Development of Polypyrrole Modified Screen-Printed Carbon Electrode Based Sensors for Determination of L-Tyrosine in Pharmaceutical Products

Abstract

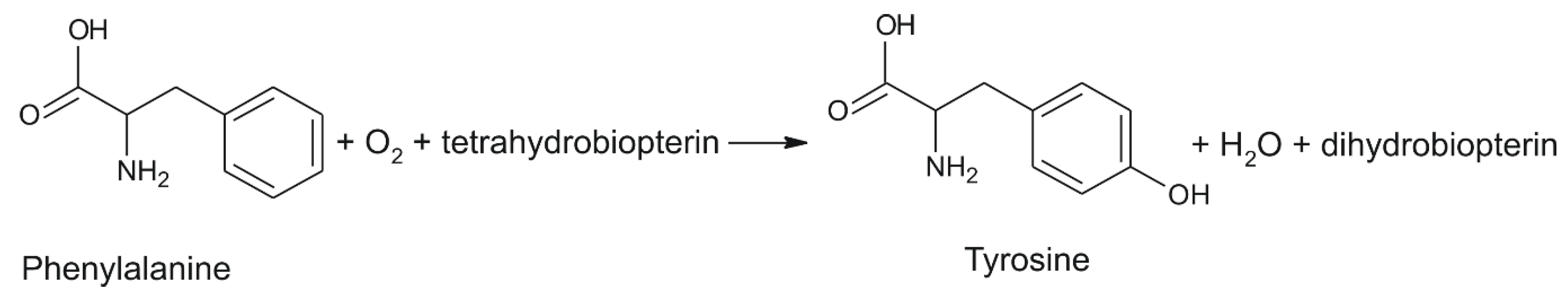

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Solutions

2.2. Equipment

2.3. Sensor Configuration and Methodology

2.4. Samples Tested

3. Results and Discussions

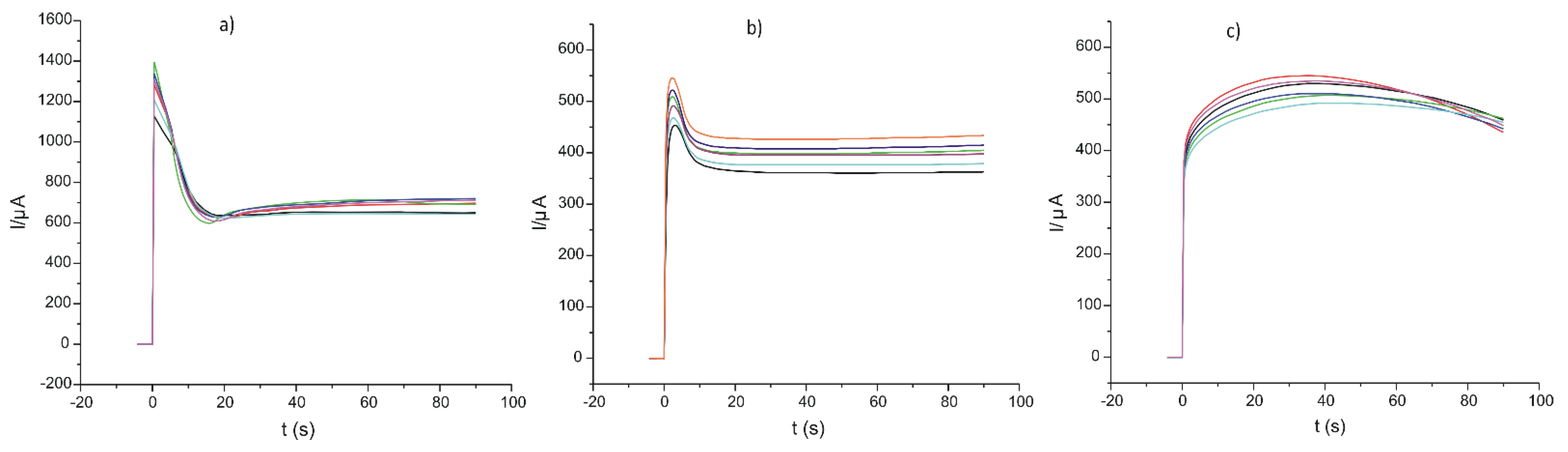

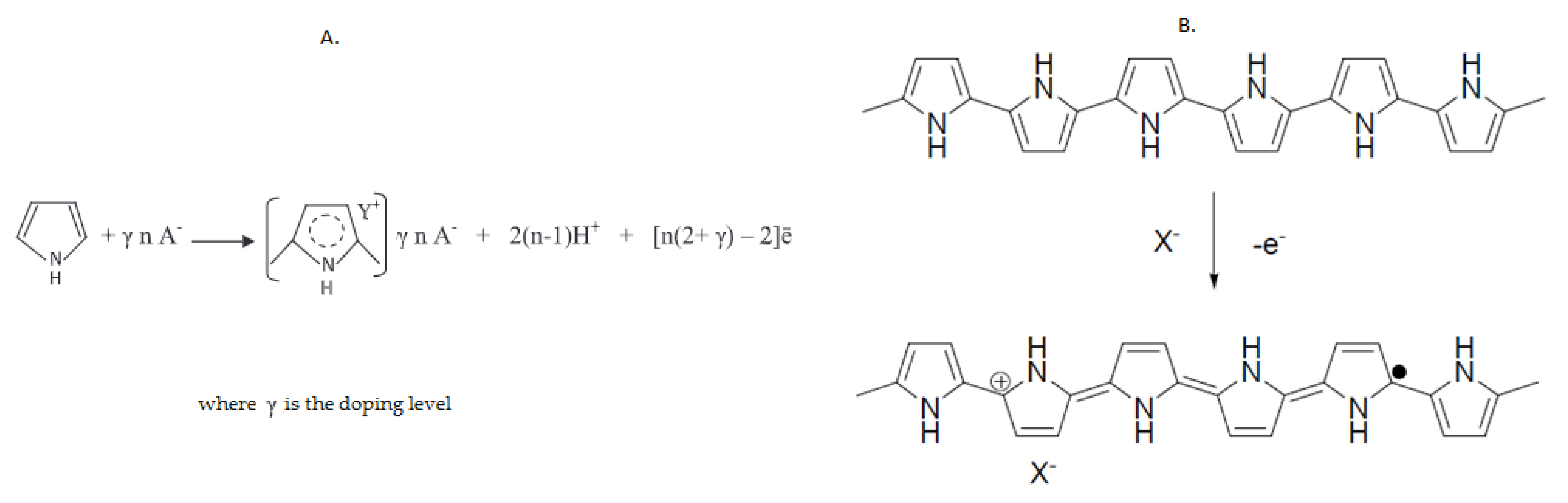

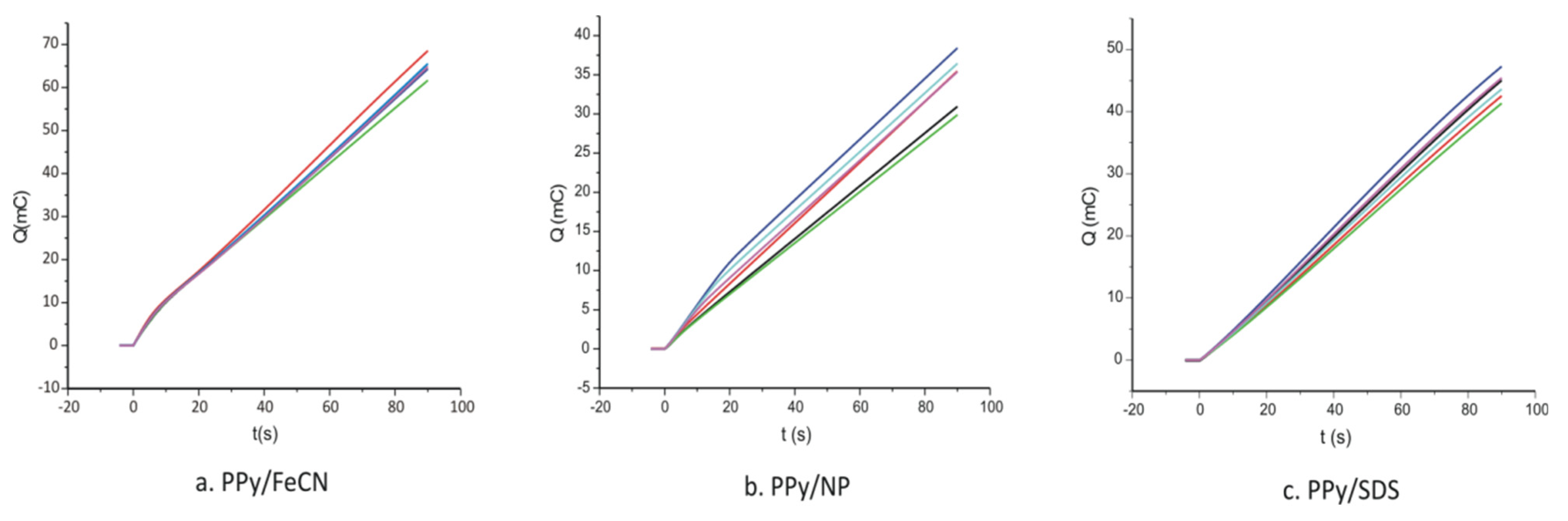

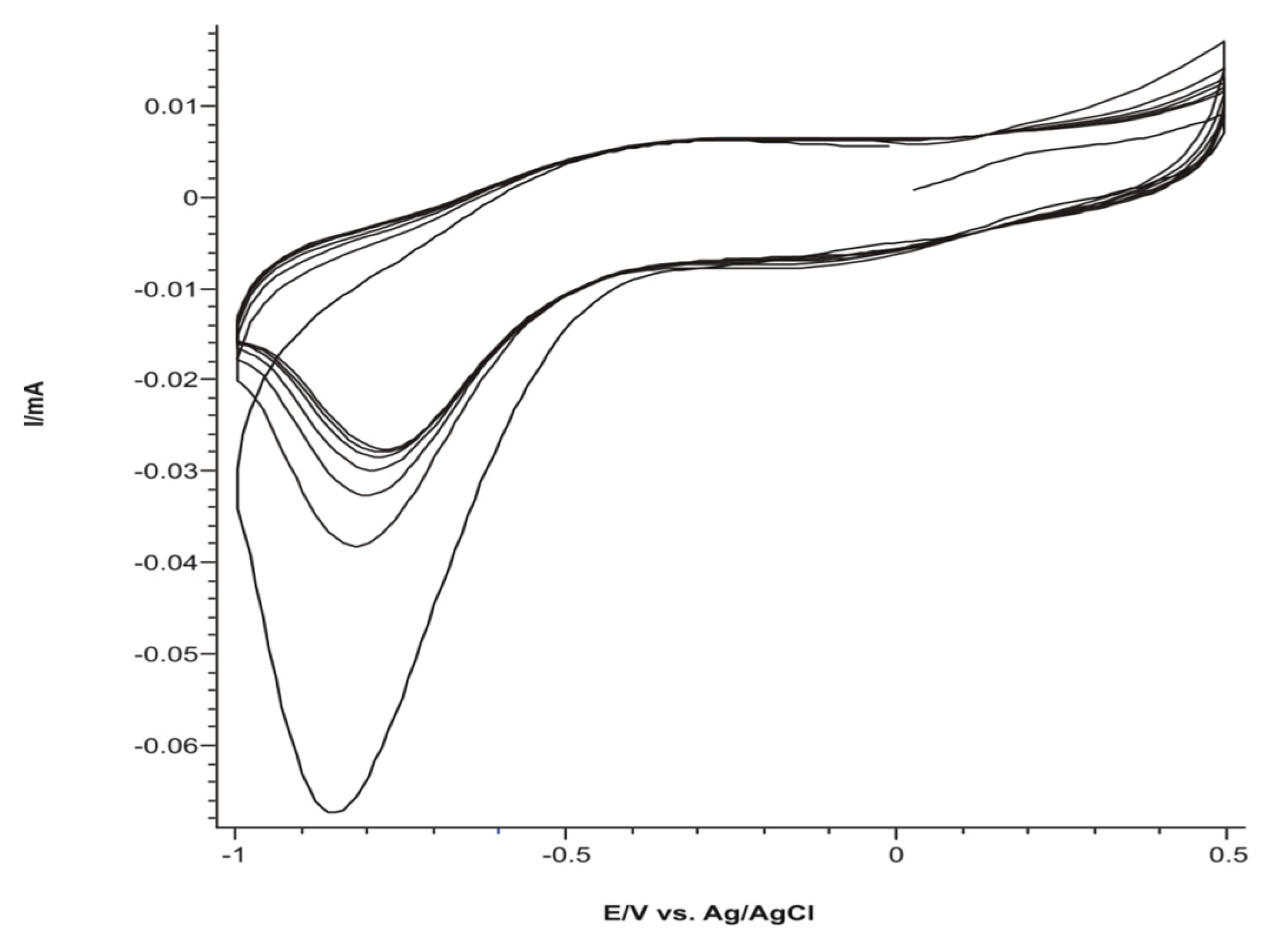

