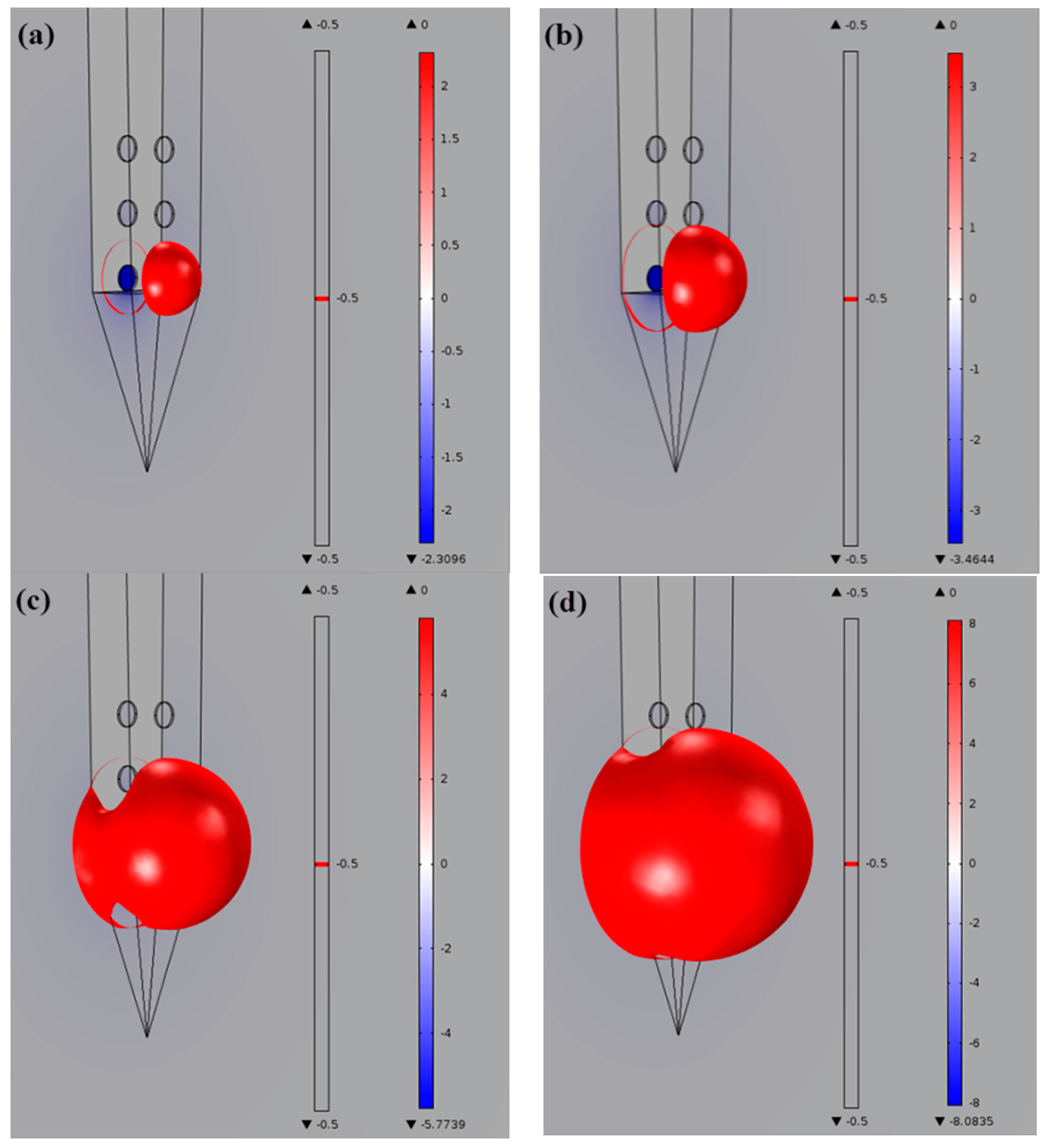

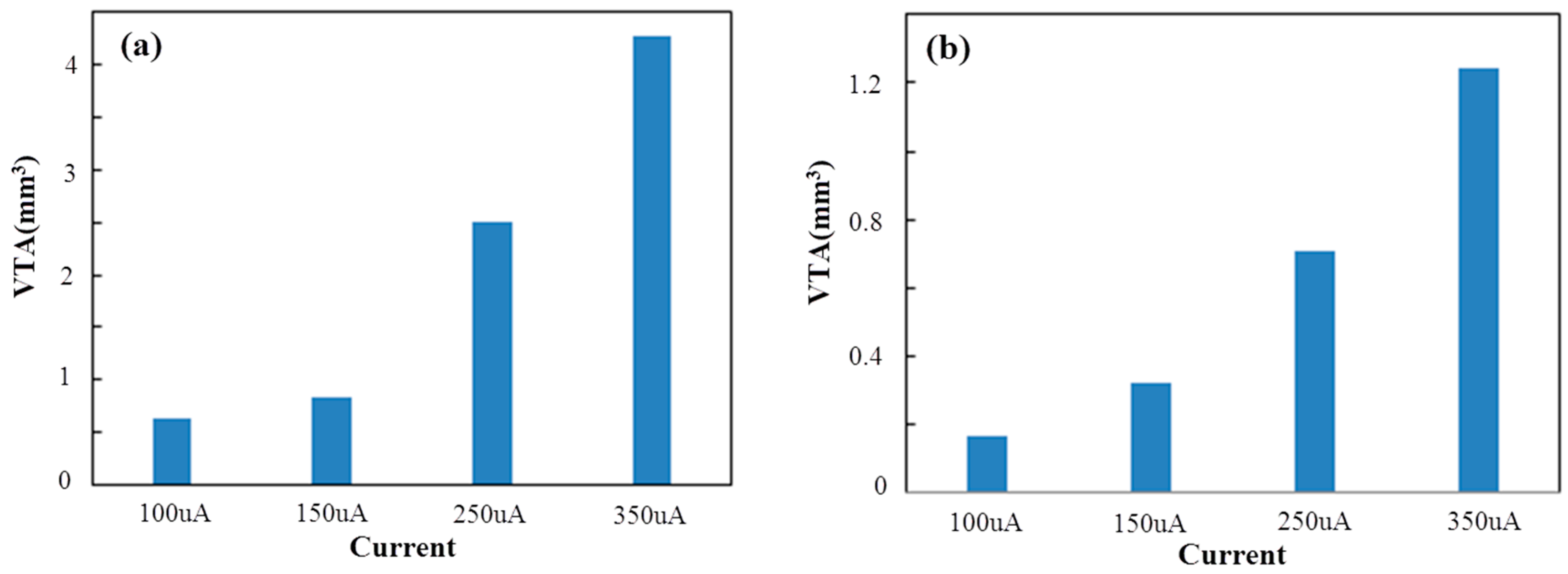

3.2. Effective Areas of STN Stimulation Based on FEM

3.3. Electrochemical Behavior of the Microelectrode Array

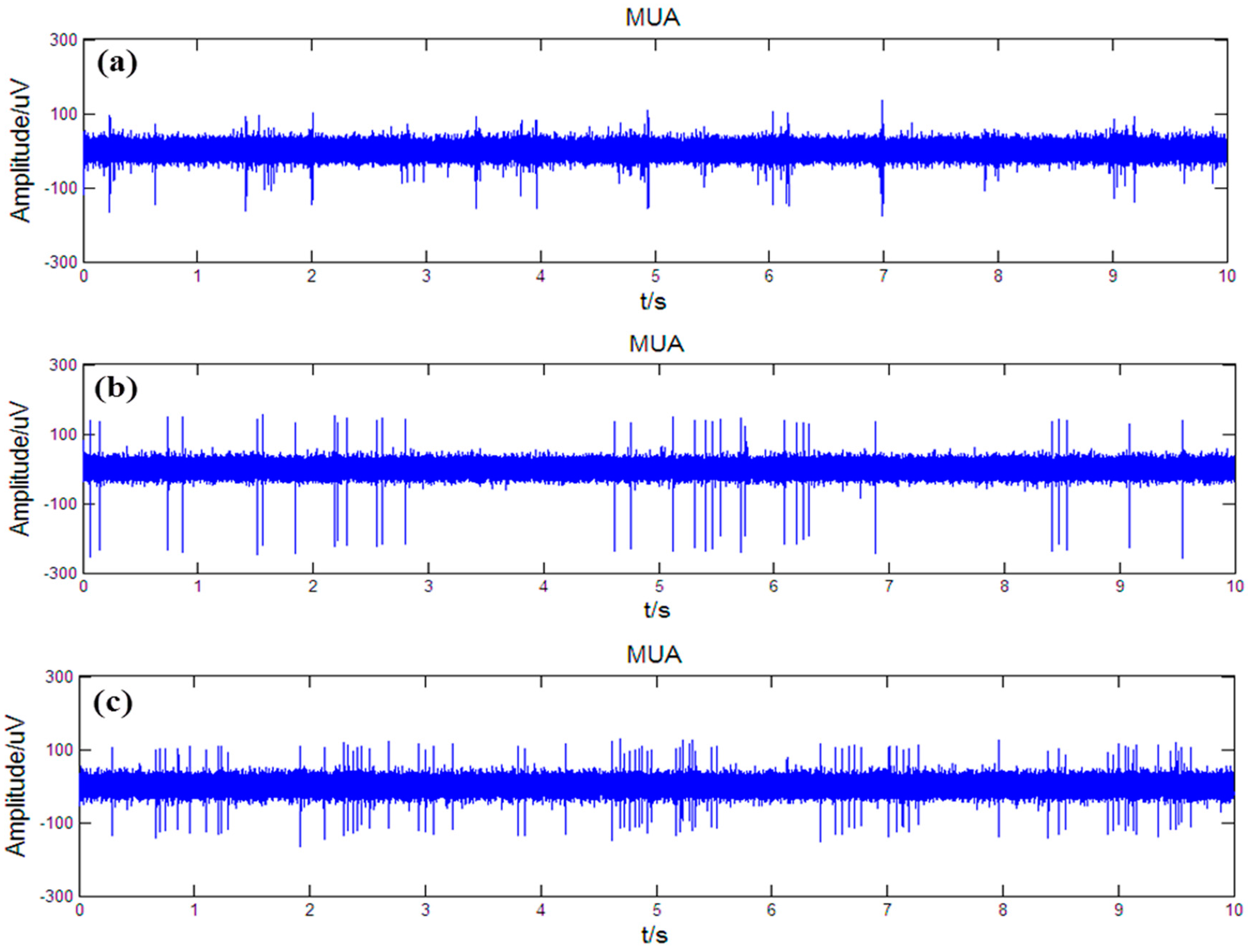

3.4. In Vivo Neural Recordings

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hagai Bergman, M.D.; Günther, M.D. Deuschl Pathophysiology of Parkinson’s disease: From clinical neurology to basic neuroscience and back. Mov. Disord. 2002, 17, S28–S40. [Google Scholar] [CrossRef] [PubMed]

- Narabayashi, H. The neural mechanisms and progressive nature of symptoms of Parkinson’s disease—Based on clinical, neurophysiological and morphological studies. J. Neural Transm. Parkinson’s Dis. Dement. Sect. 1995, 10, 63–75. [Google Scholar] [CrossRef]

