Copper-Modified Cellulose Paper: A Comparative Study of How Antimicrobial Activity Is Affected by Particle Size and Testing Standards

Abstract

1. Introduction

2. Results

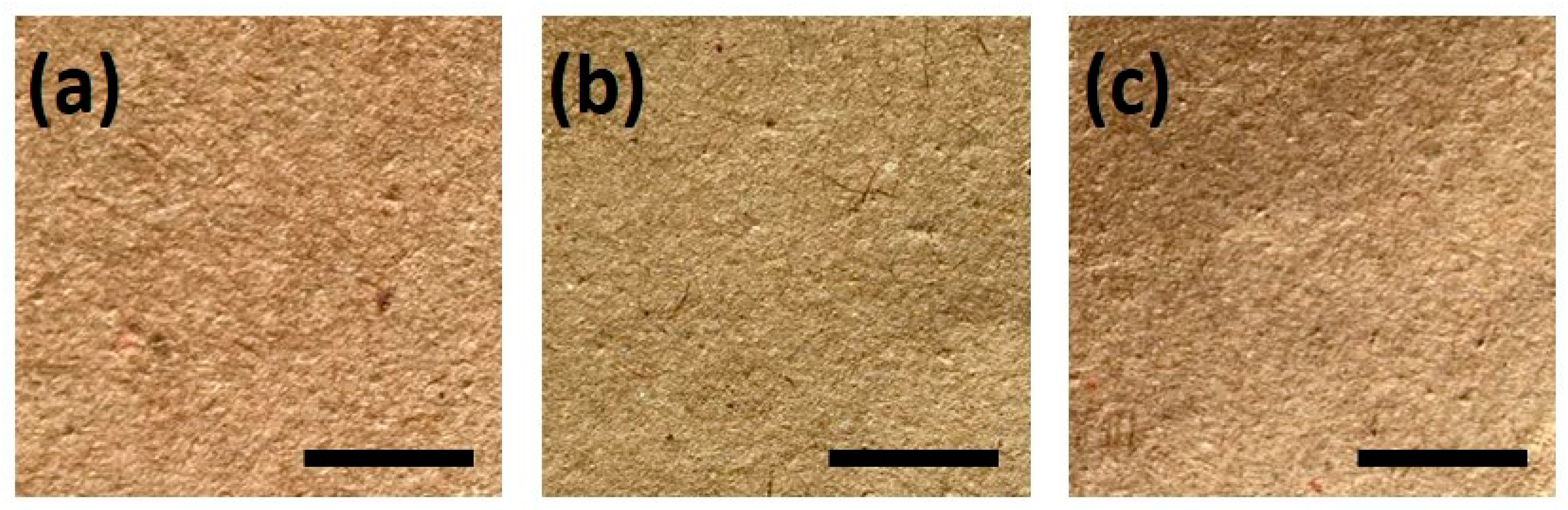

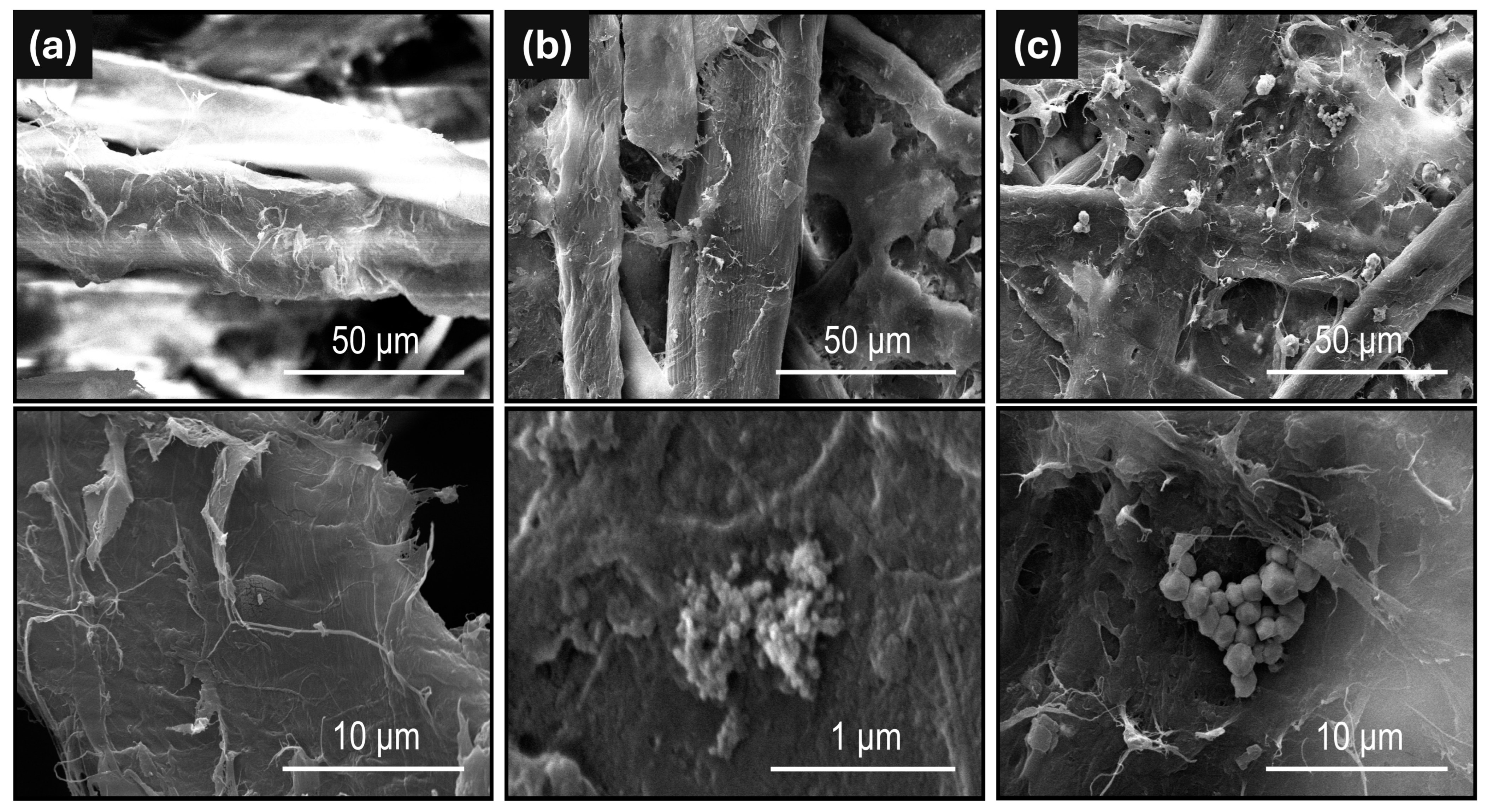

2.1. Characterization

2.2. Antimicrobial Activity

3. Discussion

4. Materials and Methods

4.1. Chemicals, Materials, and Bacterial Strains

4.2. Paper Production and Incorporation of Copper Particles

4.3. Characterization of Paper/CuPs

4.4. Antimicrobial Analysis

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Inhibition Zone [mm] Mean Value | Growth | Description | Assessment |

|---|---|---|---|

| >1 | None | Inhibition zone exceeding 1 mm; no growth | Good effect |

| 1–0 | None | Inhibition zone up to 1 mm; no growth | |

| 0 | None | No inhibition zone; no growth | Limited efficacy |

| 0 | Slight | No inhibition zone; only some restricted colonies; growth nearly totally suppressed | |

| 0 | Moderate | No inhibition zone; compared to the control, growth reduced to half | Insufficient effect |

| 0 | Heavy | No inhibition zone; compared to the control, no growth reduction or only slightly reduced growth |

Appendix B

| Antimicrobial Activity | Specific Efficacy |

|---|---|

| None | <0.5 |

| Slight | 0.5 < 1 |

| Significant | 1 < 3 |

| Strong | ≥3 |

References

- Barman, S.; Kurnaz, L.B.; Leighton, R.; Hossain, M.W.; Decho, A.W.; Tang, C. Intrinsic Antimicrobial Resistance: Molecular Biomaterials to Combat Microbial Biofilms and Bacterial Persisters. Biomaterials 2024, 311, 122690. [Google Scholar] [CrossRef]

- Quaranta, D.; Krans, T.; Santo, C.E.; Elowsky, C.G.; Domaille, D.W.; Chang, C.J.; Grass, G. Mechanisms of Contact-Mediated Killing of Yeast Cells on Dry Metallic Copper Surfaces. Appl. Environ. Microbiol. 2011, 77, 416–426. [Google Scholar] [CrossRef]

