Measuring Micro-Friction Torque in MEMS Gas Bearings

Abstract

:1. Introduction

2. System Design

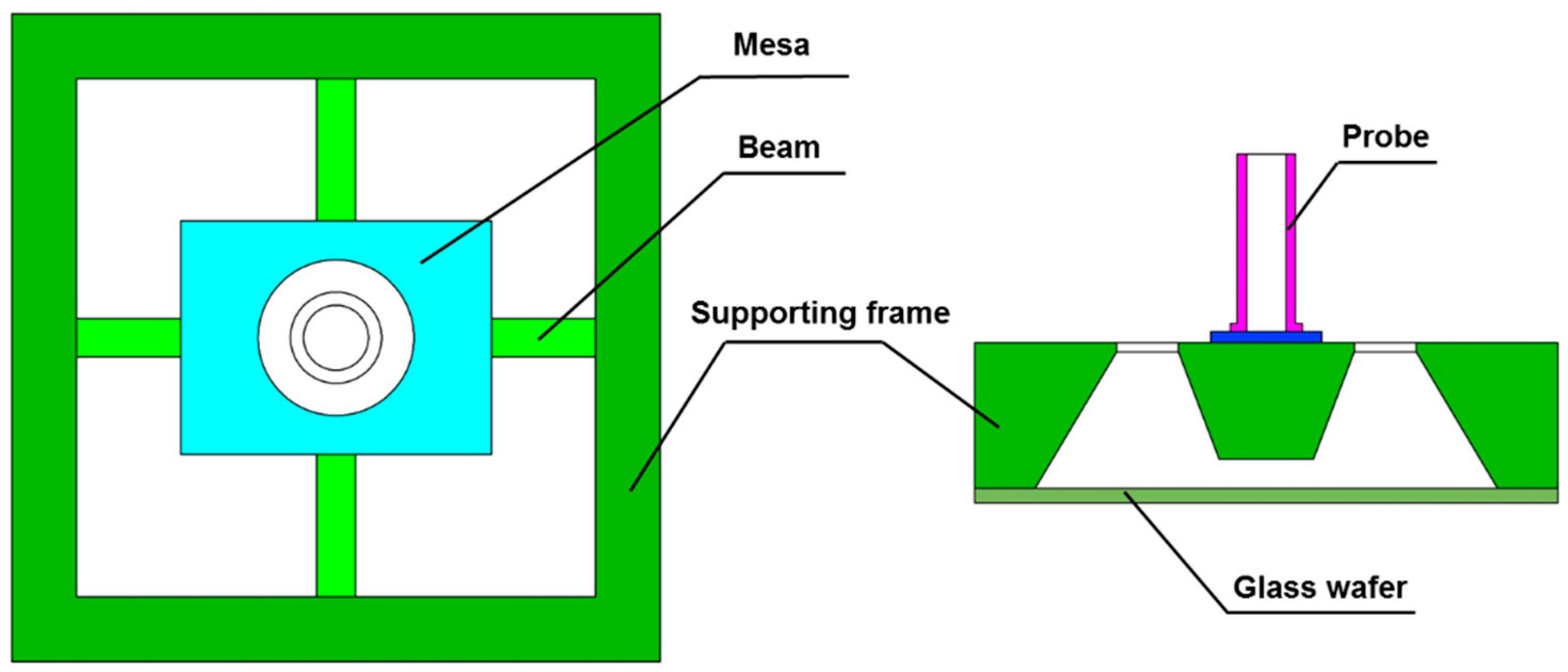

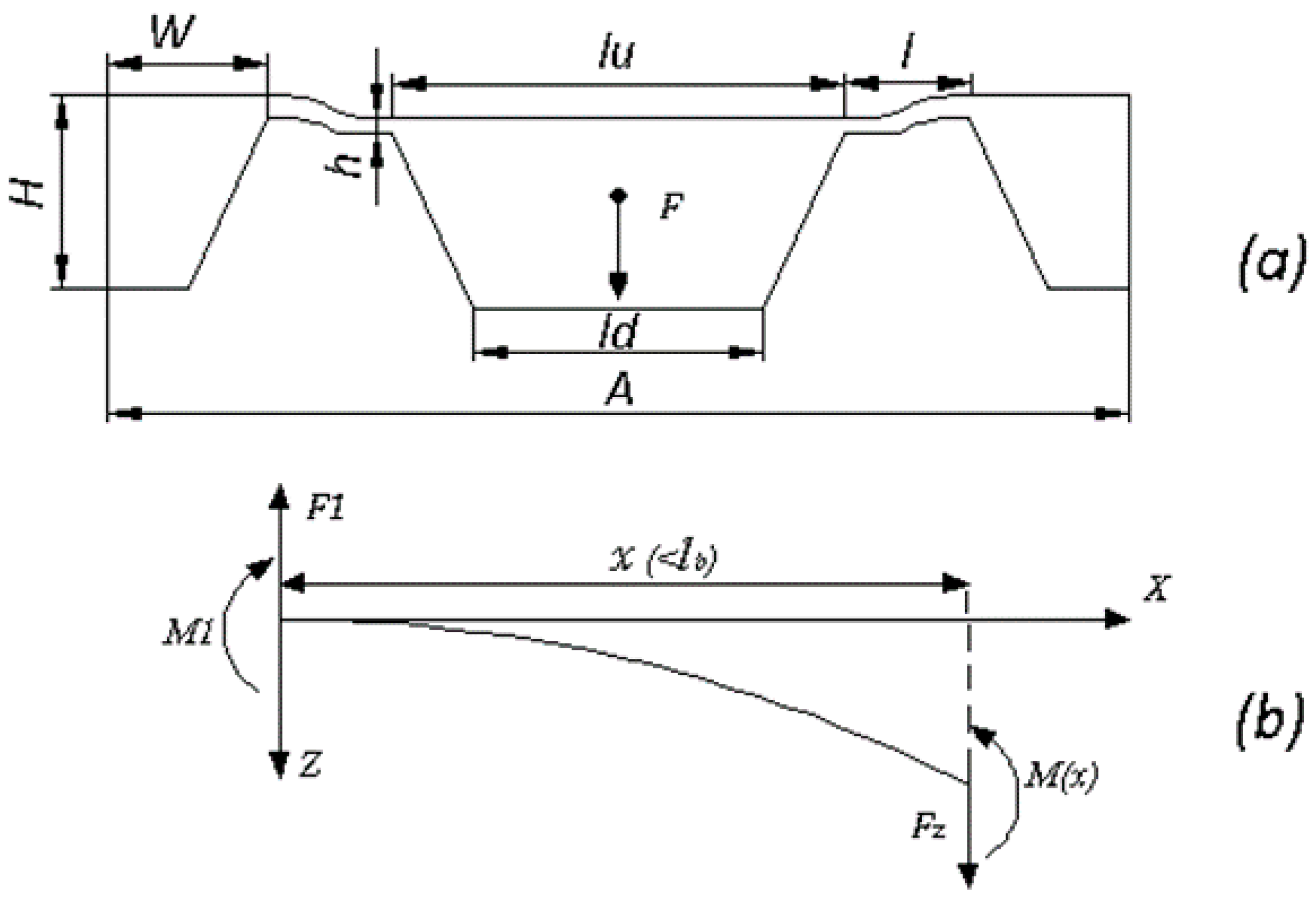

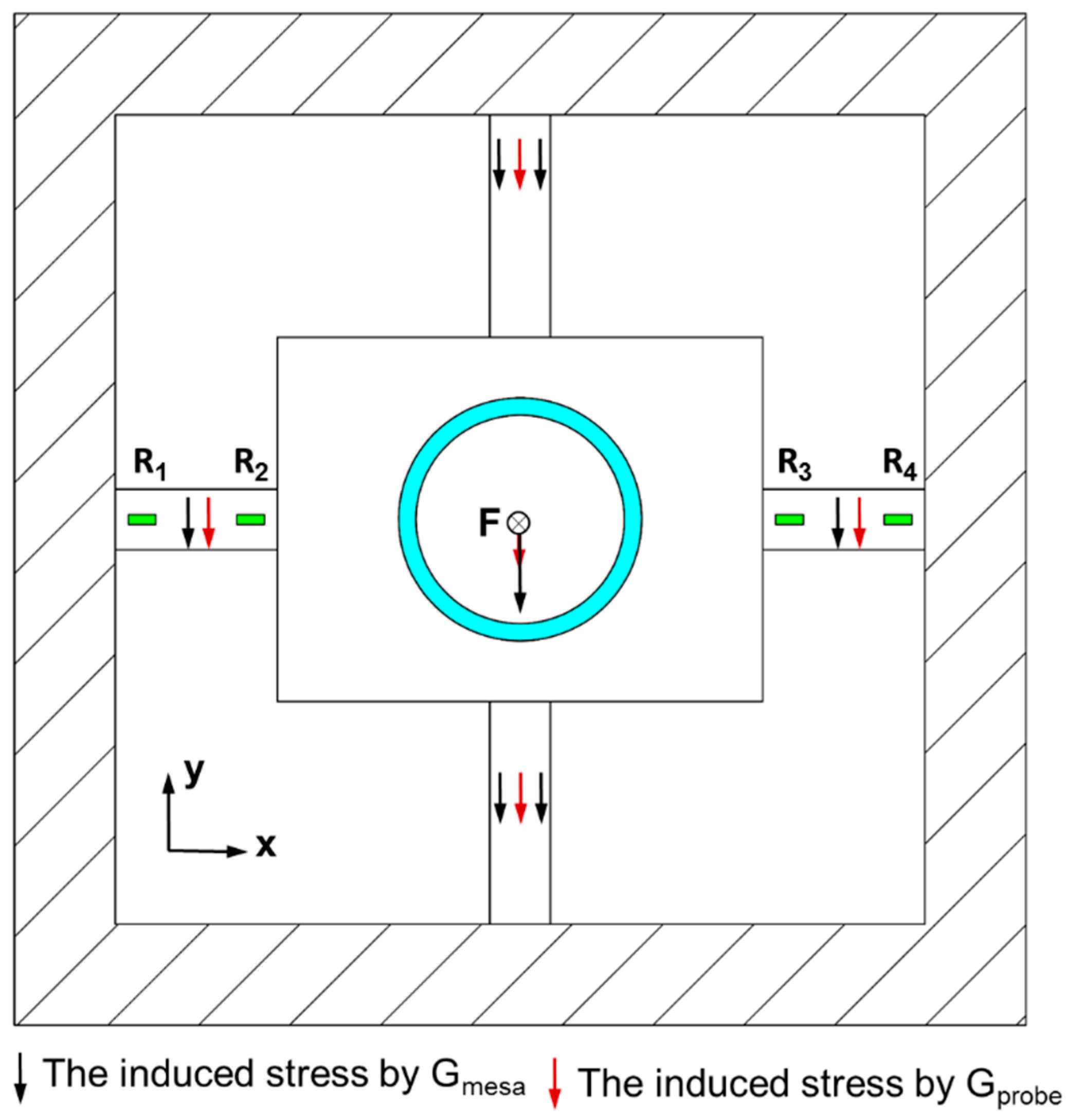

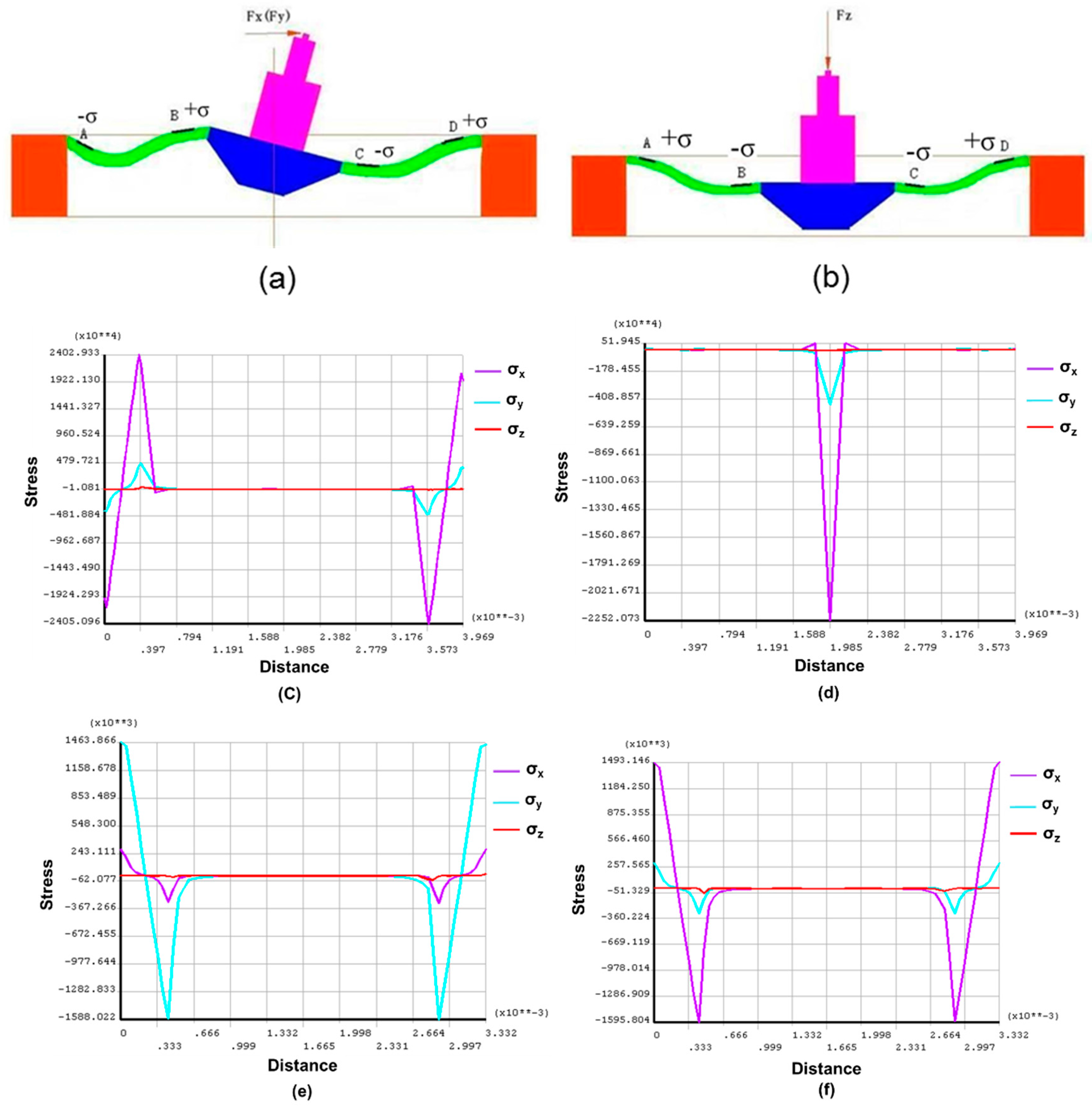

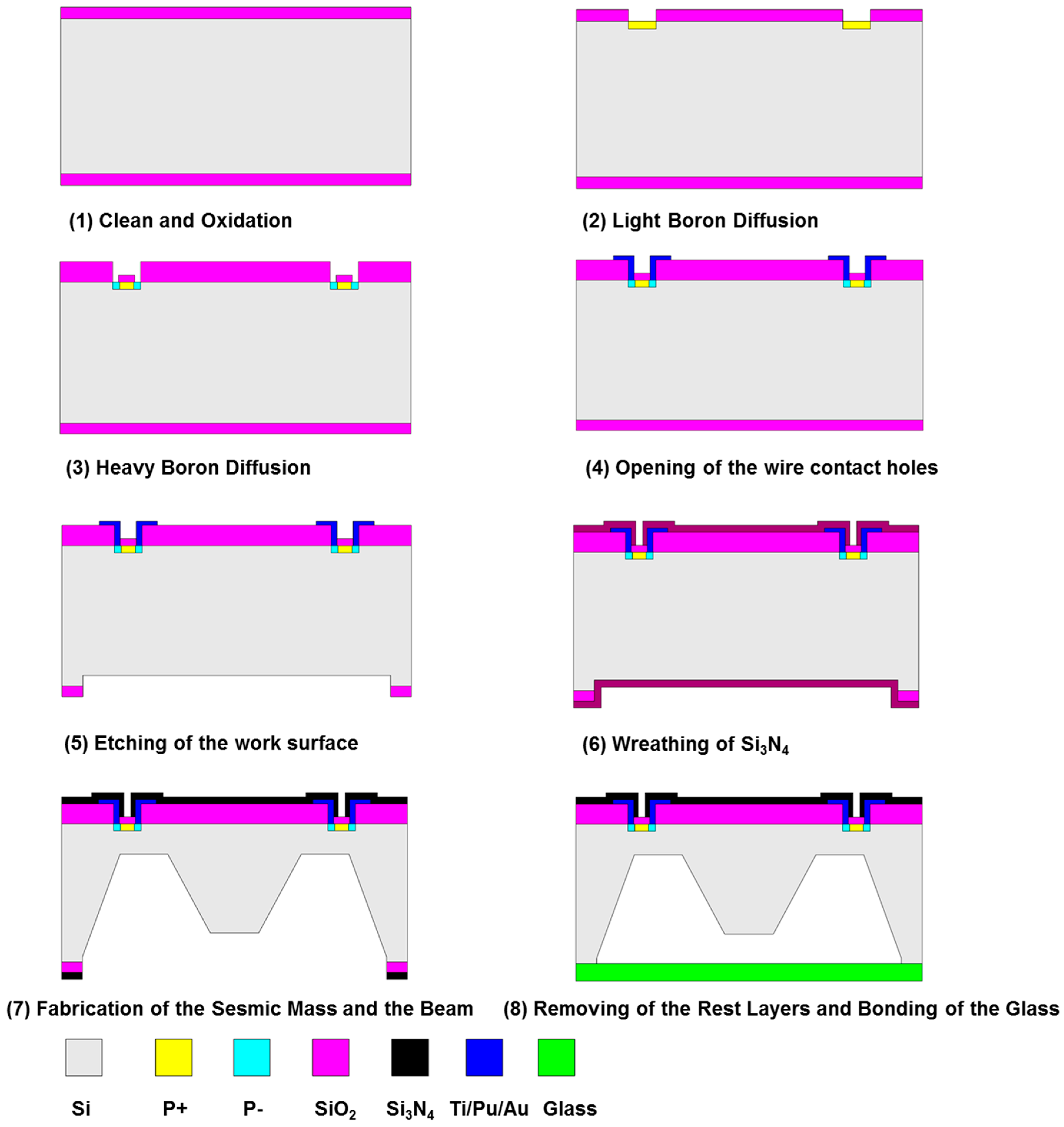

