A Laminar Flow-Based Microfluidic Tesla Pump via Lithography Enabled 3D Printing

Abstract

:1. Introduction

1.1. Microfluidic Pumps

1.2. Theoretical Design of the µTesla Pump

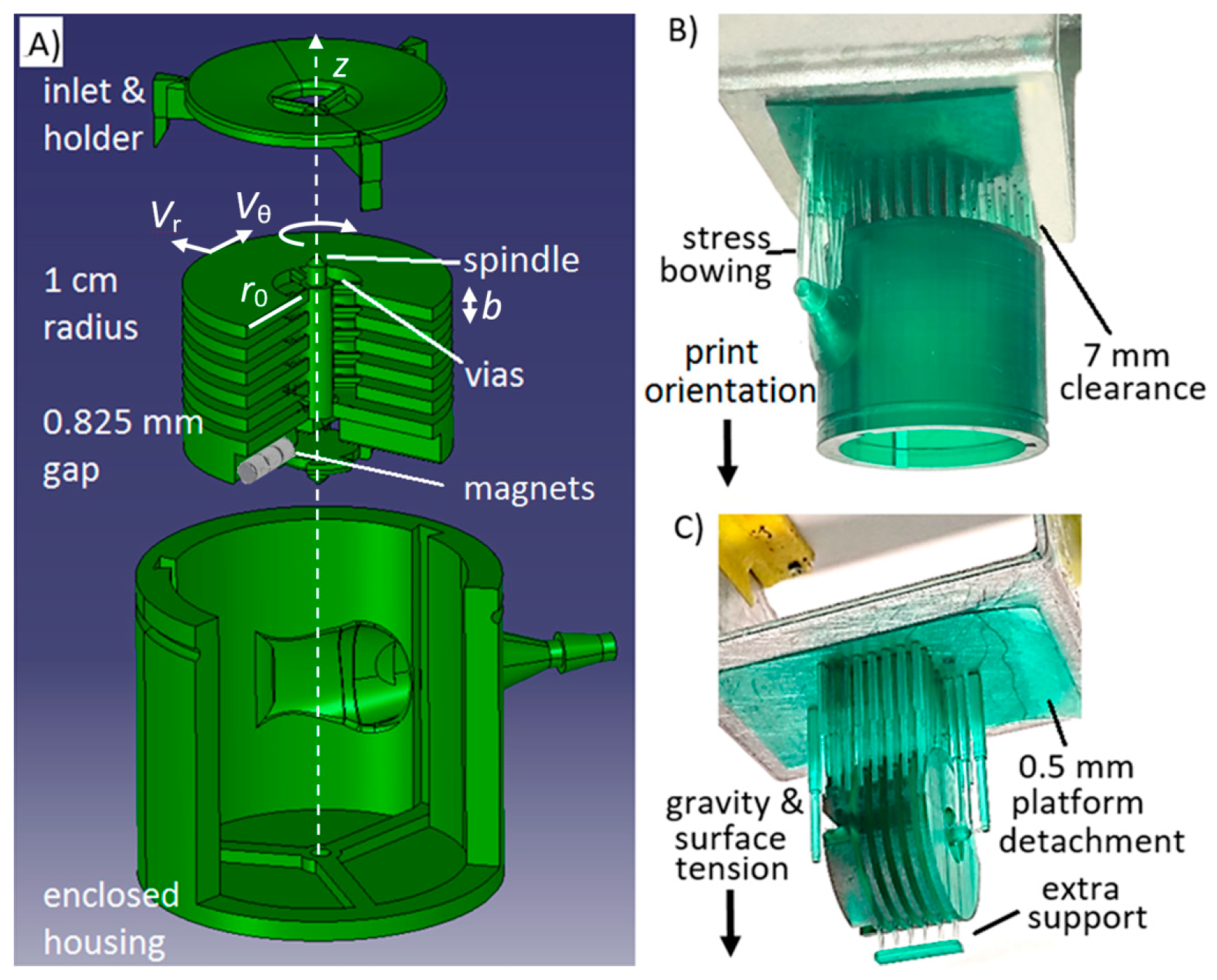

2. Rapid Prototyping Using DLP 3D Printer

Addressing DLP Printing Issues

3. Results of µTesla Performance

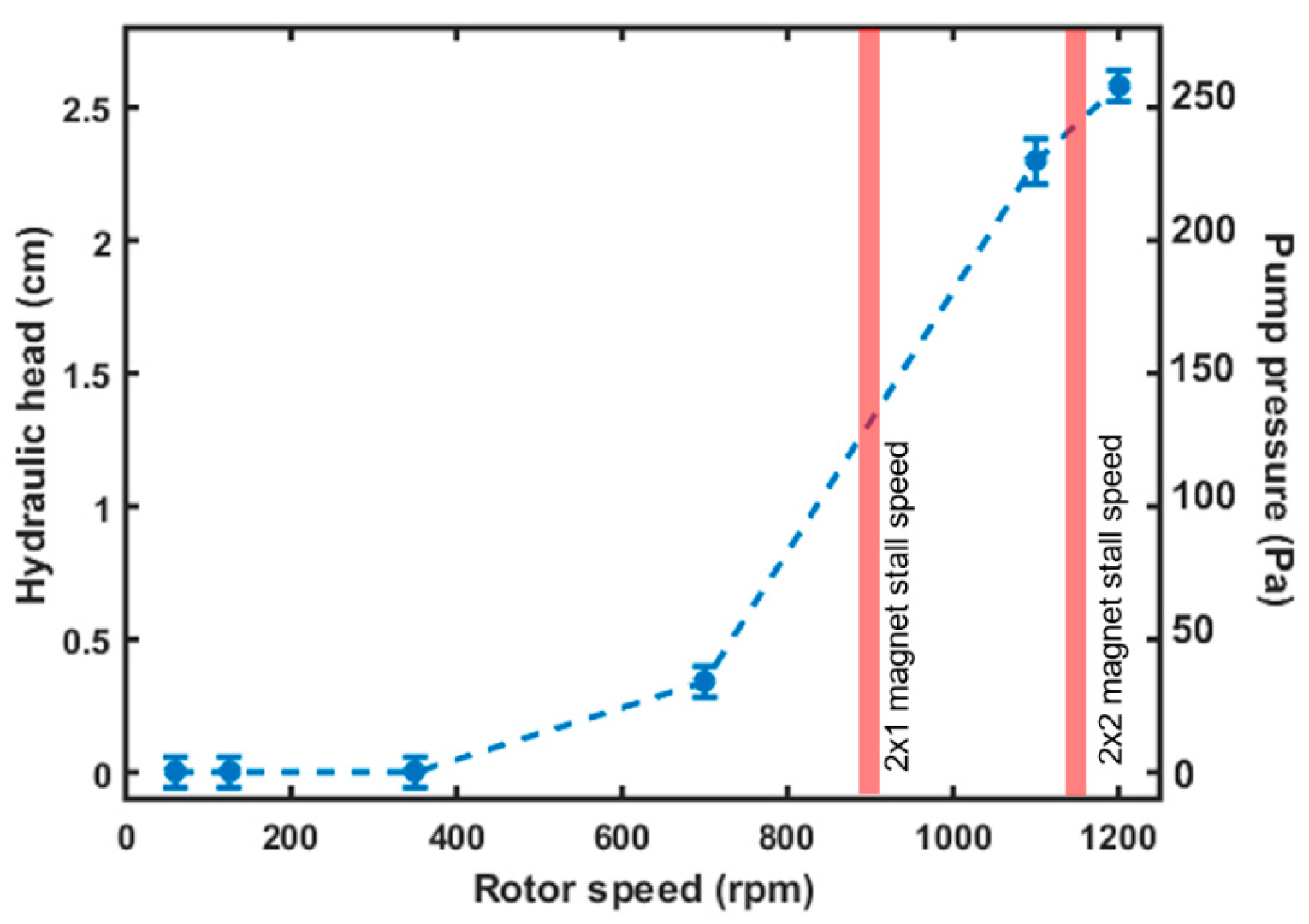

3.1. µTesla Hydraulic Head and Stall Characteristics

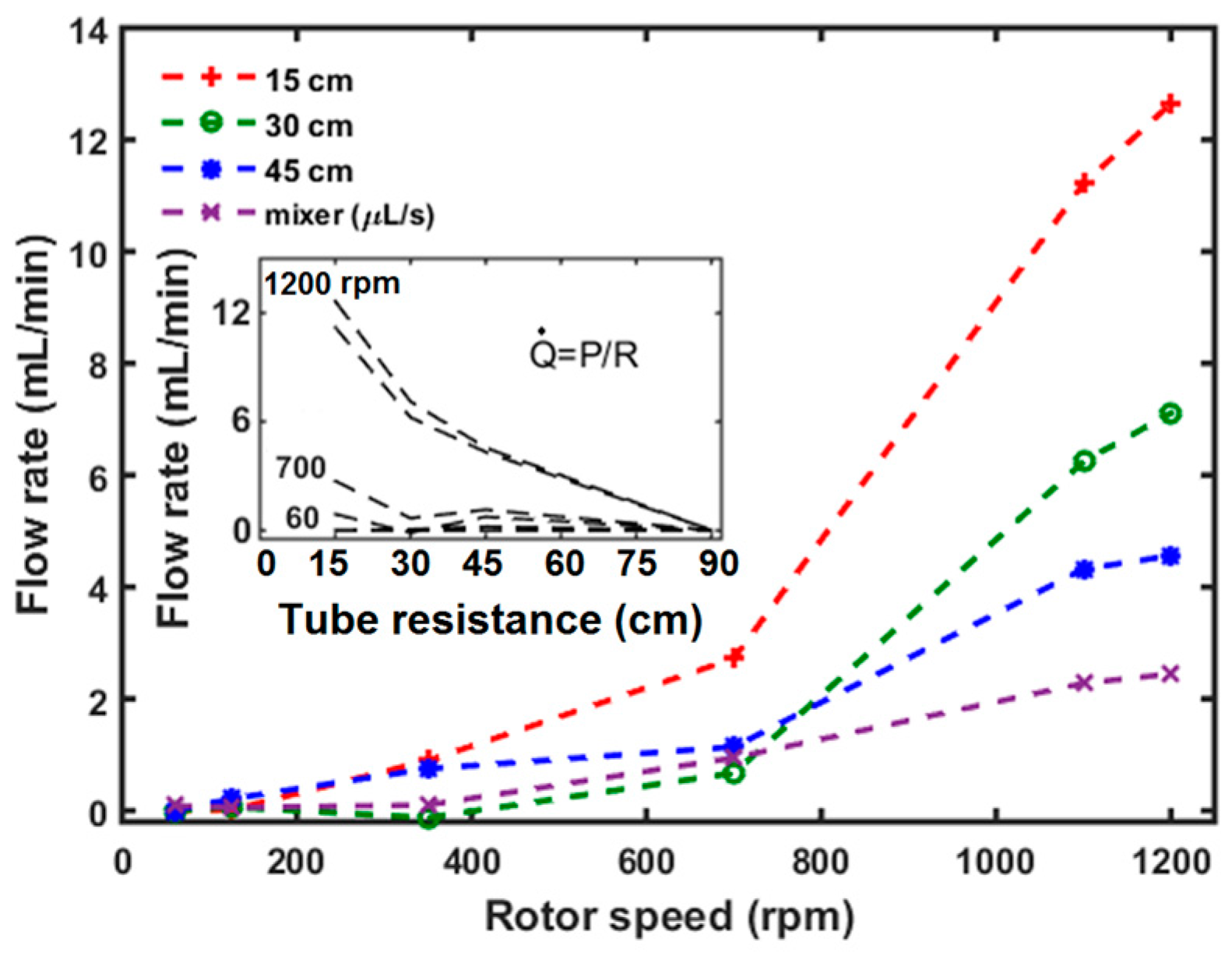