- Tamayo, L.; Azócar, M.; Kogan, M.; Riveros, A.; Páez, M. Copper-Polymer Nanocomposites: An Excellent and Cost-Effective Biocide for Use on Antibacterial Surfaces. Mater. Sci. Eng. C 2016, 69, 1391–1409. [Google Scholar] [CrossRef]

- Contreras, P.; Amenabar, A.; Apablaza, V.; Martínez, J.; Lavín, R.; Silva, N. Correlation between the Concentration and Morphology of Copper Microparticles and Their Biocidal Effect on Paper Sheets. Cellulose 2020, 27, 4721–4743. [Google Scholar] [CrossRef]

- Gonçalves, R.A.; Ku, J.W.K.; Zhang, H.; Salim, T.; Oo, G.; Zinn, A.A.; Boothroyd, C.; Tang, R.M.Y.; Gan, C.L.; Gan, Y.H.; et al. Copper-Nanoparticle-Coated Fabrics for Rapid and Sustained Antibacterial Activity Applications. ACS Appl. Nano Mater. 2022, 5, 12876–12886. [Google Scholar] [CrossRef]

- Cioffi, N.; Torsi, L.; Ditaranto, N.; Tantillo, G.; Ghibelli, L.; Sabbatini, L.; Bleve-Zacheo, T.; D’Alessio, M.; Zambonin, P.G.; Traversa, E. Copper Nanoparticle/Polymer Composites with Antifungal and Bacteriostatic Properties. Chem. Mater. 2005, 17, 5255–5262. [Google Scholar] [CrossRef]

- Abad, F.X.; Villena, C.; Guix, S.; Caballero, S.; Pintó, R.M.; Bosch, A. Potential Role of Fomites in the Vehicular Transmission of Human Astroviruses. Appl. Environ. Microbiol. 2001, 67, 3904–3907. [Google Scholar] [CrossRef]

- Corpet, D.E. Why Does SARS-CoV-2 Survive Longer on Plastic than on Paper? Med. Hypotheses 2021, 146, 110429. [Google Scholar] [CrossRef]

- Johnson, G.T.; Loehle, C.; Zhou, S.S.; Chiossone, C.; Palumbo, J.; Wiegand, P.; Johnson, G.T.; Loehle, C.; Zhou, S.S.; Chiossone, C.; et al. Evaluation of the Survivability of SARS-CoV-2 on Cardboard and Plastic Surfaces and the Transferability of Virus from Surface to Skin. Occup. Dis. Environ. Med. 2021, 9, 63–73. [Google Scholar] [CrossRef]

- Glasbrenner, D.C.; Choi, Y.W.; Middleton, J.K. SARS-CoV-2 Persistence on Common Food Covering Materials: Plastic Wrap, Fruit Wax, and Cardboard Takeout Containers. J. Appl. Microbiol. 2023, 134, lxac071. [Google Scholar] [CrossRef]

- United Nations Economic Commission for Europe (UNECE), and Food and Agriculture Organization of the United Nations (FAO). UNECE/FAO Data Brief 2023 Pulp, Paper and Paperboard. 2023. Available online: https://unece.org/forestry-timber/documents/2023/11/informal-documents/2023-data-brief-pulp-paper-and-paperboard (accessed on 29 December 2024).

- Statista Research Department Global Paper Consumption 2032 | Statista. Available online: https://www.statista.com/statistics/1089078/demand-paper-globally-until-2030/?utm_source=chatgpt.com (accessed on 29 December 2024).

- Cepi © Statistics KEY STATISTICS 2022. European Pulp & Paper Industry. Brussels, Belgium. 2023. Available online: https://www.cepi.org/cepi-statistics-2023-2/ (accessed on 29 December 2024).

- Pulp and Paper Market Size, Industry Share, Report, 2032. Available online: https://www.fortunebusinessinsights.com/pulp-and-paper-market-103447 (accessed on 29 December 2024).

