An Ultrasonic Multi-Beam Concentration Meter with a Neuro-Fuzzy Algorithm for Water Treatment Plants

Abstract

:1. Introduction

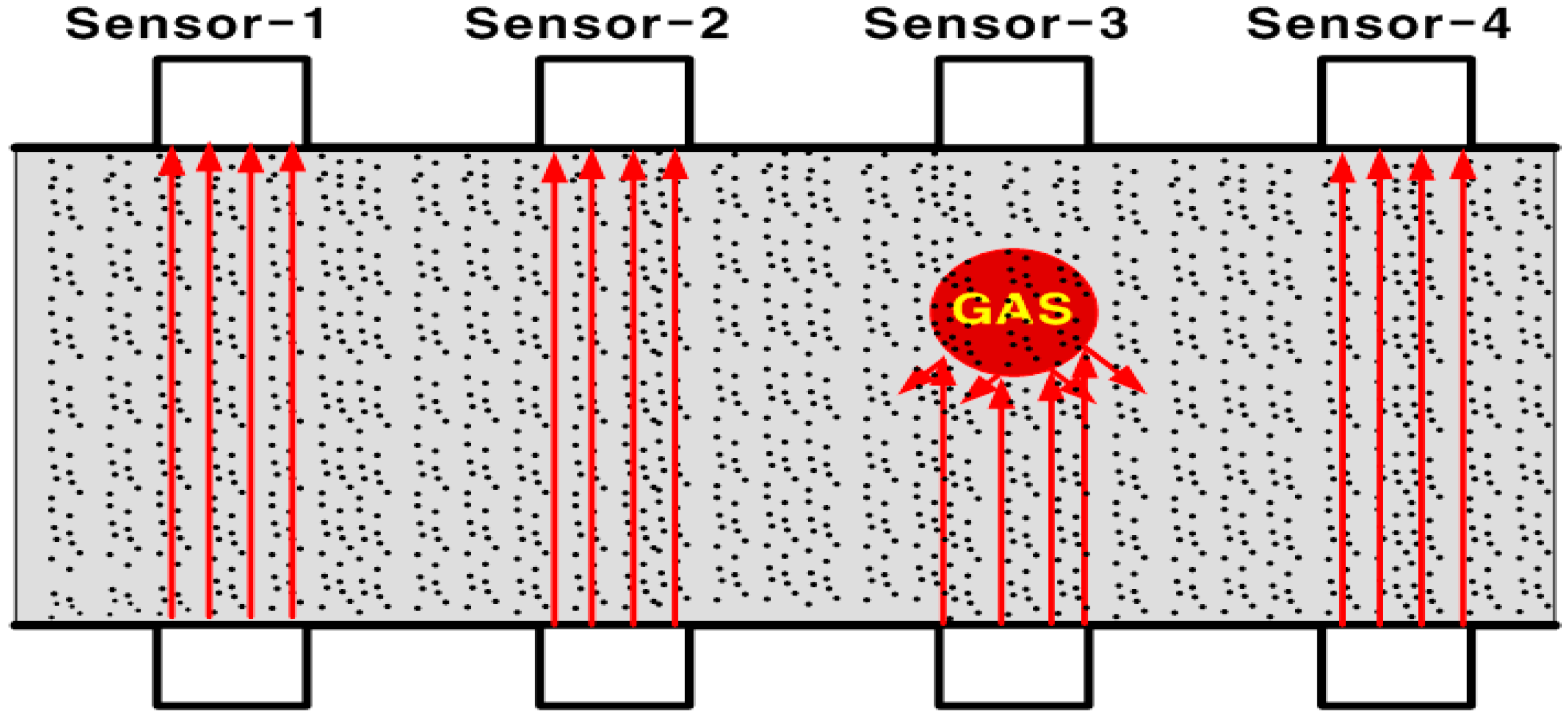

2. Development of the Ultrasonic Multi-Beam Densitometer

2.1. Development Overview

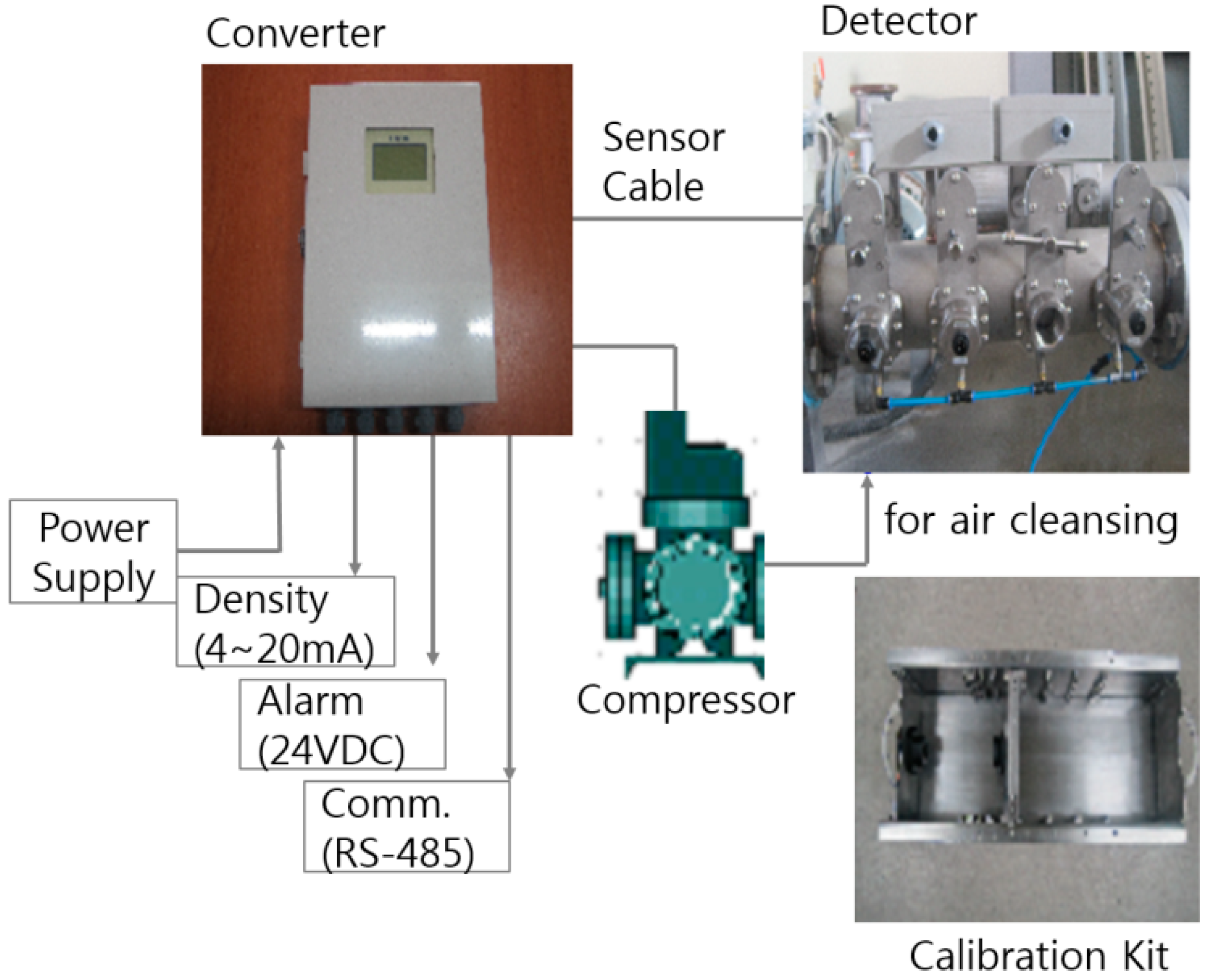

2.2. Densitometer Configuration

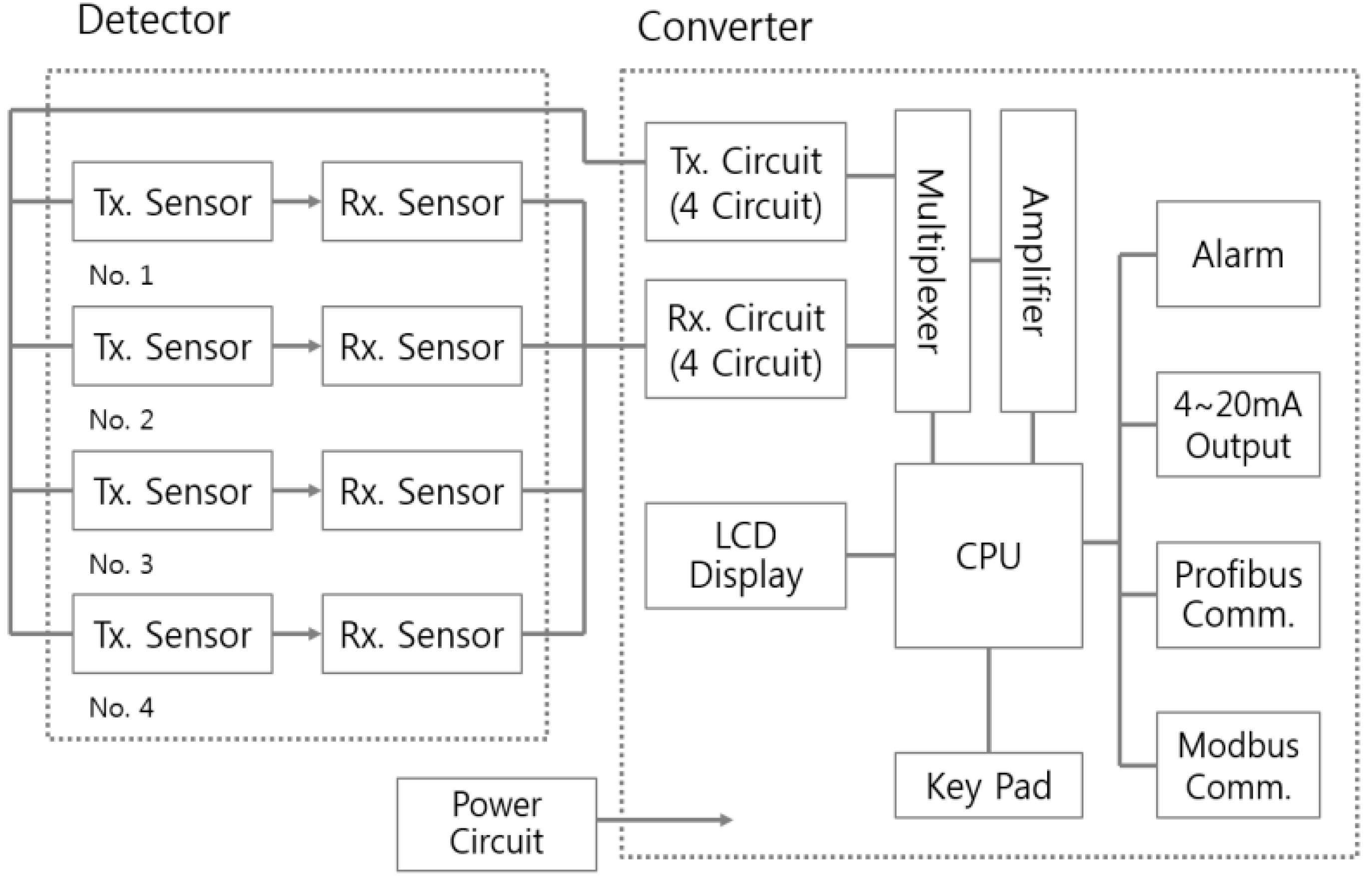

2.3. Converter Design and Function

| Item | Design Specifications |

|---|---|

| Ultrasonic Circuit | Calculates the attenuation value using the measured voltage of the receiving circuit in case of the 3 MHz AC signal transmission |

| Display | LCD WG1286A 128X64DOT |

| Converter | Switches the signal of the transmitter and reception circuit through the amplifier circuit. Multiplexer MX399 |

| Amplifier | Amplifies the outgoing signal so that the received signal is at a constant level, Amplifier VCA810 GAIN 80 dB (±40 dB) |

| CPU | CPU HD64F2357F (Hitachi, 16BIT Micro Processor) |

| Memory | ROM 128 kByte, RAM 8 kByte, External Memory(RAM 256 kByte), Clock 20 MHz |