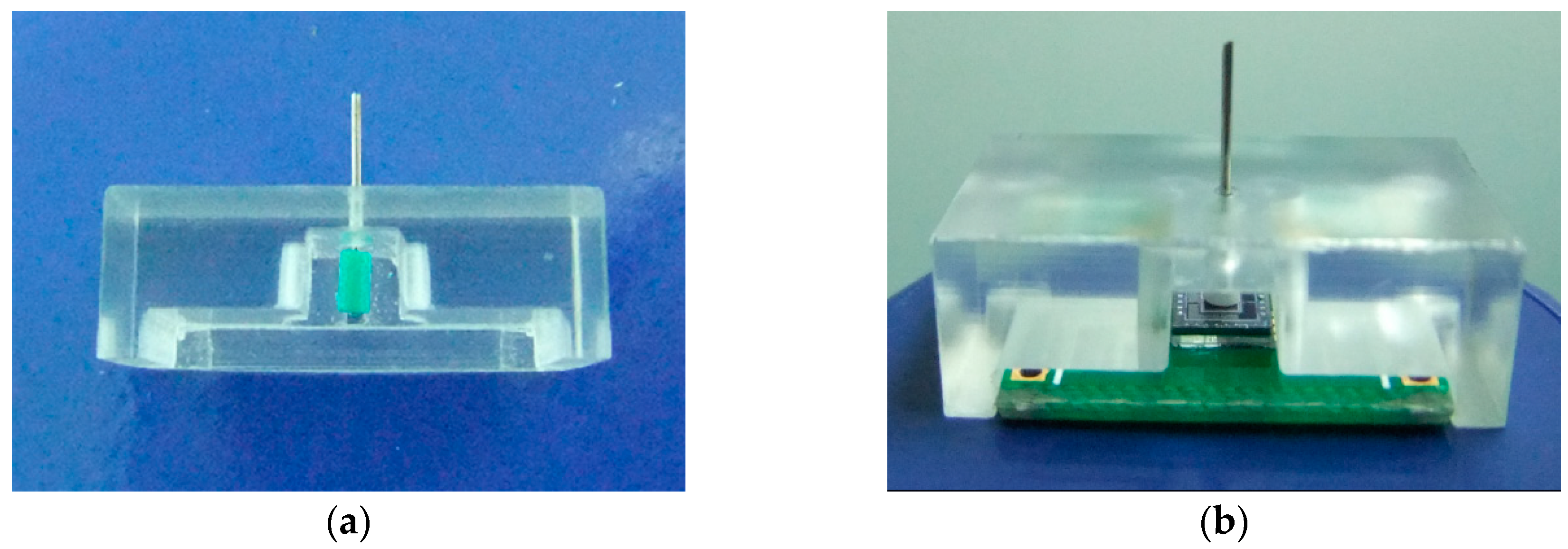

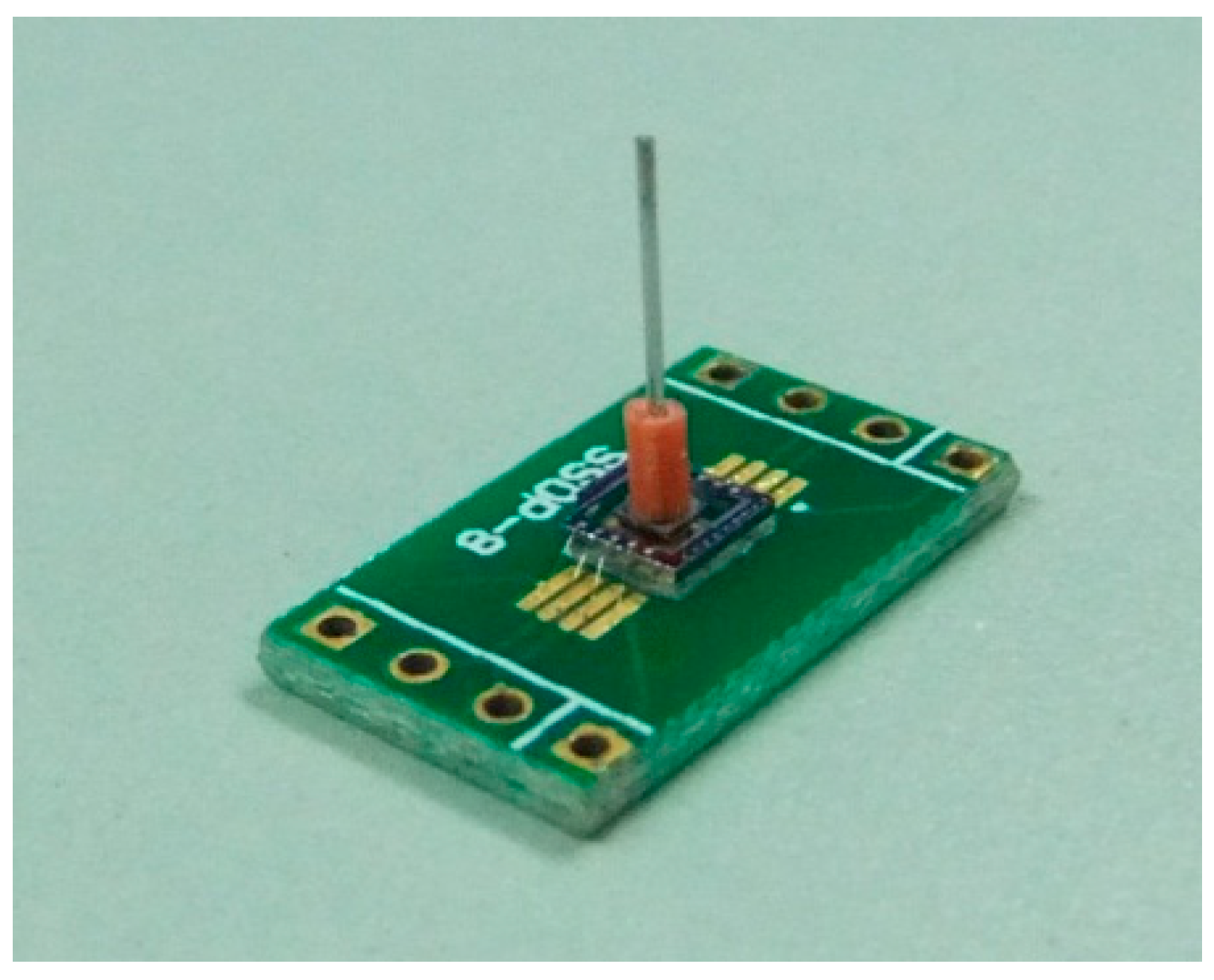

2.1. Micro-Force Sensor Design

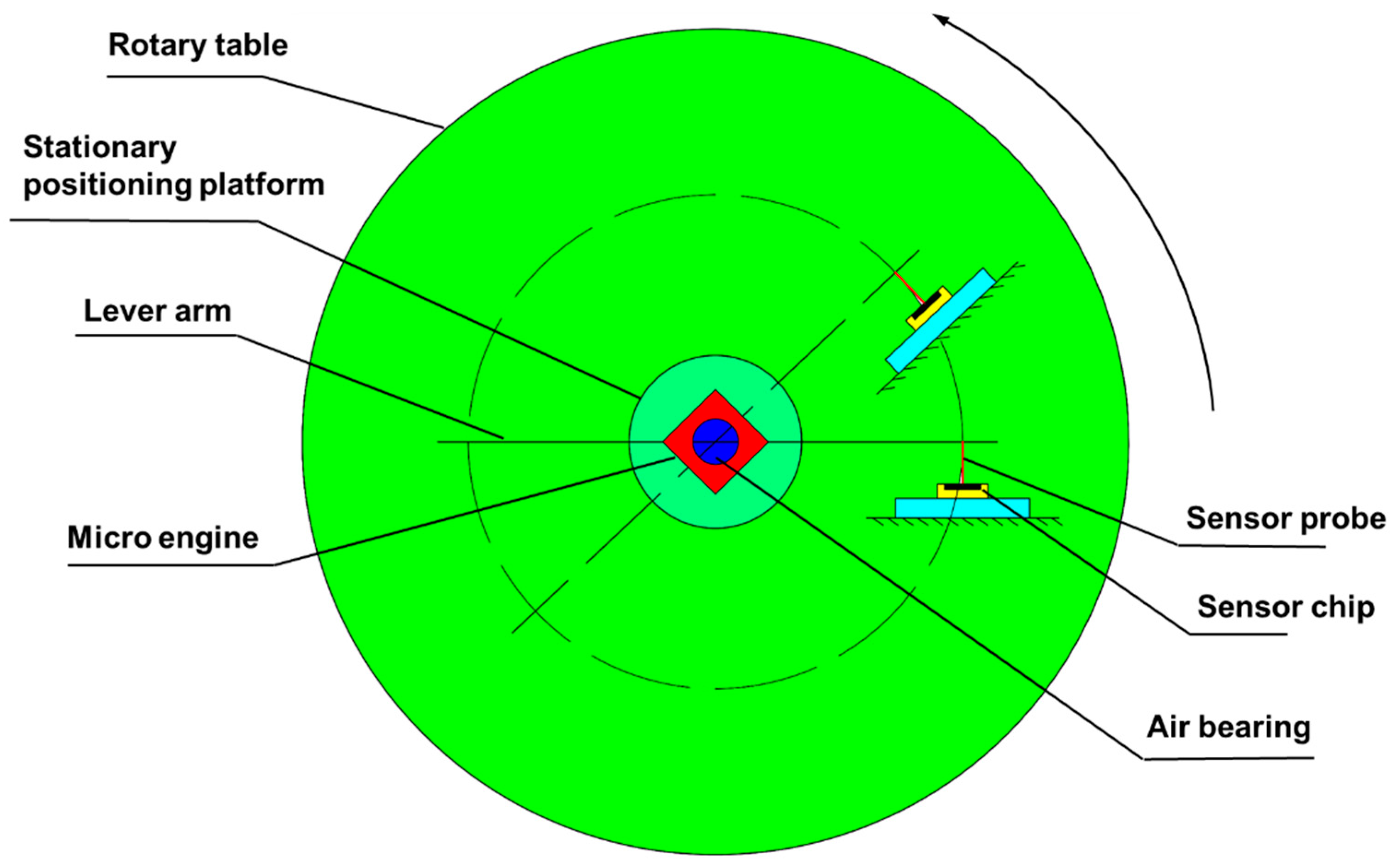

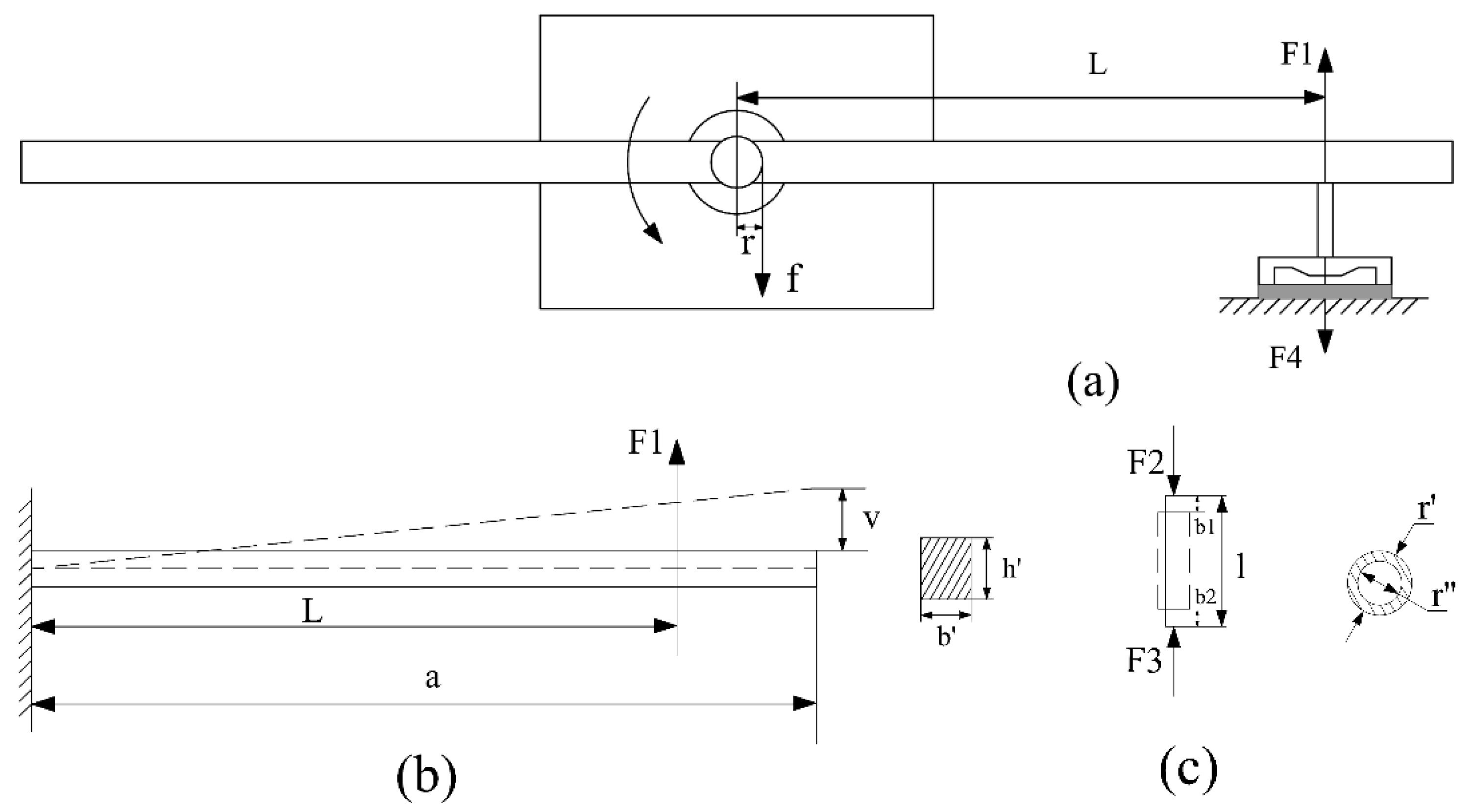

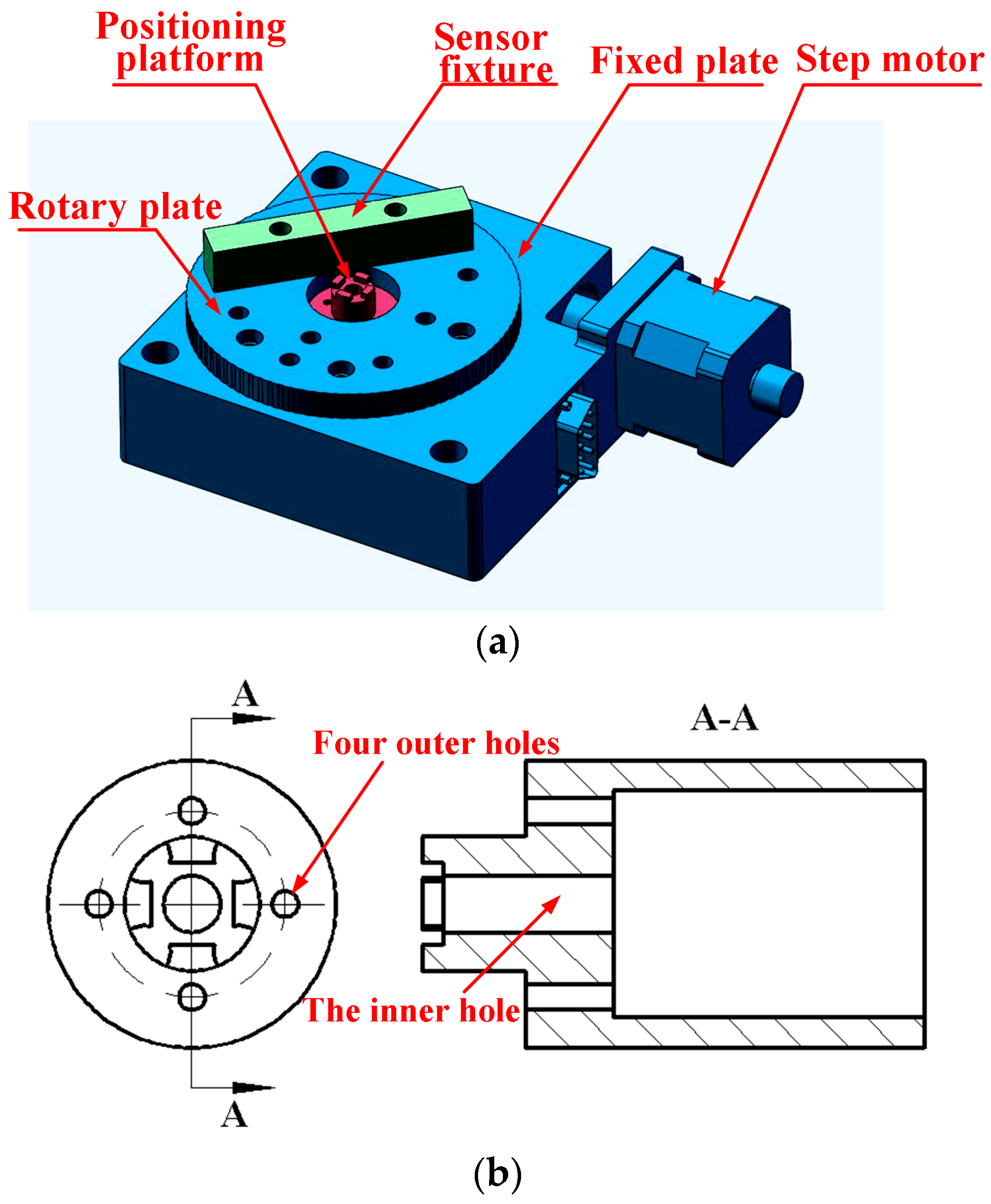

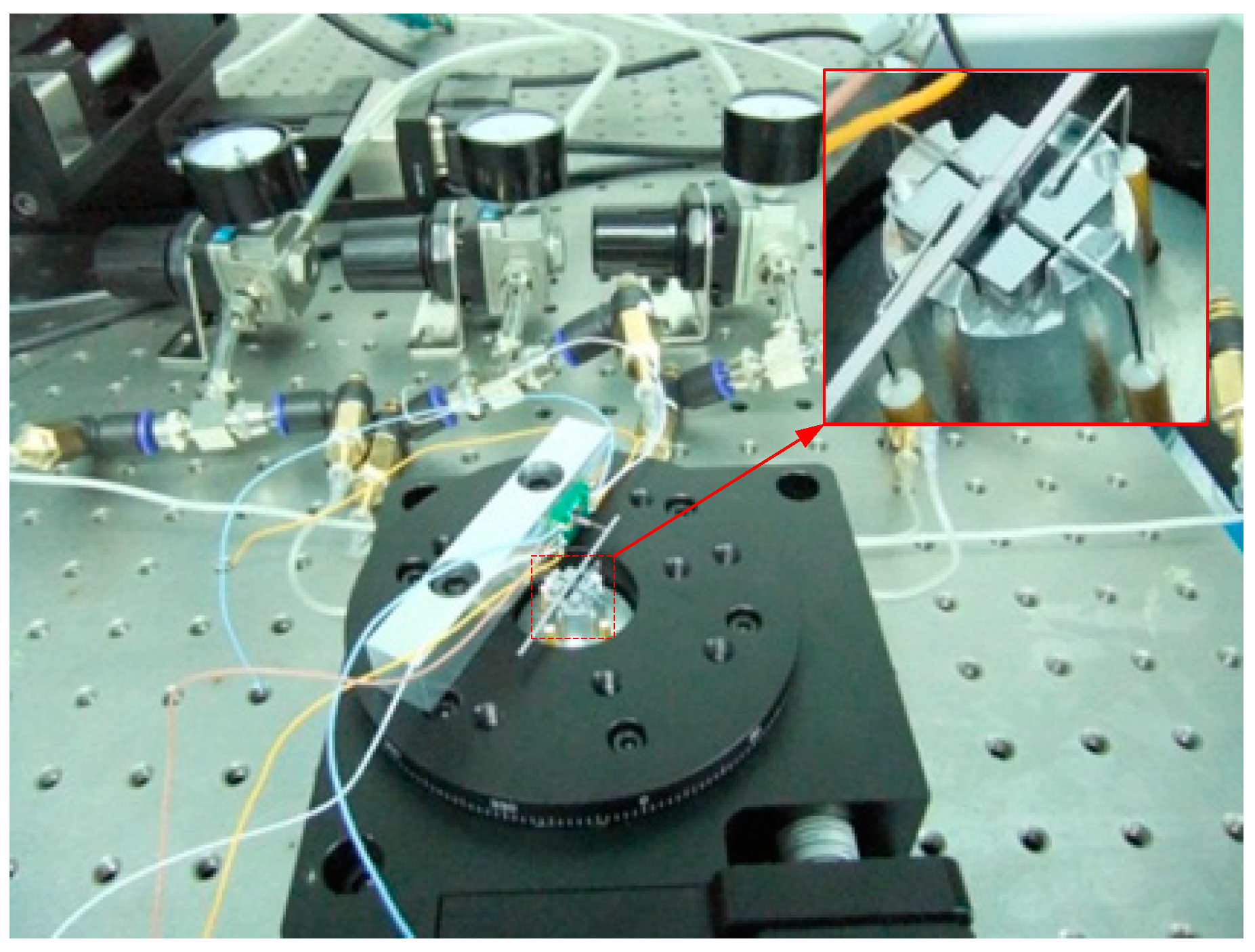

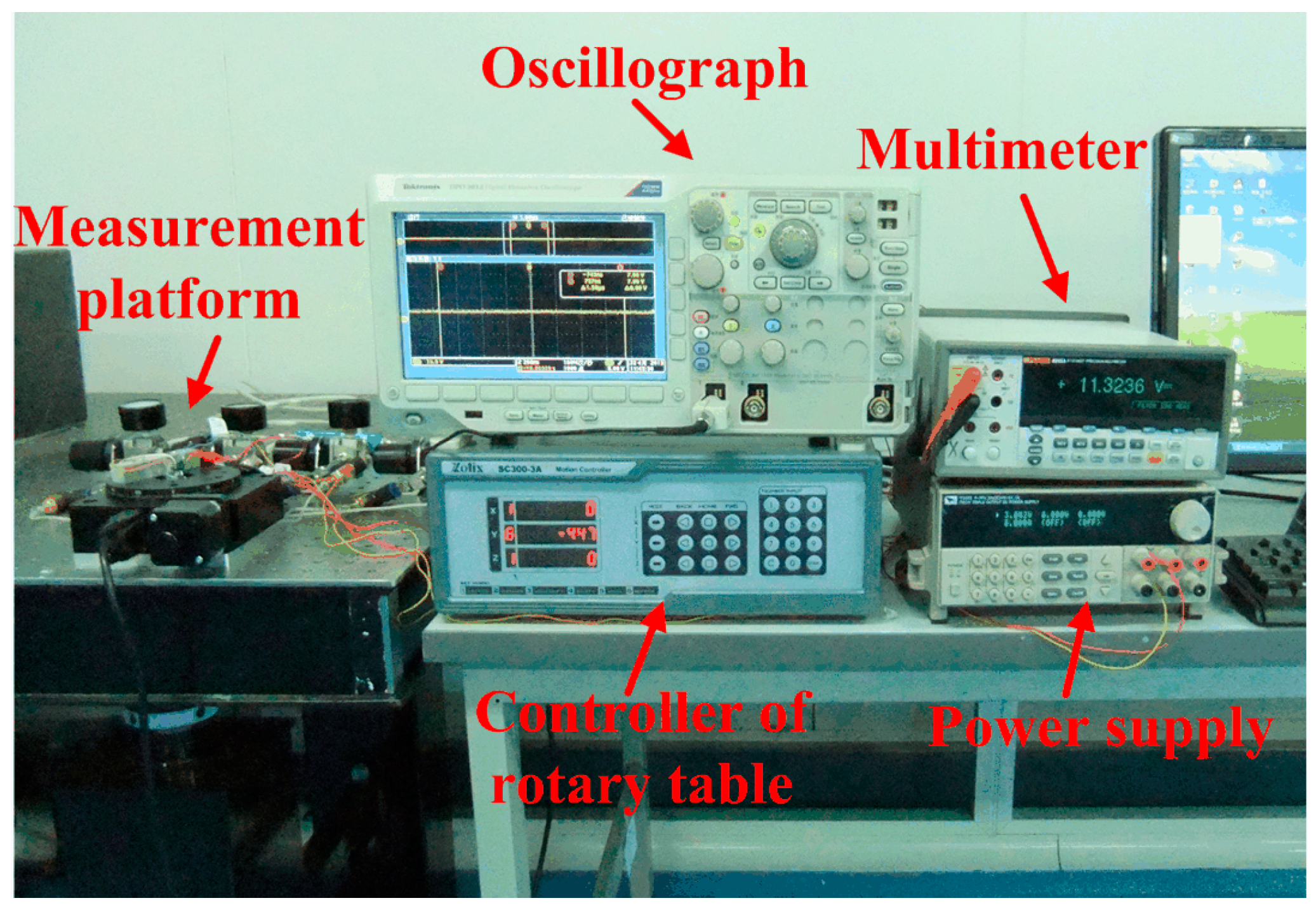

2.2. Measurement Platform Design

