Soluble Expression and Efficient Purification of Recombinant Class I Hydrophobin DewA

Abstract

1. Introduction

2. Results

2.1. Preparation and Screening of Ramp Tags for Soluble Expression of Hydrophobin DewA

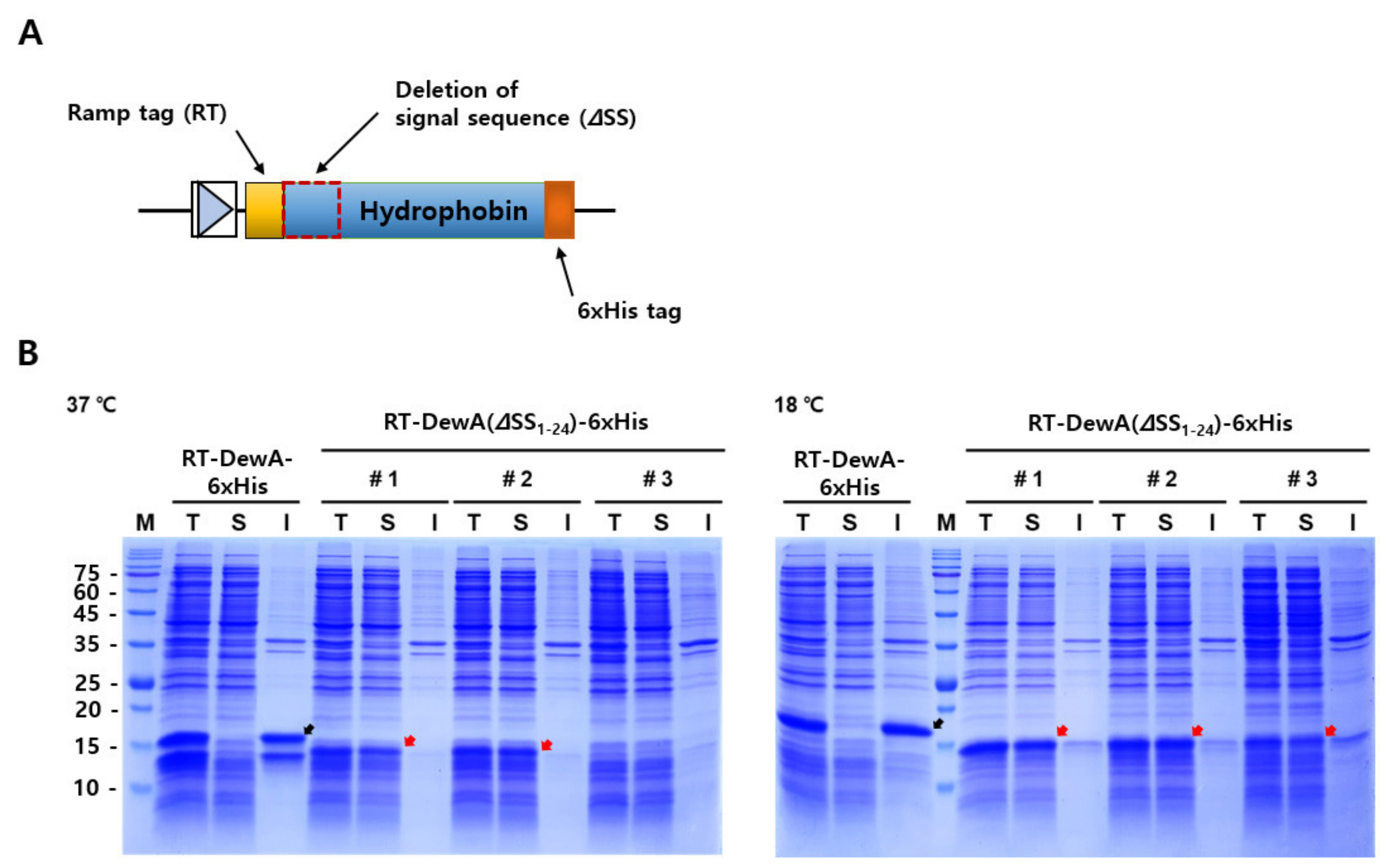

2.2. Construction and Expression Analyses of a Ramp Tag-Fused Hydrophobin DewA Lacking the Signal Sequence

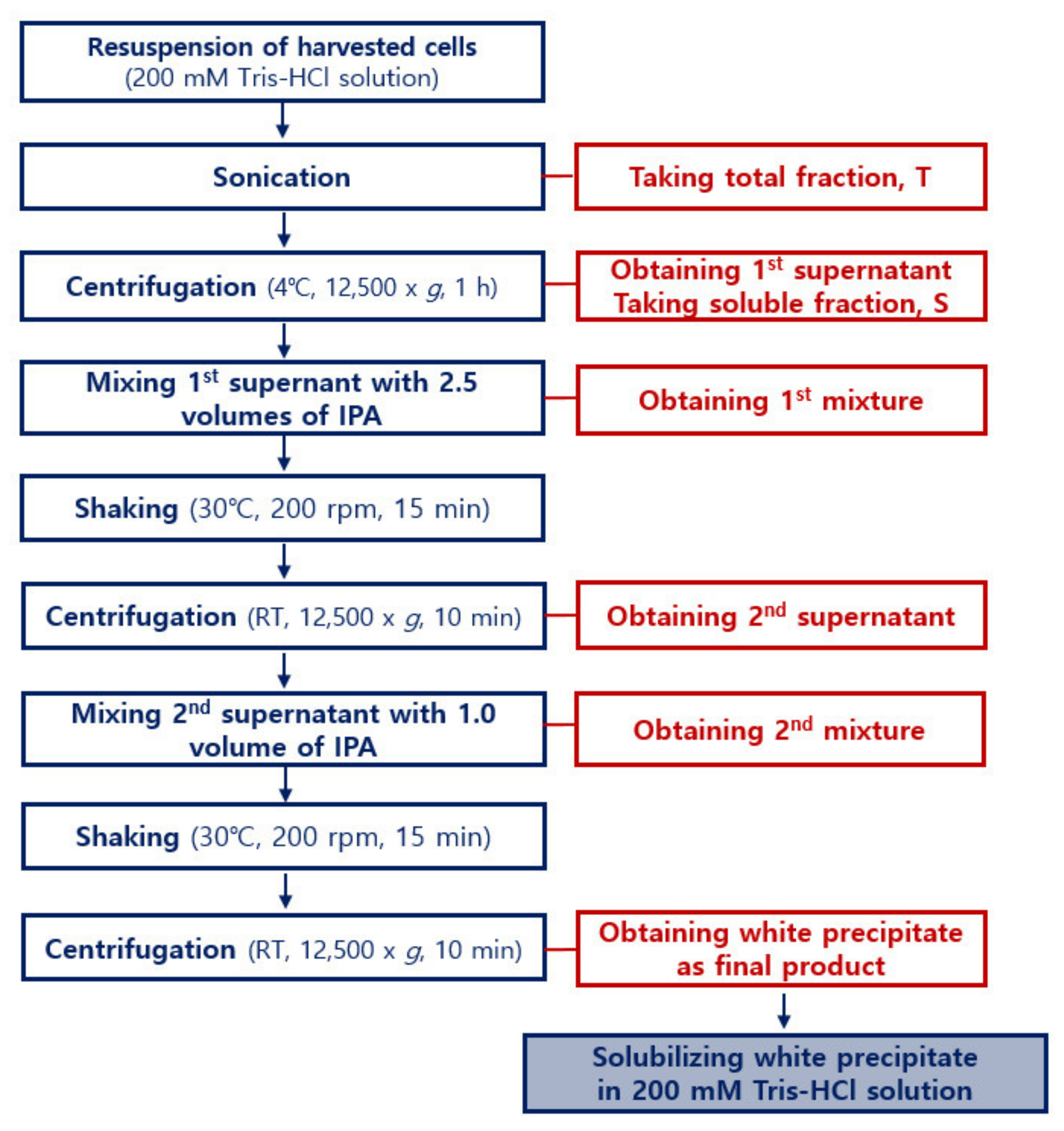

2.3. Purification of DewA by Aqueous Two-Phase Separation Using Isopropyl Alcohol

3. Discussion

4. Materials and Methods

4.1. Strains, Plasmids, and Culture Conditions

4.2. Gene Cloning and Manipulation

4.3. Expression and Analyses of the Soluble Fraction

4.4. Purification of Recombinant Protein by ATPS Using IPA

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scholtmeijer, K.; Wessels, J.; Wösten, H. Fungal hydrophobins in medical and technical applications. Appl. Microbiol. Biotechnol. 2001, 56, 1–8. [Google Scholar] [CrossRef]

