In this paper, we consider several typical Si nanophotonic waveguides operating at 1550 nm. The involved materials for nanophotonic waveguides include Si, SiO2, and gas (or liquid), whose refractive indices are assumed to be 3.455, 1.445, and 1.0 (or 1.33), respectively. In this paper, we assume that the buffer layer in various SOI optical waveguides considered here is thick enough to make the substrate leakage negligible. For example, the thickness of the SiO2 buffer layer is 3 μm in the following calculation.

2.1. SOI Nanowires

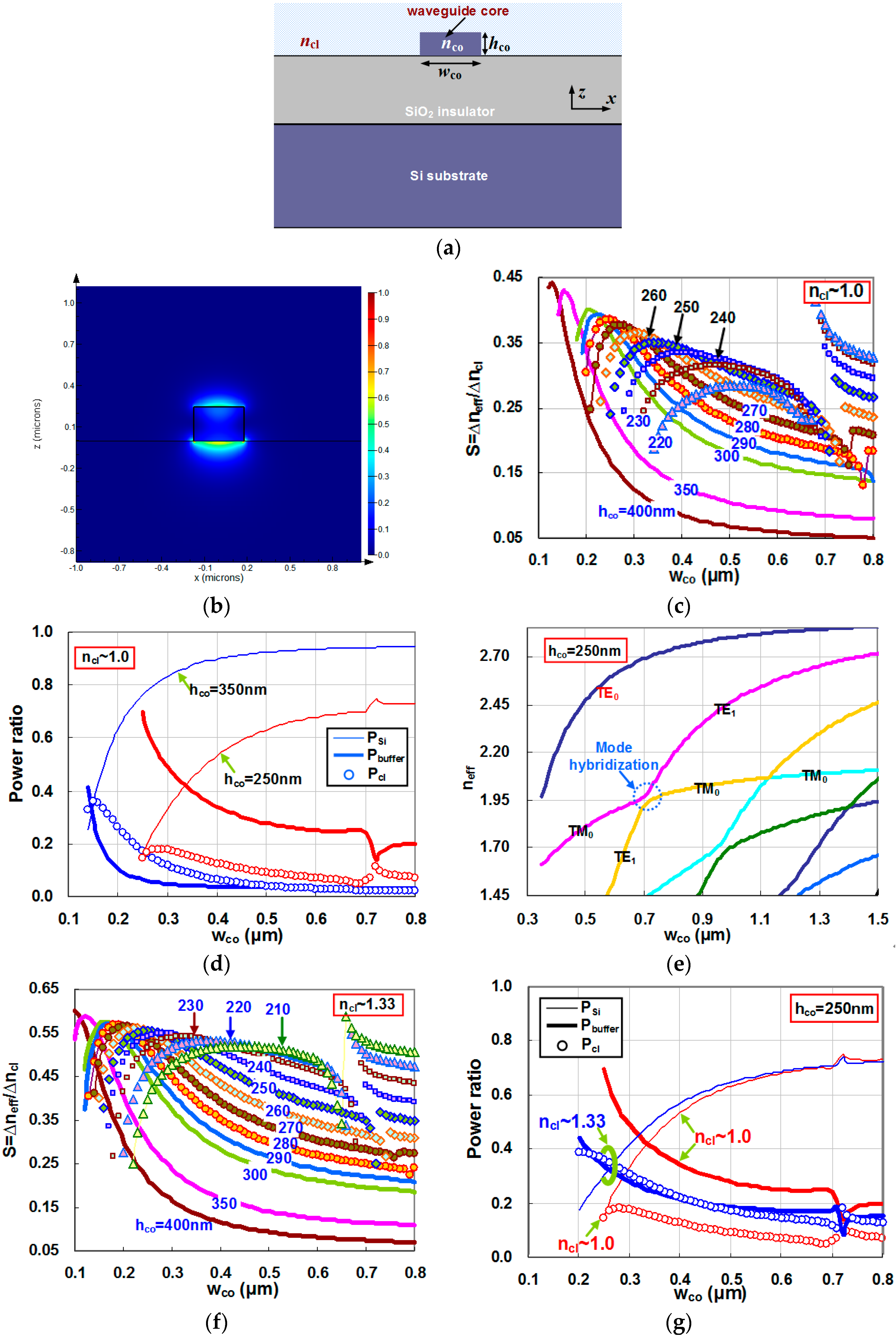

In this part, we consider a SOI nanowire, which has a Si core and a SiO

2 buffer layer, as shown in

Figure 1a, which is the most popular one used for optical sensing [

1]. The upper-cladding is the sample to be measured (

i.e., n

s = n

cl), which is a gas (n

s = n

cl ~ 1) or liquid (n

s = n

cl ~ 1.33). TM polarization is considered in the following calculation.