3.1. Deposition of the PPy on the Surface of SPCEs by Chronoamperometry

3.2. Voltammetric Responses

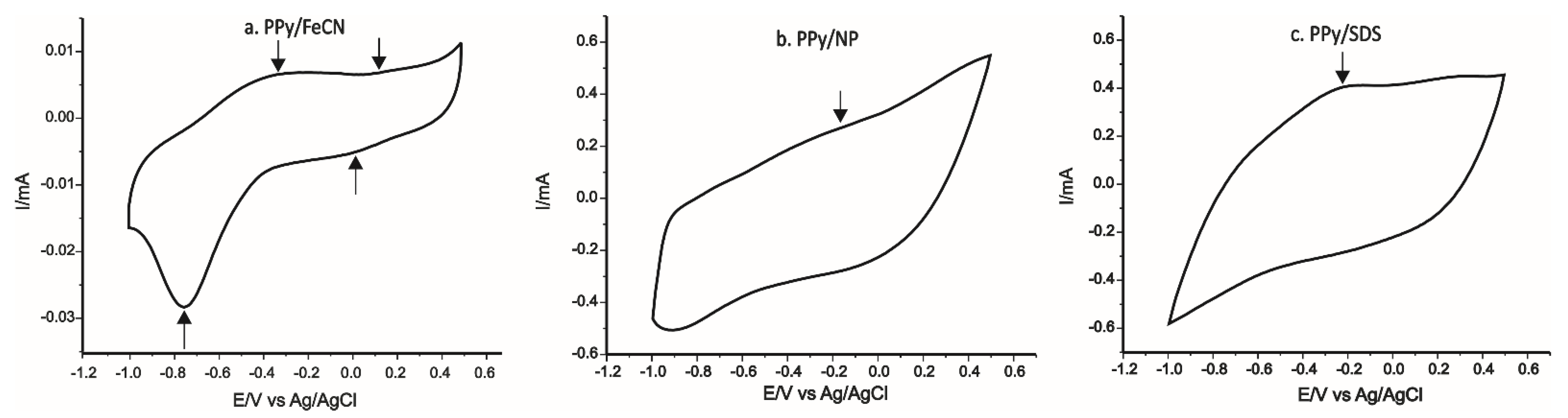

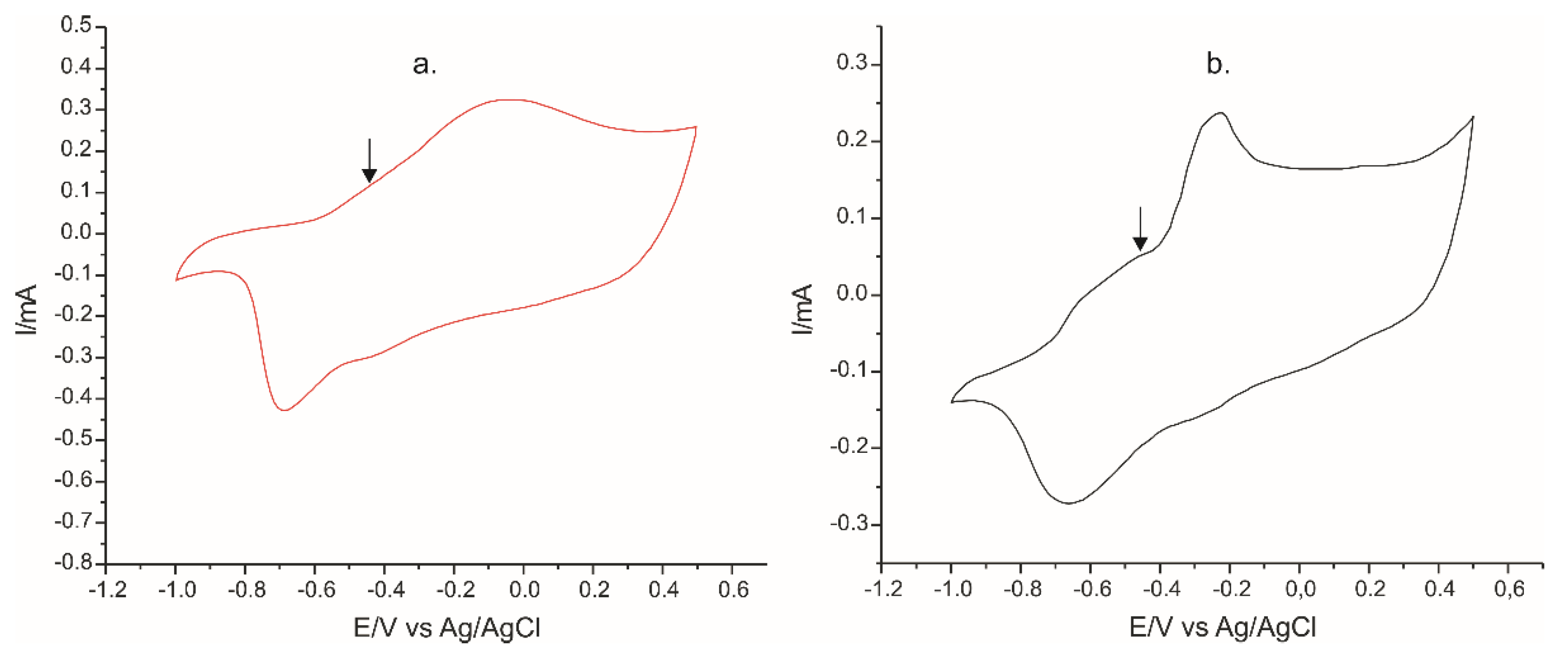

3.2.1. Electrochemical Responses of Sensor Immersed in 0.1 M KCl Solution and in 0.1 M KCl–10−3 M L-Tyr Solution before Modification

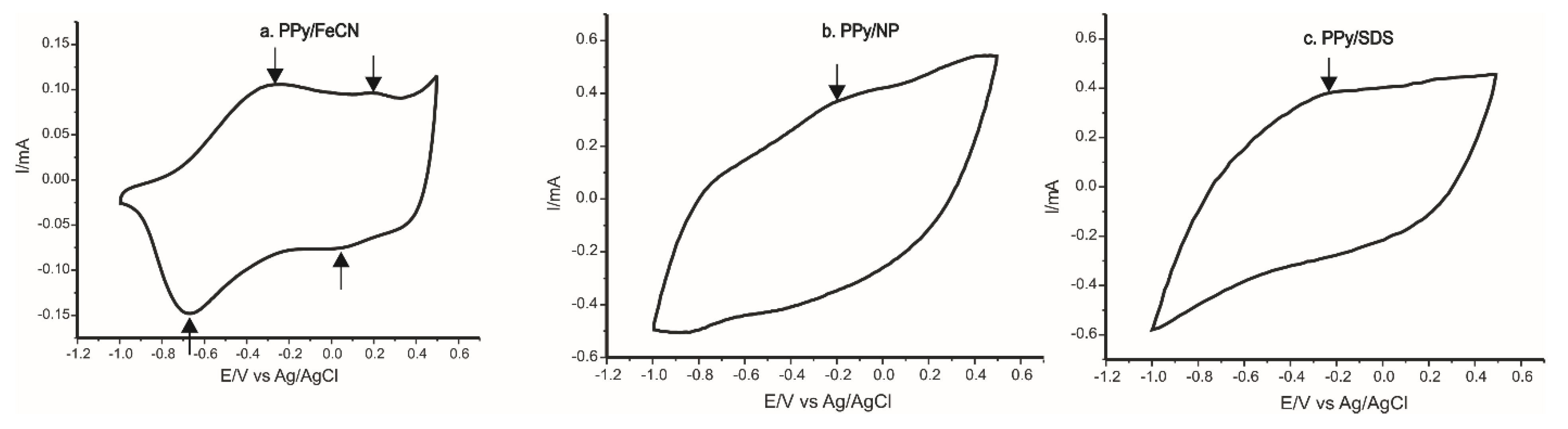

3.2.2. Stable Electrochemical Responses of Sensors in 0.1 M KCl Solutions and in Double Solution of 0.1 M KCl–10−3 M L-Tyr Solutions