| Alarm | Dry Contact and High/Low of Density |

| Output | 4–20 mA, RS485 (MODBUS) Comm. |

2.4. Design and Function of the Detector

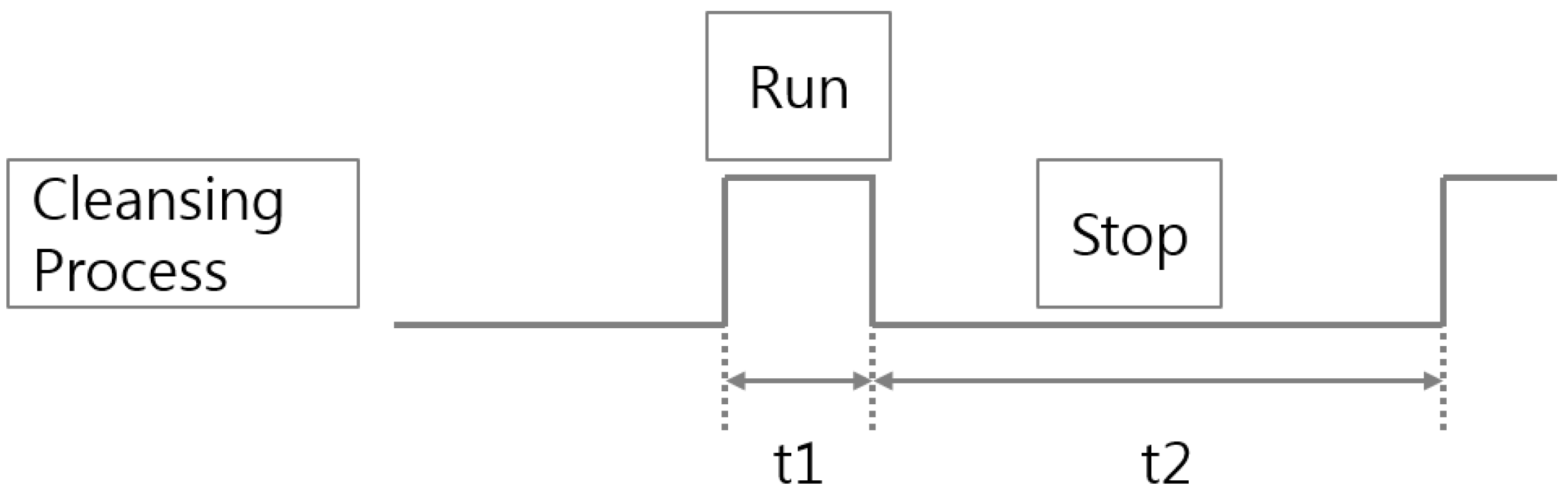

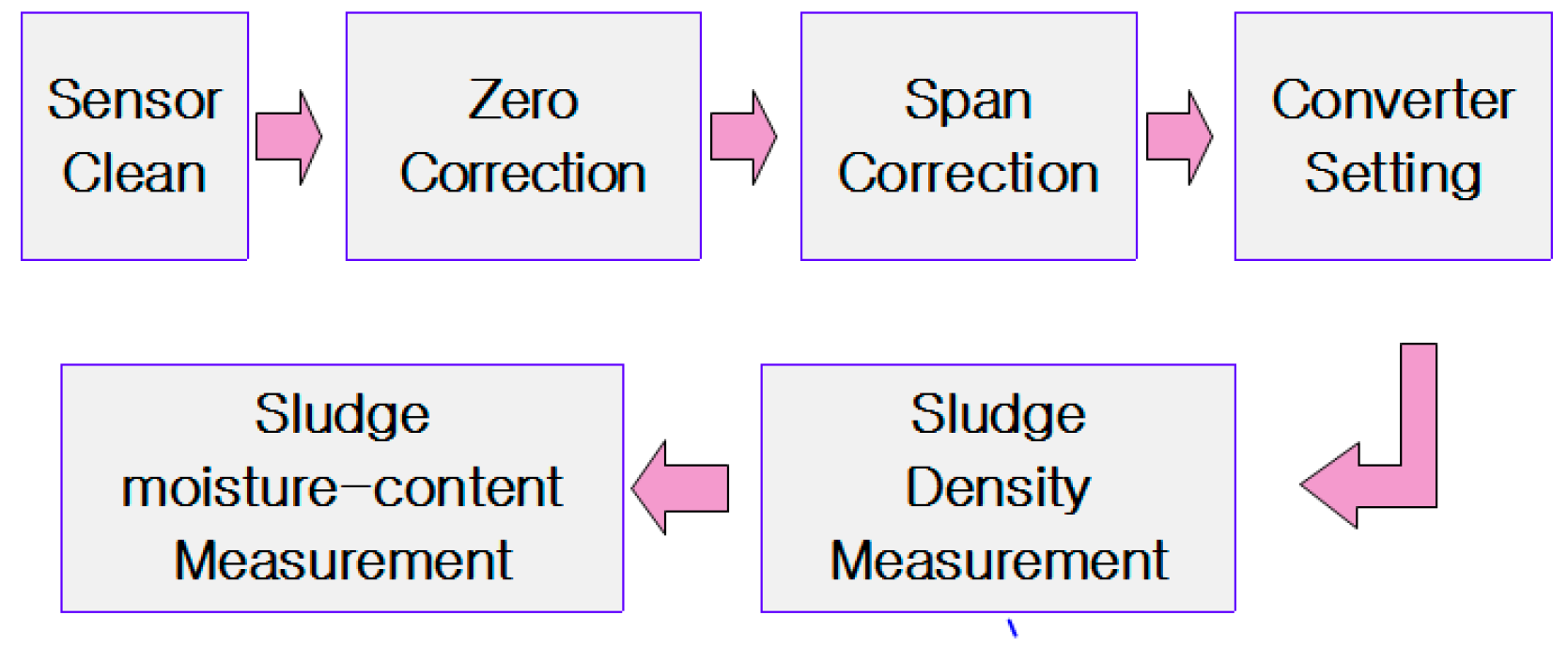

2.5. Design and Function of the Calibration Kit

3. Sludge Density Estimation Algorithm Using Neuro-Fuzzy Method

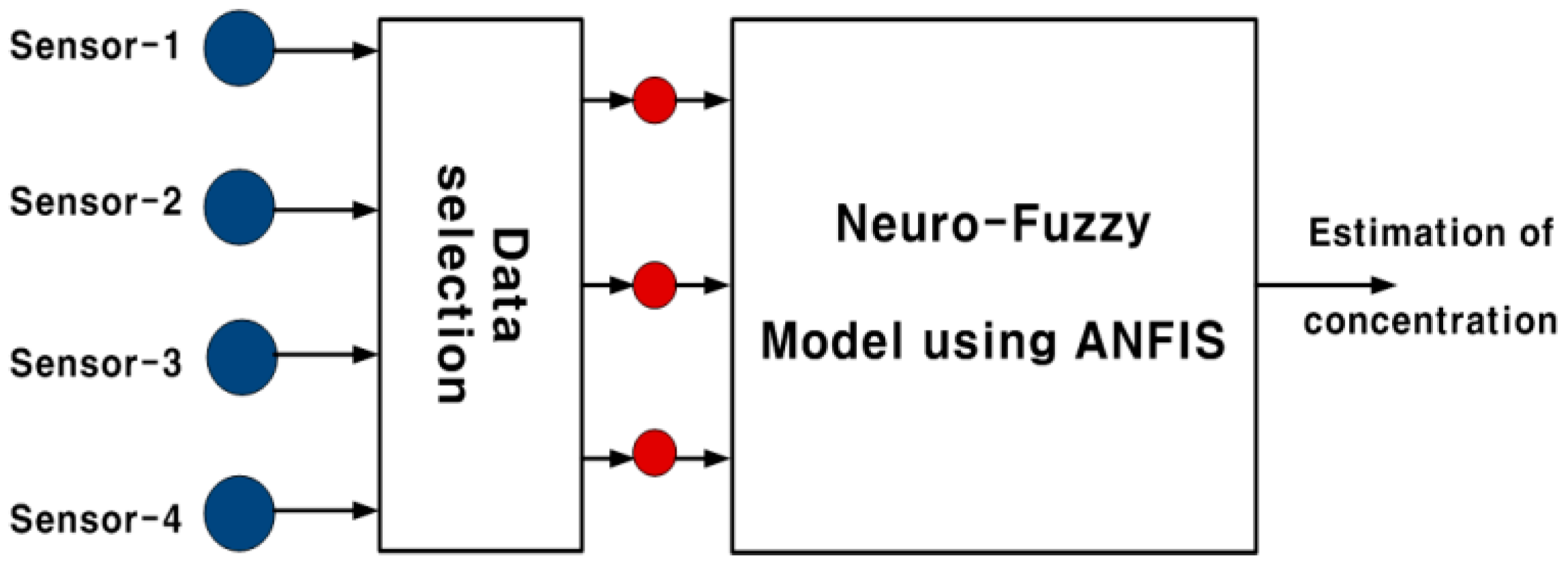

3.1. Data Selection

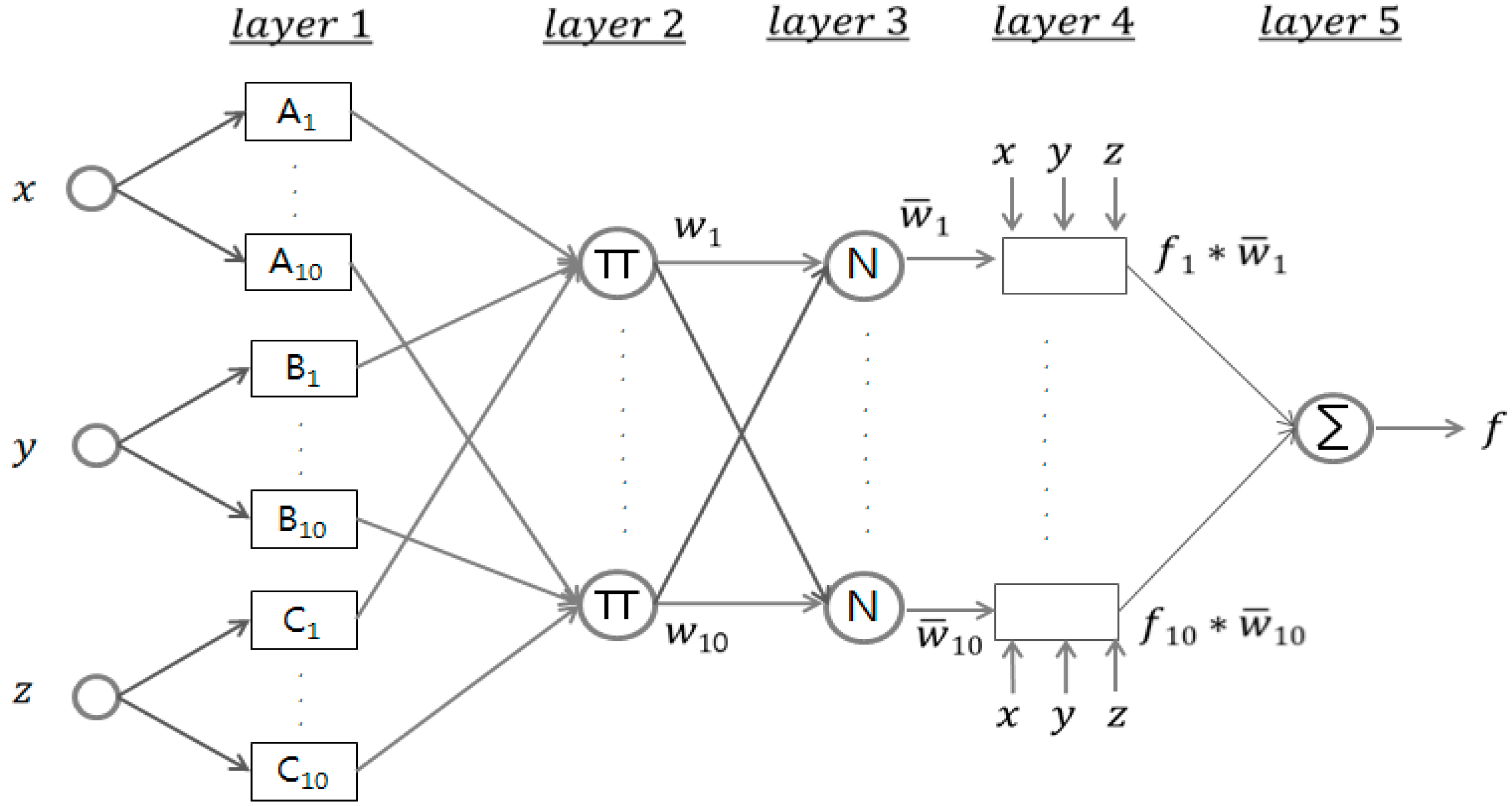

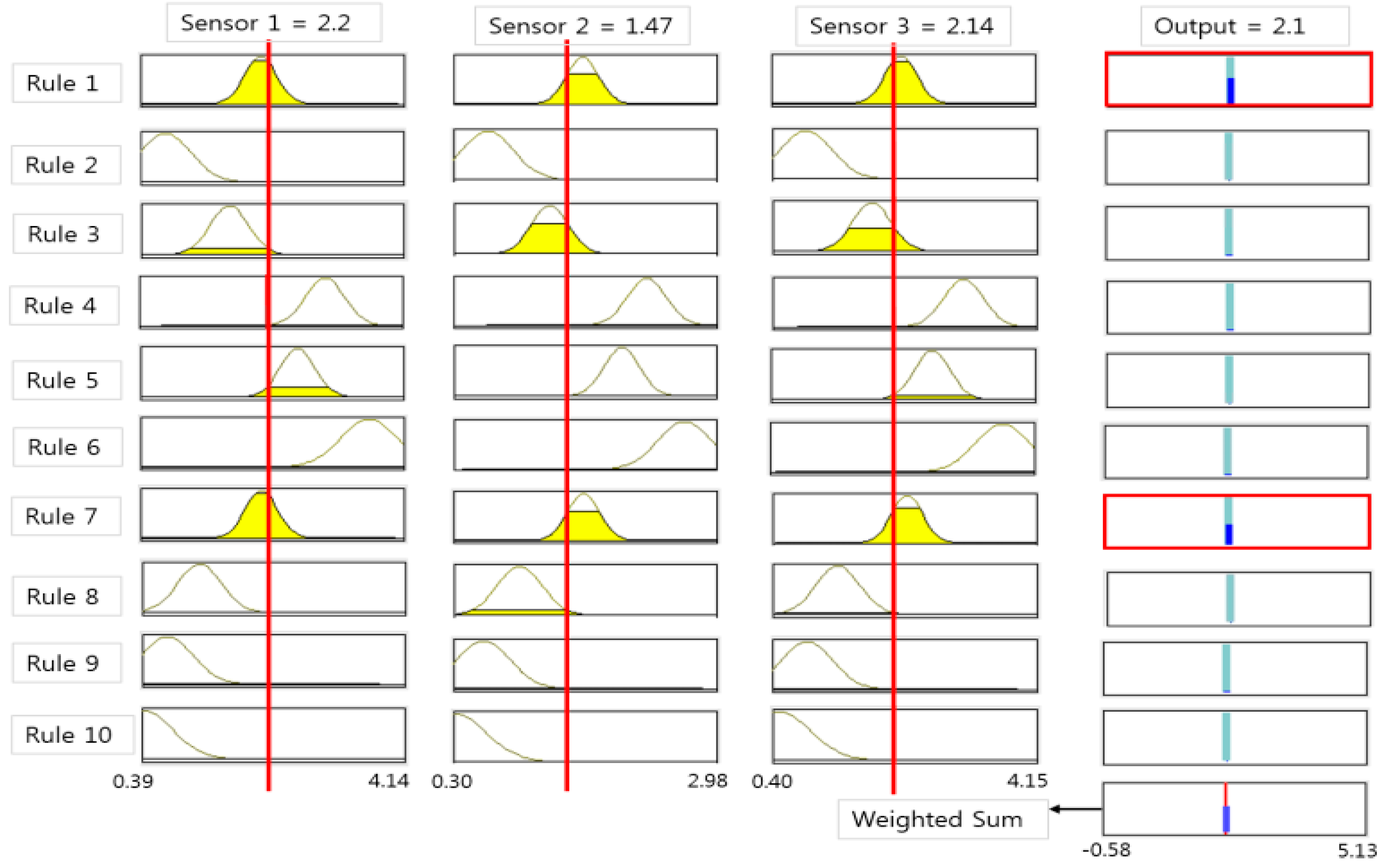

3.2. Neuro Fuzzy Algorithm

4. Experimental Results

4.1. Configuration of the Experimental Device

| Type | Specifications | Remarks |

|---|---|---|

| Sludge Tank | 5 m3 | Capacity |

| Mixer | 0.75 kW | |

| Supply Pump | Inverter 2.2 kW | Sample Circulation |

| Magnetic Flowmeter | 100 A | Velocity measurement |

| Ultrasonic Density meter | 4 CH 100 A | |

| RTU | Cimon | Real Time data logging |

| Electronic Scale | 200 g | ACCULAB |

| Oven | 550 °C | Lab House |

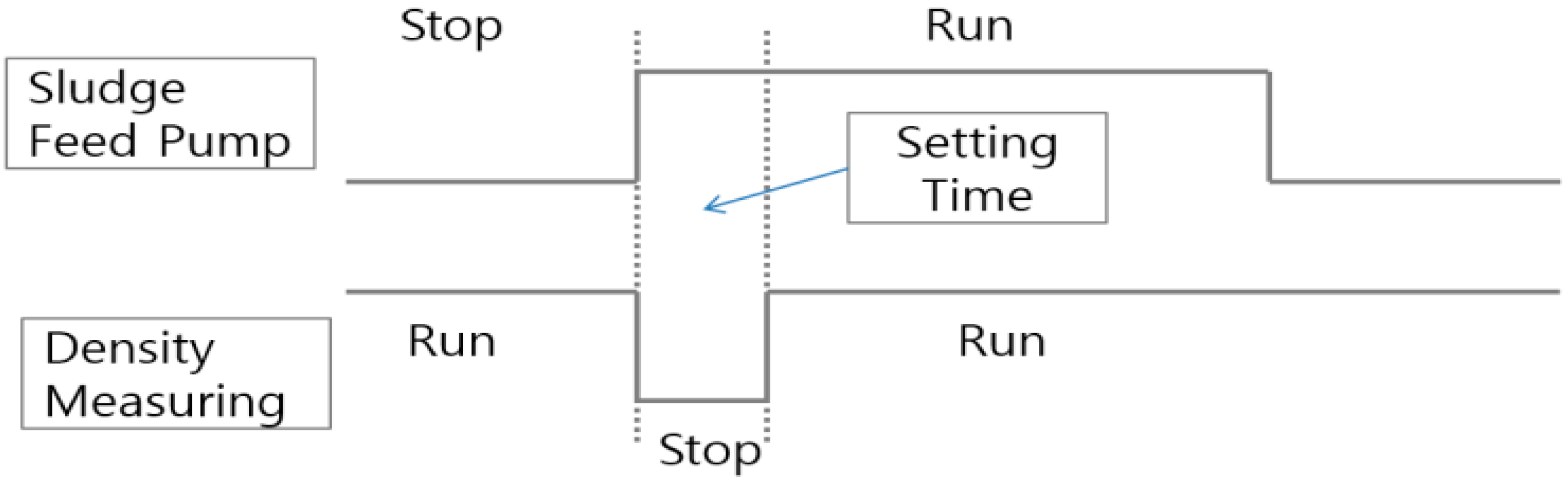

4.2. Experimental Method

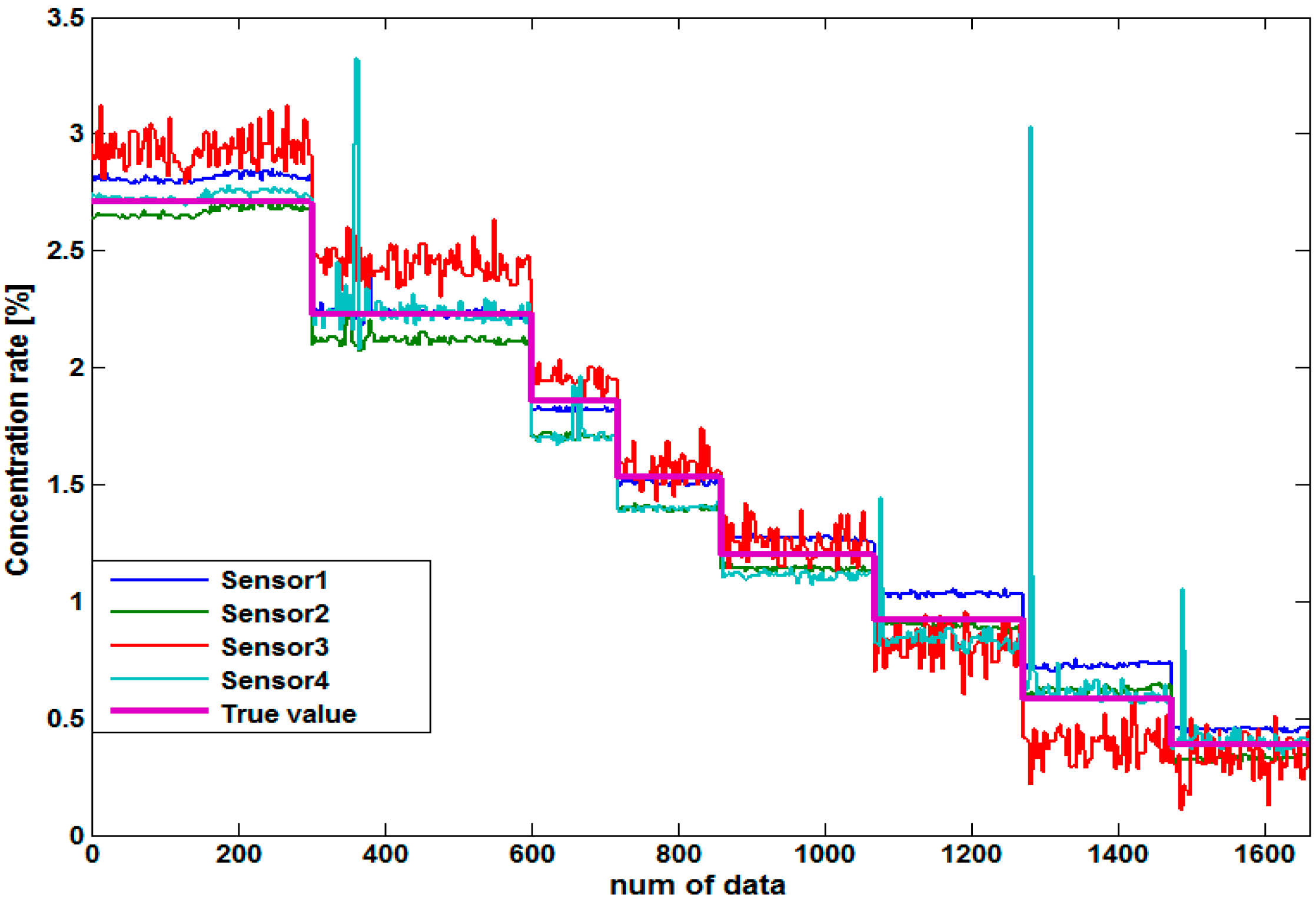

4.3. Experimental Results

| Method | Algorithm |

|---|---|

| Method 1 | Arithmetic mean with four sensors |

| Method 2 | Arithmetic mean with selected three sensors |

| Method 3 | Multiple regression with four sensors |

