Nondestructive In Situ Measurement Method for Kernel Moisture Content in Corn Ear

Abstract

:1. Introduction

2. Materials and Methods

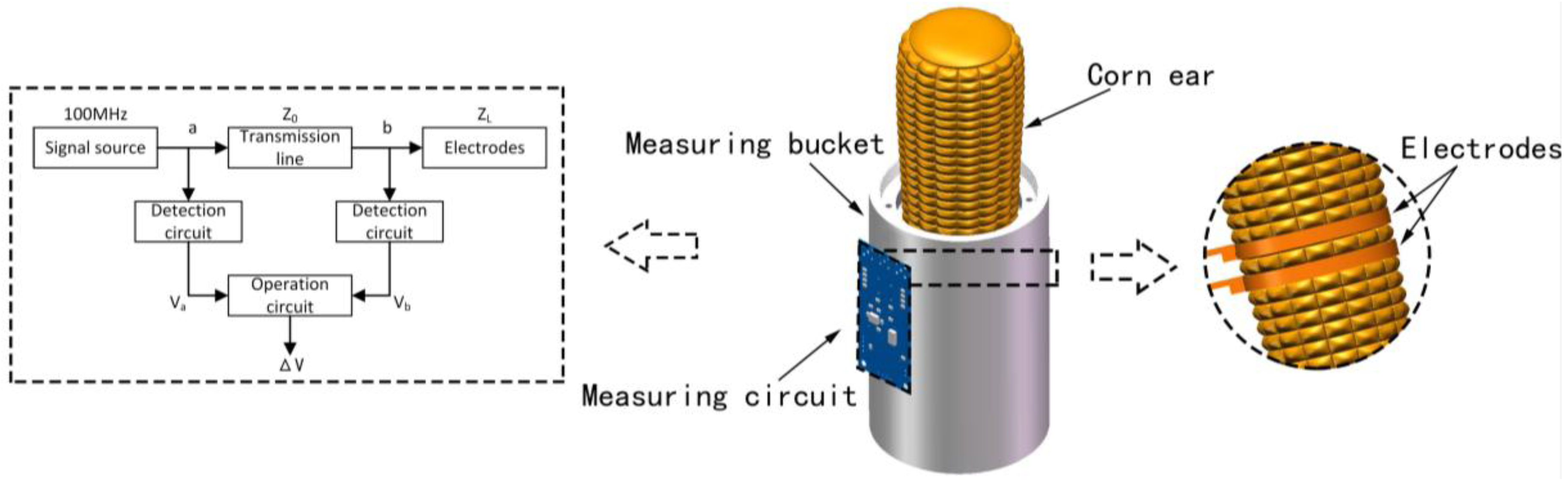

2.1. Measurement Principle

2.2. Electrode Design

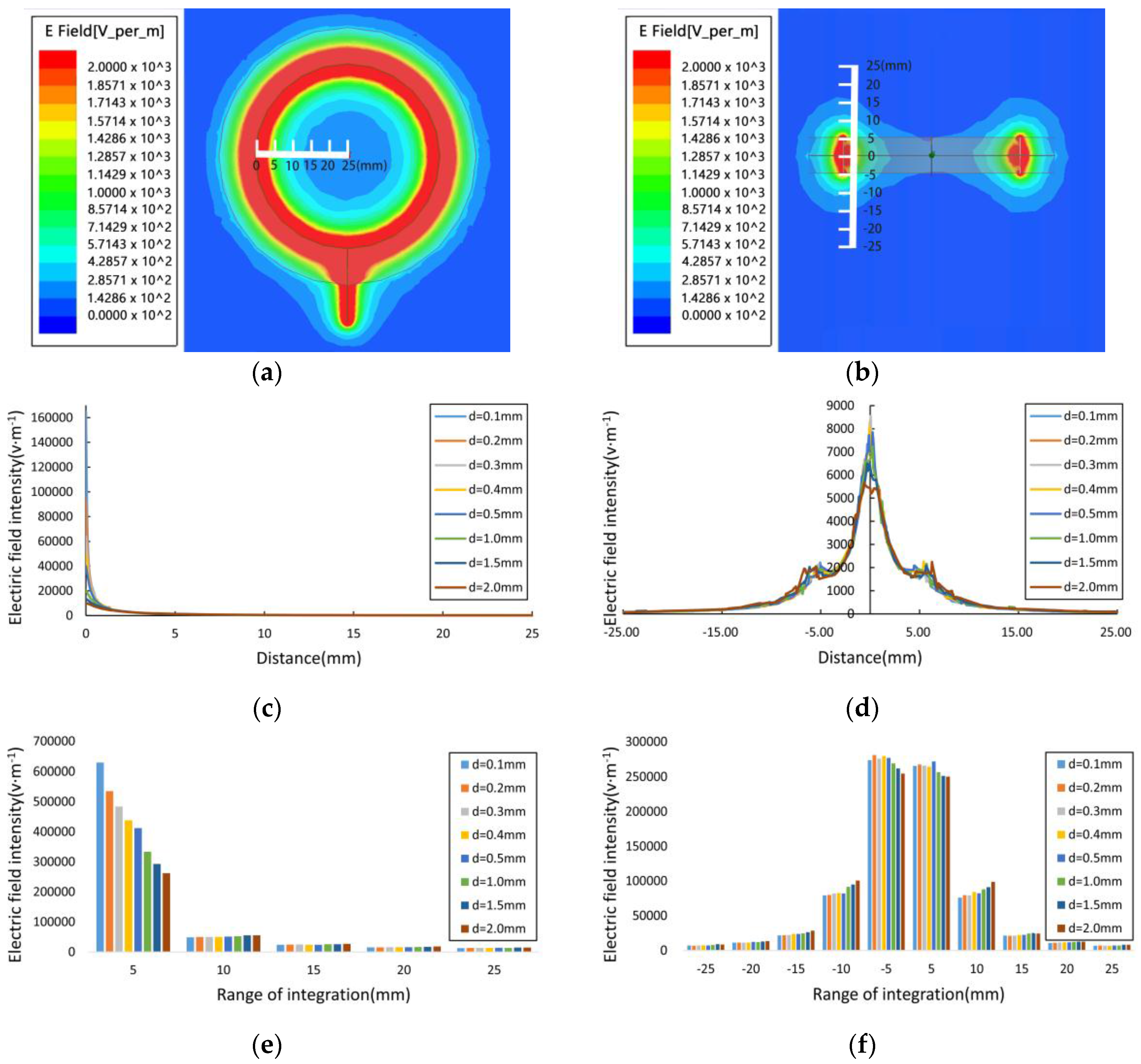

