The Role of Rapid Curing on the Interrelationship Between Temperature Rise, Light Transmission, and Polymerisation Kinetics of Bulk-Fill Composites

Abstract

1. Introduction

- (I)

- There is no difference between different materials in light transmittance, temperature rise, and degree of conversion when 3s curing is used in comparison to other curing protocols.

- (II)

- There is no difference in light transmittance, temperature rise, and degree of conversion of the same material when different curing units are used for 3s curing.

2. Results

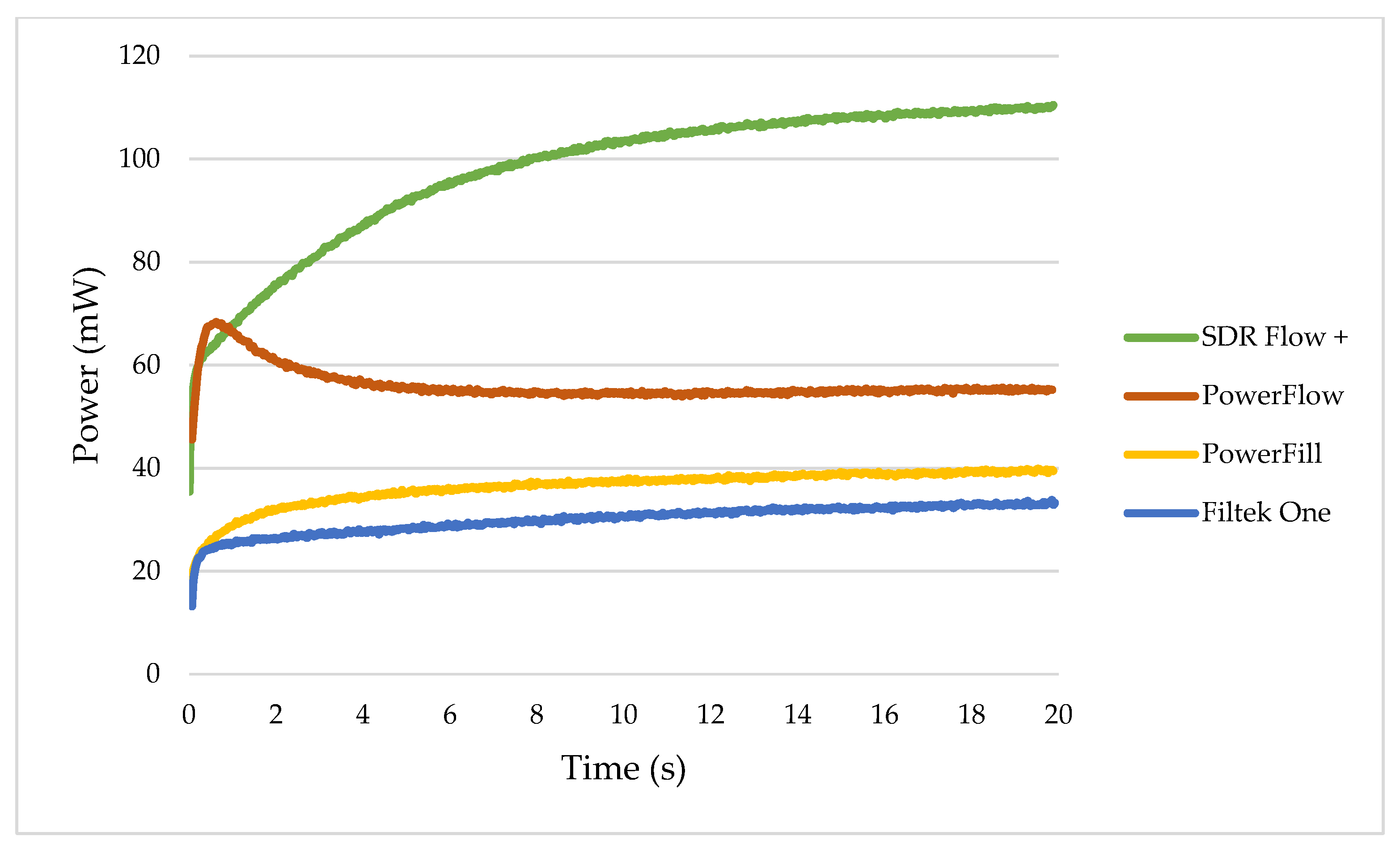

2.1. Radiant Exitance of LCUs

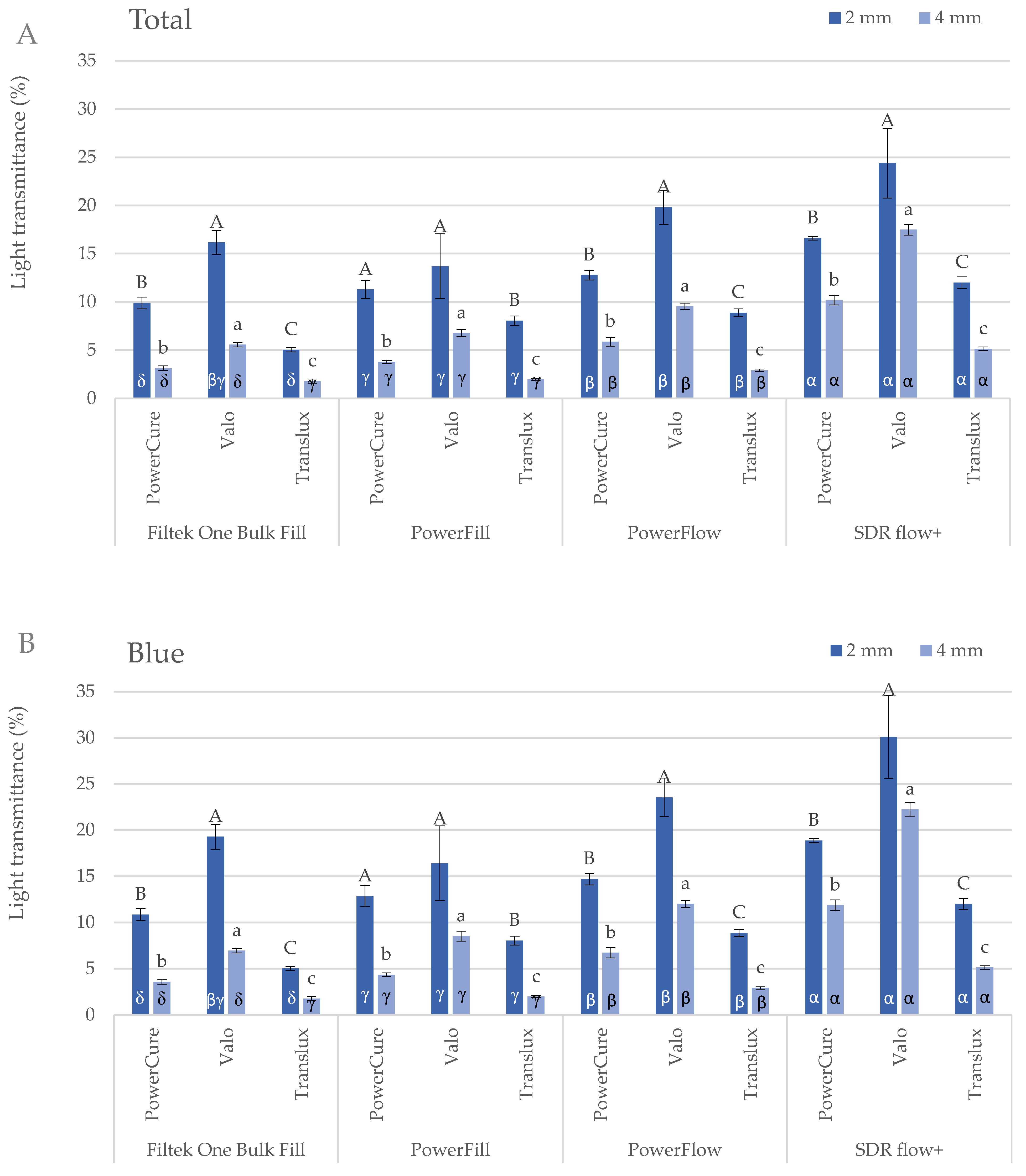

2.2. Light Transmission

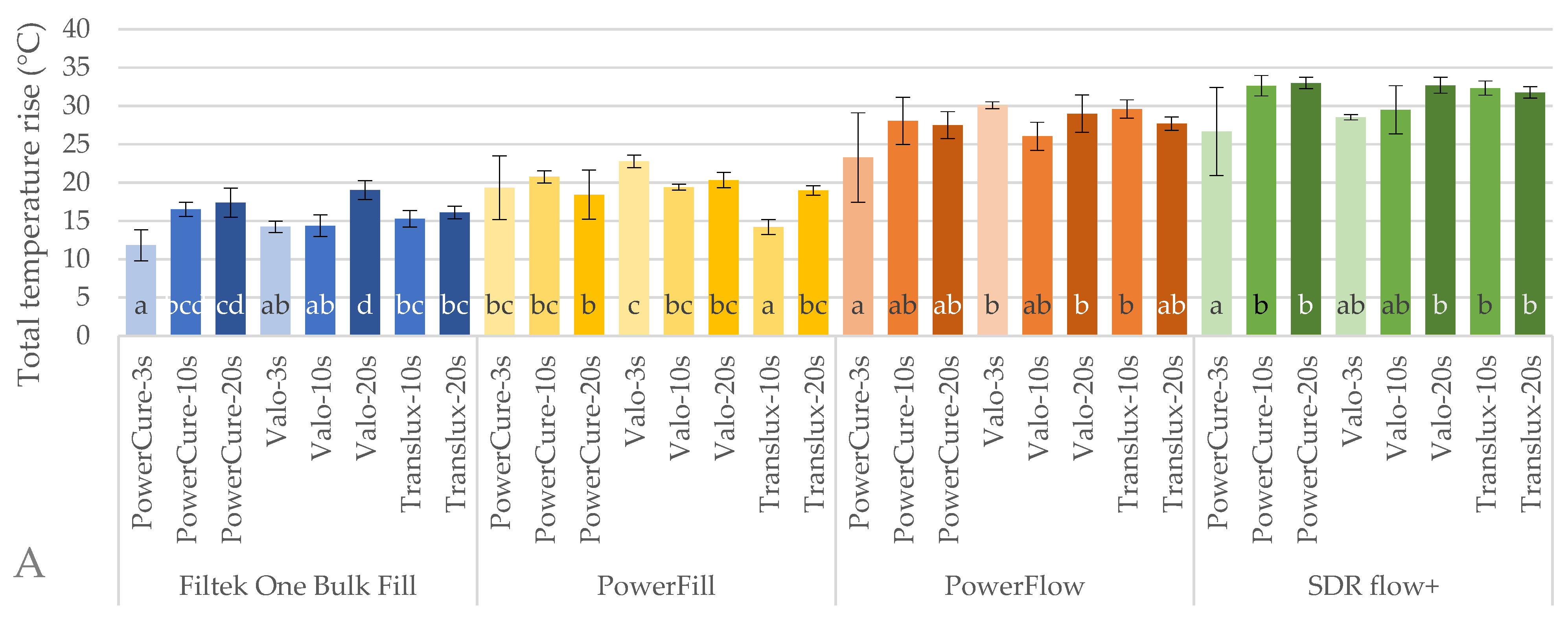

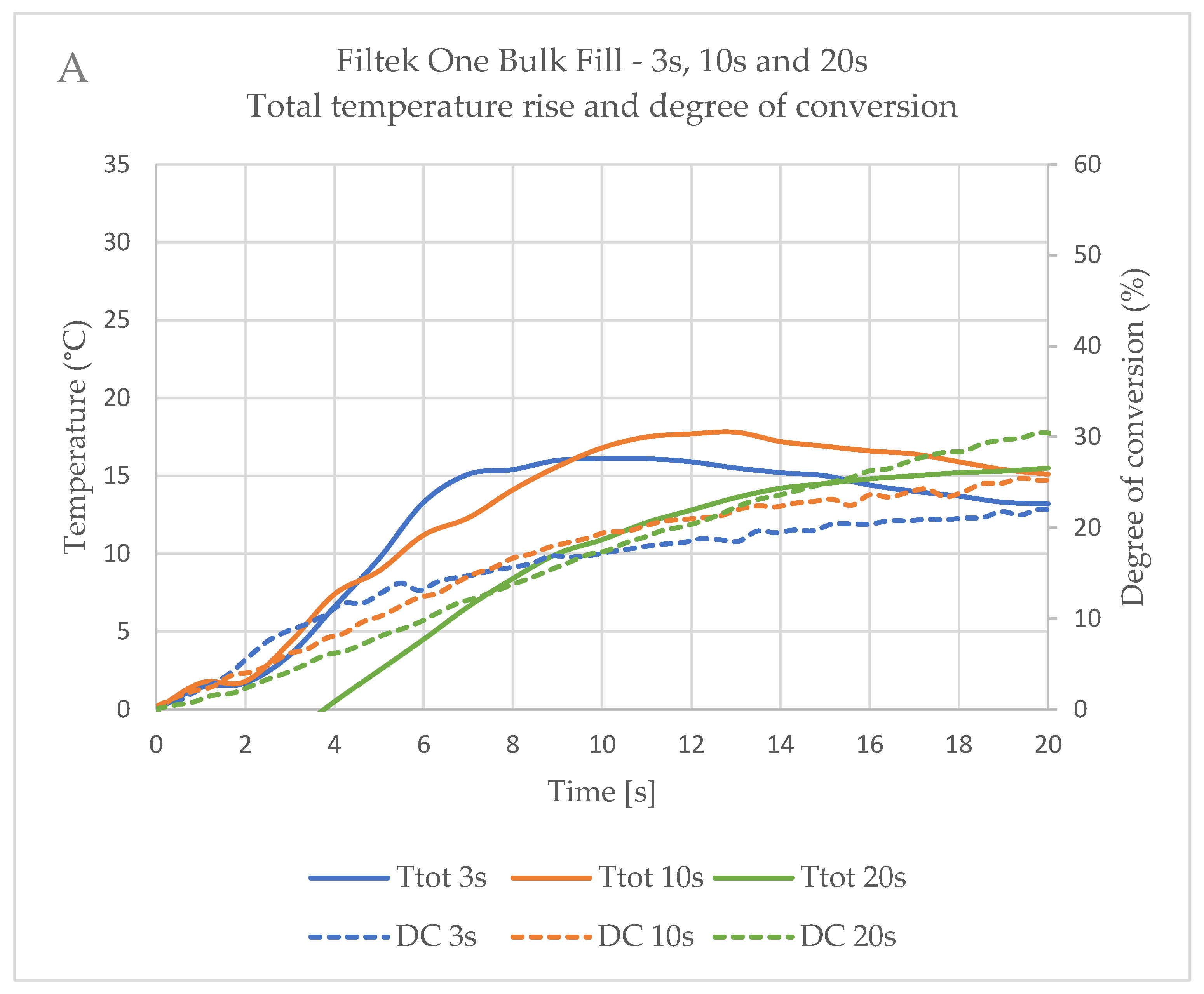

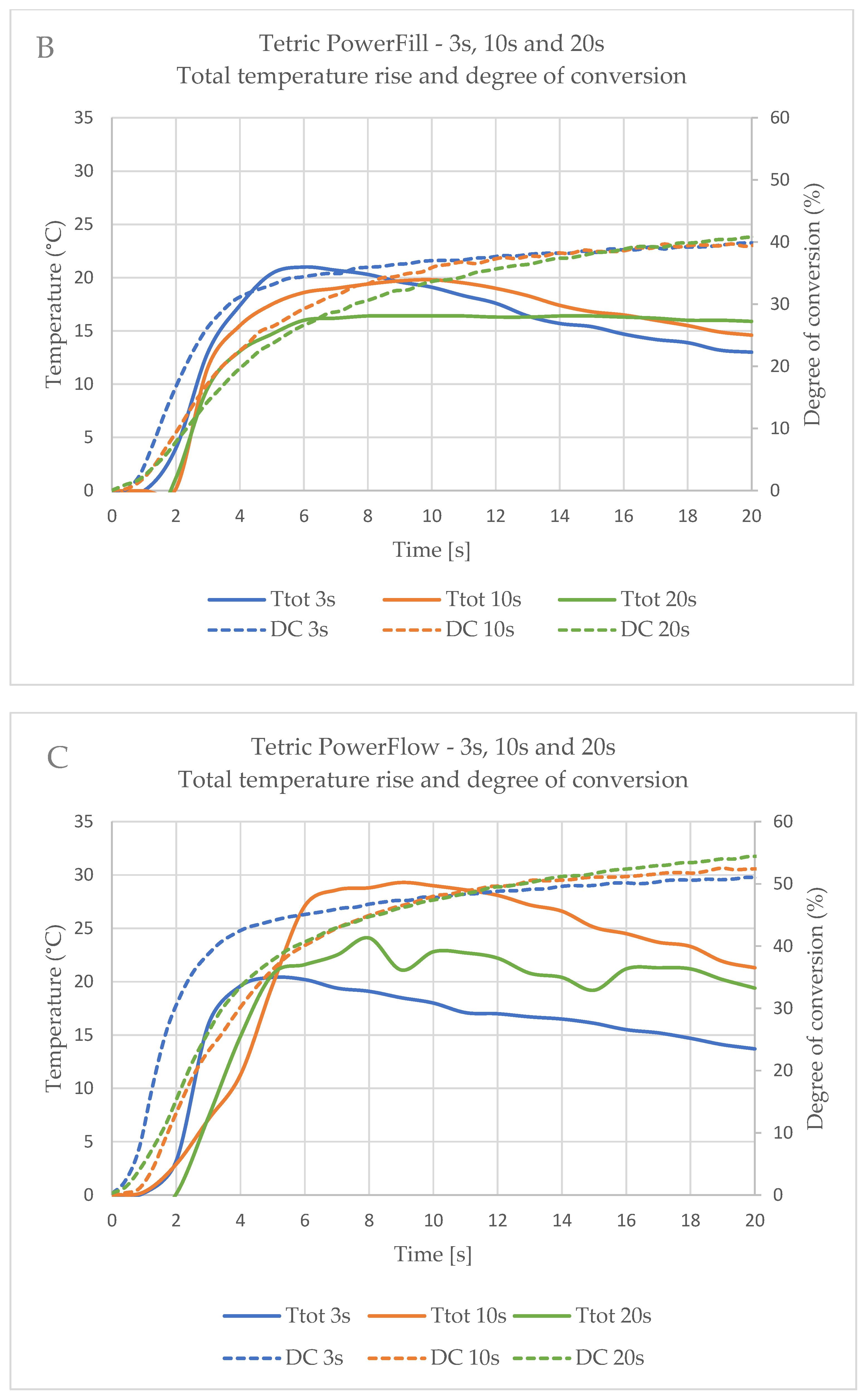

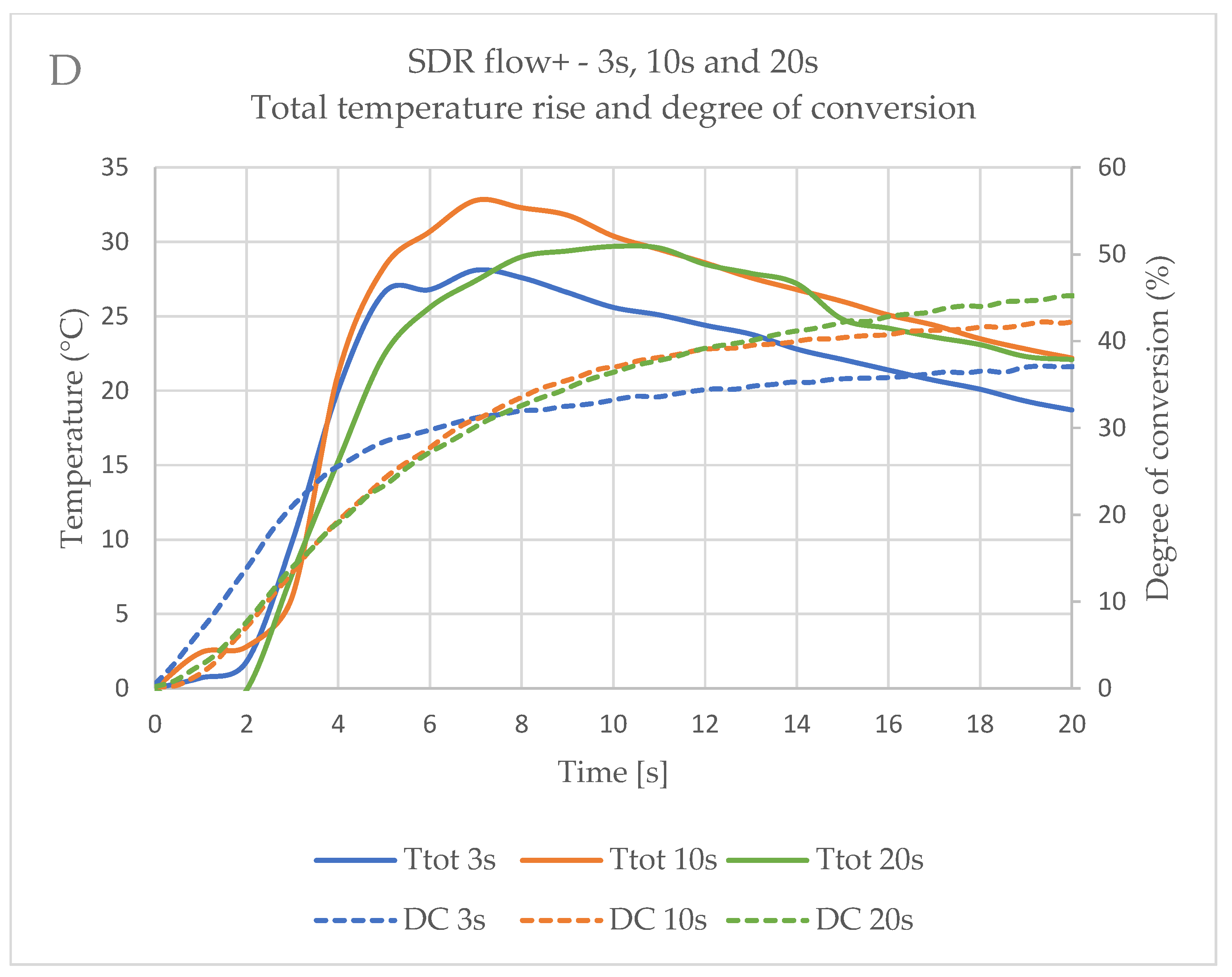

2.3. Temperature Rise

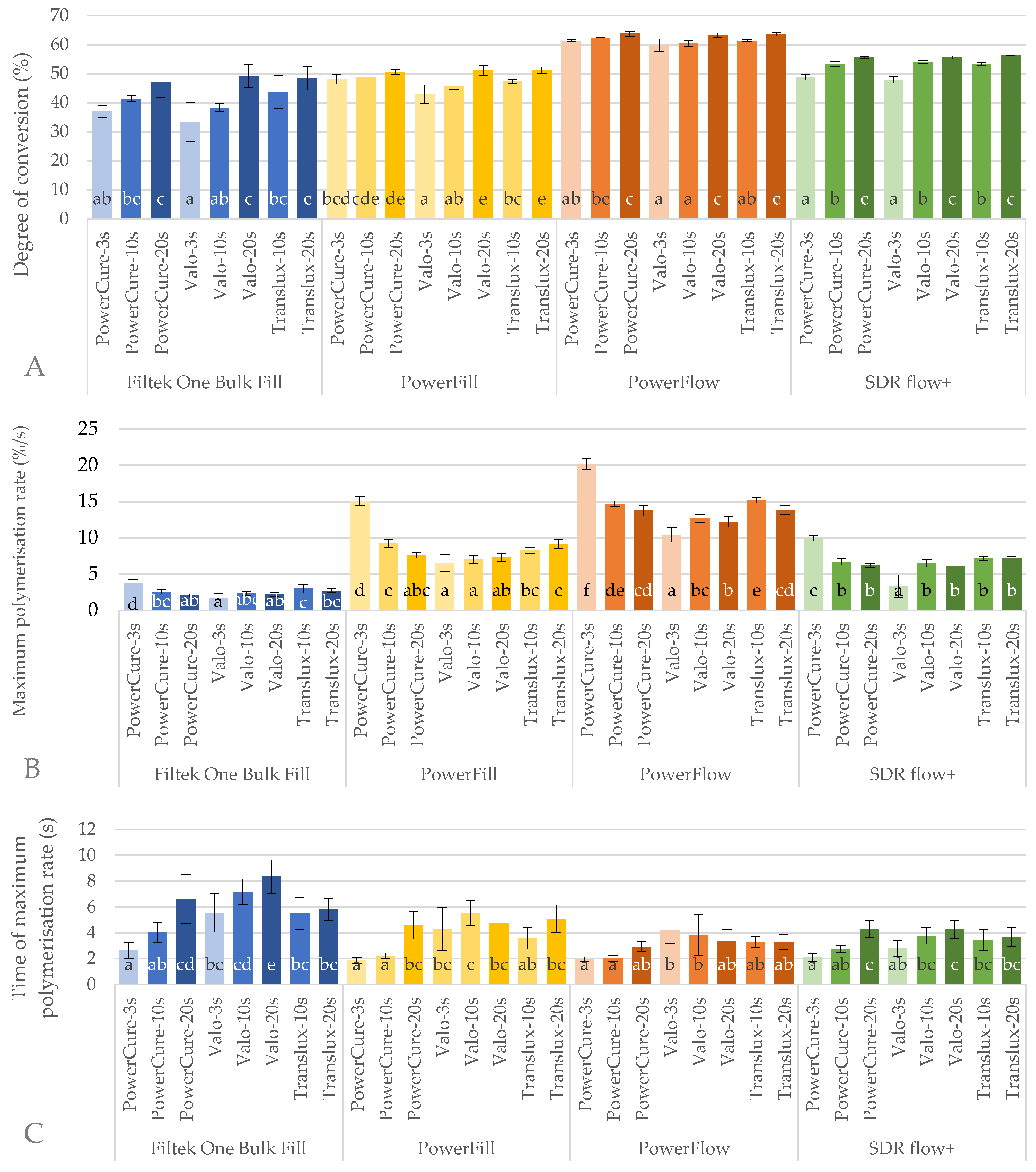

2.4. Polymerisation Kinetics

2.5. Pearson Correlation

3. Discussion

4. Materials and Methods

- (I)

- VALO Cordless (Ultradent, South Jordan, UT, USA; VC) as LCU with three spectral peaks:

- 3s protocol: 3 s with 3 W/cm2,

- 10s protocol: 10 s with 1 W/cm2, and

- 20s protocol: 20 s with 1 W/cm2.

- (II)

- Bluephase PowerCure (Ivoclar; BPC) As LCU with two spectral peaks:

- 3s protocol: 3 s with 3 W/cm2,

- 10s protocol: 10 s with 1 W/cm2, and

- 20s protocol: 20 s with 1 W/cm2.

- (III)

- Translux Wave (Kulzer GmbH, Hanau, Germany; TW) as LCU with one spectral peak:

- 10s protocol: 10 s with 1 W/cm2, and

- 20s protocol: 20 s with 1 W/cm2.

4.1. Characterisation of the Curing Units

4.2. Light Transmittance

4.3. Temperature Rise

4.4. Polymerisation Kinetics

4.5. Statistical Analysis

5. Conclusions

- The interplay between temperature rise, light transmission and polymerisation kinetics is complex and material dependent.

