Rate and Product Studies with 1-Adamantyl Chlorothioformate under Solvolytic Conditions

Abstract

:1. Introduction

2. Results

3. Discussion

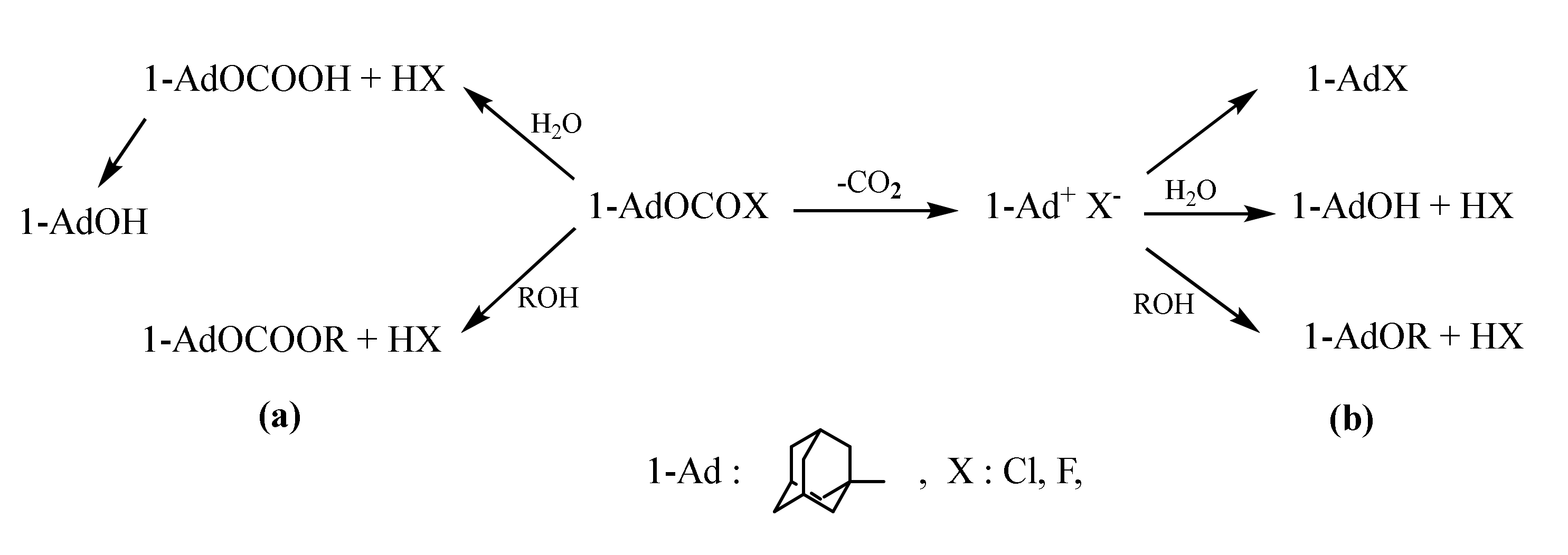

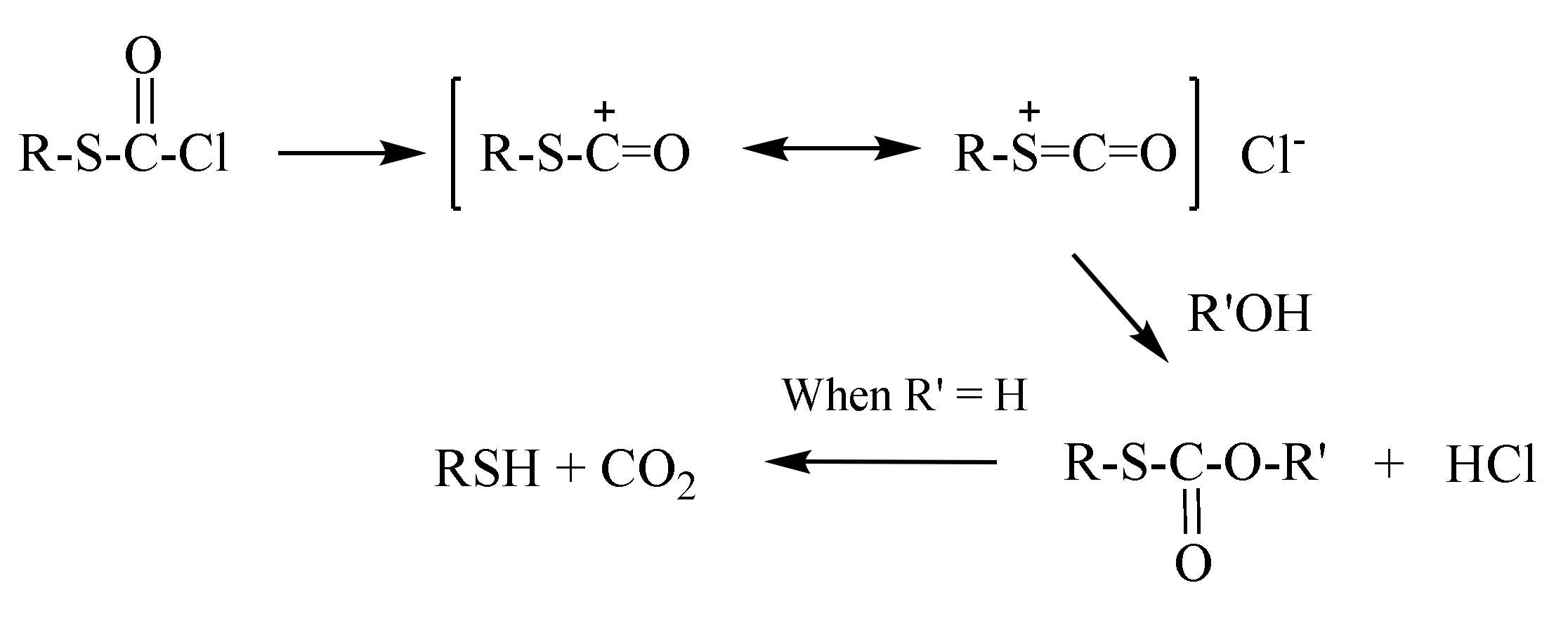

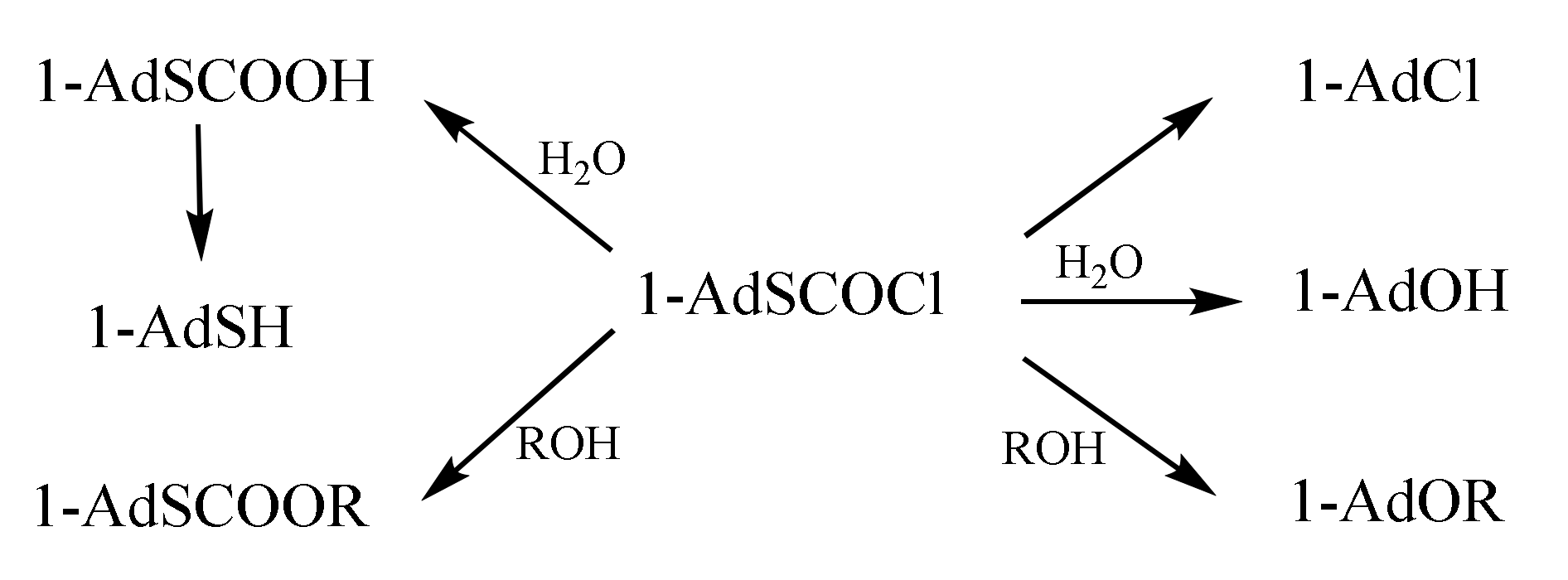

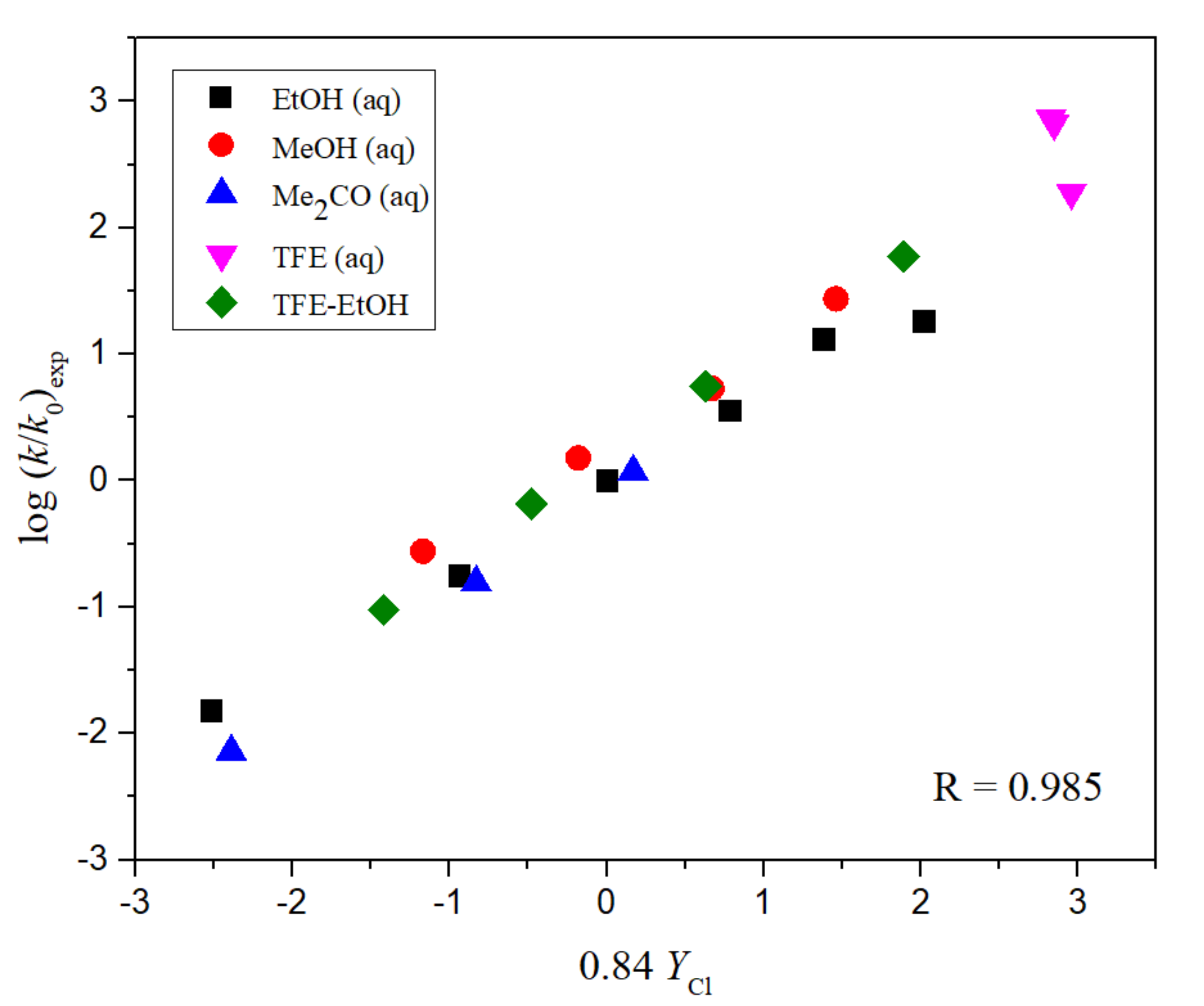

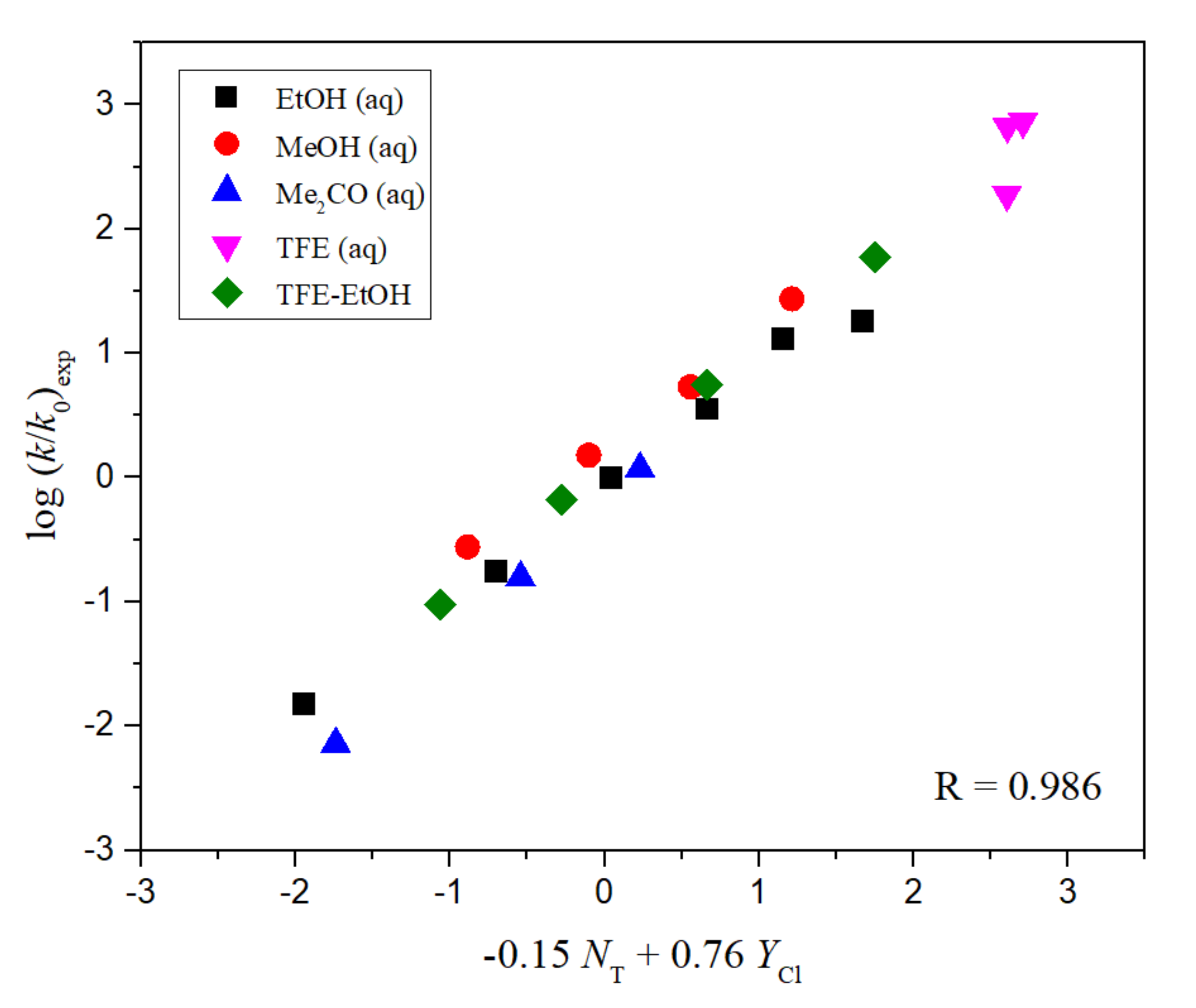

3.1. Kinetic Studies

3.2. Product Studies and Effects of Added Salt