- Adrian, W.; Steven, G.; Thelekat, V.; Crispin, J.; Niall, Q.; Rosalind, M.; Richard, S.; Natalie, I.; Caroline, R. Jane Deep brain stimulation plus best medical therapy versus best medical therapy alone for advanced Parkinson’s disease (PD SURG trial): A randomised, open-label trial. Lancet Neurol. 2010, 9, 581–591. [Google Scholar]

- Okun, M.S.; Gallo, B.V.; Mandybur, G.; Jagid, J.; Foote, K.D.; Revilla, F.J.; Alterman, R.; Jankovic, J.; Simpson, R. Junn Subthalamic deep brain stimulation with a constant-current device in Parkinson’s disease: An open-label randomised controlled trial. Lancet Neurol. 2012, 11, 140–149. [Google Scholar] [CrossRef]

- Limousin-Dowsey, P.; Pollak, P.; Blercom, N.V.; Krack, P.; Benazzouz, A.; Benabid, A.L. Thalamic, subthalamic nucleus and internal pallidum stimulation in Parkinson’s disease. J. Neurol. 1999, 246, II42–II45. [Google Scholar] [CrossRef] [PubMed]

- Myrandele, D.; Davis, T.L.; Konrad, P.E.; Roberts, A.G.; Pfister, A.A.; David, C.P. Deep brain stimulation: A new treatment for Parkinson’s disease. Tenn. Med. 2003, 96, 33–35. [Google Scholar]

- Deep-Brain Stimulation for Parkinson’s Disease Study Group. Deep-brain stimulation of the subthalamic nucleus or the pars interna of the globus pallidus in Parkinson’s disease. N. Engl. J. Med. 2001, 345, 956–963. [Google Scholar]