- Rapid curing offers several advantages, including shorter treatment time and greater patient comfort. However, the potentially lower degree of conversion in the deepest layers poses a risk to the long-term success of some bulk-fill composite restorations.

- Extended curing times with moderate irradiance (≈1 W/cm2) were beneficial for all tested materials.

- Rapid curing with ≈3 W/cm2 should be reserved exclusively for materials specifically designed for this curing protocol and is not recommended for use with other materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FO | Filtek One |

| PFill | Tetric PowerFill |

| PFlow | Tetric PowerFlow |

| SDR+ | SDR flow+ |

| VC | Valo Cordless |

| BPC | Bluephase PowerCure |

| TW | Translux Wave |

| DC | Degree of conversion |

| LCU | Light-curing unit |

| RAFT | Reversible addition fragmentation chain transfer |

| Bis-GMA | Bisphenol A-diglycidyl dimethacrylate |

| Bis-EMA | Ethoxylated bisphenol A dimethacrylate |

| Bis-PMA | Propoxylated bisphenol A dimethacrylate |

| DCP | Tricyclodecane–dimethanol dimethacrylate |

| DMA | Dimethacrylate |

| UDMA | Urethane dimethacrylate |

| AUDMA | Aromatic dimethacrylate |

| TEGDMA | Triethylene glycol dimethacrylate |

| PEGDMA | Polyethylene glycol dimethacrylate |

| D3MA | Decandiol dimethacrylate |

| DDDMA | 1,12-Dodecanediol dimethacrylate |

| AFM | Addition fragmentation monomers |

| NIST | National Institute of Standards and Technology |

| PET | Polyethylene terephthalate |

| FTIR | Fourier transform infrared |

| ATR | Attenuated total reflectance |

References

- Ferracane, J.L. Resin composite-state of the art. Dent. Mater. 2011, 27, 29–38. [Google Scholar] [CrossRef] [PubMed]

- Ilie, N.; Hickel, R. Investigations on mechanical behaviour of dental composites. Clin. Oral. Investig. 2009, 13, 427–438. [Google Scholar] [CrossRef] [PubMed]

- Ilie, N.; Hickel, R. Macro-, micro- and nano-mechanical investigations on silorane and methacrylate-based composites. Dent. Mater. 2009, 25, 810–819. [Google Scholar] [CrossRef] [PubMed]

- Haugen, H.J.; Ma, Q.; Linskens, S.; Par, M.; Mandic, V.N.; Mensikova, E.; Nogueira, L.P.; Taubock, T.T.; Attin, T.; Gubler, A.; et al. 3D micro-CT and O-PTIR spectroscopy bring new understanding of the influence of filler content in dental resin composites. Dent. Mater. 2024, 40, 1881–1894. [Google Scholar] [CrossRef]

- Marovic, D.; Haugen, H.J.; Par, M.; Linskens, S.; Mensikova, E.; Negovetic Mandic, V.; Leeuwenburgh, S.; Nogueira, L.P.; Vallittu, P.K.; Ma, Q. Emerging technologies for the evaluation of spatio-temporal polymerisation changes in flowable vs. sculptable dental resin-based composites. Dent. Mater. 2024, 40, 1895–1908. [Google Scholar] [CrossRef]

- Yadav, R.; Saini, S.; Sonwal, S.; Meena, A.; Huh, Y.S.; Brambilla, E.; Ionescu, A.C. Optimization and ranking of dental restorative composites by ENTROPY-VIKOR and VIKOR-MATLAB. Polym. Adv. Technol. 2024, 35, e6526. [Google Scholar] [CrossRef]

- Watts, D.C. Light-curing dental resin-based composites: How it works and how you can make it work. Front. Dent. Med. 2023, 4, 1108316. [Google Scholar] [CrossRef]

- Watts, D.C. Reaction kinetics and mechanics in photo-polymerised networks. Dent. Mater. 2005, 21, 27–35. [Google Scholar] [CrossRef]

- Soh, M.S.; Yap, A.U. Influence of curing modes on crosslink density in polymer structures. J. Dent. 2004, 32, 321–326. [Google Scholar] [CrossRef]

- da Silva, E.M.; Poskus, L.T.; Guimaraes, J.G.; de Araujo Lima Barcellos, A.; Fellows, C.E. Influence of light polymerization modes on degree of conversion and crosslink density of dental composites. J. Mater. Sci. Mater. Med. 2008, 19, 1027–1032. [Google Scholar] [CrossRef]

- Fronza, B.M.; Ayres, A.; Pacheco, R.R.; Rueggeberg, F.A.; Dias, C.; Giannini, M. Characterization of Inorganic Filler Content, Mechanical Properties, and Light Transmission of Bulk-fill Resin Composites. Oper. Dent. 2017, 42, 445–455. [Google Scholar] [CrossRef]

- Fidalgo-Pereira, R.; Carpio, D.; Torres, O.; Carvalho, O.; Silva, F.; Henriques, B.; Ozcan, M.; Souza, J.C.M. The influence of inorganic fillers on the light transmission through resin-matrix composites during the light-curing procedure: An integrative review. Clin. Oral. Investig. 2022, 26, 5575–5594. [Google Scholar] [CrossRef] [PubMed]

- Ferracane, J.L.; Berge, H.X.; Condon, J.R. In vitro aging of dental composites in water-effect of degree of conversion, filler volume, and filler/matrix coupling. J. Biomed. Mater. Res. 1998, 42, 465–472. [Google Scholar] [CrossRef]

- Stansbury, J.W. Dimethacrylate network formation and polymer property evolution as determined by the selection of monomers and curing conditions. Dent. Mater. 2012, 28, 13–22. [Google Scholar] [CrossRef] [PubMed]

- Sullivan, B.; Kalliecharan, D.; Kostylev, I.; Earle, G.; Stansbury, J.W.; Price, R.B.; Labrie, D. Photo-polymerization kinetics of a dental resin at a high temporal resolution. J. Mech. Behav. Biomed. Mater. 2021, 124, 104884. [Google Scholar] [CrossRef]

- Alrahlah, A.; Silikas, N.; Watts, D.C. Post-cure depth of cure of bulk fill dental resin-composites. Dent. Mater. 2014, 30, 149–154. [Google Scholar] [CrossRef]

- Al-Ahdal, K.; Ilie, N.; Silikas, N.; Watts, D.C. Polymerization kinetics and impact of post polymerization on the Degree of Conversion of bulk-fill resin-composite at clinically relevant depth. Dent. Mater. 2015, 31, 1207–1213. [Google Scholar] [CrossRef]

- Sideridou, I.; Tserki, V.; Papanastasiou, G. Study of water sorption, solubility and modulus of elasticity of light-cured dimethacrylate-based dental resins. Biomaterials 2003, 24, 655–665. [Google Scholar] [CrossRef]

- Bucuta, S.; Ilie, N. Light transmittance and micro-mechanical properties of bulk fill vs. conventional resin based composites. Clin. Oral. Investig. 2014, 18, 1991–2000. [Google Scholar] [CrossRef]