4. Materials and Methods

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Matzner, M.; Kurkjy, R.P.; Cotter, R.J. The Chemistry of Chloroformates. Chem. Rev. 1964, 64, 645–687. [Google Scholar] [CrossRef]

- Kevill, D.N. Chloroformate Esters and Related Compounds. In The Chemistry of the Functional Groups: The Chemistry of Acyl Halides; Patai, S., Ed.; Wiley: New York, NY, USA, 1972; pp. 381–453. [Google Scholar]

- Digenis, G.A.; Agha, B.J.; Tsuji, K.; Kato, M.; Shinogi, M. Peptidyl carbamates incorporating amino acid isosteres as novel elastase inhibitors. J. Med. Chem. 1986, 29, 1468–1476. [Google Scholar] [CrossRef] [PubMed]

- Parrish, J.P.; Salvatore, R.N.; Jung, K.W. Perspectives of alkyl carbonates in organic synthesis. Tetrahedron 2000, 56, 8207–8237. [Google Scholar] [CrossRef]

- Ryan, B.; Pelto, R.B.; Pratt, R.F. Kinetics and Mechanism of Inhibition of a Serine-Lactamase by O-Aryloxycarbonyl Hydroxamates. Biochemistry 2008, 47, 12037–12046. [Google Scholar]

- Banerjee, S.S.; Aher, N.; Patel, R.; Khandare, J. Poly(ethylene glycol)-prodrug conjugates: Concepts, design, and application. J. Drug Deliv. 2012, 2012, 103973. [Google Scholar] [CrossRef] [Green Version]

