State of the Art in the Antibacterial and Antiviral Applications of Carbon-Based Polymeric Nanocomposites

Abstract

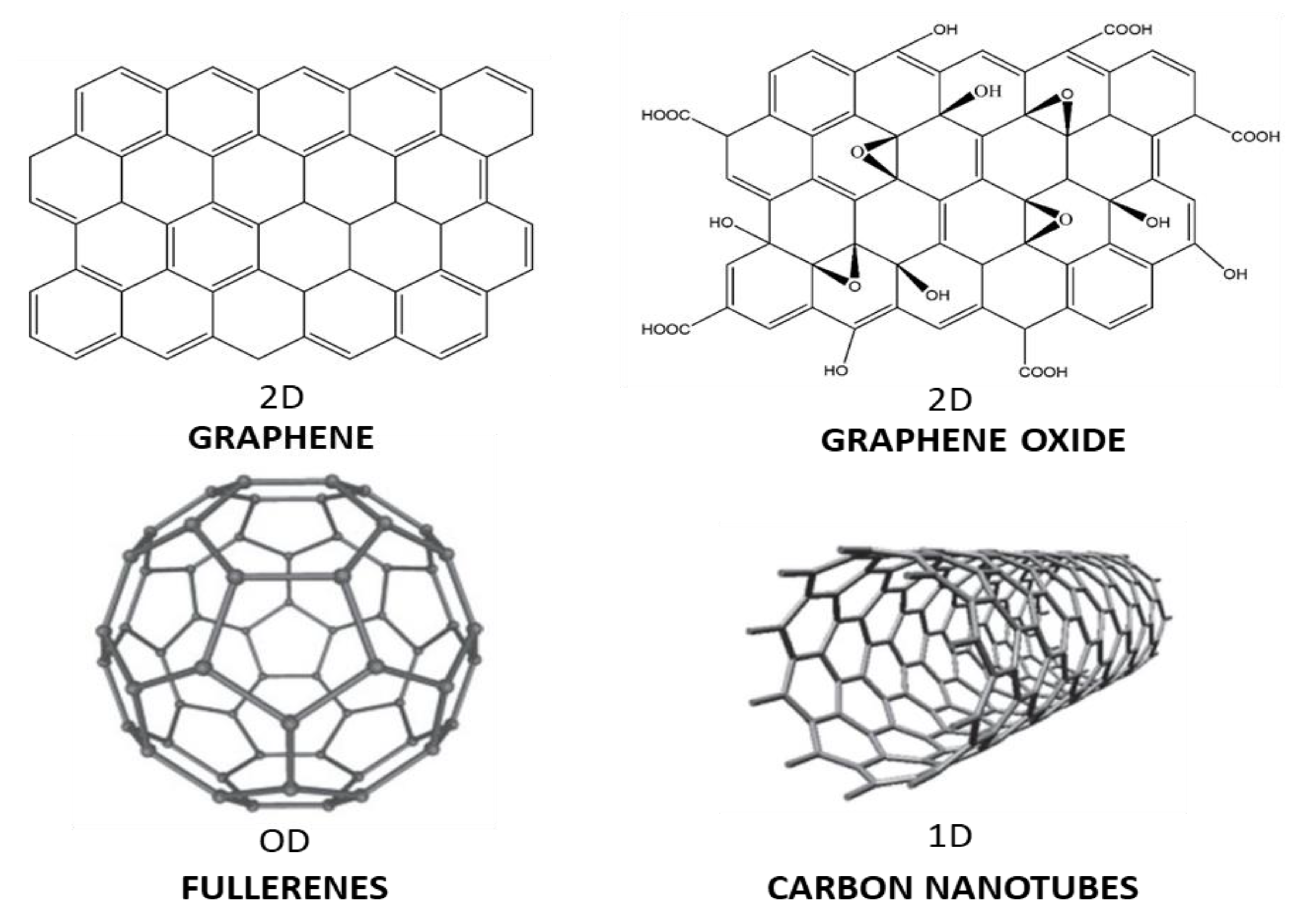

1. Introduction

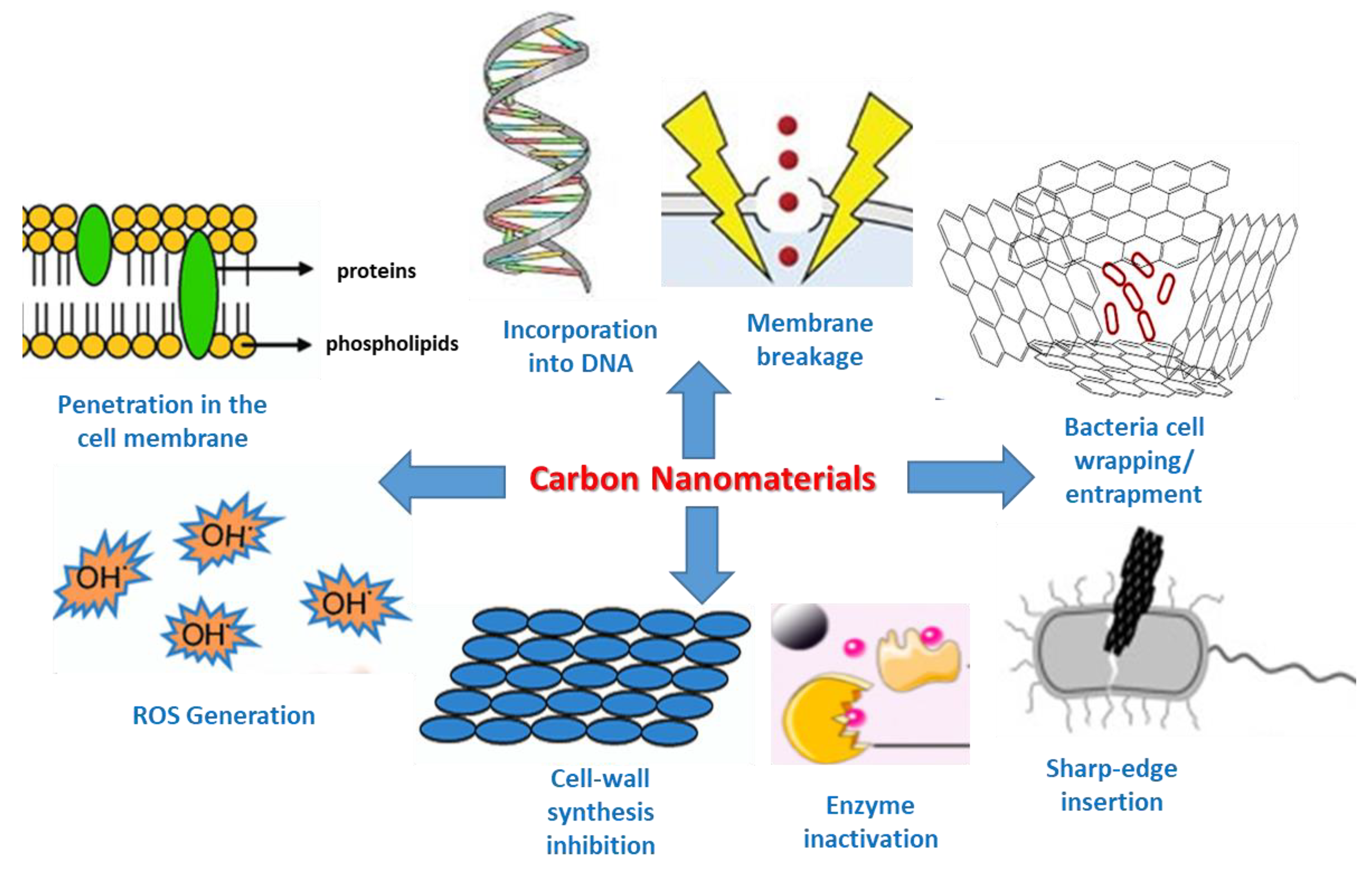

2. Mechanisms of Antimicrobial Action of Carbon Nanomaterials

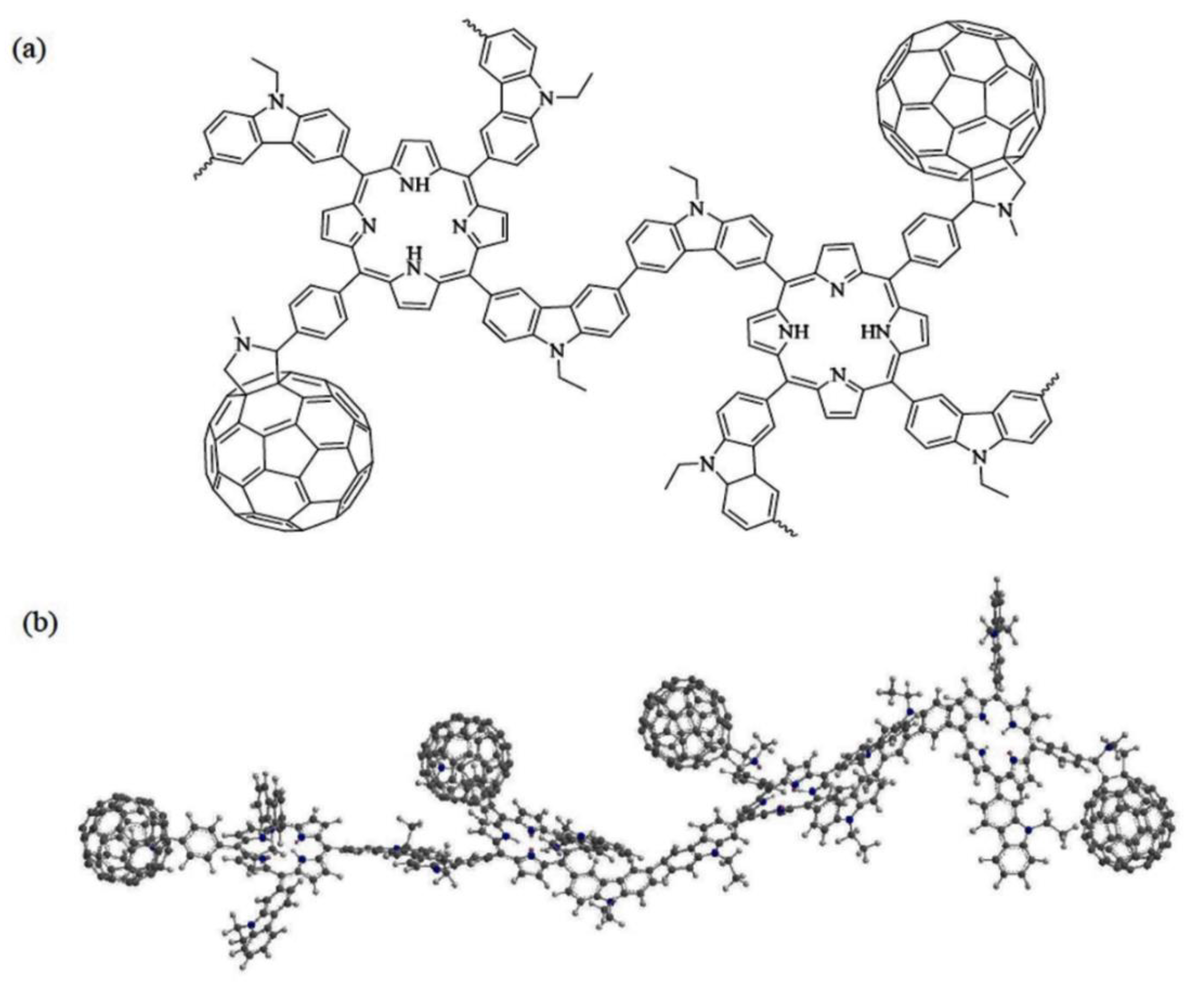

2.1. Antimicrobial Activity of Fullerenes

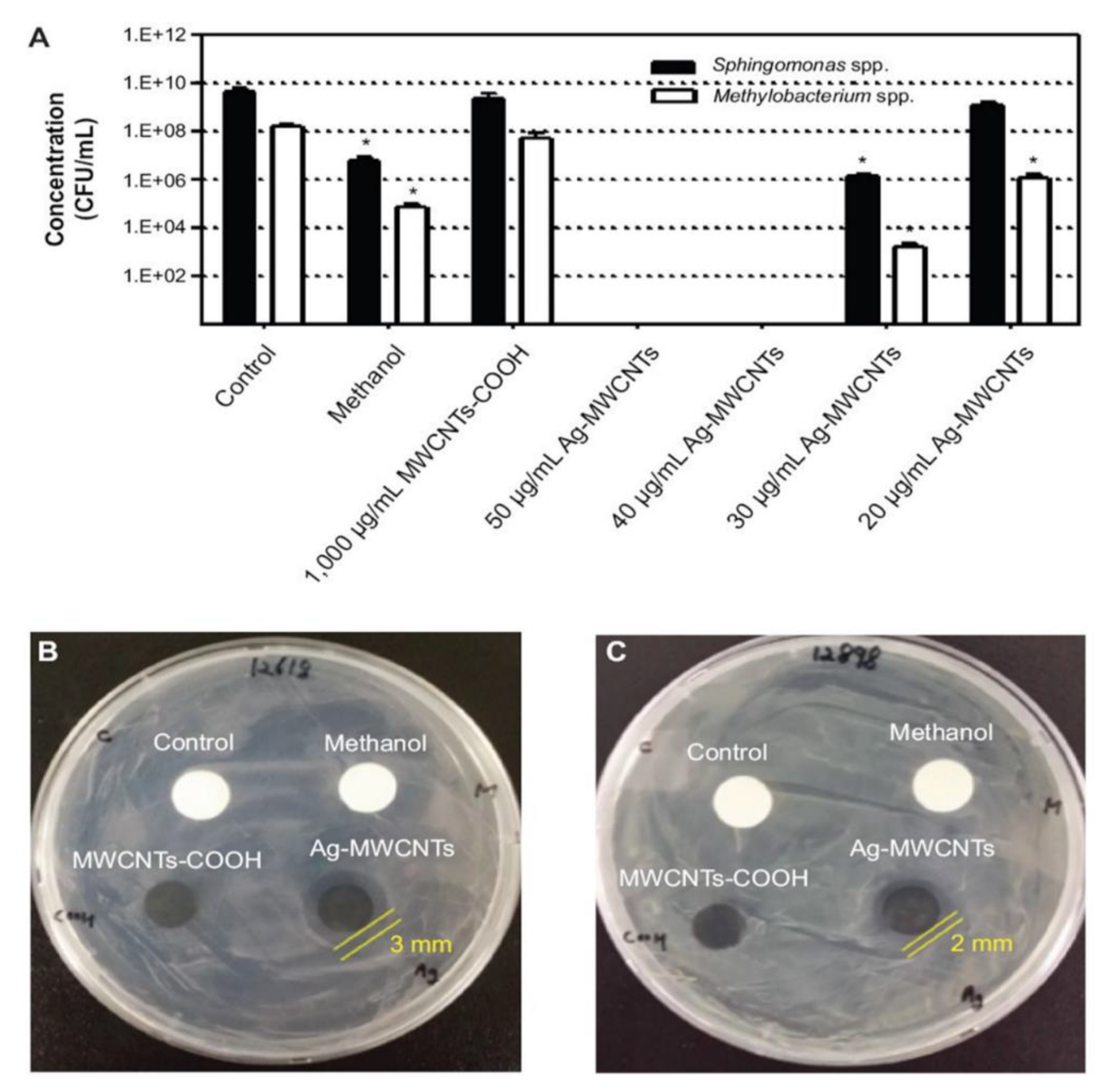

2.2. Antimicrobial Activity of Carbon Nanotubes

2.3. Antimicrobial Action of Graphene, Graphene Oxide and Reduced Graphene Oxide

3. Antibacterial Action of Polymer Nanocomposites with Carbon-Based Nanomaterials

3.1. Antibacterial Properties of Nanocomposites Incorporating Fullerenes

3.2. Antibacterial Properties of Nanocomposites with Carbon Nanotubes

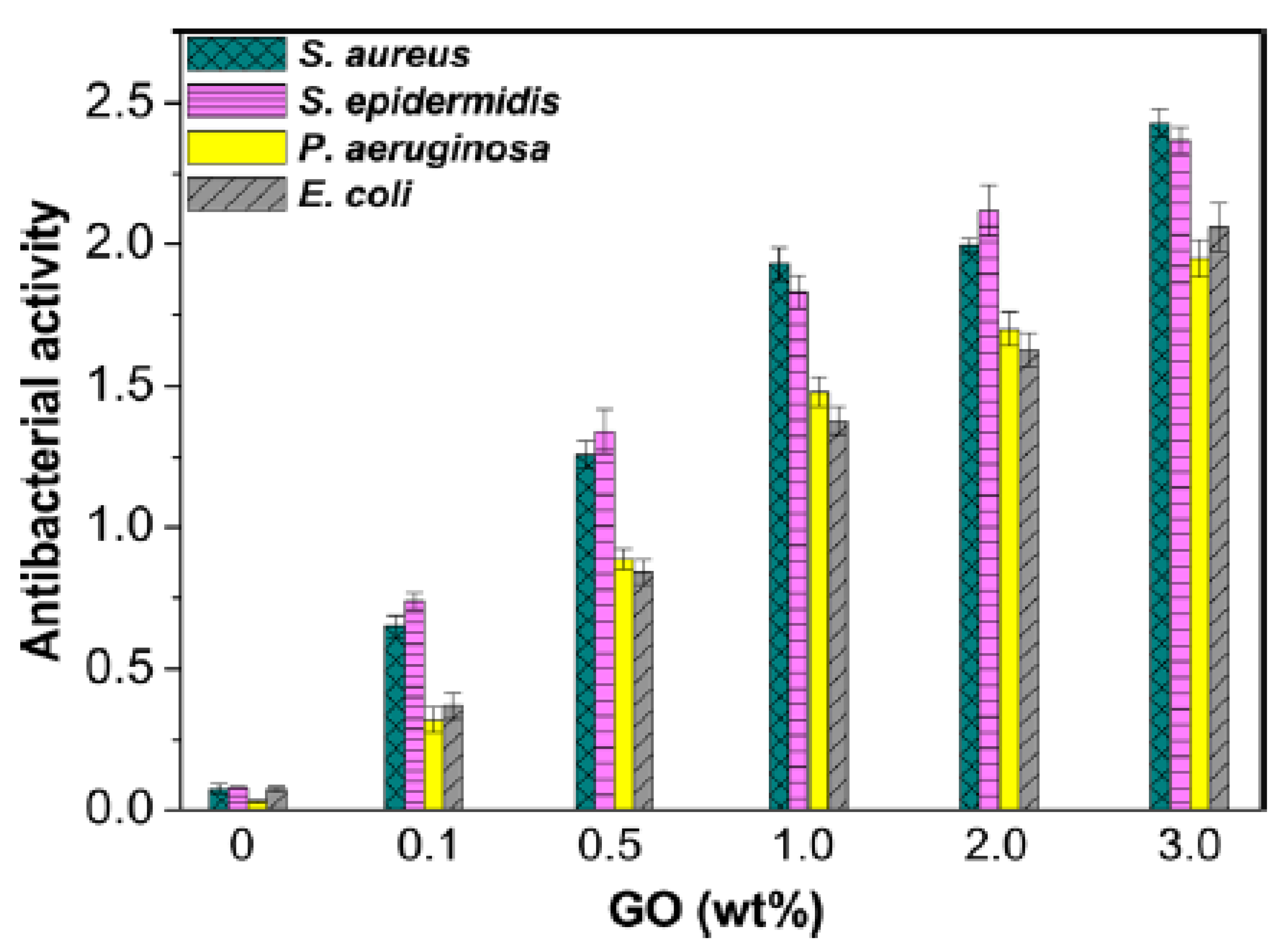

3.3. Antibacterial Properties of Nanocomposites with Graphene and Its Derivatives

4. Applications for Antimicrobial Polymeric Nanocomposites with Carbon Materials

5. Conclusions

6. Future Perspectives

Funding

Conflicts of Interest

References

- Wadi, A.K.A. Preparation and Characterization of Polymeric Composites as Antibacterial Surfaces for Medical Applications. Master’s Thesis, University of Babylon, Hillah, Iraq, 2017. [Google Scholar]

- Zaman, S.B.; Hussain, M.A.; Nye, R.; Mehta, V.; Mamun, K.T.; Hossain, N. A Review on Antibiotic Resistance: Alarm Bells are Ringing. Cureus 2017, 9, 1403. [Google Scholar] [CrossRef] [PubMed]

- Price, R. O′Neill report on antimicrobial resistance: Funding for antimicrobial specialists should be improved. Eur. J. Hosp. Phar. Sci. Prac. 2016, 23, 245–247. [Google Scholar] [CrossRef] [PubMed]

- Díez-Pascual, A.M. Antibacterial Activity of Nanomaterials. Nanomaterials 2018, 8, 359. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, M.M.; Julian, S.A.; Mariya, M.; Vejerano, E.P. Nanoantibiotics: Functions and Properties at the Nanoscale to Combat Antibiotic Resistance. Front. Chem. 2021, 9, 348. [Google Scholar] [CrossRef]