| Method 4 | Multiple regression with selected three sensors |

| Method 5 | Neuro fuzzy with four sensors |

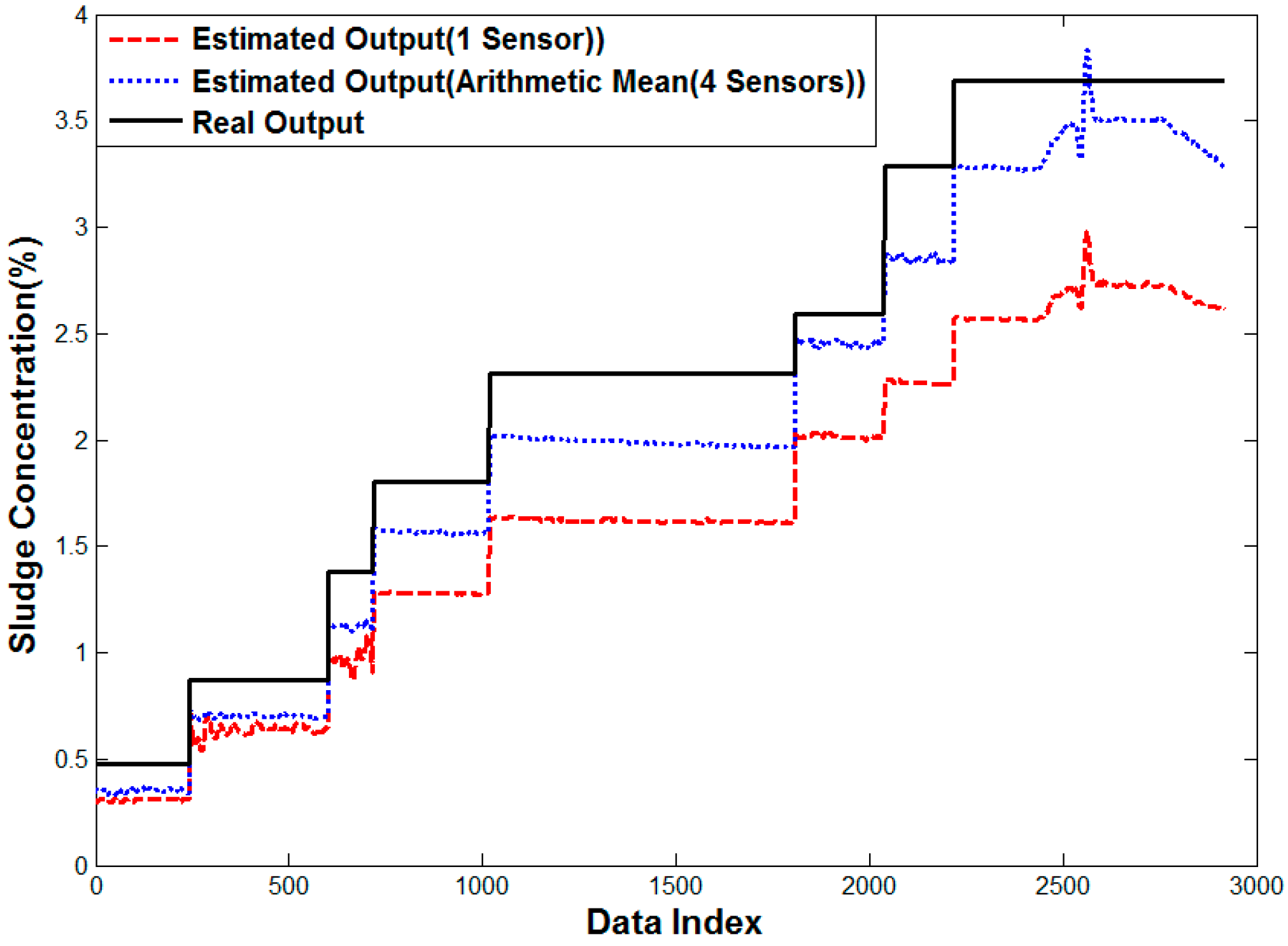

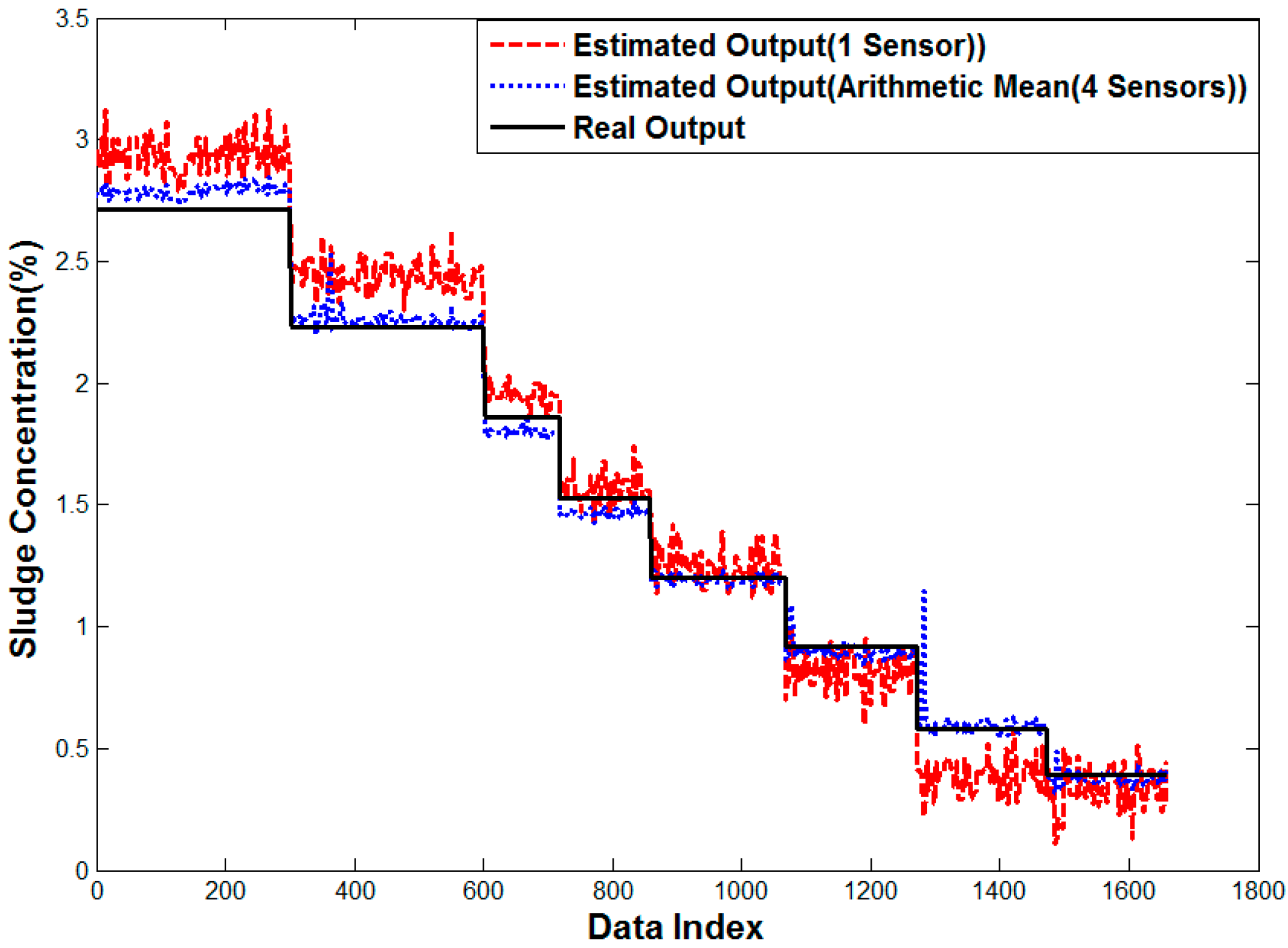

4.3.1. Kaolin Solution Test in the Pilot Plant

| Algorithm | All Data | |||

| MAPE | MAE | RMSE | R-Squared | |

| One Sensor | 28.8819 | 0.6554 | 0.7212 | 0.1164 |

| Method 1 | 13.5682 | 0.2603 | 0.2781 | 0.9239 |

| Method 2 | 8.9533 | 0.1459 | 0.1604 | 0.9783 |

| Algorithm | Training Data | |||

| MAPE | MAE | RMSE | R-Squared | |

| Method 3 | 3.3183 | 0.0638 | 0.0820 | 0.9940 |

| Method 4 | 5.2251 | 0.0817 | 0.1073 | 0.9903 |

| Method 5 | 0.0431 | 0.0003 | 0.0011 | 1.0000 |

| Method 6 | 0.0009 | 0.0001 | 0.0001 | 1.0000 |

| Algorithm | Testing Data | |||

| MAPE | MAE | RMSE | R-Squared | |

| Method 3 | 3.3123 | 0.0637 | 0.0820 | 0.9941 |

| Method 4 | 5.2335 | 0.0815 | 0.1072 | 0.9904 |

| Method 5 | 0.0424 | 0.0003 | 0.0011 | 1.0000 |

| Method 6 | 0.0009 | 0.0001 | 0.0001 | 1.0000 |

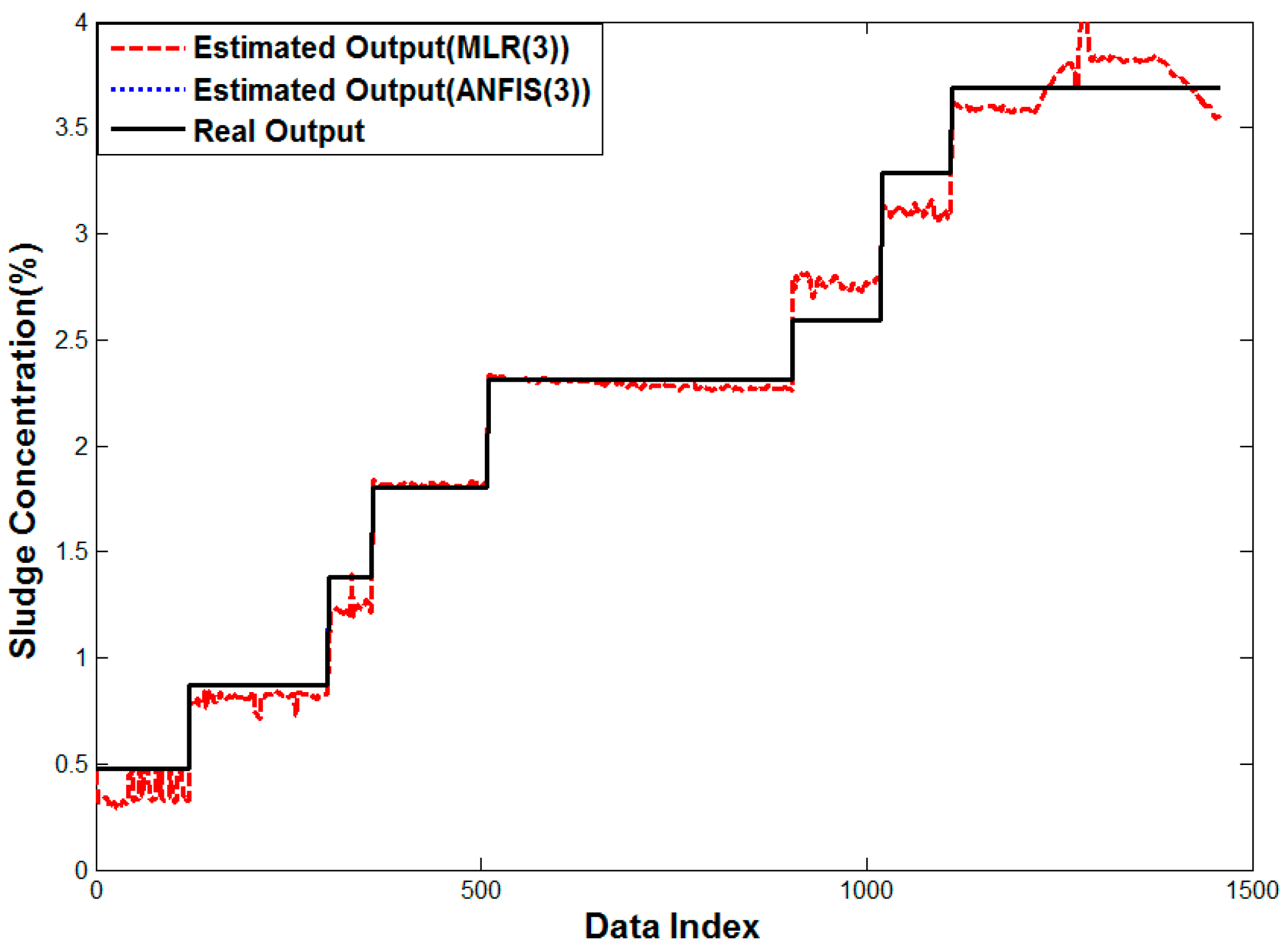

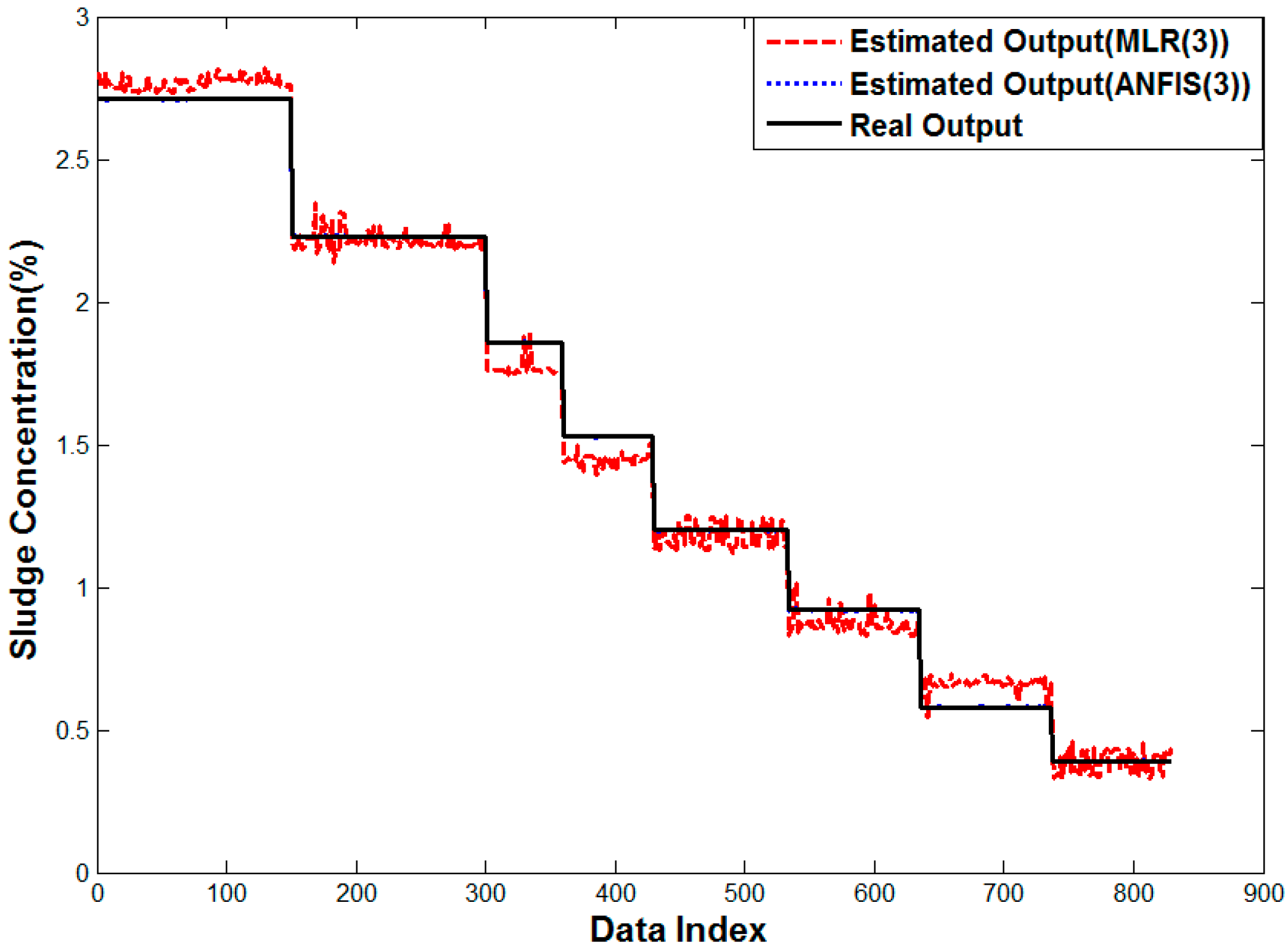

4.3.2. Real Sludge Test in the Pilot Plant

| Algorithm | All Data | ||||

| MAPE | MAE | RMSE | R-Squared | ||

| One Sensor | 12.6388 | 0.1459 | 0.1722 | 0.9677 | |

| Method 1 | 3.1092 | 0.0412 | 0.0573 | 0.9954 | |

