IL-Functionalized Mg3Al-LDH as New Efficient Adsorbent for Pd Recovery from Aqueous Solutions

Abstract

:1. Introduction

2. Results and Discussion

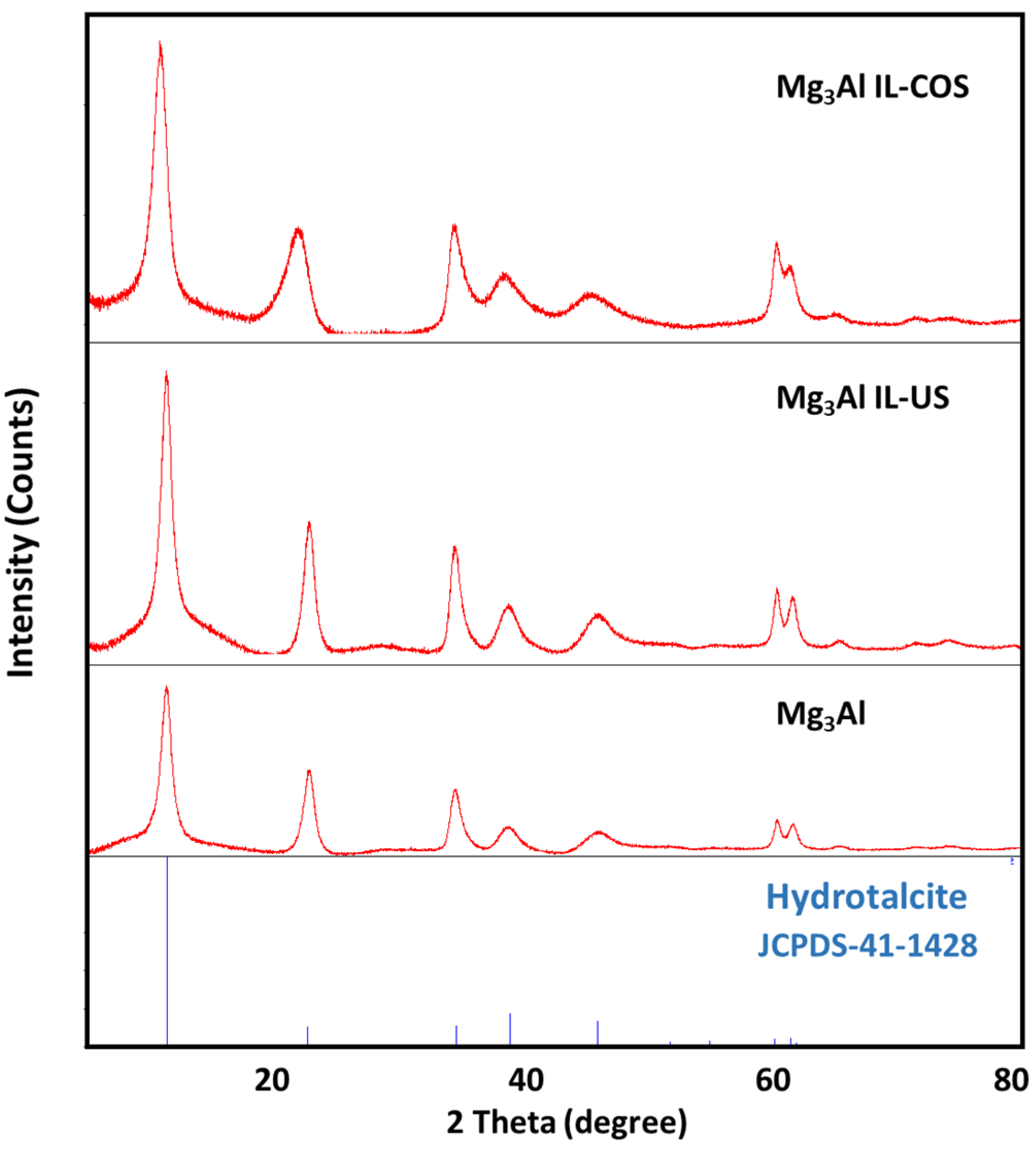

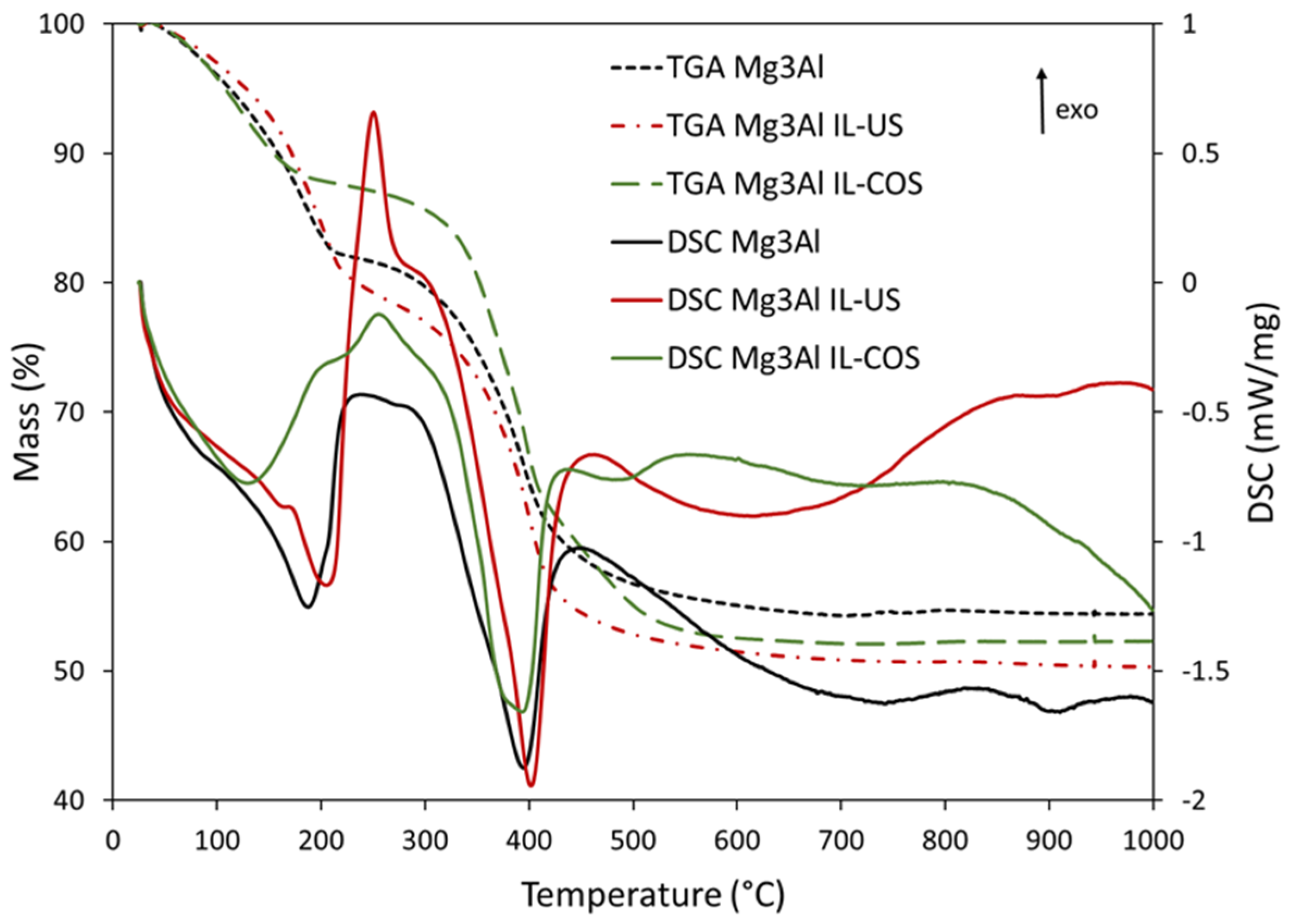

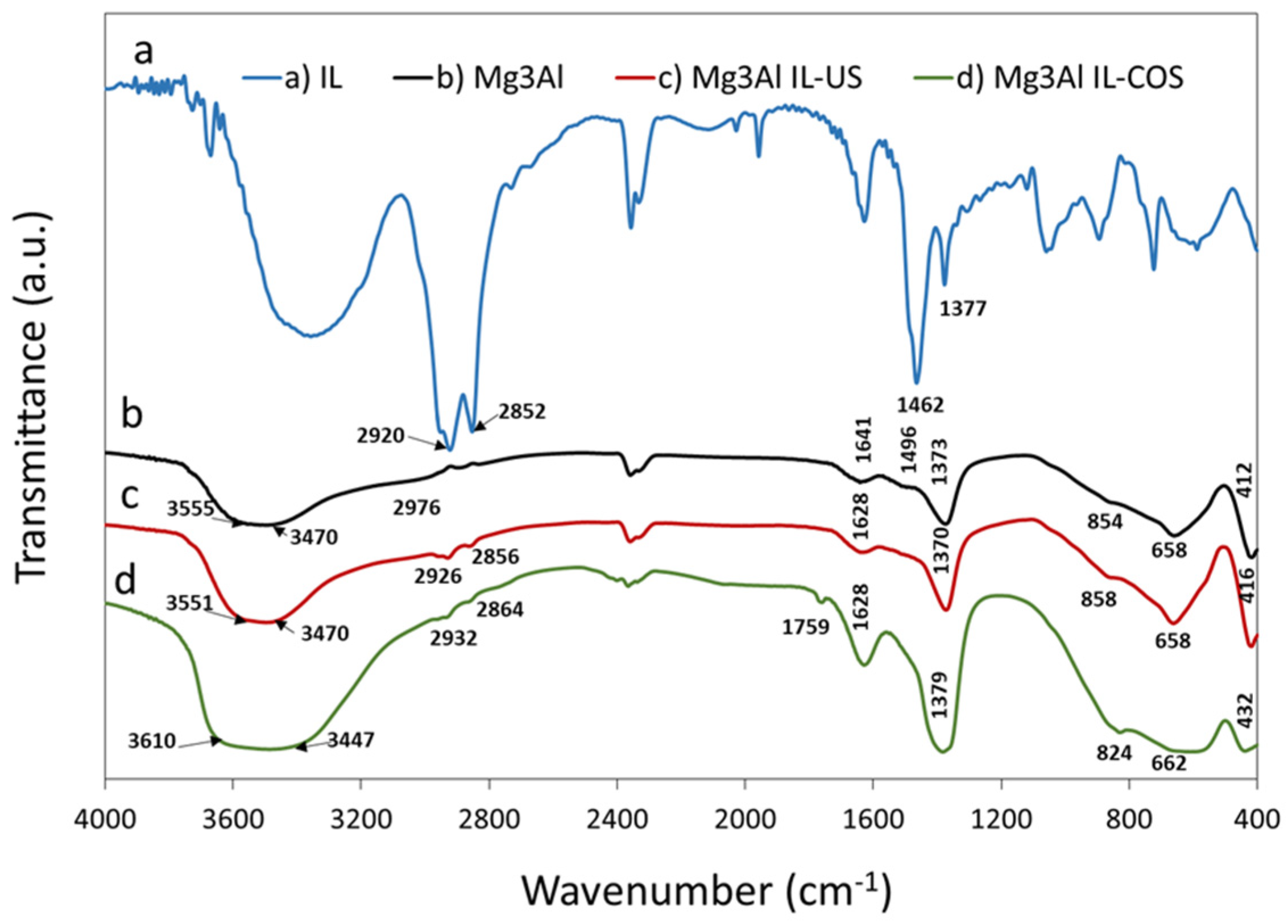

2.1. Adsorbent Materials Characterization

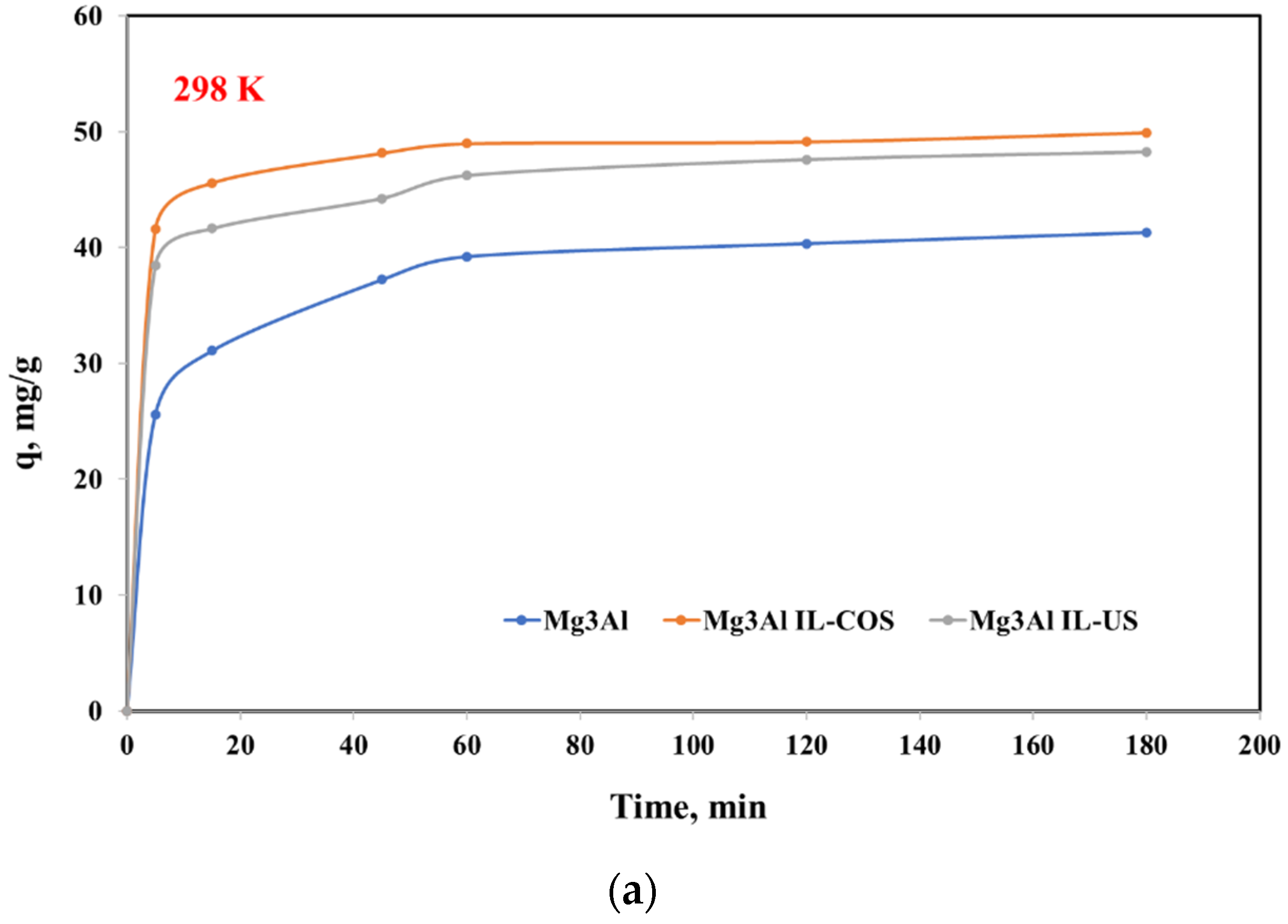

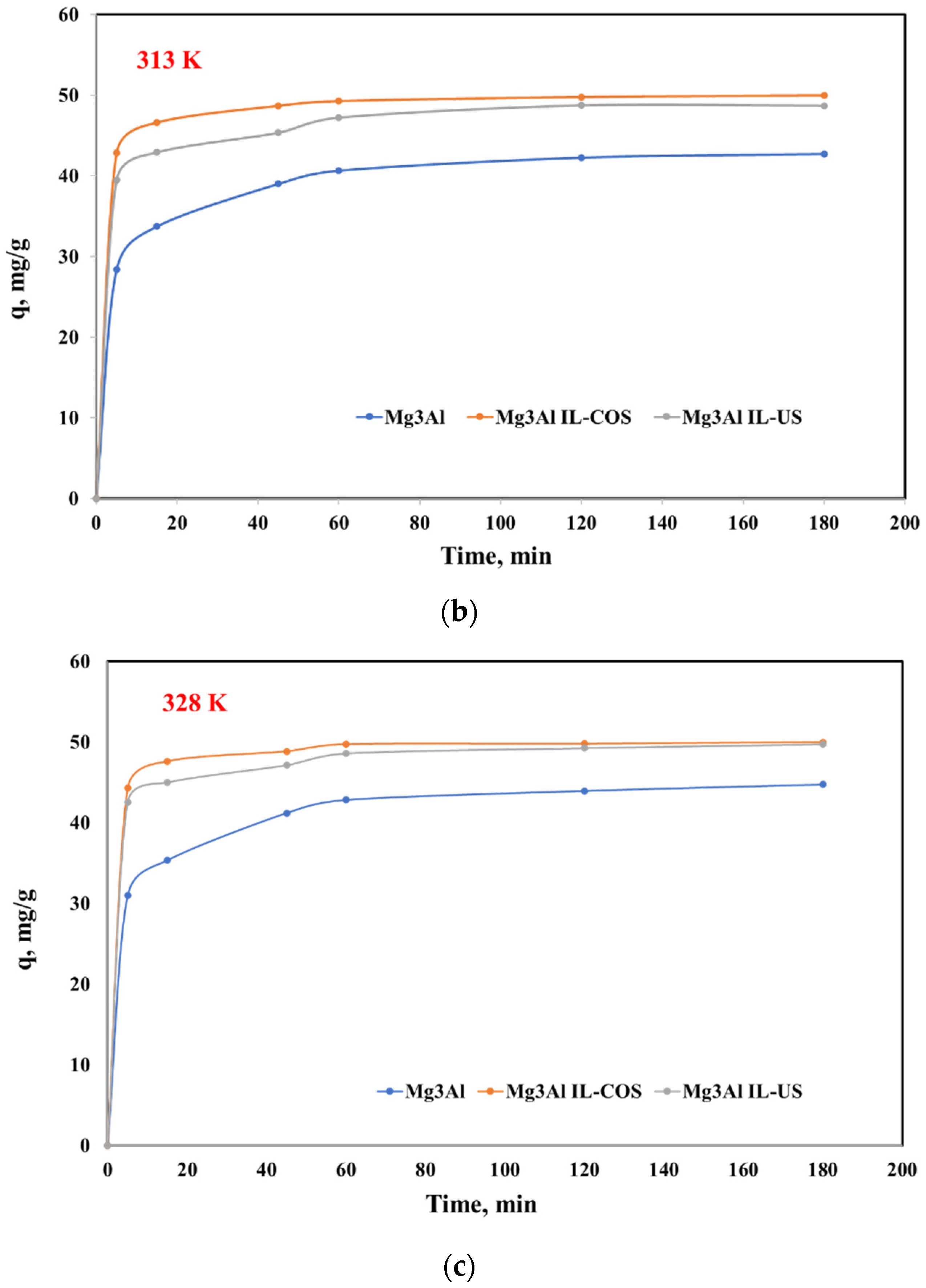

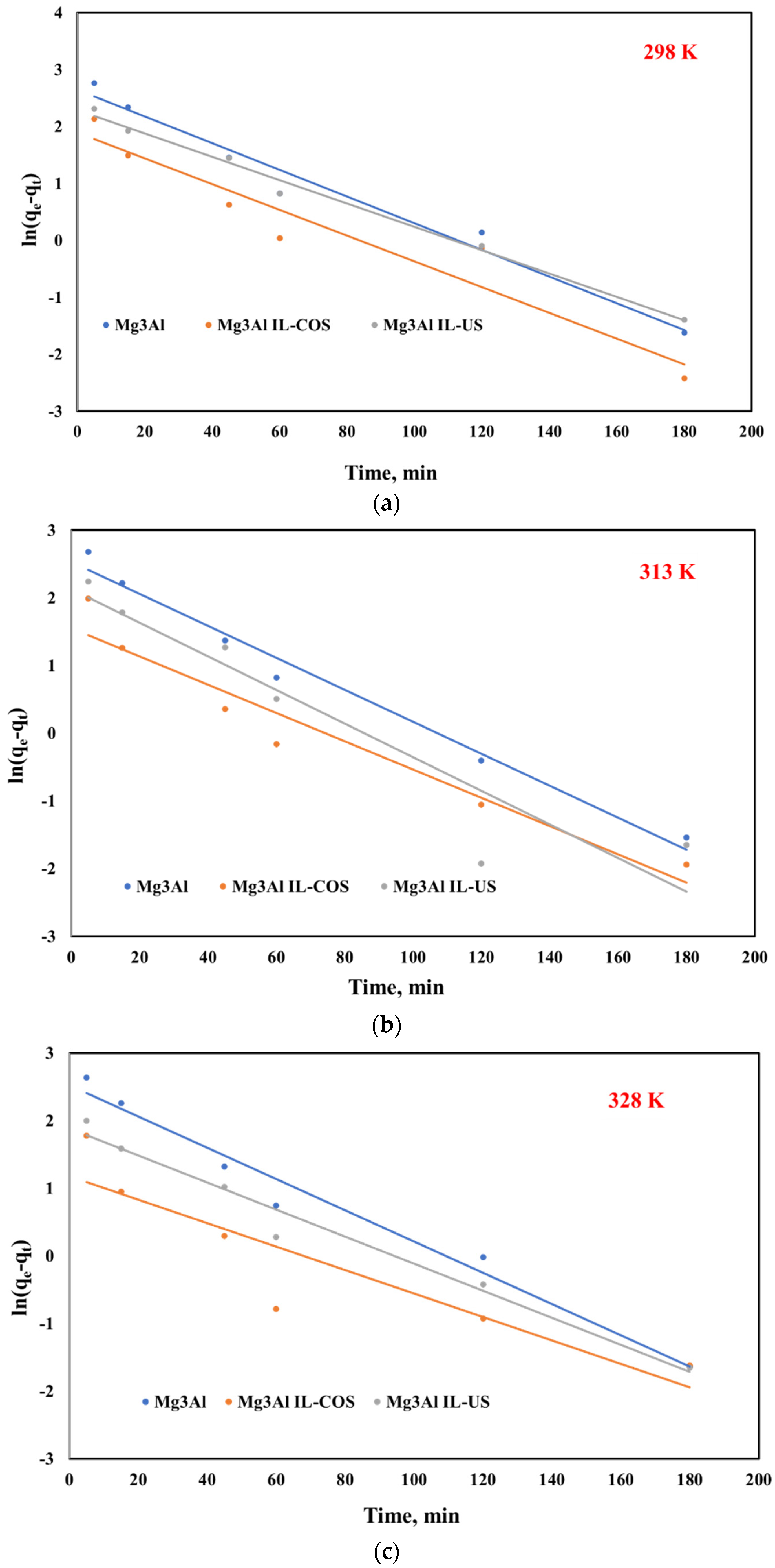

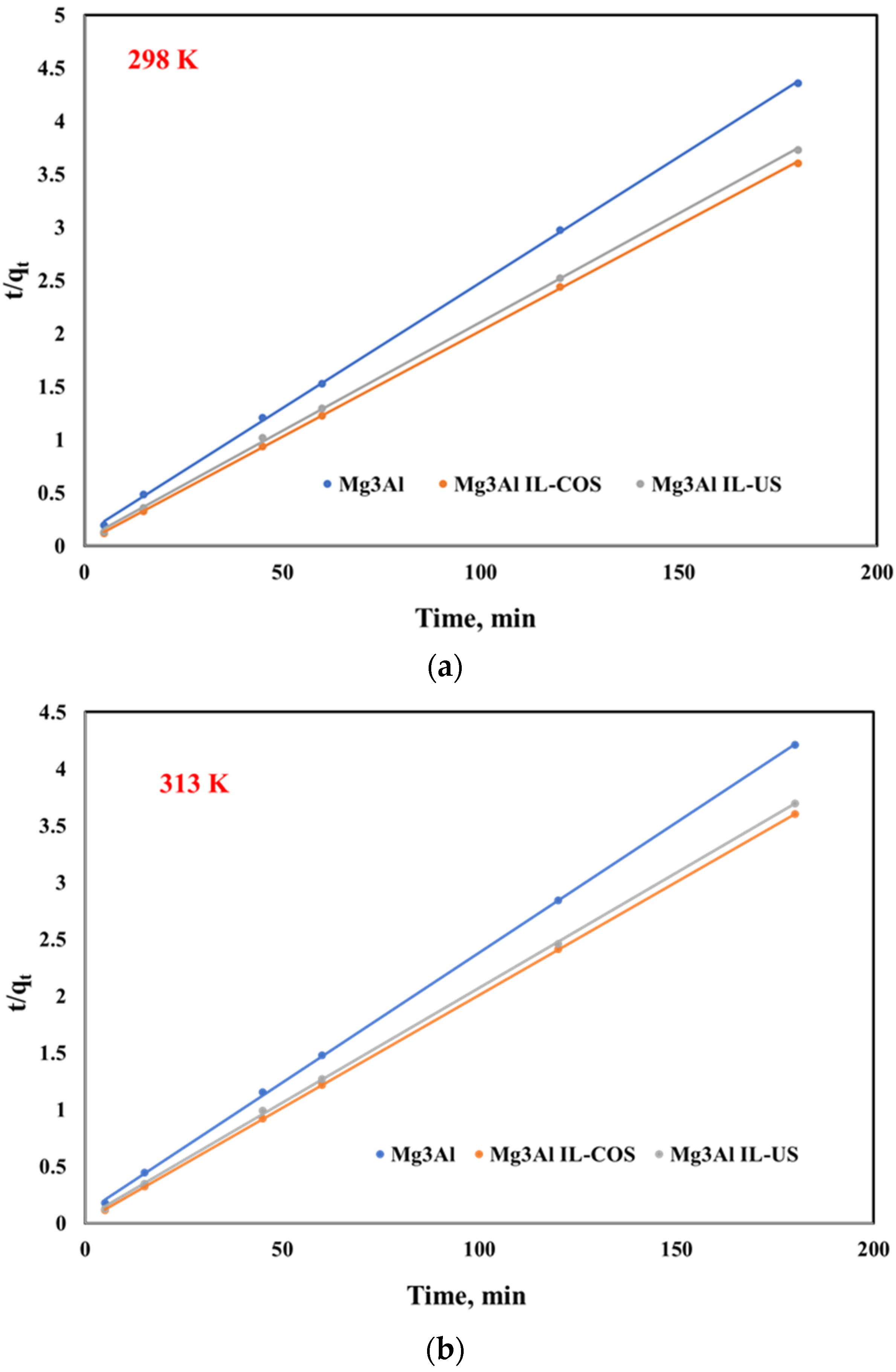

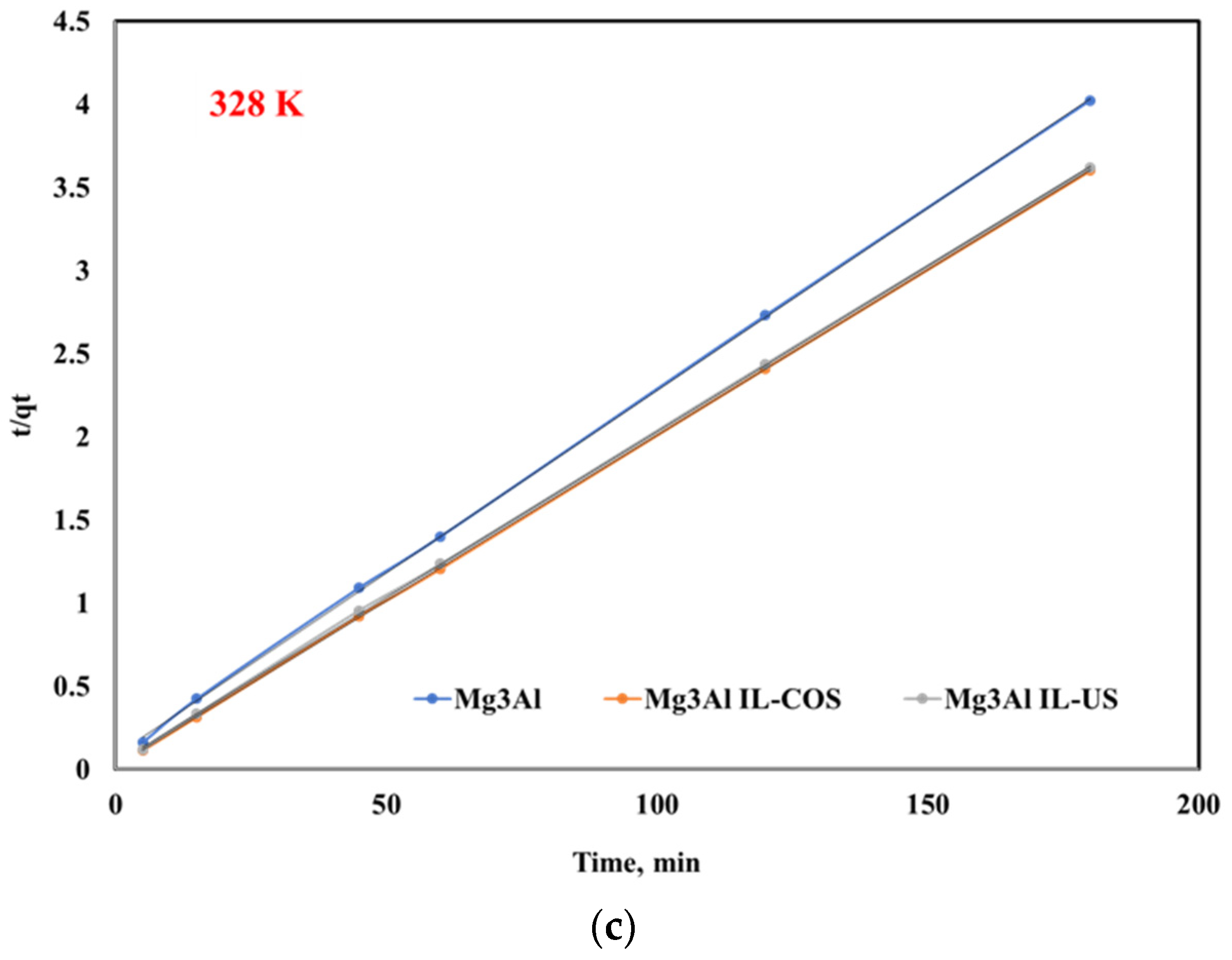