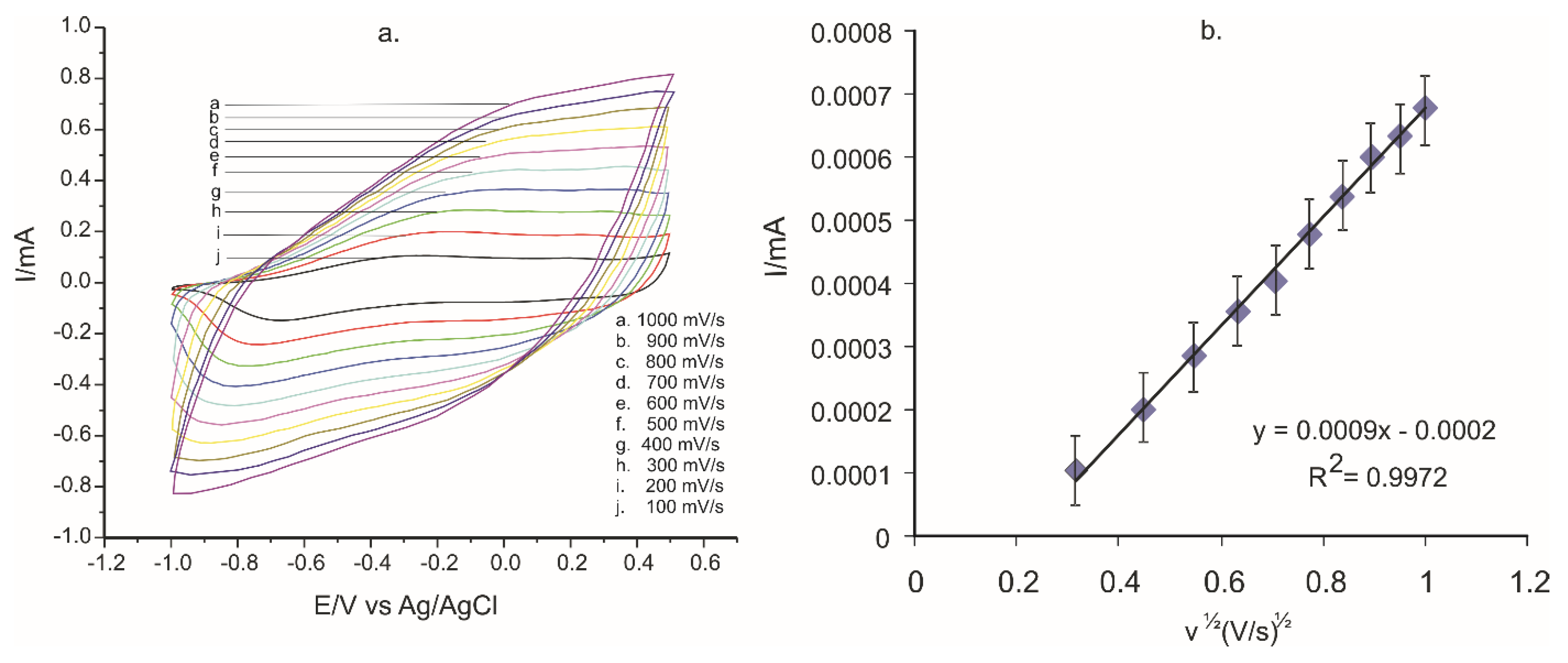

3.2.3. The Influence of the Scan Rate on the Responses of the Sensors Immersed into 0.1 M KCl and 0.1 M KCl–10−3 M L-Tyr Solutions