| Method 2 | 4.0933 | 0.0453 | 0.0694 | 0.9926 | |

| Algorithm | Training Data | ||||

| MAPE | MAE | RMSE | R-Squared | ||

| Method 3 | 2.5247 | 0.0305 | 0.0385 | 0.9978 | |

| Method 4 | 5.4544 | 0.0560 | 0.0632 | 0.9941 | |

| Method 5 | 0.0271 | 0.0002 | 0.0004 | 1.0000 | |

| Method 6 | 0.0172 | 0.0001 | 0.0003 | 1.0000 | |

| Algorithm | Testing Data | ||||

| MAPE | MAE | RMSE | R-Squared | ||

| Method 3 | 2.5358 | 0.0310 | 0.0388 | 0.9977 | |

| Method 4 | 5.4620 | 0.0553 | 0.0625 | 0.9942 | |

| Method 5 | 0.0276 | 0.0002 | 0.0004 | 1.0000 | |

| Method 6 | 0.0159 | 0.0001 | 0.0003 | 1.0000 | |

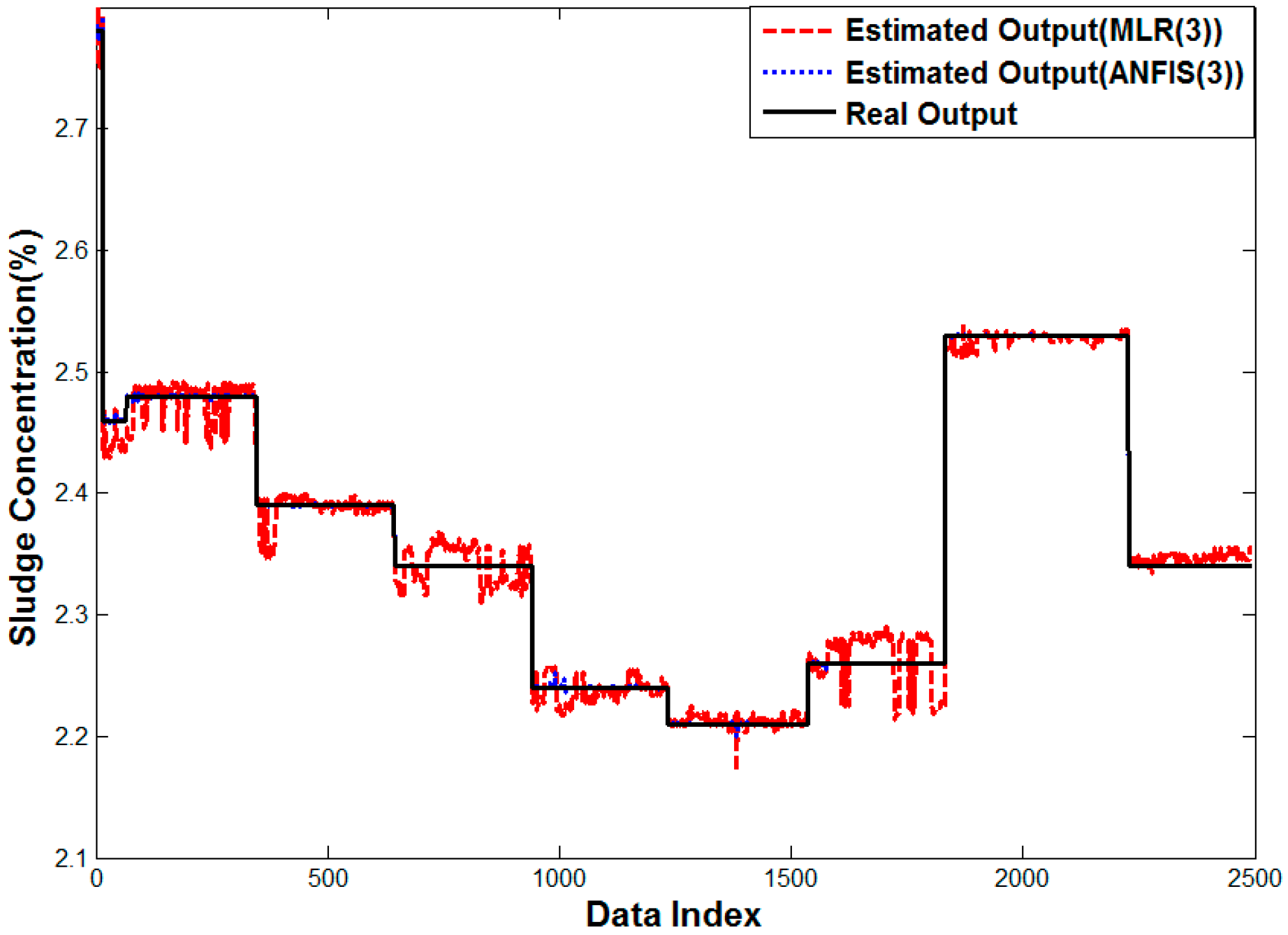

4.3.3. Real Sludge Test in a Real Water Treatment Plant

| Algorithm | All Data | |||

| MAPE | MAE | RMSE | R-Squared | |

| One Sensor | 2.7421 | 0.0638 | 0.0696 | 0.5204 |

| Method 1 | 0.6932 | 0.0161 | 0.0176 | 0.9748 |

| Method 2 | 0.0962 | 0.0023 | 0.0027 | 0.9994 |

| Algorithm | Training Data | |||

| MAPE | MAE | RMSE | R-Squared | |

| Method 3 | 0.0984 | 0.0023 | 0.0027 | 0.9994 |

| Method 4 | 0.4288 | 0.0100 | 0.0138 | 0.9852 |

| Method 5 | 0.0221 | 0.0006 | 0.0012 | 0.9999 |

| Method 6 | 0.0191 | 0.0005 | 0.0012 | 0.9999 |

| Algorithm | Testing Data | |||

| MAPE | MAE | RMSE | R-Squared | |

| Method 3 | 0.0974 | 0.0023 | 0.0027 | 0.9994 |