- Koop, M.M.; Andrzejewski, A.; Hill, B.C.; Heit, G.; Bronte-Stewart, H.M. Improvement in a quantitative measure of bradykinesia after microelectrode recording in patients with Parkinson’s disease during deep brain stimulation surgery. Mov. Disord. 2006, 21, 673–678. [Google Scholar] [CrossRef] [PubMed]

- Etienne, P.; Damien, D.; Malin, M.; Francois, V.; Josephs, G.; Jean-Guy, V. Effect of deep brain stimulation of GPI on neuronal activity of the thalamic nucleus ventralis oralis in a dystonic patient. Neurophysiol. Clin. 2003, 33, 169–173. [Google Scholar]

- Galati, S.; Mazzone, P.; Fedele, E.; Pisani, A.; Peppe, A.; Pierantozzi, M.; Brusa, L.; Tropepi, D.; Moschella, V.; Raiteri, M. Biochemical and electrophysiological changes of substantia nigra pars reticulata driven by subthalamic stimulation in patients with Parkinson’s disease. Eur. J. Neurosci. 2006, 23, 2923–2928. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, E.B. Effects of GPi stimulation on human thalamic neuronal activity. Clin. Neurophysiol. 2006, 117, 2691–2702. [Google Scholar] [CrossRef] [PubMed]

- Takao, H.; Elder, C.M.; Okun, M.S.; Patrick, S.K.; Vitek, J.L. Stimulation of the subthalamic nucleus changes the firing pattern of pallidal neurons. J. Neurosci. 2003, 23, 1916–1923. [Google Scholar]

- Hitoshi, K.; Yoshihisa, T.; Atsushi, N.; Satomi, C. Balance of monosynaptic excitatory and disynaptic inhibitory responses of the globus pallidus induced after stimulation of the subthalamic nucleus in the monkey. J. Neurosci. 2005, 25, 585–594. [Google Scholar]

- Weidong, X.; Russo, G.S.; Takao, H.; Jianyu, Z.; Vitek, J.L. Subthalamic nucleus stimulation modulates thalamic neuronal activity. J. Neurosci. 2008, 28, 11916–11924. [Google Scholar]

- Johnson, M.D.; Vitek, J.L.; Mcintyre, C.C. Pallidal stimulation that improves parkinsonian motor symptoms also modulates neuronal firing patterns in primary motor cortex in the MPTP-treated monkey. Exp. Neurol. 2009, 219, 359–362. [Google Scholar] [CrossRef] [PubMed]

- Kopell, B.H.; Rezai, A.R.; Jin, W.C.; Vitek, J.L. Anatomy and physiology of the basal ganglia: Implications for deep brain stimulation for Parkinson’s disease. Mov. Disord. 2006, 21, S238–S246. [Google Scholar] [CrossRef] [PubMed]

- Delong, M.; Wichmann, T. Circuits and circuit disorders of the basal ganglia. Arch. Neurol. 2007, 64, 20–24. [Google Scholar] [CrossRef] [PubMed]

- Parent, A.; Hazrati, L.N. Functional anatomy of the basal ganglia. I. The cortico-basal ganglia-thalamo-cortical loop. Brain Res. Rev. 1995, 20, 91–127. [Google Scholar] [CrossRef]

- André, P.; Lili-Naz, H. Functional anatomy of the basal ganglia. II. The place of subthalamic nucleus and external pallidium in basal ganglia circuitry. Brain Res. Rev. 1995, 20, 128–154. [Google Scholar]

- Mcintyre, C.C.; Hahn, P.J. Network perspectives on the mechanisms of deep brain stimulation. Neurobiol. Dis. 2009, 38, 329–337. [Google Scholar] [CrossRef] [PubMed]

- Shi, L.H.; Luo, F.; Woodward, D.J.; Chang, J.Y. Basal ganglia neural responses during behaviorally effective deep brain stimulation of the subthalamic nucleus in rats performing a treadmill locomotion test. Synapse 2006, 59, 445–457. [Google Scholar] [CrossRef] [PubMed]

- Fiáth, R.; Grand, L.; Kerekes, B.; Pongrácz, A.; Vázsonyi, É.; Márton, G.; Battistig, G.; Ulbert, I. A novel multisite silicon probe for laminar neural recordings. Procedia Comput. Sci. 2011, 7, 310–311. [Google Scholar] [CrossRef]