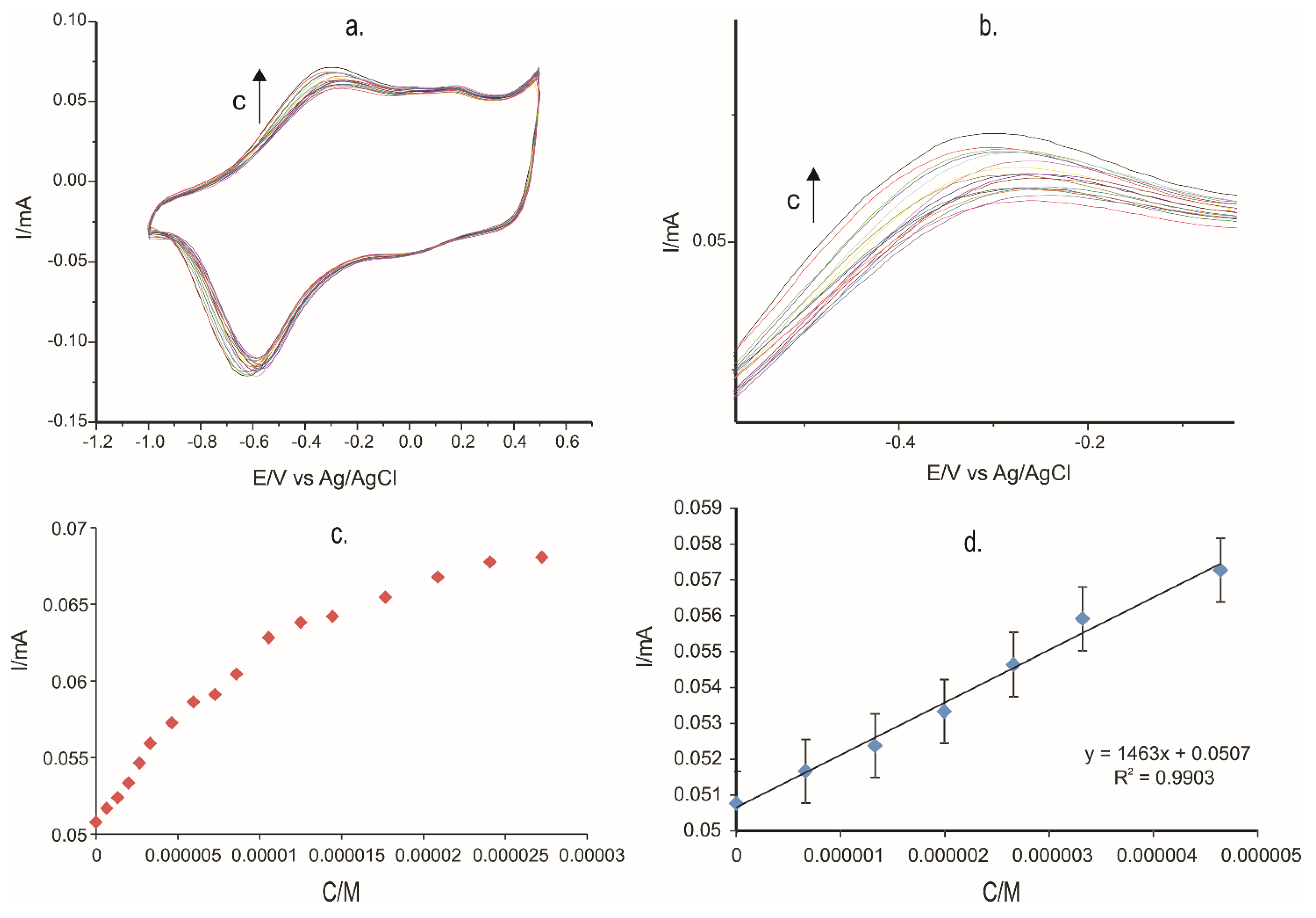

3.2.4. Development of Calibration Curve

3.2.5. Precision, Reproducibility, and Stability of the Modified Sensor

3.2.6. Interference Study

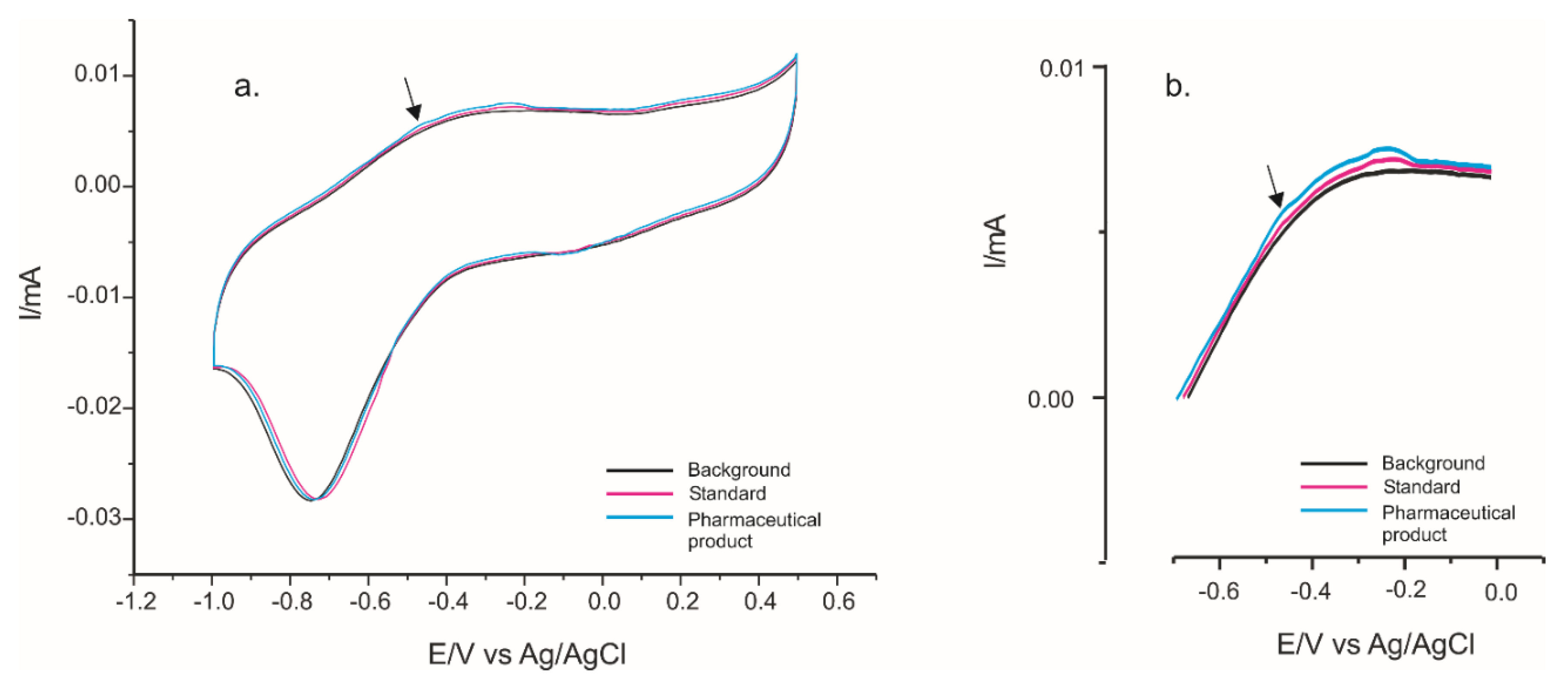

3.2.7. Validation of Modified Sensors on Real Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dubey, S.; Biswas, P.; Ghosh, R.; Chatterjee, S.; Dubey, M.J.; Chatterjee, S.; Lahirir, D.; Lavie, C.J. Psychosocial impact of COVID-19. Diabetes Metab. Syndr. Clin. Res. Rev. 2020, 14, 779–788. [Google Scholar] [CrossRef]

- Fotuhi, M.; Mian, A.; Meysami, S.; Raji, C.A. Neurobiology of COVID-19. J. Alzheimers Dis. 2020, 76, 3–19. [Google Scholar] [CrossRef] [PubMed]

- Liguori, C.; Pierantozzi, M.; Spanetta, M.; Sarmati, L.; Cesta, N.; Iannetta, M.; Ora, J.; Mina, G.G.; Puxeddu, E.; Balbi, O.; et al. Depressive and anxiety symptoms in patients with SARS-CoV2 infection. J. Affect. Disord. 2021, 278, 339–340. [Google Scholar] [CrossRef] [PubMed]

- Salamanca, N.; Giráldez, I.; Morales, E.; de la Rosa, I.; Herrera, M. Phenylalanine and Tyrosine as Feed Additives for Reducing Stress and Enhancing Welfare in Gilthead Seabream and Meagre. Animals 2020, 11, 45. [Google Scholar] [CrossRef] [PubMed]

- Brock, W.H. Justus von Liebig: The Chemical Gatekeeper; Cambridge University Press: Cambridge, UK, 2002; pp. 37–45. [Google Scholar]

- Zheng, F.; Zhou, J.; Wang, C.; Hu, W.; Krischek, B. There may be no significant increase of cerebrospinal fluid tyrosine levels in patients with Parkinson’s disease. Eur. J. Neurol. 2021, 28, e15–e16. [Google Scholar] [CrossRef] [PubMed]

- Hughes, J.H.; Wilson, P.J.M.; Sutherland, H.; Judd, S.; Hughes, A.T.; Milan, A.M.; Jarvis, J.C.; Bou-Gharios, G.; Ranganath, L.; Gallagher, J.A. Dietary restriction of tyrosine and phenylalanine lowers tyrosinemia associated with nitisinone therapy of alkaptonuria. J. Inherit. Metab. Dis. 2020, 43, 259–268. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hakim, M.R.; Krausz, M.J.; Spiegel, M.R. Degenerative osteoarthritis with multiple joint arthroplasties due to alkaptonuria: A rare inborn error of tyrosine metabolism. Isr. Med. Assoc. J. 2018, 20, 260–261. [Google Scholar]

- Park, H.J.; Nam, B.E.; Moon, S.Y.; Kim, S.-G.; Joo, Y.; Kim, J.G. Reduced host plant growth and increased tyrosine-derived secondary metabolites under climate change and negative consequences on its specialist herbivore. Sci. Total Environ. 2021, 759, 143507. [Google Scholar] [CrossRef]

- Coley, P.D.; Endara, M.J.; Ghabash, G.; Kidner, C.A.; Nicholls, J.A.; Pennington, R.T.; Mills, A.G.; Soule, A.J.; Lemes, M.R.; Stone, G.N.; et al. Macroevolutionary patterns in overexpression of tyrosine: An anti-herbivore defence in a speciose tropical tree genus Inga (Fabaceae). J. Ecol. 2019, 107, 1620–1632. [Google Scholar] [CrossRef]