| Method 4 | 0.4240 | 0.0099 | 0.0137 | 0.9856 |

| Method 5 | 0.0224 | 0.0006 | 0.0012 | 0.9999 |

| Method 6 | 0.0190 | 0.0005 | 0.0011 | 0.9999 |

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Kawamura, S. Integrated Design and Operation of Water Treatment Facilities, 2nd ed.; Wiley: New York, NY, USA, 2003. [Google Scholar]

- Panter, K. Comparison of Centrifuge and Belt Press for Compressible Digested After Thermal Hydrolysis. Proc. Water Environ. Fed. 2009, 2009, 6220–6229. [Google Scholar] [CrossRef]

- Sun, F.; Hu, W.R.; Pei, H.Y.; Li, X.Q.; Xu, X.C.; Ma, C.X. Evaluation on the dewatering process of cyanobacteria-containing AlCl3 and PACl drinking water sludge. Sep. Purif. Technol. 2015, 150, 52–62. [Google Scholar] [CrossRef]

- Sun, Y.; Fan, W.; Zheng, H.; Zhang, Y.; Li, F.; Chen, W. Evaluation of Dewatering Performance and Fractal Characteristics of Alum Sludge. PLoS ONE 2015, 10. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, S. New type of sludge density meter using microwaves for application in sewage treatment plants. Water Sci. Technol. 1996, 33, 53–60. [Google Scholar] [CrossRef]

- Baek, S.S.; Park, Y.O.; Ban, J.H. Study on optimal operation of residual treatment process automation. J. Korea Soc. Fluid Mach. 2008, 20, 77–81. [Google Scholar]