- Stübner, M.; Lutterschmid, G.; Vogel, R.F.; Niessen, L. Heterologous expression of the hydrophobin FcHyd5p from Fusarium culmorum in Pichia pastoris and evaluation of its surface activity and contribution to gushing of carbonated beverages. Int. J. Food Microbiol. 2010, 141, 110–115. [Google Scholar] [CrossRef]

- Wösten, H.A.B.; de Vocht, M.L. Hydrophobins, the fungal coat unravelled. Biochim. Biophys. Acta (BBA) Rev. Biomembr. 2000, 1469, 79–86. [Google Scholar] [CrossRef]

- Wessels, J.G.H. Hydrophobins: Proteins that Change the Nature of the Fungal Surface. In Advances in Microbial Physiology; Poole, R.K., Ed.; Academic Press: Waltham, MA, USA, 1996; Volume 38, pp. 1–45. [Google Scholar]

- Bayry, J.; Aimanianda, V.; Guijarro, J.I.; Sunde, M.; Latgé, J.-P. Hydrophobins—Unique Fungal Proteins. PLoS Pathog. 2012, 8, e1002700. [Google Scholar] [CrossRef] [PubMed]

- De Vocht, M.L.; Reviakine, I.; Wösten, H.A.B.; Brisson, A.; Wessels, J.G.H.; Robillard, G.T. Structural and Functional Role of the Disulfide Bridges in the Hydrophobin SC3*. J. Biol. Chem. 2000, 275, 28428–28432. [Google Scholar] [CrossRef] [PubMed]

- Khalesi, M.; Gebruers, K.; Derdelinckx, G. Recent Advances in Fungal Hydrophobin towards Using in Industry. Protein J. 2015, 34, 243–255. [Google Scholar] [CrossRef] [PubMed]