- Kühn, S.; Duzel, S.; Colzato, L.; Norman, K.; Gallinat, J.; Brandmaier, A.M.; Lindenberger, U.; Widaman, K.F. Food for thought: Association between dietary tyrosine and cognitive performance in younger and older adults. Psychol. Res. 2019, 83, 1097–1106. [Google Scholar] [CrossRef] [Green Version]

- Varmira, K.; Mohammadi, G.; Mahmoudi, M.; Khodarahmi, R.; Rashidi, K.; Hedayati, M.; Goicoechea, H.C.; Jalalvand, A.R. Fabrication of a novel enzymatic electrochemical biosensor for determination of tyrosine in some food samples. Talanta 2018, 183, 1–10. [Google Scholar] [CrossRef]

- Dinu, A.; Apetrei, C. A Review on Electrochemical Sensors and Biosensors Used in Phenylalanine Electroanalysis. Sensors 2020, 20, 2496. [Google Scholar] [CrossRef] [PubMed]

- Dinu, A.; Apetrei, C. Voltammetric Determination of Phenylalanine Using Chemically Modified Screen-Printed Based Sensors. Chemosensors 2020, 8, 113. [Google Scholar] [CrossRef]

- Daly, A.; Evans, S.; Chahal, S.; Santra, S.; Pinto, A.; Gingell, C.; Rocha, J.; van Spronsen, F.; Jackson, R.; MacDonald, A. The Effect of Glycomacropeptide versus Amino Acids on Phenylalanine and Tyrosine Variability over 24 Hours in Children with PKU: A Randomized Controlled Trial. Nutrients 2019, 11, 520. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Litwack, G. Proteins. In Human Biochemistry; Academic Press: Cambridge, MA, USA, 2017; Chapter 4; pp. 65–80. [Google Scholar]

- Hatada, T.; Sakanoue, Y.; Kusunoki, M.; Kobayashi, A.; Utsunomiya, J. Variable Activity of Protein Tyrosine Kinase in Apparently Normal Thyroid Glands. Cancer Investig. 1994, 12, 26–32. [Google Scholar] [CrossRef] [PubMed]

- Ishihara, S.; Onoda, N.; Noda, S.; Tauchi, Y.; Morisaki, T.; Asano, Y.; Kashiwagi, S.; Takashima, T.; Ohira, M. Treatment of anaplastic thyroid cancer with tyrosine kinase inhibitors targeted on the tumor vasculature: Initial experience in clinical practice. Endocr. J. 2020, EJ20-0287. [Google Scholar] [CrossRef] [PubMed]

- Atta, N.F.; Galal, A.; Ahmed, Y.M. An Innovative Design of an Efficient Layered Electrochemical Sensor for Determination of Tyrosine and Tryptophan in the Presence of Interfering Compounds in Biological Fluids. J. Electrochem. Soc. 2020, 167, 027505. [Google Scholar] [CrossRef]

- Phelane, L.; Gouveia-Caridade, C.; Barsan, M.M.; Baker, P.G.L.; Brett, C.M.A.; Iwuoha, E.I. Electrochemical Determination of Tyrosine using a Novel Tyrosinase Multi-Walled Carbon Nanotube (MWCNT) Polysulfone Modified Glassy Carbon Electrode (GCE). Anal. Lett. 2020, 53, 308–321. [Google Scholar] [CrossRef]