- Ilie, N.; Hogg, C. Kinetic of Light Transmission during Setting and Aging of Modern Flowable Bulk-Fill Composites. Materials 2024, 17, 4292. [Google Scholar] [CrossRef]

- Arikawa, H.; Kanie, T.; Fujii, K.; Takahashi, H.; Ban, S. Effect of filler properties in composite resins on light transmittance characteristics and color. Dent. Mater. J. 2007, 26, 38–44. [Google Scholar] [CrossRef] [PubMed]

- Shortall, A.C.; Palin, W.M.; Burtscher, P. Refractive index mismatch and monomer reactivity influence composite curing depth. J. Dent. Res. 2008, 87, 84–88. [Google Scholar] [CrossRef] [PubMed]

- Shimokawa, C.; Sullivan, B.; Turbino, M.L.; Soares, C.J.; Price, R.B. Influence of Emission Spectrum and Irradiance on Light Curing of Resin-Based Composites. Oper. Dent. 2017, 42, 537–547. [Google Scholar] [CrossRef] [PubMed]

- Andrzejewska, E. Photopolymerization kinetics of multifunctional monomers. Prog. Polym. Sci. 2001, 26, 605–665. [Google Scholar] [CrossRef]

- Hadis, M.A.; Shortall, A.C.; Palin, W.M. The power of light—From dental materials processing to diagnostics and therapeutics. Biomater. Investig. Dent. 2024, 11, 40308. [Google Scholar] [CrossRef]

- Kowalska, A.; Sokolowski, J.; Bociong, K. The Photoinitiators Used in Resin Based Dental Composite-A Review and Future Perspectives. Polymers 2021, 13, 470. [Google Scholar] [CrossRef]

- Moszner, N.; Fischer, U.K.; Ganster, B.; Liska, R.; Rheinberger, V. Benzoyl germanium derivatives as novel visible light photoinitiators for dental materials. Dent. Mater. 2008, 24, 901–907. [Google Scholar] [CrossRef]

- Braga, S.S.L.; Price, R.B.; Juckes, S.M.; Sullivan, B.; Soares, C.J. Effect of the violet light from polywave light-polymerizing units on two resin cements that use different photoinitiators. J. Prosthet. Dent. 2024, 131, 744–751. [Google Scholar] [CrossRef]

- Labrie, D.; Price, R.B.; Sullivan, B.; Salazar, A.M.; Gautam, D.; Stansbury, J.W.; Ferracane, J.L. Effect of thickness on the degree of conversion of two bulk-fill and one conventional posterior resin-based composites at high irradiance and high temporal resolution. J. Mech. Behav. Biomed. Mater. 2022, 136, 105489. [Google Scholar] [CrossRef]

- Ilie, N. Resin-Based Bulk-Fill Composites: Tried and Tested, New Trends, and Evaluation Compared to Human Dentin. Materials 2022, 15, 8095. [Google Scholar] [CrossRef]

- Clewell, D.H. Scattering of Light by Pigment Particles. J. Opt. Soc. Am. 1941, 31, 521–527. [Google Scholar] [CrossRef]

- Ismail, E.H.; Paravina, R.D. Color adjustment potential of resin composites: Optical illusion or physical reality, a comprehensive overview. J. Esthet. Restor. Dent. 2022, 34, 42–54. [Google Scholar] [CrossRef] [PubMed]

- Todd, J. Scientific documentation 3s PowerCure; Ivoclar Vivadent: Schaan, Liechtenstein, 2019. [Google Scholar]

- Marovic, D.; Par, M.; Crnadak, A.; Sekelja, A.; Negovetic Mandic, V.; Gamulin, O.; Rakic, M.; Tarle, Z. Rapid 3 s Curing: What Happens in Deep Layers of New Bulk-Fill Composites? Materials 2021, 14, 515. [Google Scholar] [CrossRef] [PubMed]

- Graf, N.; Ilie, N. Long-Term Stability of a RAFT-Modified Bulk-Fill Resin-Composite under Clinically Relevant Versus ISO-Curing Conditions. Materials 2020, 13, 5350. [Google Scholar] [CrossRef]

- Marovic, D.; Par, M.; Macan, M.; Klaric, N.; Plazonic, I.; Tarle, Z. Aging-Dependent Changes in Mechanical Properties of the New Generation of Bulk-Fill Composites. Materials 2022, 15, 902. [Google Scholar] [CrossRef]

- Macan, M.; Marošević, A.; Špiljak, B.; Šimunović, L.; Par, M.; Marovic, D.; Juric-Kacunic, D.; Tarle, Z. Proposition of New Testing Procedure for the Mechanical Properties of Bulk-Fill Materials. Materials 2023, 16, 4868. [Google Scholar] [CrossRef]

- Klaric, E.; Bosnic, J.V.; Par, M.; Tarle, Z.; Marovic, D. One-Year Evaluation of High-Power Rapid Curing on Dentin Bond Strength. Materials 2024, 17, 2297. [Google Scholar] [CrossRef]

- Hayashi, J.; Tagami, J.; Chan, D.; Sadr, A. New bulk-fill composite system with high irradiance light polymerization: Integrity and degree of conversion. Dent. Mater. 2020, 36, 1615–1623. [Google Scholar] [CrossRef]

- 3M. Filtek One Bulk Fill Restaurative. Shrinkage, Stress and Bulk Fill Restoratives 2020. Available online: https://multimedia.3m.com/mws/media/1317665O/1317663m-filtek-one-bulk-fill-restorative-shrink-stressand-bulk-fill-restoratives.pdf (accessed on 1 December 2024).

- Ilie, N.; Watts, D.C. Outcomes of ultra-fast (3 s) photo-cure in a RAFT-modified resin-composite. Dent. Mater. 2020, 36, 570–579. [Google Scholar] [CrossRef]

- Moad, C.L.; Moad, G. Fundamentals of reversible addition–fragmentation chain transfer (RAFT). Chem. Teach. Int. 2021, 3, 3–17. [Google Scholar] [CrossRef]

- Gorsche, C.; Griesser, M.; Gescheidt, G.; Moszner, N.; Liska, R. β-Allyl Sulfones as Addition–Fragmentation Chain Transfer Reagents: A Tool for Adjusting Thermal and Mechanical Properties of Dimethacrylate Networks. Macromolecules 2014, 47, 7327–7336. [Google Scholar] [CrossRef]

- Gorsche, C.; Koch, T.; Moszner, N.; Liska, R. Exploring the benefits of β-allyl sulfones for more homogeneous dimethacrylate photopolymer networks. Polym. Chem. 2015, 6, 2038–2047. [Google Scholar] [CrossRef]

- Howard, B.; Wilson, N.D.; Newman, S.M.; Pfeifer, C.S.; Stansbury, J.W. Relationships between conversion, temperature and optical properties during composite photopolymerization. Acta Biomater. 2010, 6, 2053–2059. [Google Scholar] [CrossRef] [PubMed]

- Randolph, L.D.; Palin, W.M.; Watts, D.C.; Genet, M.; Devaux, J.; Leloup, G.; Leprince, J.G. The effect of ultra-fast photopolymerisation of experimental composites on shrinkage stress, network formation and pulpal temperature rise. Dent. Mater. 2014, 30, 1280–1289. [Google Scholar] [CrossRef]

