Quantitative Ethylene Measurements with MOx Chemiresistive Sensors at Different Relative Air Humidities

Abstract

:1. Introduction

2. Background

3. Experimental Section

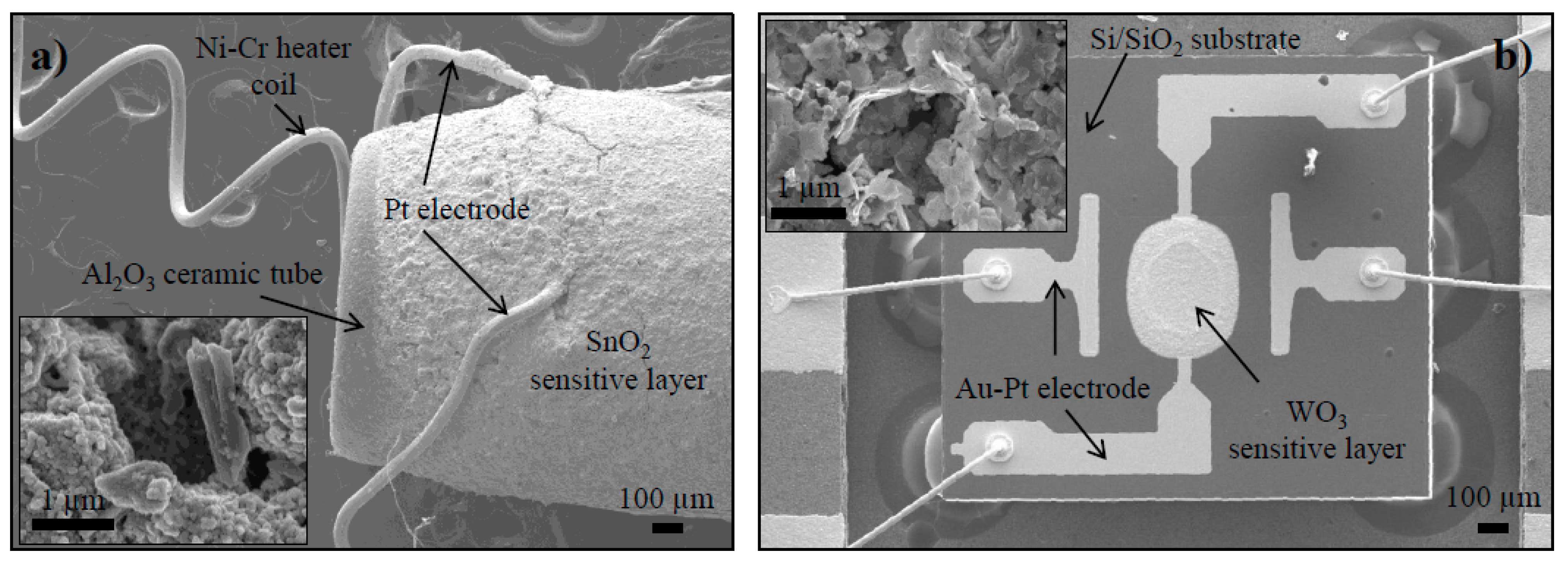

3.1. Scanning Electron Microscope (SEM) Characterization

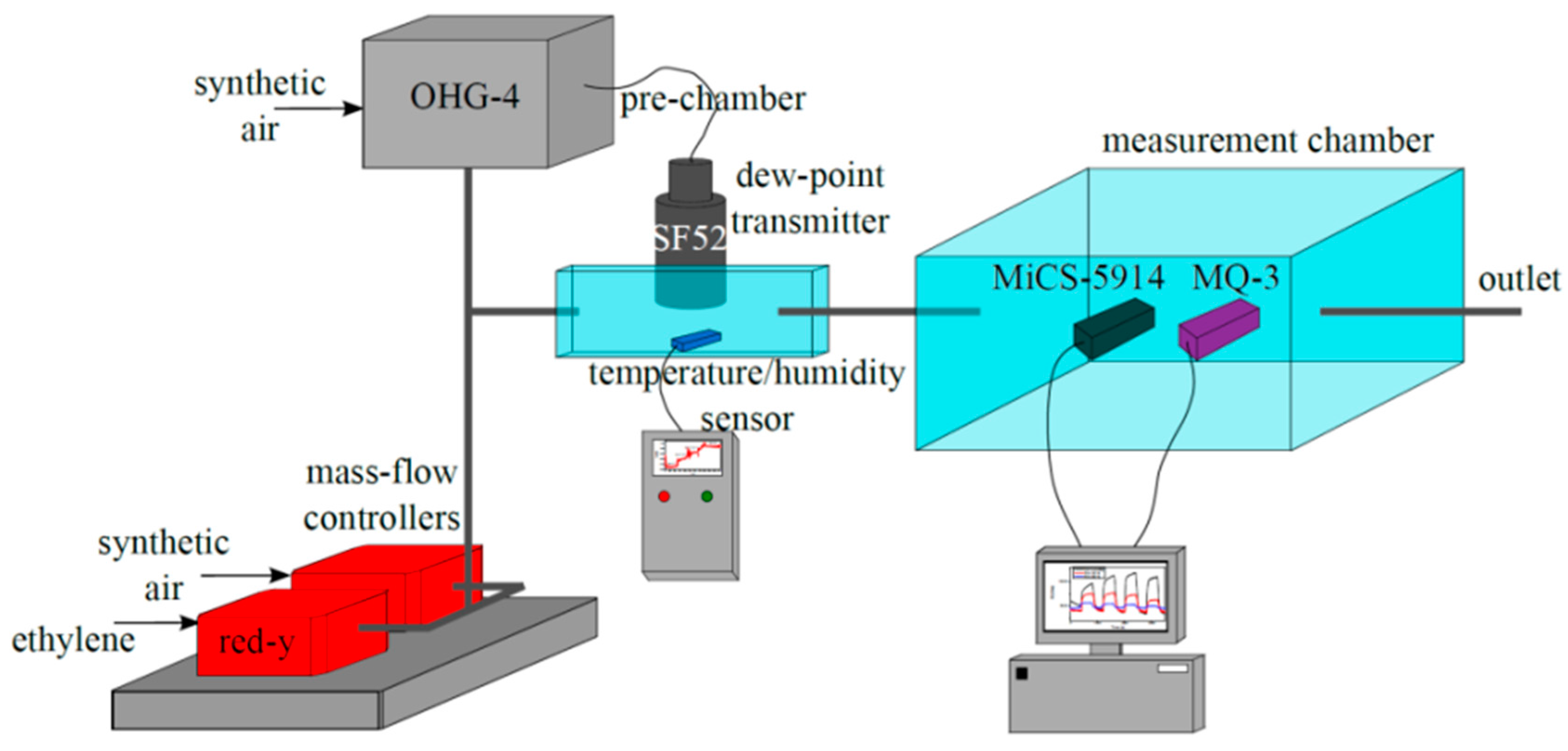

3.2. Gas Sensitivity Measurements

- a MOx-sensing layer (SnO2 and WO3 functional layer),

- an integrated heater to be connected to a 5 V power supply,

- two read-out contacts. The resistivity of the MQ-3 sensor is measured directly. The MiCS-5914 sensor and an external resistor form a voltage divider; the voltage across the external resistor is taken as the output.

