Design and Characterization of a High Resolution Microfluidic Heat Flux Sensor with Thermal Modulation

Abstract

:1. Introduction

2. Heat Flux Sensor Design

2.1. Heat flux sensor principle

2.2. Fabrication process

3. Experiments

3.1. Thermal modulation

3.2. Sensitivity and resolution

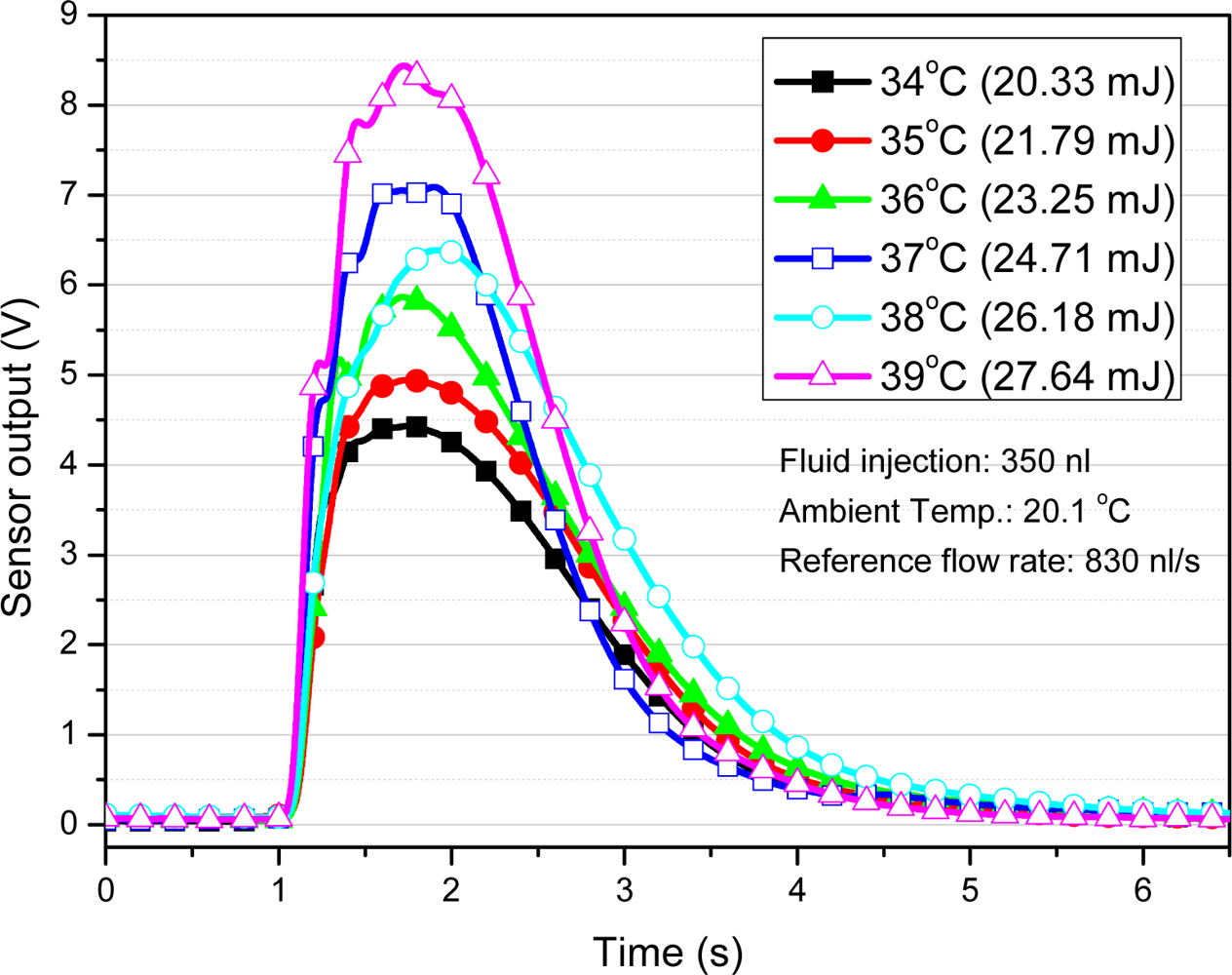

3.3. Fluidic experiments

4. System Modeling

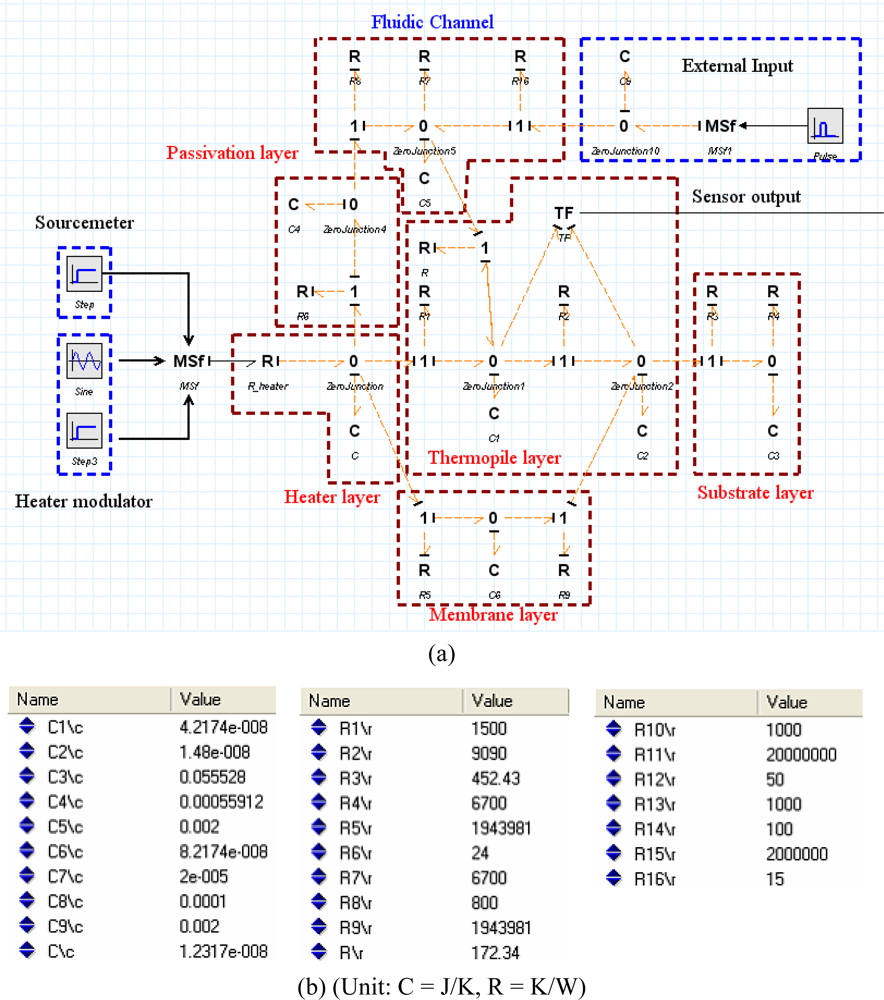

4.1. Bond graph methodology

4.2. Thermal domain modeling

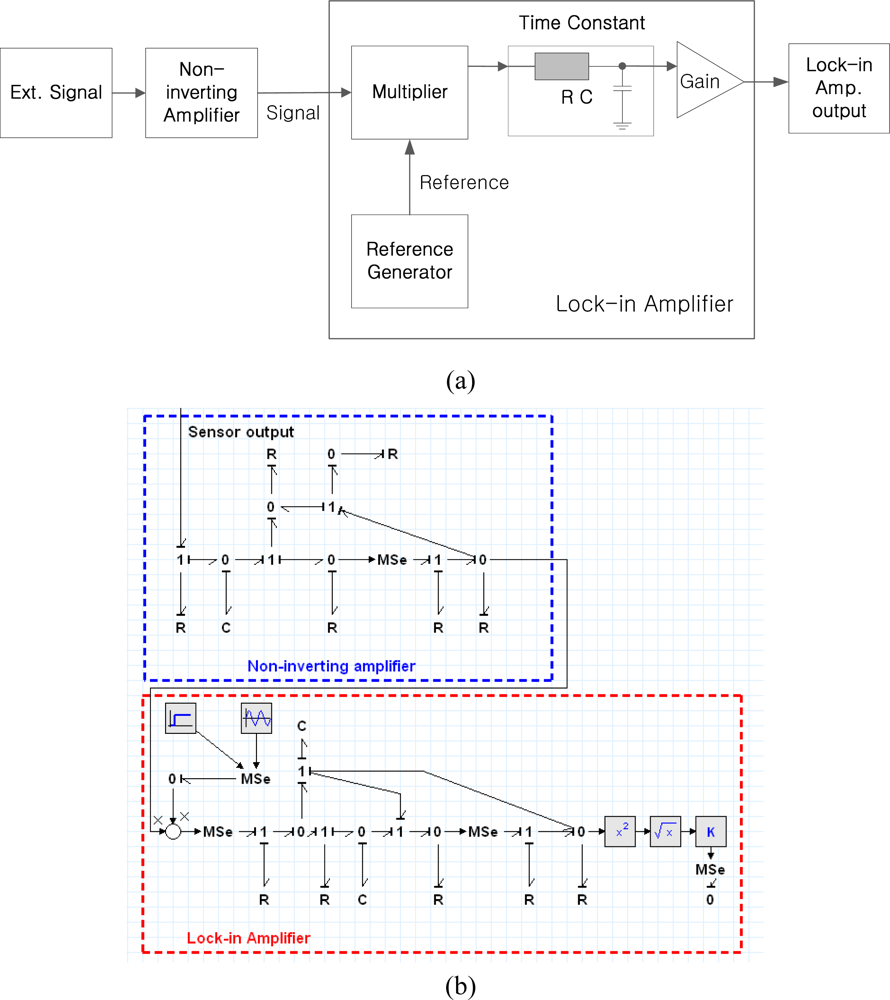

4.3. Electrical domain modeling

4.4. System model identification

4.5. Results

5. Conclusions

Abbreviations Used

| C | Capacitance |

| R | Resistance |

| T | Temperature |

| T | Time |

| V | Voltage |

| ω | Frequency |

| Φ | Phase lag |

| Subscripts | |

|---|---|

| AC | AC component |

| amb | Ambient |

| DC | DC component |

| e | Electrical domain |

| ext | External input |

| heater | Heater |

| out | Lock-in amplifier output |

| sensor | Sensor |

| th | Thermal domain |

| ref | Reference component |

| ref_f | Reference fluid |

| ω | ω frequency component |

| 2ω | 2ω frequency component |

Acknowledgments

References

- Diller, TE. Advances in heat flux measurement. In Advances in Heat Transfer; Academic Press: Boston, MA, USA, 1993; Volume 23, pp. 279–368. [Google Scholar]