2.3. Experiments on the Effective Scope of the Electrode’s Electric Field

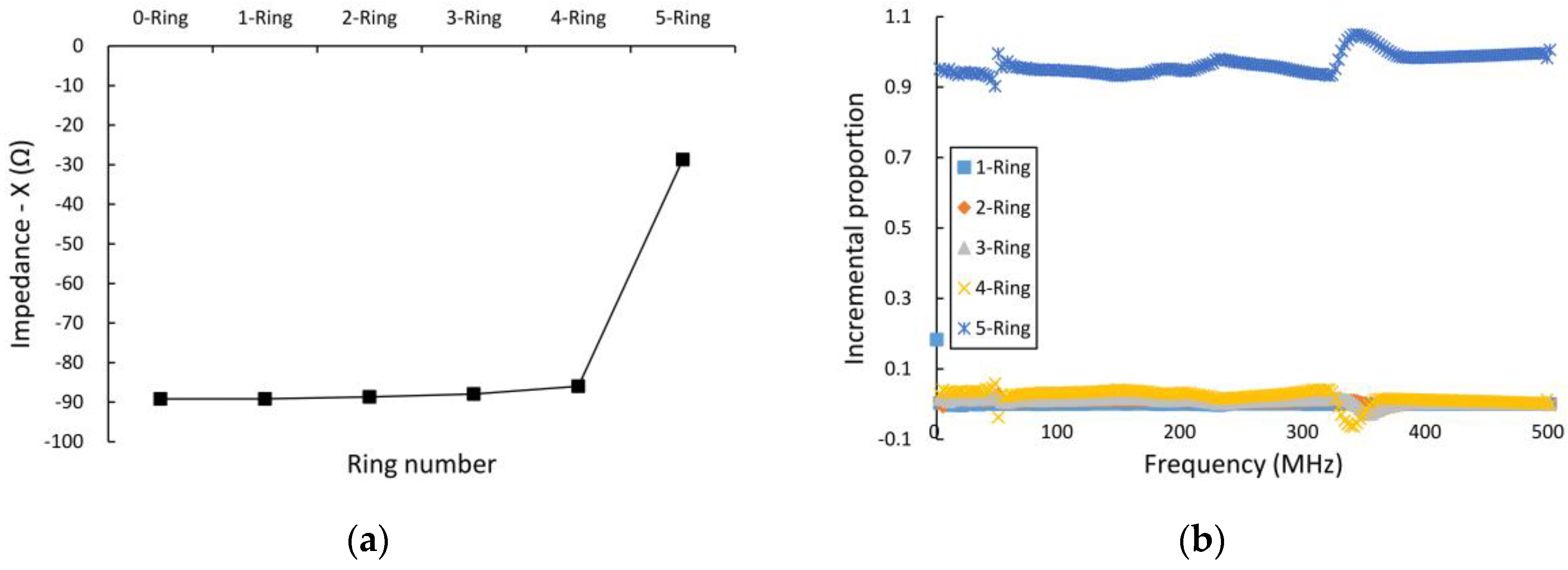

2.3.1. Horizontal Effective Scope Depth of the Electrode’s Electric Field

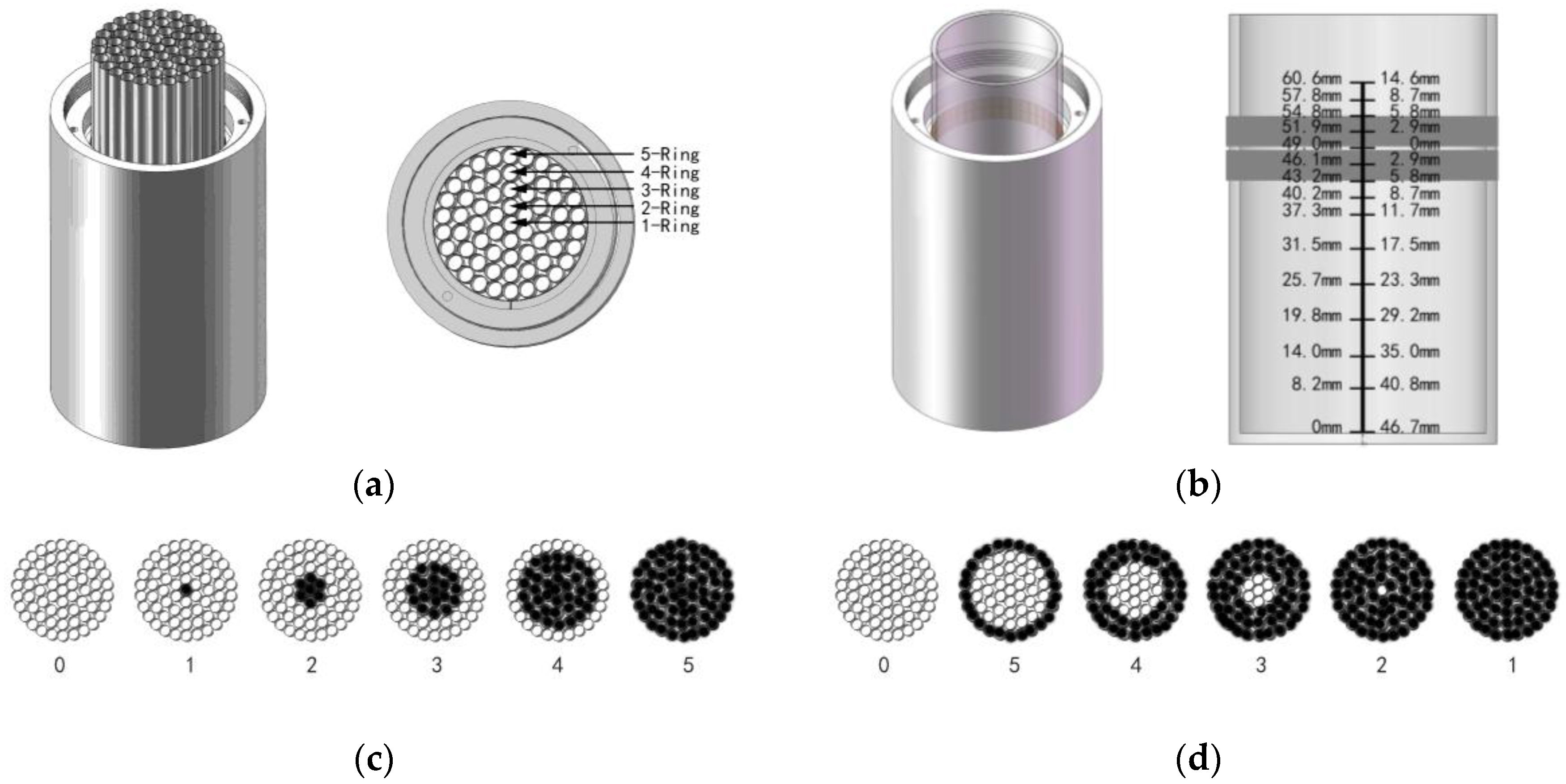

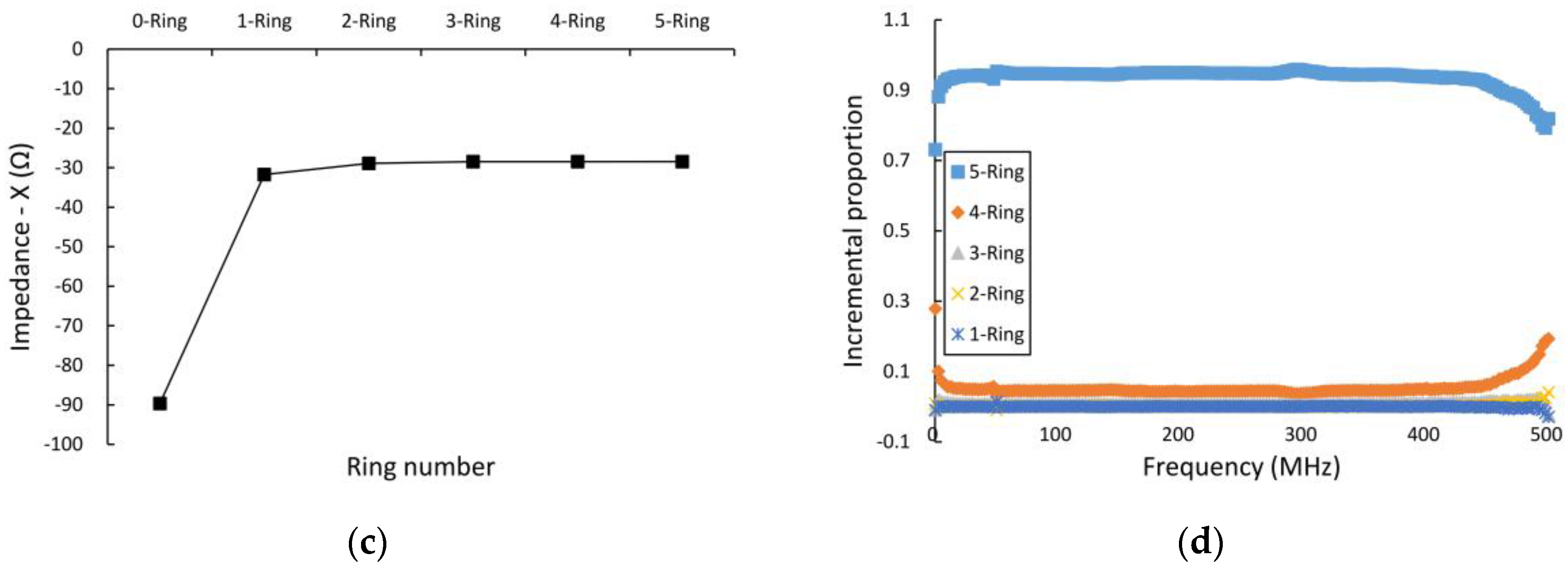