- Yu, D.-H.; Yu, X.; Wang, C.; Liu, X.-C.; Xing, Y. Synthesis of Natural Cellulose-Templated TiO 2 /Ag Nanosponge Composites and Photocatalytic Properties. ACS Appl. Mater. Interfaces 2012, 4, 2781–2787. [Google Scholar] [CrossRef]

- Pal, S.; Nisi, R.; Stoppa, M.; Licciulli, A. Silver-Functionalized Bacterial Cellulose as Antibacterial Membrane for Wound-Healing Applications. ACS Omega 2017, 2, 3632–3639. [Google Scholar] [CrossRef]

- Haslinger, S.; Ye, Y.; Rissanen, M.; Hummel, M.; Sixta, H. Cellulose Fibers for High-Performance Textiles Functionalized with Incorporated Gold and Silver Nanoparticles. ACS Sustain. Chem. Eng. 2020, 8, 649–658. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, Q.; Payne, G.F.; Sun, R.; Wang, X. A Highly Conductive, Pliable and Foldable Cu/Cellulose Paper Electrode Enabled by Controlled Deposition of Copper Nanoparticles. Nanoscale 2019, 11, 725–732. [Google Scholar] [CrossRef] [PubMed]

- Muthulakshmi, L.; Varada, A.; Saravanan, G. Preparation of Cellulose / Copper Nanoparticles Bionanocomposite Films Using a Bioflocculant Polymer as Reducing Agent for Antibacterial and Anticorrosion Applications. Compos. Part B 2019, 175, 107177. [Google Scholar] [CrossRef]

- Dankovich, T.A.; Smith, J.A. Incorporation of Copper Nanoparticles into Paper for Point-of-Use Water Purification. Water Res. 2014, 63, 245–251. [Google Scholar] [CrossRef] [PubMed]

- Herrera-rivera, M.R.; Torres-arellanes, S.P.; Inocencio, C.; Navarro-ibarra, D.C. Nanotechnology in Food Packaging Materials: Role and Application of Nanoparticles. RSC Adv. 2024, 14, 21832–21858. [Google Scholar] [CrossRef]

- ISO 20645:2004; Textiles—Determination of Antibacterial Activity—Agar Diffusion Plate Test. International Organization for Standardization: Geneva, Switzerland, 2004.

- ISO 20743:2013; Textiles—Determination of Antibacterial Activity of Textile Products. International Organization for Standardization: Geneva, Switzerland, 2013.

- Adeleye, A.S.; Conway, J.R.; Perez, T.; Rutten, P.; Keller, A.A. Influence of Extracellular Polymeric Substances on the Long-Term Fate, Dissolution, and Speciation of Copper-Based Nanoparticles. Environ. Sci. Technol. 2014, 48, 12561–12568. [Google Scholar] [CrossRef]

- Zeng, Z.; Yu, L.; Yang, S.; Guo, K.; Xu, C.; Chen, C.; Wang, Z. Tuning Water-Cellulose Interactions via Copper-Coordinated Mercerization for Hydro-Actuated, Shape-Memory Cellulosic Hydroplastics. Matter 2024, 7, 3036–3052. [Google Scholar] [CrossRef]

- Marcuello, C.; Foulon, L.; Chabbert, B.; Aguié-Béghin, V.; Molinari, M. Atomic Force Microscopy Reveals How Relative Humidity Impacts the Young’s Modulus of Lignocellulosic Polymers and Their Adhesion with Cellulose Nanocrystals at the Nanoscale. Int. J. Biol. Macromol. 2020, 147, 1064–1075. [Google Scholar] [CrossRef]

- Araya-Hermosilla, R.; Martínez, J.; Loyola, C.Z.; Ramírez, S.; Salazar, S.; Henry, C.S.; Lavín, R.; Silva, N. Fast and Easy Synthesis of Silver, Copper, and Bimetallic Nanoparticles on Cellulose Paper Assisted by Ultrasound. Ultrason. Sonochem. 2023, 99, 106545. [Google Scholar] [CrossRef]

- Slavin, Y.N.; Asnis, J.; Häfeli, U.O.; Bach, H. Metal Nanoparticles: Understanding the Mechanisms behind Antibacterial Activity. J. Nanobiotechnol. 2017, 15, 65. [Google Scholar] [CrossRef]

- Spinnrock, A.; Martens, M.; Enders, F.; Boldt, K.; Cölfen, H. Controlled Preparation of Nanoparticle Gradient Materials by Diffusion. Nanomaterials 2019, 9, 988. [Google Scholar] [CrossRef]

- ISO 5269-1:2005; Pulps—Preparation of Laboratory Sheets for Physical Testing—Part 1: Conventional Method. International Organization for Standardization: Geneva, Switzerland, 2005.