- Eminoglu, S; Sabuncouglu Tezcan, D; Yusuf Tanrikulu, M; Akin, T. Low-cost uncooled infrared detectors in CMOS process. Sensor. Actuator. A-Phys 2003, 109, 102–113. [Google Scholar]

- Matsumiya, M; Shin, W; Izu, N; Murayama, N. Nano-structured thin-film Pt catalyst for thermoelectric hydrogen gas sensor. Sensor. Actuator. B-Chem 2003, 93, 309–315. [Google Scholar]

- Baciocchi, M; Bearzotti, A; Gentili, M; Lucchesini, A. Cu/Pd Thin-film thermopile as a temperature and hydrogen sensor. Sensor. Actuator. A-Phys 1990, 22, 631–635. [Google Scholar]

- Buchner, R; Sosna, C; Maiwald, M; Benecke, W; Lang, W. A high-temperature thermopile fabrication process for thermal flow sensors. Sensor Actuator A-Phys 2006, 130–131, 262–266. [Google Scholar]

- Kim, TH; Kim, SJ. Development of a micro-thermal flow sensor with thin-film thermocouples. J. Micromech. Microeng 2006, 16, 2502–2508. [Google Scholar]

- Hopper, RH. Use of carbon micro-particles for improved infrared temperature measurement of CMOS MEMS devices. Meas. Sci. Technol 2010, 21, 045107. [Google Scholar]

- Johannessen, EA; Waver, JMR; Cobbold, PH; Cooper, JMA. Suspended membrane nanocalorimeter for ultralow volume bioanalysis. IEEE Trans. Nanobiosci 2002, 1, 29–36. [Google Scholar]