2.3.2. Vertical Effective Scope Depth of the Electrode’s Electric Field

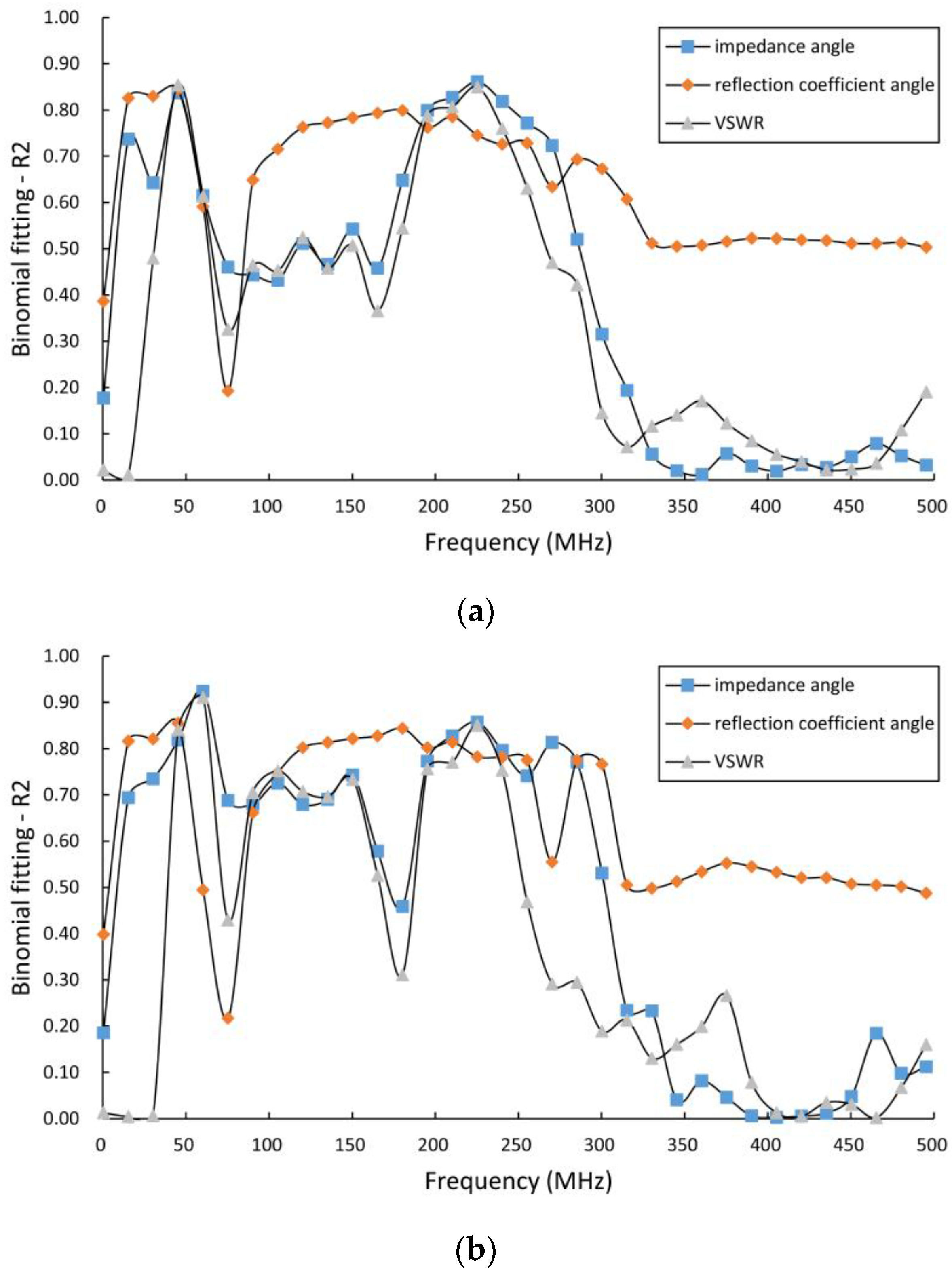

2.4. Measurement of Sensor Characteristics

2.4.1. Effects of Temperature Variation

2.4.2. Effects of Conductivity Variation

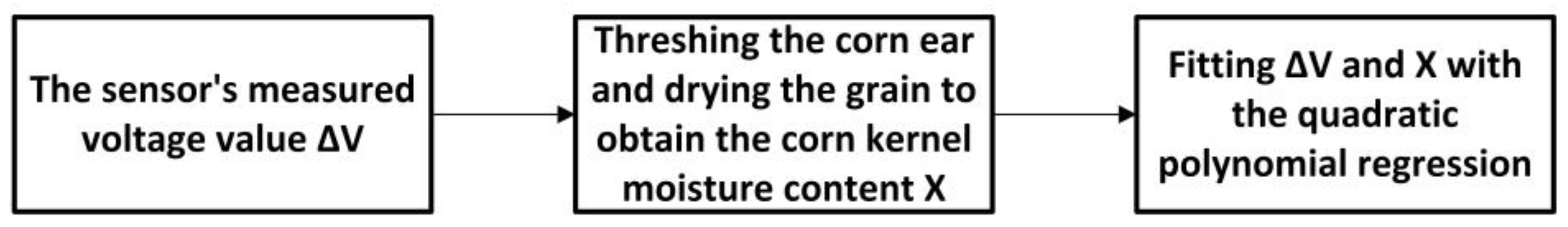

2.5. Experiments for Corn Sample Measurement

- (1)

- Five to 10 selected samples were measured using the corn ear moisture sensor and the output impedance of the sensor’s electrodes was acquired using the VNA at the same time;

- (2)

- The test corn samples were threshed, and the absolute moisture value was obtained via the oven-drying method at 130 °C for 24 h. The reference moisture value is calculated as follows:

- (3)

- The moisture in the remaining selected corn samples was allowed to dry naturally for one to two days, and Steps (1) and (2) were repeated.