3.2. Flow Characteristics of µTesla at Different Resistances

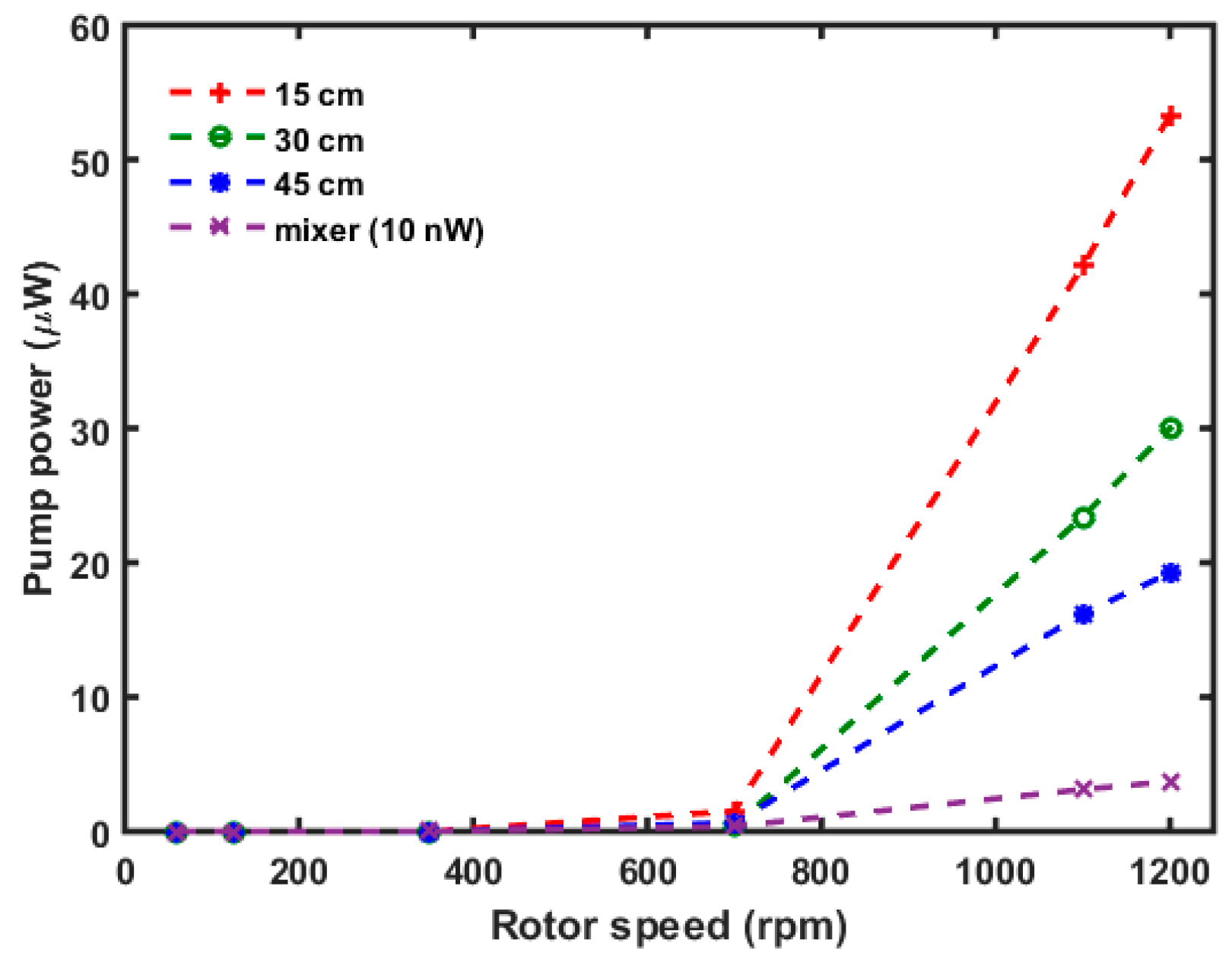

3.3. µTesla Pump Power Calculations

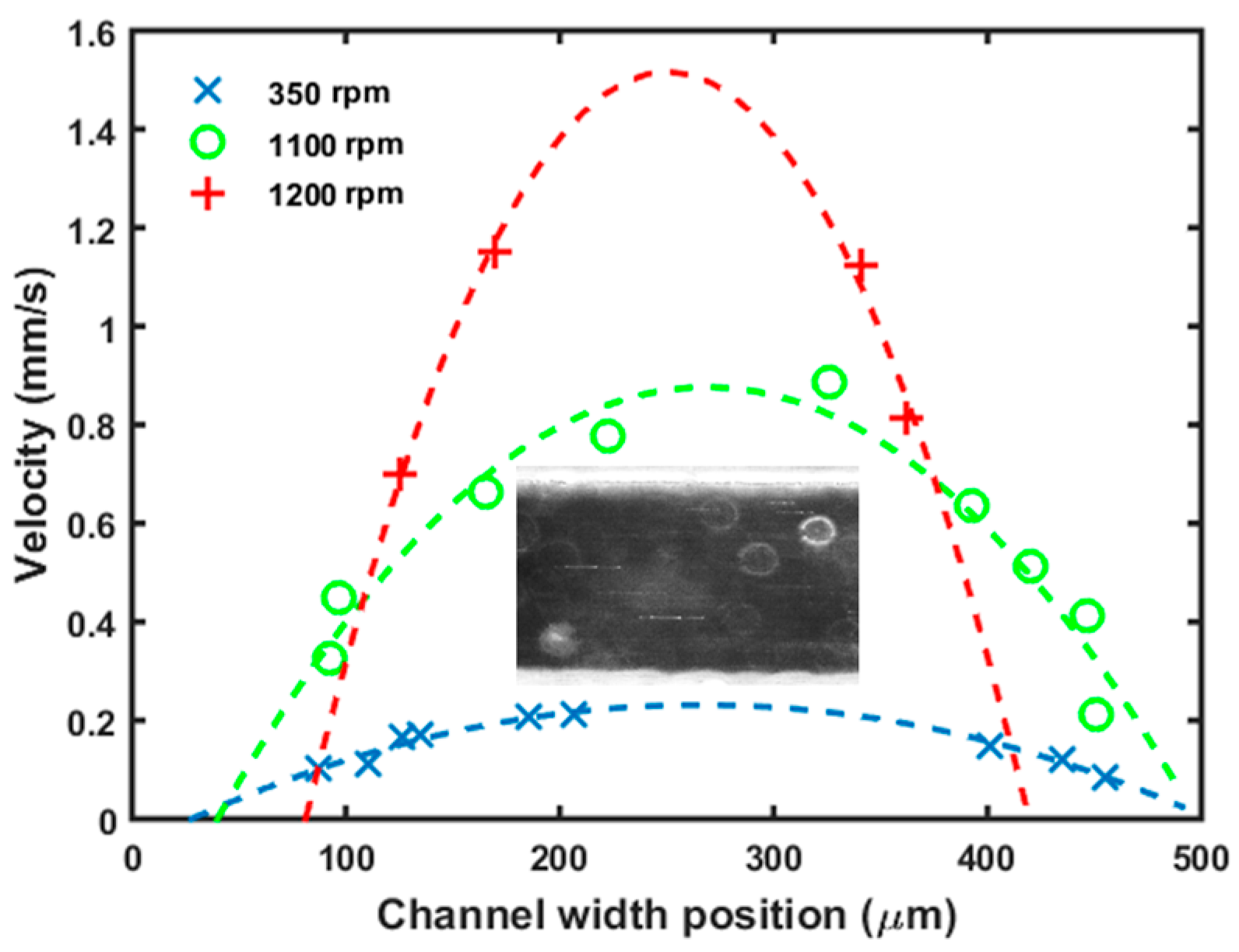

3.4. Laminar Flow Velocity Profile in Microchannels

4. Results of Driving the Tesla Inspired Microfluidic Mixer

5. Future Works

6. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tesla, N. Fluid Propulsion. U.S. Patent 1061142 A, 6 May 1913. [Google Scholar]