- Lee, J.K.; Lee, K.G. Prediction of two-phase taylor flow characteristics in a rectangular micro channel. Trans. Korean Soc. Mech. Eng. 2015, 39, 557–566. [Google Scholar] [CrossRef]

- Nuryadin, S.; Ignacazk, M.; Lucas, D. On the accuracy of wire mesh sensors in dependence of bubble sizes and liquid flow rates. Exp. Therm. Fluid Sci. 2015, 65, 73–81. [Google Scholar] [CrossRef]

- Jang, J.S.R. ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Lee, H.H.; Jang, S.B.; Hong, S.T.; Chun, M.G. Intelligent Controller for Constant Control of Residual Chlorine in Water Treatment Process. Int. J. Fuzzy Intell. Syst. 2014, 24, 147–154. [Google Scholar] [CrossRef]

- Lei, Y.G.; Lin, J.; He, Z.J.; Kong, D.T. A Method Based on Multi-Sensor Data Fusion for Falut Detection of Planetary Gearboxes. Sensors 2012, 12, 2005–2017. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.G.; He, Z.J.; Zi, Y.Y. A new approach to intelligent fault diagnosis of rotating machinery. Expert Syst. Appl. 2008, 35, 1593–1600. [Google Scholar] [CrossRef]

- Jang, J.; Sun, C.; Mizutani, E. Neuro-Fuzzy and Soft Computing; Prentice-Hall Inc.: Upper Saddle River, NJ, USA, 1997. [Google Scholar]

- Wang, B.H. Short-Term Electrical Load Forecasting Using Neuro-Fuzzy Model with Error Compensation. Int. J. Fuzzy Intell. Syst. 2009, 9, 327–332. [Google Scholar] [CrossRef]