Figure 1b shows the calculated field distribution of the TM fundamental mode for a Silicon nanowire waveguide with h

co = 250 nm, w

co = 350 nm , n

cl = 1.0 as an example.

Figure 1c shows the calculated sensitivity as the core width w

co varies from 0.1 μm to 0.8 μm when the upper-cladding is filled with gas (n ~ 1.0). The Si core layer is 220, 230, 240, 250, 260, 270, 280, 290, 300, 350, and 400 nm thick, respectively. For the case with a relatively thick core (e.g., h

co ≥ 350 nm), the sensitivity is low, especially when the core width is large. This is because most power of the fundamental mode is confined in the core region while the evanescent field is very small, as shown in

Figure 1d, where P

co, P

cl, and P

buffer are the power confinement ratio in the regions of core, upper-cladding, and buffer, respectively. When the core width decreases, the confinement becomes weaker and more evanescent field penetrates to the upper-cladding (see

Figure 1d). The sensitivity consequently increases, as shown in

Figure 1c.

On the other hand, one should note that the present waveguide is asymmetrical in the vertical direction,

i.e., the upper-cladding (gas) has a lower refractive index than the buffer layer (SiO

2). Therefore, when the core becomes very narrow, the optical waveguide cannot confine the optical field well and less power is confined in the upper-cladding region, while more power moves to the SiO

2 buffer region (see

Figure 1d). For example, when w

co = 140 nm, the power ratios in the regions of Si core, SiO

2 buffer, and gas upper-cladding are 25.4%, 41.6%, and 32.9%, respectively. Thus, the sensitivity becomes smaller as the core width decreases further. This explains the existence of an optimal core width w

opt for a maximal sensitivity when the core width varies in

Figure 1c. For example, when h

co = 400 nm, the maximal sensitivity S

max = 0.441 when choosing the optimal core width w

opt = 130 nm. However, the sensitivity decreases significantly when the core width deviates from the optimal value. Furthermore, such a SOI nanowire with a high aspect ratio is not a good option when considering to the fabrication (e.g., the etching process) and the scattering loss. When choosing a thinner SOI nanowire, there is also an optimal core width w

opt for maximal sensitivity. A significant decrease of the sensitivity is also observed when choosing a core width much smaller than the optimal width w

opt. And the sensitivity around w = w

opt is less dependent on the core width in comparison to the case with a large thickness (e.g., h

co = 400 nm). Therefore, one could achieve high sensitivity when the core width varies in a large range around w

opt.

From

Figure 1c, we also observe that the sensitivity curve for thin SOI nanowires is discontinuous as the core width decreases from 0.8 μm to 0.6 μm. This is due to the mode hybridization in that width range. In order to explain this,

Figure 1d shows the effective index of an SOI nanowire with h

co = 250 nm as the core width varies. From this figure, it can be seen that there is a region (see the circle in

Figure 1e) around w

co = 700 nm, where the TM fundamental mode (TM

0) and the first-order mode of TE polarization (TE

1) are hybridized. Therefore, when we consider the sensitivity of TM

0, a jump appears, as shown in

Figure 1c. As can be seen, higher sensitivity S

WG can be achieved when choosing the waveguide width around the mode hybridization region. However, when higher-order modes are involved, there might be some undesired multimode effect. For example, when using a microring-resonator sensor, more resonance peaks will appear and the Q-factor will degrade. Therefore, we still focus on the singlemode silicon optical waveguides for optical sensing. Here we also calculate the sensitivity for SOI nanowires with a liquid cladding (n ~ 1.33), which is very popular for biosensing.

