Precious-Metal-Decorated Chromium(IV) Oxide Nanowires as Efficient Catalysts for 2,4-Toluenediamine Synthesis

Abstract

1. Introduction

2. Results and Discussion

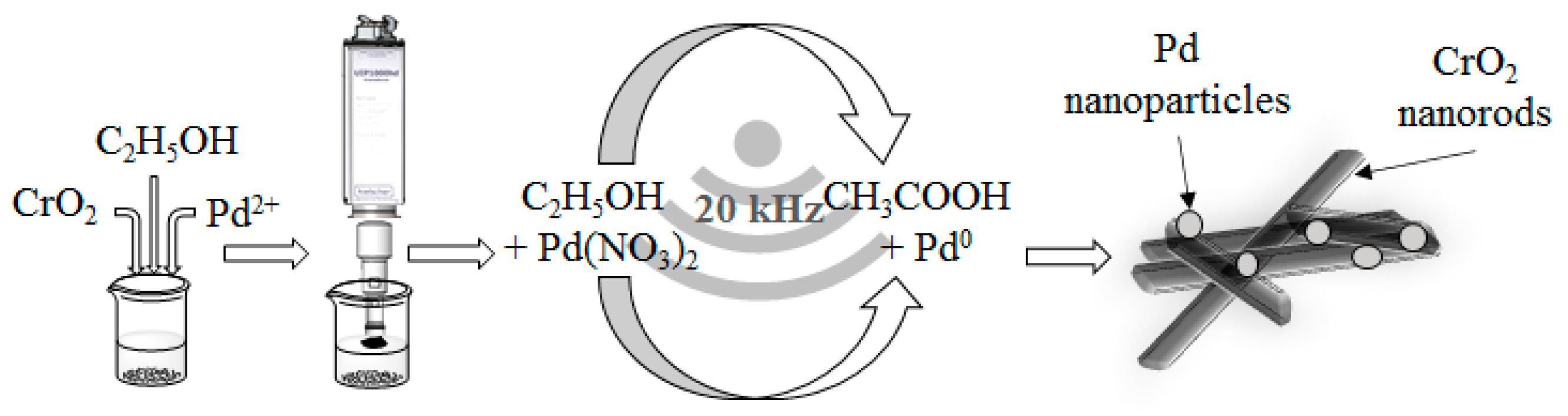

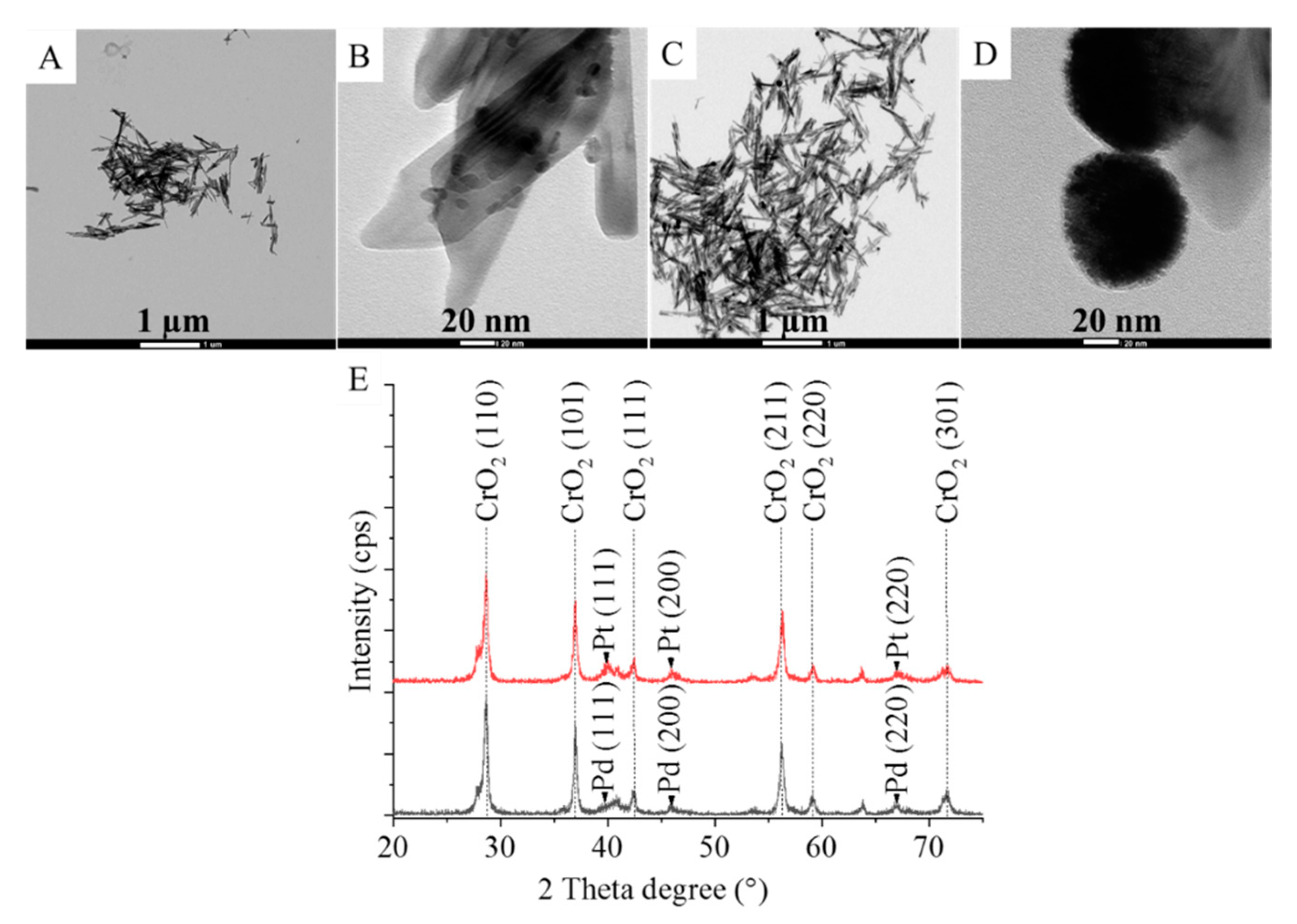

2.1. Preparation and Characterization