- Sargazi, S.; Mukhtar, M.; Rahdar, A.; Barani, M.; Pandey, S.; Díez-Pascual, A.M. Active Targeted of Nanoparticles for Delivery of Antibiotics: A Preliminary Review. Int. J. Mol. Sci. 2021, 22, 10319, in press. [Google Scholar] [CrossRef]

- Carver, J.A.; Simpson, A.L.; Rathi, R.P.; Normil, N.; Lee, A.G.; Force, M.D.; Fiocca, K.A.; Maley, C.E. Functionalized Single-Walled Carbon Nanotubes and Nanographene Oxide to Overcome Antibiotic Resistance in Tetracycline-Resistant Escherichia coli. ACS Appl. Nano Mater. 2020, 3, 3910–3921. [Google Scholar] [CrossRef]

- Kenawy, E.; Worley, S.D.; Broughton, R. The Chemistry and Applications of Antimicrobial Polymers: A State-of-the-Art Review. Biomacromolecules 2007, 8, 1359–1384. [Google Scholar] [CrossRef]

- Kamaruzzaman, N.F.; Tan, L.P.; Hamdan, R.H.; Choong, S.S.; Wong, W.K.; Gibson, A.J.; Chivu, A.; Pina, M.F. Antimicrobial Polymers: The Potential Replacement of Existing Antibiotics? Int. J. Mol. Sci. 2019, 20, 2747. [Google Scholar] [CrossRef]

- Muñoz-Bonilla, A.; Fernández-García, M. Polymeric materials with antimicrobial activity. Prog. Polym. Sci. 2012, 37, 281–339. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. Antibacterial SnO2 nanorods as efficient fillers of poly(propylene fumarate-co-ethylene glycol) biomaterials. Mater. Sci. Eng. C 2017, 78, 806–816. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. Poly(propylene fumarate)/Polyethylene Glycol-Modified Graphene Oxide Nanocomposites for Tissue Engineering. ACS Appl. Mater. Interfaces 2016, 8, 17902–17914. [Google Scholar] [CrossRef]

- Lukowiak, A.; Kedziora, A.; Strek, W. Antimicrobial graphene family materials: Progress, advances, hopes and fears. Adv. Colloid Interface Sci. 2016, 236, 101–112. [Google Scholar] [CrossRef]

- Maqbool, Q.; Barucca, G.; Sabbatini, S.; Parlapiano, M.; Ruello, M.L.; Tittarelli, F. Transformation of industrial and organic waste into titanium doped activated carbon–cellulose nanocomposite for rapid removal of organic pollutant. J. Hazard. Mater. 2022, 423, 126958. [Google Scholar] [CrossRef] [PubMed]

- Panayiotis, B.; Dimitrios, K.; Apostolos, A.; Georgios, S. Non-covalent functionalization of carbon nanotubes with Polymers. RSC Adv. 2014, 4, 2911–2934. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M. Chemical Functionalization of Carbon Nanotubes with Polymers: A Brief Overview. Macromol 2021, 1, 6. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2009, 39, 228–240. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Luceño Sánchez, J.A.; Peña Capilla, R.; García Díaz, P. Recent Developments in Graphene/Polymer Nanocomposites for Application in Polymer Solar Cells. Polymers 2018, 10, 217. [Google Scholar] [CrossRef] [PubMed]

- Díez-Pascual, A.M.; Naffakh, M. Grafting of an aminated poly(phenylene sulphide) derivative to functionalized single-walled carbon nanotubes. Carbon 2012, 50, 857–868. [Google Scholar] [CrossRef]

- Kroto, H.W. C60: Buckminsterfullerene, The Celestial Sphere that Fell to Earth. Ang. Chem. Int. Ed. 1992, 31, 111–129. [Google Scholar] [CrossRef]

- Ahmed, A.-J.; Surjith, A.; Kateryna, B.; Mohan, V.J. Review on the Antimicrobial Properties of Carbon Nanostructures. Materials 2017, 10, 1066. [Google Scholar] [CrossRef]

- Han, W.; Wu, Z.; Li, Y.; Wang, Y. Graphene family nanomaterials (GFNs)—promising materials for antimicrobial coating and film: A review. Chem. Eng. J. 2019, 358, 1022–1037. [Google Scholar] [CrossRef]

- Zheng, H.; Ma, R.; Gao, M.; Tian, X.; Li, Y.; Zeng, L.; Li, R. Antibacterial applications of graphene oxides: Structure-activity relationships, molecular initiating events and biosafety. Sci. Bull. 2018, 63, 133–142. [Google Scholar] [CrossRef]

- Hancock, J.T.; Desikan, R.; Neill, S.J. Role of reactive oxygen species in cell signalling pathways. Biochem. Soc. Trans. 2001, 29, 345–350. [Google Scholar] [CrossRef]

- Panda, S.; Rout, T.; Prusty, A.; Ajayan, P.; Nayak, S. Electron Transfer Directed Antibacterial Properties of Graphene Oxide on Metals. Adv. Mater. 2018, 30, 1702149. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wang, G.; Zhu, H.; Zhang, M.; Zheng, X.; Di, Z.; Liu, X.; Wang, X. Antibacterial activity of large-area monolayer graphene film manipulated by charge transfer. Sci. Rep. 2014, 4, 4349. [Google Scholar] [CrossRef] [PubMed]

- Luan, B.; Huynh, T.; Zhao, L.; Zhou, R. Potential Toxicity of Graphene to Cell Functions via Disrupting Protein–Protein Interactions. ACS Nano 2015, 9, 663–669. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E. Toxicity of Graphene and Graphene Oxide Nanowalls against Bacteria. ACS Nano 2010, 4, 5731–5736. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Cong, H.; Yu, B.; Chen, Q. Recent advances of water-soluble fullerene derivatives in biomedical applications. Mini-Rev. Org. Chem. 2019, 16, 92–99. [Google Scholar] [CrossRef]

- Deryabin, D.G.; Davydova, O.K.; Yankina, Z.Z.; Vasilchenko, A.S.; Miroshnikov, S.A.; Kornev, A.B. The activity of [60] fullerene derivatives bearing amine and carboxylic solubilizing groups against Escherichia coli: A comparative study. J. Nanomater. 2014, 2014, 907435. [Google Scholar] [CrossRef]

- Berry, T.D.; Filley, T.R.; Clavijo, A.P.; Gray, M.B.; Turco, R. Degradation and microbial uptake of C60 fullerols in contrasting agricultural soils. Environ. Sci. Technol. 2017, 51, 1387–1394. [Google Scholar] [CrossRef] [PubMed]

- Maksimova, Y.G. Microorganisms and carbon nanotubes: Interaction and applications. Appl. Biochem. Microbiol. 2019, 55, 1–12. [Google Scholar] [CrossRef]

- Ding, L.; Wang, H.; Liu, D.; Zeng, X.-A.; Mao, Y. Bacteria capture and inactivation with functionalized multi-walled carbon nanotubes (MWCNTs). J. Nanosci. Nanotechnol. 2020, 20, 2055–2062. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Mamouni, J.; Tang, Y.; Yang, L. Antimicrobial activity of single-walled carbon nanotubes: Length effect. Langmuir 2010, 26, 16013–16019. [Google Scholar] [CrossRef] [PubMed]

- Smith, S.C.; Rodrigues, D.F. Carbon-based nanomaterials for removal of chemical and biological contaminants from water: A review of mechanisms and applications. Carbon 2015, 91, 122–143. [Google Scholar] [CrossRef]

- Yuan, W.; Jiang, G.; Che, J.; Qi, X.; Xu, R.; Chang, M.W. Deposition of silver nanoparticles on multiwalled carbon nanotubes grafted with hyperbranched poly (amidoamine) and their antimicrobial effects. J. Phys. Chem. C 2008, 112, 18754–18759. [Google Scholar] [CrossRef]

- Morsi, R.E.; Alsabagh, A.M.; Nasr, S.A.; Zaki, M.M. Multifunctional nanocomposites of chitosan, silver nanoparticles, copper nanoparticles and carbon nanotubes for water treatment: Antimicrobial characteristics. Int. J. Biol. Macromol. 2017, 97, 264–269. [Google Scholar] [CrossRef] [PubMed]

- Seo, Y.; Hwang, J.; Kim, J.; Jeong, Y.; Hwang, M.; Choi, J. Antibacterial activity and cytotoxicity of multi-walled carbon nanotubes decorated with silver nanoparticles. Int. J. Nanomed. 2014, 9, 4621–4629. [Google Scholar] [CrossRef]

- Hui, L.; Piao, J.; Auletta, J.; Hu, K.; Zhu, Y.; Meyer, T.; Liu, H.; Yang, L. Availability of the Basal Planes of Graphene Oxide Determines Whether It Is Antibacterial. ACS Appl. Mater. Interfaces 2014, 6, 13183–13190. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zeng, T.H.; Hofmann, M.; Burcombe, E.; Wei, J.; Jiang, R.; Kong, J.; Chen, Y. Antibacterial Activity of Graphite, Graphite Oxide, Graphene Oxide, and Reduced Graphene Oxide: Membrane and Oxidative Stress. ACS Nano 2011, 5, 6971–6980. [Google Scholar] [CrossRef]

- Zhang, W.; Yan, L.; Li, M.; Zhao, R.; Yang, X.; Ji, T.; Gu, Z.; Yin, J.; Gao, X.; Nie, G. Deciphering the underlying mechanisms of oxidation-state dependent cytotoxicity of graphene oxide on mammalian cells. Toxicol. Lett. 2015, 237, 61–71. [Google Scholar] [CrossRef]

- Dallavalle, M.; Calvaresi, M.; Bottoni, A.; Melle-Franco, M.; Zerbetto, F. Graphene Can Wreak Havoc with Cell Membranes. ACS Appl. Mater. Interfaces 2015, 7, 4406–4414. [Google Scholar] [CrossRef]

- Wang, J.; Wei, Y.; Shi, X.; Gao, H. Cellular entry of graphene nanosheets: The role of thickness, oxidation and surface adsorption. RSC Adv. 2013, 3, 15776. [Google Scholar] [CrossRef]

- Kumar, P.; Huo, P.; Zhang, R.; Liu, B. Antibacterial Properties of Graphene-Based Nanomaterials. Nanomaterials 2019, 9, 737. [Google Scholar] [CrossRef]

- Alekseeva, O.; Bagrovskaya, N.; Noskov, A. Polystyrene film composites filled with fullerenes. In Proceedings of the International Conference Nanomaterials: Applications and Properties, Alusha, Ukranie, 21 September 2013. [Google Scholar]

- Ballatore, M.B.; Durantini, J.; Gsponer, N.S.; Suarez, M.B.; Gervaldo, M.; Otero, L. Photodynamic inactivation of bacteria using novel electrogenerated porphyrinfullerene C60 polymeric films. Environ. Sci. Technol. 2015, 49, 7456–7463. [Google Scholar] [CrossRef] [PubMed]