Figure 1f shows the calculated sensitivity, which is similar to the case for the gas sensing (see

Figure 1c). When there is a liquid cladding, the optical waveguide becomes less asymmetrical because the liquid index is closer to that of the SiO

2 buffer layer. Therefore, less power is confined in the SiO

2 buffer region and more power is confined in the upper-cladding region, as shown in

Figure 1g. Thus, more evanescent optical fields interact with the sample and consequently the sensitivity of a SOI nanowire becomes higher for liquid sensing than that for gas sensing (see

Figure 1c,f).

2.2. SOI Nanoslot Waveguides

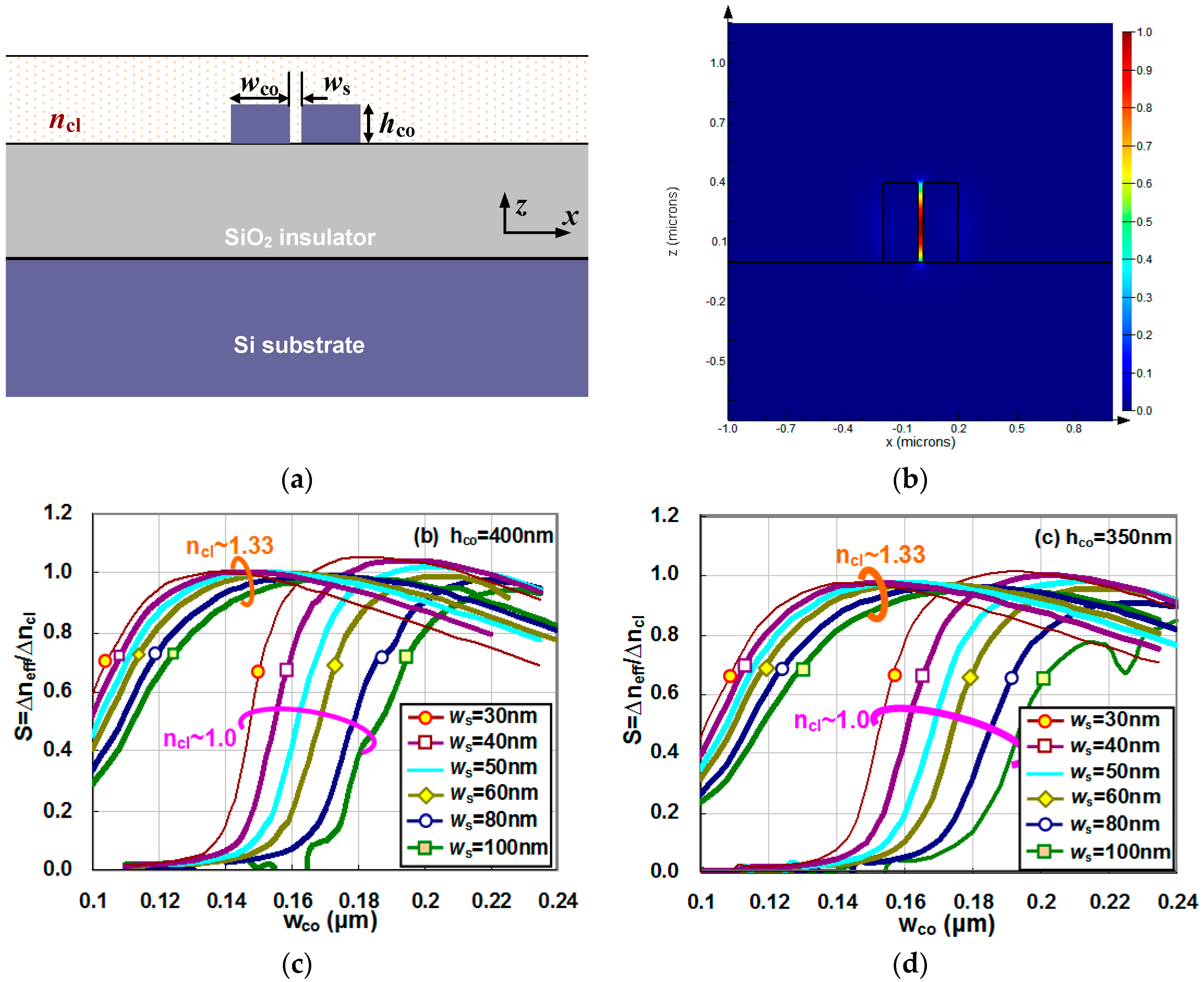

An SOI nanoslot waveguide consists of two Si regions with a nanoslot between them, as shown in

Figure 2a.

