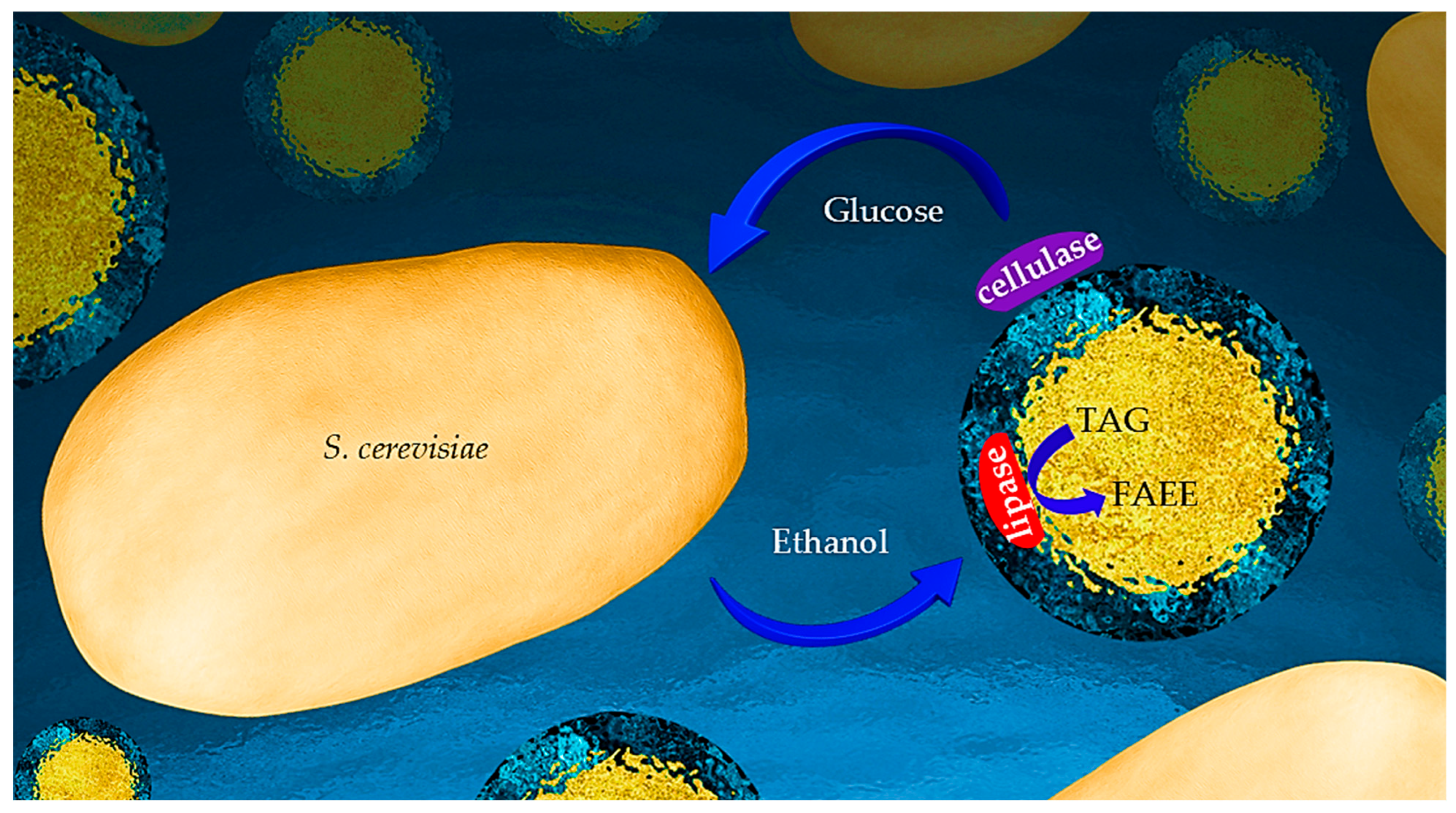

A Consolidated Saccharification, Fermentation, and Transesterification Process (cSFT) Converting Castor Oil to Biodiesel with Cellulose-Derived Ethanol