- Kevill, D.N.; Kyong, J.B.; Weitl, F.L. Solvolysis-Decomposition of 1-Adamantyl Chloroformate: Evidence for Ion Pair Return in 1-Adamantyl Chloride Solvolysis. J. Org. Chem. 1990, 55, 4304–4311. [Google Scholar] [CrossRef]

- Grunwald, E.; Winstein, S. The Correlation of Solvolysis Rates. J. Am. Chem. Soc. 1948, 70, 846–854. [Google Scholar] [CrossRef]

- Winstein, S.; Grunwald, E.; Jones, H.W. The Correlation of Solvolysis Rates and the Classification of Solvolysis Reactions into Mechanistic Categories. J. Am. Chem. Soc. 1951, 73, 2700–2707. [Google Scholar] [CrossRef]

- Moss, R.A.; Tian, J.; Sauers, R.R. Solvent-Equilibrated Homoadamantyl Chloride Ion Pairs from Chloroformate or Oxachlorocarbene Fragmentations. Org. Lett. 2004, 6, 4293–4296. [Google Scholar] [CrossRef]

- Kevill, D.N.; Kyong, J.B. Multiple Pathways in the Solvolysis of 1-Adamantyl Fluoroformate. J. Org. Chem. 1992, 57, 258–265. [Google Scholar] [CrossRef]

- Queen, A.; Nour, T.A.; Bock, E. Electric Moments, Sulfur Bonding, and Conformations of Substituted Thiochloroformate Esters in Benzene. Can. J. Chem. 1969, 47, 343–348. [Google Scholar] [CrossRef] [Green Version]

- Queen, A.; Nour, T.A.; Paddon-Row, M.N.; Preston, K. Kinetics and Hydrolysis of Thiochloroformate Esters in Pure Water. Can. J. Chem. 1970, 48, 522–527. [Google Scholar] [CrossRef]

- McKinnon, D.M.; Queen, A. Kinetics and Mechanism for the Hydrolysis of Chlorothionoformate and Chlorodithioformate Esters in Water and Aqueous Acetone. Can. J. Chem. 1972, 50, 1401–1406. [Google Scholar] [CrossRef]

- D’Souza, M.J.; Hailey, S.M.; Kevill, D.N. Use of Empirical Correlations to Determine Solvent Effects in the Solvolysis of S-Methyl Chlorothioformate. Int. J. Mol. Sci. 2010, 11, 2253–2266. [Google Scholar] [CrossRef]

- Kevill, D.N.; D’Souza, M.J. Concerning the Two Reaction Channels for the Solvolyses of Ethyl Chloroformate and Ethyl Chlorothioformate. J. Org. Chem. 1998, 63, 2120–2124. [Google Scholar] [CrossRef]

- Kyong, J.B.; Lee, Y.; D’Souza, M.J.; Mahon, B.P.; Kevill, D.N. Correlation of the Rates of Solvolysis of tert-Butyl Chlorothioformate and Observations Concerning Reaction Mechanism. Eur. J. Chem. 2012, 3, 267–272. [Google Scholar] [CrossRef] [Green Version]

- Kevill, D.N.; D’Souza, M.J. Dual Pathways in the Solvolyses of Phenyl Chlorothioformate. J. Org. Chem. 1997, 62, 7869–7871. [Google Scholar] [CrossRef]

- D’Souza, M.J.; Mahon, B.P.; Kevill, D.N. Analysis of the Nucleophilic Solvation Effects in Isopropyl Chlorothioformate Solvolysis. Int. J. Mol. Sci. 2010, 11, 2597–2611. [Google Scholar] [CrossRef] [Green Version]

- Frisch, M.J.; Trucks, G.W.; Schlegel, H.B.; Scuseria, G.E.; Robb, M.A.; Cheeseman, J.R.; Montgomery, J.A., Jr.; Vreven, T.; Kudin, K.N.; Burant, J.C.; et al. Gaussian 03; revision C.02; Gaussian, Inc.: Wallingford, CT, USA, 2004. [Google Scholar]

- Kevill, D.N.; Anderson, S.W. An improved scale of solvent nucleophilicity based on the solvolysis of the S-methyldibenzothiophenium ion. J. Org. Chem. 1991, 56, 1845–1850. [Google Scholar] [CrossRef]

- Kevill, D.N.; D’Souza, M.J. Additional YCl Values and the Correlation of the Specific Rates of Solvolysis of tert-Butyl Chloride in Terms of NT and YCl Scales. J. Chem. Res. Synop. 1993, 174–175. [Google Scholar]