- Holik, H. (Ed.) Handbook of Paper and Board; Wiley: Weinheim, Germany, 2006; ISBN 9783527309979. [Google Scholar]

| L | a | b | |

|---|---|---|---|

| Paper (Control) | 61.9 ± 0.2 | 6.5 ±0.1 | 13.4 ± 0.1 |

| Paper/CuNPs | 59.8 ± 0.2 | 4.5 ± 0.1 | 13.7 ± 0.1 |

| Paper/CuMPs | 61.5 ± 0.2 | 6.5 ± 0.1 | 12.4 ± 0.1 |

| Sample | Strain | Inhibition Zone [mm] Mean Value | Growth | Assessment |

|---|---|---|---|---|

| Paper | S. aureus | 0.00 ± 0.00 | Heavy | Insufficient effect |

| Paper/CuNPs | S. aureus | 1.97 ± 0.29 | None | Good effect |

| Paper/CuMPs | S. aureus | 0.00 ± 0.00 | Moderate | Insufficient effect |

| Paper | E. coli | 0.00 ± 0.00 | Heavy | Insufficient effect |

| Paper/CuNPs | E. coli | 4.13 ± 0.29 | None | Good effect |

| Paper/CuMPs | E. coli | 0.00 ± 0.00 | Heavy | Insufficient effect |

| Sample | Strain | Incubation Time (h) | UFC/cm2 | Log 10 | A Value | Antimicrobial Activity | Reduction % |

|---|---|---|---|---|---|---|---|

| Paper | S. aureus | 0 | 2.0 × 105 | 5.3 | - | - | - |

| 24 | 1.2 × 107 | 7.1 | |||||

| Paper/CuNPs | S. aureus | 0 | 2.0 × 105 | 5.3 | 6.1 | Strong | 100 |

| 24 | 0 | 1 | |||||

| Paper/CuMPs | S. aureus | 0 | 2.0 × 105 | 5.3 | 4.8 | Strong | 99.99 |

| 24 | 2.0 × 102 | 2.3 | |||||

| Paper | E. coli | 0 | 2.0 × 105 | 5.3 | - | - | - |

| 24 | 1.9 × 107 | 7.3 | |||||

| Paper/CuNPs | E. coli | 0 | 2.0 × 105 | 5.3 | 6.2 | Strong | 100 |

| 24 | 0 | 1 | |||||

| Paper/CuMPs | E. coli | 0 | 2.0 × 105 | 5.3 | 3.8 | Strong | 99.25 |

| 24 | 3.5 × 103 | 3.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramírez, S.; Zúñiga, F.; Amenábar, A.; Contreras, P.; Benavides, V.; Norambuena, J.; Martínez, J.; Silva, N. Copper-Modified Cellulose Paper: A Comparative Study of How Antimicrobial Activity Is Affected by Particle Size and Testing Standards. Int. J. Mol. Sci. 2025, 26, 480. https://doi.org/10.3390/ijms26020480

Ramírez S, Zúñiga F, Amenábar A, Contreras P, Benavides V, Norambuena J, Martínez J, Silva N. Copper-Modified Cellulose Paper: A Comparative Study of How Antimicrobial Activity Is Affected by Particle Size and Testing Standards. International Journal of Molecular Sciences. 2025; 26(2):480. https://doi.org/10.3390/ijms26020480

Chicago/Turabian StyleRamírez, Sara, Fabian Zúñiga, Alejandra Amenábar, Paulina Contreras, Viviana Benavides, Javiera Norambuena, Jessica Martínez, and Nataly Silva. 2025. "Copper-Modified Cellulose Paper: A Comparative Study of How Antimicrobial Activity Is Affected by Particle Size and Testing Standards" International Journal of Molecular Sciences 26, no. 2: 480. https://doi.org/10.3390/ijms26020480

APA StyleRamírez, S., Zúñiga, F., Amenábar, A., Contreras, P., Benavides, V., Norambuena, J., Martínez, J., & Silva, N. (2025). Copper-Modified Cellulose Paper: A Comparative Study of How Antimicrobial Activity Is Affected by Particle Size and Testing Standards. International Journal of Molecular Sciences, 26(2), 480. https://doi.org/10.3390/ijms26020480