Abstract

1. Introduction

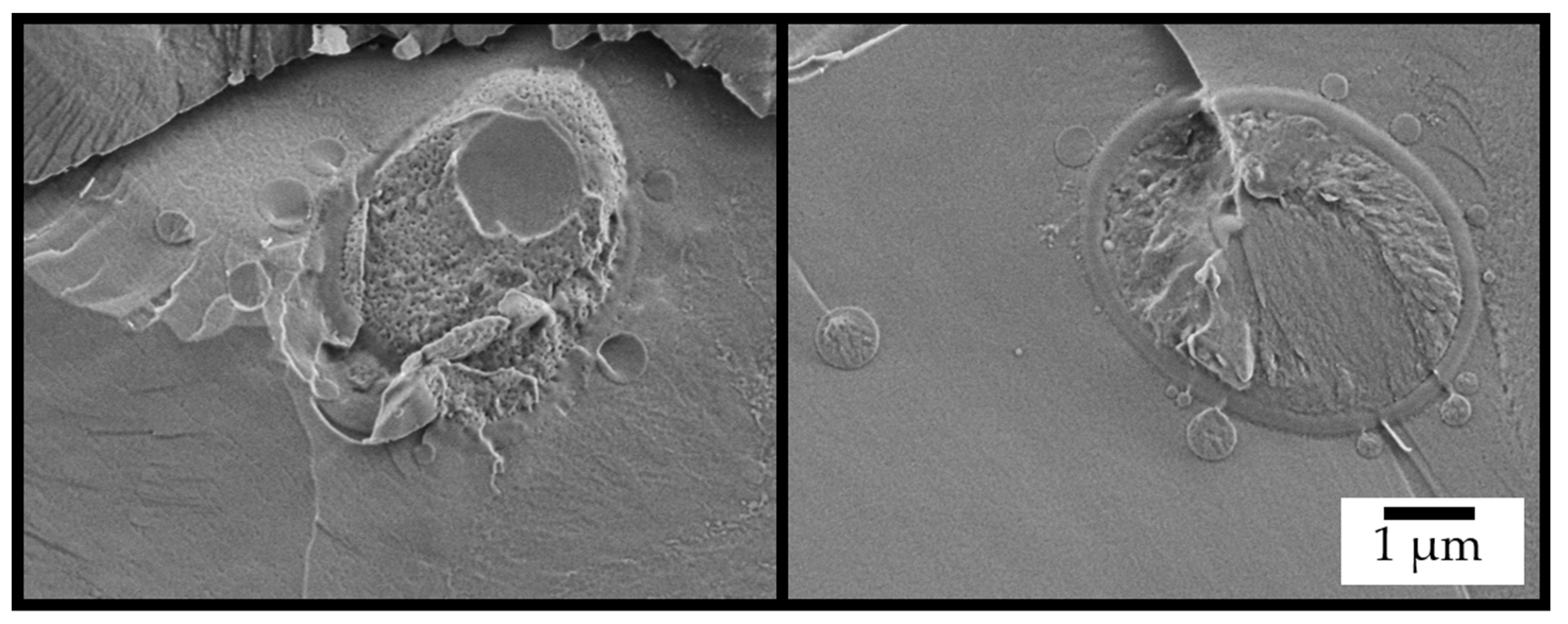

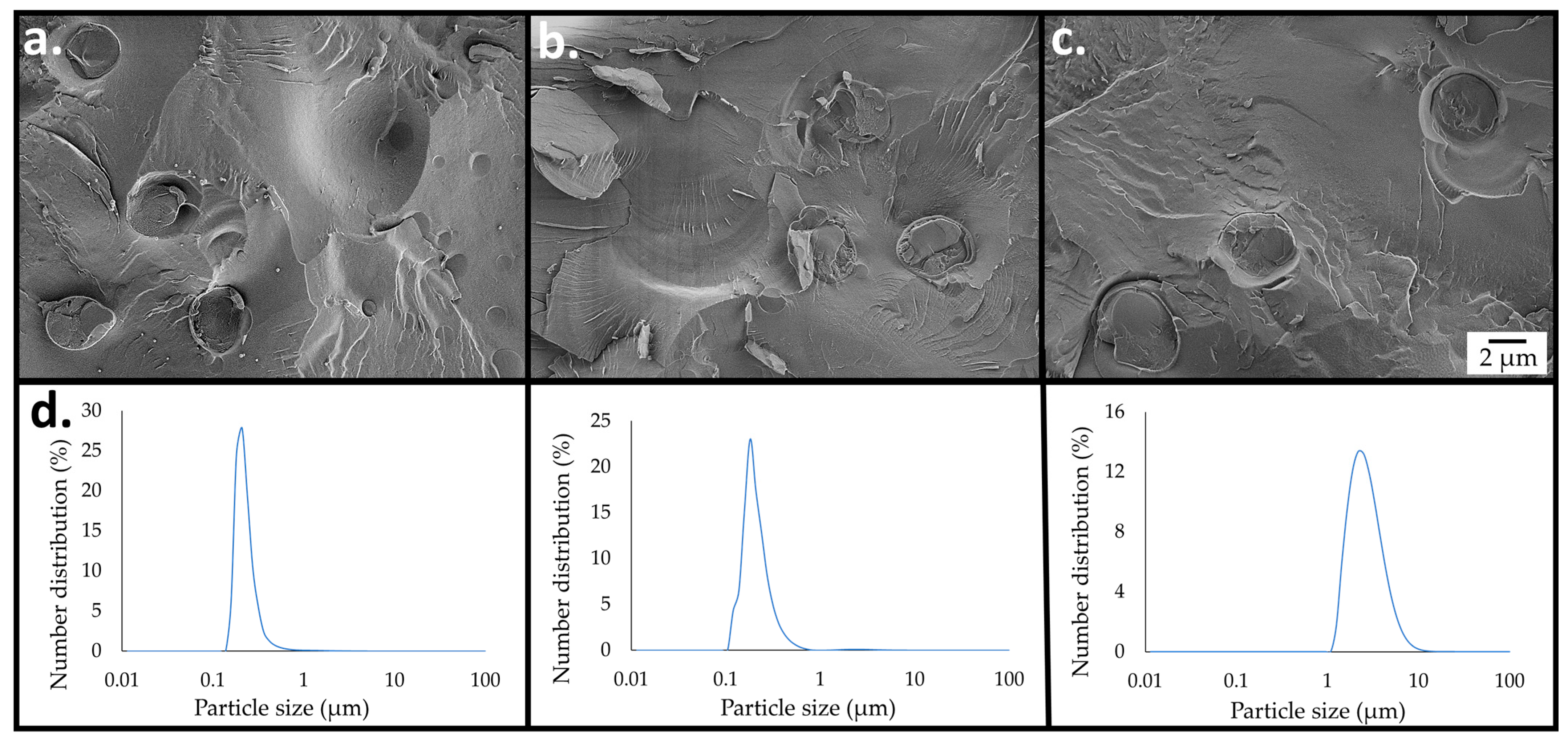

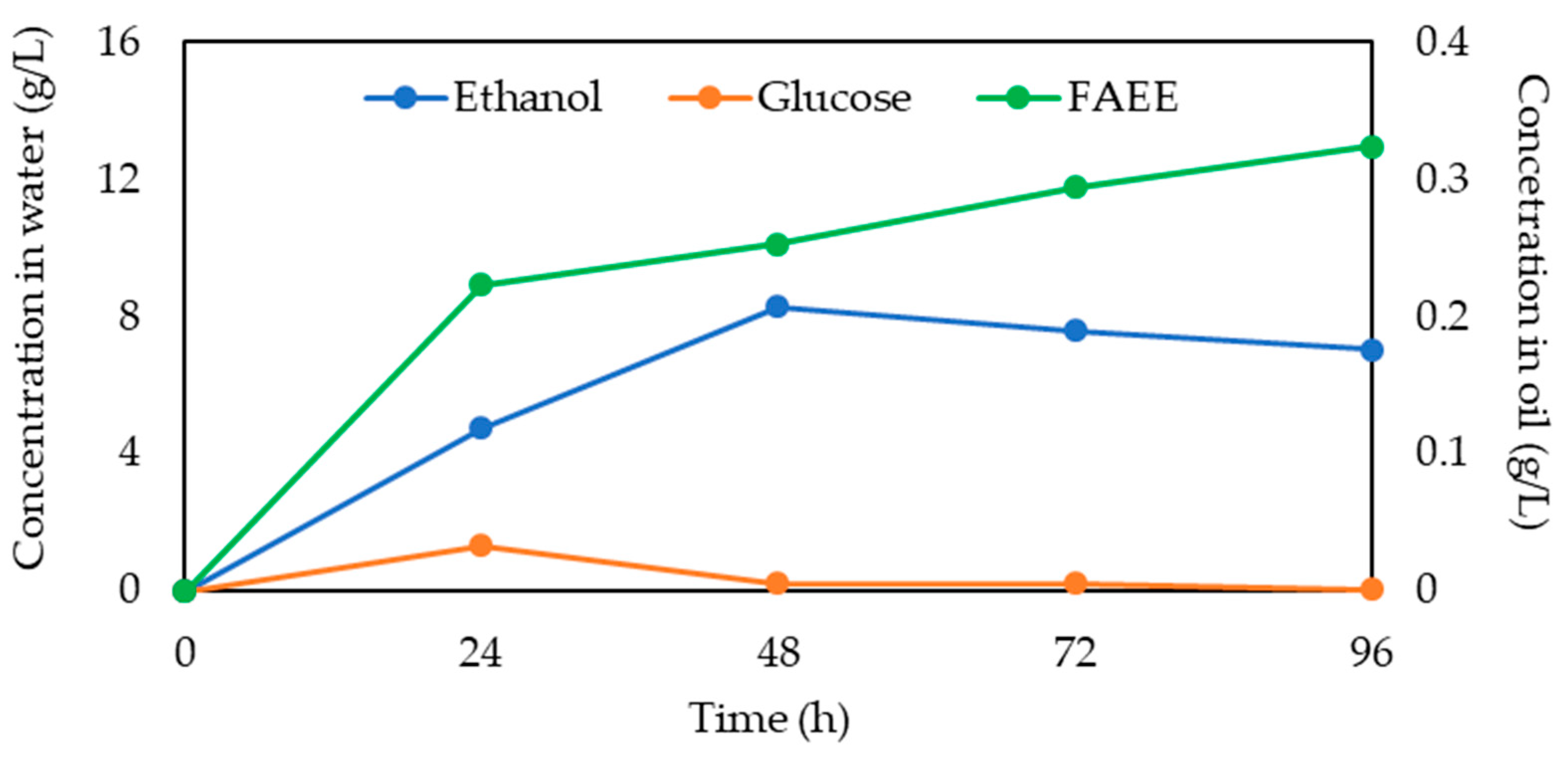

2. Results

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Methods

4.2.1. Preparation of Emulsion Integrated with S. cerevisiae

4.2.2. Imaging by Cryogenic Scanning Electron Microscopy (Cryo-SEM)

4.2.3. One-Pot Reaction and Bio-Conversion of Cellulose to Biodiesel

4.2.4. Nuclear Magnetic Resonance (NMR) Analysis

4.2.5. Dinitrosalicylic Acid (DNS) Method

4.2.6. Gas Chromatography Analysis (GC)

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CDCl3 | Deuterated chloroform |

| Cryo-SEM | Cryogenic scanning electron microscopy |

| cSFT | Consolidated bioprocess of saccharification, fermentation, and transesterification |

| DNS | Dinitrosalicylic acid |

| EsB | Energy-selective backscattered electron |

| eSSF | Emulsion-based simultaneous saccharification and fermentation |

| FAEE | Fatty acid ethanol ester |