- Schadt, F.L.; Bentley, T.W.; Schleyer, P.v.R. The SN2-SN1 spectrum. 2. Quantitative treatments of nucleophilic solvent assistance. A scale of solvent nucleophilicities. J. Am. Chem. Soc. 1976, 98, 7667–7674. [Google Scholar] [CrossRef]

- Bentley, T.W.; Carter, G.E. The SN2-SN1 spectrum. 4. The SN2 (intermediate) mechanism for solvolyses of tert-butyl chloride: A revised Y scale of solvent ionizing power based on solvolyses of 1-adamantyl chloride. J. Am. Chem. Soc. 1982, 104, 5741–5747. [Google Scholar] [CrossRef]

- Bentley, T.W.; Llewellyn, G. YX Scales of Solvent Ionizing Power. Prog. Phys. Org. Chem. 1990, 17, 121–158. [Google Scholar]

- Kyong, J.B.; Suk, Y.J.; Kevill, D.N. Solvolysis-Decomposition of 2-Adamantyl Chloroformate: Evidence for Two Reaction Pathways. J. Org. Chem. 2003, 68, 3425–3432. [Google Scholar] [CrossRef]

- Lee, Y.W.; Seong, M.H.; Kyong, J.B.; Kevill, D.N. Correlation of the Rates of Solvolysis of t-Butyl Fluoroformate Using the Extended Grunwald-Winstein Equation. Bull. Korean Chem. Soc. 2010, 31, 3366–3370. [Google Scholar] [CrossRef] [Green Version]

- Kyong, J.B.; Won, H.; Kevill, D.N. Application of the Extended Grunwald-Winstein Equation to Solvolyses of n-Propyl Chloroformate. Int. J. Mol. Sci. 2005, 6, 87–96. [Google Scholar] [CrossRef]

- Kyong, J.B.; Park, B.C.; Kim, C.B.; Kevill, D.N. Rate and Product Studies with Benzyl and p-Nitrobenzyl Chloroformates under Solvolytic Conditions. J. Org. Chem. 2000, 65, 8051–8058. [Google Scholar] [CrossRef]

- D’Souza, M.J.; Kevill, D.N. Influence of Sulfur for Oxygen Substitution in the Solvolytic Reactions of Chloroformate Esters and Related Compounds. Int. J. Mol. Sci. 2014, 15, 18310–18332. [Google Scholar] [CrossRef] [Green Version]

- Gordon, I.M.; Maskill, H. Solvolysis of substituted benzyl azoxyarenesulfonates: Characterisation of the transition state and the selectivity of benzylic intermediates in 50% aqueous 2,2,2-trifluoroethanol. J. Chem. Soc. Perkin Trans. 2 2001, 11, 2059–2062. [Google Scholar] [CrossRef]

| Solvent (%) b | 104 kexp (s−1) c | j | k | NT d | YCl e |

|---|---|---|---|---|---|

| 100 MeOH f | 2.11 ± 0.05 | - | - | 0.17 | −1.17 |

| 90 MeOH | 11.5 ± 0.1 | - | - | −0.01 | −0.18 |

| 80 MeOH | 40.8 ± 0.1 | - | - | −0.06 | 0.67 |

| 70 MeOH | 209 ± 4 | - | - | −0.40 | 1.46 |

| 100 EtOH g | 0.116 ± 0.003 | 0.0411 | 0.0749 | 0.37 | −2.52 |

| 90 EtOH | 1.36 ± 0.02 | 0.899 | 0.461 | 0.16 | −0.94 |

| 80 EtOH | 7.62 ± 0.04 | 5.95 | 1.67 | 0.00 | 0.00 |

| 70 EtOH | 27.6 ± 0.2 | 23.3 | 4.28 | −0.20 | 0.78 |

| 60 EtOH | 101 ± 2 | 88.7 | 12.3 | −0.38 | 1.38 |

| 50 EtOH | 139 ± 7 | 128 | 11.3 | −0.58 | 2.02 |

| 90 Me2CO | 0.0550 ± 0.001 | - | - | −0.35 | −2.22 |

| 80 Me2CO | 1.20 ± 0.03 | 0.971 | 0.229 | −0.37 | −0.83 |

| 70 Me2CO | 9.01 ± 0.06 | 7.73 | 1.28 | −0.42 | 0.17 |

| 97 TFE | 5557 h | - | - | −3.30 | 2.83 |

| 90 TFE | 5115 h | 4803 | 311 | −2.55 | 2.85 |

| 70 TFE | 1449 h | 1343 | 107 | −1.98 | 2.96 |

| 80T-20E i | 456 ± 2 | 385 | 71.1 | −1.76 | 1.89 |

| 60T-40E i | 42.3 ± 0.6 | 35.5 | 6.81 | −0.94 | 0.63 |

| 40T-60E i | 5.01 ± 0.07 | 3.68 | 1.34 | −0.34 | −0.48 |

| 20T-80E i | 0.724 ± 0.009 | 0.439 | 0.285 | 0.08 | −1.42 |

| Solvent (%) a | Temp. (°C) | 104 k (s−1) | ΔH≠298.15, Kcal mol−1 b | ΔS≠298.15, cal mol−1 K−1 b |