3. Results

3.1. Experiments to Determine Effective Scope of the Electrode’s Electric Field

3.2. Measurement of Sensor Characteristics

3.2.1. Effects of Temperature Variation

3.2.2. Effects of Conductivity Variation

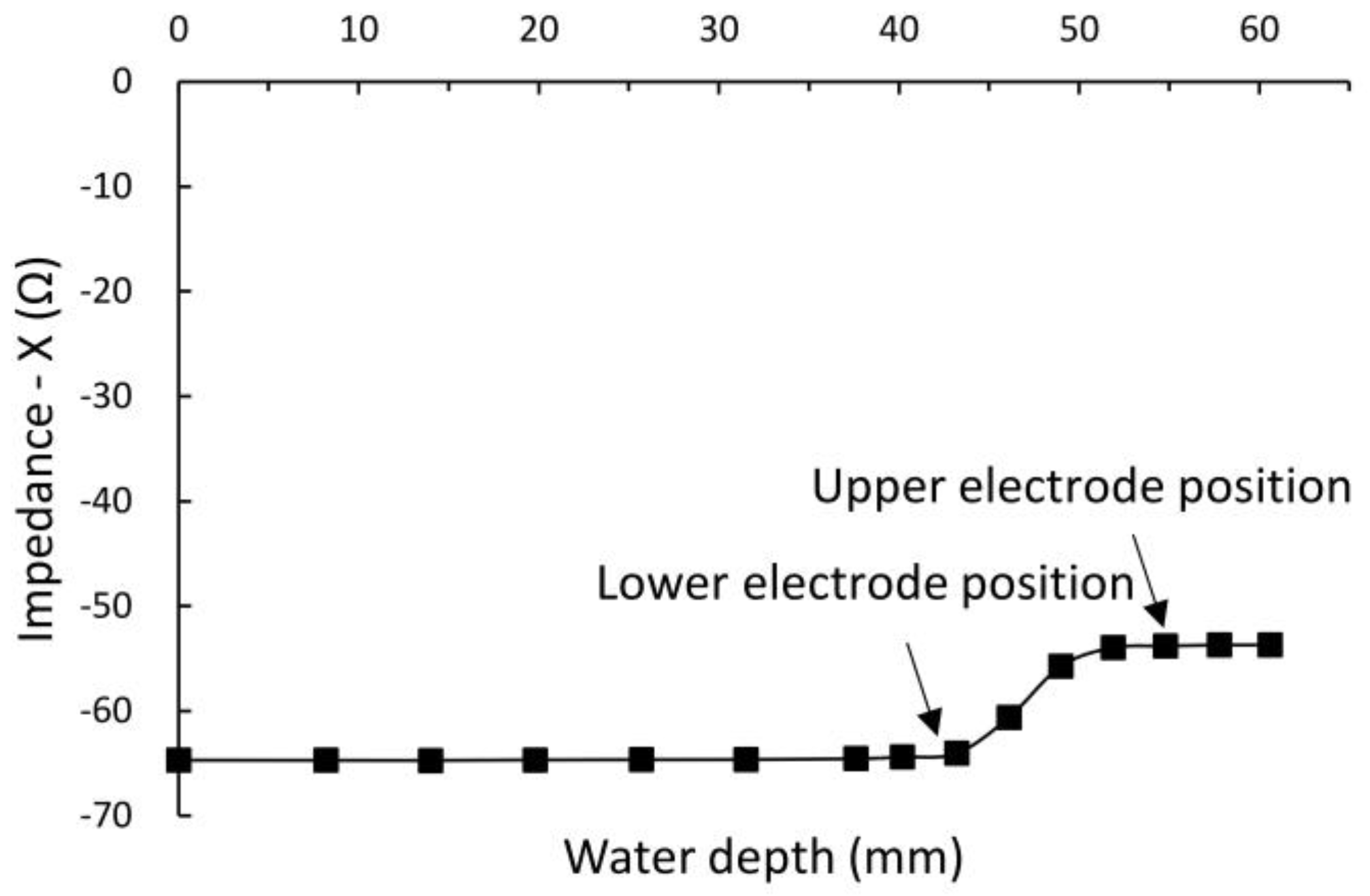

3.3. Experimental Measurements of Corn Samples

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Grain: World Markets and Trade. Available online: http://usda.mannlib.cornell.edu/usda/fas/grain-market//2010s/2016/grain-market-05-11-2016.pdf (accessed on 22 June 2016).