- Aslan, S.; Määttä, J.; Haznedaroglu, B.Z.; Goodman, J.P.; Pfefferle, L.D.; Elimelech, M. Carbon nanotube bundling: Influence on layer-by-layer assembly and antimicrobial activity. Soft Matter 2013, 9, 2136–2144. [Google Scholar] [CrossRef]

- El-Ghany, N.A.A. Antimicrobial activity of new carboxymethyl chitosan–carbon nanotube biocomposites and their swell ability in different pH media. J. Carbohydr. Chem. 2017, 36, 31–44. [Google Scholar] [CrossRef]

- Kavoosi, G.; Dadfar, S.M.M.; Dadfar, S.M.A.; Ahmadi, F.; Niakosari, M. Investigation of gelatin/multi-walled carbon nanotube nanocomposite films as packaging materials. Food Sci. Nutr. 2014, 2, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Gan, L.; Geng, A.; Jin, L.; Zhong, Q.; Wang, L.; Xu, L. Antibacterial nanocomposite based on carbon nanotubes–silver nanoparticles-co-doped polylactic acid. Polym. Bull. 2020, 77, 793–804. [Google Scholar] [CrossRef]

- Silva, F.A.G.D.J.; Vieira, S.A.; Botton, S.D.A.; Costa, M.M.D.; Oliveira, H.P.D. Antibacterial activity of polypyrrole-based nanocomposites: A mini-review. Polímeros 2020, 30, e2020048. [Google Scholar] [CrossRef]

- Tondro, G.H.; Behzadpour, N.; Keykhaee, Z.; Akbari, N.; Sattarahmady, N. Carbon@polypyrrole nanotubes as a photosensitizer in laser phototherapy of Pseudomonas aeruginosa. Colloids Surf. B 2019, 180, 481–486. [Google Scholar] [CrossRef]

- Benigno, E.; Lorente, M.A.; Olmosm, D.; González-Gaitano, G.; González-Benito, J. Nanocomposites based on LDPE filled with carbon nanotubes prepared by high energy ball milling and its potential anti-bacterial activity. Polym. Int. 2020, 68, 1155–1163. [Google Scholar] [CrossRef]

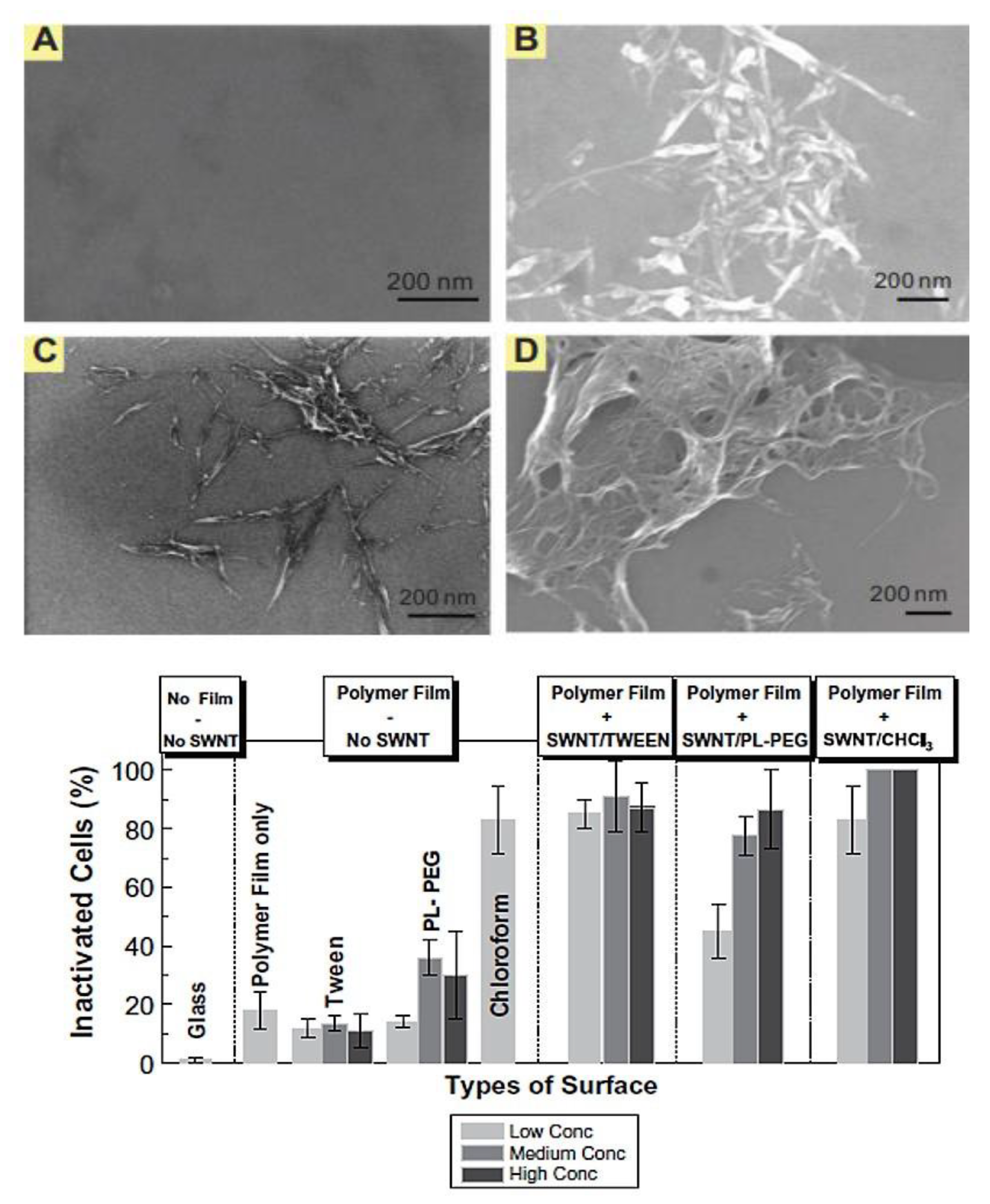

- Aslan, S.; Loebick, C.Z.; Kang, S.; Elimelech, M.; Pfefferle, L.D.; Tassel, P.R.V. Antimicrobial biomaterials based on carbon nanotubes dispersed in poly (lactic-co-glycolic acid). Nanoscale 2010, 2, 1789–1794. [Google Scholar] [CrossRef] [PubMed]

- Bacali, C.; Baldea, I.; Moldovan, M.; Carpa, R.; Olteanu, D.E.; Filip, G.A.; Nastase, V.; Lascu, L.; Badea, M.; Constantiniuc, M.; et al. Flexural strength, biocompatibility, and antimicrobial activity of a polymethyl methacrylate denture resin enhanced with graphene and silver nanoparticles. Clin. Oral Investig. 2020, 24, 2713–2725. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M. Antibacterial Action of Nanoparticle Loaded Nanocomposites Based on Graphene and Its Derivatives: A Mini-Review. Int. J. Mol. Sci. 2020, 21, 3563. [Google Scholar] [CrossRef]

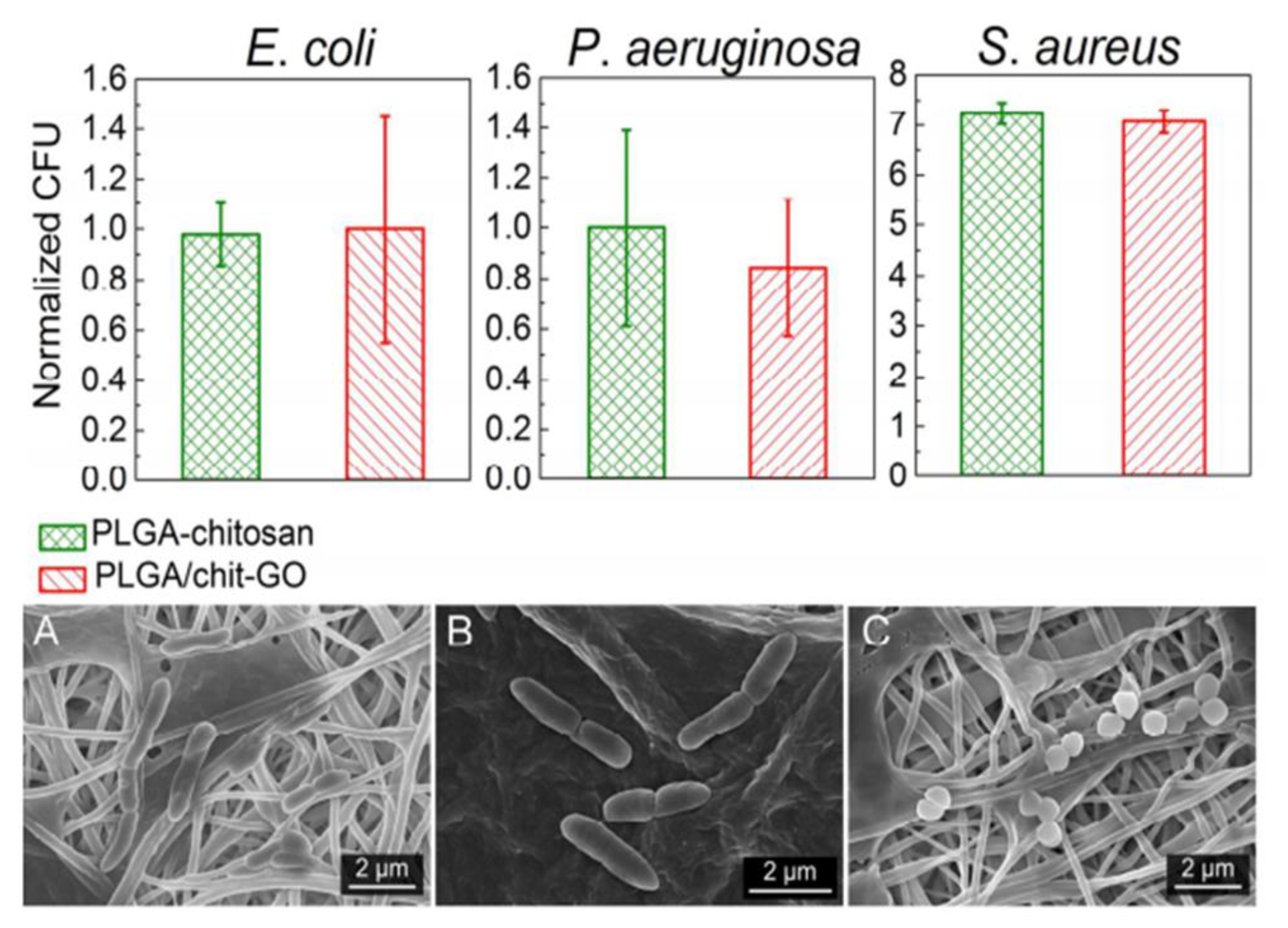

- Matharu, R.K.; Tabish, T.A.; Trakoolwilaiwan, T.; Mansfield, J.; Moger, J.; Wu, T.; Lourenço, C.; Chen, B.; Ciric, L.; Parkin, I.P.; et al. Microstructure and antibacterial efficacy of graphene oxide nanocomposite fibres. J. Colloid Interface Sci. 2020, 571, 239–252. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Liu, B.; Wang, J.; Zhang, S.; Lin, Q.; Gong, P.; Ma, L.; Yang, S. A Novel Wound Dressing Based on Ag/Graphene Polymer Hydrogel: Effectively Kill Bacteria and Accelerate Wound Healing. Adv. Funct. Mater 2014, 24, 3933–3943. [Google Scholar] [CrossRef]