Figure 2b shows the calculated field distribution of the TE fundamental mode for a SOI nanoslot waveguide with h

co = 400 nm, w

co = 180 nm, and w

s = 30 nm as an example. It can be seen that there is a significant field enhancement in the nanoslot region. This field enhancement makes it very attractive for optical sensing when the sample to be measured fills the whole region of upper-cladding (including the nanoslot region).

Figure 2c–f show the calculated waveguide sensitivity for gas sensing as well as liquid sensing as the core width w

co varies for the cases of h

co = 400, 350, 300, and 250 nm, respectively.The nanoslot width is chosen as 100, 80, 60, 50, 40, and 30 nm for any given core height h

co. In

Figure 2c–f, it can be seen that the sensitivity of a nanoslot waveguide is similar for different values of h

co when it is covered by gas or liquid. For a nanoslot waveguide with a given slot width w

s and core height h

co, the sensitivity increases rapidly and then decreases slightly as the core width varies in the range from 0.12 μm to 0.24 μm. It can be seen that there exists an optimal core width w

opt for obtaining a maximal sensitivity S

max for both cases based on claddings of gas and liquids.

When the core width becomes small (e.g., wco = 0.1 μm), the optical confinement is very weak and the power at the under-cladding becomes dominant due to the vertical asymmetry, especially in the case with a gas cladding. In this case, the optical waveguide become insensitive to the index change of the upper-cladding. In contrast, when there is a liquid cladding, the vertical asymmetry is alleviated and consequently the sensitivity is still relatively high even when the Si core width is reduced to 0.1 μm. On the other hand, when the core width becomes larger (e.g., 0.24 μm), the optical confinement becomes stronger and more power is confined in the Si core region, and consequently the field enhancement in the nanoslot is significantly limited. Therefore, the sensitivity of the nanoslot optical waveguide decreases as the core width increases.

We also note that a nanoslot waveguide with a larger core height gives a higher maximal sensitivity, which could be larger than that of a free-space beam (S = 1). This is because a larger optical field overlaps with the upper-cladding when the core height increases. In contrast, when the core height turns small, more power moves down to the SiO

2 under-cladding because of the asymmetry in the vertical direction. From

Figure 2c–f and

Figure 1b, it can be seen that nanoslot waveguides have a much higher sensitivity than conventional SOI nanowires.