- Hektor, H.J.; Scholtmeijer, K. Hydrophobins: Proteins with potential. Curr. Opin. Biotechnol. 2005, 16, 434–439. [Google Scholar] [CrossRef] [PubMed]

- Linder, M.B. Hydrophobins: Proteins that self assemble at interfaces. Curr. Opin. Colloid Interface Sci. 2009, 14, 356–363. [Google Scholar] [CrossRef]

- Morris, V.K.; Kwan, A.H.; Mackay, J.P.; Sunde, M. Backbone and sidechain 1H, 13C and 15N chemical shift assignments of the hydrophobin DewA from Aspergillus nidulans. Biomol. NMR Assign. 2012, 6, 83–86. [Google Scholar] [CrossRef] [PubMed]

- Morris, V.K.; Linser, R.; Wilde, K.L.; Duff, A.P.; Sunde, M.; Kwan, A.H. Solid-State NMR Spectroscopy of Functional Amyloid from a Fungal Hydrophobin: A Well-Ordered β-Sheet Core Amidst Structural Heterogeneity. Angew. Chem. Int. Ed. 2012, 51, 12621–12625. [Google Scholar] [CrossRef]

- Morris, V.K.; Kwan, A.H.; Sunde, M. Analysis of the Structure and Conformational States of DewA Gives Insight into the Assembly of the Fungal Hydrophobins. J. Mol. Biol. 2013, 425, 244–256. [Google Scholar] [CrossRef]