| FFAs | Free fatty acids |

| FPU | Filter paper unit |

| GC | Gas chromatography |

| 1H NMR | Proton nuclear magnetic resonance |

| HPH | High-pressure homogenization |

| KLU | Kilo lipase units |

| LS | Light scattering |

| MCC | Micro-crystalline cellulose |

| NaOH | Sodium hydroxide |

| PE | Pickering emulsions |

| SE2 | Secondary electron |

| SSF | Simultaneous saccharification and fermentation |

| TGA | Triacyl glyceride |

References

- Wang, C.; Zhang, W.; Qiu, X.; Xu, C. Hydrothermal treatment of lignocellulosic biomass towards low-carbon development: Production of high-value-added bioproducts. EnergyChem 2024, 6, 100133. [Google Scholar] [CrossRef]

- Seki, Y.; Selli, F. A review on alternative raw materials for sustainable production: Novel plant fibers. Cellulose 2022, 29, 4877–4918. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, L.; Khoo, K.S.; Gupta, V.K.; Sharma, M.; Show, P.L.; Yap, P.S. Exploitation of lignocellulosic-based biomass biorefinery: A critical review of renewable bioresource, sustainability and economic views. Biotechnol. Adv. 2023, 69, 108265. [Google Scholar] [CrossRef] [PubMed]

- Mujtaba, M.; Fraceto, L.F.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; de Medeiros, G.A.; Santo Pereira, A.D.E.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic biomass from agricultural waste to the circular economy: A review with focus on biofuels, biocomposites and bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- Trache, D.; Hussin, M.H.; Chuin, C.T.H.; Sabar, S.; Fazita, M.N.; Taiwo, O.F.; Hassan, T.M.; Haafiz, M.M. Microcrystalline cellulose: Isolation, characterization and bio-composites application—A review. Int. J. Biol. Macromol. 2016, 93, 789–804. [Google Scholar] [CrossRef]

- Wang, F.; Ouyang, D.; Zhou, Z.; Page, S.J.; Liu, D.; Zhao, X. Lignocellulosic biomass as sustainable feedstock and materials for power generation and energy storage. J. Energy Chem. 2021, 57, 247–280. [Google Scholar] [CrossRef]