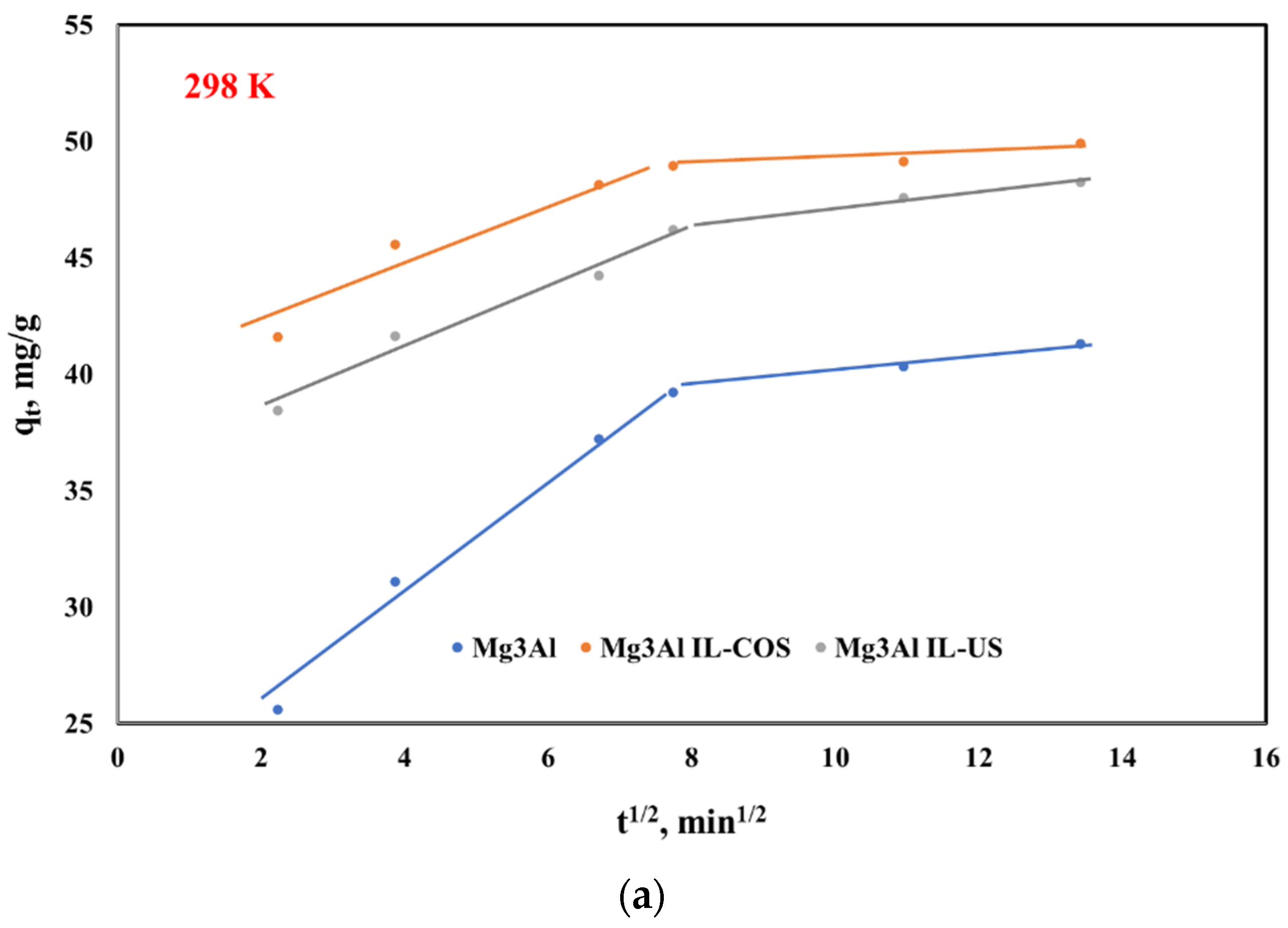

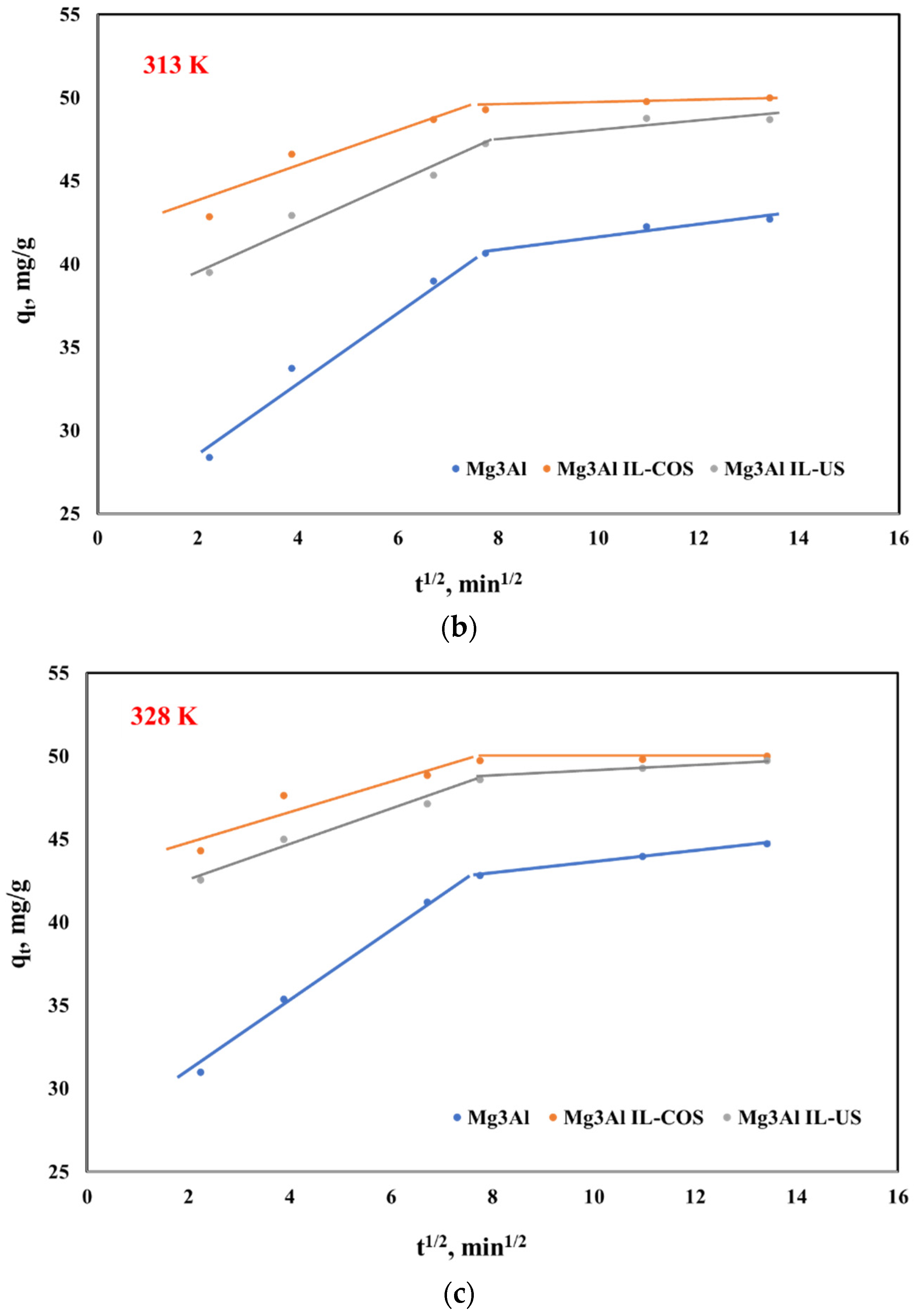

2.2. Kinetic Studies

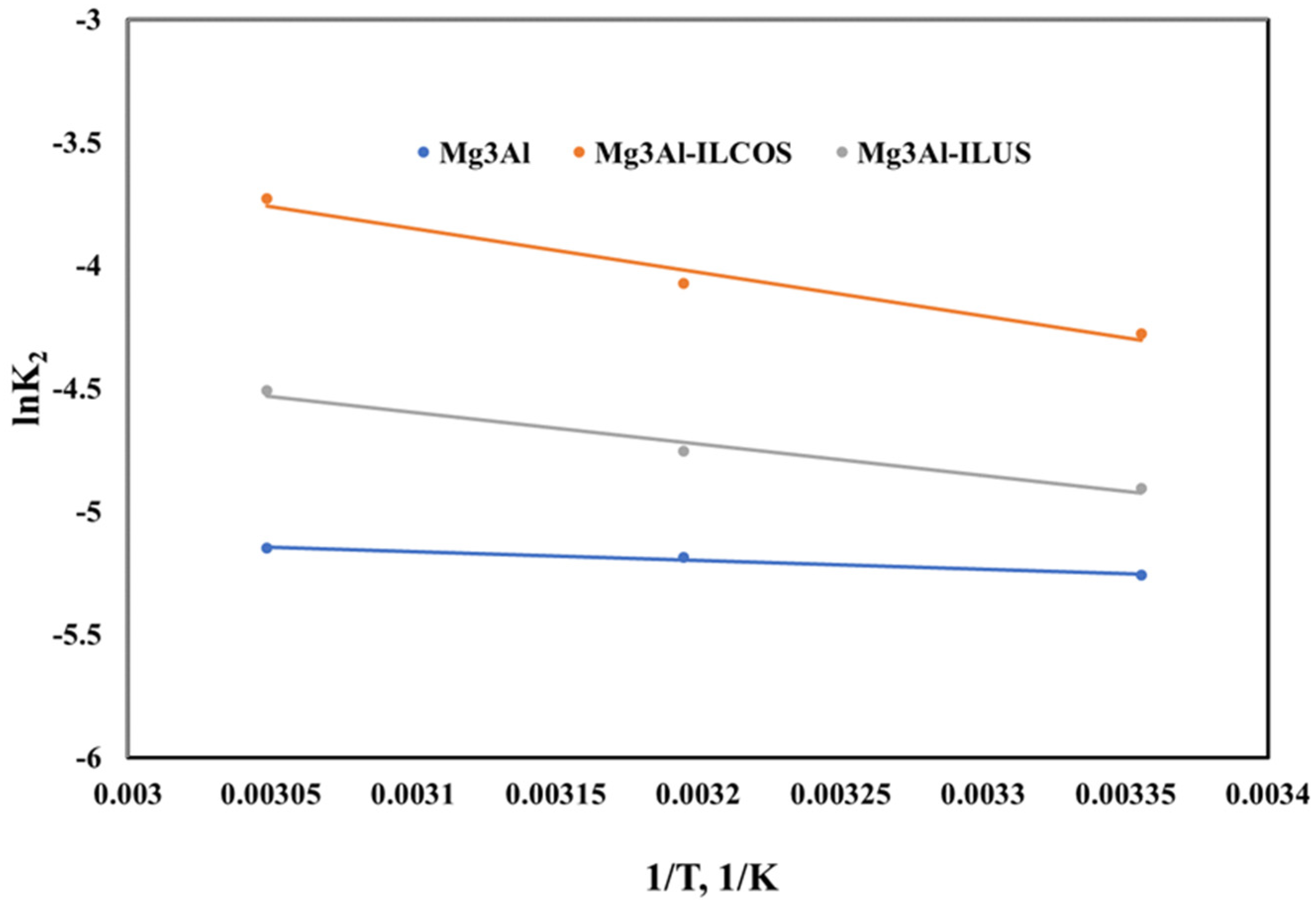

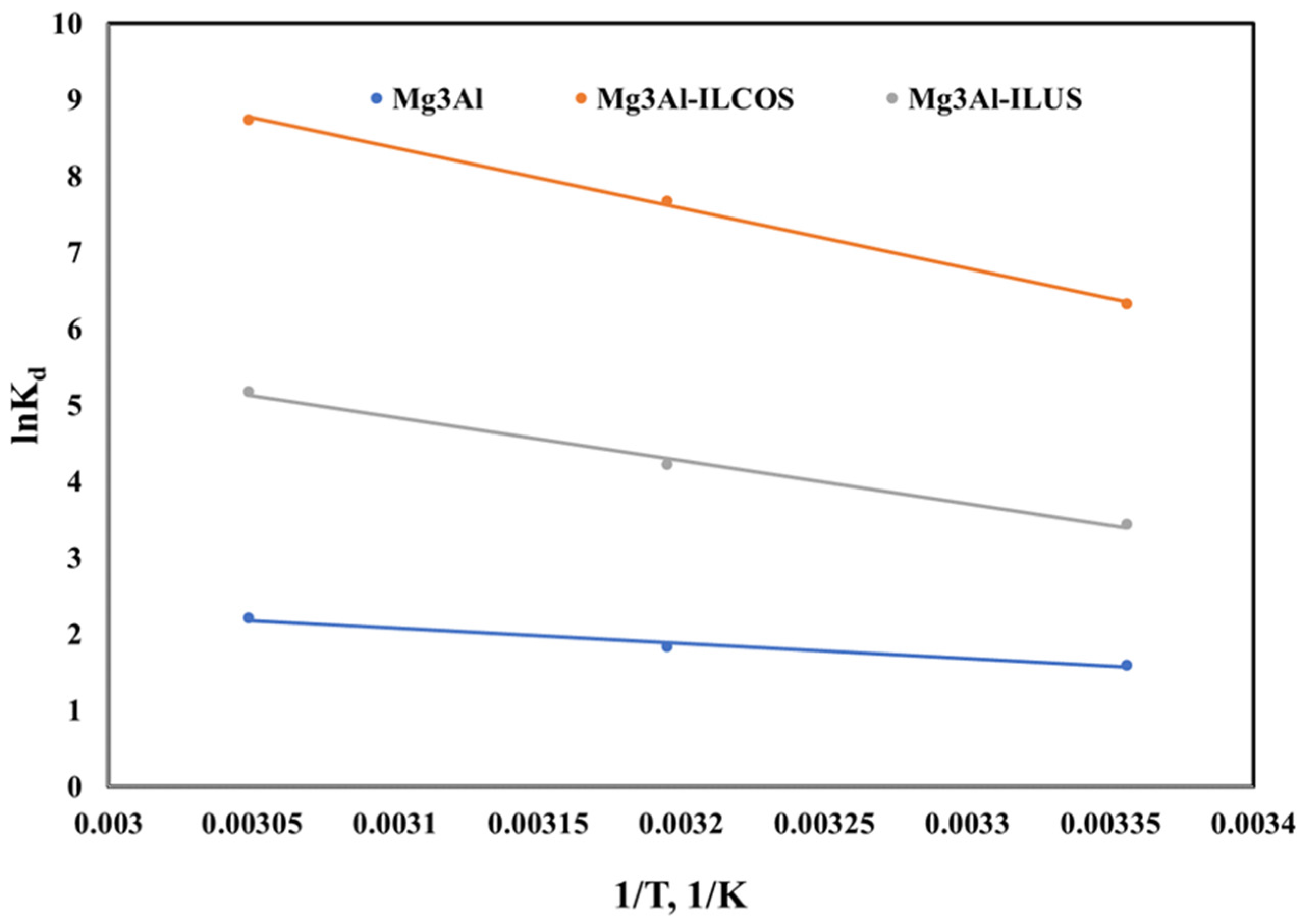

2.3. Thermodynamic Studies

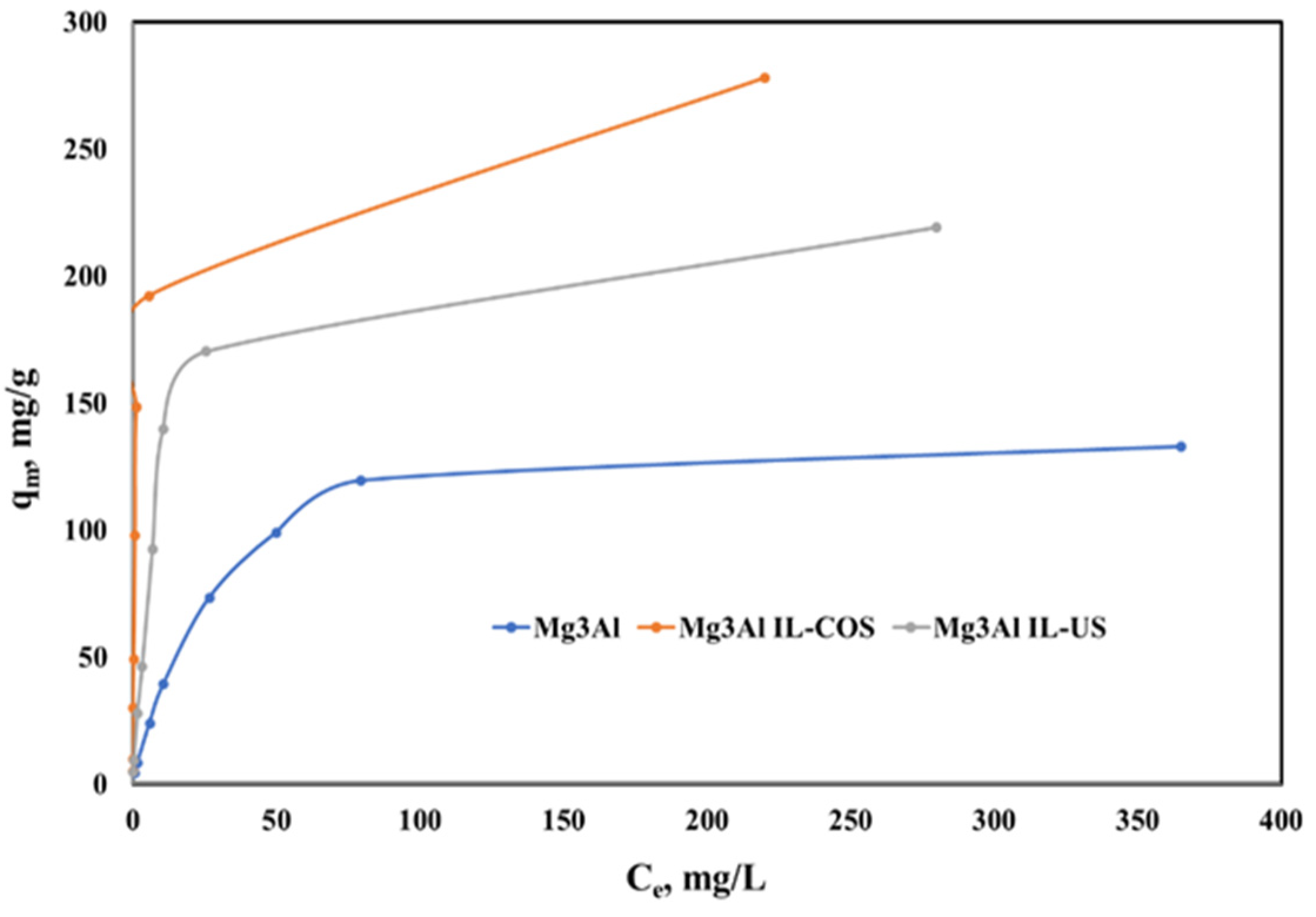

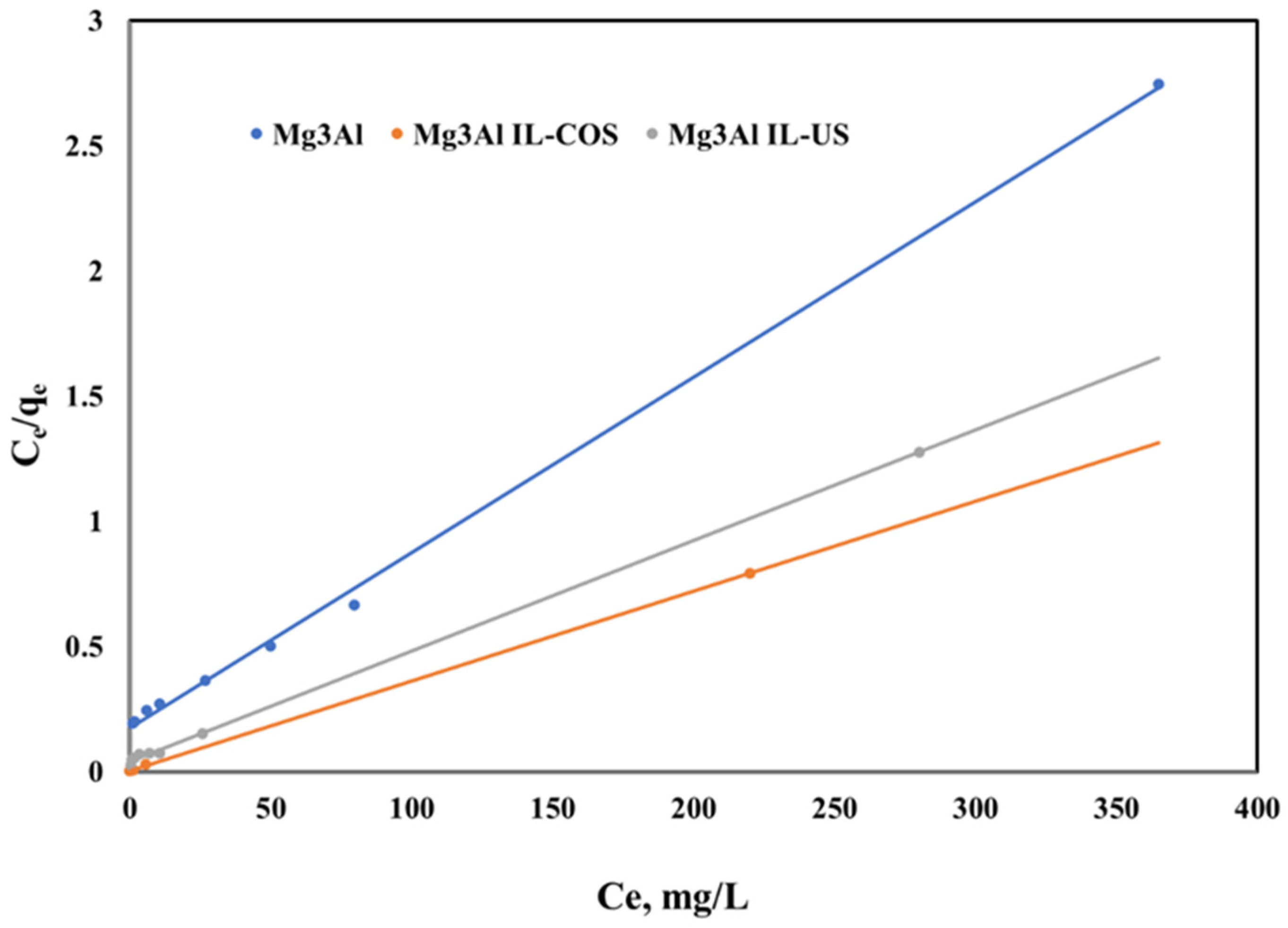

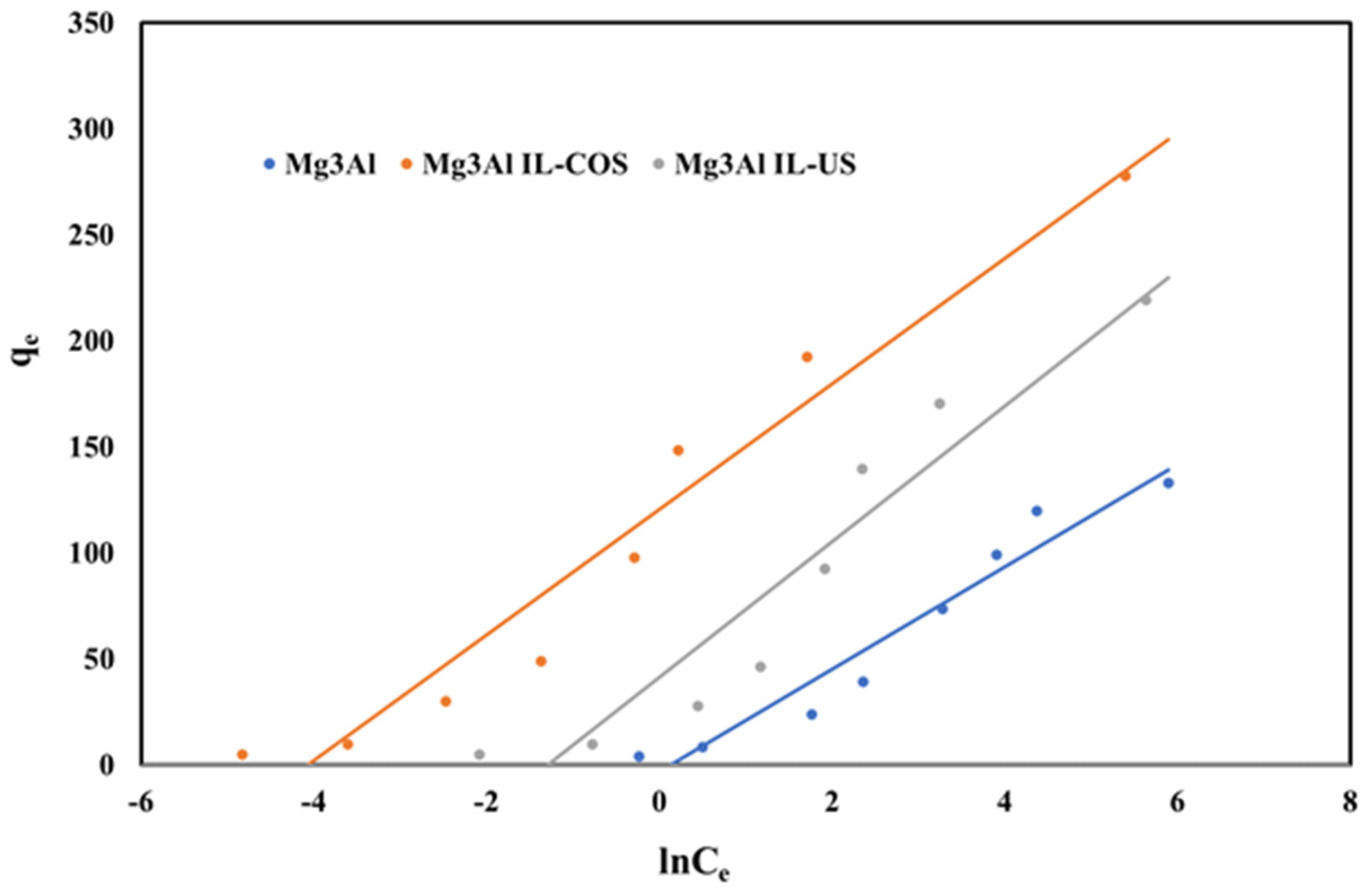

2.4. Equilibrium Studies

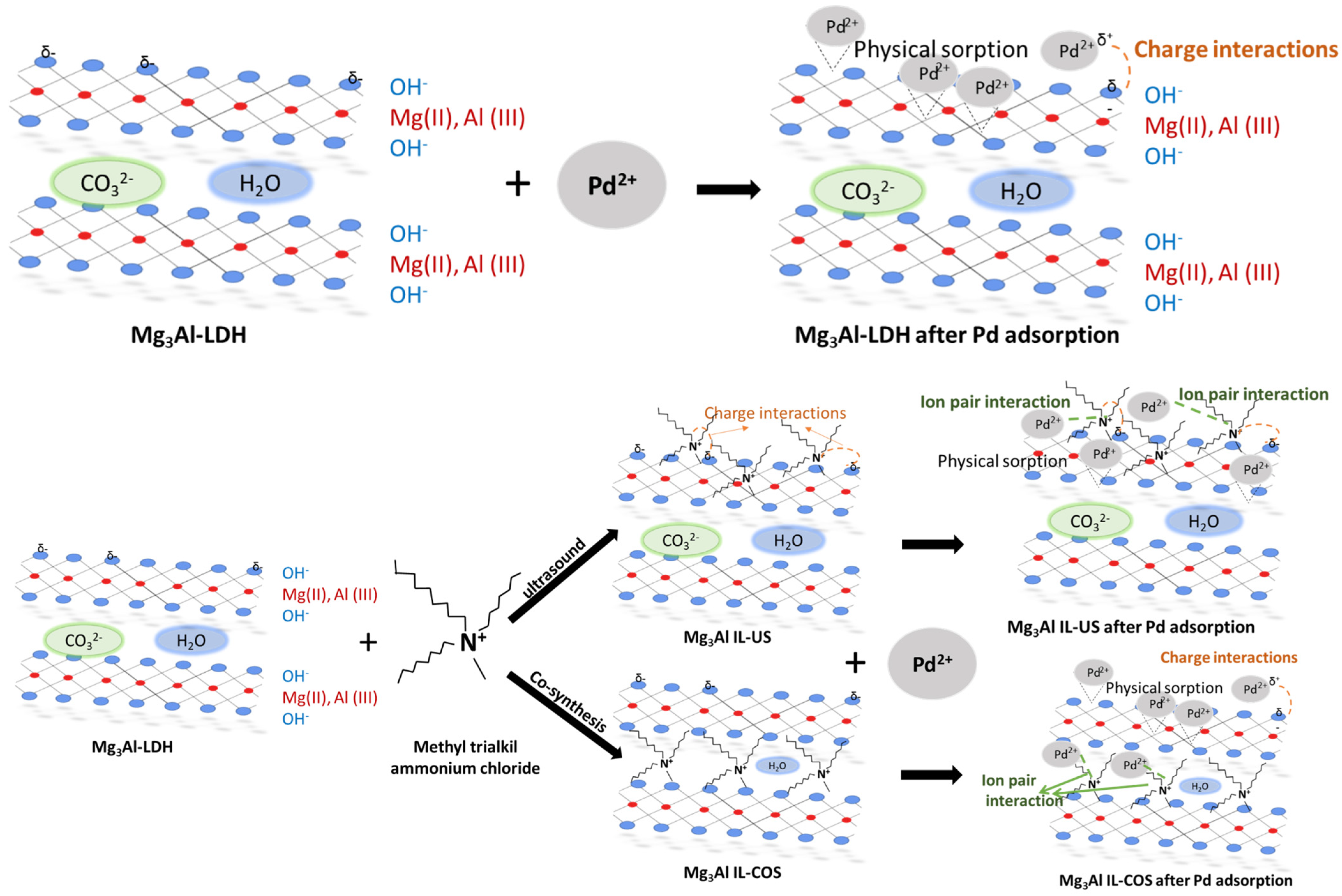

2.5. Mechanism of Palladium Adsorption onto the Studied Materials

2.6. Comparison of the Adsorption Capacity Developed by the Studied Materials with other Materials Reported in Literature