- Trujillo, M.; Newman, S.M.; Stansbury, J.W. Use of near-IR to monitor the influence of external heating on dental composite photopolymerization. Dent. Mater. 2004, 20, 766–777. [Google Scholar] [CrossRef]

- Kim, R.J.; Son, S.A.; Hwang, J.Y.; Lee, I.B.; Seo, D.G. Comparison of photopolymerization temperature increases in internal and external positions of composite and tooth cavities in real time: Incremental fillings of microhybrid composite vs. bulk filling of bulk fill composite. J. Dent. 2015, 43, 1093–1098. [Google Scholar] [CrossRef]

- Lee, C.H.; Lee, I.B. Effect of translucency and absorbance of composite on temperature change during photopolymerization. Dent. Mater. J. 2023, 42, 894–900. [Google Scholar] [CrossRef]

- Price, R.B.; Ferracane, J.L.; Shortall, A.C. Light-Curing Units: A Review of What We Need to Know. J. Dent. Res. 2015, 94, 1179–1186. [Google Scholar] [CrossRef]

- Price, R.B.; Whalen, J.M.; Price, T.B.; Felix, C.M.; Fahey, J. The effect of specimen temperature on the polymerization of a resin-composite. Dent. Mater. 2011, 27, 983–989. [Google Scholar] [CrossRef]

- Negovetic Mandic, V.; Par, M.; Marovic, D.; Rakić, M.; Tarle, Z.; Klarić Sever, E. Blue Laser for Polymerization of Bulk-Fill Composites: Influence on Polymerization Kinetics. Nanomaterials 2023, 13, 303. [Google Scholar] [CrossRef]

- Almeida, R.; Manarte-Monteiro, P.; Domingues, J.; Falcao, C.; Herrero-Climent, M.; Rios-Carrasco, B.; Lemos, B.F. High-Power LED Units Currently Available for Dental Resin-Based Materials-A Review. Polymers 2021, 13, 2165. [Google Scholar] [CrossRef] [PubMed]

- Rueggeberg, F.A.; Giannini, M.; Arrais, C.A.G.; Price, R.B.T. Light curing in dentistry and clinical implications: A literature review. Braz. Oral. Res. 2017, 31, e61. [Google Scholar] [CrossRef] [PubMed]

- Ilie, N.; Schmalz, G.; Fujioka-Kobayashi, M.; Lussi, A.; Price, R.B. Correlation of the mechanical and biological response in light-cured RBCs to receiving a range of radiant exposures: Effect of violet light. J. Dent. 2021, 105, 103568. [Google Scholar] [CrossRef] [PubMed]

- Par, M.; Repusic, I.; Skenderovic, H.; Tarle, Z. Wavelength-dependent light transmittance in resin composites: Practical implications for curing units with different emission spectra. Clin. Oral. Investig. 2019, 23, 4399–4409. [Google Scholar] [CrossRef]

- Ilie, N. Impact of light transmittance mode on polymerisation kinetics in bulk-fill resin-based composites. J. Dent. 2017, 63, 51–59. [Google Scholar] [CrossRef]

- Palin, W.M.; Leprince, J.G.; Hadis, M.A. Shining a light on high volume photocurable materials. Dent. Mater. 2018, 34, 695–710. [Google Scholar] [CrossRef]

- Emami, N.; Sjodahl, M.; Soderholm, K.J. How filler properties, filler fraction, sample thickness and light source affect light attenuation in particulate filled resin composites. Dent. Mater. 2005, 21, 721–730. [Google Scholar] [CrossRef]

- Musanje, L.; Darvell, B.W. Curing-light attenuation in filled-resin restorative materials. Dent. Mater. 2006, 22, 804–817. [Google Scholar] [CrossRef]

- Son, S.A.; Park, J.K.; Seo, D.G.; Ko, C.C.; Kwon, Y.H. How light attenuation and filler content affect the microhardness and polymerization shrinkage and translucency of bulk-fill composites? Clin. Oral. Investig. 2017, 21, 559–565. [Google Scholar] [CrossRef]

- dos Santos, G.B.; Alto, R.V.; Filho, H.R.; da Silva, E.M.; Fellows, C.E. Light transmission on dental resin composites. Dent. Mater. 2008, 24, 571–576. [Google Scholar] [CrossRef]

- Harlow, J.E.; Rueggeberg, F.A.; Labrie, D.; Sullivan, B.; Price, R.B. Transmission of violet and blue light through conventional (layered) and bulk cured resin-based composites. J. Dent. 2016, 53, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Rocha, M.G.; Roulet, J.F.; Sinhoreti, M.A.C.; Correr, A.B.; Oliveira, D. Light Transmittance and Depth of Cure of a Bulk Fill Composite Based on the Exposure Reciprocity Law. Braz. Dent. J. 2021, 32, 78–84. [Google Scholar] [CrossRef] [PubMed]

- Marovic, D.; Danicic, P.; Bojo, G.; Par, M.; Tarle, Z. Monowave vs. Polywave Light—Curing Units: Effect on Light Transmission of Composite without Alternative Photoinitiators. Acta Stomatol. Croat. 2024, 58, 30–38. [Google Scholar] [CrossRef] [PubMed]

- Par, M.; Repusic, I.; Skenderovic, H.; Milat, O.; Spajic, J.; Tarle, Z. The effects of extended curing time and radiant energy on microhardness and temperature rise of conventional and bulk-fill resin composites. Clin. Oral. Investig. 2019, 23, 3777–3788. [Google Scholar] [CrossRef]

- Marovic, D.; Bota, M.; Tarle, F.; Par, M.; Haugen, H.J.; Zheng, K.; Pavic, D.; Milos, M.; Cizmek, L.; Babic, S.; et al. The influence of copper-doped mesoporous bioactive nanospheres on the temperature rise during polymerization, polymer cross-linking density, monomer release and embryotoxicity of dental composites. Dent. Mater. 2024, 40, 1078–1087. [Google Scholar] [CrossRef]

- Plant, C.G.; Jones, D.W.; Darvell, B.W. The heat evolved and temperatures attained during setting of restorative materials. Br. Dent. J. 1974, 137, 233–238. [Google Scholar] [CrossRef]

- Hori, M.; Fujimoto, K.; Hori, T.; Sekine, H.; Ueno, A.; Kato, A.; Kawai, T. Development of image analysis using Python: Relationship between matrix ratio of composite resin and curing temperature. Dent. Mater. J. 2020, 39, 648–656. [Google Scholar] [CrossRef]

- Braga, S.; Oliveira, L.; Ribeiro, M.; Vilela, A.; da Silva, G.R.; Price, R.B.; Soares, C.J. Effect of Simulated Pulpal Microcirculation on Temperature When Light Curing Bulk Fill Composites. Oper. Dent. 2019, 44, 289–301. [Google Scholar] [CrossRef]