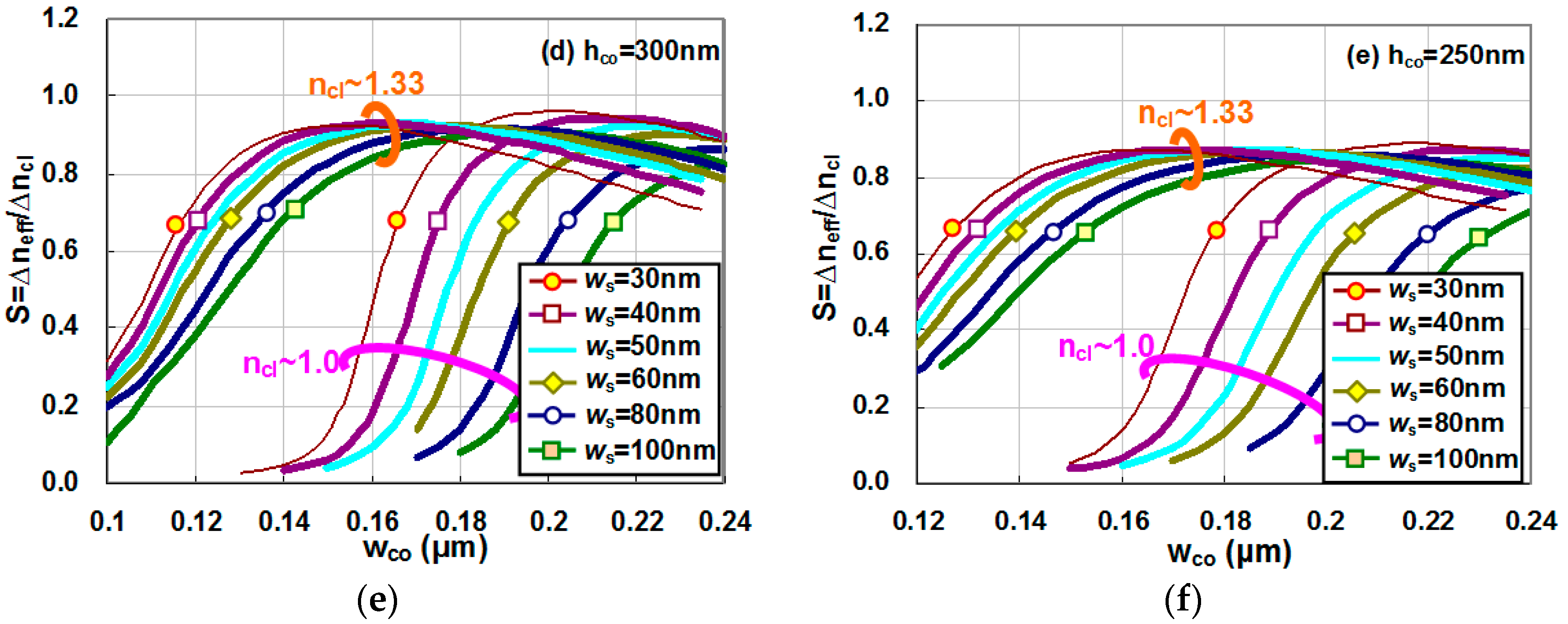

2.3. Suspended Si Nanowires

In this part, we give an analysis for a suspended Si nanowire, which includes a Si core surrounded by the sample, as shown in

Figure 3a. Such a suspended waveguide could be achieved with supported arms [

21,

22].

Figure 3b shows the calculated field distribution of the TM fundamental mode for a suspended Si nanowire waveguide with h

co = 220 nm, w

co = 525 nm, and n

cl = 1.0 as an example.

Figure 3c shows the calculated sensitivity for a suspended Si nanowire with different core heights h

co as the core width varies from 0.1 μm to 0.8 μm. From this figure, it can be seen that the sensitivity is slightly higher than 1.0 (

i.e., the sensitivity of free space) when the core height is small (e.g., 150 nm). This is because the power confined in the Si core is very small while most power of the guided mode locates at the surrounded media, which is very similar to the free space case.

When the core height becomes larger, a significant sensitivity enhancement is observed. For a suspended Si nanowire with a fixed core height (e.g., hco = 100 ~ 200 nm), the sensitivity increases monotonously when the core width ranges from 0.1 μm to 0.8 μm. When increasing the core height further (e.g., hco = 250, 240, 230, 220, and 210 nm), one sees that in the range of 0.1 μm < wco < 0.8 μm there exists an optimal core width wco_opt (which gives a maximal sensitivity Smax of >1.0).

In order to explain this, one can use the formula for the sensitivity of a three-layer slab optical waveguide given in [

15],

i.e.,

where n

eff is the effective index, n

cl is the index of the cladding, and P

cl/P

tot is the power confinement ratio in the cladding region. In

Figure 3d, we show the power confinement ratio in the regions of core and cladding. In this figure, one sees that the power confinement ratio in the cladding region increases monotonously as the core width decreases, which is easy to understand. Intuitively speaking, one expects to have a higher sensitivity when more power is confined in the cladding region. However, according to Equation (1), the sensitivity depends not only on the ratio of P

cl/P

tot but also the ratio of n

eff/n

cl. When the core width decreases, the ratio P

cl/P

tot increases while the ratio n

eff/n

cl decreases, which causes an optimal core width for obtaining a maximal sensitivity.

One can imagine that a wide suspended waveguide should have similar result with a slab waveguide.

