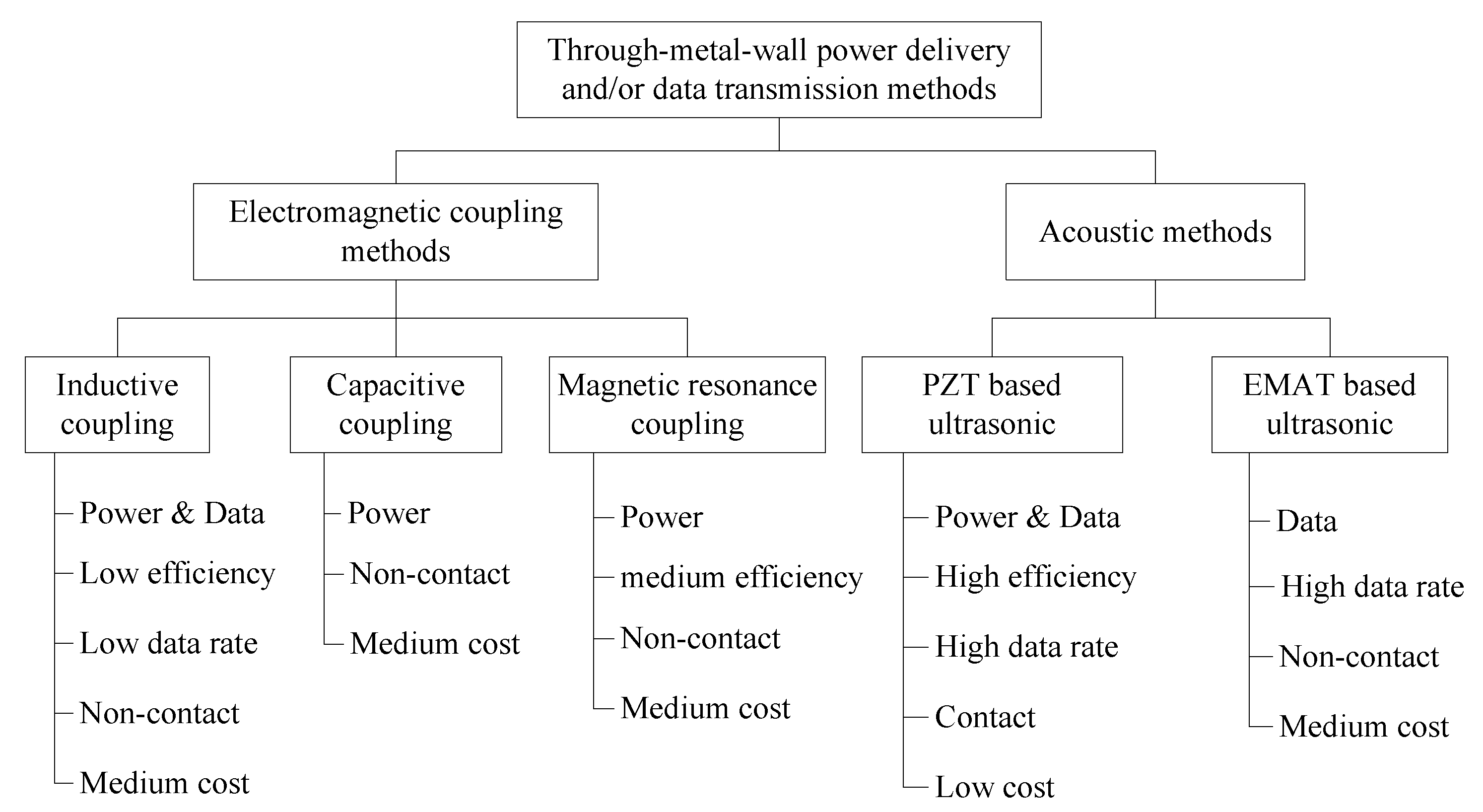

Through-Metal-Wall Power Delivery and Data Transmission for Enclosed Sensors: A Review