3.3. Development of an Ethylene Prediction Model as a Function of Relative Humidity

4. Results and Discussion

4.1. SEM Characterization of the Sensors

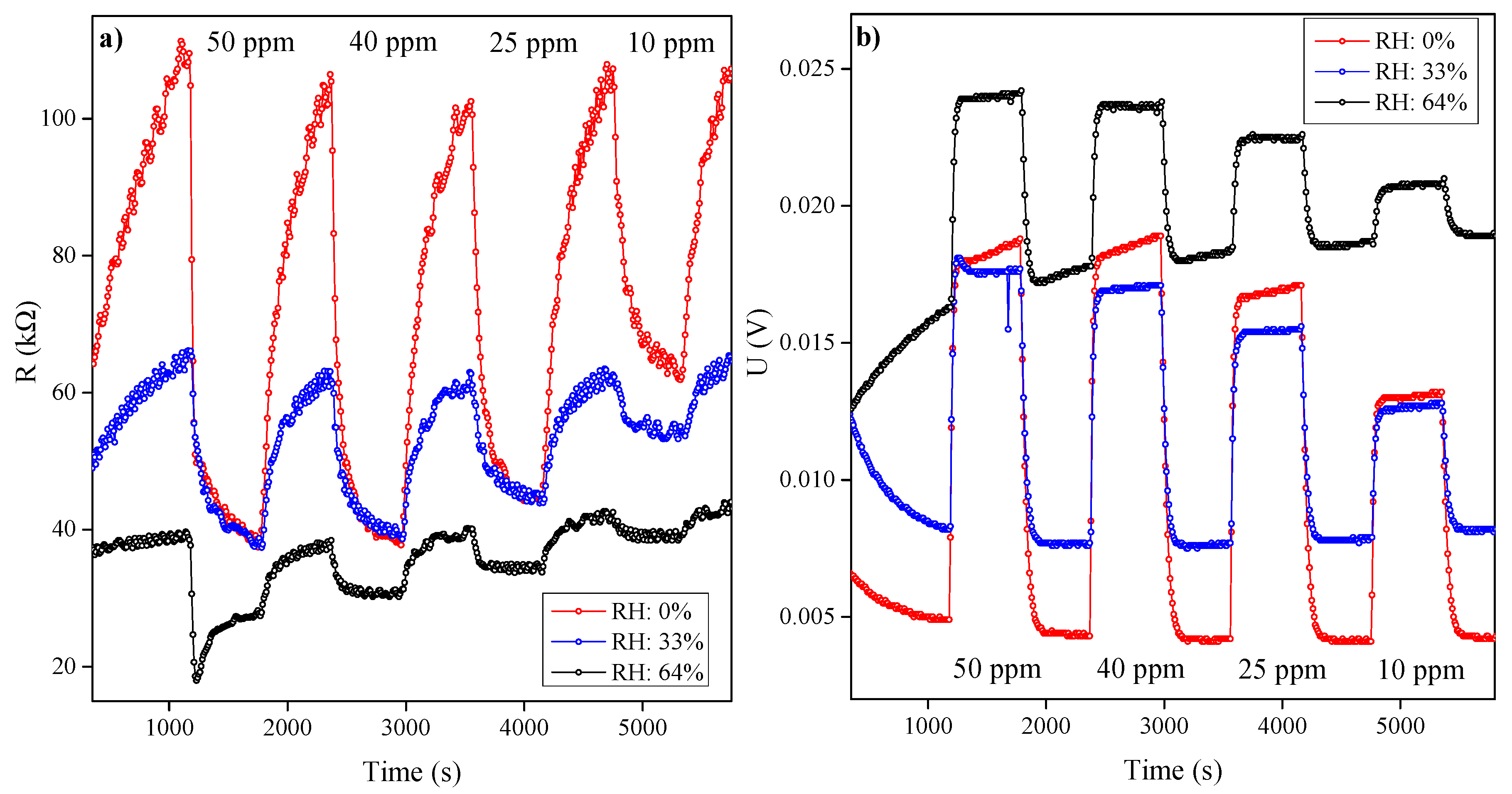

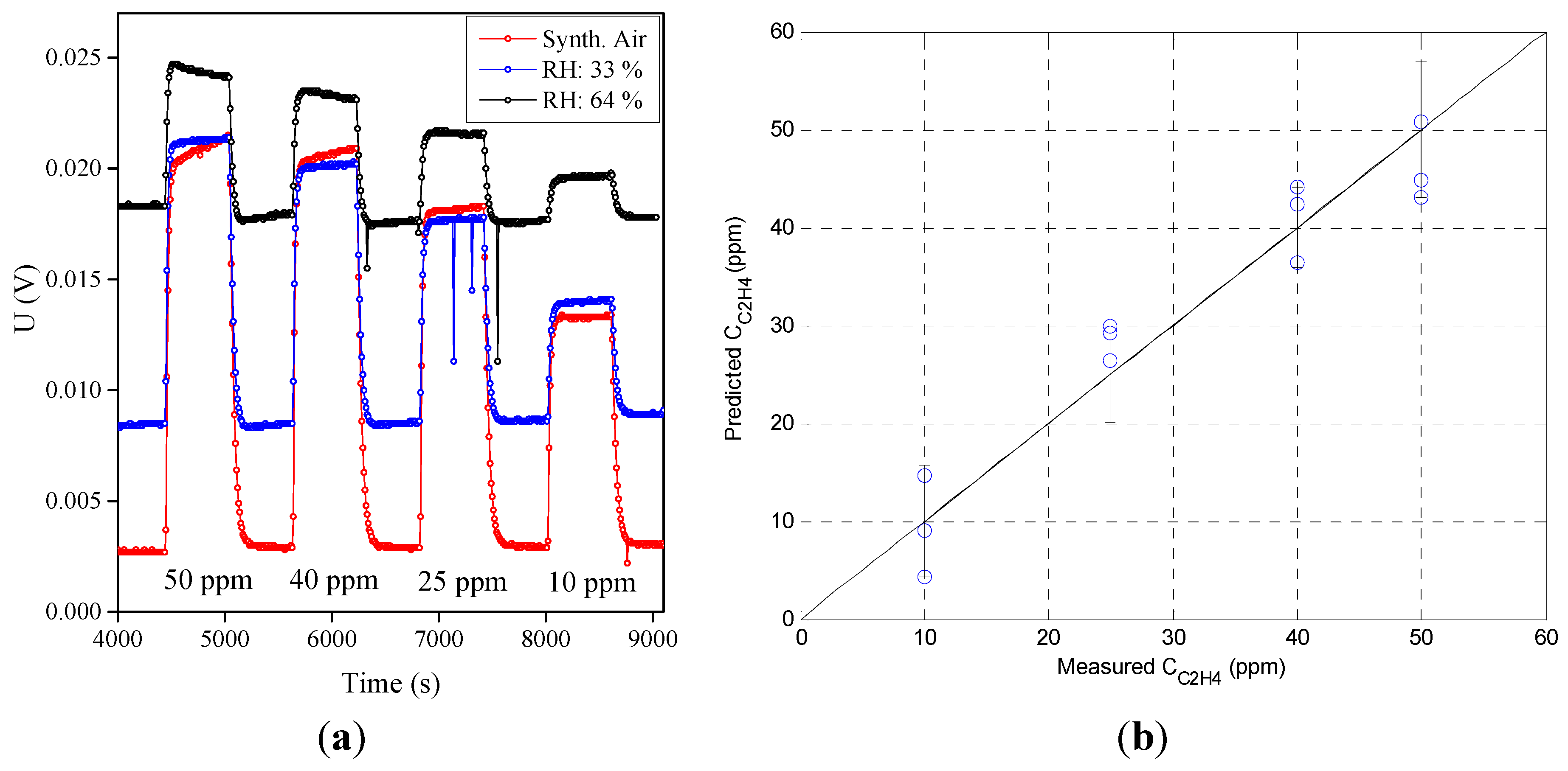

4.2. Qualitative Description of the Sensor Responses

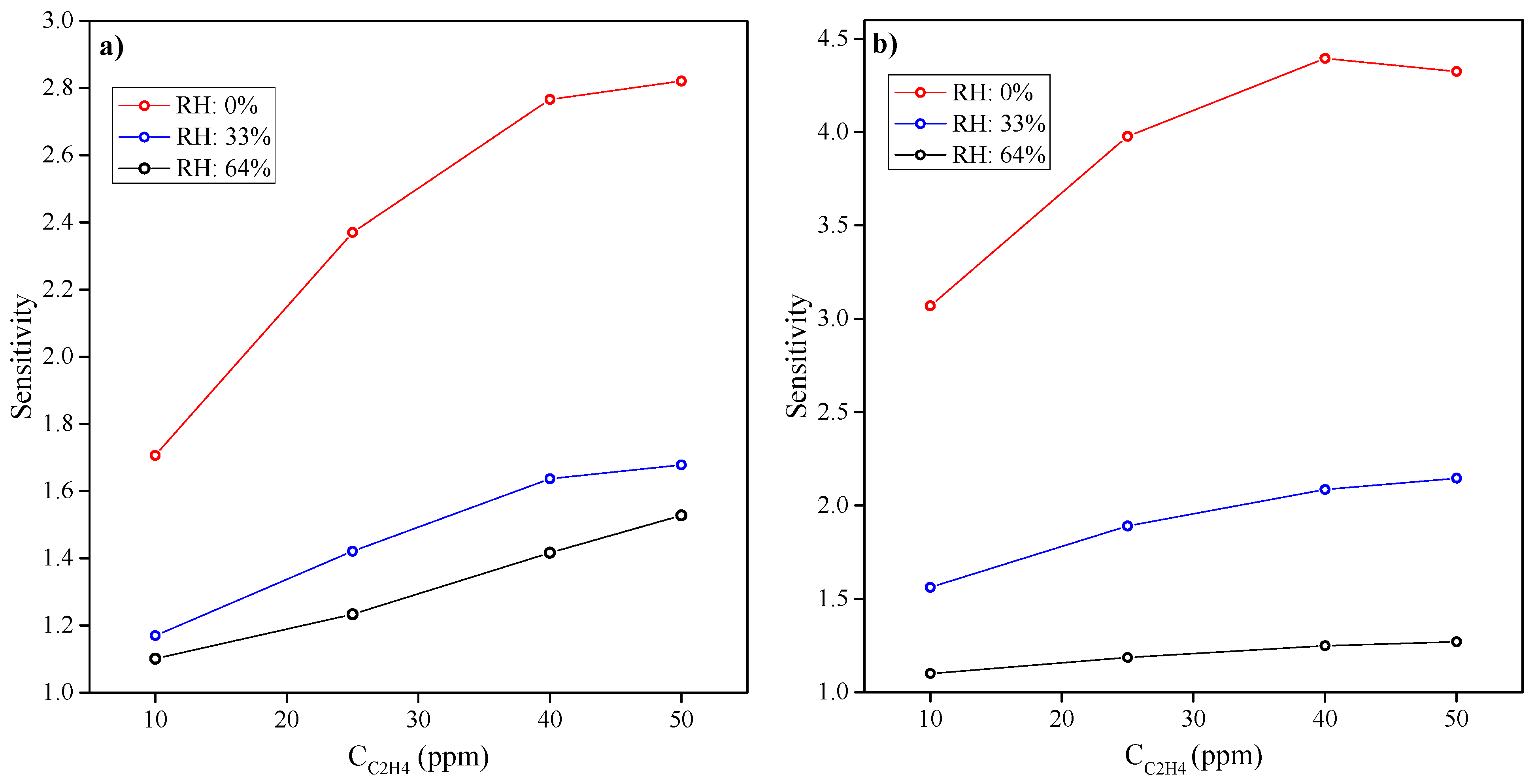

