Effects of Different Surface Treatments of Woven Glass Fibers on Mechanical Properties of an Acrylic Denture Base Material

Abstract

:1. Introduction

2. Results

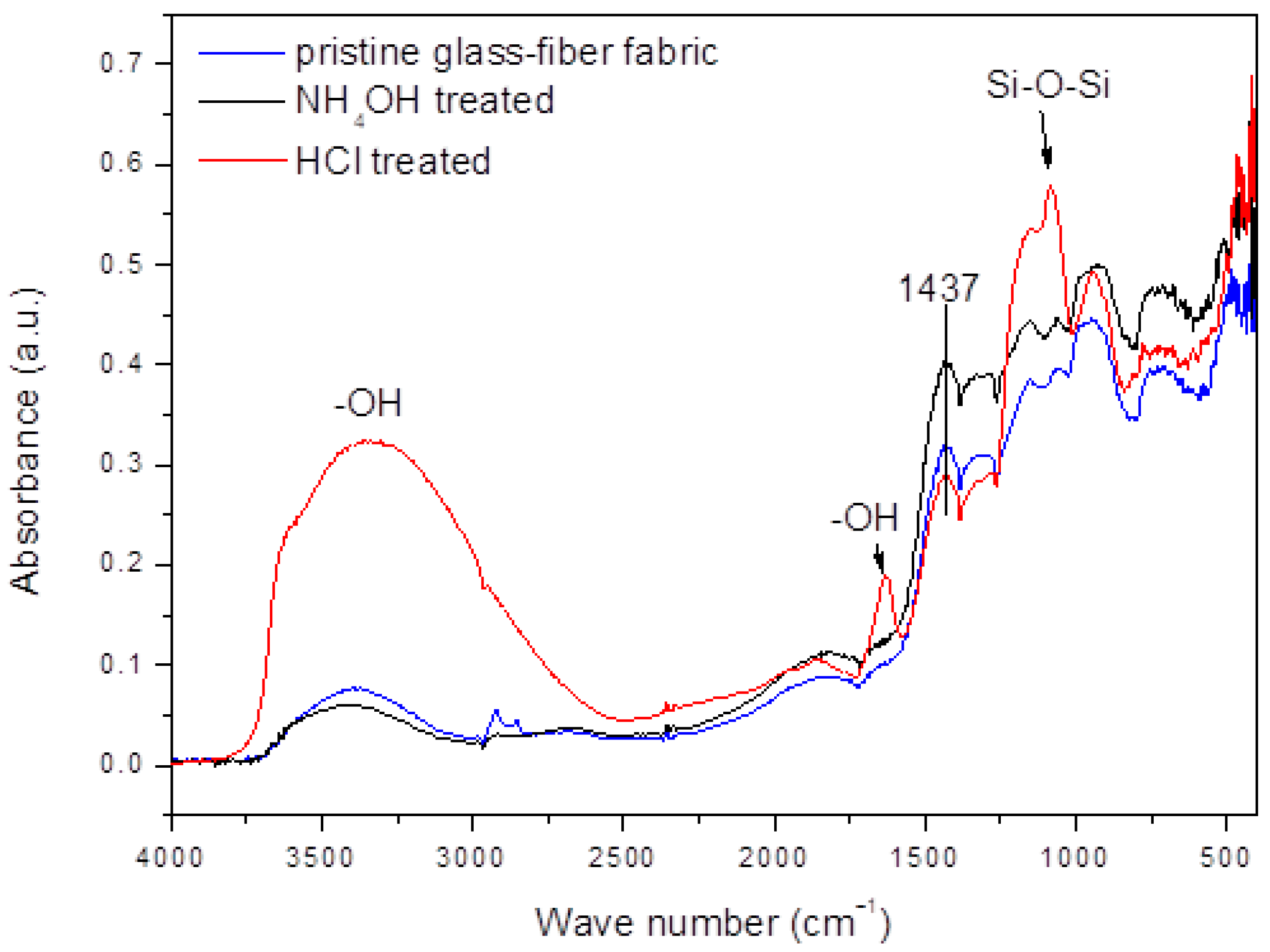

2.1. FTIR Analysis

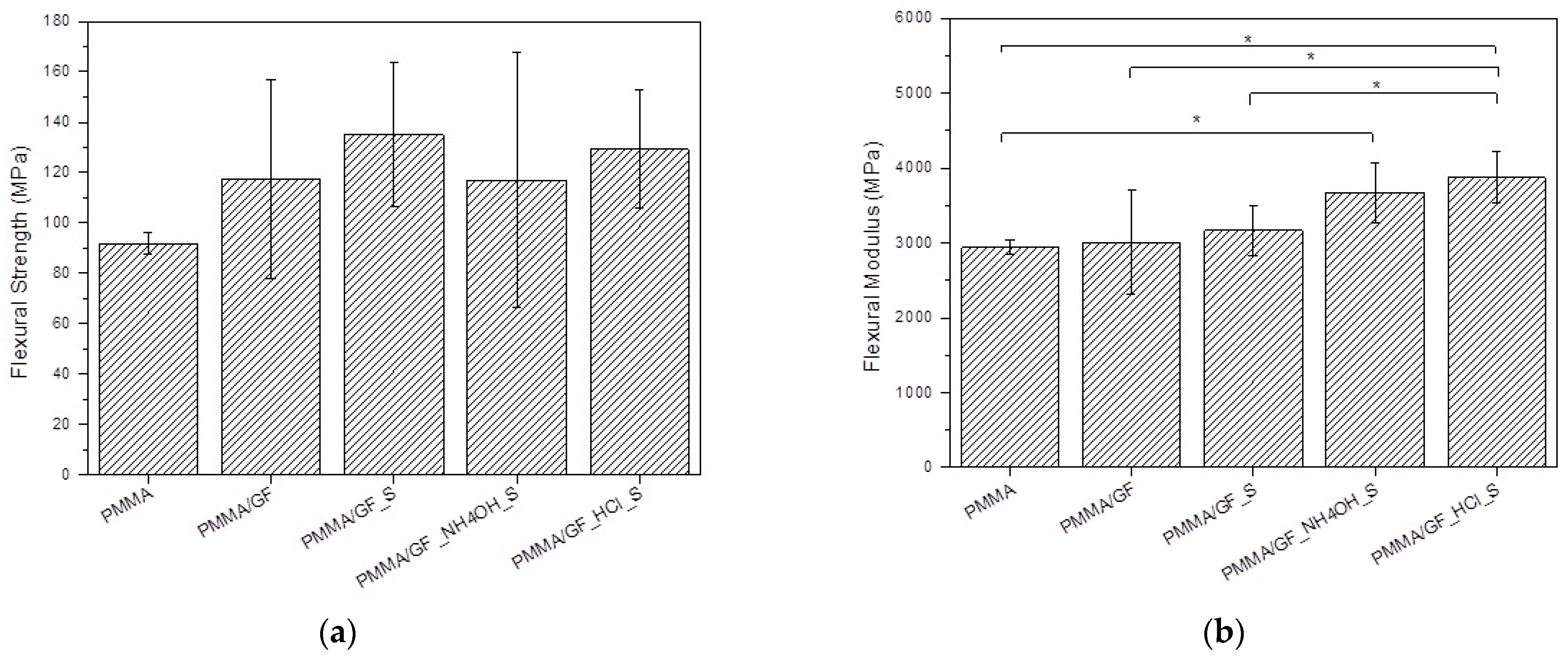

