Experimental Validation of Normalized Uniform Load Surface Curvature Method for Damage Localization

Abstract

:1. Introduction

2. Theory

2.1. Uniform Load Surface (ULS) Method

2.2. ULS Curvature Method

2.3. Normalized Uniform Load Surface (NULS) Curvature Method

2.4. Damage Localization by NULS Curvature Method under Noisy Measurements

3. Experimental Validation of the NULS Curvature Method

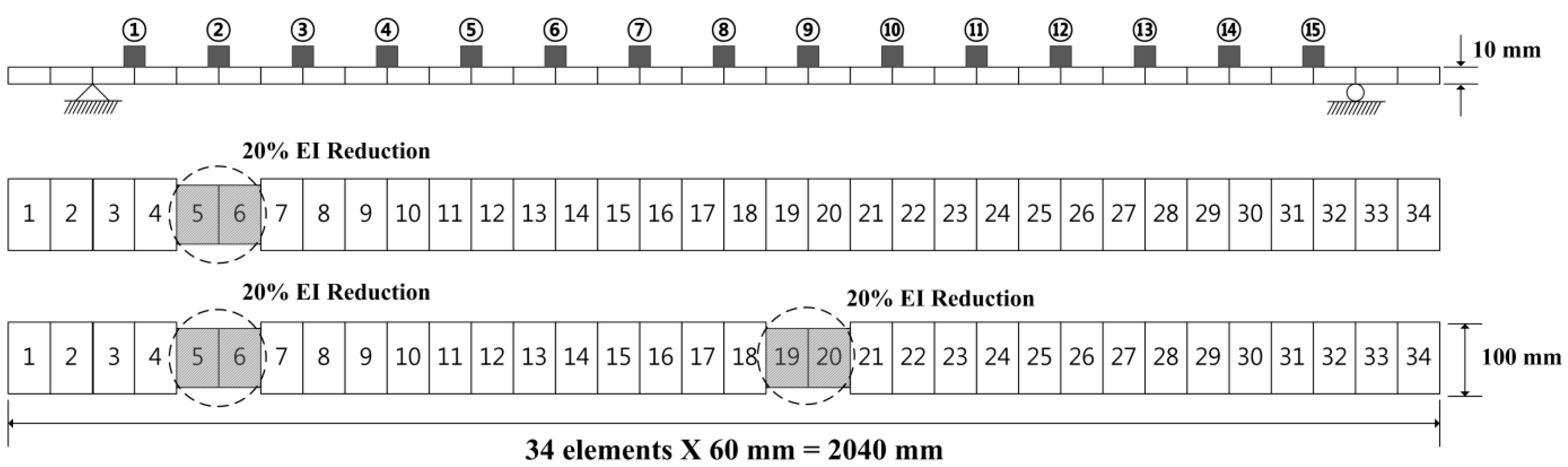

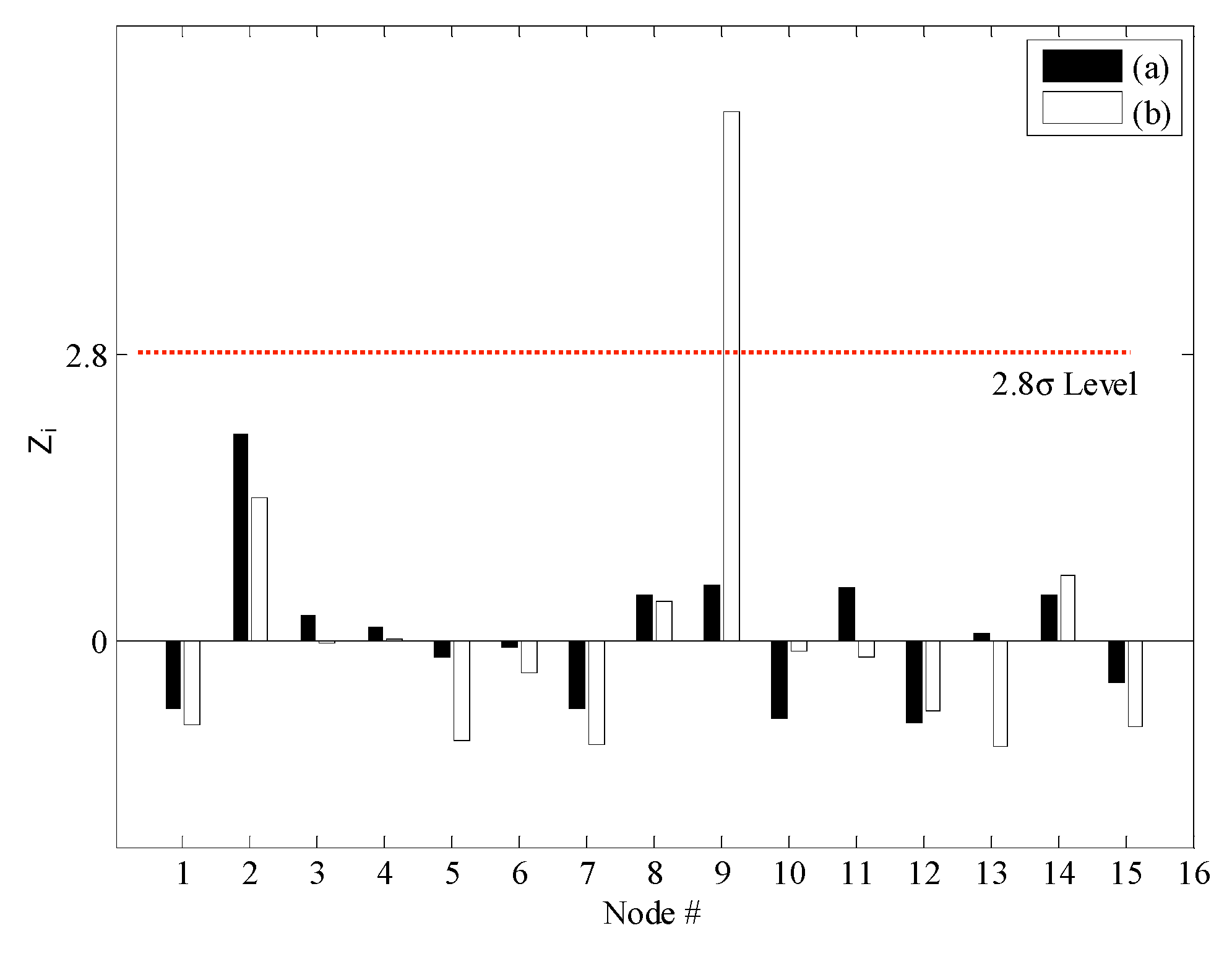

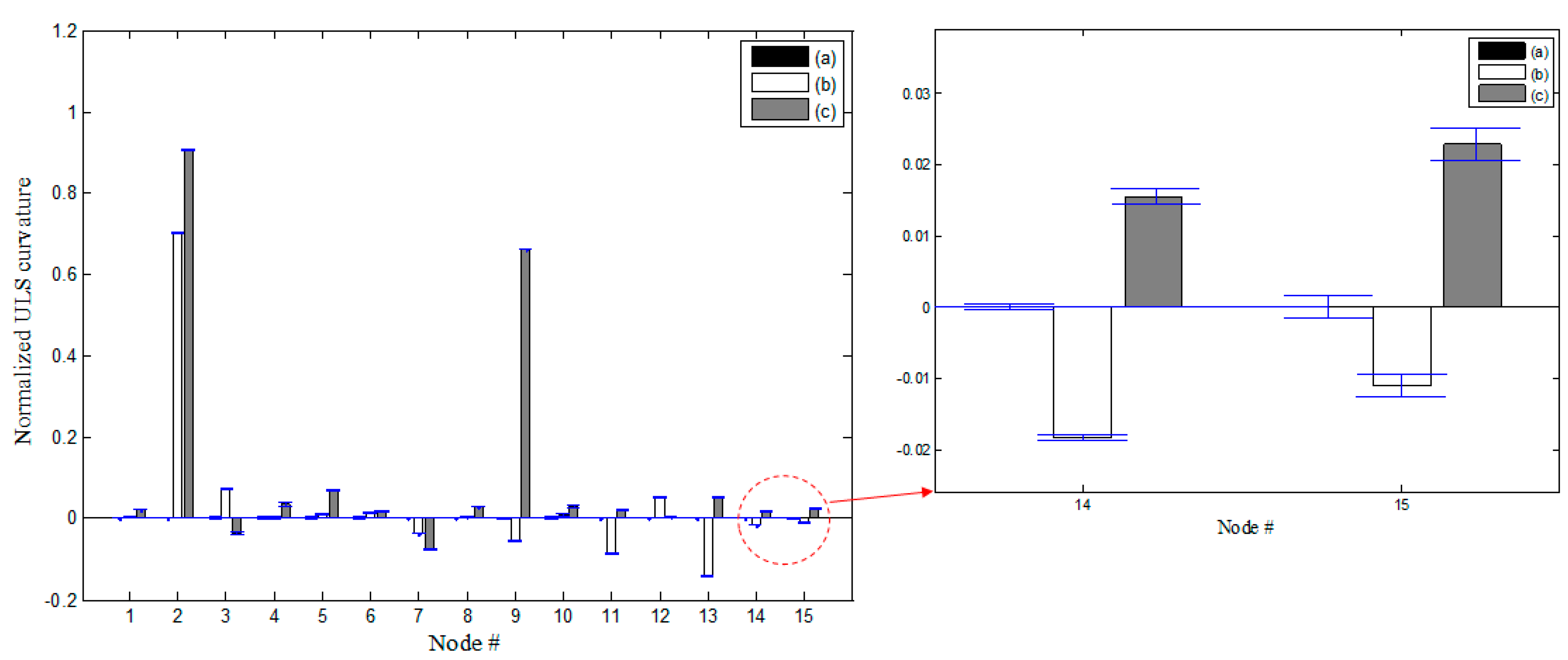

3.1. Numerical Simulations as a Preliminary Step

| Parameters | Value |

|---|---|

| Damping ratio | 0.005 |