- Zykwinska, A.; Guillemette, T.; Bouchara, J.-P.; Cuenot, S. Spontaneous self-assembly of SC3 hydrophobins into nanorods in aqueous solution. Biochim. Biophys. Acta (BBA) Proteins Proteom. 2014, 1844, 1231–1237. [Google Scholar] [CrossRef]

- Wösten, H.A.B.; Scholtmeijer, K. Applications of hydrophobins: Current state and perspectives. Appl. Microbiol. Biotechnol. 2015, 99, 1587–1597. [Google Scholar] [CrossRef]

- Khalesi, M.; Deckers, S.M.; Gebruers, K.; Vissers, L.; Verachtert, H.; Derdelinckx, G. Hydrophobins: Exceptional proteins for many applications in brewery environment and other bio-industries. Cerevisia 2012, 37, 3–9. [Google Scholar] [CrossRef]

- Piscitelli, A.; Cicatiello, P.; Gravagnuolo, A.M.; Sorrentino, I.; Pezzella, C.; Giardina, P. Applications of Functional Amyloids from Fungi: Surface Modification by Class I Hydrophobins. Biomolecules 2017, 7, 45. [Google Scholar] [CrossRef] [PubMed]

- Berger, B.W.; Sallada, N.D. Hydrophobins: Multifunctional biosurfactants for interface engineering. J. Biol. Eng. 2019, 13, 10. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, S.; Huang, Y.; Qiao, M.; Zhang, B.; Xu, H. Prokaryotic expression, purification, and polyclonal antibody production of a hydrophobin from Grifola frondosa. Acta Biochim. Biophys. Sin. 2010, 42, 388–395. [Google Scholar] [CrossRef][Green Version]

- Gandier, J.A.; Master, E.R. Pichia pastoris is a suitable host for the heterologous expression of predicted class I and class II hydrophobins for discovery, study, and application in biotechnology. Microorganisms 2018, 6, 3. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, S.; Nene, S.; Joshi, K. Production of Hydrophobins from fungi. Process Biochem. 2017, 61, 1–11. [Google Scholar] [CrossRef]

- Häkkinen, S.T.; Reuter, L.; Nuorti, N.; Joensuu, J.J.; Rischer, H.; Ritala, A. Tobacco BY-2 Media Component Optimization for a Cost-Efficient Recombinant Protein Production. Front. Plant Sci. 2018, 9, 45. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, S.S.; Nene, S.N.; Joshi, K.S. A comparative study of production of hydrophobin like proteins (HYD-LPs) in submerged liquid and solid state fermentation from white rot fungus Pleurotus ostreatus. Biocatal. Agric. Biotechnol. 2020, 23, 101440. [Google Scholar] [CrossRef]

- Wohlleben, W.; Subkowski, T.; Bollschweiler, C.; von Vacano, B.; Liu, Y.; Schrepp, W.; Baus, U. Recombinantly produced hydrophobins from fungal analogues as highly surface-active performance proteins. Eur. Biophys. J. 2010, 39, 457–468. [Google Scholar] [CrossRef]

- Linder, M.; Selber, K.; Nakari-Setälä, T.; Qiao, M.; Kula, M.-R.; Penttilä, M. The Hydrophobins HFBI and HFBII from Trichoderma reesei Showing Efficient Interactions with Nonionic Surfactants in Aqueous Two-Phase Systems. Biomacromolecules 2001, 2, 511–517. [Google Scholar] [CrossRef]

- Schmoll, M.; Seibel, C.; Kotlowski, C.; Wöllert Genannt Vendt, F.; Liebmann, B.; Kubicek, C.P. Recombinant production of an Aspergillus nidulans class I hydrophobin (DewA) in Hypocrea jecorina (Trichoderma reesei) is promoter-dependent. Appl. Microbiol. Biotechnol. 2010, 88, 95–103. [Google Scholar] [CrossRef]