Abstract

:1. Introduction

2. Methods for Through-Metal-Wall Power Delivery and Data Transmission Based on Electromagnetic Coupling

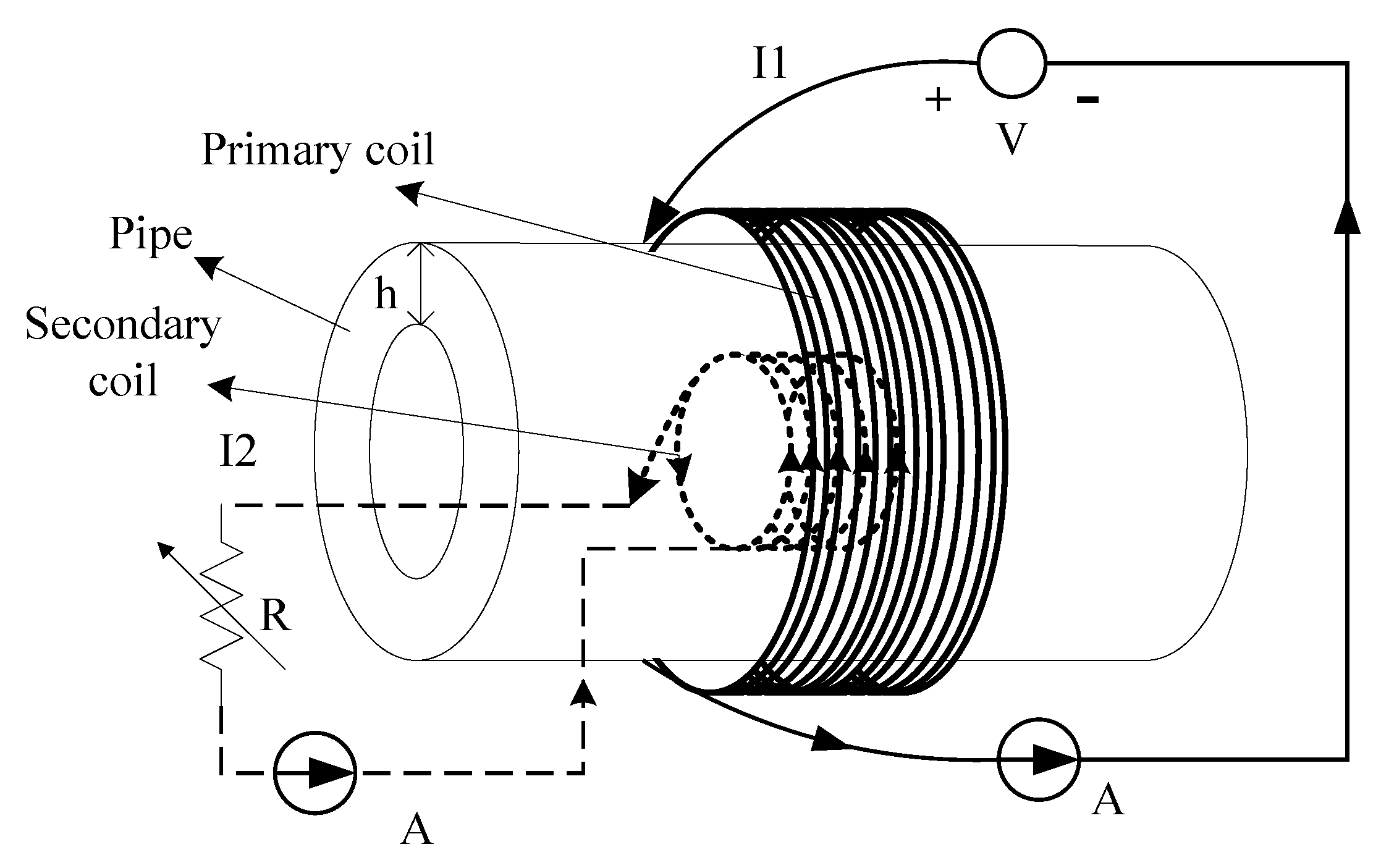

2.1. Power Delivery and/or Data Transmission Based on Inductive Coupling

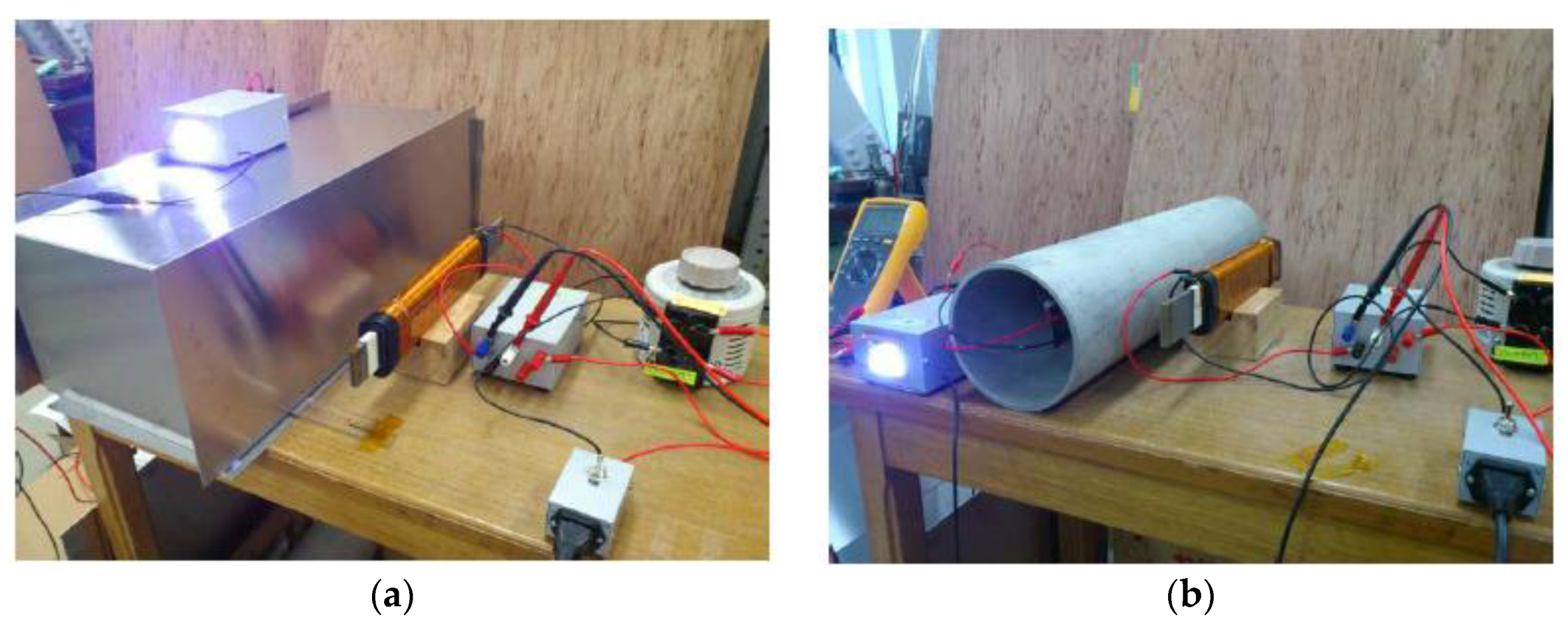

2.1.1. Inductive Power Transfer Technology through Metal Walls

2.1.2. Inductive Power Transfer and Through-metal-wall Data Transmission

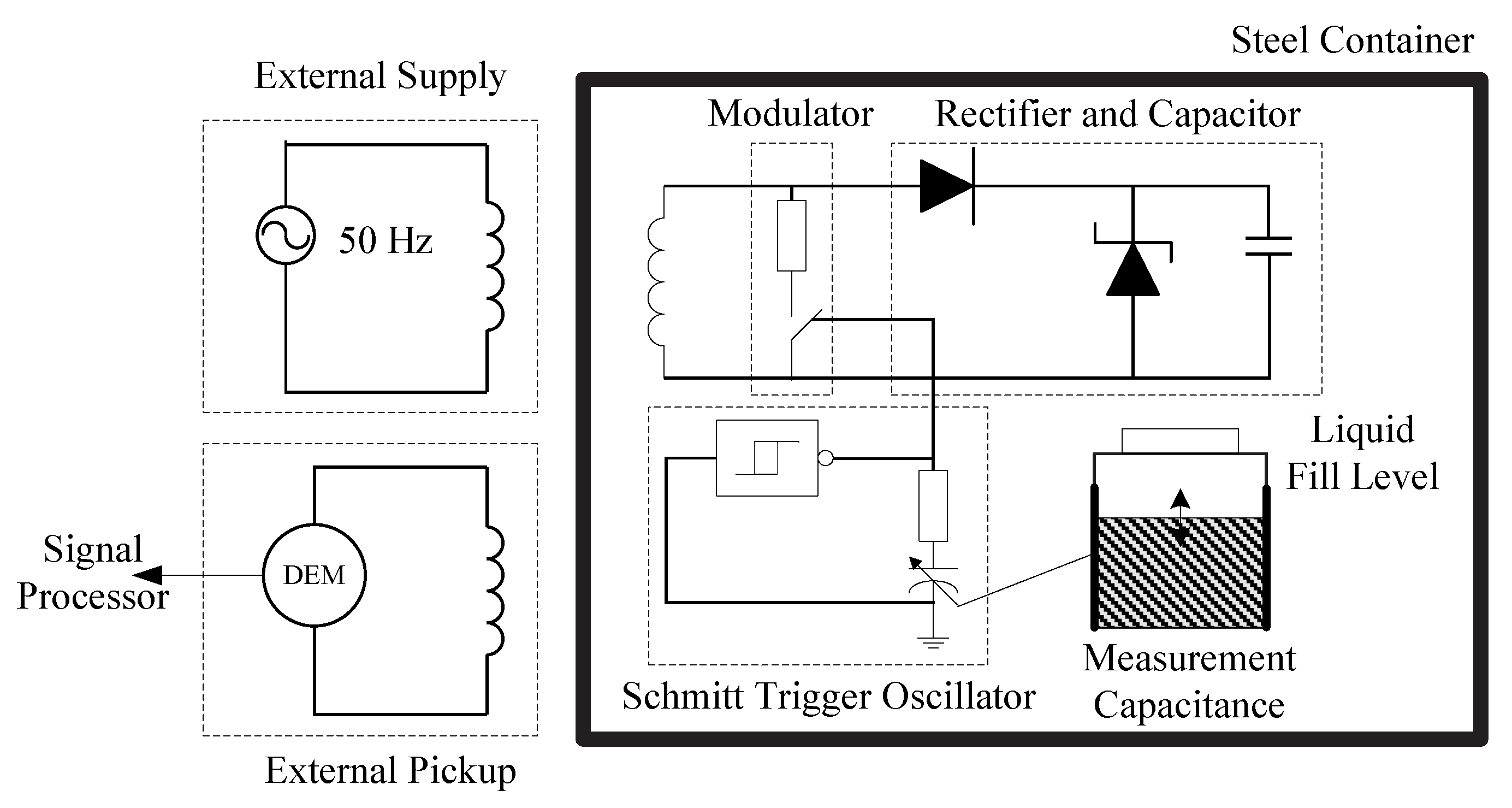

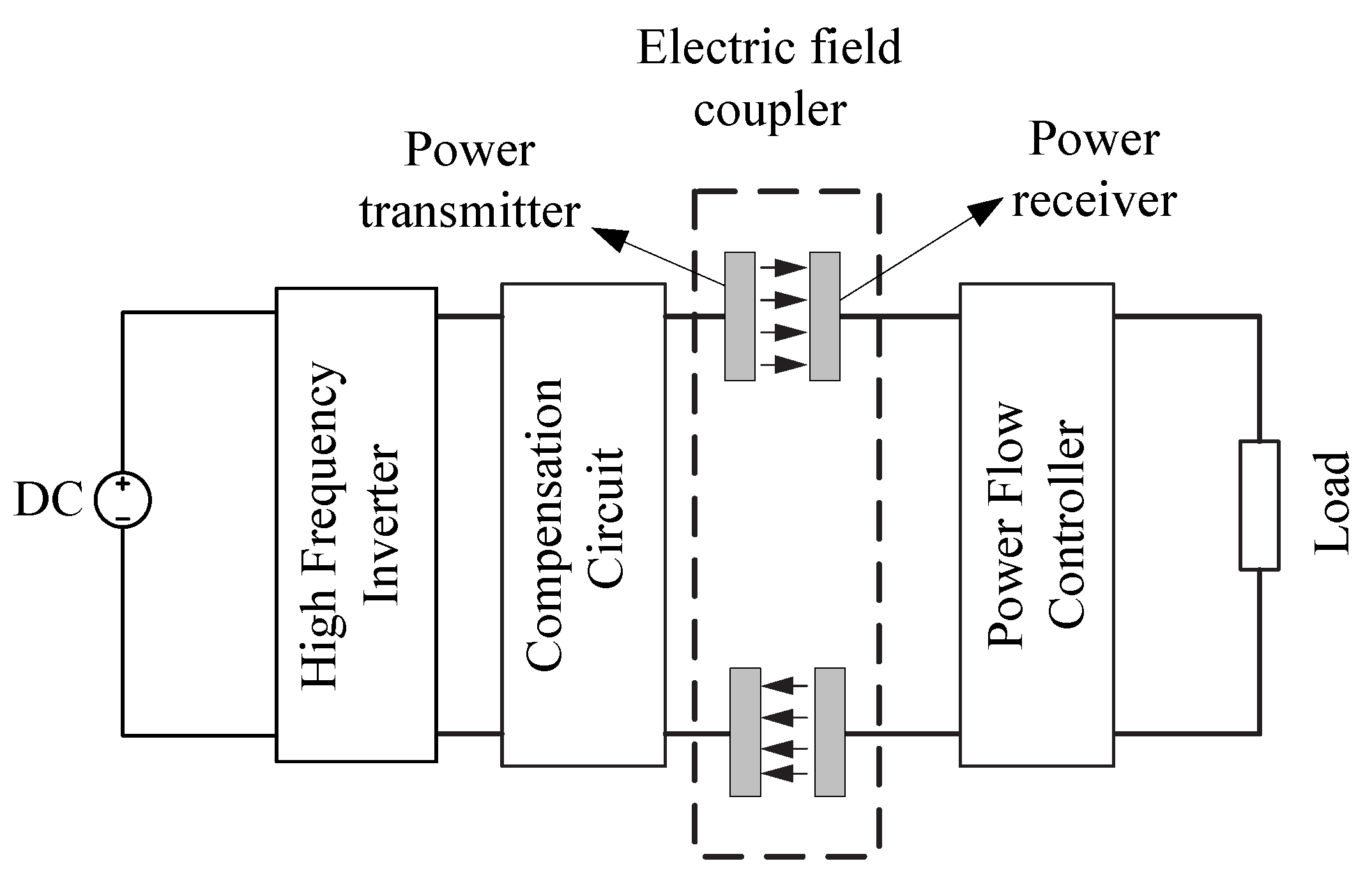

2.2. Power Delivery and/or Data Transmission Base on Capacitive Coupling

2.3. Power Delivery through Metal Based on Magnetic Resonance Coupling

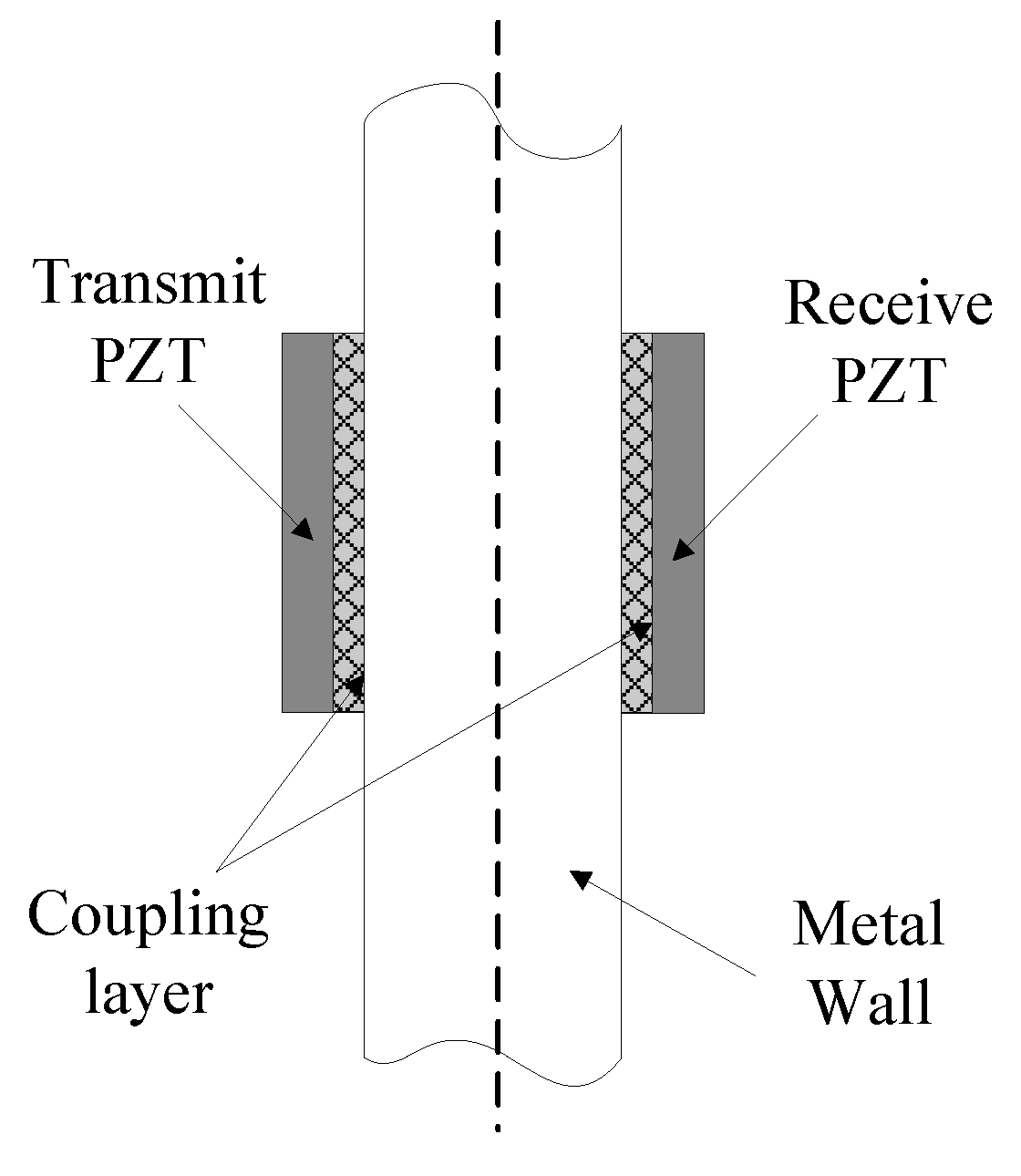

3. Ultrasonic Through-Metal-Wall Power Delivery and Data Transmission Technology

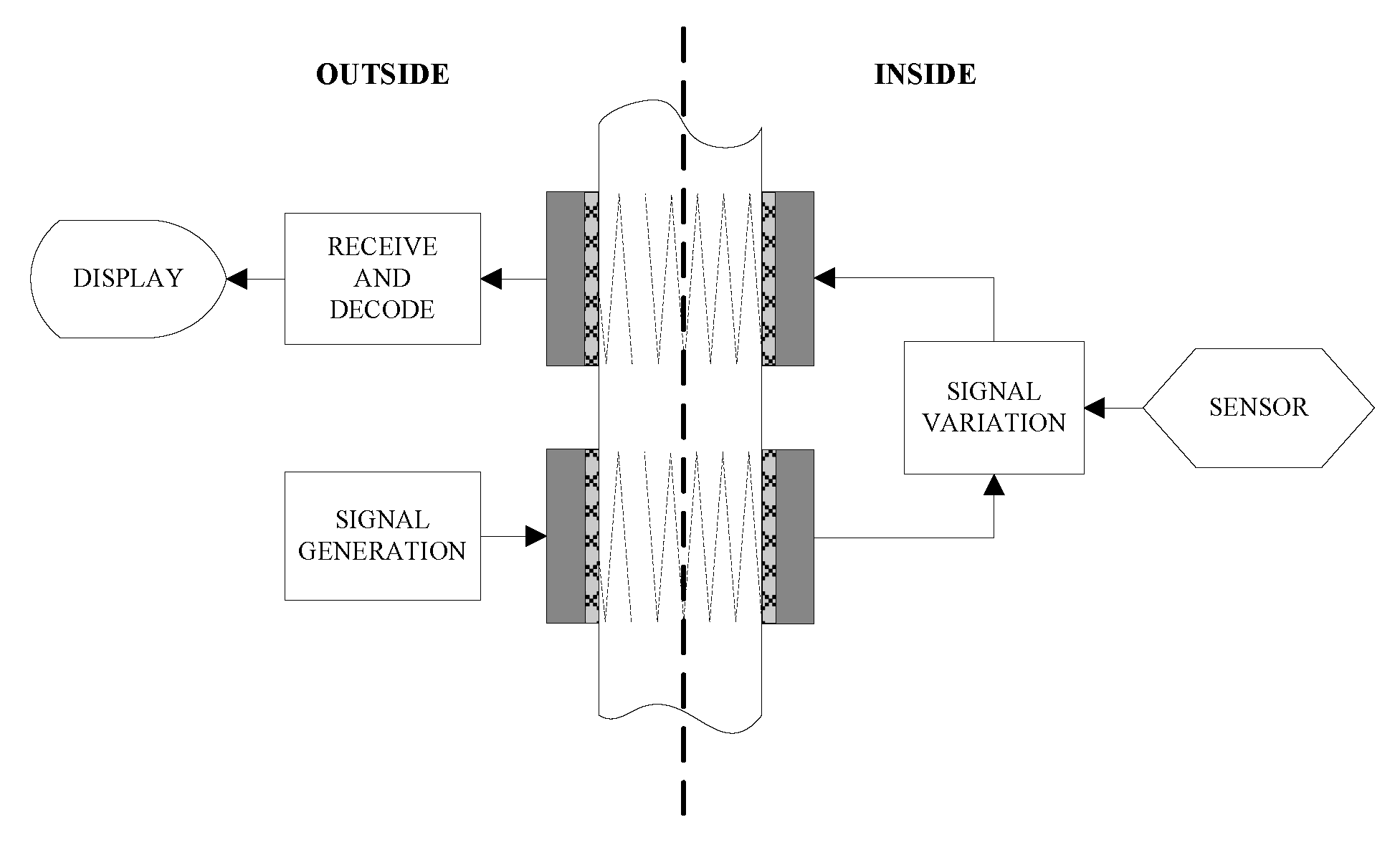

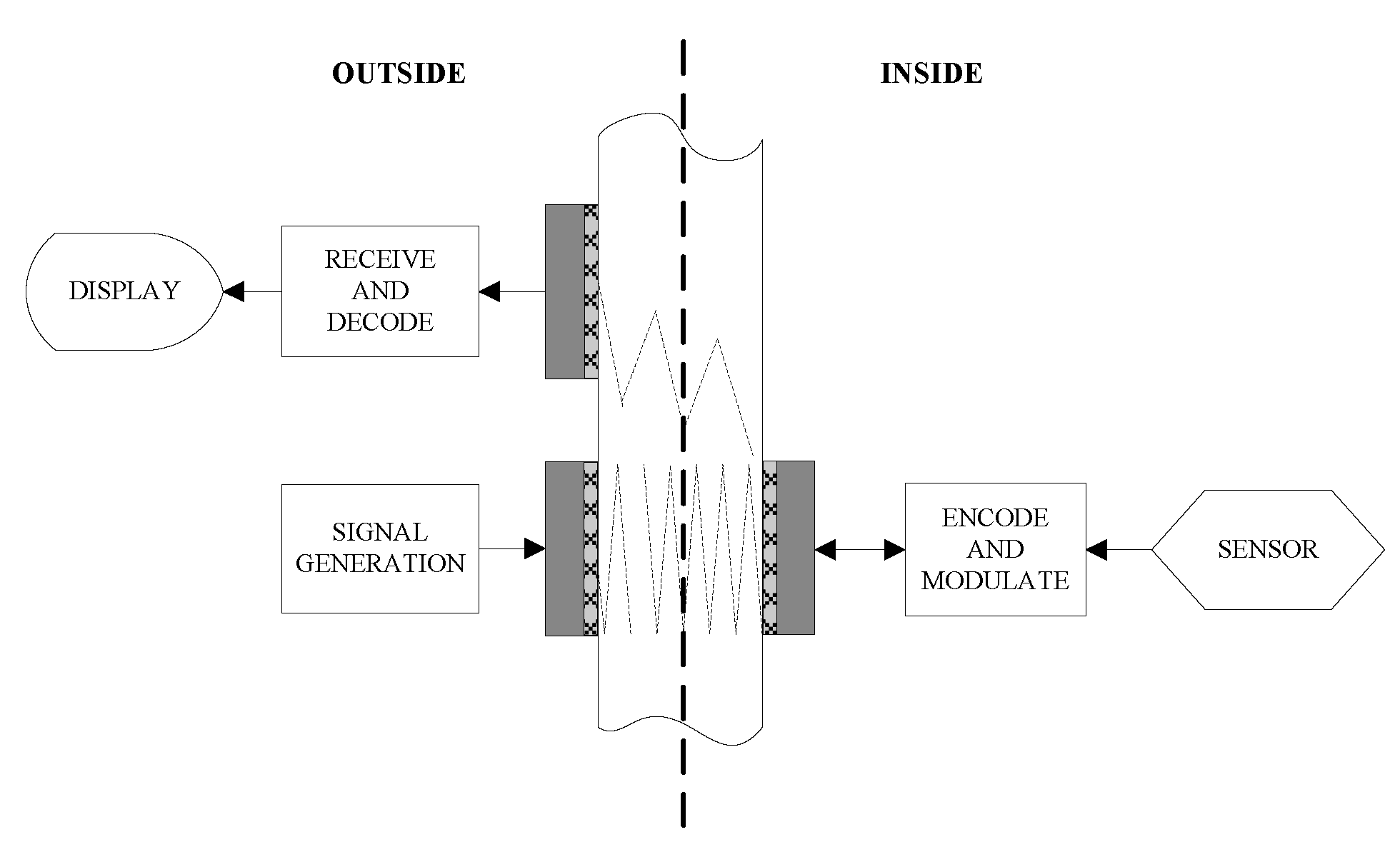

3.1. Initial Development of Ultrasound Through-Metal-Wall Power Delivery and Data Transmission

3.2. Ultrasonic Through-Metal-Wall Power Delivery

3.3. Ultrasonic Through-Metal-Wall Data Transmission

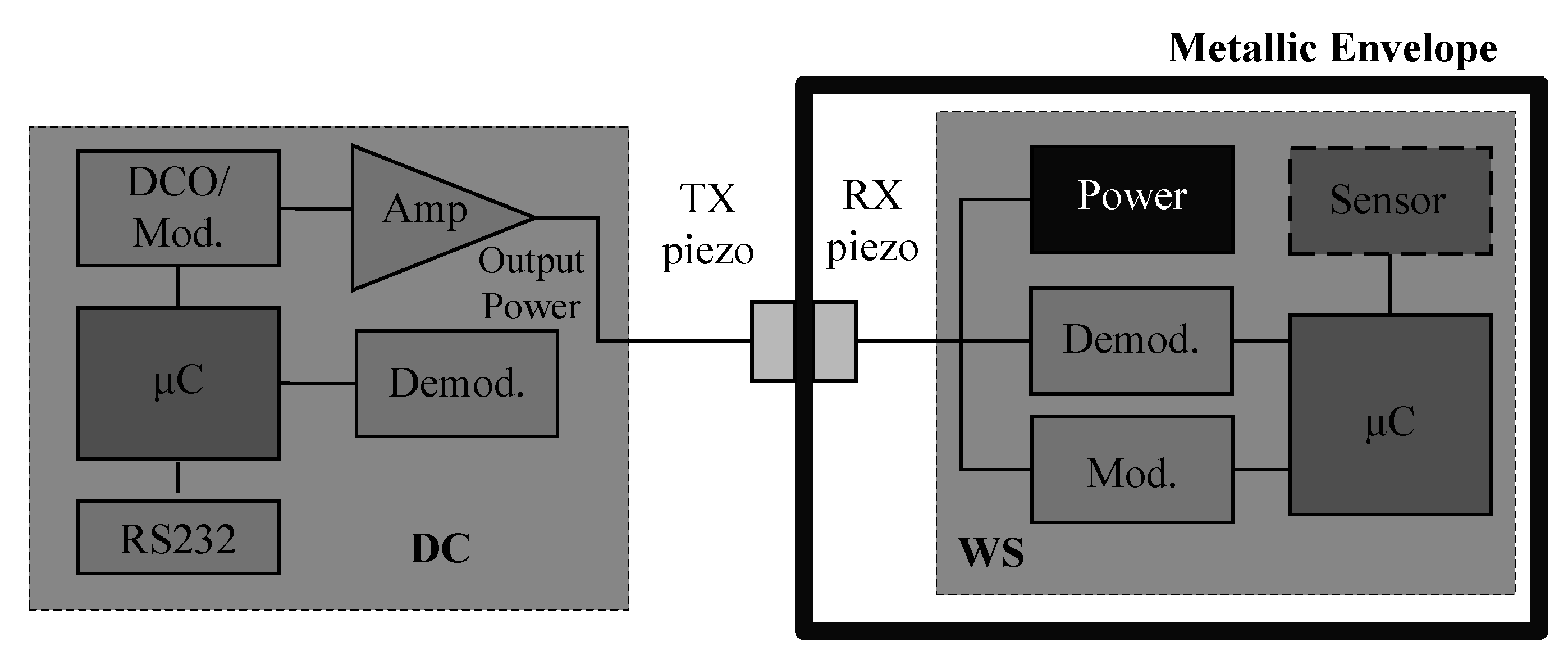

3.4. Simultaneous Through-Metal-Wall Power Delivery and Data Transmission Based on Ultrasonic