|---|---|---|---|---|

| 100 MeOH | 25.0 | 2.11 ± 0.01 c | 20.9 ± 0.4 | −5.1 ± 1.4 |

| 45.0 | 21.6 ± 0.3 | |||

| 50.0 | 36.9 ± 0.6 | |||

| 55.0 | 56.6 ± 0.3 | |||

| 100 EtOH | 25.0 | 0.116 ± 0.003 c | 23.5 ± 0.2 | −2.2 ± 0.7 |

| 45.0 | 1.57 ± 0.01 | |||

| 50.0 | 2.76 ± 0.03 | |||

| 55.0 | 4.73 ± 0.01 | |||

| 80 EtOH | 25.0 | 7.62 ± 0.01 c | 20.0 ± 0.1 | −5.8 ± 0.4 |

| 35.0 | 23.8 ± 0.4 | |||

| 40.0 | 40.8 ± 0.5 | |||

| 45.0 | 67.5 ± 0.5 | |||

| i-PrOH | 25.0 d | 0.013 | 24.4 ± 0.2 | −3.7 ± 0.6 |

| 60.0 | 1.05 ± 0.03 | |||

| 65.0 | 1.85 ± 0.03 | |||

| 70.0 | 3.16 ± 0.03 | |||

| 97 TFE | −10.0 | 163 ± 5.3 | ||

| −5.0 | 327 ± 4.4 | |||

| 5.0 | 825 ± 0.6 | |||

| 25.0 d | 5557 | 14.9 ± 1.5 | −9.8 ± 5.0 | |

| 90 TFE | −5.0 | 201 ± 7 | ||

| 0.0 | 344 ± 11 | |||

| 5.0 | 642 ± 64 | |||

| 25.0 d | 5115 | 16.6 ± 0.8 | −4.1 ± 2.8 | |

| 70 TFE | −5.0 | 65.0 ± 3 | ||

| 0.0 | 116 ± 4 | |||

| 5.0 | 201 ± 0.4 | |||

| 10.0 | 331 ± 10 | |||

| 25.0 d | 1449 | 15.8 ± 0.2 | −9.4 ± 0.6 |

| Solvent (%) a | 1-AdOTFE | 1-AdOEt | 1-AdCl | 1-AdSH | 1-AdOH | 1-AdSCO2Et | SS-D c | d |

|---|---|---|---|---|---|---|---|---|

| 3.9 b | 4.0 b | 4.8 b | 6.1 b | 9.7 b | 33.0 b | |||

| 100 EtOH | 28.326 | 7.0309 | 64.644 | |||||

| 90 EtOH | 34.221 | 10.165 | 10.250 | 21.680 | 23.683 | 0.45 | 0.81 | |

| 80 EtOH | 27.268 | 9.3617 | 12.399 | 41.512 | 9.4608 | 0.44 | 0.60 | |

| 70 EtOH | 22.569 | 8.8448 | 11.020 | 53.082 | 4.4833 | 0.50 | 0.55 | |

| 60 EtOH | 17.789 | 8.0432 | 9.7912 | 61.946 | 2.4305 | 0.52 | 0.52 | |

| 50 EtOH | 14.692 | 8.0376 | 8.1526 | 69.118 | trace | 0.58 | ||

| 80 Me2CO | 8.6036 | 19.054 | 72.343 | |||||

| 70 Me2CO | 7.9451 | 14.179 | 77.876 | |||||

| 60 Me2CO | 7.6772 | 11.175 | 81.148 | |||||

| 100 TFE | 83.983 | 13.521 | 2.4967 | |||||

| 90 TFE | 50.511 | 10.631 | 5.9244 | 32.934 | 0.78 | |||

| 70 TFE | 37.030 | 9.3801 | 7.1622 | 46.428 | 1.57 | |||

| 50 TFE | 25.675 | 11.252 | 7.3537 | 55.719 | 2.12 |

| Solvent (%) a | 1-AdOEt | 1-AdOTFE | 1-AdCl | 1-AdOH | 1-AdSCO2TFE | 1-AdSCO2Et | SS-D c | d |