- Cheung, K.C. Implantable microscale neural interfaces. Biomed. Microdevices 2008, 9, 923–938. [Google Scholar] [CrossRef] [PubMed]

- Norlin, P.; Kindlundh, M.; Mouroux, A.; Yoshida, K.; Hofmann, U.G. A 32-site neural recording probe fabricated by DRIE of SOI substrates. J. Micromech. Microeng. 2002, 12, 414–419. [Google Scholar] [CrossRef]

- Ruther, P.; Herwik, S.; Kisban, S.; Seidl, K.; Paul, O. Recent Progress in Neural Probes Using Silicon MEMS Technology. IEEJ Trans. Electr. Electron. 2010, 5, 505–515. [Google Scholar] [CrossRef]

- Wise, K.D. Silicon microsystems for neuroscience and neural prostheses. IEEE Eng. Med. Biol. Mag. 2005, 24, 22–29. [Google Scholar] [CrossRef] [PubMed]

- Wise, K.D.; Angell, J.B.; Starr, A. An Integrated-Circuit Approach to Extracellular Microelectrodes. IEEE Trans. Biomed. Eng. 1970, BME-17, 238–247. [Google Scholar] [CrossRef]

- Bai, Q.; Wise, K.D.; Anderson, D.J. A high-yield microassembly structure for three-dimensional microelectrode arrays. IEEE Trans. Biomed. Eng. 2000, 47, 281–289. [Google Scholar] [PubMed]

- Yao, Y.; Gulari, M.N.; Wiler, J.A.; Wise, K.D. A Microassembled Low-Profile Three-Dimensional Microelectrode Array for Neural Prosthesis Applications. J. Microelectromech. Syst. 2007, 16, 977–988. [Google Scholar] [CrossRef]

- Rousche, P.J.; Normann, R.A. Chronic recording capability of the Utah intracortical electrode array in cat sensory cortex. J. Neurosci. Methods 1998, 82, 1–15. [Google Scholar] [CrossRef]

- Maynard, E.M.; Nordhausen, C.T.; Normann, R.A. The Utah Intracortical Electrode Array: A recording structure for potential brain-computer interfaces. Electroencephalogr. Clin. Neurophysiol. 1997, 102, 228–239. [Google Scholar] [CrossRef]

- Campbell, P.K.; Jones, K.E.; Huber, R.J.; Horch, K.W.; Normann, R.A. A silicon-based, three-dimensional neural interface: Manufacturing processes for an intracortical electrode array. IEEE Trans. Biomed. Eng. 1991, 38, 758–768. [Google Scholar] [CrossRef] [PubMed]

- Fekete, Z. Recent advances in silicon-based neural microelectrodes and microsystems: A review. Sens. Actuators B Chem. 2015, 215, 300–315. [Google Scholar] [CrossRef]

- Aarts, A.A.A.; Neves, H.P.; Puers, R.P.; Hoof, C.V. An interconnect for out-of-plane assembled biomedical probe arrays. J. Micromech. Microeng. 2008, 18, 777–786. [Google Scholar] [CrossRef]

- Du, J.; Roukes, M.L.; Masmanidis, S.C. Dual-side and three-dimensional microelectrode arrays fabricated from ultra-thin silicon substrates. J. Micromech. Microeng. 2009, 19, 1403–1407. [Google Scholar] [CrossRef]

- Lee, Y.T.; Moser, D.; Holzhammer, T.; Fang, W.; Paul, O.; Ruther, P. Ultrathin, dual-sided silicon neural microprobes realized using BCB bonding and aluminum sacrificial etching. In Proceedings of the IEEE 26th International Conference on Micro Electro Mechanical Systems (MEMS), Taipei, Taiwan, 20–24 January 2013.

- Du, J.; Blanche, T.J.; Harrison, R.R.; Lester, H.A.; Masmanidis, S.C. Multiplexed, high density electrophysiology with nanofabricated neural probes. PLoS ONE 2011, 6, e26204. [Google Scholar] [CrossRef] [PubMed]

- Tanghe, S.J.; Wise, K.D. A 16-channel CMOS neural stimulating array. IEEE J. Solid-State Circuits 1992, 27, 1819–1825. [Google Scholar] [CrossRef]

- Seidl, K.; Lemke, B.; Ramirez, H.; Herwik, S. CMOS-based high-density silicon microprobe for stress mapping in intracortical applications. In Proceedings of the 23rd IEEE International Conference on Micro Electro Mechanical Systems, Hong Kong, China, 24–28 January 2010; Voulme 33, pp. 35–38.