4. Comparison of Various Ultrasonic Through-Metal-Wall Power Delivery and Data Transmission Systems

4.1. Methods for Modeling the Acoustic-Electric Channel

4.2. Different Transducer Configuration and Communication Mode with Enclosed Sensors

4.3. Summary of Ultrasonic Through-Metal-Wall Power Delivery and Data Transmission Systems

| Systems | Configuration | Metal Wall and Thickness (mm) | Power Delivery | Data Rate (bps) | Data Transmission Mode | |

|---|---|---|---|---|---|---|

| Power Efficiency | ||||||

| Sherrit et al. [42] | One pair of PZTs | Titanium (2.5 mm) | — | 53% | — | — |

| Bao et al. [44] | One pair of 38 mm diameter PZTs | Titanium (3.4 mm) | 100 W | 88% | — | — |

| Bao et al. [45,46] | One pair PZT stacks (four 50.8 mm diameter PZTs in each stack) | Titanium (5 mm) | 1068 W | 80%–90% | — | — |

| Moss et al. [47,48] | One pair of 38 mm diameter PZTs | Aluminum (1.6–5 mm) | 300 mW | 30% | — | — |

| Moss et al. [49,50,51] | One pair of 38 mm diameter PZTs | Aluminum (1.6 mm) | 420 mW | 42% | 115 k | Half-duplex |

| Murphy [55] | One pair of PZTs with power reflected mode | Steel (148 mm) | — | — | 300 | Half-duplex |