- Devi, A.; Bajar, S.; Kour, H.; Kothari, R.; Pant, D.; Singh, A. Lignocellulosic Biomass Valorization for Bioethanol Production: A Circular Bioeconomy Approach. BioEnergy Res. 2022, 15, 1820–1841. [Google Scholar] [CrossRef]

- Beluhan, S.; Mihajlovski, K.; Šantek, B.; Ivančić Šantek, M. The Production of Bioethanol from Lignocellulosic Biomass: Pretreatment Methods, Fermentation, and Downstream Processing. Energies 2023, 16, 7003. [Google Scholar] [CrossRef]

- Żywicka, A.; Banach, A.; Junka, A.F.; Drozd, R.; Fijałkowski, K. Bacterial cellulose as a support for yeast immobilization—Correlation between carrier properties and process efficiency. J. Biotechnol. 2019, 291, 1–6. [Google Scholar] [CrossRef]

- Winkelhausen, E.; Velickova, E.; Amartey, S.A.; Kuzmanova, S. Ethanol production using immobilized Saccharomyces cerevisiae in lyophilized cellulose gel. Appl. Biochem. Biotechnol. 2010, 162, 2214–2220. [Google Scholar] [CrossRef]

- El-Dalatony, M.M.; Kurade, M.B.; Abou-Shanab, R.A.; Kim, H.; Salama, E.S.; Jeon, B.H. Long-term production of bioethanol in repeated-batch fermentation of microalgal biomass using immobilized Saccharomyces cerevisiae. Bioresour. Technol. 2016, 219, 98–105. [Google Scholar] [CrossRef] [PubMed]

- Orrego, D.; Zapata-Zapata, A.D.; Kim, D. Ethanol production from coffee mucilage fermentation by S. cerevisiae immobilized in calcium-alginate beads. Bioresour. Technol. Rep. 2018, 3, 200–204, Erratum in Bioresour. Technol. Rep. 2020, 11, 100502. [Google Scholar] [CrossRef]

- Khanpanuek, S.; Lunprom, S.; Reungsang, A.; Salakkam, A. Repeated-batch simultaneous saccharification and fermentation of cassava pulp for ethanol production using amylases and Saccharomyces cerevisiae immobilized on bacterial cellulose. Biochem. Eng. J. 2022, 177, 108258. [Google Scholar] [CrossRef]

- Karagoz, P.; Bill, R.M.; Ozkan, M. Lignocellulosic ethanol production: Evaluation of new approaches, cell immobilization and reactor configurations. Renew. Energy 2019, 143, 741–752. [Google Scholar] [CrossRef]

- Öhgren, K.; Bura, R.; Lesnicki, G.; Saddler, J.; Zacchi, G. A comparison between simultaneous saccharification and fermentation and separate hydrolysis and fermentation using steam-pretreated corn stover. Process Biochem. 2007, 42, 834–839. [Google Scholar] [CrossRef]

- Wingren, A.; Galbe, M.; Zacchi, G. Techno-economic evaluation of producing ethanol from softwood: Comparison of SSF and SHF and identification of bottlenecks. Biotechnol. Prog. 2003, 19, 1109–1117. [Google Scholar] [CrossRef]

- Szambelan, K.; Nowak, J.; Szwengiel, A.; Jeleń, H.; Łukaszewski, G. Separate hydrolysis and fermentation and simultaneous saccharification and fermentation methods in bioethanol production and formation of volatile by-products from selected corn cultivars. Ind. Crops Prod. 2018, 118, 355–361. [Google Scholar] [CrossRef]

- Kim, G.B.; Kim, H.R.; Lee, S.Y. Comprehensive evaluation of the capacities of microbial cell factories. Nat. Commun. 2025, 16, 2869. [Google Scholar] [CrossRef]

- Yang, Z.; Leero, D.D.; Yin, C.; Yang, L.; Zhu, L.; Zhu, Z.; Jiang, L. Clostridium as microbial cell factory to enable the sustainable utilization of three generations of feedstocks. Bioresour. Technol. 2022, 361, 127656. [Google Scholar] [CrossRef]

- Cowan, A.E.; Klass, S.H.; Winegar, P.H.; Keasling, J.D. Microbial production of fuels, commodity chemicals, and materials from sustainable sources of carbon and energy. Curr. Opin. Syst. Biol. 2023, 36, 100482. [Google Scholar] [CrossRef]