3. System Execution

4. Results and Discussions

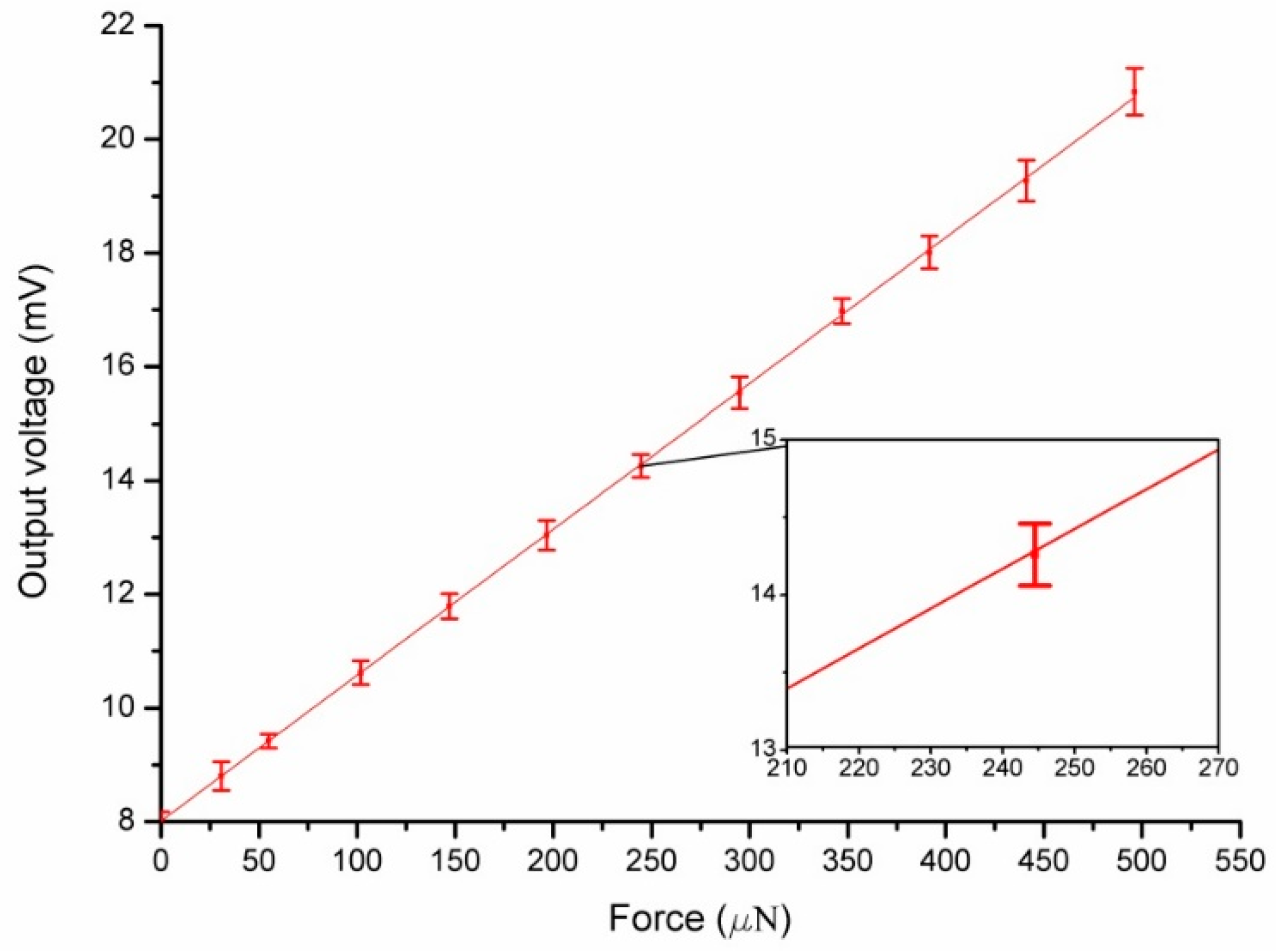

4.1. Calibration of the Force Sensor

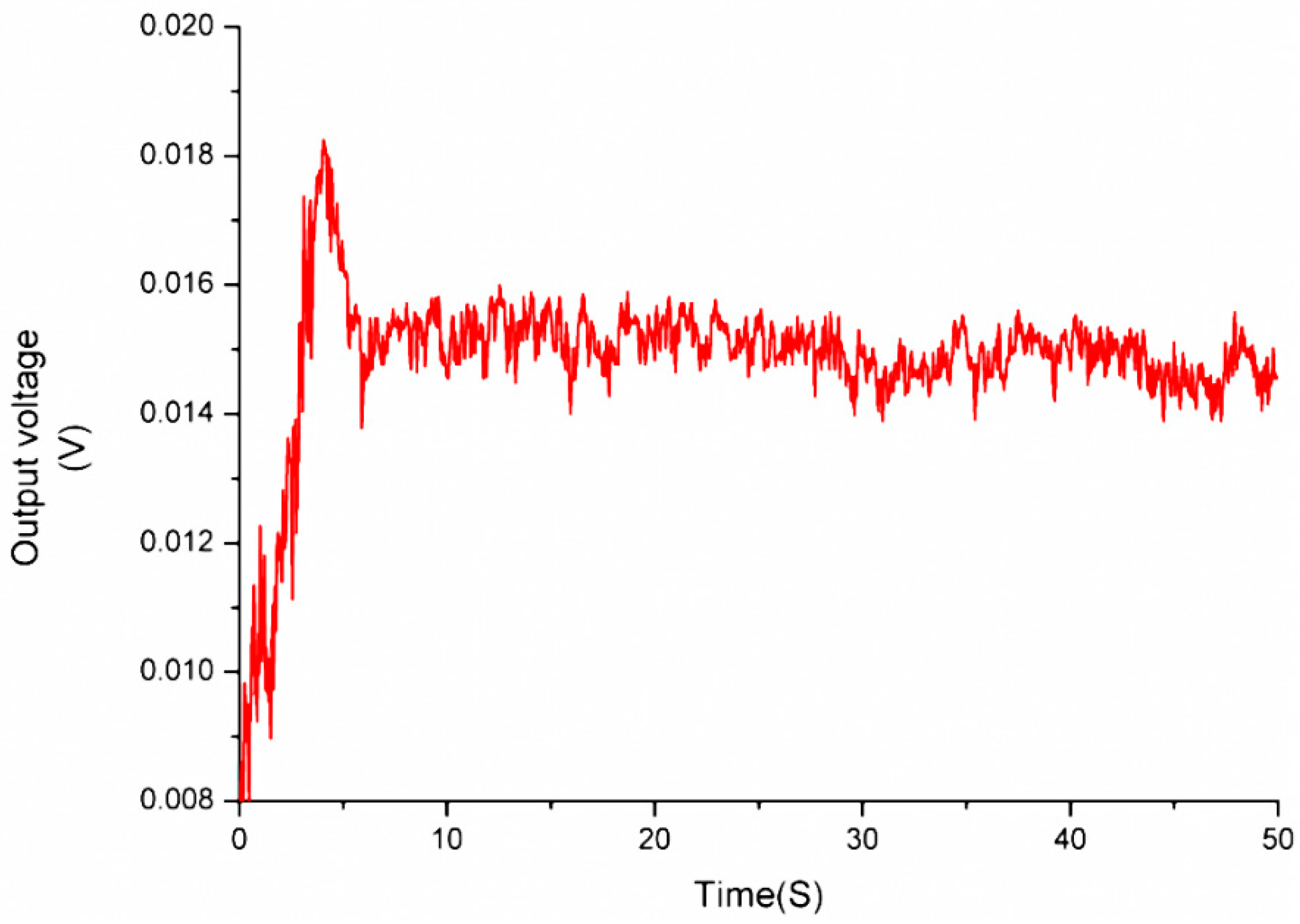

4.2. Measurement of the Micro-Friction Torque

5. Conclusions

Author Contributions

Conflicts of Interest

Abbreviations