- Kim, G.-J.; Park, W.J.; You, S.-H.; Lee, J.-Y.; Lee, E.-B.; Min, S.-Y. Universal Protein Overexpression Tag Comprising Ramp Function, and Application Thereof. U.S. Patent 10,227,595, 12 March 2019. [Google Scholar]

- Tuller, T.; Carmi, A.; Vestsigian, K.; Navon, S.; Dorfan, Y.; Zaborske, J.; Pan, T.; Dahan, O.; Furman, I.; Pilpel, Y. An Evolutionarily Conserved Mechanism for Controlling the Efficiency of Protein Translation. Cell 2010, 141, 344–354. [Google Scholar] [CrossRef]

- Grünbacher, A.; Throm, T.; Seidel, C.; Gutt, B.; Röhrig, J.; Strunk, T.; Vincze, P.; Walheim, S.; Schimmel, T.; Wenzel, W.; et al. Six Hydrophobins Are Involved in Hydrophobin Rodlet Formation in Aspergillus nidulans and Contribute to Hydrophobicity of the Spore Surface. PLoS ONE 2014, 9, e94546. [Google Scholar] [CrossRef]

- Kottmeier, K.; Ostermann, K.; Bley, T.; Rödel, G. Hydrophobin signal sequence mediates efficient secretion of recombinant proteins in Pichia pastoris. Appl. Microbiol. Biotechnol. 2011, 91, 133–141. [Google Scholar] [CrossRef]

- Iqbal, M.; Tao, Y.; Xie, S.; Zhu, Y.; Chen, D.; Wang, X.; Huang, L.; Peng, D.; Sattar, A.; Shabbir, M.A.B.; et al. Aqueous two-phase system (ATPS): An overview and advances in its applications. Biol. Proced. Online 2016, 18, 18. [Google Scholar] [CrossRef]

- Schelle, M. Methods of Purifying Hydrophobin. U.S. Patent 20150057434A1, 18 October.

- Dosemeci, A.; Rodnight, R. Demonstration by phase-partitioning in Triton X-114 solutions that phosphoprotein B-50 (F-1) from rat brain is an integral membrane protein. Neurosci. Lett. 1987, 74, 325–330. [Google Scholar] [CrossRef]

- Joensuu, J.J.; Conley, A.J.; Linder, M.B.; Menassa, R. Bioseparation of Recombinant Proteins from Plant Extract with Hydrophobin Fusion Technology. In Recombinant Gene Expression; Lorence, A., Ed.; Humana Press: Totowa, NJ, USA, 2012; pp. 527–534. [Google Scholar]

- Kwan, A.H.; Macindoe, I.; Vukašin, P.V.; Morris, V.K.; Kass, I.; Gupte, R.; Mark, A.E.; Templeton, M.D.; Mackay, J.P.; Sunde, M. The Cys3–Cys4 Loop of the Hydrophobin EAS Is Not Required for Rodlet Formation and Surface Activity. J. Mol. Biol. 2008, 382, 708–720. [Google Scholar] [CrossRef]

- Hou, S.; Li, X.; Li, X.; Feng, X.-Z.; Wang, R.; Wang, C.; Yu, L.; Qiao, M.-Q. Surface modification using a novel type I hydrophobin HGFI. Anal. Bioanal. Chem. 2009, 394, 783–789. [Google Scholar] [CrossRef] [PubMed]

- Rieder, A.; Ladnorg, T.; Wöll, C.; Obst, U.; Fischer, R.; Schwartz, T. The impact of recombinant fusion-hydrophobin coated surfaces on E. coli and natural mixed culture biofilm formation. Biofouling 2011, 27, 1073–1085. [Google Scholar] [CrossRef]