3. Materials and Methods

3.1. Adsorbent Materials Obtaining and Characterization

3.2. Pd Recover from Aqueous Solutions

- C0—initial concentration of Pd(II) in aqueous solutions, mg/L.

- Ce—equilibrium concentration of Pd(II), mg/L.

- V—volume of the solution containing Pd(II) used in the adsorption process, L.

- m—mass of adsorbent material used in the adsorption process, g.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- European Commission. Report on Critical Raw Materials in the Circular Economy; European Commission: Brussels, Belgium, 2018.

- Zhang, B.; Fu, L.; Wang, S.; Zhang, L. Adsorption of palladium (II) from aqueous solution using nanosilica modified with imidazoline groups. Mater. Chem. Phys. 2018, 214, 533–539. [Google Scholar] [CrossRef]

- Trucillo, P.; Di Maio, E.; Lancia, A.; Di Natale, F. Selective Gold and Palladium Adsorption from Standard Aqueous Solutions. Processes 2021, 9, 1282. [Google Scholar] [CrossRef]

- Nagarjuna, R.; Sharma, S.; Rajesh, N.; Ganesan, R. Effective Adsorption of Precious Metal Palladium over Polyethyleneimine-Functionalized Alumina Nanopowder and Its Reusability as a Catalyst for Energy and Environmental Applications. ACS Omega 2018, 2, 4494–4504. [Google Scholar] [CrossRef] [PubMed]

- Maranescu, B.; Lupa, L.; Mihali, M.T.-L. Synthesis, characterizations and Pb(II) sorption properties of cobalt phosphonate materials. Pure Appl. Chem. 2016, 88, 979–992. [Google Scholar] [CrossRef]

- Wojnicki, M.; Socha, R.P.; Pędzich, Z.; Mech, K.; Tokarski, T.; Fitzner, K. Palladium(II) Chloride Complex Ion Recovery from Aqueous Solutions Using Adsorption on Activated Carbon. J. Chem. Eng. Data 2018, 63, 702–711. [Google Scholar] [CrossRef]

- Limin, Z.; Jinhui, L.; Zhirong, L. Adsorption of platinum (IV) and palladium (II) from aqueous solution by thiourea-modified chitosan microspheres. J. Hazard. Mater. 2009, 172, 439–446. [Google Scholar]

- Sharififard, H.; Ashtiani, F.Z.; Soleimani, M. Adsorption of palladium and platinum from aqueous solutions by chitosan and activated carbon coated with chitosan. Asia-Pac. J. Chem. Eng. 2012, 8, 384–395. [Google Scholar] [CrossRef]