| Mass density () | 7850 kg m−3 |

| Poisson’s ratio () | 0.28 |

| Elasticity modulus (E) | 200 GPa |

| Length (L) | 2.04 m |

| Width (w) | 100 mm |

| Thickness (t) | 10 mm |

| Case | First Mode | Second Mode | ||||

|---|---|---|---|---|---|---|

| f1 (Hz) | Δ f1/f1 (%) | MAC | f2 (Hz) | Δ f2/f2 (%) | MAC | |

| IC | 6.1018 | - | 1.0000 | 24.273 | - | 1.0000 |

| DC1 | 6.0979 | −0.064% | 0.9999 | 24.217 | −0.230% | 0.9999 |

| DC2 | 6.0619 | −0.654% | 0.9999 | 24.193 | −0.328% | 0.9999 |

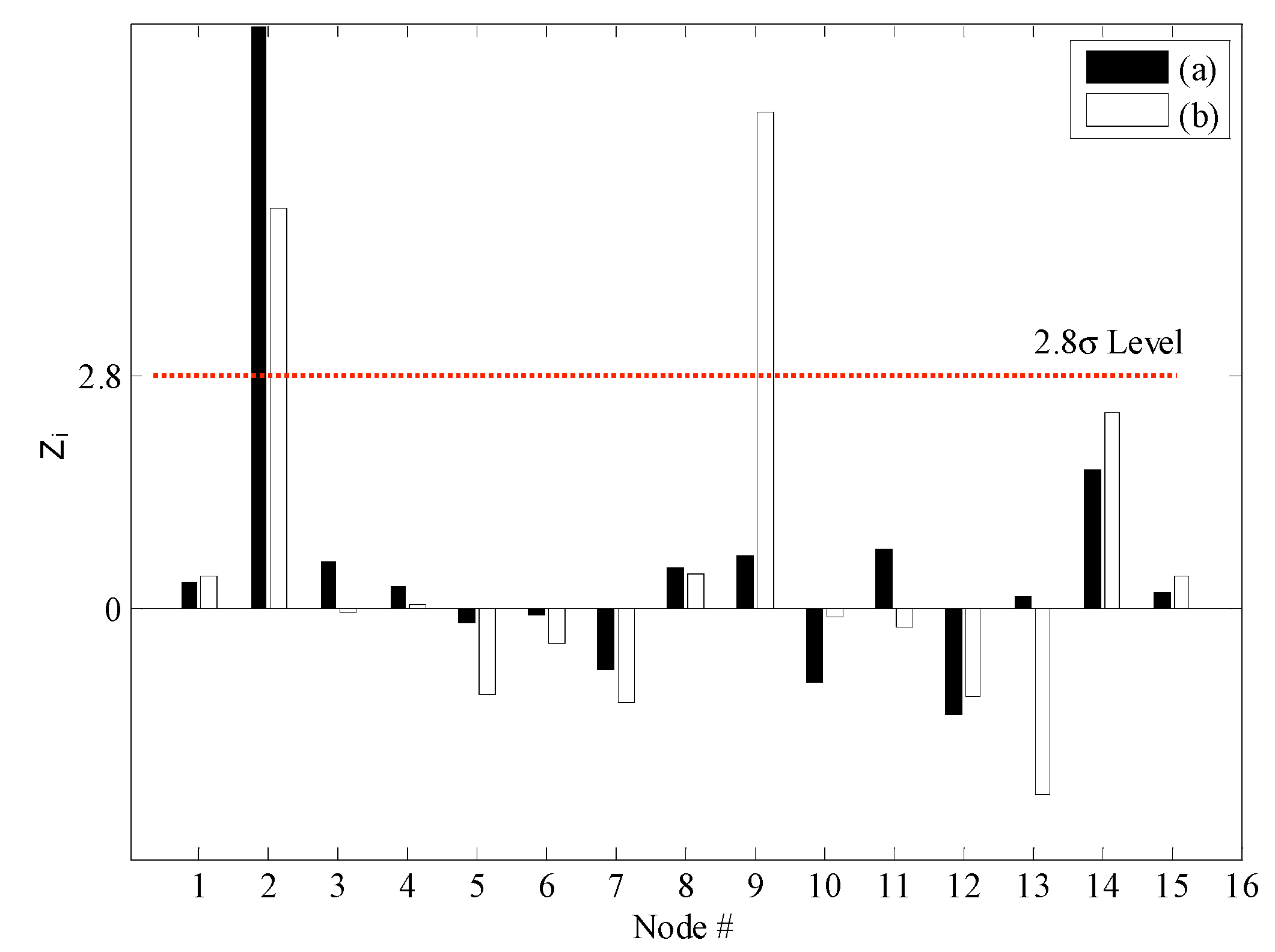

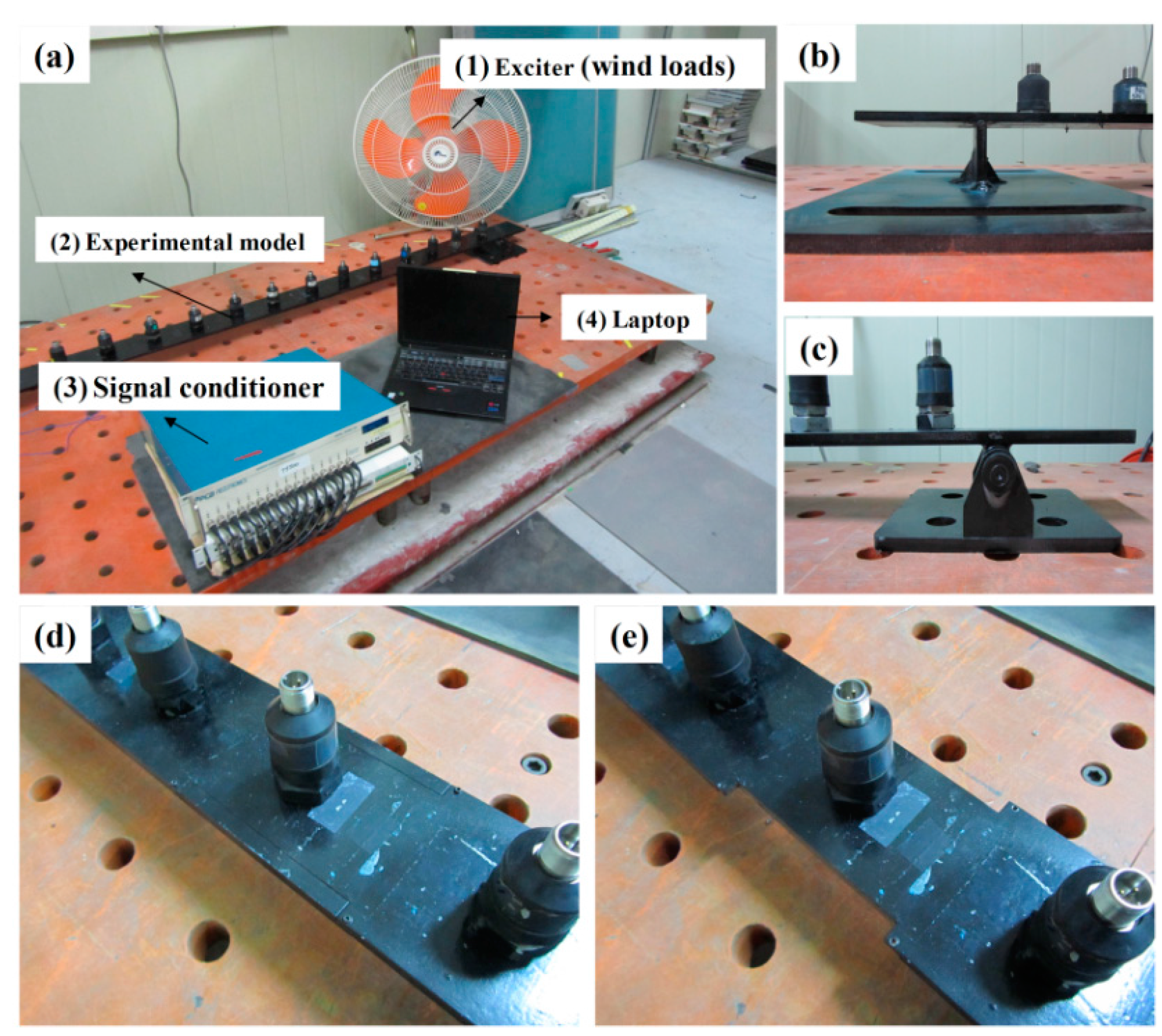

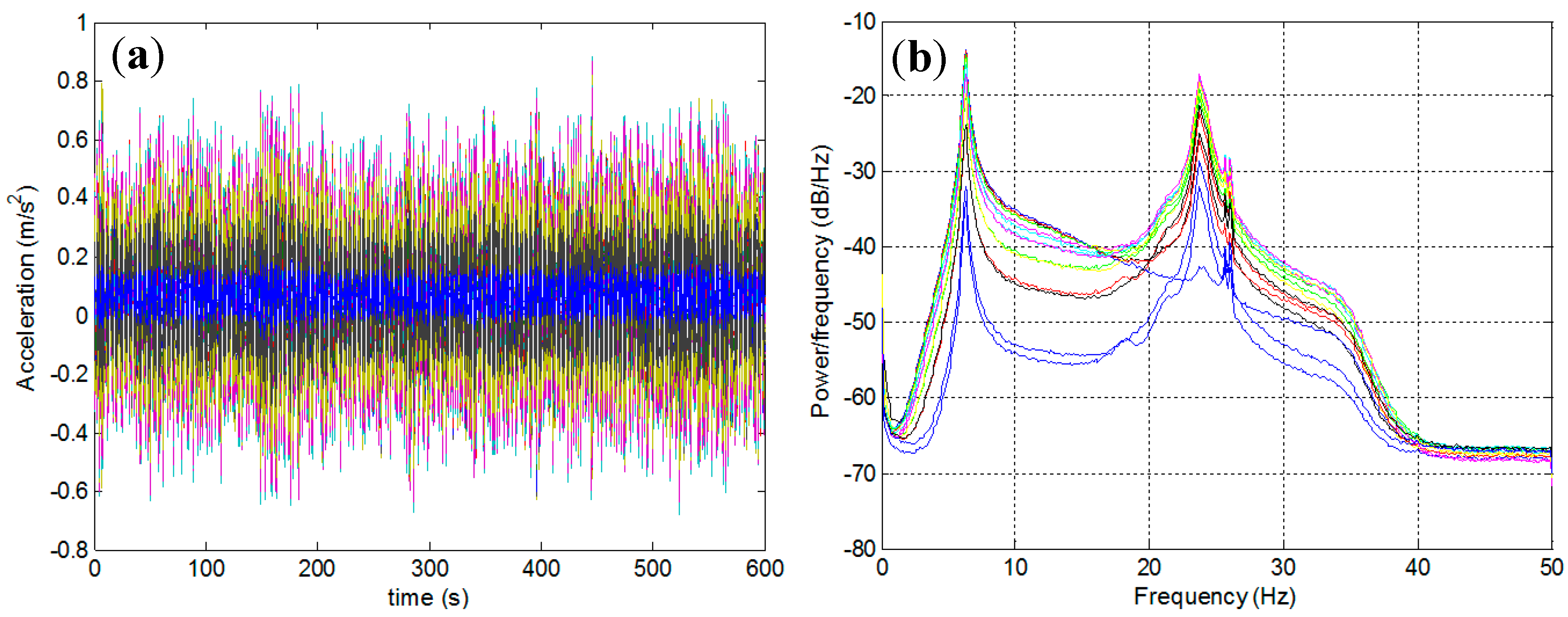