| Murphy [55] | Two pairs of PZTs | Steel (148 mm) | — | — | 5 k | Full-duplex |

| Murphy [56] | Three PZTs | Steel (152.4 mm) | — | — | 500 | Half-duplex |

| Kluge et al. [3,65] | One pair of PZTs | Aluminum (7 mm) | 30 mW | — | 1 k | Half-duplex |

| Shoudy et al. [67] | One pair of 25.4 mm diameter PZTs | Steel (57 mm) | 250 mW | — | 55 k | Half-duplex |

| Lawry et al. [71] | One pair of PZTs with diameter from 12.7 mm to 66.7 mm | Steel (9.5–63.5 mm) | 81 W | 55% | — | — |

| Lawry et al. [72] | One pair of high temperature PZTs, operating at 260 °C | Steel (≈16 mm) | 1 W | ≈63% | 50 k | Half-duplex |

| Wilt et al. [73] | One pair of 25.4 mm diameter PZTs | Stainless steel (57.2 mm) | >100 W | >60% | — | — |

| Lawry et al. [74,75,76,77,78] | Two pairs of PZTs | Steel (63.5 mm) | 50 W | — | 17.37 M | Full-duplex |

| Chakraborty et al. [79] | One pair of 25.4 mm diameter PZTs | Steel (15.97 mm)-water (88.3 mm)-steel (10.92 mm) | — | 30% | 4 M | Half-duplex |

| Ashdown et al. [81,82] | One pair of 25.4 mm PZTs | Steel (57.15 mm) | ≈100 mW | — | >30 k | Full-duplex |

| Graham et al. [5,6,84] | One pair of EMATs with liftoff of 0.8 mm to the surface of the metal wall | Steel (25.4 mm) | — | — | 1 M | Half-duplex |