| MEMS | MicroElectroMechanical Systems |

| ICP | Inductively Coupled Plasma |

| DRIE | Deep Reactive Ion Etching |

References

- Camarillo, E.A.; Flores, H. Construction, calibration and testing of a micro-combustion calorimeter. J. Chem. Thermodyn. 2006, 38, 1269–1273. [Google Scholar] [CrossRef]

- Nascimento, M.A.; Lora, E.S.; Correa, P.S.; Andrade, R.V.; Rendon, M.A.; Venturini, O.J.; Ramirez, G.A. Biodiesel fuel in diesel micro-turbine engines: Modelling and experimental evaluation. Energy 2008, 33, 233–240. [Google Scholar] [CrossRef]

- Nie, W.; He, J. Performance analysis of a thermosize micro/nano heat engine. Phys. Lett. A 2008, 372, 1168–1173. [Google Scholar] [CrossRef]

- Sakurai, T.; Yuasa, S.; Honda, T.; Shimotori, S. Heat loss reduction and hydrocarbon combustion in ultra-micro combustors for ultra-micro gas turbines. Proc. Combust. Inst. 2009, 32, 3067–3073. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, Y.; Yang, W.; Liu, J.; Wang, Z.; Cen, K. Improvement of micro-combustion stability through electrical heating. Appl. Therm. Eng. 2009, 29, 2373–2378. [Google Scholar] [CrossRef]

- Cho, J.-H.; Lin, C.S.; Richards, C.D.; Richards, R.F.; Ahn, J.; Ronney, P.D. Demonstration of an external combustion micro-heat engine. Proc. Combust. Inst. 2009, 32, 3099–3105. [Google Scholar] [CrossRef]