Figure 3e gives a comparison between the calculated sensitivities for a suspended Si nanowire with w

co = 0.8 μm and w

co = ∞ (slab waveguide). Here, the results for the slab waveguide (w

co = ∞) is calculated with Equation (1). It can be seen that these results are quite similar and there is an optimal core height h

co around h

co = 220 nm for the maximal sensitivity. For the suspended waveguide with a given core height h

co,

Figure 3c shows that the optimal core width for the maximal sensitivities S

max are slightly dependent on the core height. One should choose h

co = 220 nm to maximize the sensitivity and the corresponding maximal sensitivity S

max is close to 1.5, which is much higher than 1.0 (which is the sensitivity in a free space system). This high sensitivity is due to the high index contrast between the core and the surrounding media (see Equation (1)). The design of h

co = 220 nm also has a large tolerance to the variation of the core width. Even when the core width deviates from its optimal value w

co_opt (= 0.525 μm), the sensitivity does not decrease much. In comparison with the sensitivity for a SOI nanoslot waveguide (shown in

Figure 2c–f), the suspended Si nanowire could provide a much higher sensitivity even though it does not have a field enhancement in the low-index region. Such a significant sensitivity enhancement in a suspended Si nanowire makes it very attractive for the application of optical sensing, especially since it is also relatively easy to fabricate.

Figure 3f shows the sensitivity of a suspended Si nanowire for liquid sensing (

i.e., n

cl ~ 1.33).

Figure 3g shows the power confinement ratios in the regions of core and cladding. It can be seen that the results are similar to those for gas sensing (

i.e., n

cl ~ 1.0). The power ratio in the cladding region is higher because of the lower index-contrast. However, the maximal sensitivity is lower when there is a higher cladding index, as predicted in Equation (1).