5. Concluding Remarks

5.1. Characteristics of Through-Metal-Wall Power Delivery and Data Transmission Systems

5.2. Challenges and Developing Trends of Through-Metal-Wall Power Delivery and Data Transmission Technology

Acknowledgments

Conflicts of Interest

References

- BAE Systems. Walls Have Ears—The Technology that Can Communicate Electronically through Solid Steel. Available online: http://www.baesystems.com/Newsroom/NewsReleases/autoGen110618172929.html (accessed on 27 August 2010).

- Sherrit, S.; Badescu, M.; Bao, X.; Bar-Cohen, Y.; Chang, Z. Efficient electromechanical network model for wireless acoustic-electric feed-throughs. Proc. SPIE 2005, 5758, 362–372. [Google Scholar]

- Kluge, M.; Becker, T.; Schalk, J.; Otterpohl, T. Remote acoustic powering and data transmission for sensors inside of conductive envelopes. In Proceedings of the 2008 IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 41–44.

- Imoru, O.; Jassal, A.; Polinder, H.; Nieuwkoop, E.; Tsado, J.; Jimoh, A.A. An Inductive Power Transfer through metal object. In Proceedings of the 2013 1st International Future Energy Electronics Conference (IFEEC), Tainan, Taiwan, 3–6 November 2013; pp. 246–251.