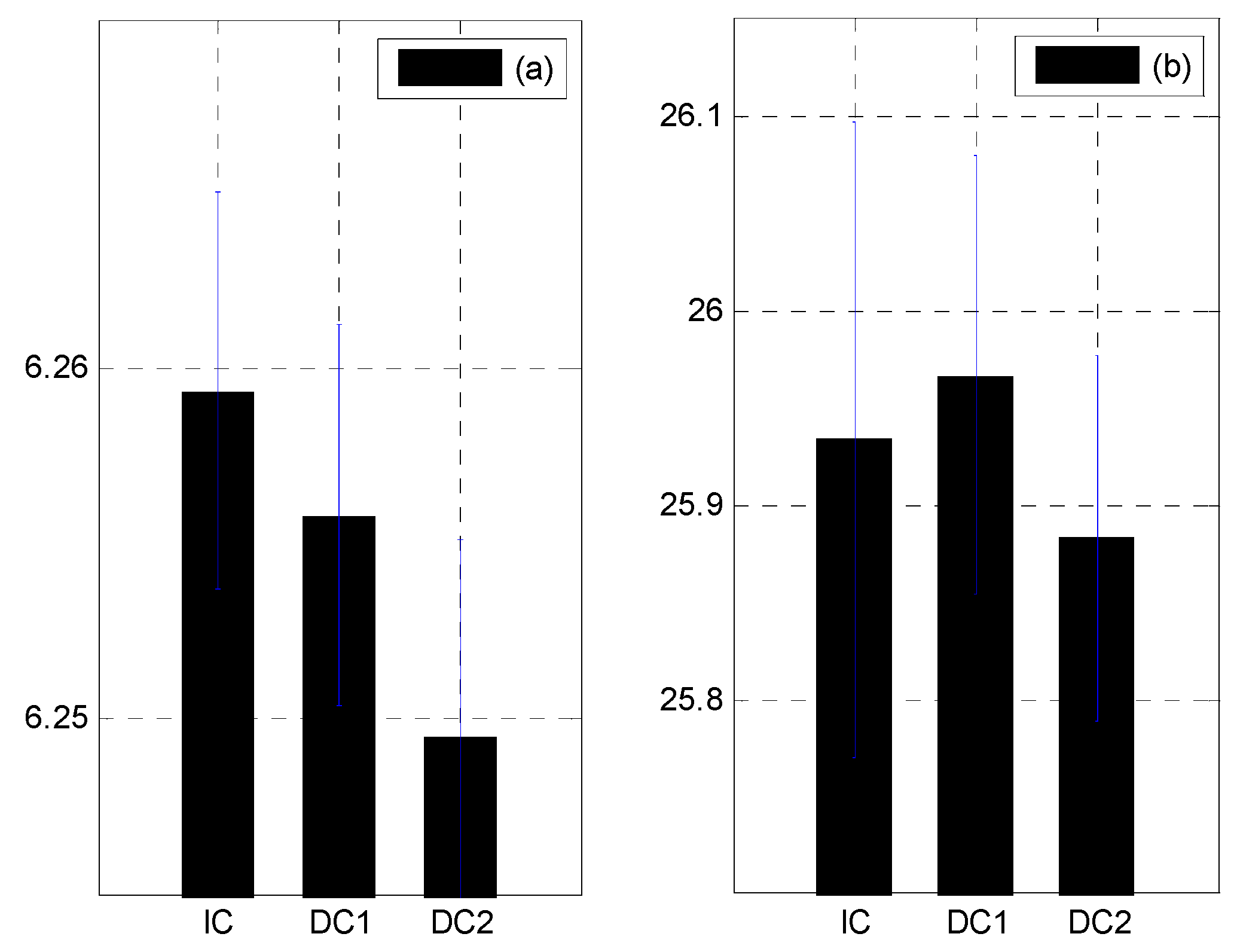

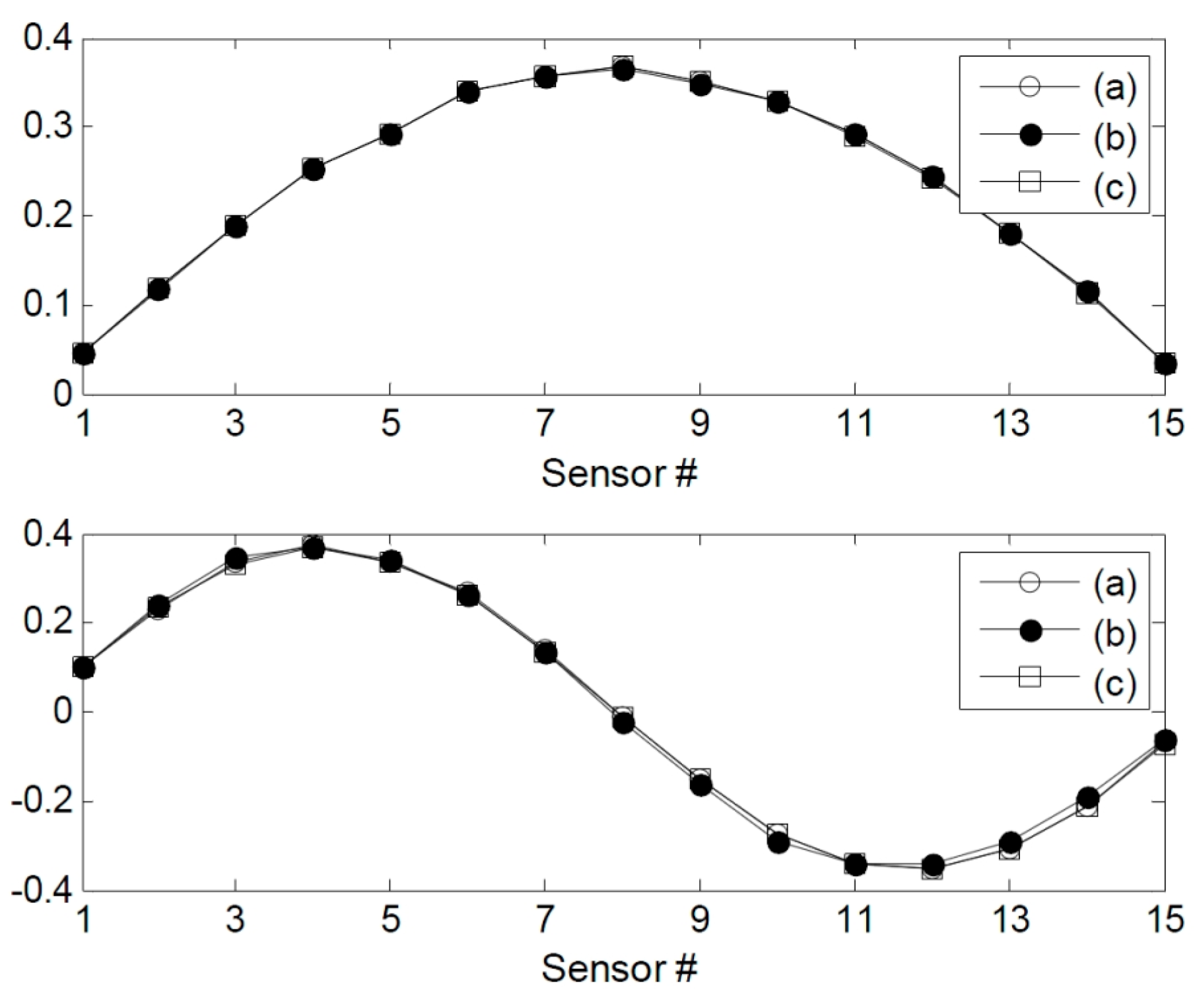

3.2. Experimental Results

| Case | First Mode | Second Mode | ||||

|---|---|---|---|---|---|---|

| f1 (Hz) | Δ f1/f1 (%) | MAC | f2 (Hz) | Δ f2/f2 (%) | MAC | |

| IC | 6.2593 | - | 1.0000 | 25.934 | - | 1.0000 |