- Miller, M.F.; Hughes, H.D.M. Co-operative variety tests of corn: Variety of corn at Columbia. Univ. Arch. Univ. Mo.-Columbia 1910, 87, 101–158. [Google Scholar]

- Kang, M.S.; Zuber, M.S. Effect of certain agronomic traits on and relationship between rates of grain moisture reduction and grain fill during the filling period in maize. Field Crops Res. 1986, 14, 339–346. [Google Scholar] [CrossRef]

- Baute, T.; Hayes, A.; McDonald, I.; Reid, K. Agronomy Guide for Field Crops—Publication 811. Available online: http://www.omafra.gov.on.ca/english/crops/pub811/p811toc.html (accessed on 5 November 2016).

- Briggs, L.J. An Electrical Resistance Method for the Rapid Determination of the Moisture Content of Grain. Science 1908, 28, 810–813. [Google Scholar] [CrossRef] [PubMed]

- Nelson, S.O.; Trabelsi, S. A Century of grain and seed moisture measurement by sensing electrical properties. ASABE 2012, 55, 629–636. [Google Scholar] [CrossRef]

- Nelson, S.O. Dielectric Properties of Agricultural Materials and Their Applications, 1st ed.; Academic Press: Lindon, UK, 2015. [Google Scholar]

- Zhang, H.; Liu, W.; Tan, B.; Lu, W. Corn moisture measurement using a capacitive sensor. J. Comput. 2013, 8, 1627–1631. [Google Scholar] [CrossRef]

- Soltani, M.; Alimardani, R. Prediction of corn and lentil moisture content using dielectric properties. J. Agric. Technol. 2011, 7, 1223–1232. [Google Scholar]

- McIntosh, R.B.; Casada, M.E. Fringing field capacitance sensor for measuring the moisture content of agricultural commodities. IEEE Sens. J. 2008, 8, 240–247. [Google Scholar] [CrossRef]

- Kang, M.S.; Colbert, T.R.; Zuber, M.S.; Horrocks, R.D. Grain Moisture Loss as Related to Dry-down Rates in Corn. In Agronomy Abstracts; American Society of Agronomy (ASA): Madison, WI, USA, 1975; p. 57. [Google Scholar]

- Kang, M.S.; Zuber, M.S.; Horrocks, R.D. An electronic probe for estimating ear moisture content of maize. Crop Sci. 1978, 18, 1083–1084. [Google Scholar] [CrossRef]

- Freppon, J.T.; St Martin, S.K.; Pratt, R.C.; Henderlong, P.R. Section for low ear moisture in corn, using a hand-held meter. Crop Sci. 1992, 32, 1062–1064. [Google Scholar] [CrossRef]

- Reid, L.M.; Zhu, X.; Morrison, M.J.; Woldemariam, T.; Voloaca, C.; Wu, J.; Xiang, K. A non-destructive method for measuring maize kernel moisture in a breeding program. Maydica 2010, 55, 163–171. [Google Scholar]

- Xiang, K. Genetic Analysis and Measuring Method Development of Kernel Fast Dry down Rate in Maize. Ph.D. Thesis, Sichuan Agricultural University, Ya’an, China, 2011. [Google Scholar]

- Andrei, F.; Valentin, M.; Gabriela, V.; Florin, I.; Ion, C. Efficiency of Utilization of Aselection Index in Assessment of Drydown of Corn Genotypes (Zea Mays L.). Sci. Pap. Ser. A Agron. 2013, 56, 249–252. [Google Scholar]

- Agilent Basics of Measuring the Dielectric Properties of Materials. Available online: http://101.96.8.165/cp.literature.agilent.com/litweb/pdf/5989-2589EN.pdf (accessed on 16 November 2016).

- Nelson, S.O.; Trabelsi, S. Factors Influencing the Dielectric Properties of Agricultural and Food Products. J. Microware Power Electromagn. Energy 2012, 46, 93–107. [Google Scholar] [CrossRef]

- Material Characteristic Guide. Available online: http://www.omega.com/green/pdf/MaterialChar_Guide.pdf (accessed on 29 August 2016).