4.3. Response of the Sensors to Ethylene and Humidity

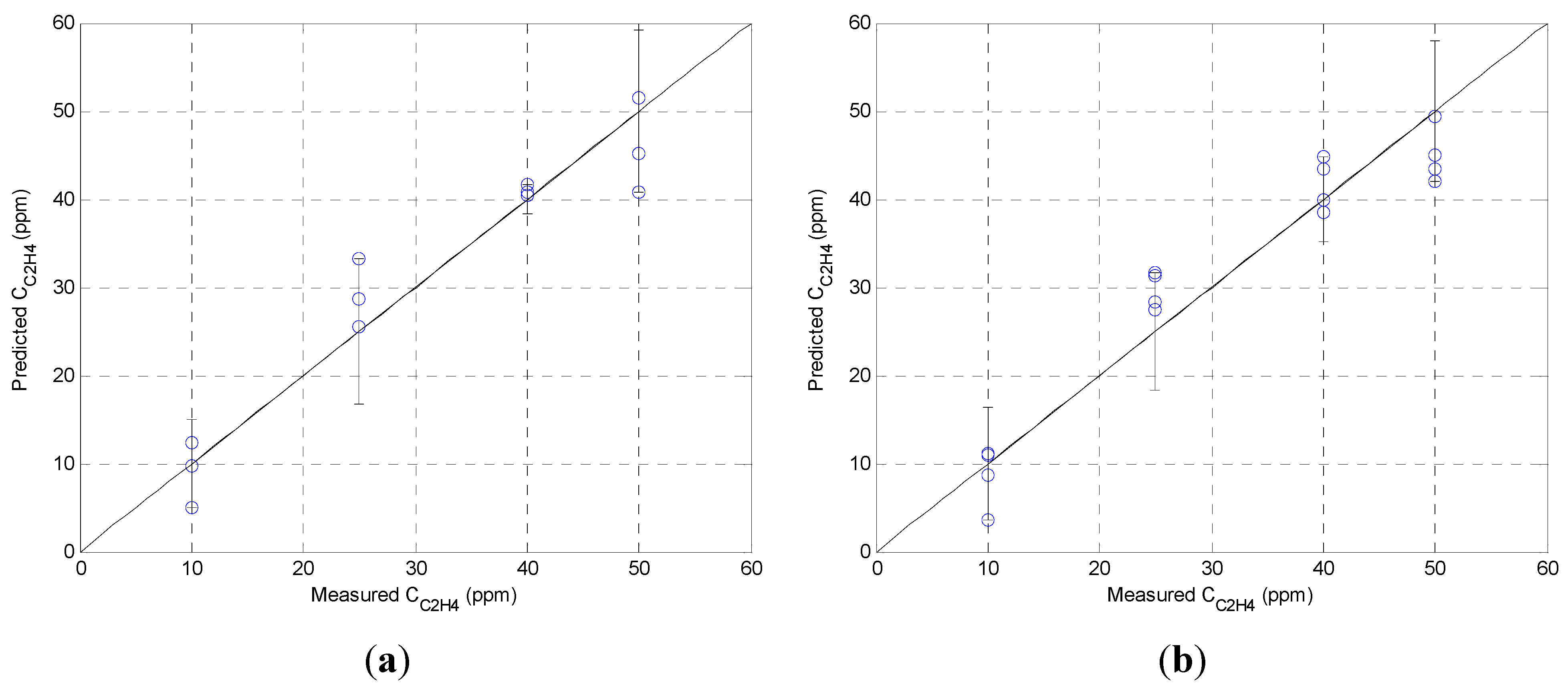

4.4. Ethylene Prediction Model as a Function of Relative Humidity

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Esser, B.; Schnorr, J.M.; Swager, T.M. Selective Detection of Ethylene Gas Using Carbon Nanotube-based Devices: Utility in Determination of Fruit Ripeness. Angew. Chem. Int. Ed. 2012, 51, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Janssen, S.; Schmitt, K.; Blanke, M.; Bauersfeld, M.L.; Wöllenstein, J.; Lang, W. Ethylene Detection in Fruit Supply Chain. Phil. Trans. R. Soc. A 2014, 372. [Google Scholar] [CrossRef] [PubMed]

- Povarov, V.G.; Lopatnikov, A.I.; Geibo, D.S.; Bulatova, A.V.; Razgonyaev, A.O. Use of Semiconductor Oxide Film for the Detection of Volatile Organic Compounds in the Gas Phase. J. Anal. Chem. 2013, 68, 300–304. [Google Scholar] [CrossRef]

- Nenova, Z.; Dimchev, G. Compensation of the Impact of Disturbing Factors on Gas Sensor Characteristics. Acta. Polytech. Hung. 2013, 10, 97–111. [Google Scholar]