- Sharma, R.; Arizaga, G.G.C.; Saini, A.K.; Shandilya, P. Layered double hydroxide as multifunctional materials for environmental remediation: From chemical pollutants to microorganisms. SM&T 2021, 29, e00319. [Google Scholar]

- Mishra, G.; Dash, B.; Pandey, S. Layered double hydroxides: A brief review from fundamentals to application as evolving biomaterials. Appl. Clay Sci. 2018, 153, 172–186. [Google Scholar] [CrossRef]

- Tang, Z.; Qiu, Z.; Lu, S.; Shi, X. Functionalized layered double hydroxide applied to heavy metal ions absorption: A review. Nanotechnol. Rev. 2020, 9, 800–819. [Google Scholar] [CrossRef]

- Ishak, S.N.; Nizam Nik Malek, N.A. Functionalized layered double hydroxide with compound to remove cationic and anionic pollutants: A review. Environ. Toxicol. Manag. 2021, 1, 26–29. [Google Scholar] [CrossRef]

- Tamilarasan, P.; Ramaprabhu, S. Ionic liquid functionalization—An effective way to tune carbon dioxide adsorption properties of carbon nanotubes. RSC Adv. 2015, 5, 35098–35106. [Google Scholar] [CrossRef]

- Erto, A.; Silvestre-Albero, A.; Silvestre-Albero, J.; Rodríguez-Reinoso, F.; Balsamo, M.; Lancia, A.; Montagnaro, F. Carbon-supported ionic liquids as innovative adsorbents for CO2 separation from synthetic flue-gas. J. Colloid Interface Sci. 2015, 448, 41–50. [Google Scholar] [CrossRef] [PubMed]

- Zarezadeh-Mehrizi, M.; Badiei, A.; Mehrabadi, A.R. Ionic liquid functionalized nanoporous silica for removal of anionic dye. J. Mol. Liq. 2013, 180, 95–100. [Google Scholar] [CrossRef]

- Zambare, R.; Song, X.; Bhuvana, S.; Antony Prince, J.S.; Nemade, P. Ultrafast Dye Removal Using Ionic Liquid–Graphene Oxide Sponge. ACS Sustain. Chem. Eng. 2017, 5, 6026–6035. [Google Scholar] [CrossRef]

- Lupa, L.; Negrea, P.; Popa, A. Use of Ionic Liquids in Solid-Liquid Separation Processes, Progress and Developments in Ionic Liquids, Scott Handy; IntechOpen: London, UK, 2017. [Google Scholar]

- Wieszczycka, K.; Filipowiak, K.; Wojciechowska, I.; Aksamitowski, P. Novel ionic liquid-modified polymers for highly effective adsorption of heavy metals ions. Sep. Purif. Technol. 2020, 236, 116313. [Google Scholar] [CrossRef]

- Bujok, S.; Konefał, M.; Abbrent, S.; Pavlova, E.; Svoboda, J.; Trhlikova, O.; Beneš, H. Ionic liquid-functionalized LDH as catalytic-initiating nanoparticles for microwave-activated ring opening polymerization of ε-caprolactone. React. Chem. Eng. 2020, 5, 506–518. [Google Scholar] [CrossRef]

- Bujok, S.; Hodan, J.; Beneš, H. Effects of Immobilized Ionic Liquid on Properties of Biodegradable Polycaprolactone/LDH Nanocomposites Prepared by In Situ Polymerization and Melt-Blending. Nanomaterials 2020, 10, 969. [Google Scholar] [CrossRef] [PubMed]

- Alhumaimess, M.S.; HotanAlsohaimi, I.; Hassan, H.M.A.; El-Sayed, M.Y.; Alshammari, M.S.; Aldosari, O.F.; Kamel, M.M. Synthesis of ionic liquid intercalated layered double hydroxides of magnesium and aluminum: A greener catalyst of Knoevenagel condensation. J. Saudi Chem. Soc. 2020, 24, 321–333. [Google Scholar] [CrossRef]

- Pizzoferrato, R.; Ciotta, E.; Ferrari, I.V.; Narducci, R.; Pasquini, L.; Varone, A.; Di Vona, M.L. Layered Double Hydroxides Containing an Ionic Liquid: Ionic Conductivity and Use in Composite Anion Exchange Membranes. ChemElectroChem 2018, 5, 2781–2788. [Google Scholar] [CrossRef]

- Cocheci, L.; Lupa, L.; Ţolea, N.S.; Muntean, C.; Negrea, P. Sequential use of ionic liquid functionalized Zn-Al layered double hydroxide as adsorbent and photocatalyst. Sep. Purif. Technol. 2020, 250, 117104. [Google Scholar] [CrossRef]

- Cui, H.; Chen, J.; Yang, H.; Wang, W.; Liu, Y.; Zou, D.; Liu, W.; Men, G. Preparation and application of Aliquat 336 functionalized chitosan adsorbent for the removal of Pb(II). Chem. Eng. J. 2013, 232, 372–379. [Google Scholar] [CrossRef]

- Ranjbari, S.; Tanhaei, B.; Ayati, A.; Sillanpää, M. Novel Aliquat-336 impregnated chitosan beads for the adsorptive removal of anionic azo dyes. Int. J. Biol. Macromol. 2018, 125, 989–998. [Google Scholar] [CrossRef]

- Lupa, L.; Cocheci, L.; Pode, R.; Hulka, I. Phenol adsorption using Aliquat 336 functionalized Zn-Al layered double hydroxide. Sep. Purif. Technol. 2017, 196, 82–95. [Google Scholar] [CrossRef]

- Wei, W.; Song, M.H.; Kim, S.; Bediako, J.K.; Yun, Y.S. Selective Recovery of Au(III) from Binary Metal Solution Using Aliquat-336-Impregnated Alginate Capsule. AMR 2015, 1130, 511–514. [Google Scholar] [CrossRef]

- Wiyantoko, B.; Kurniawati, P.; Purbaningtias, T.E.; Fatimah, I. Synthesis and Characterization of Hydrotalcite at Different Mg/Al Molar Ratios. Procedia Chem. 2015, 17, 21–26. [Google Scholar] [CrossRef]

- Macala, G.S.; Robertson, A.W.; Day, Z.B.; Lewis, R.S.; Iretskii, A.V.; Ford, P.C. Transesterification Catalysts from Iron Doped Hydrotalcite-like Precursors: Solid Bases for Biodiesel Production. Catal. Lett. 2008, 122, 205–209. [Google Scholar] [CrossRef]

- Kwon, D.; Kang, J.Y.; An, S.; Yang, I.; Jung, J.C. Tuning the base properties of Mg–Al hydrotalcite catalysts using their memory effect. J. Energy Chem. 2020, 46, 229–236. [Google Scholar] [CrossRef]

- Dietmann, K.M.; Linke, T.; del Nogal Sánchez, M.; Pérez Pavón, J.L.; Rives, V. Layered Double Hydroxides with Intercalated Permanganate and Peroxydisulphate Anions for Oxidative Removal of Chlorinated Organic Solvents Contaminated Water. Minerals 2020, 10, 462. [Google Scholar] [CrossRef]

- Dietmann, K.M.; Linke, T.; Trujillano, R.; Rives, V. Effect of Chain Length and Functional Group of Organic Anions on the Retention Ability of MgAl- Layered Double Hydroxides for Chlorinated Organic Solvents. ChemEngineering 2019, 3, 89. [Google Scholar] [CrossRef]

- Villegas, J.C.; Giraldo, O.H.; Laubernds, K.; Suib, S.L. New Layered Double Hydroxides Containing Intercalated Manganese Oxide Species: Synthesis and Characterization. Inorg. Chem. 2003, 42, 5621–5631. [Google Scholar] [CrossRef] [PubMed]

- Tolea, N.S.; Cocheci, L.; Lupa, L.; Voda, R.; Pode, R. Development of New Efficient Adsorbent by Functionalization of Mg 3 Al-LDH with Methyl Trialkyl Ammonium Chloride Ionic Liquid. Molecules 2021, 26, 7384. [Google Scholar] [CrossRef] [PubMed]

- Stanimirova, T.; Vergilov, I.; Kirov, G.; Petrova, N. Thermal decomposition products of hydrotalcite-like compounds: Low-temperature metaphases. J. Mater. Sci. 1999, 34, 4153–4161. [Google Scholar] [CrossRef]

- Kozak, M.; Domka, L. Adsorption of the quaternary ammonium salts on montmorillonite. J. Phys. Chem. Solids 2004, 65, 441–445. [Google Scholar] [CrossRef]

- Kloprogge, J.T.; Frost, R.L. Fourier Transform Infrared and Raman Spectroscopic Study of the Local Structure of Mg-, Ni-, and Co-Hydrotalcites. J. Solid State Chem. 1999, 146, 506–515. [Google Scholar] [CrossRef]

- Labajos, F.M.; Rives, V.; Ulibarri, M.A. Effect of hydrothermal and thermal treatments on the physicochemical properties of IVIg-AI hydrotalcite-like materials. J. Mat. Sci. 1992, 27, 1546–1552. [Google Scholar] [CrossRef]

- Prikhod’ko, R.V.; Sychev, M.V.; Astrelin, I.M.; Erdmann, K.; Mangel, A.; Van Santen, R.A. Synthesis and structural transformations of hydrotalcite-like materials Mg3Al and Zn3Al. Russ. J. Appl. Chem. 2001, 74, 1573–1577. [Google Scholar]

- Visa, A.; Maranescu, B.; Lupa, L.; Crisan, L.; Borota, A. New Efficient Adsorbent Materials in the Removal Process of Cd(II) from Aqueous Solutions. Nanomaterials 2020, 10, 899. [Google Scholar] [CrossRef]

- Nistor, M.A.; Muntean, S.G.; Maranescu, B.; Visa, A. Phosphonate metal-organic frameworks used as dye removal materials from wastewaters. Appl. Organomet. Chem. 2020, 34, e5939. [Google Scholar] [CrossRef]

- Lupa, L.; Maranescu, B.; Visa, A. Equilibrium and kinetic studies of chromium ions adsorption on Co(II) based phosphonate metal organic frameworks. Sep. Sci. Technol. 2018, 53, 1017–1026. [Google Scholar] [CrossRef]

- Anitha, T.; Senthil Kumar, P.; Kumar Sathish, K.; Sriram, K.; Feroze Ahmed, J. Biosorption of lead(II) ions onto nano-sized chitosan particle blended polyvinyl alcohol (PVA): Adsorption isotherms, kinetics and equilibrium studies. Desalin. Water Treat. 2016, 57, 13711–13721. [Google Scholar] [CrossRef]