- Giraldo-Gutierréz, L; Moreno-Piraján, JC. Determination of the temperature change by means of an outcoming signal of electric resistance in an isoperibolic calorimetric cell. Obtainment of heat solution. Sensors 2005, 5, 633–643. [Google Scholar]

- Kao, PH; Shih, PJ; Dai, CL; Liu, MC. Fabrication and characterization of CMOS-MEMS thermoelectric micro generators. Sensors 2010, 10, 1315–1325. [Google Scholar]

- Maskow, T; Harms, H. Real time insights into bioprocesses using calorimetry: State of the art and potential. Eng. Life Sci 2006, 6, 266–277. [Google Scholar]

- Macfarlane, GG. A Theory of contact noise in semiconductors. Proc. Phys. Soc. B 1950, 63, 807–814. [Google Scholar]

- Randjelović, D; Petropoulos, A; Kaltsas, G; Stojanović, M; Lazić, Ž; Djurić, Z; Matić, M. Multipurpose MEMS thermal sensor based on thermopiles. Sensor. Actuator. A-Phys 2008, 141, 404–413. [Google Scholar]

- Oh, SH; Lee, KC; Chun, J; Kim, MH; Lee, SS. Micro heat flux sensor using copper electroplating in SU-8 microstructures. J. Micromech. Microeng 2001, 11, 221–225. [Google Scholar]

- Oh, SH; Lee, SH; Jeon, JC; Kim, MH; Lee, SS. Bulk-micromachined circular foil type micro heat-flux sensor. Sensor. Actuator. A-Phys 2006, 132, 581–586. [Google Scholar]

- Zhang, Y; Tadigadapa, S. Calorimetric biosensors with integrated microfluidic channels. Biosens. Bioelectron 2004, 19, 1733–1743. [Google Scholar]