- Santos, M.; Fidalgo-Pereira, R.; Torres, O.; Carvalho, O.; Henriques, B.; Ozcan, M.; Souza, J.C.M. The impact of inorganic fillers, organic content, and polymerization mode on the degree of conversion of monomers in resin-matrix cements for restorative dentistry: A scoping review. Clin. Oral. Investig. 2024, 28, 454. [Google Scholar] [CrossRef]

- Leprince, J.G.; Palin, W.M.; Hadis, M.A.; Devaux, J.; Leloup, G. Progress in dimethacrylate-based dental composite technology and curing efficiency. Dent. Mater. 2013, 29, 139–156. [Google Scholar] [CrossRef]

- Thanoon, H.; Price, R.B.; Watts, D.C. Thermography and conversion of fast-cure composite photocured with quad-wave and laser curing lights compared to a conventional curing light. Dent. Mater. 2024, 40, 546–556. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Sun, Q.; Zhang, Y.; Feng, Y.; Su, X. Rapid RAFT Polymerization of Acrylamide with High Conversion. Molecules 2023, 28, 2588. [Google Scholar] [CrossRef] [PubMed]

- Odum, N.C.; Ross, J.T.; Citrin, N.S.; Tantbirojn, D.; Versluis, A. Fast Curing with High-power Curing Lights Affects Depth of Cure and Post-gel Shrinkage and Increases Temperature in Bulk-fill Composites. Oper. Dent. 2023, 48, 98–107. [Google Scholar] [CrossRef] [PubMed]

- Ultradent. Valo Cordless Instructions for Use; Ultradent Products Inc.: Cologne, Germany, 2021. [Google Scholar]

- Par, M.; Prskalo, K.; Taubock, T.T.; Skenderovic, H.; Attin, T.; Tarle, Z. Polymerization kinetics of experimental resin composites functionalized with conventional (45S5) and a customized low-sodium fluoride-containing bioactive glass. Sci. Rep. 2021, 11, 21225. [Google Scholar] [CrossRef]

- Par, M.; Gamulin, O.; Marovic, D.; Klaric, E.; Tarle, Z. Raman spectroscopic assessment of degree of conversion of bulk-fill resin composites-changes at 24 hours post cure. Oper. Dent. 2015, 40, E92–E101. [Google Scholar] [CrossRef]

| Light-Curing Unit | Curing Protocol | Mean Irradiance ± s.d. at 0 mm (mW/cm2) | Total Energy ± s.d. from 360 to 540 nm (J/cm2) |

|---|---|---|---|

| VALO Cordless | 3s | 2522.6 ± 10.9 | 7.7 ± 0.0 |

| 10s | 1050.8 ± 1.8 | 10.6 ± 0.0 | |

| 20s | 1057.0 ± 4.9 | 21.2 ± 0.1 | |

| Bluephase PowerCure | 3s | 3045.6 ± 16.3 | 9.1 ± 0.0 |

| 10s | 1187.4 ± 3.4 | 11.9 ± 0.0 | |

| 20s | 1203.8 ± 4.0 | 24.1 ± 0.1 | |

| Translux Wave | 10s | 805.2 ± 3.4 | 7.9 ± 0.0 |

| 20s | 789.0 ± 7.1 | 16.1 ± 0.3 |

| DC | Total Temperature Rise | Exotherm Temperature Rise | Light Transmittance | |

|---|---|---|---|---|

| DC | - | R = 0.742 p < 0.001 | R = 0.641 p < 0.001 | R = 0.217 p = 0.232 |

| Total temperature rise | - | - | R = 0.973 p < 0.001 | R = 0.609 p < 0.001 |

| Exotherm temperature rise | - | - | - | R = 0.655 p < 0.001 |

| Material | LOT No. | Composition | Filler Load (wt%/vol%) |

|---|---|---|---|

| Filtek One Bulk Fill (3M ESPE) A2 | NC09993 | AUDMA, AFM, DDDMA, UDMA, ytterbium trifluoride, 4 to 11 nm zirconia filler, an aggregated zirconia/silica cluster filler (comprised of 20 nm silica and 4 to 11 nm zirconia particles) | ≈76.5/≈58.5 |

| Tetric PowerFill (Ivoclar) IVA | Z01SDW | Bis-GMA, Bis-EMA, UDMA, Bis-PMA, DCP, D3MA, β-allyl sulfone, barium glass, ytterbium trifluoride, copolymer, mixed oxide camphorquinone, tertiary amines, Ivocerin | 76–77/53–54 |

| Tetric PowerFlow (Ivoclar) IVA | Z03236 | Bis-GMA, Bis-EMA, UDMA, DCP, barium glass, ytterbium trifluoride, copolymer, mixed oxide camphorquinone, tertiary amines, Ivocerin | 68.2/46.4 |

| SDR flow+ Bulk Fill Flowable (Dentsply Sirona) A2 | 2101000559 | modified UDMA, TEGDMA, dimethacrylate, trimethacrylate resins, camphorquinone; ethyl-4(dimethylamino)benzoate photoaccelerator; BHT; barium-alumino-fluoro-borosilicate glass; silanated strontium alumino-fluoro-silicate glass; surface treated fume silicas; ytterbium fluoride; synthetic inorganic iron oxide pigments, and titanium dioxide | 70.5/47.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marovic, D.; Par, M.; Daničić, P.; Marošević, A.; Bojo, G.; Alerić, M.; Antić, S.; Puljić, K.; Badovinac, A.; Shortall, A.C.; et al. The Role of Rapid Curing on the Interrelationship Between Temperature Rise, Light Transmission, and Polymerisation Kinetics of Bulk-Fill Composites. Int. J. Mol. Sci. 2025, 26, 2803. https://doi.org/10.3390/ijms26062803

Marovic D, Par M, Daničić P, Marošević A, Bojo G, Alerić M, Antić S, Puljić K, Badovinac A, Shortall AC, et al. The Role of Rapid Curing on the Interrelationship Between Temperature Rise, Light Transmission, and Polymerisation Kinetics of Bulk-Fill Composites. International Journal of Molecular Sciences. 2025; 26(6):2803. https://doi.org/10.3390/ijms26062803

Chicago/Turabian StyleMarovic, Danijela, Matej Par, Paulina Daničić, Ana Marošević, Gloria Bojo, Marta Alerić, Svenia Antić, Krunoslav Puljić, Ana Badovinac, Adrian C. Shortall, and et al. 2025. "The Role of Rapid Curing on the Interrelationship Between Temperature Rise, Light Transmission, and Polymerisation Kinetics of Bulk-Fill Composites" International Journal of Molecular Sciences 26, no. 6: 2803. https://doi.org/10.3390/ijms26062803

APA StyleMarovic, D., Par, M., Daničić, P., Marošević, A., Bojo, G., Alerić, M., Antić, S., Puljić, K., Badovinac, A., Shortall, A. C., & Tarle, Z. (2025). The Role of Rapid Curing on the Interrelationship Between Temperature Rise, Light Transmission, and Polymerisation Kinetics of Bulk-Fill Composites. International Journal of Molecular Sciences, 26(6), 2803. https://doi.org/10.3390/ijms26062803