- Hasni, M.H.; Ahmad, F.B.; Athoillah, A.Z. The production of microbial biodiesel from cellulose-derived fungal lipid via consolidated bioprocessing. Environ. Technol. Innov. 2023, 30, 103123. [Google Scholar] [CrossRef]

- Liu, Z.; Ho, S.-H.; Sasaki, K.; den Haan, R.; Inokuma, K.; Ogino, C.; van Zyl, W.H.; Hasunuma, T.; Kondo, A. Engineering of a novel cellulose-adherent cellulolytic Saccharomyces cerevisiae for cellulosic biofuel production. Sci. Rep. 2016, 6, 24550. [Google Scholar] [CrossRef] [PubMed]

- Asemoloye, M.D.; Bello, T.S.; Oladoye, P.O.; Remilekun Gbadamosi, M.; Babarinde, S.O.; Ebenezer Adebami, G.; Olowe, O.M.; Temporiti, M.E.E.; Wanek, W.; Marchisio, M.A. Engineered yeasts and lignocellulosic biomaterials: Shaping a new dimension for biorefinery and global bioeconomy. Bioengineered 2023, 14, 2269328. [Google Scholar] [CrossRef] [PubMed]

- Periyasamy, S.; Isabel, J.B.; Kavitha, S.; Karthik, V.; Mohamed, B.A.; Gizaw, D.G.; Sivashanmugam, P.; Aminabhavi, T.M. Recent advances in consolidated bioprocessing for conversion of lignocellulosic biomass into bioethanol—A review. Chem. Eng. J. 2023, 453, 139783. [Google Scholar] [CrossRef]

- Kim, H.M.; Chae, T.U.; Choi, S.Y.; Kim, W.J.; Lee, S.Y. Engineering of an oleaginous bacterium for the production of fatty acids and fuels. Nat. Chem. Biol. 2019, 15, 721–729. [Google Scholar] [CrossRef]

- Steen, E.J.; Kang, Y.; Bokinsky, G.; Hu, Z.; Schirmer, A.; McClure, A.; Del Cardayre, S.B.; Keasling, J.D. Microbial production of fatty-acid-derived fuels and chemicals from plant biomass. Nature 2010, 463, 6–10. [Google Scholar] [CrossRef]

- Gihaz, S.; Bash, Y.; Rush, I.; Shahar, A.; Pazy, Y.; Fishman, A. Bridges to Stability: Engineering Disulfide Bonds Towards Enhanced Lipase Biodiesel Synthesis. ChemCatChem 2020, 12, 181–192. [Google Scholar] [CrossRef]

- Tan, T.; Lu, J.; Nie, K.; Deng, L.; Wang, F. Biodiesel production with immobilized lipase: A review. Biotechnol. Adv. 2010, 28, 628–634, Erratum in Biotechnol. Adv. 2010, 28, 937. [Google Scholar] [CrossRef]

- Sathvika, T.; Manasi Rajesh, V.; Rajesh, N. Microwave assisted immobilization of yeast in cellulose biopolymer as a green adsorbent for the sequestration of chromium. Chem. Eng. J. 2015, 279, 38–46. [Google Scholar] [CrossRef]

- Pérignon, M.; Lecomte, J.; Pina, M.; Renault, A.; Simonneau-Deve, C.; Villeneuve, P. Activity of immobilized thermomyces lanuginosus and candida antarctica B lipases in interesterification reactions: Effect of the aqueous microenvironment. J. Am. Oil Chem. Soc. 2013, 90, 1151–1156. [Google Scholar] [CrossRef]

- Hincapié, G.M.; Valange, S.; Barrault, J.; Moreno, J.A.; López, D.P. Effect of microwave-assisted system on transesterification of castor oil with ethanol. Univ. Sci. 2014, 19, 193–200. [Google Scholar] [CrossRef]

- Long, B.; Zhang, F.; Dai, S.Y.; Foston, M.; Tang, Y.J.; Yuan, J.S. Engineering strategies to optimize lignocellulosic biorefineries. Nat. Rev. Bioeng. 2025, 3, 230–244. [Google Scholar] [CrossRef]

- Benítez-mateos, A.I.; Padrosa, D.R.; Paradisi, F. Multistep enzyme cascades as a route towards green and sustainable pharmaceutical syntheses. Nat. Chem. 2022, 14, 489–499. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Qiao, X.; Chen, H.; Wang, L.; Liu, X.; Huang, X. Synthetic-Cell-Based Multi-Compartmentalized Hierarchical Systems. Small Methods 2023, 7, 2201712. [Google Scholar] [CrossRef]