- Pereyra, J.Y.; Cuello, E.A.; Rodriguez, R.C.; Barbero, C.A.; Yslas, E.I.; Salavagione, H.J.; Acevedo, D.F. Synthesis and characterization of GO-hydrogels composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 258, 012002. [Google Scholar] [CrossRef]

- Cao, Y.; Wei, W.; Liu, J.; You, Q.; Liu, F.; Lan, Q.; Zhang, C.; Liu, C.; Zhao, J. The Preparation of Graphene Reinforced Poly(vinyl alcohol) Antibacterial Nanocomposite Thin Film. Int. J. Polym. Sci. 2015, 2015, 407043. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. PEGylated boron nitride nanotube-reinforced poly(propylene fumarate) nanocomposite biomaterials. RSC Adv. 2016, 6, 79507–79519. [Google Scholar] [CrossRef]

- Gautam, S.; Sharma, S.; Sharma, B.; Jain, P. Antibacterial efficacy of poly (vinyl alcohol) nanocomposites reinforced with graphene oxide and silver nanoparticles for packaging applications. Polym. Compos. 2021, 42, 2829–2837. [Google Scholar] [CrossRef]

- Cobos, M.; De-La-Pinta, I.; Quindós, G.; Fernández, M.J.; Fernández, M.D. Synthesis, Physical, Mechanical and Antibacterial Properties of Nanocomposites Based on Poly(vinyl alcohol)/Graphene Oxide-Silver Nanoparticles. Polymers 2020, 12, 723. [Google Scholar] [CrossRef] [PubMed]

- Usman, A.; Hussain, Z.; Riaz, A.; Khan, A.N. Enhanced mechanical, thermal and antimicrobial properties of poly(vinyl alcohol)/graphene oxide/starch/silver nanocomposites films. Carbohydr. Polym. 2016, 153, 592–599. [Google Scholar] [CrossRef] [PubMed]

- Carpio, I.E.M.; Santos, C.M.; Wei, X.; Rodrigues, D.F. Toxicity of a polymer–graphene oxide composite against bacterial planktonic cells, biofilms, and mammalian cells. Nanoscale 2012, 4, 4746–4756. [Google Scholar] [CrossRef] [PubMed]

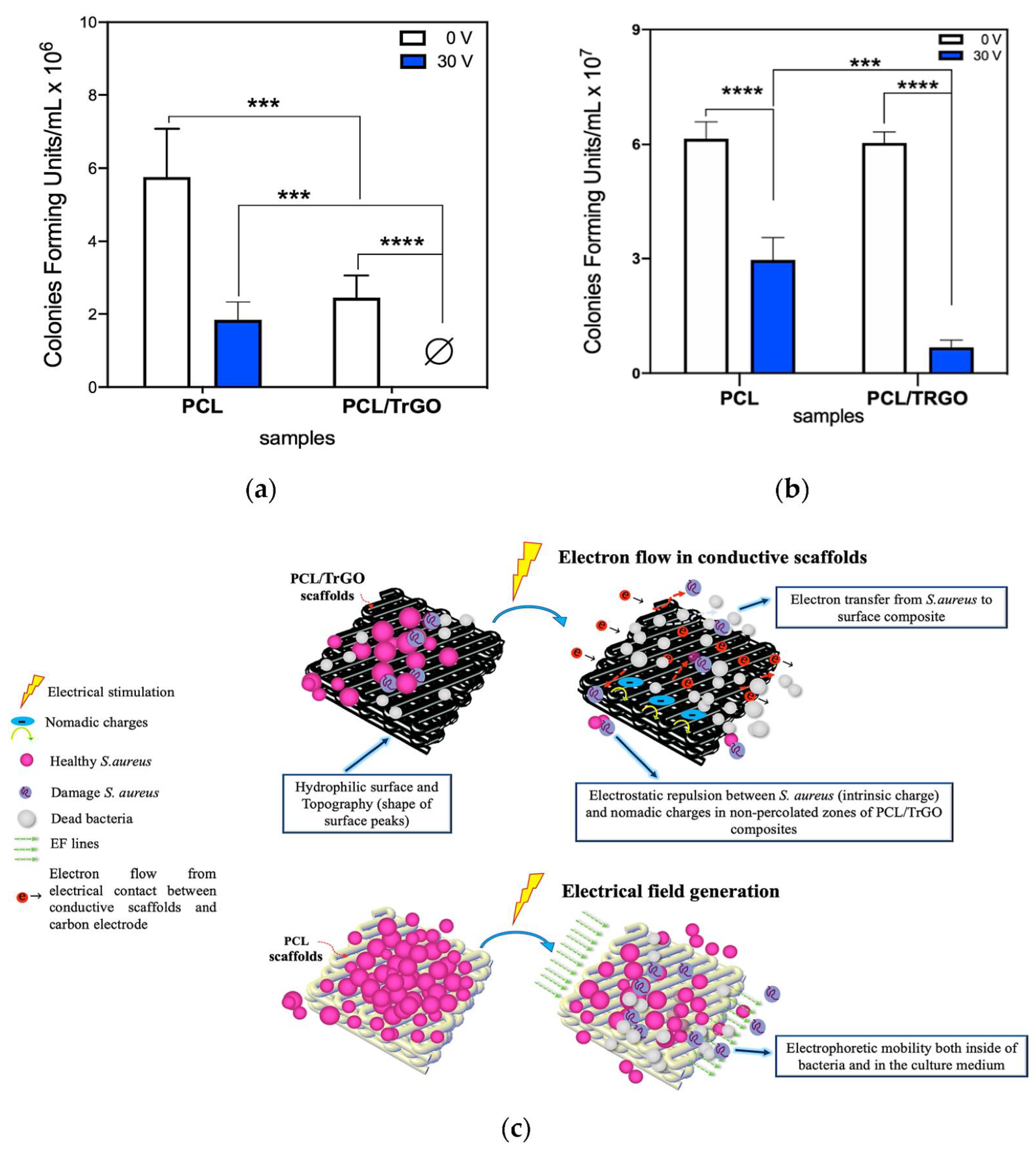

- Arriagada, P.; Palza, H.; Palma, P.; Flores, M.; Caviedes, P. Poly(lactic acid) composites based on graphene oxide particles with antibacterial behavior enhanced by electrical stimulus and biocompatibility. J. Biomed. Mater. Res. A 2018, 106, 1051–1060. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, T.; Zhao, X.; Wang, X.; Zhou, L.; Yang, Y.; Liao, F.; Ju, Y. Poly(lactic acid)/graphene oxide–ZnO nanocomposite films with good mechanical, dynamic mechanical, anti-UV and antibacterial properties. J. Chem. Technol. Biotechnol. 2015, 90, 1677–1684. [Google Scholar] [CrossRef]

- Pal, N.; Dubey, P.; Gopinath, P.; Pal, K. Combined effect of cellulose nanocrystal and reduced graphene oxide into poly-lactic acid matrix nanocomposite as a scaffold and its antibacterial activity. Int. J. Biol. Macromol. 2017, 95, 94–105. [Google Scholar] [CrossRef]

- Shen, X.; Yang, S.; Shen, J.; Ma, J.; Wu, Y.; Zeng, X.; Fu, S. Improved mechanical and antibacterial properties of silver-graphene oxide hybrid/polylactid acid composites by in-situ polymerization. Ind. Crop. Prod. 2019, 130, 571–579. [Google Scholar] [CrossRef]

- Kumar, S.; Raj, S.; Jain, S.; Chatterjee, K. Multifunctional biodegradable polymer nanocomposite incorporating graphene-silver hybrid for biomedical applications. Mater. Des. 2016, 108, 319–332. [Google Scholar] [CrossRef]

- Angulo-Pineda, C.; Srirussamee, K.; Palma, P.; Fuenzalida, V.M.; Cartmell, S.H.; Palza, H. Electroactive 3D Printed Scaffolds Based on Percolated Composites of Polycaprolactone with Thermally Reduced Graphene Oxide for Antibacterial and Tissue Engineering Applications. Nanomaterials 2020, 10, 428. [Google Scholar] [CrossRef]

- Liu, C.; Shen, J.; Liao, C.Z.; Yeung, K.W.K.; Tjong, S.C. Novel electrospun polyvinylidene fluoride-graphene oxide-silver nanocomposite membranes with protein and bacterial antifouling characteristics. Express Polym. Lett. 2018, 12, 365–382. [Google Scholar] [CrossRef]

- Diez-Pascual, A.M. Antibacterial Nanocomposites Based on Thermosetting Polymers Derived from Vegetable Oils and Metal Oxide Nanoparticles. Polymers 2019, 11, 1790. [Google Scholar] [CrossRef]

- Liu, Z.; Robinson, J.T.; Sun, X.; Dai, H. PEGylated Nanographene Oxide for Delivery of Water-Insoluble Cancer Drugs. J. Am. Chem. Soc. 2008, 130, 10876–10877. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. Multifunctional poly(glycolic acid-co-propylene fumarate) electrospun fibers reinforced with graphene oxide and hydroxyapatite nanorods. J. Mater. Chem. B 2017, 5, 4084–4096. [Google Scholar] [CrossRef]

- Chook, S.W.; Chia, C.H.; Zakaria, S.; Ayob, M.K.; Huang, N.M.; Neoh, H.M.; Jamal, R. Antibacterial hybrid cellulose-graphene oxide nanocomposite immobilized with silver nanoparticles. RSC Adv. 2015, 5, 26263–26268. [Google Scholar] [CrossRef]

- Naskar, A.; Khan, H.; Sarkar, R.; Kumar, S.; Halder, D.; Jana, S. Anti-biofilm activity and food packaging application of room temperature solution process based polyethylene glycol capped Ag-ZnO-graphene nanocomposite. Mater. Sci. Eng. C 2018, 91, 743–753. [Google Scholar] [CrossRef]