|---|---|---|---|---|---|---|---|---|

| 13.6 b | 14.7 b | 15.9 b | 26.0 b | 40.4 b | 53.0 b | |||

| 80T-20E e | 5.5971 | 67.920 | 10.018 | 3.2089 | 15.382 | trace | ||

| 60T-40E e | 18.604 | 51.805 | 11.266 | 2.6036 | 10.155 | 5.5678 | 2.58 | 1.97 |

| 40T-60E e | 30.945 | 31.145 | 9.2791 | 2.7028 | 9.5517 | 16.379 | 2.10 | 1.41 |

| 20T-80E e | 38.671 | 11.240 | 9.5095 | 2.1470 | trace | 38.433 | 1.62 |

| % Composition as a Function of X in 1-AdX b | 104 k (s−1) c | |||

|---|---|---|---|---|

| [Salt], M | –OEt | –Cl | –OCO2Et | |

| 0.00 | 28.552 | 7.0869 | 64.361 | 0.116 ± 0.003 |

| 0.01 | 32.914 | 7.7458 | 59.340 | 0.158 ± 0.004 |

| 0.02 | 34.499 | 8.0563 | 57.445 | 0.159 ± 0.005 |

| 0.04 | 40.509 | 9.3071 | 50.484 | 0.185 ± 0.003 |

| 0.08 | 40.309 | 9.2941 | 50.397 | 0.202 ± 0.006 |

| Substrate | n a | l b | m b | c b | R c | Mechanism v |

|---|---|---|---|---|---|---|

| 1-AdSCOCl (1) d | 20 k | - | 0.84 ± 0.03 | 0.11 ± 0.06 | 0.985 | I |

| 20 k | −0.15 ± 0.09 (0.087) v | 0.76 ± 0.05 | 0.03 ± 0.07 | 0.986 | I | |

| 14 l | - | 0.86 ± 0.04 | 0.03 ± 0.06 | 0.989 | I | |

| 14 m | - | 0.64 ± 0.05 | 0.04 ± 0.08 | 0.966 | I | |

| 1-AdOCOCl (2) e | 15 | - | 0.47 ± 0.03 | 0.03 ± 0.05 | 0.985 | I |

| 1-AdOCOF (3) f | 10 n | 2.78 ± 0.21 | 1.01 ± 0.06 | 0.09 ± 0.16 | 0.987 | A–E |

| 16 o | - | 0.70 ± 0.01 | −0.02 ± 0.05 | 0.999 | I | |

| i-PrSCOCl (4) g | 19 p | 0.38 ± 0.11 | 0.72 ± 0.09 | −0.28 ± 0.10 | 0.961 | I |

| t-BuSCOCl (5) h | 19 q | - | 0.73 ± 0.03 | −0.10 ± 0.05 | 0.988 | I |

| 19 r | 0.13 ± 0.09 (0.17) u | 0.80 ± 0.06 | −0.03 ± 0.07 | 0.989 | I | |

| MeSCOCl i | 12 n | 1.48 ± 0.18 | 0.44 ± 0.06 | 0.08 ± 0.08 | 0.949 | A–E |

| 8 s | 0.79 ± 0.06 | 0.85 ± 0.07 | −0.27 ± 0.08 | 0.987 | I | |

| EtSCOCl j | 19 t | 0.66 ± 0.08 | 0.93 ± 0.07 | −0.16 ± 0.11 | 0.961 | I |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, K.H.; Seong, M.H.; Kyong, J.B.; Kevill, D.N. Rate and Product Studies with 1-Adamantyl Chlorothioformate under Solvolytic Conditions. Int. J. Mol. Sci. 2021, 22, 7394. https://doi.org/10.3390/ijms22147394

Park KH, Seong MH, Kyong JB, Kevill DN. Rate and Product Studies with 1-Adamantyl Chlorothioformate under Solvolytic Conditions. International Journal of Molecular Sciences. 2021; 22(14):7394. https://doi.org/10.3390/ijms22147394

Chicago/Turabian StylePark, Kyoung Ho, Mi Hye Seong, Jin Burm Kyong, and Dennis N. Kevill. 2021. "Rate and Product Studies with 1-Adamantyl Chlorothioformate under Solvolytic Conditions" International Journal of Molecular Sciences 22, no. 14: 7394. https://doi.org/10.3390/ijms22147394

APA StylePark, K. H., Seong, M. H., Kyong, J. B., & Kevill, D. N. (2021). Rate and Product Studies with 1-Adamantyl Chlorothioformate under Solvolytic Conditions. International Journal of Molecular Sciences, 22(14), 7394. https://doi.org/10.3390/ijms22147394