- Tesla, N. Turbine. U.S. Patent 1061206 A, 6 May 1913. [Google Scholar]

- Steidel, R.; Weiss, H. Performance Test of a Bladeless Turbine for Geothermal Applications; Report No. UCID-17068; Lawrence Livermore Laboratory: Livermore, CA, USA, 1974. [Google Scholar]

- Ho-Yan, B.P. Tesla turbine for pico hydro applications. Guelph Eng. J. 2011, 4, 1–8. [Google Scholar]

- Hoya, G.P.; Guha, A. The design of a test rig and study of the performance and efficiency of a Tesla disc turbine. J. Power Energy 2009, 223, 451–465. [Google Scholar] [CrossRef]

- Miller, G.E.; Sidhu, A.; Fink, R.; Etter, B.D. Evaluation of a multiple disk centrifugal pump as an artificial ventricle. Artif. Organs 1993, 17, 590–592. [Google Scholar] [CrossRef] [PubMed]

- Miller, G.E.; Madigan, M.; Fink, R. A preliminary flow visualization study in a multiple disk centrifugal artificial ventricle. Artif. Organs 1995, 19, 680–684. [Google Scholar] [CrossRef] [PubMed]

- Du, X.Y.; Fu, Y.Q.; Luo, J.K.; Flewitt, A.J.; Milne, W.I. Microfluidic pumps employing surface acoustic waves generated in ZnO thin films. J. Appl. Phys. 2009, 105, 024508. [Google Scholar] [CrossRef]

- Gallas, Q.; Holman, R.; Nishida, T.; Carroll, B.; Sheplak, M.; Cattafesta, L. Lumped element modeling of piezoelectric-driven synthetic jet actuators. AIAA J. 2003, 41, 240–247. [Google Scholar] [CrossRef]