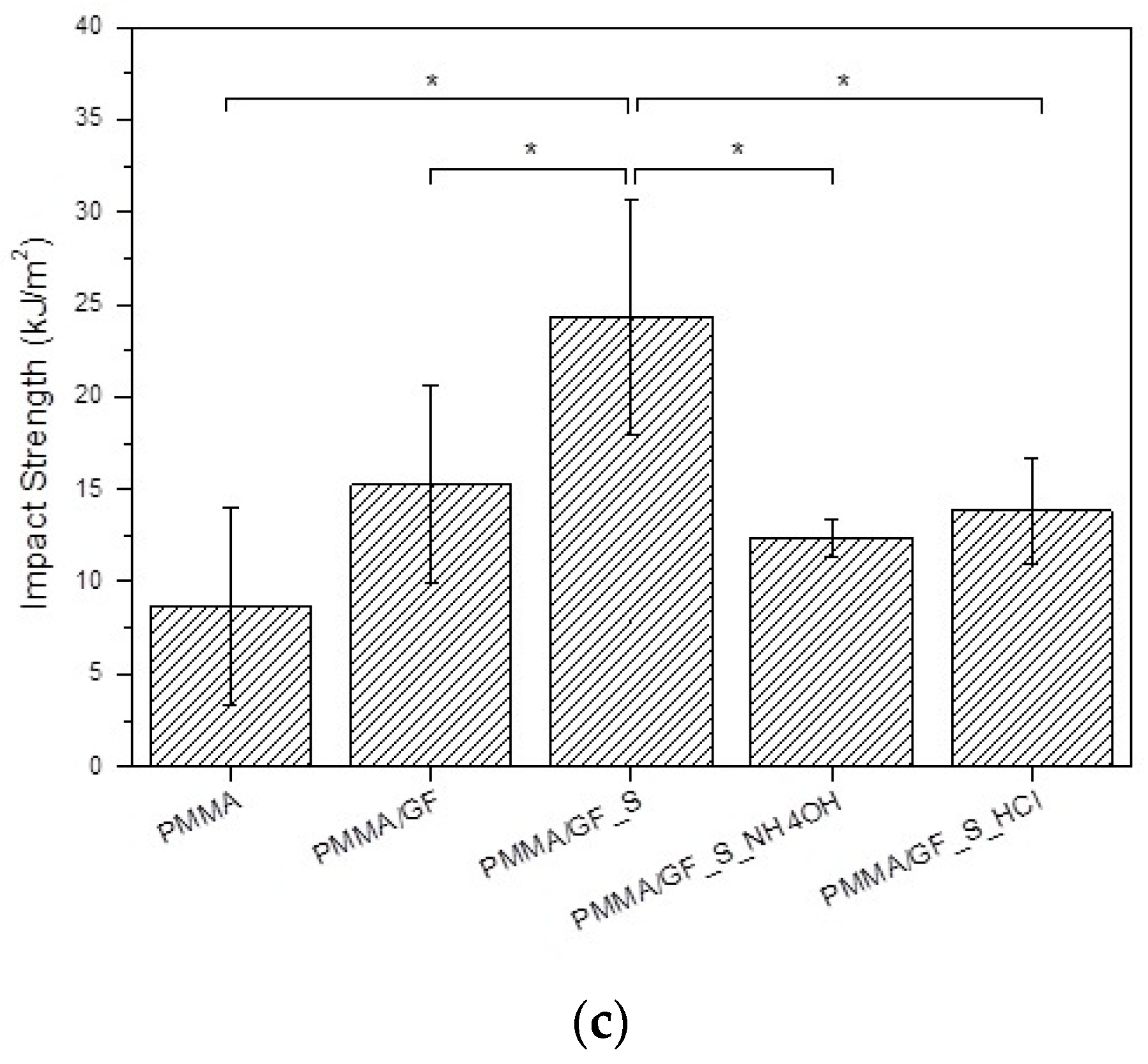

2.2. Mechanical Testing

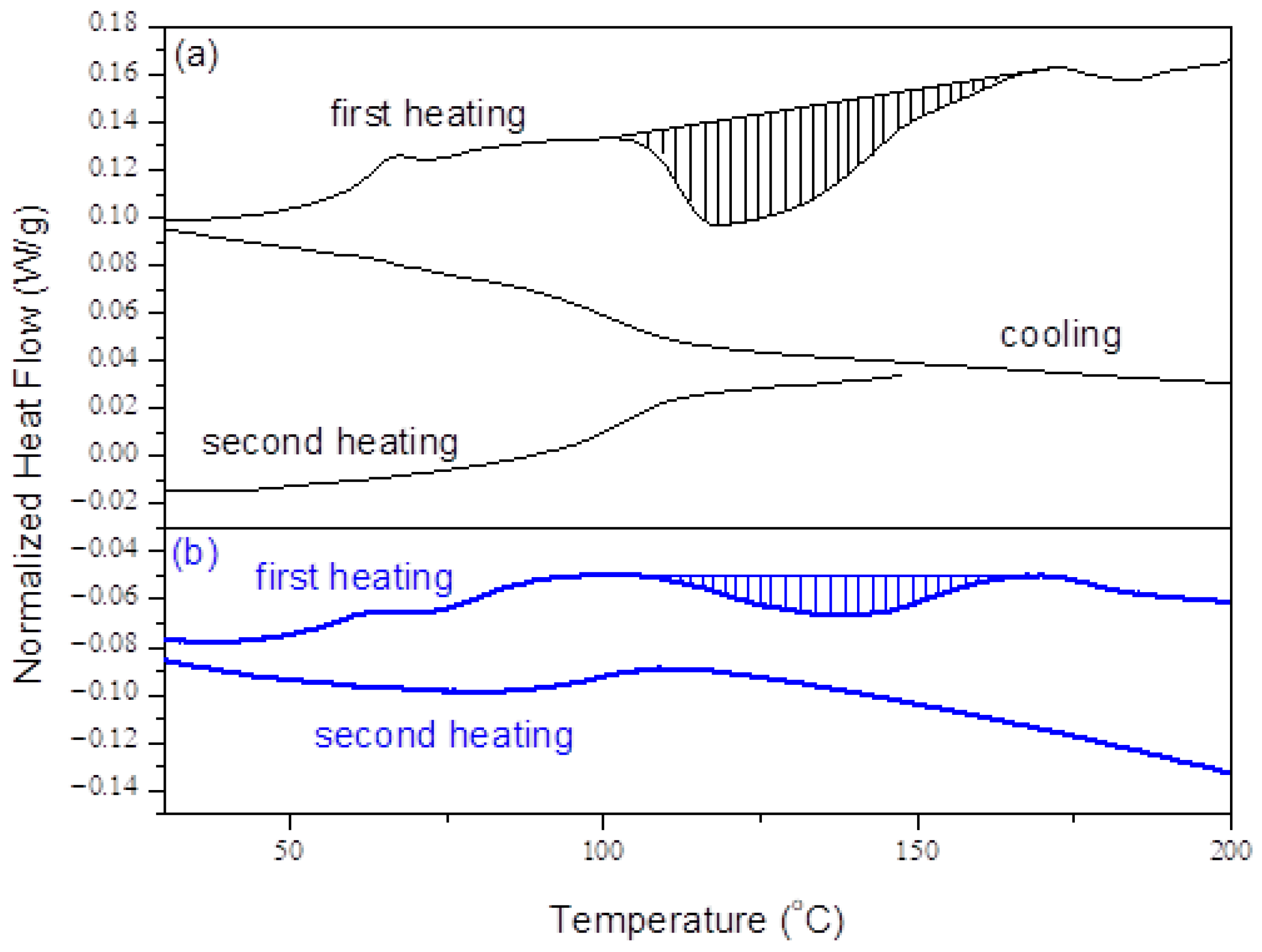

2.3. DSC Analysis

3. Discussion

4. Materials and Methods

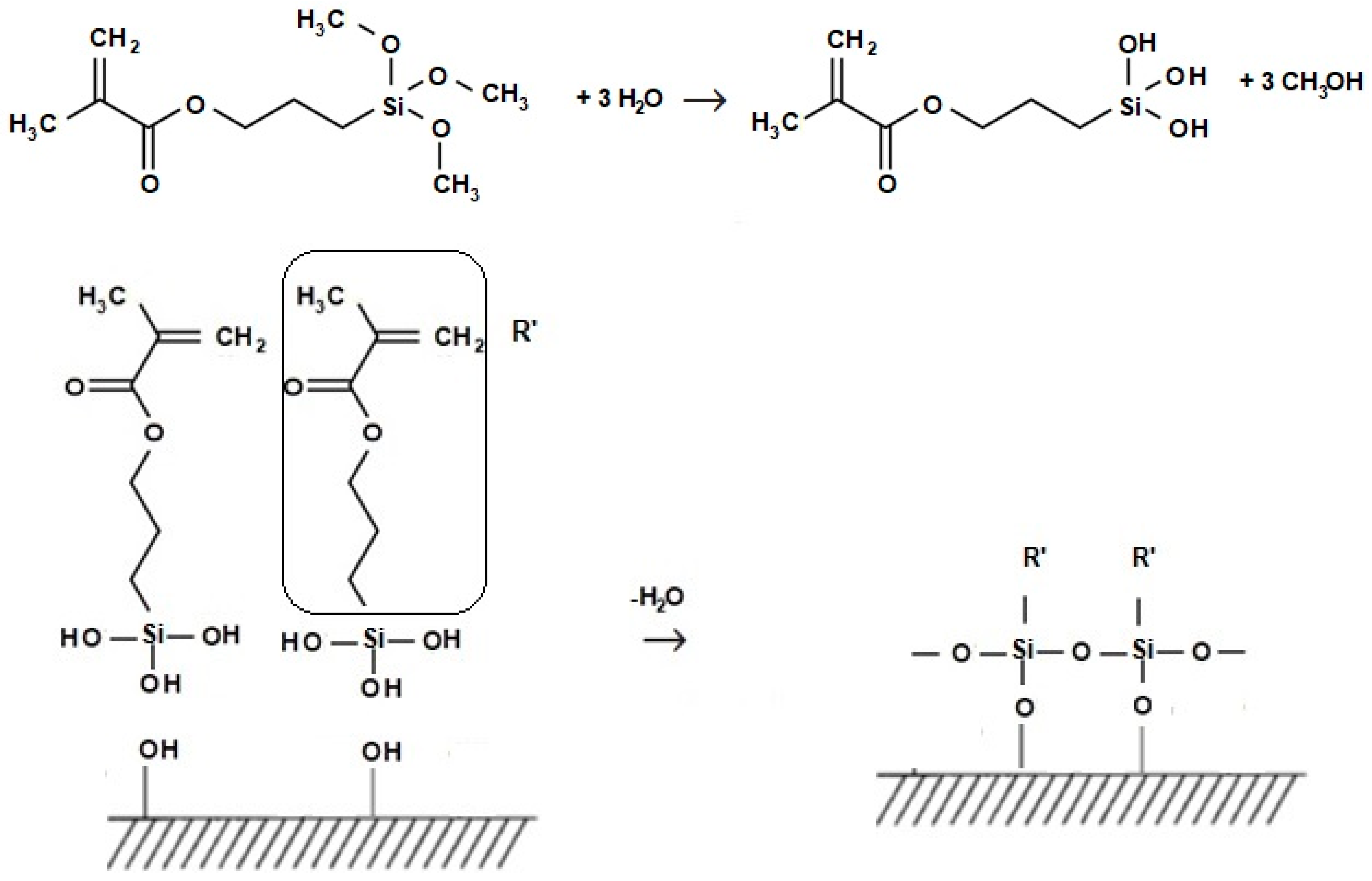

4.1. Surface Functionalization of Glass Fibers

4.2. FTIR Analysis

4.3. Preparation of Composite Materials

4.4. Mechanical Testing

4.4.1. Flexural Strength Test

4.4.2. Charpy Impact Test

4.5. DSC Analysis

4.6. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Emami, E.; de Souza, R.F.; Kabawat, M.; Feine, J.S. The impact of edentulism on oral and general health. Int. J. Dent. 2013, 2013, 498305. [Google Scholar] [CrossRef] [PubMed]

- Zafar, M.S. Prosthodontic Applications of Polymethyl Methacrylate (PMMA): An Update. Polymers 2020, 12, 2299. [Google Scholar] [CrossRef] [PubMed]

- Hersek, N.; Uzun, G. Comparison of the fracture resistance of six denture base acrylic resins. J. Biomater. Appl. 2002, 17, 19–29. [Google Scholar]

- Darbar, U.R.; Huggett, R.; Harrison, A. Denture fracture-a survey. Br. Dent. J. 1994, 176, 342–345. [Google Scholar] [CrossRef]

- Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef]