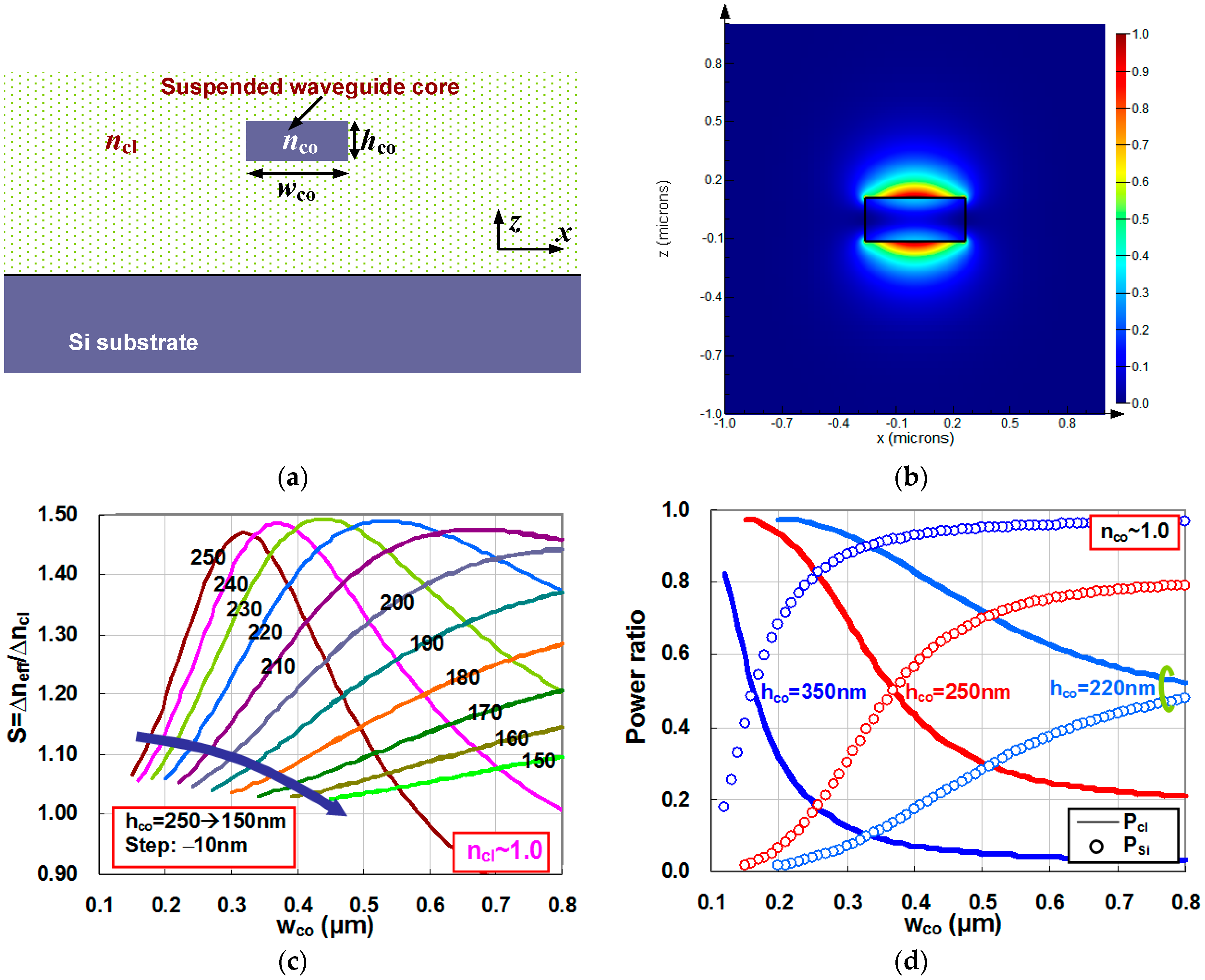

2.4. Nanofibers

Nanofibers are another candidate for the use as a suspended waveguide for optical sensing. Since Si is considered for the core of the planar nanophotonic waveguides in the analysis above, we also choose nanofibers based on Si.

Figure 4a shows the calculated waveguide sensitivity for a Si nanofiber with gas cladding as the core radius R varies from 0.06 μm to 0.3 μm. The inset shows the cross section of the Si nanofiber. From this figure, one sees that there is an optimal core radius giving a maximal sensitivity, which is similar to the result for suspended Si nanowires. This could be explained as follows: when the core radius is small, the optical confinement is very weak and most power of the guided mode is in the cladding. In this case, the nanofiber behaves like in free space sensing. When the core radius becomes large, the optical confinement becomes very strong. Consequently the evanescent field is very small, which reduces the sensitivity. One might see it in

Figure 4a, when it is used for gas sensing, the optimal core radius is about 0.15 μm and the maximal sensitivity S

max is about 1.43, which is slightly lower than that of an optimized suspended Si nanowire (see

Figure 3b) In contrast, for the case of liquid sensing, the optimal core radius is about 0.14 μm and the maximal sensitivity S

max is about 1.2.

When one chooses the optimal core radius for the highest sensitivity, care must be taken because of the strong tolerance upon the core radius dimension. For example, when the core radius varies from the optimal value (

i.e., 150 nm) to 165 nm, the sensitivity decreases from 1.43 to 0.943 and one has ∆S/∆R = 32.5/μm (here ∆R is the radius variation and ∆S is the sensitivity decrease). This indicates that one should control the diameter of the nanofiber very carefully in order to achieve the maximal sensitivity. In contrast, the suspended Si nanowire is more tolerant to the lateral dimension variation ∆w

co. For example, when the core width w

co of a suspended waveguide (with h

co = 220 nm) varies from the optimal value (

i.e., 440 nm) to 455 nm, the sensitivity decreases from 1.477 to 1.475 and one has ∆S/∆w

co = 0.13/μm, which is ~240 times less than that of a silicon nanofiber. We note that it is still not easy to fabricate Si nanofibers with the dimension s required for the highest sensitivity. On the other hand, it is well known that nanofibers have been fabricated successfully in the past years using SiO

2 or polymer [

23].

Figure 4b shows the calculated sensitivity of a SiO

2 nanofiber with air cladding. In this figure, it can be seen that one has a maximal sensitivity close to 1.0 when the core radius of the nanofiber is small. Due to the lower index contrast, one cannot obtain an enhanced waveguide sensitivity of more than 1.0 using SiO

2 or polymer nanofibers.