- Ghoreishi, S.M.; Behpour, M.; Jafari, N.; Golestaneh, M. Electrochemical Determination of Tyrosine in the Presence of Dopamine and Uric Acid at the Surface of Gold Nanoparticles Modified Carbon Paste Electrode. J. Chin. Chem. Soc. 2012, 59, 1015–1020. [Google Scholar] [CrossRef]

- Babaei, A.; Mirzakhani, S.; Khalilzadeh, B. A sensitive simultaneous determination of epinephrine and tyrosine using an iron(III) doped zeolite-modified carbon paste electrode. J. Braz. Chem. Soc. 2009, 20, 1862–1869. [Google Scholar] [CrossRef]

- Orhan, H.; Vermeulen, N.P.; Tump, C.; Zappey, H.; Meerman, J.H. Simultaneous determination of tyrosine, phenylalanine and deoxyguanosine oxidation products by liquid chromatography–tandem mass spectrometry as non-invasive biomarkers for oxidative damage. J. Chromatogr. B 2004, 799, 245–254. [Google Scholar] [CrossRef] [PubMed]

- Neurauter, G.; Scholl-Burgi, S.; Haara, A.; Geisler, S.; Mayersbach, P.; Schennach, H.; Fuchs, D. Simultaneous measurement of phenylalanine and tyrosine by high performance liquid chromatography (HPLC) with fluorescence detection. Clin. Biochem. 2013, 46, 1848–1851. [Google Scholar] [CrossRef]

- Li, S.; Xing, M.; Wang, H.; Zhang, L.; Zhong, Y.; Chen, L. Determination of tryptophan and tyrosine by chemiluminescence based on a luminol–N-bromosuccinimide–ZnS quantum dots system. RSC Adv. 2015, 5, 59286–59291. [Google Scholar] [CrossRef]

- Rigobello-Masini, M.; Masini, J.C. Sequential injection chromatography for fluorimetric determination of intracellular amino acids in marine microalgae. In Amino Acid Analysis; Springer: Berlin, Germany, 2012; pp. 305–315. [Google Scholar]

- Dailey, C.A.; Garnier, N.; Rubakhin, S.S.; Sweedler, J.V. Automated method for analysis of tryptophan and tyrosine metabolites using capillary electrophoresis with native fluorescence detection. Anal. Bioanal. Chem. 2013, 405, 2451–2459. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alam, M.M.; Uddin, M.T.; Asiri, A.M.; Rahman, M.M.; Islam, M.A. Detection of L-Tyrosine by electrochemical method based on binary mixed CdO/SnO2 nanoparticles. Measurement 2020, 163, 107990. [Google Scholar] [CrossRef]

- Huang, G.G.; Yang, J. Development of infrared optical sensor for selective detection of tyrosine in biological fluids. Biosens. Bioelectron. 2005, 3, 408–418. [Google Scholar] [CrossRef]

- Satheeshkumar, E.; Yang, J. Analyte-induced photoreduction method for visual and colorimetric detection of tyrosine. Anal. Chim. Acta 2015, 879, 111–117. [Google Scholar] [CrossRef]

- Karthika, A.; Rosaline, D.R.; Inbanathan, S.S.R.; Suganthi, A.; Rajarajan, M. Fabrication of Cupric oxide decorated β-cyclodextrin nanocomposite solubilized Nafion as a high performance electrochemical sensor for l-tyrosine detection. J. Phys. Chem. Solids 2020, 136, 109145. [Google Scholar] [CrossRef]

- Jin, G.-P.; Lin, X.-Q. The electrochemical behavior and amperometric determination of tyrosine and tryptophan at a glassy carbon electrode modified with butyrylcholine. Electrochem. Commun. 2004, 6, 454–460. [Google Scholar] [CrossRef]

- Yola, M.L.; Eren, T.; Atar, N. A sensitive molecular imprinted electrochemical sensor based on gold nanoparticles decorated graphene oxide: Application to selective determination of tyrosine in milk. Sens. Actuators B Chem. 2015, 210, 149–157. [Google Scholar] [CrossRef]

- Kavitha, C.; Bramhaiah, K.; John, N.S. Low-cost electrochemical detection of L-tyrosine using an rGO–Cu modified pencil graphite electrode and its surface orientation on a Ag electrode using an ex situ spectroelectrochemical method. RSC Adv. 2020, 10, 22871–22880. [Google Scholar] [CrossRef]

- D’Souza, E.S.; Manjunatha, J.G.; Chenthatti, R.; Tigari, G.; Ravishankar, D.K. Rapid Electrochemical Monitoring of Tyrosine by Poly (Riboflavin) Modified Carbon Nanotube Paste Electrode as a Sensitive Sensor and its Applications in Pharmaceutical Samples. Biointerface Res. Appl. Chem. 2021, 11, 14661–14672. [Google Scholar]

- Zhang, J. Electrochemical Determination of Tyrosine and Nitrite Using CS/CMWNTs/GCE-modified Electrode. Int. J. Electrochem. Sci. 2018, 13, 3527–3534. [Google Scholar] [CrossRef]

- Wang, Y.; Xiong, C.; Qu, H.; Chen, W.; Ma, A.; Zheng, L. Highly sensitive real-time detection of tyrosine based on organic electrochemical transistors with poly-(diallyldimethylammonium chloride), gold nanoparticles and multi-walled carbon nanotubes. J. Electroanal. Chem. 2017, 799, 321–326. [Google Scholar] [CrossRef]

- Feng, J.; Deng, P.; Xiao, J.; Li, J.; Tian, Y.; Wu, Y.; Liu, J.; Li, G.; He, Q. New voltammetric method for determination of tyrosine in foodstuffs using an oxygen-functionalized multi-walled carbon nanotubes modified acetylene black paste electrode. J. Food Compos. Anal. 2021, 96, 103708. [Google Scholar] [CrossRef]

- Liu, M.; Lao, J.; Wang, H.; Xu, Z.; Li, J.; Wen, L.; Yin, Z.; Luo, C.; Peng, H. Electrochemical Determination of Tyrosine Using Graphene and Gold Nanoparticle Composite Modified Glassy Carbon Electrode. Russ. J. Electrochem. 2021, 57, 41–50. [Google Scholar] [CrossRef]

- Kerman, K.; Kraatz, H.-B. Electrochemical detection of protein tyrosine kinase-catalysed phosphorylation using gold nanoparticles. Biosens. Bioelectron. 2009, 24, 1484–1489. [Google Scholar] [CrossRef] [PubMed]

- Rasmussen, S. Early History of Polypyrrole: The First Conducting Organic Polymer. Bull. Hist. Chem. Div. Hist. Chem. Am. Chem. Soc. 2015, 40, 45–55. [Google Scholar]

- Yussuf, A.; Al-Saleh, M.; Al-Enezi, S.; Abraham, G. Synthesis and Characterization of Conductive Polypyrrole: The Influence of the Oxidants and Monomer on the Electrical, Thermal, and Morphological Properties. Int. J. Polym. Sci. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Gniadek, M.; Wichowska, A.; Antos-Bielska, M.; Orlowski, P.; Krzyzowska, M.; Donten, M. Synthesis and characterization of polypyrrole and its composites coatings on flexible surface and its antibacterial properties. Synth. Met. 2020, 266, 116430. [Google Scholar] [CrossRef]

- Tat’yana, V.V.; Efimov, O.N. Polypyrrole: A conducting polymer; its synthesis, properties and applications. Russ. Chem. Rev. 1997, 66, 443. [Google Scholar]