- Winandy, L.; Hilpert, F.; Schlebusch, O.; Fischer, R. Comparative analysis of surface coating properties of five hydrophobins from Aspergillus nidulans and Trichoderma reseei. Sci. Rep. 2018, 8, 12033. [Google Scholar] [CrossRef] [PubMed]

| Ramp Tag (RT) | ||

|---|---|---|

| Name | DNA Sequence | Amino Acid Sequence |

| RT1 | AGTCCTAATCACCCGGGA | SPNHPG |

| RT2 | AGTCCTCCGCACCTTCCC | SPPHLP |

| RT3 | CTTCCCAGTCCTAATCAC | LPSPNH |

| RT4 | AGTCCTAATCCCCCGTCC | SPNPPS |

| RT5 | CTTCACAGTCCTAATCCC | LHSPNP |

| Name | Nucleotide Sequence |

|---|---|

| DewA NdeI forward primer | ATCATATGCTTCACAGTCCTAATCCCAAGAACGCGAAGCTGGCC |

| DewA XhoI reverse primer | ATACTCGAGTTAGTGGTGGTGGTGGTGGTGCTCAGCCTTGGTACCGGCG |

| RT5-DewA | CTTCACAGTCCTAATCCCCGCTTCATCGTCTCTCTCCTCGCCTTCACTGCCGCGGCCACCGCAACCGCCCTCCCGGCCTCTGCCGCAAAGAACGCGAAGCTGGCCACCTCGGCGGCCTTCGCCAAGCAGGCTGAAGGCACCACCTGCAATGTCGGCTCGATCGCTTGCTGCAACTCCCCCGCTGAGACCAACAACGACAGTCTGTTGAGCGGTCTGCTCGGTGCTGGCCTTCTCAACGGGCTCTCGGGCAACACTGGCAGCGCCTGCGCCAAGGCGAGCTTGATTGACCAGCTGGGTCTGCTCGCTCTCGTCGACCACACTGAGGAAGGCCCCGTCTGCAAGAACATCGTCGCTTGCTGCCCTGAGGGAACCACCAACTGTGTTGCCGTCGACAACGCTGGCGCCGGTACCAAGGCTGAG |

| RT5-DewA (ΔSS1-24) | CTTCACAGTCCTAATCCCAAGAACGCGAAGCTGGCCACCTCGGCGGCCTTCGCCAAGCAGGCTGAAGGCACCACCTGCAATGTCGGCTCGATCGCTTGCTGCAACTCCCCCGCTGAGACCAACAACGACAGTCTGTTGAGCGGTCTGCTCGGTGCTGGCCTTCTCAACGGGCTCTCGGGCAACACTGGCAGCGCCTGCGCCAAGGCGAGCTTGATTGACCAGCTGGGTCTGCTCGCTCTCGTCGACCACACTGAGGAAGGCCCCGTCTGCAAGAACATCGTCGCTTGCTGCCCTGAGGGAACCACCAACTGTGTTGCCGTCGACAACGCTGGCGCCGGTACCAAGGCTGAG |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, S.-O.; Lim, H.-D.; You, S.-H.; Cheong, D.-E.; Kim, G.-J. Soluble Expression and Efficient Purification of Recombinant Class I Hydrophobin DewA. Int. J. Mol. Sci. 2021, 22, 7843. https://doi.org/10.3390/ijms22157843

Ahn S-O, Lim H-D, You S-H, Cheong D-E, Kim G-J. Soluble Expression and Efficient Purification of Recombinant Class I Hydrophobin DewA. International Journal of Molecular Sciences. 2021; 22(15):7843. https://doi.org/10.3390/ijms22157843

Chicago/Turabian StyleAhn, Sang-Oh, Ho-Dong Lim, Sung-Hwan You, Dae-Eun Cheong, and Geun-Joong Kim. 2021. "Soluble Expression and Efficient Purification of Recombinant Class I Hydrophobin DewA" International Journal of Molecular Sciences 22, no. 15: 7843. https://doi.org/10.3390/ijms22157843

APA StyleAhn, S.-O., Lim, H.-D., You, S.-H., Cheong, D.-E., & Kim, G.-J. (2021). Soluble Expression and Efficient Purification of Recombinant Class I Hydrophobin DewA. International Journal of Molecular Sciences, 22(15), 7843. https://doi.org/10.3390/ijms22157843