- Graham, D.J.; Neasham, J.A.; Sharif, B.S. Investigation of Methods for Data Communication and Power Delivery through Metals. IEEE Trans. Ind. Electron. 2011, 58, 4972–4980. [Google Scholar] [CrossRef]

- Graham, D.J. Investigation of Methods for Data Communication and Power Delivery through Metals. Ph.D. Thesis, University of Newcastle upon Tyne, Newcastle upon Tyne, UK, 2012. [Google Scholar]

- Zangl, H.; Fuchs, A.; Bretterklieber, T.; Moser, M.; Holler, G. An Investigation on Wireless Communication and Power Supply Through Metal Tank Walls. In Proceedings of the 2008 IEEE Instrumentation and Measurement Technology Conference Proceedings, Victoria, BC, Canada, 12–15 May 2008; pp. 1452–1457.

- Zangl, H.; Fuchs, A.; Bretterklieber, T.; Moser, M.J.; Holler, G. Wireless Communication and Power Supply Strategy for Sensor Applications Within Closed Metal Walls. IEEE Trans. Instrum. Meas. 2010, 59, 1686–1692. [Google Scholar] [CrossRef]

- Liu, C.; Hu, A.P.; Nair, N.C. Coupling study of a rotary Capacitive Power Transfer system. In Proceedings of the 2009 IEEE International Conference on Industrial Technology, Gippsland, Australia, 10–13 February 2009; pp. 1–6.

- Liu, C.; Hu, A.P.; Wang, B.; Nair, N.C. A Capacitively Coupled Contactless Matrix Charging Platform with Soft Switched Transformer Control. IEEE Trans. Ind. Electron. 2013, 60, 249–260. [Google Scholar] [CrossRef]

- Huang, L.; Hu, A.P.; Swain, A.; Kim, S.; Ren, Y. An overview of capacitively coupled power transfer—A new contactless power transfer solution. In Proceedings of the 2013 8th IEEE Conference on Industrial Electronics and Applications (ICIEA), Melbourne, Australia, 19–21 June 2013; pp. 461–465.

- Yamakawa, M.; Mizuno, Y.; Ishida, J.; Komurasaki, K.; Koizumi, H. Wireless Power Transmission into a Space Enclosed by Metal Walls Using Magnetic Resonance Coupling. Wirel. Eng. Technol. 2014, 5, 19–24. [Google Scholar] [CrossRef]

- Seo, Y.-S.; Hughes, Z.; Hoang, M.; Isom, D.; Nguyen, M.; Rao, S.; Chiao, J.-C. Investigation of wireless power transfer in through-wall applications. In Proceedings of the Microwave Conference Proceedings, Kaohsiung, Taiwan, 4–7 December 2012; pp. 403–405.

- Covic, G.A.; Boys, J.T. Inductive Power Transfer. IEEE Proc. 2013, 101, 1276–1289. [Google Scholar] [CrossRef]

- Pantic, Z. Inductive Power Transfer Systems for Charging of Electric Vehicles. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2013. [Google Scholar]

- Kurs, A.; Karalis, A.; Moffatt, R.; Joannopoulos, J.D.; Fisher, P.; Soljacic, M. Wireless power transfer via strongly coupled magnetic resonances. Science 2007, 317, 83–86. [Google Scholar] [CrossRef] [PubMed]

- Georgakopoulos, S.V.; Jonah, O. Optimized wireless power transfer to RFID sensors via magnetic resonance. In Proceedings of the 2011 IEEE International Symposium on Antennas and Propagation, Spokane, WA, USA, 3–8 July 2011; pp. 1421–1424.

- RamRakhyani, A.K.; Mirabbasi, S.; Chiao, M. Design and Optimization of Resonance-Based Efficient Wireless Power Delivery Systems for Biomedical Implants. IEEE Trans. Biomed. Circuits Syst. 2011, 5, 48–63. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Liu, S.; Zhou, Y.C.; Cui, T.J. An Optimizable Circuit Structure for High-Efficiency Wireless Power Transfer. IEEE Trans. Ind. Electron. 2013, 60, 339–349. [Google Scholar] [CrossRef]

- Smeets, J.P.C.; Overboom, T.T.; Jansen, J.W.; Lomonova, E.A. Modeling Framework for Contactless Energy Transfer Systems for Linear Actuators. IEEE Trans. Ind. Electron. 2013, 60, 391–399. [Google Scholar] [CrossRef]

- Ishida, H.; Furukawa, H. Wireless Power Transmission through Concrete Using Circuits Resonating at Utility Frequency of 60 Hz. IEEE Trans. Power Electron. 2015, 30, 1220–1229. [Google Scholar] [CrossRef]

- Wilhelm, G.R.; Jaskolski, C.; Berkenpas, E. Magnetic Communication through Metal Barriers. U.S. Patent 20,080,070,499 A1, 20 March 2008. [Google Scholar]

- Li, C.; Hutchins, D.A.; Green, R.J. Short-range ultrasonic digital communications in air. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 908–918. [Google Scholar] [PubMed]

- Li, C.; Hutchins, D.A.; Green, R.J. Short-range ultrasonic communications in air using quadrature modulation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 2060–2072. [Google Scholar] [PubMed]

- Du, L.; Zhe, J. An integrated ultrasonic-inductive pulse sensor for wear debris detection. Smart Mater. Struct. 2013, 22, 025003. [Google Scholar] [CrossRef]

- Arra, S.; Leskinen, J.; Heikkila, J.; Vanhala, J. Ultrasonic Power and Data Link for Wireless Implantable Applications. In Proceedings of the 2nd International Symposium on Wireless Pervasive Computing, San Juan, Puerto Rico, 5–7 February 2007; pp. 567–571.

- Ozeri, S.; Shmilovitz, D. Ultrasonic transcutaneous energy transfer for powering implanted devices. Ultrasonics 2010, 50, 556–566. [Google Scholar] [CrossRef] [PubMed]

- Sanni, A.; Vilches, A.; Toumazou, C. Inductive and Ultrasonic Multi-Tier Interface for Low-Power, Deeply Implantable Medical Devices. IEEE Trans. Biomed. Circuits Syst. 2012, 6, 297–308. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Q.; Youm, W.; Hwang, G.; Moon, K.S.; Ozturk, Y. Resonant ultrasonic wireless power transmission for bio-implants. Proc. SPIE 2014, 9057. [Google Scholar] [CrossRef]

- Connor, D.J.; Cummings, G.F.; Star, M.J. Acoustic Transformer with Non-Piezoelectric Core. U.S. Patent 5,594,705 A, 14 January 1997. [Google Scholar]

- Welle, R.P. Ultrasonic Data Communication System. U.S. Patent 5,982,297 A, 9 November 1999. [Google Scholar]

- Welle, R.P. Ultrasonic Power Communication System. U.S. Patent 6,037,704 A, 14 March 2000. [Google Scholar]

- Rein, C. Remote Energy Supply Process and System for an Electronic Information Carrier. Patent WO 1,999,030,266 A3, 22 July 1999. [Google Scholar]

- Hu, Y.; Zhang, X.; Yang, J.; Jiang, Q. Transmitting electric energy through a metal wall by acoustic waves using piezoelectric transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 773–781. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Yang, J.; Hu, Y. Energy trapping in power transmission through an elastic plate by finite piezoelectric transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 2493–2501. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.T.; Guo, S.H. Energy trapping in power transmission through a circular cylindrical elastic shell by finite piezoelectric transducers. Ultrasonics 2008, 48, 716–723. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Guo, S.; Yang, J. Transmitting electric energy through a closed elastic wall by acoustic waves and piezoelectric transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 1380–1386. [Google Scholar] [CrossRef] [PubMed]

- Lü, C.F.; Yang, J.S.; Wang, J.; Chen, W.Q. Power transmission through a hollow cylinder by acoustic waves and piezoelectric transducers with radial polarization. J. Sound Vib. 2009, 325, 989–999. [Google Scholar] [CrossRef]

- Hu, H.; Hu, Y.; Chen, C. Wireless energy transmission through a thin metal wall by shear wave using two piezoelectric transducers. In Proceedings of the IEEE Ultrasonics Symposium, Beijing, China, 2–5 November 2008; pp. 2165–2168.