- Geană, E.-I.; Artem, V.; Apetrei, C. Discrimination and classification of wines based on polypyrrole modified screen-printed carbon electrodes coupled with multivariate data analysis. J. Food Compos. Anal. 2021, 96, 103704. [Google Scholar] [CrossRef]

- Apetrei, C. Novel method based on polypyrrole-modified sensors and emulsions for the evaluation of bitterness in extra virgin olive oils. Food Res. Int. 2012, 48, 673–680. [Google Scholar] [CrossRef]

- Choudhary, M.; Islam, R.U.; Witcomb, M.J.; Mallick, K. In situ generation of a high-performance Pd-polypyrrole composite with multi-functional catalytic properties. Dalton Trans 2014, 43, 6396–6405. [Google Scholar] [CrossRef] [PubMed]

- Rezaei, B.; Irannejad, N. Electrochemical detection techniques in biosensor applications. In Electrochemical Biosensors; Elsevier: Amsterdam, The Netherlands, 2019; pp. 11–43. [Google Scholar]

- Mortimer, R.J. Spectroelectrochemistry, Applications. In Encyclopedia of Spectroscopy and Spectrometry; Elsevier: Amsterdam, The Netherlands, 2017; pp. 160–171. [Google Scholar]

- Oukil, D.; Benhaddad, L.; Aitout, R.; Makhloufi, L.; Pillier, F.; Saidani, B. Electrochemical synthesis of polypyrrole films doped by ferrocyanide ions onto iron substrate: Application in the electroanalytical determination of uric acid. Sens. Actuators B Chem. 2014, 204, 203–210. [Google Scholar] [CrossRef]

- Neri, G. First Fifty Years of Chemoresistive Gas Sensors. Chemosensors 2015, 3, 1–20. [Google Scholar] [CrossRef]

- Bieńkowski, K.; Strawski, M.; Szklarczyk, M. The determination of the thickness of electrodeposited polymeric films by AFM and electrochemical techniques. J. Electroanal. Chem. 2011, 662, 196–203. [Google Scholar] [CrossRef]

- Arrieta, A.A.; Apetrei, C.; Rodríguez-Méndez, M.L.; de Saja, J.A. Voltammetric sensor array based on conducting polymer-modified electrodes for the discrimination of liquids. Electrochim. Acta 2004, 49, 4543–4551. [Google Scholar] [CrossRef]

- P Gros, H.D.; Comtat, M. Use of polypyrrole film containing Fe (CN) 63− as pseudo-reference electrode: Application for amperometric biosensors. Electrochim. Acta 2001, 46, 643–650. [Google Scholar] [CrossRef]

- Apetrei, I.; Apetrei, C. Development of a Novel Biosensor Based on Tyrosinase/Platinum Nanoparticles/Chitosan/Graphene Nanostructured Layer with Applicability in Bioanalysis. Materials 2019, 12, 1009. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rahman, M.; Lopa, N.S.; Kim, K.; Lee, J.-J. Selective detection of l-tyrosine in the presence of ascorbic acid, dopamine, and uric acid at poly(thionine)-modified glassy carbon electrode. J. Electroanal. Chem. 2015, 754, 87–93. [Google Scholar] [CrossRef]

- Wei, Z. Simultaneous Determination of Acetaminophen and Tyrosine Using Screen-printed Electrochemical Sensor Based on MWCNTs-doped Poly(glycine)/Poly(acrylic acid) Conducting Polymers. Int. J. Electrochem. Sci. 2019, 14, 6748–6758. [Google Scholar] [CrossRef]

- Taei, M.; Ramazani, G. Simultaneous determination of norepinephrine, acetaminophen and tyrosine by differential pulse voltammetry using Au-nanoparticles/poly(2-amino-2-hydroxymethyl-propane-1,3-diol) film modified glassy carbon electrode. Colloids Surf. B Biointerfaces 2014, 123, 23–32. [Google Scholar] [CrossRef] [PubMed]

- Raril, C.; Manjunatha, J.G.; Ravishankar, D.K.; Fattepur, S.; Siddaraju, G.; Nanjundaswamy, L. Validated Electrochemical Method for Simultaneous Resolution of Tyrosine, Uric Acid, and Ascorbic Acid at Polymer Modified Nano-Composite Paste Electrode. Surf. Eng. Appl. Electrochem. 2020, 56, 415–426. [Google Scholar] [CrossRef]

- Li, C. Voltammetric determination of tyrosine based on an l-serine polymer film electrode. Colloids Surf. B Biointerfaces 2006, 50, 147–151. [Google Scholar] [CrossRef] [PubMed]

- Turkey, S.; Ermiş, N. Preparation of Molecularly Imprınted Polypyrrole Modified Gold Electrode for Determination of Tyrosine in Biological Samples. Int. J. Electrochem. Sci. 2018, 13, 2286–2298. [Google Scholar]

- Atta, N.F.; Ahmed, Y.M.; Galal, A. Layered-designed composite sensor based on crown ether/Nafion®/polymer/carbon nanotubes for determination of norepinephrine, paracetamol, tyrosine and ascorbic acid in biological fluids. J. Electroanal. Chem. 2018, 828, 11–23. [Google Scholar] [CrossRef]

- Roy, S.; Nagabooshanam, S.; Wadhwa, S.; Chauhan, N.; Mathur, A.; Khan, S.A.; Davis, J. Ultra-sensitive detection of l-tyrosine using molecularly imprinted electrochemical sensor towards diabetic foot ulcer detection. Electrochem. Commun. 2020, 117, 106782. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, Y.; Lin, L.; Chen, H.; Zhao, M. Au nanoparticles @metal organic framework/polythionine loaded with molecularly imprinted polymer sensor: Preparation, characterization, and electrochemical detection of tyrosine. J. Electroanal. Chem. 2020, 863, 114052. [Google Scholar] [CrossRef]

- Ramya, R.; Muthukumaran, P.; Wilson, J. Electron. beam-irradiated polypyrrole decorated with Bovine serum albumin pores: Simultaneous determination of epinephrine and L-tyrosine. Biosens. Bioelectron. 2018, 108, 53–61. [Google Scholar] [CrossRef] [PubMed]

| Electrode | Thickness (µm) |

|---|---|

| PPy/FeCN-SPCE 1 | 0.163 |

| PPy/NP–SPCE 2 | 0.065 |

| PPy/SDS–SPCE 3 | 0.077 |

| Sensor | Electrochemical Parameters | ||||||

|---|---|---|---|---|---|---|---|

| Epa 1 (V) | Epc 2 (V) | ΔE 3 (V) | Ipa 4 (mA) | Ipc 5 (mA) | Ipc/Ipa | ||

| PPy/FeCN-SPCE | Redox system I | −0.32 | −0.74 | 0.42 | 0.00656 | −0.02830 | 4.31 |

| Redox system II | 0.20 | 0.03 | 0.17 | 0.007264 | −0.004976 | 0.69 | |

| PPy/NP-SPCE | −0.06 | −0.02 | −0.04 | 0.30196 | −0.23940 | 0.79 | |

| PPy/SDS-SPCE | −0.26 | −0.09 | −0.17 | 0.39094 | −0.25168 | 0.64 | |

| Sensor | Electrochemical Parameters | ||||||

|---|---|---|---|---|---|---|---|

| Epa (V) | Epc (V) | ΔE (V) | Ipa (mA) | Ipc (mA) | Ipc/Ipa | ||

| PPy/FeCN-SPCE | Redox system I | −0.28 | −0.66 | −0.38 | 0.125608 | −0.13802 | 1.09 |

| Redox system II | 0.19 | 0.08 | 0.11 | 0.094318 | −0.085659 | 0.90 | |

| PPy/NP-SPCE | −0.17 | −0.12 | −0.05 | 0.376208 | −0.317410 | 0.84 | |

| PPy/SDS-SPCE | −0.23 | −0.13 | −0.10 | 0.384051 | −0.265026 | 0.68 | |

| Electrode | Solution | Slope (mA·s1/2·V−1/2) | R2 | Active Area (cm2) | Roughness Factor |