- Chen, J.; Wise, K.D.; Hetke, J.F.; Bledsoe, S.C. A multichannel neural probe for selective chemical delivery at the cellular level. IEEE Trans. Biomed. Eng. 1997, 44, 760–769. [Google Scholar] [CrossRef] [PubMed]

- Seidl, K.; Spieth, S.; Herwik, S.; Steigert, J.; Zengerle, R.; Paul, O.; Ruther, P. In-plane silicon probes for simultaneous neural recording and drug delivery. J. Micromech. Microeng. 2010, 20, 105006–105011. [Google Scholar] [CrossRef]

- Pongrácz, A.; Fekete, Z.; Márton, G.; Bérces, Z.; Ulbert, I.; Fürjes, P. Deep-brain silicon multielectrodes for simultaneous in vivo neural recording and drug delivery. Sens. Actuators B Chem. 2013, 189, 97–105. [Google Scholar] [CrossRef]

- Fekete, Z.; Pálfi, E.; Márton, G.; Handbauer, M.; Bérces, Z.; Ulbert, I.; Pongrácz, A.; Négyessy, L. Combined in vivo recording of neural signals and iontophoretic injection of pathway tracers using a hollow silicon microelectrode. Sens. Actuators B Chem. 2016. [Google Scholar] [CrossRef]

- Wu, F.; Stark, E.; Ku, P.C.; Wise, K.D.; Buzsáki, G.; Yoon, E. Monolithically Integrated μLEDs on Silicon Neural Probes for High-Resolution Optogenetic Studies in Behaving Animals. Neuron 2015, 88, 1136–1148. [Google Scholar] [CrossRef] [PubMed]

- Kiss, M.; Földesy, P.; Fekete, Z. Optimization of a Michigan-type silicon microprobe for infrared neural stimulation. Sens. Actuators B Chem. 2015, 224, 676–682. [Google Scholar] [CrossRef]

- Xu, H.; Weltman, A.; Hsiao, M.C.; Scholten, K.; Meng, E.; Berger, T.W.; Song, D. Design of a flexible parylene-based multi-electrode array for multi-region recording from the rat hippocampus. IEEE Eng. Med. Biol. 2015, 2015, 7139–7142. [Google Scholar]

- Márton, G.; Baracskay, P.; Cseri, B.; Plósz, B.; Juhász, G.; Fekete, Z.; Pongrácz, A. A silicon-based microelectrode array with a microdrive for monitoring brainstem regions of freely moving rats. J. Neural Eng. 2016, 13, 026025. [Google Scholar] [CrossRef] [PubMed]

- Lozano, A.M.; Dostrovsky, J.; Chen, R.; Ashby, P. Deep brain stimulation for Parkinson’s disease: Disrupting the disruption. Lancet Neurol. 2002, 1, 225–231. [Google Scholar] [CrossRef]

- Johnson, M.D.; Franklin, R.K.; Gibson, M.D.; Brown, R.B.; Kipke, D.R. Implantable microelectrode arrays for simultaneous electrophysiological and neurochemical recordings. J. Neurosci. Methods 2008, 174, 62–70. [Google Scholar] [CrossRef] [PubMed]

- Frey, O.; Holtzman, T.; Mcnamara, R.M.; Theobald, D.E.H.; van der Wal, P.D.; de Rooij, N.F.; Dalley, J.W.; Koudelka-Hep, M. Simultaneous neurochemical stimulation and recording using an assembly of biosensor silicon microprobes and SU-8 microinjectors. Sens. Actuators B Chem. 2011, 154, 96–105. [Google Scholar] [CrossRef]

- Mcintyre, C.C.; Mori, S.; Sherman, D.L.; Thakor, N.V.; Vitek, J.L. Electric field and stimulating influence generated by deep brain stimulation of the subthalamic nucleus. Clin. Neurophysiol. 2004, 115, 589–595. [Google Scholar] [CrossRef] [PubMed]

- Butson, C.R.; Mcintyre, C.C. Role of electrode design on the volume of tissue activated during deep brain stimulation. J. Neural Eng. 2006, 3, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Yousif, N.; Bayford, R.; Liu, X. The influence of reactivity of the electrode-brain interface on the crossing electric current in therapeutic deep brain stimulation. Neuroscience 2008, 156, 597–606. [Google Scholar] [CrossRef] [PubMed]