- Baier, V; Födisch, R; Ihring, A; Kessler, E; Lerchner, J; Wolf, G; Köhler, JM; Nietzsch, M; Krügel, M. Highly sensitive thermopile heat power sensor for micro-fluid calorimetry of biochemical processes. Sensor Actuator A-Phys 2005, 123–124, 354–359. [Google Scholar]

- Dehé, A; Fricke, K; Hartnagel, HL. Infrared thermopile sensor based on AlGaAs-GaAs micromachining. Sensor Actuator A-Phys 1995, 46–47, 432–436. [Google Scholar]

- Johannessen, EA; Weaver, JMR; Cobbold, PH; Cooper, JM. Heat conduction nanocalorimeter for pl-scale single cell measurements. Appl. Phys. Lett 2002, 80, 2029–2031. [Google Scholar]

- Kemp, RB; Guan, Y. Heat flux and the calorimetric-respirometric ratio as measured of catabolic flux in mammalian cells. Thermochim. Acta 1997, 300, 199–211. [Google Scholar]

- Olmo, E. Nucleotype and cell size in vertebrates: A review. Basic Appl. Histochem 1983, 27, 227–256. [Google Scholar]

- Paynter, HM. Analysis and Design of Engineering Systems; The MIT Press: Cambridge, MA, USA, 1961. [Google Scholar]

- Karnopp, D; Rosenberg, R. Analysis and Simulation of Multiport Systems; The MIT Press: Cambridge, MA, USA, 1968. [Google Scholar]

- Granda, JJ. The role of bond graph modeling and simulation in mechatronics systems-an integrated software tool: CAMP-G, MATLAB-SIMULINK. Mechatronics 2002, 12, 1271–1295. [Google Scholar]

- Thoma, JU. Bond graphs for thermal energy transport and entropy flow. J. Franklin Inst-Eng. Appl. Math 1971, 292, 109–120. [Google Scholar]

- Pal, SK; Linkens, DA. Temperature distribution in steel during hot rolling: pseudo-bond graph view. Simul. Modell. Practice Theory 2002, 10, 68–85. [Google Scholar]

- Kim, SM; Lee, SK. Prediction of thermo-elastic behavior in a spindle-bearing system considering bearing surroundings. Int. J. Machine Tools Manuf 2001, 41, 809–831. [Google Scholar]

- Kim, JK; Nakayama, W; Ito, Y; Shin, SM; Lee, SK. Estimation of thermal parameters of the enclosed electronic package system by using dynamic thermal response. Mechatronics 2009, 19, 1034–1040. [Google Scholar]

- 20-sim program. Available online: http://.20sim.com/ (accessed on 16 October 2007).

- Incropera, FP; DeWitt, DP; Bergman, TL; Lavine, AS. Fundamentals of Heat and Mass Transfer; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

- JEDEC. Integrated Circuits Thermal Measurement Method-Electrical Test Method (Single Semiconductor Device) EIA/JESD Standard. 1995, 51, 3–23.

- Kim, JK; Kim, TH; Cho, SC; Shin, SM; Lee, SK. Modeling and fabrication of thin film thermopile sensor. J. Vac. Sci. Technol. B 2009, 27, 1466–1472. [Google Scholar]

| Modulation condition | Frequency | 7 HZ |

| Peak to peak voltage | 1 Vvv | |

| Offset voltage | 1 VOffest | |

| Lock-in amp. setting Value | Time constant | 300 ms |

| Sensitivity | 200 | |

| Expand gain | × 100 | |

© 2010 by the authors licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Nam, S.-K.; Kim, J.-K.; Cho, S.-C.; Lee, S.-K. Design and Characterization of a High Resolution Microfluidic Heat Flux Sensor with Thermal Modulation. Sensors 2010, 10, 6594-6611. https://doi.org/10.3390/s100706594

Nam S-K, Kim J-K, Cho S-C, Lee S-K. Design and Characterization of a High Resolution Microfluidic Heat Flux Sensor with Thermal Modulation. Sensors. 2010; 10(7):6594-6611. https://doi.org/10.3390/s100706594

Chicago/Turabian StyleNam, Sung-Ki, Jung-Kyun Kim, Sung-Cheon Cho, and Sun-Kyu Lee. 2010. "Design and Characterization of a High Resolution Microfluidic Heat Flux Sensor with Thermal Modulation" Sensors 10, no. 7: 6594-6611. https://doi.org/10.3390/s100706594

APA StyleNam, S.-K., Kim, J.-K., Cho, S.-C., & Lee, S.-K. (2010). Design and Characterization of a High Resolution Microfluidic Heat Flux Sensor with Thermal Modulation. Sensors, 10(7), 6594-6611. https://doi.org/10.3390/s100706594