- Park, J.I.; Cho, J.H.; Chun, M.G.; Song, C.K. Neuro-Fuzzy Rule Generation for Backing up Navigation of Car-like Mobile Robots. Int. J. Fuzzy Syst. 2009, 11, 192–201. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.-H.; Jang, S.-B.; Shin, G.-W.; Hong, S.-T.; Lee, D.-J.; Chun, M.G. An Ultrasonic Multi-Beam Concentration Meter with a Neuro-Fuzzy Algorithm for Water Treatment Plants. Sensors 2015, 15, 26961-26977. https://doi.org/10.3390/s151026961

Lee H-H, Jang S-B, Shin G-W, Hong S-T, Lee D-J, Chun MG. An Ultrasonic Multi-Beam Concentration Meter with a Neuro-Fuzzy Algorithm for Water Treatment Plants. Sensors. 2015; 15(10):26961-26977. https://doi.org/10.3390/s151026961

Chicago/Turabian StyleLee, Ho-Hyun, Sang-Bok Jang, Gang-Wook Shin, Sung-Taek Hong, Dae-Jong Lee, and Myung Geun Chun. 2015. "An Ultrasonic Multi-Beam Concentration Meter with a Neuro-Fuzzy Algorithm for Water Treatment Plants" Sensors 15, no. 10: 26961-26977. https://doi.org/10.3390/s151026961

APA StyleLee, H.-H., Jang, S.-B., Shin, G.-W., Hong, S.-T., Lee, D.-J., & Chun, M. G. (2015). An Ultrasonic Multi-Beam Concentration Meter with a Neuro-Fuzzy Algorithm for Water Treatment Plants. Sensors, 15(10), 26961-26977. https://doi.org/10.3390/s151026961