| DC1 | 6.2558 | −0.0567% | 0.9999 | 25.967 | 0.1273% | 0.9992 |

| DC2 | 6.2495 | −0.1580% | 0.9999 | 25.883 | −0.1960% | 0.9999 |

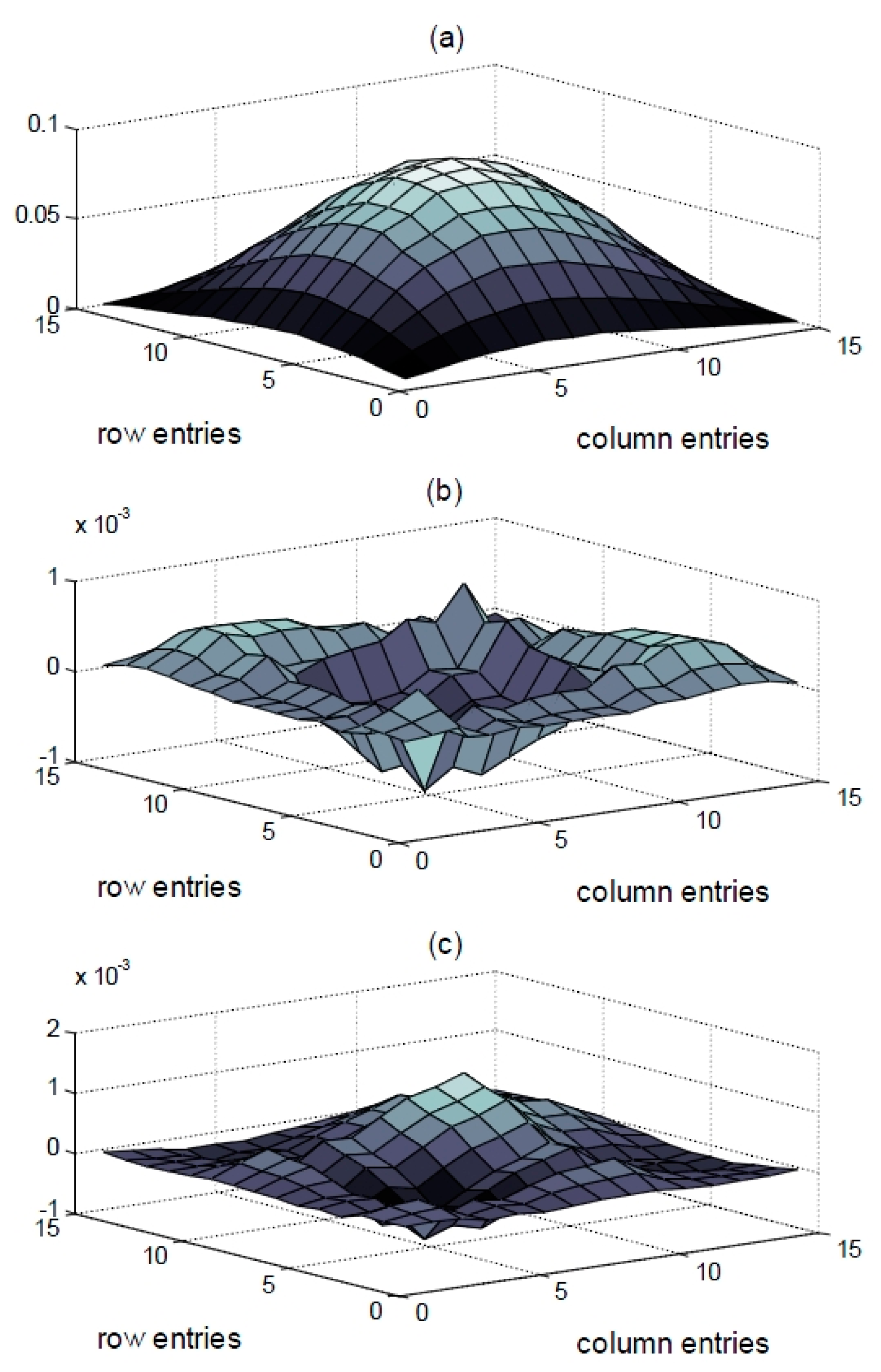

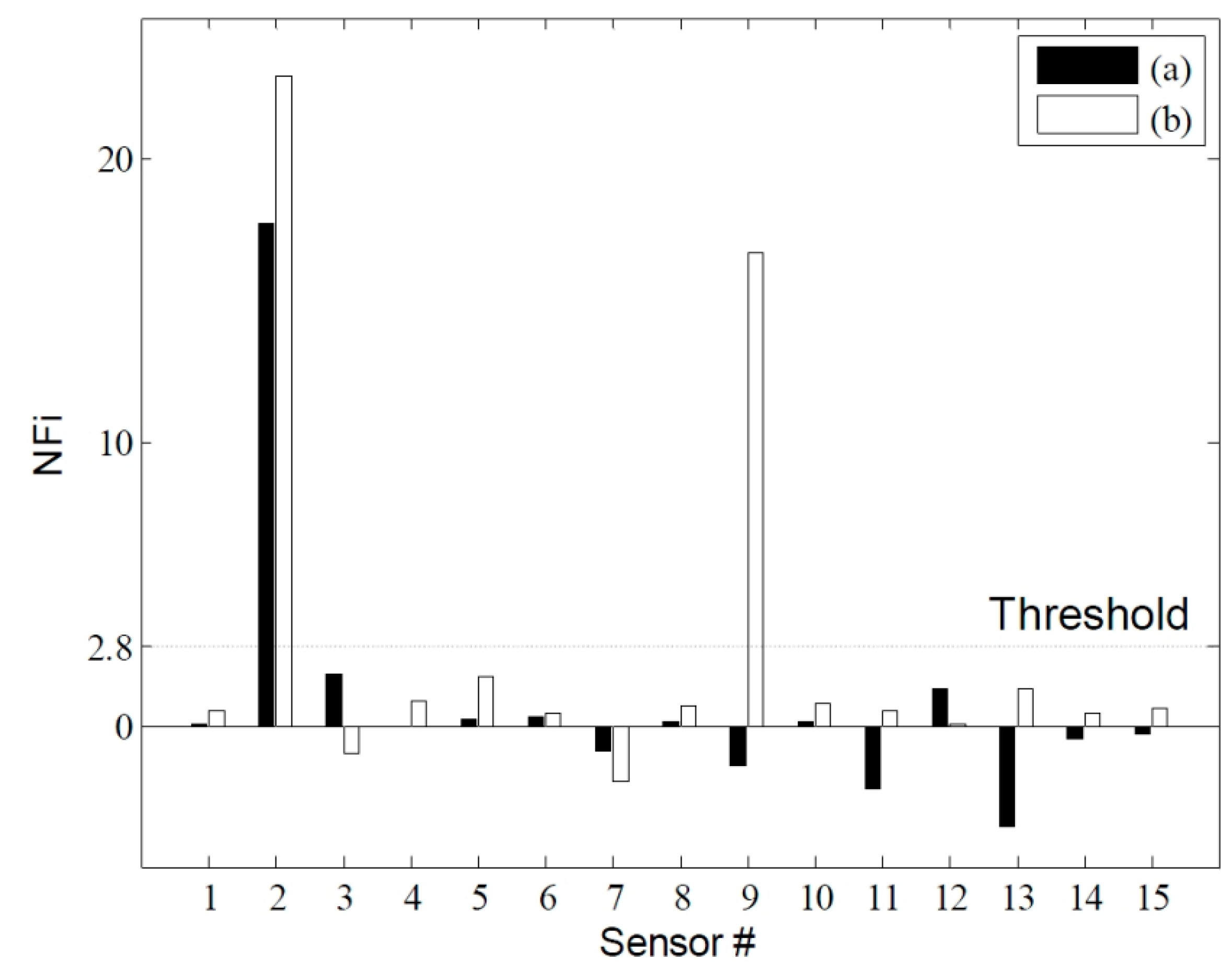

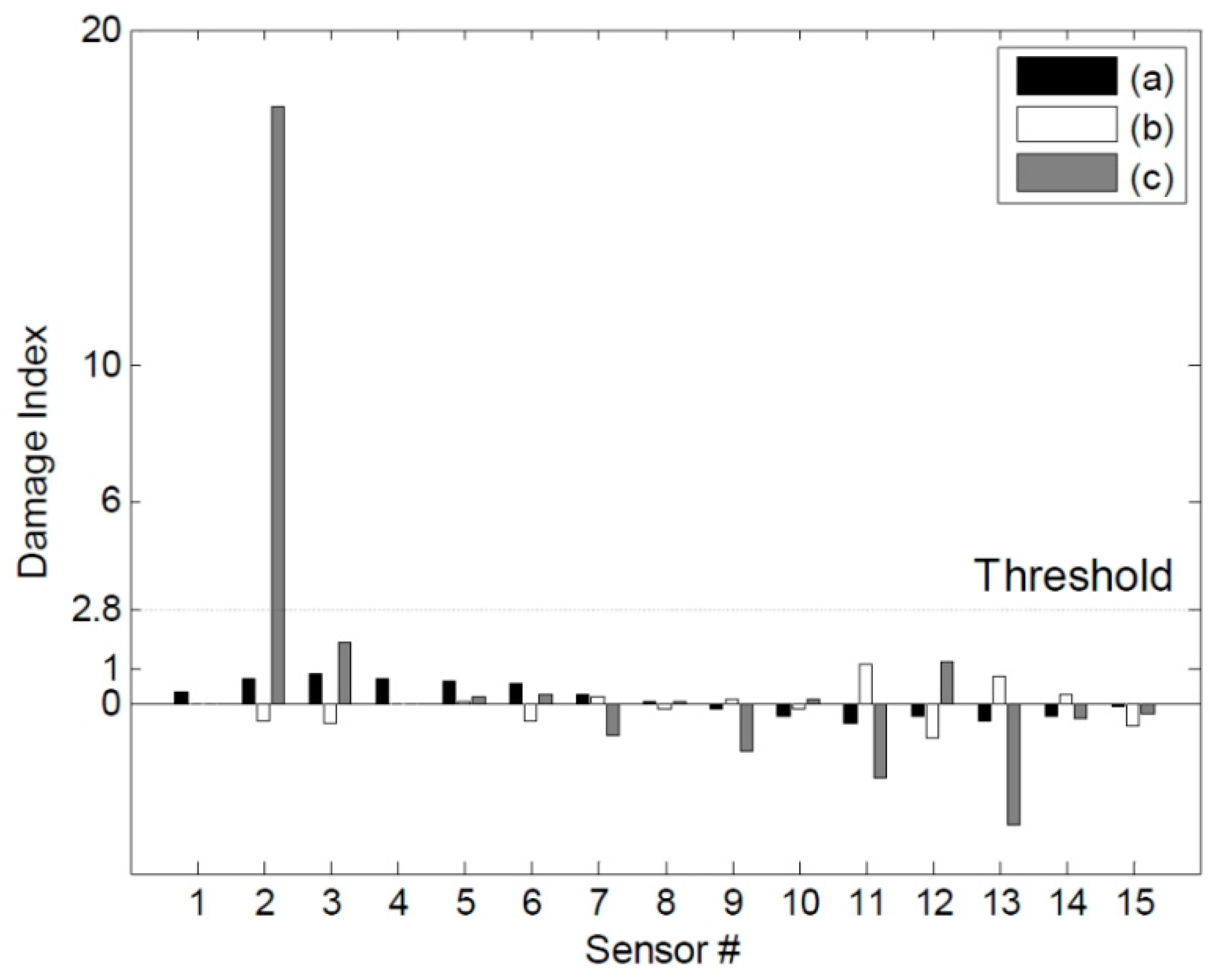

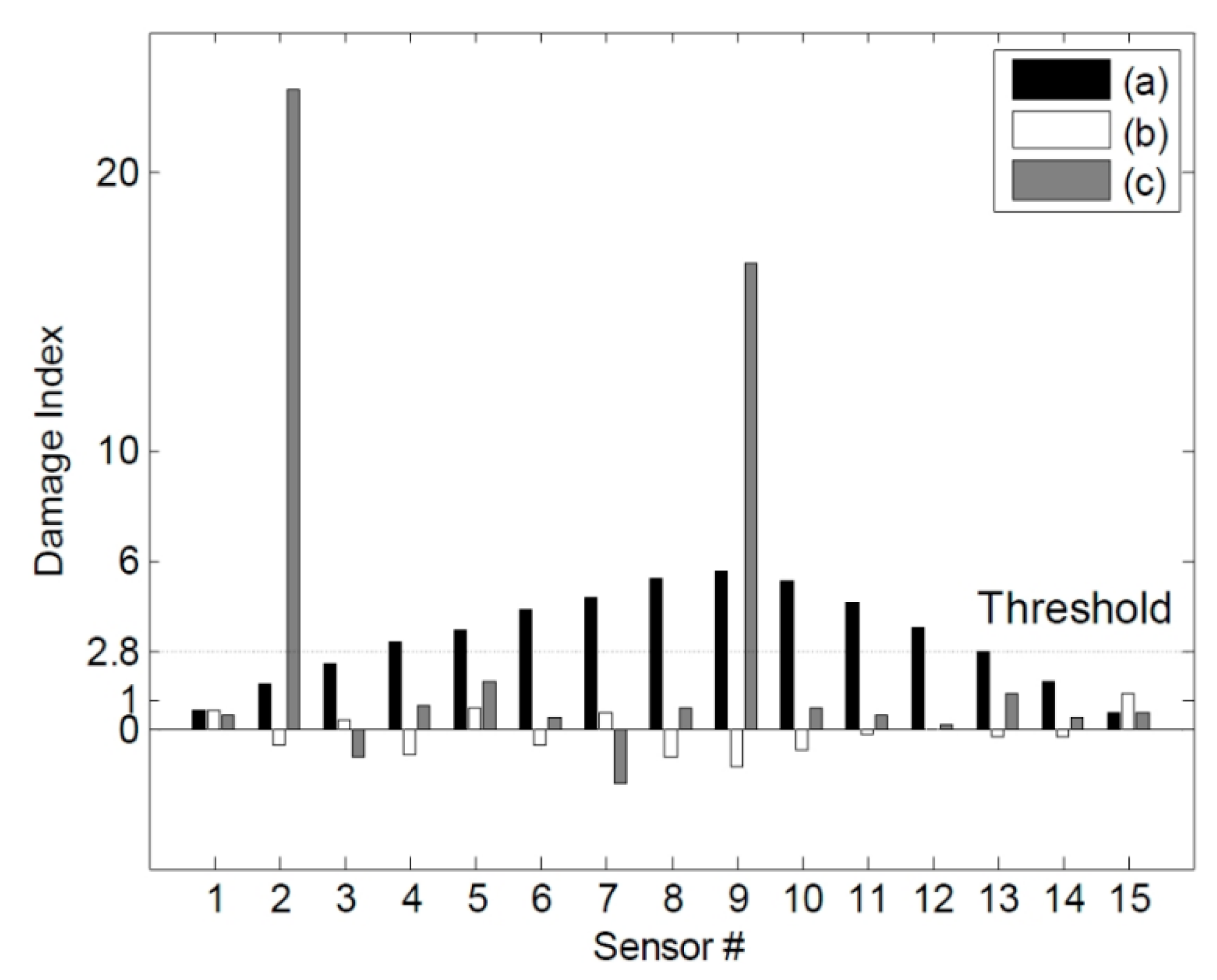

3.3. Comparative Study

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nagarajaiah, S. Adaptive passive, semiactive, smart tuned mass damper: Identification and control using empirical mode decomposition, Hilbert transform, and short-time Fourier transform. Struct. Control Health Monit. 2009, 16, 800–841. [Google Scholar] [CrossRef]