- Hao, R.; Zhang, M.; Tian, D.; Lei, F.; Qin, Z.; Wu, T.; Yang, H. Bottom-Up Synthesis of Multicompartmentalized Microreactors for Continuous Flow Catalysis. J. Am. Chem. Soc. 2023, 145, 20319–20327. [Google Scholar] [CrossRef]

- Fujiwara, K.; Adachi, T.; Doi, N. Artificial Cell Fermentation as a Platform for Highly Efficient Cascade Conversion. ACS Synth. Biol. 2018, 7, 363–370. [Google Scholar] [CrossRef]

- Bastida, A.; Blanco, R.M.; Zárate, S.G.; García-Junceda, E.; Guisán, J.M. Highly improved enzymatic peptide synthesis by using biphasic reactors. Biocatal. Biotransform. 2018, 36, 271–278. [Google Scholar] [CrossRef]

- Ni, L.; Yu, C.; Wei, Q.; Liu, D.; Qiu, J. Pickering Emulsion Catalysis: Interfacial Chemistry, Catalyst Design, Challenges, and Perspectives. Angew. Chem.-Int. Ed. 2022, 61, e202115885. [Google Scholar] [CrossRef]

- Nini, L.; Sarda, L.; Comeau, L.C.; Boitard, E.; Dubès, J.P.; Chahinian, H. Lipase-catalysed hydrolysis of short-chain substrates in solution and in emulsion: A kinetic study. Biochim. Biophys. Acta (BBA)-Mol. Cell Biol. Lipids 2001, 1534, 34–44. [Google Scholar] [CrossRef]

- Gonzalez Ortiz, D.; Pochat-Bohatier, C.; Cambedouzou, J.; Bechelany, M.; Miele, P. Current Trends in Pickering Emulsions: Particle Morphology and Applications. Engineering 2020, 6, 468–482. [Google Scholar] [CrossRef]

- Jiang, H.; Sheng, Y.; Ngai, T. Pickering emulsions: Versatility of colloidal particles and recent applications. Curr. Opin. Colloid Interface Sci. 2020, 49, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Rein, D.M.; Khalfin, R.; Cohen, Y. Cellulose as a novel amphiphilic coating for oil-in-water and water-in-oil dispersions. J. Colloid Interface Sci. 2012, 386, 456–463. [Google Scholar] [CrossRef] [PubMed]

- Napso, S.; Rein, D.M.; Fu, Z.; Radulescu, A.; Cohen, Y. Structural Analysis of Cellulose-Coated Oil-in-Water Emulsions Fabricated from Molecular Solution. Langmuir 2018, 34, 8857–8865. [Google Scholar] [CrossRef] [PubMed]

- Korkus Hamal, E.; Alfassi, G.; Khalfin, R.; Rein, D.; Cohen, Y. Structural Insights into Cellulose-Coated Oil in Water Emulsions. Langmuir 2022, 38, 11171–11179. [Google Scholar] [CrossRef]

- Alfassi, G.; Rein, D.M.; Cohen, Y. Cellulose emulsions and their hydrolysis. J. Chem. Technol. Biotechnol. 2019, 94, 178–184. [Google Scholar] [CrossRef]

- Hoffman, S.M.; Alvarez, M.; Alfassi, G.; Rein, D.M.; Garcia-Echauri, S.; Cohen, Y.; Avalos, J.L. Cellulosic biofuel production using emulsified simultaneous saccharification and fermentation (eSSF) with conventional and thermotolerant yeasts. Biotechnol. Biofuels 2021, 14, 157–174. [Google Scholar] [CrossRef]

- Meirelles, A.A.D.; da Cunha, R.L.; Gombert, A.K. The role of Saccharomyces cerevisiae in stabilizing emulsions of hexadecane in aqueous media. Appl. Microbiol. Biotechnol. 2018, 102, 3411–3424. [Google Scholar] [CrossRef]

- Korkus Hamal, E.; Alfassi, G.; Rein, D.; Cohen, Y. Towards one-pot consolidated bioprocessing of cellulose to biodiesel: Lipase-catalyzed transesteri fi cation at cellulose-coated oil-in-water emulsions as micro-reactors. J. Chem. Technol. Biotechnol. 2022, 97, 2607–2612. [Google Scholar] [CrossRef]

- Hamal, E.K.; Alfassi, G.; Antonenko, M.; Rein, D.M. Cellulose-coated emulsion micro-particles self-assemble with yeasts for cellulose bio-conversion. Sci. Rep. 2024, 14, 5499. [Google Scholar] [CrossRef]