- Urbanski, J.P.; Levitan, J.A.; Burch, D.N.; Thorsen, T.; Bazant, M.Z. The effect of step height on the performance of three-dimensional ac electro-osmotic microfluidic pumps. J. Colloid Interface Sci. 2007, 309, 332–341. [Google Scholar] [CrossRef] [PubMed]

- Munyan, J.W.; Fuentes, H.V.; Draper, M.; Kelly, R.T.; Woolley, A.T. Electrically actuated, pressure-driven microfluidic pumps. Lab Chip 2003, 3, 217–220. [Google Scholar] [CrossRef] [PubMed]

- Steigert, J.; Brenner, T.; Grumann, M.; Riegger, L.; Lutz, S.; Zengerle, R.; Ducrée, J. Integrated siphon-based metering and sedimentation of whole blood on a hydrophilic lab-on-a-disk. Biomed. Microdevices 2007, 9, 675–679. [Google Scholar] [CrossRef] [PubMed]

- Martinez, A.W.; Phillips, S.T.; Butte, M.J.; Whitesides, G.M. Patterned paper as a platform for inexpensive, low-volume, portable bioassays. Angew. Chem. Int. Ed. 2007, 46, 1318–1320. [Google Scholar] [CrossRef] [PubMed]

- Osborn, J.L.; Lutz, B.; Fu, E.; Kauffman, P.; Stevens, D.Y.; Yager, P. Microfluidics without pumps: Reinventing the T-sensor and H-filter in paper networks. Lab Chip 2010, 10, 2659–2665. [Google Scholar] [CrossRef] [PubMed]

- Unger, M.A.; Chou, H.P.; Thorsen, T.; Scherer, A.; Quake, S.R. Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 2000, 288, 113–116. [Google Scholar] [CrossRef] [PubMed]

- Grover, W.H.; Skelley, A.M.; Liu, C.N.; Lagally, E.T.; Mathies, R.A. Monolithic membrane valves and diaphragm pumps for practical large-scale integration into glass microfluidic devices. Sens. Actuators B Chem. 2003, 89, 315–323. [Google Scholar] [CrossRef]

- Anhalt, H.; Bohannon, N.J. Insulin patch pumps: Their development and future in closed-loop systems. Diabetes Technol. Ther. 2010, 12, S51–S58. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, N.T.; Truong, T.Q.; Wong, K.K.; Ho, S.S.; Low, C.L.N. Micro check valves for integration into polymeric microfluidic devices. J. Micromech. Microeng. 2003, 14, 69. [Google Scholar] [CrossRef]

- Hong, C.C.; Choi, J.W.; Ahn, C.H. A novel in-plane passive microfluidic mixer with modified Tesla structures. Lab Chip 2004, 4, 109–113. [Google Scholar] [CrossRef] [PubMed]

- Tesla, N. Valvular Conduit. U.S. Patent 1329559 A, 3 February 1920. [Google Scholar]

- Ladino, A.F.R. Numerical Simulation of the Flow Field in a Friction-Type Turbine (Tesla Turbine). Ph.D. Thesis, National University of Colombia, Bogotá, Colombia, 2004. [Google Scholar]

- Rice, W. An analytical and experimental investigation of multiple-disk turbines. J. Eng. Power 1965, 87, 29–36. [Google Scholar] [CrossRef]

- Rice, W. Tesla turbomachinery. In Handbook of Turbomachinery; Logan, E., Ed.; Marcel Dekker: New York, NY, USA, 2003; pp. 861–874. [Google Scholar]

- Lawn, M.J., Jr.; Rice, W. Calculated design data for the multiple-disk turbine using incompressible fluid. J. Fluids Eng. 1974, 96, 252–258. [Google Scholar] [CrossRef]

- Carey, V.P. Assessment of Tesla turbine performance for small scale Rankine combined heat and power systems. J. Eng. Gas Turbines Power 2010, 132, 122301. [Google Scholar] [CrossRef]

- Sengupta, S.; Guha, A. A theory of Tesla disc turbine. J. Power Energy 2012, 226, 650–663. [Google Scholar] [CrossRef]

- Sochol, R.D.; Sweet, E.; Glick, C.C.; Venkatesh, S.; Avetisyan, A.; Ekman, K.F.; Raulinaitis, A.; Tsai, A.; Wienkers, A.; Korner, K.; et al. 3D printed microfluidic circuitry via multijet-based additive manufacturing. Lab Chip 2016, 16, 668–678. [Google Scholar] [CrossRef] [PubMed]