- Geddes, L.A.; Baker, L.E. The specific resistance of biological material—A compendium of data for the biomedical engineer and physiologist. Med. Biol. Eng. Comput. 1967, 5, 271–293. [Google Scholar] [CrossRef]

- Li, S.J.; Deng, D.H.; Shi, Q.; Liu, S.R. Electrochemical synthesis of a graphene sheet and gold nanoparticle-based nanocomposite, and its application to amperometric sensing of dopamine. Microchim. Acta 2012, 177, 325–331. [Google Scholar] [CrossRef]

- Yong, H.K.; Kim, A.Y.; Kim, G.H.; Han, Y.H.; Chung, M.A.; Jung, S.D. Electrochemical and in vitro neuronal recording characteristics of multi-electrode arrays surface-modified with electro-co-deposited gold-platinum nanoparticles. Biomed. Microdevices 2016, 18, 1–7. [Google Scholar]

- Butson, C.R.; Maks, C.B.; Mcintyre, C.C. Sources and effects of electrode impedance during deep brain stimulation. Clin. Neurophysiol. 2006, 117, 447–454. [Google Scholar] [CrossRef] [PubMed]

- Butson, C.R.; Cooper, S.E.; Henderson, J.M.; Mcintyre, C.C. Patient-specific analysis of the volume of tissue activated during deep brain stimulation. Neuroimage 2007, 34, 661–670. [Google Scholar] [CrossRef] [PubMed]

- Shahrokhian, S.; Rastgar, S. Construction of an electrochemical sensor based on the electrodeposition of Au-Pt nanoparticles mixtures on multi-walled carbon nanotubes film for voltammetric determination of cefotaxime. Analyst 2012, 137, 2706–2715. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Zhang, M.; Chen, X.; Li, Y.; Wang, J. Electrochemical Co-Reduction Synthesis of AuPt Bimetallic Nanoparticles-Graphene Nanocomposites for Selective Detection of Dopamine in the Presence of Ascorbic Acid and Uric Acid. Sensors 2015, 15, 16614–16631. [Google Scholar] [CrossRef] [PubMed]

- Fang, B.; Wang, G.; Zhang, W.; Li, M.; Kan, X. Fabrication of Fe3O4 Nanoparticles Modified Electrode and Its Application for Voltammetric Sensing of Dopamine. Electroanal 2005, 17, 744–748. [Google Scholar] [CrossRef]

- Qin, G.; Liu, Y.; Liu, H.; Ding, Y.; Qi, X.; Du, R. Fabrication of bio-microelectrodes for deep-brain stimulation using microfabrication and electroplating process. Microsyst. Technol. 2009, 15, 933–939. [Google Scholar] [CrossRef]

- Suzuki, I.; Mao, F.; Shirakawa, K.; Jiko, H.; Gotoh, M. Carbon nanotube multi-electrode array chips for noninvasive real-time measurement of dopamine, action potentials, and postsynaptic potentials. Biosens. Bioelectron. 2013, 49, 270–275. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Gong, R.; Huang, H.; Wang, J. Design, Fabrication, Simulation and Characterization of a Novel Dual-Sided Microelectrode Array for Deep Brain Recording and Stimulation. Sensors 2016, 16, 880. https://doi.org/10.3390/s16060880

Zhao Z, Gong R, Huang H, Wang J. Design, Fabrication, Simulation and Characterization of a Novel Dual-Sided Microelectrode Array for Deep Brain Recording and Stimulation. Sensors. 2016; 16(6):880. https://doi.org/10.3390/s16060880

Chicago/Turabian StyleZhao, Zongya, Ruxue Gong, Hongen Huang, and Jue Wang. 2016. "Design, Fabrication, Simulation and Characterization of a Novel Dual-Sided Microelectrode Array for Deep Brain Recording and Stimulation" Sensors 16, no. 6: 880. https://doi.org/10.3390/s16060880

APA StyleZhao, Z., Gong, R., Huang, H., & Wang, J. (2016). Design, Fabrication, Simulation and Characterization of a Novel Dual-Sided Microelectrode Array for Deep Brain Recording and Stimulation. Sensors, 16(6), 880. https://doi.org/10.3390/s16060880