- Jamróz, E.; Kopel, P.; Tkaczewska, J.; Dordevic, D.; Jancikova, S.; Kulawik, P.; Milosavljevic, V.; Dolezelikova, K.; Smerkova, K.; Svec, P.; et al. Nanocomposite Furcellaran Films—the Influence of Nanofillers on Functional Properties of Furcellaran Films and Effect on Linseed Oil Preservation. Polymers 2019, 11, 2046. [Google Scholar] [CrossRef]

- Faria, A.F.D.; Perreault, F.; Shaulsky, E.; Chavez, L.H.A.; Elimelech, M. Antimicrobial Electrospun Biopolymer Nanofiber Mats Functionalized with Graphene Oxide–Silver Nanocomposites. ACS Appl. Mater. Interfaces 1900, 7, 12751–12759. [Google Scholar] [CrossRef]

- Barra, A.; Ferreira, N.M.; Martins, M.A.; Lazar, O.; Pantazi, A.; Jderu, A.A.; Neumayer, S.M.; Rodriguez, B.J.; Enăchescu, M.; Ferreira, P.; et al. Eco-friendly preparation of electrically conductive chitosan–reduced graphene oxide flexible bionanocomposites for food packaging and biological applications. Compos. Sci. Technol. 2019, 173, 53–60. [Google Scholar] [CrossRef]

- Xu, W.; Xie, W.; Huang, X.; Chen, X.; Huang, N.; Wang, X.; Liu, J. The graphene oxide and chitosan biopolymer loads TiO2 for antibacterial and preservative research. Food Chem. 2017, 221, 267–277. [Google Scholar] [CrossRef] [PubMed]

- Mahmoudi, N.; Ostadhossein, F.; Simchi, A. Physicochemical and antibacterial properties of chitosan-polyvinylpyrrolidone films containing self-organized graphene oxide nanolayers. J. Appl. Polym. Sci. 2016, 133, 43194. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. Electrospun fibers of chitosan-grafted polycaprolactone/poly(3-hydroxybutyrate-co-3–hydroxyhexanoate) blends. J. Mater. Chem. B 2016, 4, 600. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, K.B.; Park, G.T.; Han, S.S. Antibacterial properties of starch-reduced graphene oxide–polyiodide nanocomposite. Food Chem. 2021, 342, 128385. [Google Scholar] [CrossRef]

- Martí, M.; Frígols, B.; Salesa, B.; Serrano-Aroca, Á. Calcium alginate/graphene oxide films: Reinforced composites able to prevent Staphylococcus aureus and methicillin-resistant Staphylococcus epidermidis infections with no cytotoxicity for human keratinocyte HaCaT cells. Eur. Polym. J. 2019, 110, 14–21. [Google Scholar] [CrossRef]

- Frígols, B.; Martí, M.; Salesa, B.; Hernández-Oliver, C.; Aarstad, O.; Ulset, A.T.; Sӕtrom, G.I.; Aachmann, F.L.; Serrano-Aroca, Á. Graphene oxide in zinc alginate films: Antibacterial activity, cytotoxicity, zinc release, water sorption/diffusion, wettability and opacity. PLoS ONE 2019, 14, e0212819. [Google Scholar] [CrossRef]

- AbuDalo, M.A.; Al-Mheidat, I.R.; Al-Shurafat, A.W.; Grinham, C.; Oyanedel-Craver, V. Synthesis of silver nanoparticles using a modified Tollens’ method in conjunction with phytochemicals and assessment of their antimicrobial activity. PeerJ 2019, 7, e6413. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. Antimicrobial and sustainable food packaging based on poly(butylene adipate-co-terephthalate) and electrospun chitosan nanofibers. RSC Adv. 2015, 5, 93095–93107. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. ZnO-Reinforced Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Bionanocomposites with Antimicrobial Function for Food Packaging. ACS Appl. Mater. Inferfaces 2014, 6, 9822–9834. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. Poly(3-hydroxybutyrate)/ZnO bionanocomposites with improved mechanical, barrier and antibacterial properties. Int. J. Mol. Sci. 2014, 15, 10950–10973. [Google Scholar] [CrossRef]

- Rivera-Briso, A.L.; Aachmann, F.L.; Moreno-Manzano, V.; Serrano-Aroca, Á. Graphene oxide nanosheets versus carbon nanofibers: Enhancement of physical and biological properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) films for biomedical applications. Int. J. Biol. Macromol. 2020, 143, 1000–1008. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Yu, H.; Wang, Y.; Zhou, Y.; Zhang, H.; Yao, J.; Abdalkarim, S.Y.H.; Tam, K.C. Natural Biodegradable Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Nanocomposites with Multifunctional Cellulose Nanocrystals/Graphene Oxide Hybrids for High-Performance Food Packaging. J. Agric. Food Chem. 2019, 67, 10954–10967. [Google Scholar] [CrossRef] [PubMed]

- Gouvêa, R.F.; Aguila, E.M.D.; Paschoalin, V.M.F.; Andrade, C.T. Extruded hybrids based on poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and reduced graphene oxide composite for active food packaging. Food Packag. Shelf Life 2018, 16, 77–85. [Google Scholar] [CrossRef]

- Pal, S.; Tak, Y.K.; Song, J.M. Does the Antibacterial Activity of Silver Nanoparticles Depend on the Shape of the Nanoparticle? A Study of the Gram-Negative Bacterium Escherichia coli. Appl. Environ. Microbiol. 2007, 73, 1712–1720. [Google Scholar] [CrossRef] [PubMed]

- Morones, J.R.; Elechiguerra, J.L.; Camacho, A.; Holt, K.; Kouri, J.B.; Ramírez, J.T.; Yacaman, M.J. The bactericidal effect of silver nanoparticles. Nanotechnology 2005, 16, 2346–2353. [Google Scholar] [CrossRef] [PubMed]

- Zowalaty, M.E.; Ibrahim, N.A.; Salama, M.; Shameli, K.; Usman, M.; Zainuddin, N. Synthesis, characterization, and antimicrobial properties of copper nanoparticles. Int. J. Nanomed. 2013, 8, 4467–4479. [Google Scholar] [CrossRef]

- Ren, G.; Hu, D.; Cheng, E.W.; Vargas-Reus, M.A.; Reip, P.; Allaker, R.P. Characterisation of copper oxide nanoparticles for antimicrobial applications. Int. J. Antimicrob. Agents 2009, 33, 587–590. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. Development of linseed oil–TiO2 green nanocomposites as antimicrobial coatings. J. Mater. Chem. B 2015, 3, 4458. [Google Scholar] [CrossRef]

- Markowitz, N.; Quinn, E.L.; Saravolatz, L.D. Trimethoprim-sulfamethoxazole compared with vancomycin for the treatment of Staphylococcus aureus infection. Ann. Intern. Med. 1992, 117, 390–398. [Google Scholar] [CrossRef]

- Chudobova, D.; Dostalova, S.; Blazkova, I.; Michalek, P.; Ruttkay-Nedecky, B.; Sklenar, M.; Nejdl, L.; Kudr, J.; Gumulec, J.; Tmejova, K.; et al. Effect of ampicillin, streptomycin, penicillin and tetracycline on metal resistant and non-resistant Staphylococcus aureus. Int. J. Environ. Res. Public Health 2014, 11, 3233–3255. [Google Scholar] [CrossRef]

- Cid, S.R.C.; Cruz, M.C.; Faustino, V.; Tuazon, A.O. In vitro study on the antimicrobial activity of probiotic milk against common pediatric community acquired respiratory pathogens. PIDSP J. 2005, 9, 25–29. [Google Scholar]

- Matsuura, M.; Nakazawa, H.; Hashimoto, T.; Mitsuhashi, S. Combined antibacterial activity of amoxicillin with clavulanic acid against ampicillin-resistant strains. Antimicrob. Agents Chemother. 1980, 17, 908–911. [Google Scholar] [CrossRef]

- Rezić, I.; Haramina, T.; Rezić, T. Metal Nanoparticles and Carbon Nanotubes—Perfect Antimicrobial Nano-Fillers in Polymer-Based Food Packaging Materials. In Food Packaging; Academic Press: Cambridge, MA, USA, 2017; pp. 497–532. [Google Scholar]

- Penkova, A.V.; Acquah, S.F.; Piotrovskiy, L.B.; Markelov, D.A.; Semisalova, A.S.; Kroto, H.W. Fullerene derivatives as nano-additives in polymer composites. Russ. Chem. Rev. 2017, 86, 530. [Google Scholar] [CrossRef]

- Sharon, M.; Sharon, M. Carbon nanomaterials: Applications in physico-chemical systems and biosystems. Def. Sci. J. 2008, 58, 460. [Google Scholar] [CrossRef][Green Version]

- Jasim, A. Use of Graphene/Graphene Oxide in Food Packaging Materials: Thermomechanical, Structural and Barrier Properties. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Grande, C.D.; Mangadlao, J.; Fan, J.; Leon, A.D.; Delgado-Ospina, J.; Rojas, J.G.; Rodrigues, D.F.; Advincula, R. Chitosan Cross-Linked Graphene Oxide Nanocomposite Films with Antimicrobial Activity for Application in Food Industry. Macromol. Symp. 2017, 374, 1600114. [Google Scholar] [CrossRef]

- Arfat, Y.A.; Ahmed, J.; Ejaz, M.; Mullah, M. Polylactide/graphene oxide nanosheets/clove essential oil composite films for potential food packaging applications. Int. J. Biol. Macromol. 2018, 107, 194–203. [Google Scholar] [CrossRef] [PubMed]

- Konwar, A.; Kalita, S.; Kotoky, J.; Chowdhury, D. Chitosan–Iron Oxide Coated Graphene Oxide Nanocomposite Hydrogel: A Robust and Soft Antimicrobial Biofilm. ACS Appl. Mater. Interfaces 2016, 8, 20625–20634. [Google Scholar] [CrossRef]