- Elsheikh, A.; Panchal, H.; Sengottain, S.; Muthuramalingam, T.; El-Kassas, A.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Rangasamy, G.; Mani, S.; Kolandavelu, S.K.S.; Alsoufi, M.S.; Ibrahim, A.M.M.; Muthusamy, S.; Panchal, H.; Sadasivuni, K.K.; Elsheikh, A.H. An extensive analysis of mechanical, thermal and physical properties of jute fiber composites with different fiber orientations. Case Stud. Therm. Eng. 2021, 28, 101612. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Abd Elaziz, M.; Ramesh, B.; Egiza, M.; Al-qaness, M.A.A. Modeling of drilling process of GFRP composite using a hybrid random vector functional link network/parasitism-predation algorithm. J. Mater. Res. Technol. 2021, 14, 298–311. [Google Scholar] [CrossRef]

- Raj, M.K.A.; Muthusamy, S.; Panchal, H.; Ibrahim, A.M.M.; Alsoufi, M.S.; Elsheikh, A.H. Investigation of mechanical properties of dual-fiber reinforcement in polymer composite. J. Mater. Res. Technol. 2022, 18, 3908–3915. [Google Scholar] [CrossRef]

- Ekstrand, K.; Ruyter, I.E.; Wellendorf, H. Carbon/graphite fiber reinforced poly(methyl methacrylate): Properties under dry and wet conditions. J. Biomed. Mater. Res. 1987, 21, 1065–1080. [Google Scholar] [CrossRef]

- Gutteridge, D.L. The effect of including ultra-high-modulus polyethylene fibre on the impact strength of acrylic resin. Br. Dent. J. 1988, 164, 177–180. [Google Scholar] [CrossRef] [PubMed]

- Vallittu, P.K.; Vojtkova, H.; Lassila, V.P. Impact strength of denture polymethyl methacrylate reinforced with continuous glass fibers or metal wire. Acta Odontol. Scand. 1995, 53, 392–396. [Google Scholar] [CrossRef] [PubMed]

- Vallittu, P.K. Glass fiber reinforcement in repaired acrylic resin removable dentures: Preliminary results of a clinical study. Quintessence Int. 1997, 28, 39–44. [Google Scholar]

- Foo, S.H.; Lindquist, T.J.; Aquilino, S.A.; Schneider, R.L.; Williamson, D.L.; Boyer, D.B. Effect of polyaramid fiber reinforcement on the strength of 3 denture base polymethyl methacrylate resins. J. Prosthodont. 2001, 10, 148–153. [Google Scholar] [CrossRef] [PubMed]

- Hamouda, I.M.; Beyari, M.M. Addition of glass fibers and titanium dioxide nanoparticles to the acrylic resin denture base material: Comparative study with the conventional and high impact types. Oral Health Dent. Manag. 2014, 13, 107–112. [Google Scholar]

- Solnit, G.S. The effect of methyl methacrylate reinforcement with silane-treated and untreated glass fibers. J. Prosthet. Dent. 1991, 66, 310–314. [Google Scholar] [CrossRef]

- Matinlinna, J.P.; Lassila, L.V.J.; Ozcan, M.; Yli-Urpo, A.; Vallittu, P.K. An Introduction to Silanes and Their Clinical Applications in Dentistry. Int. J. Prosthodont. 2004, 17, 155–164. [Google Scholar] [PubMed]

- Uzun, G.; Hersek, N.; Tinçer, T. Effect of five woven fiber reinforcements on the impact and transverse strength of a denture base resin. J. Prosthet. Dent. 1999, 81, 616–620. [Google Scholar] [CrossRef]

- Kim, S.H.; Watts, D.C. The effect of reinforcement with woven E-glass fibers on the impact strength of complete dentures fabricated with high-impact acrylic resin. J. Prosthet. Dent. 2004, 91, 274–280. [Google Scholar] [CrossRef]

- Unalan, F.D.I.; Gurbuz, O. Transverse strength of polymethyl methacrylate reinforced with different forms and concentrations of e-glass fibres. Oral Health Dent. Manag. 2010, 9, 144–147. [Google Scholar]

- Rantala, L.I.; Lastumäki, T.M.; Peltomäki, T.; Vallittu, P.K. Fatigue resistance of removable orthodontic appliance reinforced with glass fibre weave. J. Oral Rehabil. 2003, 30, 501–506. [Google Scholar] [CrossRef] [PubMed]