- Yang, C.Q.; He, Q.; Lyon, R.E.; Hu, Y. Investigation of the flammability of different textile fabrics using micro-scale combustion calorimetry. Polymer Degrad. Stab. 2010, 95, 108–115. [Google Scholar] [CrossRef]

- Kim, D.; Lee, S.; Jin, Y.; Desta, Y.; Bryant, M.; Goettert, J. Micro gas bearings fabricated by deep x-ray lithography. Microsyst. Technol. 2004, 10, 456–461. [Google Scholar] [CrossRef]

- Kim, D.; Cao, D.; Bryant, M.D.; Meng, W.; Ling, F.F. Tribological study of microbearings for MEMS applications. J. Tribol. 2005, 127, 537–547. [Google Scholar] [CrossRef]

- Spakovszky, Z.; Liu, L. Scaling Laws for Ultra-Short Hydrostatic Gas Journal Bearings. J. Vib. Acoust. 2005, 127, 254–261. [Google Scholar]

- Boedo, S.; Booker, J. Modal and nodal EHD analysis for gas journal bearings. J. Tribol. 2005, 127, 306–314. [Google Scholar] [CrossRef]

- Liu, L.; Teo, C.; Epstein, A.; Spakovszky, Z. Hydrostatic gas journal bearings for micro-turbomachinery. J. Vib. Acoust. 2005, 127, 157–164. [Google Scholar] [CrossRef]

- Lee, Y.-B.; Kwak, H.-D.; Kim, C.-H.; Lee, N.-S. Numerical prediction of slip flow effect on gas-lubricated journal bearings for mems/mst-based micro-rotating machinery. Tribol. Int. 2005, 38, 89–96. [Google Scholar] [CrossRef]

- Ren, L.; Zhu, K.Q.; Wang, X.L. Effects of the slip velocity boundary condition on the characteristics of microbearings. J. Micromech. Microeng. 2004, 14, 116–124. [Google Scholar] [CrossRef]

- Kim, D.; Lee, S.; Bryant, M.D.; Ling, F.F. Hydrodynamic performance of gas microbearings. J. Tribol. 2004, 126, 711–718. [Google Scholar] [CrossRef]

- Ehrich, F.F.; Jacobson, S.A. Development of high-speed gas bearings for high-power density microdevices. J. Eng. Gas Turbines Power 2002, 125, 141–148. [Google Scholar] [CrossRef]

- Savoulides, N.; Breuer, K.; Jacobson, S.; Ehrich, F. Low-order models for very short hybrid gas bearings. J. Tribol. 2001, 123, 368–375. [Google Scholar] [CrossRef]

- Ku, I.; Reddyhoff, T.; Choo, J.; Holmes, A.; Spikes, H. A novel tribometer for the measurement of friction in MEMS. Tribol. Int. 2010, 43, 1087–1090. [Google Scholar] [CrossRef]

- Guo, Z.; Meng, Y.; Wu, H.; Su, C.; Wen, S. Measurement of static and dynamic friction coefficients of sidewalls of bulk-microfabricated MEMS devices with an on-chip micro-tribotester. Sens. Actuators A Phys. 2007, 135, 863–869. [Google Scholar] [CrossRef]

- Subhash, G.; Corwin, A.D.; de Boer, M.P. Evolution of wear characteristics and frictional behavior in mems devices. Tribol. Lett. 2011, 41, 177–189. [Google Scholar] [CrossRef]

- Flater, E.E.; Corwin, A.D.; de Boer, M.P.; Carpick, R.W. In situ wear studies of surface micromachined interfaces subject to controlled loading. Wear 2006, 260, 580–593. [Google Scholar] [CrossRef]

- Zhang, W.-M.; Zhou, J.-B.; Meng, G. Performance and stability analysis of gas-lubricated journal bearings in MEMS. Tribol. Int. 2011, 44, 887–897. [Google Scholar] [CrossRef]

- McCarthy, M.; Waits, C.M.; Ghodssi, R. Dynamic friction and wear in a planar-contact encapsulated microball bearing using an integrated microturbine. Microelectromech. Syst. 2009, 18, 263–273. [Google Scholar] [CrossRef]

- Chan, M.L.; Yoxall, B.; Park, H.; Kang, Z.; Izyumin, I.; Chou, J.; Megens, M.M.; Wu, M.C.; Boser, B.E.; Horsley, D.A. Design and characterization of MEMS micromotor supported on low friction liquid bearing. Sens. Actuators A Phys. 2012, 177, 1–9. [Google Scholar] [CrossRef]

- Bouyer, J.; Fillon, M. Experimental measurement of the friction torque on hydrodynamic plain journal bearings during start-up. Tribol. Int. 2011, 44, 772–781. [Google Scholar] [CrossRef]

- Beerschwinger, U.; Reuben, R.; Yang, S. Frictional study of micromotor bearings. Sens. Actuators A Phys. 1997, 63, 229–241. [Google Scholar] [CrossRef]

- FT-S1000 Micro Force Sensing Probe. Available online: http://www.femtotools.com/fileadmin/datasheets/FT-S1000_Datasheet.pdf (accessed on 22 August 2013).

- Song, A.; Wu, J.; Qin, G.; Huang, W. A novel self-decoupled four degree-of-freedom wrist force/torque sensor. Measurement 2007, 40, 883–891. [Google Scholar] [CrossRef]

- Ma, J.; Song, A. Fast estimation of strains for cross-beams six-axis force/torque sensors by mechanical modeling. Sensors 2013, 13, 6669–6686. [Google Scholar] [CrossRef] [PubMed]

- Qin, G.; Cao, X.; Song, A.; Huang, W. Finite element analysis for elastic body of new 4-axis wrist force sensor. J. Transcluction Technol. 2003, 3, 1–7. [Google Scholar]

- Baki, P.; Székely, G.; Kósa, G. Design and characterization of a novel, robust, tri-axial force sensor. Sens. Actuators A Phys. 2013, 192, 101–110. [Google Scholar] [CrossRef]

- Valdastri, P.; Roccella, S.; Beccai, L.; Cattin, E.; Menciassi, A.; Carrozza, M.; Dario, P. Characterization of a novel hybrid silicon three-axial force sensor. Sens. Actuators A Phys. 2005, 123, 249–257. [Google Scholar] [CrossRef]

- Beccai, L.; Roccella, S.; Arena, A.; Valvo, F.; Valdastri, P.; Menciassi, A.; Carrozza, M.C.; Dario, P. Design and fabrication of a hybrid silicon three-axial force sensor for biomechanical applications. Sens. Actuators A Phys. 2005, 120, 370–382. [Google Scholar] [CrossRef]

| Performance Parameters | Value |

|---|---|

| Sensitivity | 0.0257 mV/μN |

| Nonlinearity | 1.28% FS |

| Zero drift | 53.07% FS |

| Cross-sensitivity with Fx | 0.82% FS |

| Cross-sensitivity with Fy | 1.24% FS |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, X.; Liu, H. Measuring Micro-Friction Torque in MEMS Gas Bearings. Sensors 2016, 16, 726. https://doi.org/10.3390/s16050726

Fang X, Liu H. Measuring Micro-Friction Torque in MEMS Gas Bearings. Sensors. 2016; 16(5):726. https://doi.org/10.3390/s16050726

Chicago/Turabian StyleFang, Xudong, and Huan Liu. 2016. "Measuring Micro-Friction Torque in MEMS Gas Bearings" Sensors 16, no. 5: 726. https://doi.org/10.3390/s16050726

APA StyleFang, X., & Liu, H. (2016). Measuring Micro-Friction Torque in MEMS Gas Bearings. Sensors, 16(5), 726. https://doi.org/10.3390/s16050726