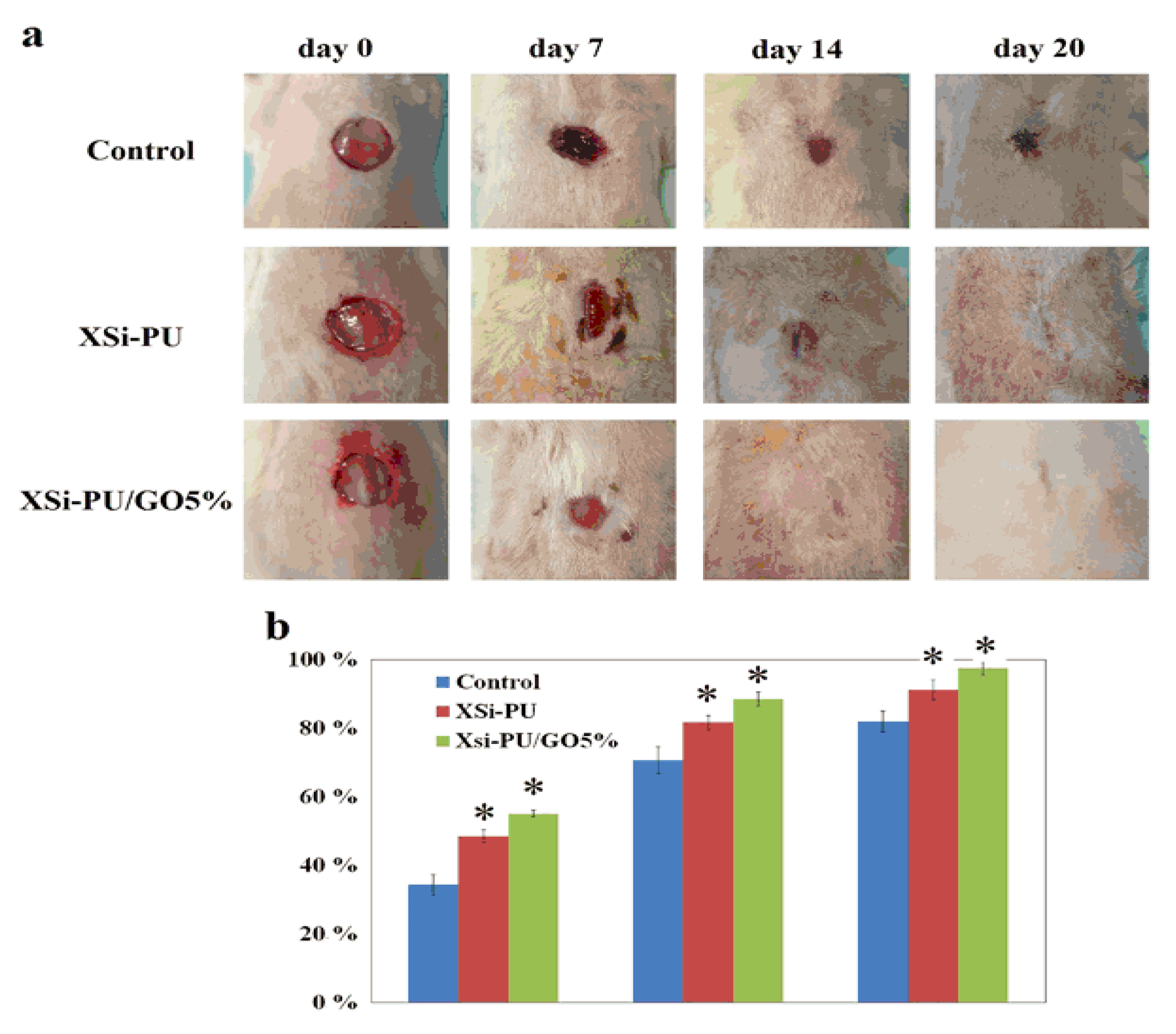

- Shams, E.; Yeganeh, H.; Naderi-Manesh, H.; Gharibi, R.; Hassan, Z.M. Polyurethane/siloxane membranes containing graphene oxide nanoplatelets as antimicrobial wound dressings: In vitro and in vivo evaluations. J. Mater. Sci. Mater. Med. 2017, 28, 1–14. [Google Scholar] [CrossRef]

- Kittana, N.; Assali, M.; Abu-Rass, H.; Lutz, S.; Hindawi, R.; Ghannam, L.; Zakarneh, M.; Mousa, A. Enhancement of wound healing by single-wall/multi-wall carbon nanotubes complexed with chitosan. Int. J. Nanomed. 2018, 13, 7195–7206. [Google Scholar] [CrossRef] [PubMed]

- Shi, H.; Liu, H.; Luan, S.; Shi, D.; Yan, S.; Liu, C.; Li, R.K.Y.; Yin, J. Effect of polyethylene glycol on the antibacterial properties of polyurethane/carbon nanotube electrospun nanofibers. RSC Adv. 2016, 6, 19238–19244. [Google Scholar] [CrossRef]

- Gao, J.; Bao, F.; Feng, L.; Shen, K.; Zhu, Q.; Wang, D.; Chen, T.; Ma, R.; Yan, C. Functionalized graphene oxide modified polysebacic anhydride as drug carrier for levofloxacin controlled release. RSC Adv. 2011, 1, 1737–1744. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Botta, L.; Gulino, E.F.; Gulli, D. Tunable release of Chlorhexidine from Polycaprolactone-based filaments containing graphene nanoplatelets. Eur. Polym. J. 2019, 110, 221–232. [Google Scholar] [CrossRef]

- Puoci, F.; Hampel, S.; Parisi, O.I.; Hassan, A.; Cirillo, G.; Picci, N. Imprinted microspheres doped with carbon nanotubes as novel electroresponsive drug-delivery systems. J. Appl. Polym. Sci. 2013, 130, 829–834. [Google Scholar] [CrossRef]

- Spizzirri, U.G.; Hampel, S.; Cirillo, C. Spherical gelatin/CNTs hybrid microgels as electro-responsive drug delivery systems. Int. J. Phar. 2013, 448, 115–122. [Google Scholar] [CrossRef] [PubMed]

- Dinescu, S.; Ionita, M.; Pandele, A.M.; Galateanu, B.; Iovu, H.; Ardelean, A.; Costache, M.; Hermenean, A. In vitro cytocompatibility evaluation of chitosan/graphene oxide 3D scaffold composites designed for bone tissue engineering. Biomed. Mater. Eng. 2014, 24, 2249–2256. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Sun, X.; Li, Y.; Wang, H.; Li, B.; Liang, C. Carbon nanotube-collagen@hydroxyapatite composites with improved mechanical and biological properties fabricated by a multi in situ synthesis process. Biomed. Microdevices 2020, 22, 64. [Google Scholar] [CrossRef] [PubMed]

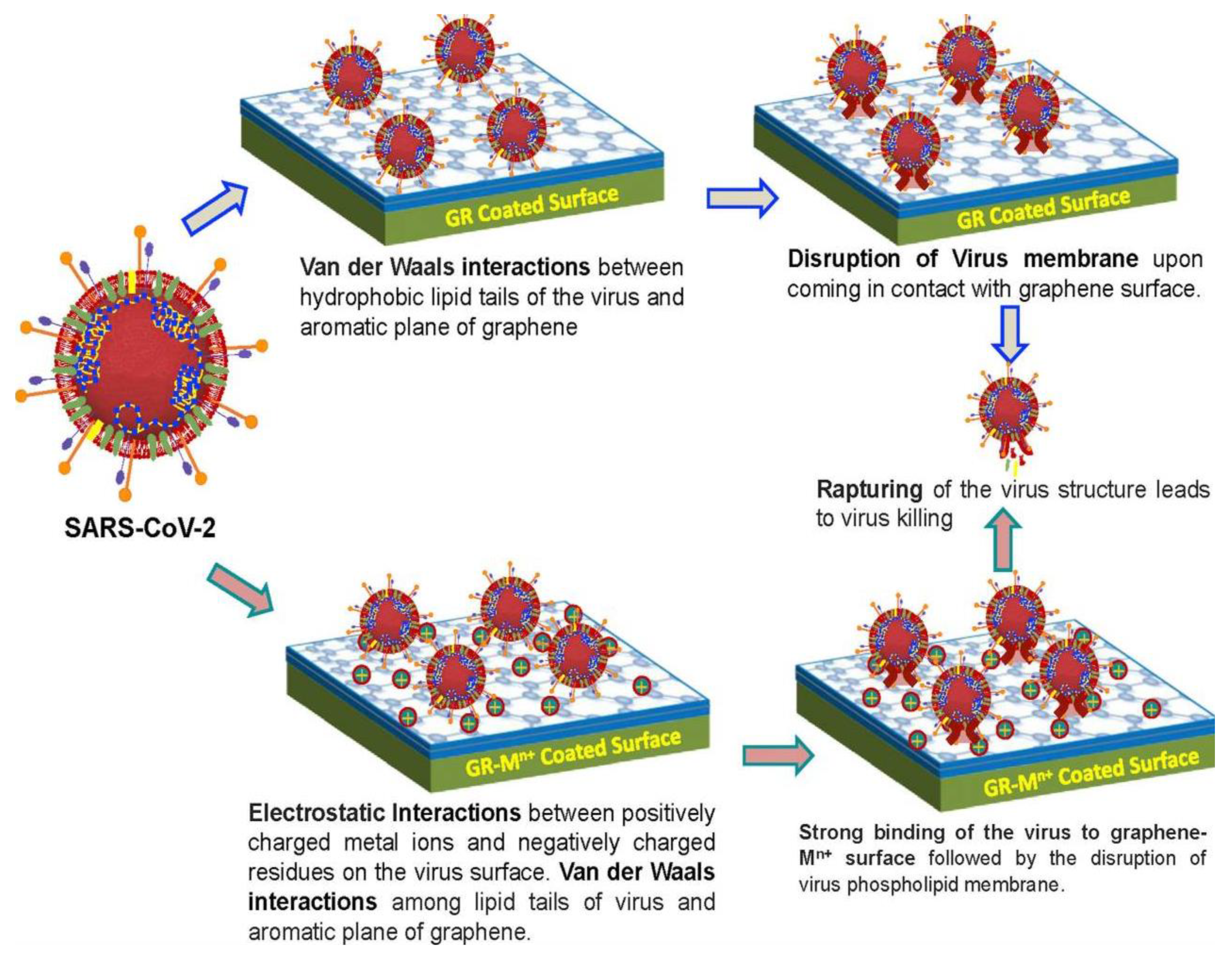

- Cordaro, A.; Neri, G.; Sciortino, M.T.; Scala, A.; Piperno, A. Graphene-Based Strategies in Liquid Biopsy and in Viral Diseases Diagnosis. Nanomaterials 2020, 10, 1014. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Dwivedi, N.; Dhand, C.; Khan, R.; Sathish, N.; Gupta, M.K.; Kumar, R.; Kumar, S. Potential of graphene-based materials to combat COVID-19: Properties, perspectives, and prospects. Mater. Today 2020, 18, 100385. [Google Scholar] [CrossRef]

- Nair, R.R.; Wu, H.A.; Jayaram, P.N.; Grigorieva, I.V.; Geim, A.K. Unimpeded Permeation of Water through Helium-Leak-Tight Graphene-Based Membranes. Science 2012, 335, 442–444. [Google Scholar] [CrossRef]

- Sadegh, H.; Ali, G.A.M.; Gupta, V.K.; Makhlouf, A.S.H.; Shahryari-ghoshekandi, R.; Nadagouda, M.N.; Sillandpää, M.; Megiel, E. The role of nanomaterials as effective adsorbents and their applications in wastewater treatment. J. Nanostruct. Chem. 2017, 7, 1–14. [Google Scholar] [CrossRef]