- Sheth, N.; Hahn, S.H.; Ngo, D.; Howzen, A.; Bermejo, R.; van Duin, A.C.T.; Mauro, J.C.; Pantano, C.G.; Kim, S.H. Influence of acid leaching surface treatment on indentation cracking of soda lime silicate glass. J. Non-Cryst. Solids 2020, 543, 120144. [Google Scholar] [CrossRef]

- Larena, A.; Martínez Urreaga, J.; de la Orden, M.U. Effects of previous leaching with hydrochloric acid of E-glass short fibre on the fibre reaction with chlorosilanes. Mater. Lett. 1992, 12, 415–418. [Google Scholar] [CrossRef]

- Kanie, T.; Fujii, K.; Arikawa, H.; Inoue, K. Flexural properties and impact strength of denture base polymer reinforced with woven glass fibers. Dent. Mater. 2000, 16, 150–158. [Google Scholar] [CrossRef] [PubMed]

- Dikbas, I.; Gurbuz, O.; Unalan, F.; Koksal, T. Impact strength of denture polymethyl methacrylate reinforced with different forms of E-glass fibers. Acta Odontol. Scand. 2013, 71, 727–732. [Google Scholar] [CrossRef] [PubMed]

- Rashid, H.; Sheikh, Z.; Vohra, F. Allergic effects of the residual monomer used in denture base acrylic resins. Eur. J. Dent. 2015, 9, 614–619. [Google Scholar] [CrossRef]

| Title 1 | Flexural Strength (MPa) Mean ± SD | Flexural Modulus (GPa) Mean ± SD | Impact Strength (kJ/m2) Mean ± SD |

|---|---|---|---|

| PMMA | 91.9 ± 4.3 a | 2.94 ± 0.10 a | 8.68 ± 5.36 a |

| PMMA/GF | 117.4 ± 39.5 a | 3.01 ± 0.69 a | 15.26 ± 5.36 a |

| PMMA/GF_S | 135.1 ± 28.57 a | 3.17 ± 0.33 a | 24.31 ± 6.34 b |

| PMMA/GF_ NH4OH _S | 117.0 ± 50.5 a | 3.67 ± 0.40 b | 12.37 ± 1.04 a |

| PMMA/GF_ HCl _S | 129.3 ± 23.5 a | 3.87 ± 0.34 b | 13.85 ± 2.87 a |

| Material | Composition |

|---|---|

| Meliodent® Rapid Repair Powder | methacrylate copolymers |

| Meliodent® Rapid Repair Liquid | methyl methacrylate, >90%, |

| Tetramethylene dimethacrylate ≥ 1–≤5% | |

| 2-(2H-Benzotriazol-2-yl)-4-methylphenol, ≥0.25–<1% | |

| N,N-Dimethyl-p-toluidine, <1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schauperl, Z.; Ivanković, L.; Bauer, L.; Šolić, S.; Ivanković, M. Effects of Different Surface Treatments of Woven Glass Fibers on Mechanical Properties of an Acrylic Denture Base Material. Int. J. Mol. Sci. 2023, 24, 909. https://doi.org/10.3390/ijms24020909

Schauperl Z, Ivanković L, Bauer L, Šolić S, Ivanković M. Effects of Different Surface Treatments of Woven Glass Fibers on Mechanical Properties of an Acrylic Denture Base Material. International Journal of Molecular Sciences. 2023; 24(2):909. https://doi.org/10.3390/ijms24020909

Chicago/Turabian StyleSchauperl, Zdravko, Luka Ivanković, Leonard Bauer, Sanja Šolić, and Marica Ivanković. 2023. "Effects of Different Surface Treatments of Woven Glass Fibers on Mechanical Properties of an Acrylic Denture Base Material" International Journal of Molecular Sciences 24, no. 2: 909. https://doi.org/10.3390/ijms24020909

APA StyleSchauperl, Z., Ivanković, L., Bauer, L., Šolić, S., & Ivanković, M. (2023). Effects of Different Surface Treatments of Woven Glass Fibers on Mechanical Properties of an Acrylic Denture Base Material. International Journal of Molecular Sciences, 24(2), 909. https://doi.org/10.3390/ijms24020909