|---|---|---|---|---|---|

| SPCE | 0.00005820 | 0.9946 | 0.0803 | 0.63 | |

| PPy/FeCN-SPCE | 0.1 M KCl and 10−3 M L-Tyr | 0.00085700 | 0.9972 | 1.1824 | 9.41 |

| PPy/NP-SPCE | 0.00027890 | 0.972 | 0.3847 | 3.06 | |

| PPy/SDS-SPCE | 0.00034100 | 0.9910 | 0.4700 | 3.74 |

| Sensor | LOD 1 (M) | LOQ 2 (M) |

|---|---|---|

| PPy/FeCN-SPCE | 8.20 × 10−8 | 2.73 × 10−7 |

| PPy/NP-SPCE | 4.30 × 10−7 | 1.43 × 10−6 |

| PPy/SDS-SPCE | 3.51 × 10−7 | 1.17 × 10−6 |

| No. | Sensitive Material | Electroanalytical Technique | Linearity Range (M) | LOD (M) | Real Samples Analyzed | Reference |

|---|---|---|---|---|---|---|

| 1 | In situ copper oxide modified MIPPy coated GCE | DPV 1 | 1.0 × 10−8–8.0 × 10−6 | 4.0 × 10−9 | human serum | [56] |

| 2 | MWCNTs-doped Poly(glycine)/Poly(acrylic acid)/SPE | LSV 2 | 4.0 × 10−7−1.5 × 10−4 | 1.3 × 10−7 | human serum | [57] |

| 3 | AuNPs/poly (trisamine)/GCE | DPV, EIS 3 | 3.9 × 10−6–6.18 × 10−5 | 9.0 × 10−7 | human blood serum | [58] |

| 4 | Poly threonine modified graphite-carbon nanotube paste electrode | CV 4 | 2.0 × 10–6–2.5 × 10–5 | 2.9 × 10–7 | black tea | [59] |

| 5 | Poly-L-serine/GCE | Amperometry | 3.0 × 10−7–1.0 × 10−4 | 1.0 × 10–7 | commercial amino acid oral solution | [60] |

| 6 | MIP-polypyrrole/AuE | SWV 5 | 5.0 × 10−9–2.5 × 10−8 | 2.5 × 10−9 | human plasma | [61] |

| 7 | GC/CNT/PEDOT/NF/Crown (glassy carbon/multi-walled carbon nanotubes/poly (3-4-ethylene dioxythiophene/Nafion/Crown) | DPV | 6.0 × 10−8–2.0 × 10−5 | 4.29 × 10−10 | blood serum | [62] |

| 8 | over-oxidized polypyrrole film on indium tin oxide | CV | 1.0 × 10−13–1.0 × 10−6 | 1.73 × 10−12 | - | [63] |

| 9 | MIP/pTH/Au@ZIF-67 (molecularly imprinted polyaniline/polythionine/gold nanoparticles@zeolitic imidazolate framework-67 composite () | DPV | 1.0 ×10−8–4.0 ×10−6 | 7.9 × 10−10 | human serum | [64] |

| 10 | EB-Ppy-BSA/GCE (Electron beam irradiated polypyrrole nanospheres embedded over bovine serum albumin/) | SWV | 1.0 × 10−7–8.0 × 10−4 | 8.8 × 10−9 | black tea and chicken extract | [65] |

| 11 | BuCh/GCE (butyrylcholine/glassy carbon electrode) | DPV | 4.0 × 10−6–1.0 × 10−4 | 4.0 × 10−7 | mixture of amino acids | [32] |

| 12 | cAuNPs/2-AETGO/GCE (cubic gold nanoparticles/2-aminoethanethiol functionalized graphene oxide/glassy carbon electrode) | DPV | 1.0 × 10−9–2.0 × 10−8 | 1.5 × 10−10 | milk | [33] |

| 13 | GC/RGO/ILC/CNT/Fe–Zn (glassy carbon electrode/graphene oxide/ionic liquid crystal/multi-walled carbon nanotubes/Fe–Zn nanoalloy) | DPV | 2.0 × 10−8 −5.0 × 10−5 | 5.1 × 10−9 | biological fluids | [19] |

| Precision (RSD%) | Reproducibility (RSD%) | Stability | ||

|---|---|---|---|---|

| Intra-day | Inter-day | 3.3 | Time (days) | Relative Current response (%) |

| 4.4 | 5.7 | 5 | 97 | |

| 16 | 94 | |||

| 21 | 91 | |||

| Amino Acid | c/M | [Tyr]/M | RE (%) | Recovery (%) |

|---|---|---|---|---|

| L-Tryptophan | 0.001 | 3.812 × 10−6 | −4.7 | 95.3 |

| L-Cysteine | 0.001 | 3.815 × 10−6 | −4.625 | 95.375 |

| L-Phenylalanine | 0.001 | 4.813 × 10−6 | 4.575 | 104.575 |

| Pharmaceutical Product | [Tyr]/M Added | I vs. [Tyr] Equation | [Tyr]/M Found | Recovery (%) |

|---|---|---|---|---|

| Cebrium EVER NEURO PHARMA [Tyr] 3 × 10−6 M | 2 × 10−6 | I = 1.0814c + 5 × 10−5 R2 = 0.9982 | 5.17847 × 10−6 | 103.57 ± 1.50 |

| 3 × 10−6 | 6.14944 × 10−6 | 102.49 ± 1.47 | ||

| 4 × 10−6 | 7.02793 × 10−6 | 100.40 ± 1.08 | ||

| L-Tyrosine 500 SOLARAY [Tyr] 3 × 10−6 M | 2 × 10−6 | I = 1.0869c + 5 × 10−5 R2 = 0.9975 | 5.19827 × 10−6 | 103.97 ± 1.55 |

| 3 × 10−6 | 6.15512 × 10−6 | 102.59 ± 1.52 | ||

| 4 × 10−6 | 7.01997 × 10−6 | 100.29 ± 1.02 | ||

| Tiroidin PARAPHARM [Tyr] 3 × 10−6 M | 2 × 10−6 | I = 1.0937c + 5 × 10−5 R2 = 0.9991 | 5.10195 × 10−6 | 102.04 ± 1.53 |

| 3 × 10−6 | 6.0437 × 10−6 | 100.73 ± 1.12 | ||

| 4 × 10−6 | 6.99461 × 10−6 | 99.92 ± 1.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dinu, A.; Apetrei, C. Development of Polypyrrole Modified Screen-Printed Carbon Electrode Based Sensors for Determination of L-Tyrosine in Pharmaceutical Products. Int. J. Mol. Sci. 2021, 22, 7528. https://doi.org/10.3390/ijms22147528

Dinu A, Apetrei C. Development of Polypyrrole Modified Screen-Printed Carbon Electrode Based Sensors for Determination of L-Tyrosine in Pharmaceutical Products. International Journal of Molecular Sciences. 2021; 22(14):7528. https://doi.org/10.3390/ijms22147528

Chicago/Turabian StyleDinu, Ancuța, and Constantin Apetrei. 2021. "Development of Polypyrrole Modified Screen-Printed Carbon Electrode Based Sensors for Determination of L-Tyrosine in Pharmaceutical Products" International Journal of Molecular Sciences 22, no. 14: 7528. https://doi.org/10.3390/ijms22147528

APA StyleDinu, A., & Apetrei, C. (2021). Development of Polypyrrole Modified Screen-Printed Carbon Electrode Based Sensors for Determination of L-Tyrosine in Pharmaceutical Products. International Journal of Molecular Sciences, 22(14), 7528. https://doi.org/10.3390/ijms22147528