- Mildan, E.; Gülfen, M. Equilibrium, kinetics, and thermodynamics of Pd(II) adsorption onto poly(m-aminobenzoic acid) chelating polymer. J. Appl. Polym. Sci. 2015, 132, 42533. [Google Scholar] [CrossRef]

- Saha, P.; Chawdhury, S. Insight into Adsorption Thermodynamics, Thermodynamics; Mizutani, T., Ed.; IntechOpen: London, UK,, 2011. [Google Scholar]

- Sharma, S.; Rajesh, N. Augmenting the adsorption of palladium from spent catalyst using a thiazole ligand tethered on an amine functionalized polymeric resin. Chem. Eng. J. 2016, 283, 999–1008. [Google Scholar] [CrossRef]

- Bai, F.; Ye, G.; Chen, G.; Wei, J.; Wang, J.; Chen, J. Highly selective recovery of palladium by a new silica-based adsorbent functionalized with macrocyclic ligand. Sep. Purif. Technol. 2013, 106, 38–46. [Google Scholar] [CrossRef]

- Kumar, A.S.K.; Sharma, S.; Reddy, R.S.; Barathi, M.; Rajesh, N. Comprehending the interaction between chitosan and ionic liquid for the adsorption of palladium. Int. J. Biol. Macromol. 2015, 72, 633–639. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Rajesh, N. Synergistic influence of graphene oxide and tetraoctylammonium bromide (frozen ionic liquid) for the enhanced adsorption and recovery of palladium from an industrial catalyst. J. Environ. Chem. Eng. 2016, 4, 4287–4298. [Google Scholar] [CrossRef]

- Chen, H.; Yang, H.; Li, N.; Xue, X.; He, Z.; Zeng, Q. Palladium-Catalyzed C–N Cross-Coupling of NH-Heteroarenes and Quaternary Ammonium Salts via C–N Bond Cleavage. Org. Process. Res. Develop. 2019, 28, 1679–1685. [Google Scholar] [CrossRef]

- Sun, J.; Li, D.; Gao, H.; Jin, Z.; Bao, M. Effect of the types of stabilizers and size distribution on catalytic activity of palladium nanoparticles in the carboxylative coupling reaction. SN Appl. Sci. 2019, 1, 137. [Google Scholar] [CrossRef]

- Vancea, C.; Mihailescu, M.; Negrea, A.; Mosoarca, G.; Ciopec, M.; Duteanu, N.; Negrea, P.; Minzatu, V. Batch and Fixed-Bed Column Studies on Palladium Recovery from Acidic Solution by Modified MgSiO3. Int. J. Environ. Res. Public Health 2020, 17, 9500. [Google Scholar] [CrossRef]

- Lupa, L.; Negrea, A.; Ciopec, M.; Negrea, P.; Raluca, V. Ionic liquids impregnated onto inorganic support used for thallium adsorption from aqueous solutions. Sep. Purif. Technol. 2015, 155, 75–82. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, C.; Zhao, J.; Wang, S.; Zhou, Y.; Zhang, L. Adsorption behavior of Pd(II) ions from aqueous solution onto pyromellitic acid modified-UiO-66-NH2. Arab. J. Chem. 2020, 13, 7007–7019. [Google Scholar] [CrossRef]

- Ma, H.; Liao, X.; Liu, X.; Shi, B. Recovery of platinum(IV) and palladium(II) by bayberry tannin immobilized collagen fiber membrane from water solution. J. Membr. Sci. 2006, 278, 373–380. [Google Scholar] [CrossRef]

- Godlewska-Żyłkiewicz, B.; Sawicka, S.; Karpińska, J. Removal of Platinum and Palladium from Wastewater by Means of Biosorption on Fungi aspergillus sp. and Yeast saccharomyces sp. Water 2019, 11, 1522. [Google Scholar] [CrossRef]

| Method of Synthesis | Sample Acronym | a (Å) | c (Å) | d(003) (Å) | D (nm) | SBET (m2/g) | Vp (cm3/g) |

|---|---|---|---|---|---|---|---|

| MgAl-layered double hydroxide synthesized through co-precipitation Mg:Al = 3:1 | Mg3Al | 3.073 | 23.58 | 7.86 | 4.86 | 102 | 0.628 |

| Mg3Al-LDH + IL functionalized by ultrasound method | Mg3Al IL-US | 3.071 | 23.52 | 7.84 | 4.45 | 93.9 | 0.560 |

| Mg3Al-LDH + IL functionalized by co-synthesis | Mg3Al IL-COS | 3.072 | 24.39 | 8.13 | 3.38 | 22.2 | 0.168 |

| Adsorbent Material | Pseudo First Order | Pseudo Second Order | Intra Particle Diffusion | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T = 298 K | ||||||||||

| qeexp. mg/g | qe calc. mg/g | K1, min−1 | R2 | qe calc. mg/g | K2·10−3, min/(mg/g) | R2 | Kint, mg/g min−1/2 | C | R2 | |

| Mg3Al | 41.3 | 13.1 | 0.0288 | 0.9769 | 42.2 | 0.0052 | 0.9996 | 1.9826 | 23.8 | 0.9966 |

| Mg3Al IL-COS | 49.8 | 6.0 | 0.0218 | 0.9282 | 50.0 | 0.0139 | 0.999 | 0.9670 | 41.6 | 0.9943 |

| Mg3Al IL-US | 48.2 | 9.1 | 0.0198 | 0.9929 | 48.8 | 0.0074 | 0.9997 | 0.9976 | 38.0 | 0.9701 |

| T = 313 K | ||||||||||

| qeexp. | qe calc. | K1 | R2 | qe calc. | K2 | R2 | Kint. | C | R2 | |

| Mg3Al | 42.7 | 12.5 | 0.0236 | 0.9837 | 43.7 | 0.0056 | 0.9998 | 1.2275 | 28.6 | 0.8383 |

| Mg3Al IL-COS | 49.9 | 4.7 | 0.0209 | 0.9384 | 50.3 | 0.017 | 1 | 0.5635 | 43.6 | 0.7448 |

| Mg3Al IL-US | 48.7 | 10.1 | 0.0248 | 0.8877 | 49.3 | 0.0086 | 0.9998 | 0.8110 | 39.3 | 0.8731 |

| T = 328 K | ||||||||||

| qeexp. | qe calc. | K1 | R2 | qe calc. | K2 | R2 | Kint. | C | R2 | |

| Mg3Al | 44.7 | 12.4 | 0.0231 | 0.9761 | 45.5 | 0.0058 | 0.9998 | 1.1962 | 30.9 | 0.8406 |

| Mg3Al IL-COS | 50.0 | 3.3 | 0.0173 | 0.8254 | 50.3 | 0.0240 | 1 | 0.4379 | 45.1 | 0.7061 |

| Mg3Al IL-US | 49.7 | 6.6 | 0.0200 | 0.9756 | 50.0 | 0.0110 | 0.9999 | 0.6200 | 42.4 | 0.8752 |

| Adsorbent Material | Ea, kJ/mol | Thermodynamic Parameters | |||||

|---|---|---|---|---|---|---|---|

| ΔH°, kJ/mol−1 | ΔS°, J/(mol K) | ΔG°, kJ/mol | R2 | ||||

| 298 K | 313 K | 328 K | |||||

| Mg3Al | 2.97 | 16.56 | 68.2 | −3.87 | −4.9 | −5.93 | 0.9784 |

| Mg3Al IL−COS | 14.72 | 65.38 | 272.2 | −15.6 | −19.7 | −23.8 | 0.9983 |

| Mg3Al IL−US | 10.68 | 46.98 | 185.9 | −8.41 | −11.2 | −13.9 | 0.9926 |

| Mg3Al | Mg3Al IL-COS | Mg3Al IL-US | ||

|---|---|---|---|---|

| Equilibrium isotherm | qm, exp, mg/g | 132.9 | 277.8 | 219.1 |

| Langmuir | qm, calc, mg/g | 142.9 | 277.7 | 227.3 |

| KL, L/mg | 0.0399 | 0.8782 | 0.1073 | |

| R2 | 0.9987 | 0.9999 | 0.9994 | |

| Freundlich | 1/n | 0.6063 | 0.4135 | 0.5508 |

| KF, mg/g | 7.11 | 68.3 | 21.2 | |

| R2 | 0.9214 | 0.8515 | 0.8926 | |

| Temkin | b, J/mol | 102.8 | 83.7 | 77.6 |

| KT, L/g | 0.872 | 58.8 | 3.63 | |

| R2 | 0.9432 | 0.9536 | 0.91 |

| Adsorbent | qm, mg/g | References |

|---|---|---|

| 2-Mercaptobenzothiazole functionalized Amberlite XAD-1180 resin | 50.0 | [46] |

| Silica-based adsorbent functionalized with macrocyclic ligand | 83.0 | [47] |

| Aliquat-336 (ionic liquid) impregnated onto chitosan | 187.61 | [48] |

| Tetraoctylammonium bromide impregnated onto graphene oxide | 92.67 | [49] |

| MgSiO3functionalizedwith DL-cysteine | 9.23 | [52] |

| Zn3Al | 64.4 | [23] |

| Zn3Al-IL | 100 | |

| Zn3Al-ILUS | 92.4 | |

| Mg3Al | 142.9 | Present paper |

| Mg3Al IL-COS | 277.8 | |

| Mg3Al IL-US | 227.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cocheci, L.; Lupa, L.; Tolea, N.S.; Lazău, R.; Pode, R. IL-Functionalized Mg3Al-LDH as New Efficient Adsorbent for Pd Recovery from Aqueous Solutions. Int. J. Mol. Sci. 2022, 23, 9107. https://doi.org/10.3390/ijms23169107

Cocheci L, Lupa L, Tolea NS, Lazău R, Pode R. IL-Functionalized Mg3Al-LDH as New Efficient Adsorbent for Pd Recovery from Aqueous Solutions. International Journal of Molecular Sciences. 2022; 23(16):9107. https://doi.org/10.3390/ijms23169107

Chicago/Turabian StyleCocheci, Laura, Lavinia Lupa, Nick Samuel Tolea, Radu Lazău, and Rodica Pode. 2022. "IL-Functionalized Mg3Al-LDH as New Efficient Adsorbent for Pd Recovery from Aqueous Solutions" International Journal of Molecular Sciences 23, no. 16: 9107. https://doi.org/10.3390/ijms23169107

APA StyleCocheci, L., Lupa, L., Tolea, N. S., Lazău, R., & Pode, R. (2022). IL-Functionalized Mg3Al-LDH as New Efficient Adsorbent for Pd Recovery from Aqueous Solutions. International Journal of Molecular Sciences, 23(16), 9107. https://doi.org/10.3390/ijms23169107