- Xing, R.; Xu, L.; Song, J.; Zhou, C.; Li, Q.; Liu, D.; Song, H.W. Preparation and Gas Sensing Properties of In2O3/Au Nanorods for Detection of Volatile Organic Compounds in Exhaled Breath. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Giberti, A.; Carotta, M.C.; Guidi, V.; Malagu, C.; Martinelli, G.; Piga, M.; Vendemiati, B. Monitoring of Ethylene for Agro-Alimentary Applications and Compensation of Humidity Effects. Sens. Actuators B Chem. 2004, 103, 272–276. [Google Scholar] [CrossRef]

- Neri, G. First Fifty Years of Chemoresistive Gas Sensors. Chemosensors 2015, 3, 1–20. [Google Scholar] [CrossRef]

- Wang, C.; Yin, L.; Zhang, L.; Xiang, D.; Gao, R. Metal Oxide Gas Sensors: Sensitivity and Influencing Factors. Sensors 2010, 10, 2088–2106. [Google Scholar] [CrossRef] [PubMed]

- Dai, Z.; Lee, C.-S.; Tian, Y.; Kim, I.-D.; Lee, J.-H. Highly Reversible Switching from P- to N- Type NO2 Sensing in a Monolayer Fe2O3 Inverse Opal Film and the Associated P-N transition diagram. J. Mater. Chem. 2015, 3, 3372–3381. [Google Scholar] [CrossRef]

- Lee, C.Y.; Strano, M.S. Understanding the Dynamics of Signal Transduction for Adsorption of Gases and Vapors on Carbon Nanotube Sensors. Langmuir 2005, 21, 5192–5196. [Google Scholar] [CrossRef] [PubMed]

- Qi, Q.; Zhang, T.; Zheng, X.; Fan, H.; Liu, L.; Wang, R.; Zeng, Y. Electrical Response of Sm2O3-doped SnO2 to C2H2 and Effect of Humidity Interference. Sens. Actuators B Chem. 2008, 134, 36–42. [Google Scholar] [CrossRef]

- Hübner, M.; Simion, C.E.; Tomescu-Stanoiu, A.; Pokhrel, S.; Barsan, N.; Weimar, U. Influence of Humidity on CO Sensing with P-Type CuO Thick Filme Gas Sensors. Sens. Actuators B Chem. 2011, 153, 347–353. [Google Scholar] [CrossRef]

- Krivec, M.; Leitner, R.; Waldner, R.; Gostner, J.; Überall, F. The Effect of Sensor Temperature and MOx Layer Thickness on the Sensitivity of SnO2- and WO3-based Chemiresistive Sensors to Ethylene Gas. In Proceedings of the Smart Sensors, Actuators, and MEMS VII; and Cyber Physical Systems, Barcelona, Spain, 4 May 2015.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krivec, M.; Gunnigle, G.M.; Abram, A.; Maier, D.; Waldner, R.; Gostner, J.M.; Überall, F.; Leitner, R. Quantitative Ethylene Measurements with MOx Chemiresistive Sensors at Different Relative Air Humidities. Sensors 2015, 15, 28088-28098. https://doi.org/10.3390/s151128088

Krivec M, Gunnigle GM, Abram A, Maier D, Waldner R, Gostner JM, Überall F, Leitner R. Quantitative Ethylene Measurements with MOx Chemiresistive Sensors at Different Relative Air Humidities. Sensors. 2015; 15(11):28088-28098. https://doi.org/10.3390/s151128088

Chicago/Turabian StyleKrivec, Matic, Gerald Mc Gunnigle, Anže Abram, Dieter Maier, Roland Waldner, Johanna M. Gostner, Florian Überall, and Raimund Leitner. 2015. "Quantitative Ethylene Measurements with MOx Chemiresistive Sensors at Different Relative Air Humidities" Sensors 15, no. 11: 28088-28098. https://doi.org/10.3390/s151128088

APA StyleKrivec, M., Gunnigle, G. M., Abram, A., Maier, D., Waldner, R., Gostner, J. M., Überall, F., & Leitner, R. (2015). Quantitative Ethylene Measurements with MOx Chemiresistive Sensors at Different Relative Air Humidities. Sensors, 15(11), 28088-28098. https://doi.org/10.3390/s151128088