- Zhou, H.; Sun, Y.; Tyree, M.T.; Sheng, W.; Cheng, Q.; Xue, X.; Schumann, H.; Schulze, L.P. An Improved Sensor for Precision Detection of in Situ Stem Water Content Using a Frequency Domain Fringing Capacitor. New Phytol. 2015, 206, 471–481. [Google Scholar] [CrossRef] [PubMed]

- Sheng, W. Innovation of Fringe Field Dielectric Sensing for Soil-plant Water Dynamics Observation. Ph.D. Thesis, China Agriculture University, Beijing, China, 2013. [Google Scholar]

- Sun, Y.; Schulze Lammers, P.; Ma, D.; Lin, J.; Zeng, Q. Determining Soil Physical Properties by Multi-sensor Technique. Sens. Actuators A Phys. 2008, 147, 352–357. [Google Scholar]

- Sun, Y.; Ma, D.; Schulze Lammers, P.; Schmittmann, O.; Rose, M. On-the-go measurement of soil water content and mechanical resistance by a combined horizontal penetrometer. Soil Tillage Res. 2006, 86, 209–217. [Google Scholar] [CrossRef]

- Sun, Y. Study on the Measuring Theory & Method of Dielectric Characteristics for Unsaturated Soil. Ph.D. Thesis, China Agriculture University, Beijing, China, 2000. [Google Scholar]

- Sun, Y.; Sheng, W.; Cheng, Q.; Chai, J. A novel method to determine the volume of sensitivity for soil moisture sensors. Soil Sci. Soc. Am. J. 2012, 76, 1987–1991. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; p. 57. [Google Scholar]

- User’s Guide—High Frequency Structure Simulator. Available online: http://anlage.umd.edu/HFSSv10UserGuide.pdf (accessed on 16 November 2016).

| No. | Injecting Volume (mL) | Total Volume (mL) | Water Level (mm) | Relative Height (mm) |

|---|---|---|---|---|

| 1 | 10 | 10 | 8.2 | −40.8 |

| 2 | 10 | 20 | 14.0 | −35.0 |

| 3 | 10 | 30 | 19.8 | −29.2 |

| 4 | 10 | 40 | 25.7 | −23.3 |

| 5 | 10 | 50 | 31.5 | −17.5 |

| 6 | 10 | 60 | 37.3 | −11.7 |

| 7 | 5 | 65 | 40.2 | −8.7 |

| 8 | 5 | 70 | 43.2 | −5.8 |

| 9 | 5 | 75 | 46.1 | −2.9 |

| 10 | 5 | 80 | 49.0 | 0 |

| 11 | 5 | 85 | 51.9 | 2.9 |

| 12 | 5 | 90 | 54.8 | 5.8 |

| 13 | 5 | 95 | 57.8 | 8.7 |

| 14 | 5 | 100 | 60.6 | 14.6 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.-L.; Ma, Q.; Fan, L.-F.; Zhao, P.-F.; Wang, J.-X.; Zhang, X.-D.; Zhu, D.-H.; Huang, L.; Zhao, D.-J.; Wang, Z.-Y. Nondestructive In Situ Measurement Method for Kernel Moisture Content in Corn Ear. Sensors 2016, 16, 2196. https://doi.org/10.3390/s16122196

Zhang H-L, Ma Q, Fan L-F, Zhao P-F, Wang J-X, Zhang X-D, Zhu D-H, Huang L, Zhao D-J, Wang Z-Y. Nondestructive In Situ Measurement Method for Kernel Moisture Content in Corn Ear. Sensors. 2016; 16(12):2196. https://doi.org/10.3390/s16122196

Chicago/Turabian StyleZhang, Han-Lin, Qin Ma, Li-Feng Fan, Peng-Fei Zhao, Jian-Xu Wang, Xiao-Dong Zhang, De-Hai Zhu, Lan Huang, Dong-Jie Zhao, and Zhong-Yi Wang. 2016. "Nondestructive In Situ Measurement Method for Kernel Moisture Content in Corn Ear" Sensors 16, no. 12: 2196. https://doi.org/10.3390/s16122196

APA StyleZhang, H.-L., Ma, Q., Fan, L.-F., Zhao, P.-F., Wang, J.-X., Zhang, X.-D., Zhu, D.-H., Huang, L., Zhao, D.-J., & Wang, Z.-Y. (2016). Nondestructive In Situ Measurement Method for Kernel Moisture Content in Corn Ear. Sensors, 16(12), 2196. https://doi.org/10.3390/s16122196