- Kitson, P.J.; Rosnes, M.H.; Sans, V.; Dragone, V.; Cronin, L. Configurable 3D-Printed millifluidic and microfluidic ‘lab on a chip’ reaction ware devices. Lab Chip 2012, 12, 3267–3271. [Google Scholar] [CrossRef] [PubMed]

- Au, A.K.; Bhattacharjee, N.; Horowitz, L.F.; Chang, T.C.; Folch, A. 3D-printed microfluidic automation. Lab Chip 2015, 15, 1934–1941. [Google Scholar] [CrossRef] [PubMed]

- Bishop, G.W.; Satterwhite, J.E.; Bhakta, S.; Kadimisetty, K.; Gillette, K.M.; Chen, E.; Rusling, J.F. 3D-Printed Fluidic Devices for Nanoparticle Preparation and Flow-Injection Amperometry Using Integrated Prussian Blue Nanoparticle-Modified Electrodes. Anal. Chem. 2015, 87, 5437–5443. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F.; Skommer, J.; Macdonald, M.P.; Friedrich, T.; Kaslin, J.; Wlodkowic, D. Three-dimensional printed millifluidic devices for zebrafish embryo tests. Biomicrofluidics 2015, 9, 046502. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.Y.; Yang, C.; Hsu, W.; Lin, L. 3D-printed microelectronics for integrated circuitry and passive wireless sensors. Microsyst. Nanoeng. 2015. [Google Scholar] [CrossRef]

- Zhang, C.; Anzalone, N.C.; Faria, R.P.; Pearce, J.M. Open-source 3D-printable optics equipment. PLoS ONE 2013, 8, e59840. [Google Scholar] [CrossRef] [PubMed]

- Willis, K.; Brockmeyer, E.; Hudson, S.; Poupyrev, I. Printed optics: 3D printing of embedded optical elements for interactive devices. In Proceedings of the 25th Annual ACM Symposium on User Interface Software and Technology, Cambridge, MA, USA, 7–10 October 2012; pp. 589–598.

- Zou, L.; Koslakiewicz, R.; Mahmoud, M.; Fahs, M.; Liu, R.; Lo, J.F. 3D Printed miniaturized spectral system for collagen fluorescence lifetime measurements. J. Biomed. Opt. 2016, 21, 075001. [Google Scholar] [CrossRef] [PubMed]

- Lam, R.H.; Li, W.J. A digitally controllable polymer-based microfluidic mixing module array. Micromachines 2012, 3, 279–294. [Google Scholar] [CrossRef]

- Godwin, L.A.; Deal, K.S.; Hoepfner, L.D.; Jackson, L.A.; Easley, C.J. Measurement of microchannel fluidic resistance with a standard voltage meter. Anal. Chim. Acta 2013, 758, 101–107. [Google Scholar] [CrossRef] [PubMed]

- Guha, A.; Smiley, B. Experiment and analysis for an improved design of the inlet and nozzle in Tesla disc turbines. J. Power Energy 2010, 224, 261–277. [Google Scholar] [CrossRef]

| Reynold Number | = 1000 |

| Rotational speed | |

| Disk radius | |

| Volumetric flow rate | |

| Disk Gap | b = 0.826 mm, as Dh = 1.65 mm |

| Number of disks |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habhab, M.-B.; Ismail, T.; Lo, J.F. A Laminar Flow-Based Microfluidic Tesla Pump via Lithography Enabled 3D Printing. Sensors 2016, 16, 1970. https://doi.org/10.3390/s16111970

Habhab M-B, Ismail T, Lo JF. A Laminar Flow-Based Microfluidic Tesla Pump via Lithography Enabled 3D Printing. Sensors. 2016; 16(11):1970. https://doi.org/10.3390/s16111970

Chicago/Turabian StyleHabhab, Mohammed-Baker, Tania Ismail, and Joe Fujiou Lo. 2016. "A Laminar Flow-Based Microfluidic Tesla Pump via Lithography Enabled 3D Printing" Sensors 16, no. 11: 1970. https://doi.org/10.3390/s16111970

APA StyleHabhab, M.-B., Ismail, T., & Lo, J. F. (2016). A Laminar Flow-Based Microfluidic Tesla Pump via Lithography Enabled 3D Printing. Sensors, 16(11), 1970. https://doi.org/10.3390/s16111970