- Perreault, F.; Tousley, M.E.; Elimelech, M. Thin-Film Composite Polyamide Membranes Functionalized with Biocidal Graphene Oxide Nanosheets. Environ. Sci. Technol. Lett. 2014, 1, 71–76. [Google Scholar] [CrossRef]

- Singh, S.P.; Li, Y.; Zhang, J.; Tour, J.M.; Arnusch, C.J. Sulfur-Doped Laser-Induced Porous Graphene Derived from Polysulfone-Class Polymers and Membranes. ACS Nano 2018, 12, 289–297. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Sun, C.; Ji, H.; Zhao, W.; Sun, S.; Zhao, C. Graphene oxide-based polymeric membranes for broad water pollutant removal. RSC Adv. 2015, 5, 100651–100662. [Google Scholar] [CrossRef]

- Zeng, Z.; Yu, D.; He, Z.; Liu, J.; Xiao, F.; Zhang, Y.; Wang, R.; Bhattacharyya, D.; Tan, T.T.Y. Graphene Oxide Quantum Dots Covalently Functionalized PVDF Membrane with Significantly-Enhanced Bactericidal and Antibiofouling Performances. Sci. Rep. 2016, 6, 20142. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, F.; Santos, C.M.; Mangadlao, J. Antimicrobial PVK:SWNT nanocomposite coated membrane for water purification: Performance and toxicity testing. Water Res. 2013, 47, 3966e. [Google Scholar] [CrossRef]

| Matrix | Antibacterial Agent | Processing Method | Bacteria | Inhibition | Ref. |

|---|---|---|---|---|---|

| (Shape or wt%) | (%) | ||||

| SnO2 (rod-shaped) | E. coli | 99.5 | [11] | ||

| S. aureus | 99.5 | ||||

| Ag (spherical) | E. coli | 90 | [94] | ||

| – | Ag (rod-shaped) | – | 100 | [94] | |

| Ag (cuboctahedral and dodecahedral) | E. coli | 100 | |||

| – | – | P. Aeruginosa | 100 | [95] | |

| S. Aureus | 100 | ||||

| Cu (spherical) | P. Aeruginosa | 99.5 | [96] | ||

| – | – | S. Aureus | 99.6 | ||

| B. subtilis | 99.6 | ||||

| C. Albicans | 82.5 | ||||

| P. Aeruginosa | 100 | ||||

| – | CuO | – | S. Aureus | 100 | [97] |

| (spherical) | B. subtilis | 68 | |||

| C. Albicans | 65 | ||||

| ZnO (spherical) | E. coli | 90 | [89] | ||

| S. aureus | 85 | ||||

| TiO2 (spherical) | E. coli | 98 | [98] | ||

| S. aureus | 100 | ||||

| vancomycin | S. aureus | 98.3 86 | [99] | ||

| TMP | |||||

| penicillin | S. aureus | 100 | [100] | ||

| tetracycline | 100 | ||||

| chloramphenicol | H. influenzae | 87.5 | |||

| penicillin | S. pneumoniae | 100 | [101] | ||

| oxacillin | S. aureus | 88 | |||

| amoxicillin | H. influenzae | 100 | [102] | ||

| Salmonella spp. | 100 | ||||

| Shigella spp. | 100 | ||||

| Corynebacteria spp | 100 | ||||

| PMMA | GO-Ag (1) GO-Ag (2) | SN + curing | E. coli | – | [55] |

| S. aureus | |||||

| S. mutans | |||||

| PMMA fibers | GO (8) | pressurized gyration | E. coli | 85 | [57] |

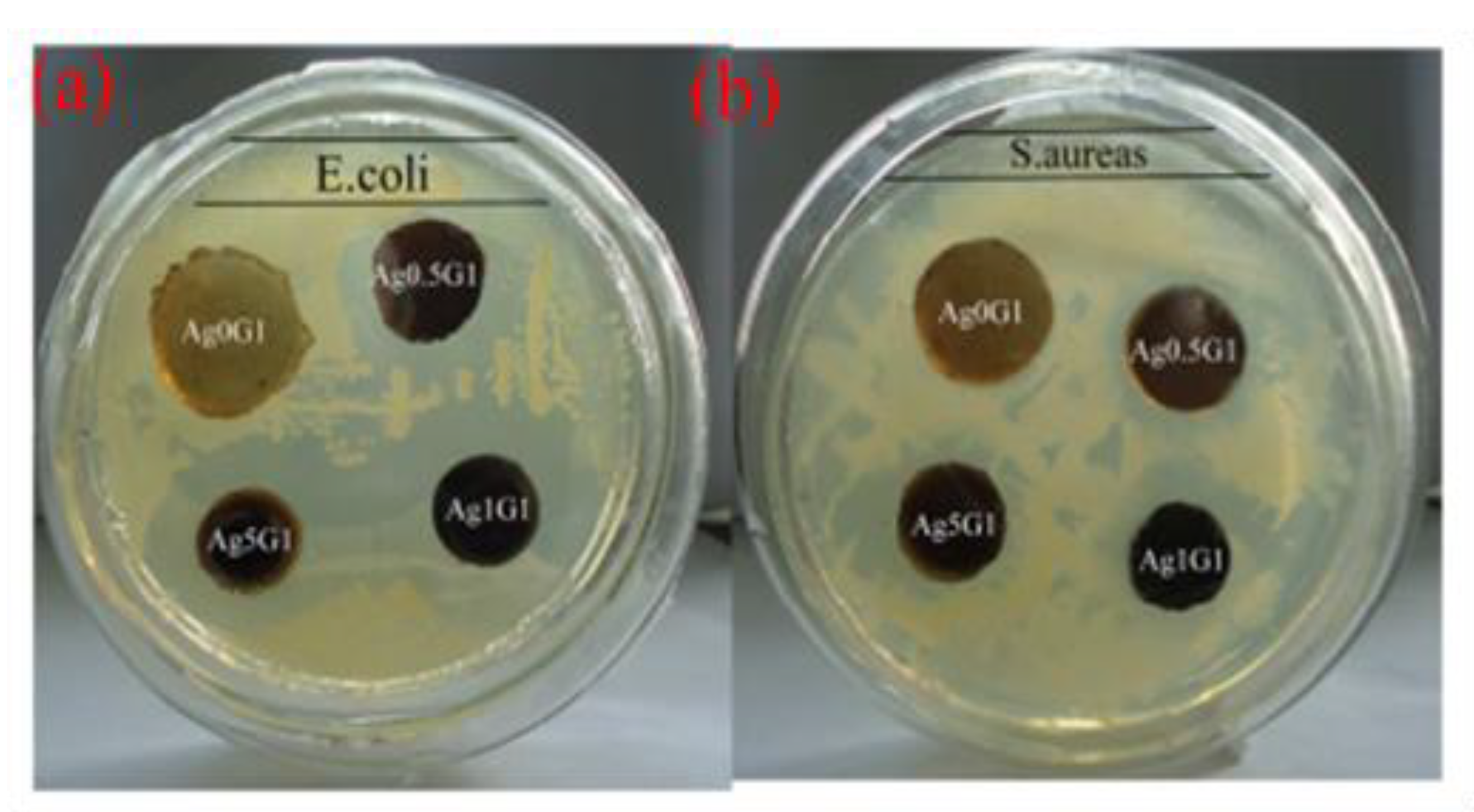

| PNIPAM | Ag/G (0.5:1) | in situ polymerization | E. coli S. aureus | – | [58] |

| Ag/G (1:1) | |||||

| Ag/G (5:1) | |||||

| PNIPAM | GO/CNT (1:1) | free radical polymerization | P. aeruginosa | – | [59] |

| PVK | GO (3) | bulk polymerization | B. subtilis | 89 | [65] |

| R. opacus | 89 | ||||

| E. coli | 89 | ||||

| C. metallidurans | 91 | ||||

| PVA | G (1) | SN+ solution casting | E. coli | 92 | [60] |

| G (10) | E.coli | 97.1 | |||

| G (1) | S. aureus | 92.3 | |||

| G (10) | S. aureus | 99.7 | |||

| PLA | GO/Ag (2) | in situ polymerization | E. coli | 99 | [69] |

| S. aureus | 99 | ||||

| PVDF fibers | GO/Ag (1:0.5) | ES | E. coli S. aureus | – | [72] |

| GO/Ag (1:1) | |||||

| GO/Ag (1:2) | |||||

| PCL | GO/Ag (5:1) | SN+ solution casting | E. coli | 59 | [70] |

| PPF | PEG-GO (3) | SN+ curing | S. aureus | 97 | [12] |

| S. epidermidis | 94 | ||||

| P. aeruginosa | 85 | ||||

| E. coli | 81 | ||||

| CS | GO/TiO2 (4/16) | SA | A. niger | 99 | [81] |

| B. subtilis | 99 | ||||

| PHBV | CNC/GO (1:1) | solution casting | E. coli | 99.7 | [92] |

| S. aureus | 99.8 | ||||

| AGAR | rGO/Ag/ZnO | solution casting | S. aureus | 95 | [77] |

| P. aeruginosa | 95 | ||||

| AG | GO (1) | SN+ solution casting | S. aureus | 99 | [85] |

| S.epidermis | 99 | ||||

| polyporphyrin | C60 | electropolymerization | S. aureus | 100 | [46] |

| E. coli | 100 | ||||

| PLL/PGA | SWCNT | LBL | E.coli | 80 | [47] |

| SWCNT-PL-PEG | E.coli | 90 | |||

| SWCNT-PL-PEG | S. epidermidis | 90 | |||

| PLGA | SWCNT (2) | solution casting | E.coli | [54] | |

| S. epidermidis | 98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díez-Pascual, A.M. State of the Art in the Antibacterial and Antiviral Applications of Carbon-Based Polymeric Nanocomposites. Int. J. Mol. Sci. 2021, 22, 10511. https://doi.org/10.3390/ijms221910511

Díez-Pascual AM. State of the Art in the Antibacterial and Antiviral Applications of Carbon-Based Polymeric Nanocomposites. International Journal of Molecular Sciences. 2021; 22(19):10511. https://doi.org/10.3390/ijms221910511

Chicago/Turabian StyleDíez-Pascual, Ana M. 2021. "State of the Art in the Antibacterial and Antiviral Applications of Carbon-Based Polymeric Nanocomposites" International Journal of Molecular Sciences 22, no. 19: 10511. https://doi.org/10.3390/ijms221910511

APA StyleDíez-Pascual, A. M. (2021). State of the Art in the Antibacterial and Antiviral Applications of Carbon-Based Polymeric Nanocomposites. International Journal of Molecular Sciences, 22(19), 10511. https://doi.org/10.3390/ijms221910511