- Hu, H.; Hu, Y.; Chen, C.; Wang, J. A system of two piezoelectric transducers and a storage circuit for wireless energy transmission through a thin metal wall. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 2312–2319. [Google Scholar] [PubMed]

- Hu, H.; Xue, H.; Hu, Y.; Chen, X. Wireless energy transmission through a sealed wall using the acoustic-electric interaction of piezoelectric ceramics. Proc. SPIE 2009, 7493. [Google Scholar] [CrossRef]

- Sherrit, S.; Doty, B.; Badescu, M.; Bao, X.; Bar-Cohen, Y.; Aldrich, J.; Chang, Z. Studies of acoustic-electric feed-throughs for power transmission through structures. Proc. SPIE 2006, 6171. [Google Scholar] [CrossRef]

- Chang, Z.; Bao, X.; Doty, B.J.; Sherrit, S.; Bar-Cohen, Y.; Badescu, M.; Aldrich, J. Power loss consideration in wireless piezoelectric acoustic-electric power feedthru. Proc. SPIE 2007, 6529. [Google Scholar] [CrossRef]

- Bao, X.; Doty, B.J.; Sherrit, S.; Badescu, M.; Bar-Cohen, Y.; Aldrich, J.; Chang, Z. Wireless piezoelectric acoustic-electric power feedthru. Proc. SPIE 2007, 6529. [Google Scholar] [CrossRef]

- Bao, X.; Biederman, W.; Sherrit, S.; Badescu, M.; Bar-Cohen, Y.; Jones, C.; Aldrich, J.; Chang, Z. High-power piezoelectric acoustic-electric power feedthru for metal walls. Proc. SPIE 2008, 6930. [Google Scholar] [CrossRef]

- Sherrit, S.; Bao, X.; Badescu, M.; Aldrich, J.; Bar-Cohen, Y.; Biederman, W.; Chang, Z. 1 kW Power Transmission Using Wireless Acoustic-Electric Feedthrough (WAEF). In Earth & Space 2008: Engineering, Science, Construction, and Operations in Challenging Environments; American Society of Civil Engineers: Long Beach, CA, USA, 2008; pp. 1–10. [Google Scholar]

- Moss, S.; McMahon, P.; Konak, C.; Phoumasavanh, C.; Rajic, N.; Galea, S.; Powlesland, I. Modelling and Experimental Validation of the Acoustic Electric Feedthrough Technique; Air Vehicles Division: Canberra, Australia, 2008. [Google Scholar]

- Moss, S.; Konak, M.; Phoumsavanh, C.; Tsoi, K.; Powlesland, I. Acoustic Electric Feedthrough Demonstrator Mk-I; Air Vehicles Division: Canberra, Australia, 2009; p. 24. [Google Scholar]

- Moss, S.; Phoumsavanh, C.; Konak, M.; Tsoi, K.; Rajic, N.; Galea, S.; Powlesland, I.; McMahon, P. Design of the acoustic electric feedthrough demonstrator mk-II. Annu. Rev. J. Inst. Mater. Eng. Aust. LTD 2009, 33, 187–200. [Google Scholar]

- Moss, S.; Skippen, J.; Konak, M.; Powlesland, I. Footprint Reduction for the Acoustic Electric Feedthrough Technique; Air Vehicles Division, Defence Science and Technology Organisation, Commonwealth of Australia: Canberra, Australia, 2010. [Google Scholar]

- Moss, S.; Skippen, J.; Konak, M.; Powlesland, I.; Galea, S. Detachable acoustic electric feedthrough. Proc. SPIE 2010, 7647. [Google Scholar] [CrossRef]

- Hobart, E.; Allsup, G.; Hosom, D.; Baldasarre, T. Acoustic modem unit. In Proceedings of the OCEANS 2000 MTS/IEEE Conference and Exhibition, Providence, RI, USA, 11–14 September 2000; pp. 769–772.

- Payton, R.M. System for Acoustically Passing Electrical Signals through a Hull. U.S. Patent 6,625,084 B1, 23 September 2003. [Google Scholar]

- Bagshaw, J.M.; Kent, L.W. Data Transfer. U.S. Patent 20,100,061,188 A1, 14 March 2010. [Google Scholar]

- Murphy, T.L. Ultrasonic Digital Communication System for a Steel Wall Multipath Channel: Methods and Results; Rensselaer Polytechnic Institute: Niskayuna, NY, USA, 2006. [Google Scholar]

- Saulnier, G.J.; Scarton, H.A.; Gavens, A.J.; Shoudy, D.A.; Murphy, T.L.; Wetzel, M.; Bard, S.; Roa-Prada, S.; Das, P. Through-Wall Communication of Low-Rate Digital Data Using Ultrasound. In Proceedings of the IEEE Ultrasonics Symposium, Vancouver, BC, Canada, 2–6 October 2006; pp. 1385–1389.

- Primerano, R.; Wanuga, K.; Dorn, J.; Kam, M.; Dandekar, K. Echo-Cancellation for Ultrasonic Data Transmission through a Metal Channel. In Proceedings of the 41st Annual Conference on Information Sciences and Systems, Baltimore, MD, USA, 14–16 March 2007; pp. 841–845.

- Primerano, R.; Kam, M.; Dandekar, K. High bit rate ultrasonic communication through metal channels. In Proceedings of the 43rd Annual Conference on Information Sciences and Systems, Baltimore, MD, USA, 18–20 March 2009; pp. 902–906.

- Primerano, R.A. High Bit-Rate Digital Communication through Metal Channels. Ph.D. Thesis, Drexel University, Philadelphia, PA, USA, 2010. [Google Scholar]

- Bielinski, M.; Wanuga, K.; Primerano, R.; Kam, M.; Dandekar, K.R. Application of Adaptive OFDM Bit Loading for High Data Rate Through-Metal Communication. In Proceedings of the 2011 IEEE Global Telecommunications Conference, Houston, TX, USA, 5–9 December 2011; pp. 1–5.

- Wanuga, K.; Bielinski, M.; Primerano, R.; Kam, M.; Dandekar, K.R. High-data-rate ultrasonic through-metal communication. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 2051–2053. [Google Scholar] [CrossRef] [PubMed]

- Bielinski, M.; Wanuga, K.; Sosa, G.; Primerano, R.; Kam, M.; Dandekar, K.R. Transceiver Design for High Data Rate Through-Metal Communication in Naval Applications. Nav. Eng. J. 2013, 125, 121–126. [Google Scholar]

- Hosman, T.; Yeary, M.; Antonio, J.K.; Hobbs, B. Multi-tone FSK for ultrasonic communication. In Proceedings of the 2010 IEEE Instrumentation and Measurement Technology Conference, Austin, TX, USA, 3–6 May 2010; pp. 1424–1429.

- Hosman, T.; Yeary, M.; Antonio, J.K. Design and Characterization of an MFSK-Based Transmitter/Receiver for Ultrasonic Communication Through Metallic Structures. IEEE Trans. Instrum. Meas. 2011, 60, 3767–3774. [Google Scholar] [CrossRef]

- Kluge, M.; Sabater, J.; Schalk, J.; Ngo, L.V.; Seidel, H.; Schmid, U. Wireless Sensing of Physical Parameters Inside Hermetically Enclosed Conductive Envelopes. In Proceedings of the ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Las Vegas, NV, USA, 4–7 September 2007; pp. 353–359.