- Nagarajaiah, S.; Basu, B. Output only identification and structural damage detection using time frequency and wavelet techniques. Earthq. Eng. Eng. Vib. 2009, 8, 583–605. [Google Scholar] [CrossRef]

- Worden, K.; Manson, G.; Allman, D.J. Experimental validation of structural health monitoring methodology I: novelty detection on a laboratory structure. J. Sound Vib. 2003, 259, 323–343. [Google Scholar] [CrossRef]

- Yang, Y.; Nagarajaiah, S. Time-Frequency Blind Source Separation Using Independent Component Analysis for Output-Only Modal Identification of Highly Damped Structures. J. Struct. Eng. 2013, 139, 1780–1793. [Google Scholar] [CrossRef]

- Doebling, S.W.; Farrar, C.R.; Prime, M.B.; Shevitz, D.W. Damage Identification and Health Monitoring of Structural and Mechanical Systems from Changes in Their Vibration Characteristics: A literature Review; Technical Report LA-13070-MS; Los Alamos, NM, USA, May 1996. [Google Scholar]

- Sohn, H.; Farrar, C.R.; Hemez, F.M.; Shunk, D.D.; Stinemates, D.W.; Nadler, B.R.; Czarnecki, J.J. A Review of Structural Health Monitoring Literature: 1996–2001; Technical Report LA-13976-MS; Los Alamos National Laboratory: Los Alamos, NM, USA, February 2004. [Google Scholar]

- Fan, W.; Qiao, P. Vibration-based damage identification methods: A review and comparative study. Struct. Health Monit. 2011, 10, 83–111. [Google Scholar] [CrossRef]

- Pandey, A.K.; Biswas, M. Damage detection in structures using changes in flexibility. J. Sound Vib. 1994, 169, 3–17. [Google Scholar] [CrossRef]

- Toksoy, T.; Aktan, A.E. Bridge-condition assessment by modal flexibility. Exp. Mech. 1994, 34, 271–278. [Google Scholar] [CrossRef]

- Catbas, F.N.; Gul, M.; Burkett, J.L. Damage assessment using flexibility and flexibility-based curvature for structural health monitoring. Smart Mater. Struct. 2008, 17, 1–12. [Google Scholar] [CrossRef]

- Wu, D.; Law, S.S. Damage localization in plate structures from uniform load surface curvature. J. Sound Vib. 2004, 276, 227–244. [Google Scholar] [CrossRef]

- Bernal, D. Load vectors for damage localization. J. Eng. Mech. 2002, 128, 7–14. [Google Scholar] [CrossRef]

- Duan, Z.; Yan, G.; Qu, J.; Spencer, B.F. Damage detection in ambient vibration using proportional flexibility matrix with incomplete measured DOFs. Struct. Control Health Monit. 2005, 14, 186–196. [Google Scholar] [CrossRef]

- Gao, Y.; Spencer, B.F. Online damage diagnosis for civil infrastructure employing a flexibility-based approach. Smart Mater. Struct. 2006, 15, 9–19. [Google Scholar] [CrossRef]

- Gao, Y.; Spencer, B.F.; Bernal, D. Experimental verification of the flexibility-based damage locating vector method. J. Eng. Mech. 2007, 133, 1043–1049. [Google Scholar] [CrossRef]

- Sung, S.H.; Jung, H.J.; Jung, H.Y. Damage detection for beam-like structures using the normalized curvature of a uniform load surface. J. Sound Vib. 2013, 332, 1501–1519. [Google Scholar] [CrossRef]

- Parloo, E.; Verboven, P.; Guillaume, P.; Overmeire, M.V. Sensitivity-based operational mode shape normalization. Mech. Syst. Sign. Process. 2002, 16, 757–767. [Google Scholar] [CrossRef]

- Parloo, E.; Cauberghe, B.; Benedettini, F.; Alaggio, R.; Guillaume, P. Sensitivity-based operational mode shape normalisation: Application to a bridge. Mech. Syst. Sign. Process. 2005, 19, 43–55. [Google Scholar] [CrossRef]

- Brincker, R.; Andersen, P. A way of getting scaled mode shapes in output only modal testing. In Proceedings of the 21th International Modal Analysis Conference (IMAC XXI), Kissimmee, FL, USA, 3–6 February 2003.

- Bernal, D. Modal scaling from known mass perturbations. J. Eng. Mech. 2004, 130, 1083–1088. [Google Scholar] [CrossRef]

- Cauberghe, B. Applied Frequency-Domain System Identification in the Field of Experimental and Operational Modal Analysis. Ph.D. Thesis, Vrije Universiteit Brussel, Brussel, Belgium, May 2004. [Google Scholar]

- Koo, K.Y.; Sung, S.H.; Park, J.W.; Jung, H.J. Damage detection of shear buildings using deflections obtained by modal flexibility. Smart Mater. Struct. 2010, 19, 115026. [Google Scholar] [CrossRef]

- Sung, S.H.; Koo, K.Y.; Jung, H.Y.; Jung, H.J. Damage-induced deflection approach for damage localization and quantification of shear buildings: Validation on a full-scale shear building. Smart Mater. Struct. 2012, 21. [Google Scholar] [CrossRef]

- An, Y.; Qu, J. Experimental and numerical studies on damage localization of simply supported beams based on curvature difference probability method of waveform fractal dimension. J. Intell. Mater. Syst. Struct. 2012, 23, 415–426. [Google Scholar] [CrossRef]

- Peeters, B.; Roeck, G.D. Reference-based stochastic subspace identification for output-only modal analysis. Mech. Syst. Sign. Process. 1999, 13, 855–878. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, H.-Y.; Sung, S.-H.; Jung, H.-J. Experimental Validation of Normalized Uniform Load Surface Curvature Method for Damage Localization. Sensors 2015, 15, 26315-26330. https://doi.org/10.3390/s151026315

Jung H-Y, Sung S-H, Jung H-J. Experimental Validation of Normalized Uniform Load Surface Curvature Method for Damage Localization. Sensors. 2015; 15(10):26315-26330. https://doi.org/10.3390/s151026315

Chicago/Turabian StyleJung, Ho-Yeon, Seung-Hoon Sung, and Hyung-Jo Jung. 2015. "Experimental Validation of Normalized Uniform Load Surface Curvature Method for Damage Localization" Sensors 15, no. 10: 26315-26330. https://doi.org/10.3390/s151026315

APA StyleJung, H.-Y., Sung, S.-H., & Jung, H.-J. (2015). Experimental Validation of Normalized Uniform Load Surface Curvature Method for Damage Localization. Sensors, 15(10), 26315-26330. https://doi.org/10.3390/s151026315