- Arslan, A.; Rancke-Madsen, A.; Brask, J. Enzymatic synthesis of estolides from castor oil. Catalysts 2020, 10, 835. [Google Scholar] [CrossRef]

- Iso, M.; Chen, B.; Eguchi, M.; Kudo, T.; Shrestha, S. Production of biodiesel fuel from triglycerides and alcohol using immobilized lipase. J. Mol. Catal.-B Enzym. 2001, 16, 53–58. [Google Scholar] [CrossRef]

- Jaiswal, S.K.; Tejo Prakash, N.; Prakash, R. 1 H NMR Based Quantification of Ethyl Ester in Biodiesel: A Comparative Study of Product-Dependent Derivations. Anal. Chem. Lett. 2016, 6, 518–525. [Google Scholar] [CrossRef]

- Bajaj, A.; Lohan, P.; Jha, P.N.; Mehrotra, R. Biodiesel production through lipase catalyzed transesterification: An overview. J. Mol. Catal. B Enzym. 2010, 62, 9–14. [Google Scholar] [CrossRef]

- Amândio, M.S.; Rocha, J.M.; Xavier, A.M. Fed-batch SSF with pre-saccharification as a strategy to reduce enzyme dosage in cellulosic ethanol production. Fuel 2024, 357, 129842. [Google Scholar] [CrossRef]

- Aristizábal-Marulanda, V.; Cardona Alzate, C.A. Methods for designing and assessing biorefineries: Review. Biofuels Bioprod. Biorefining 2019, 13, 789–808. [Google Scholar]

- Zhao, J.; Xu, Y.; Wang, W.; Gri, J.; Wang, D. High Ethanol Concentration (77 g/L) of Industrial Hemp Biomass Achieved Through Optimizing the Relationship between Ethanol Yield/Concentration and Solid Loading. ACS Omega 2020, 5, 21913–21921. [Google Scholar] [CrossRef]

- Keasling, J.; Garcia Martin, H.; Lee, T.S.; Mukhopadhyay, A.; Singer, S.W.; Sundstrom, E. Microbial production of advanced biofuels. Nat. Rev. Microbiol. 2021, 19, 701–715. [Google Scholar] [CrossRef]

- Scholz, V.; Da Silva, J.N. Prospects and risks of the use of castor oil as a fuel. Biomass Bioenergy 2008, 32, 95–100. [Google Scholar] [CrossRef]

- Osorio-González, C.S.; Gómez-Falcon, N.; Sandoval-Salas, F.; Saini, R.; Brar, S.K.; Ramírez, A.A. Production of biodiesel from castor oil: A review. Energies 2020, 13, 2467. [Google Scholar] [CrossRef]

- Koifman, N.; Talmon, Y. Cryogenic electron microscopy methodologies as analytical tools for the study of self-assembled pharmaceutics. Pharmaceutics 2021, 13, 1015. [Google Scholar] [CrossRef]

- Miller, G.L. Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Hunter, R.A. Analysis of Ethanol in Beer Using Gas Chromatography: A Side-by-Side Comparison of Calibration Methods. J. Chem. Educ. 2021, 98, 1404–1409. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korkus Hamal, E.; Alfassi, G.; Rein, D.M.; Cohen, Y. A Consolidated Saccharification, Fermentation, and Transesterification Process (cSFT) Converting Castor Oil to Biodiesel with Cellulose-Derived Ethanol. Int. J. Mol. Sci. 2025, 26, 11902. https://doi.org/10.3390/ijms262411902

Korkus Hamal E, Alfassi G, Rein DM, Cohen Y. A Consolidated Saccharification, Fermentation, and Transesterification Process (cSFT) Converting Castor Oil to Biodiesel with Cellulose-Derived Ethanol. International Journal of Molecular Sciences. 2025; 26(24):11902. https://doi.org/10.3390/ijms262411902

Chicago/Turabian StyleKorkus Hamal, Ester, Gilad Alfassi, Dmitry M. Rein, and Yachin Cohen. 2025. "A Consolidated Saccharification, Fermentation, and Transesterification Process (cSFT) Converting Castor Oil to Biodiesel with Cellulose-Derived Ethanol" International Journal of Molecular Sciences 26, no. 24: 11902. https://doi.org/10.3390/ijms262411902

APA StyleKorkus Hamal, E., Alfassi, G., Rein, D. M., & Cohen, Y. (2025). A Consolidated Saccharification, Fermentation, and Transesterification Process (cSFT) Converting Castor Oil to Biodiesel with Cellulose-Derived Ethanol. International Journal of Molecular Sciences, 26(24), 11902. https://doi.org/10.3390/ijms262411902