- Ngo, L.V.; Kluge, M.; Sabater, J.; Schalk, J.; Seidel, H.; Schmid, U. Long-Term Performance of Ultrasonic Transducers Used for Energy and Data Transmission. In Proceedings of the 2008 2nd European Conference Exhibition on Integration Issues of Miniaturized Systems, Barcelona, Spain, 9–10 April 2008; pp. 1–6.

- Shoudy, D.A.; Saulnier, G.J.; Scarton, H.A.; Das, P.K.; Roa-Prada, S.; Ashdown, J.D.; Gavens, A.J. An Ultrasonic Through-Wall Communication System with Power Harvesting. In Proceedings of the IEEE Ultrasonics Symposium, New York, NY, USA, 28–31 October 2007; pp. 1848–1853.

- Wilt, K.R.; Scarton, H.A.; Roa-Prada, S.; Saulnier, G.J.; Ashdown, J.D.; Lawry, T.J.; Das, P.K.; Gavens, A.J. Finite Element Modeling And Simulation of A Two-Transducer Through-Wall Ultrasonic Communication System. In Proceedings of the ASME 2009 International Mechanical Engineering Congress and Exposition, Lake Buena Vista, FL, USA; 2009; pp. 579–589. [Google Scholar]

- Wilt, K.R.; Lawry, T.J.; Scarton, H.A.; Roa-Prada, S.; Saulnier, G.J.; Ashdown, J.D.; Das, P.K.; Pinezich, J.D. Mechanical Design Implications on Power Transfer through Thick Metallic Barriers Using Piezoelectric Transducers. In Proceedings of the ASME 2010 International Mechanical Engineering Congress & Exposition, Vancouver, BC, Canada, 12–18 November 2010; pp. 173–182.

- Lawry, T.J.; Wilt, K.R.; Scarton, H.A.; Saulnier, G.J. Analytical modeling of a sandwiched plate piezoelectric transformer-based acoustic-electric transmission channel. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 2476–2486. [Google Scholar] [CrossRef] [PubMed]

- Lawry, T.J.; Wilt, K.R.; Roa-Prada, S.; Ashdown, J.D.; Saulnier, G.J.; Scarton, H.A.; Das, P.K.; Pinezich, J.D. Electrical optimization of power delivery through thick steel barriers using piezoelectric transducers. Proc. SPIE 2010, 7683. [Google Scholar] [CrossRef]

- Lawry, T.J.; Wilt, K.R.; Roa-Prada, S.; Ashdown, J.D.; Saulnier, G.J.; Scarton, H.A.; Das, P.K.; Gavens, A.J. A high-temperature acoustic-electric system for power delivery and data communication through thick metallic barriers. Proc. SPIE 2011, 8035. [Google Scholar] [CrossRef]

- Wilt, K.R.; Scarton, H.A.; Saulnier, G.J.; Lawry, T.J.; Ashdown, J.D. High-Power Operation of Acoustic-Electric Power Feedthroughs Through Thick Metallic Barriers. In Proceedings of the ASME 2012 International Mechanical Engineering Congress & Exposition, Houston, TX, USA, 9–15 November 2012; pp. 475–482.

- Lawry, T.J.; Saulnier, G.J.; Ashdown, J.D.; Wilt, K.R.; Scarton, H.A.; Pascarelle, S.; Pinezich, J.D. Penetration-free system for transmission of data and power through solid metal barriers. In Proceedings of the Military Communications Conference, Baltimore, MD, USA, 7–10 November 2011; pp. 389–395.

- Lawry, T. A High Performance System for Wireless Transmission of Power and Data Through Solid Metal Enclosures; Rensselaer Polytechnic Institute: Troy, NY, USA, 2011. [Google Scholar]

- Lawry, T.; Saulnier, G.; Wilt, K.; Ashdown, J.; Scarton, H. Adaptive System for Efficient Transmission of Power and Data Through Acoustic Media. U.S. Patent 9,054,826 B2, 28 March 2012. [Google Scholar]

- Lawry, T.J.; Wilt, K.R.; Ashdown, J.D.; Scarton, H.A.; Saulnier, G.J. A high-performance ultrasonic system for the simultaneous transmission of data and power through solid metal barriers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 194–203. [Google Scholar] [CrossRef] [PubMed]

- Scarton, H.; Saulnier, G.; Wilt, K. Method and Apparatus for Acoustical Power Transfer and Communication. Patent WO 2,014,035,785 A1, 6 March 2014. [Google Scholar]

- Chakraborty, S.; Wilt, K.R.; Saulnier, G.J.; Scarton, H.A.; Das, P.K. Estimating channel capacity and power transfer efficiency of a multi-layer acoustic-electric channel. Proc. SPIE 2013, 8753. [Google Scholar] [CrossRef]

- Chase, R. Microcontroller Based Handheld Acoustic Communication & Power Delivery through Metallic Barriers; Rensselaer Polytechnic Institute: Niskayuna, NY, USA, 2013. [Google Scholar]

- Ashdown, J.D.; Wilt, K.R.; Lawry, T.J.; Saulnier, G.J.; Shoudy, D.A.; Scarton, H.A.; Gavens, A.J. A full-duplex ultrasonic through-wall communication and power delivery system. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 587–595. [Google Scholar] [CrossRef] [PubMed]

- Lawry, T.; Saulnier, G.; Wilt, K.; Ashdown, J.; Scarton, H.; Gavens, A. A Full-Duplex Ultrasonic Through-Wall Communication and Power Delivery System with Frequency Tracking. Patent EP 2,832,016 A1, 21 March 2013. [Google Scholar]

- Roa-Prada, S.; Scarton, H.A.; Saulnier, G.J.; Shoudy, D.A.; Ashdown, J.D.; Das, P.K.; Gavens, A.J. An Ultrasonic Through-Wall Communication (UTWC) System Model. J. Vib. Acoust. 2013, 135. [Google Scholar] [CrossRef]

- Graham, D.J.; Neasham, J.A.; Sharif, B.S. High bit rate communication through metallic structures using electromagnetic acoustic transducers. In Proceedings of the OCEANS 2009—EUROPE, Bremen, Germany, 11–14 May 2009; pp. 1–6.

- Oruganti, S.K.; Heo, S.H.; Ma, H.; Bien, F. Wireless energy transfer-based transceiver systems for power and/or high-data rate transmission through thick metal walls using sheet-like waveguides. Electron. Lett. 2014, 50, 886–888. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.-X.; Hu, Z.; Zhao, H.; Hu, H.-F.; Sun, Y.-Z.; Hou, B.-J. Through-Metal-Wall Power Delivery and Data Transmission for Enclosed Sensors: A Review. Sensors 2015, 15, 31581-31605. https://doi.org/10.3390/s151229870

Yang D-X, Hu Z, Zhao H, Hu H-F, Sun Y-Z, Hou B-J. Through-Metal-Wall Power Delivery and Data Transmission for Enclosed Sensors: A Review. Sensors. 2015; 15(12):31581-31605. https://doi.org/10.3390/s151229870

Chicago/Turabian StyleYang, Ding-Xin, Zheng Hu, Hong Zhao, Hai-Feng Hu, Yun-Zhe Sun, and Bao-Jian Hou. 2015. "Through-Metal-Wall Power Delivery and Data Transmission for Enclosed Sensors: A Review" Sensors 15, no. 12: 31581-31605. https://doi.org/10.3390/s151229870

APA StyleYang, D.-X., Hu, Z., Zhao, H., Hu, H.-F., Sun, Y.-Z., & Hou, B.-J. (2015). Through-Metal-Wall Power Delivery and Data Transmission for Enclosed Sensors: A Review. Sensors, 15(12), 31581-31605. https://doi.org/10.3390/s151229870