of the Pd- and Pt-Decorated Chromium(IV) Oxide Nanowires

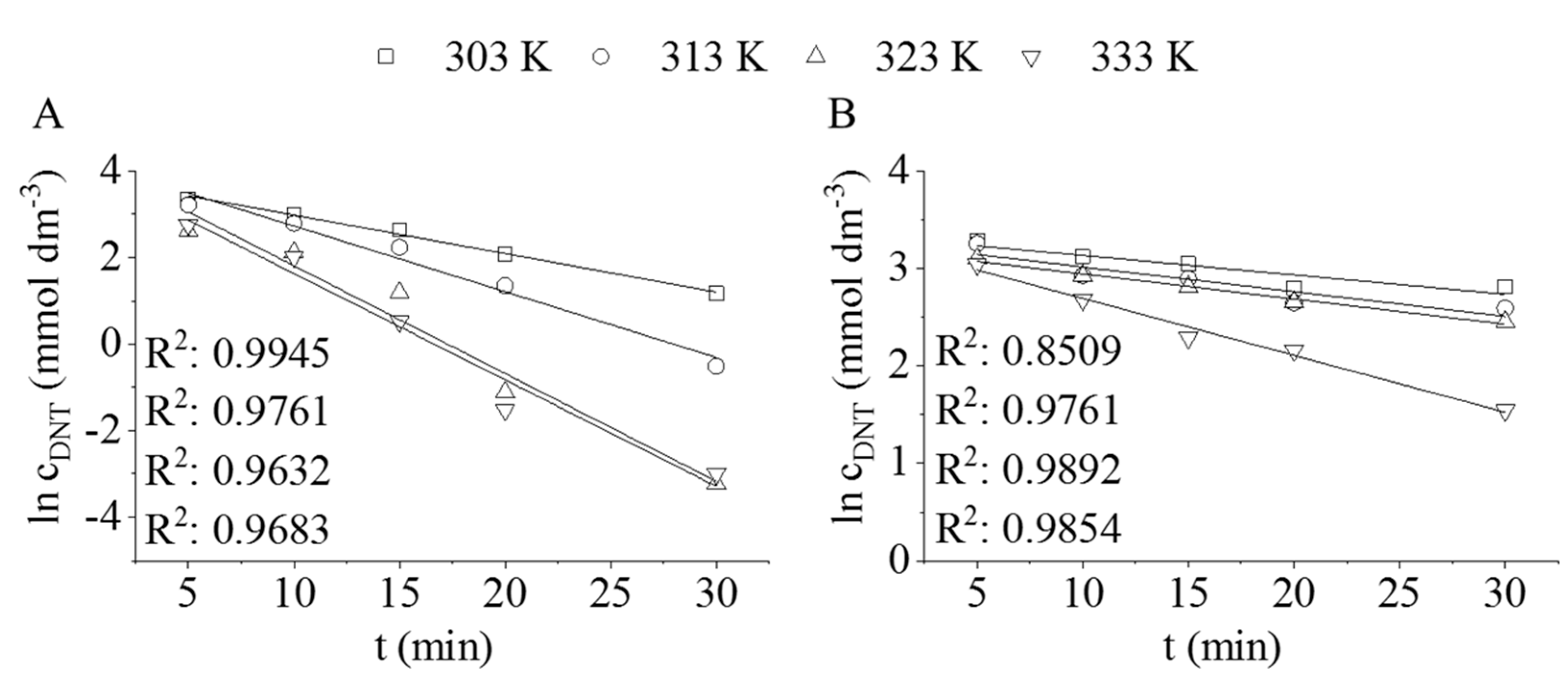

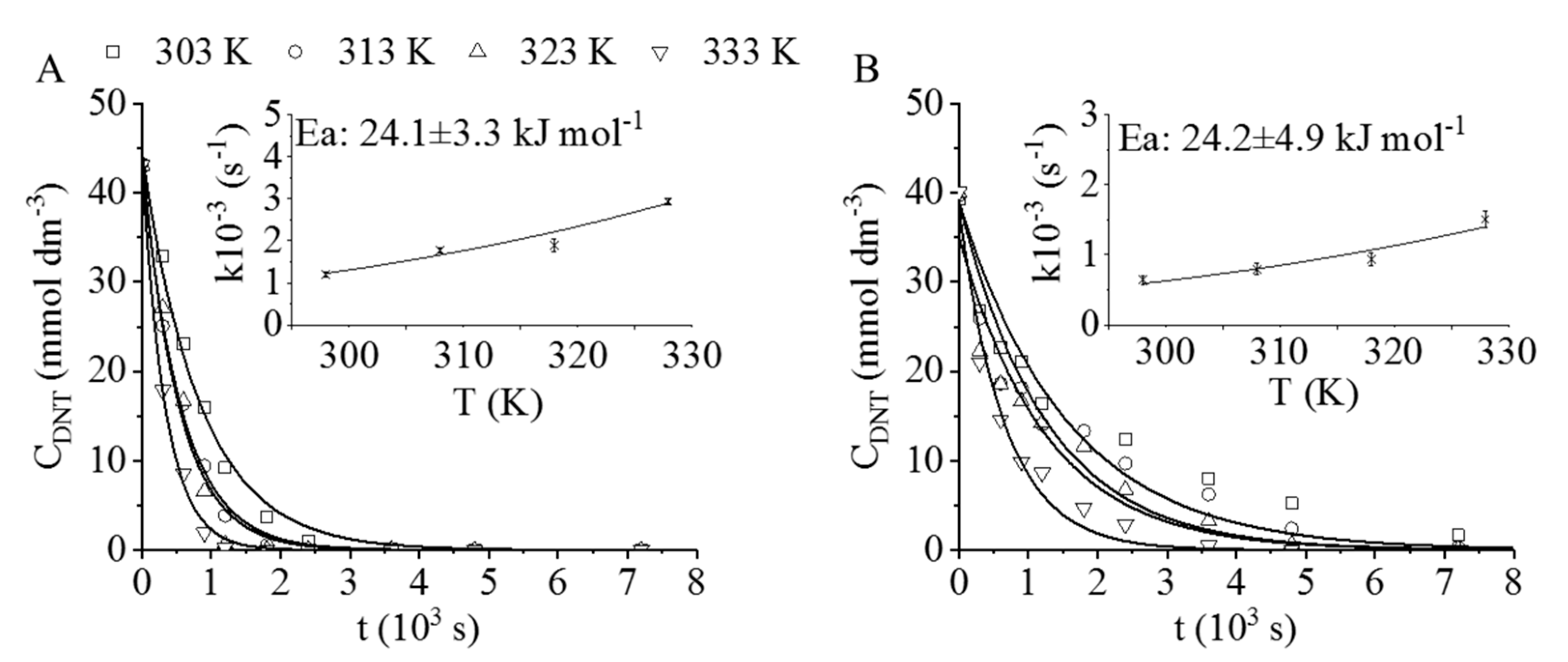

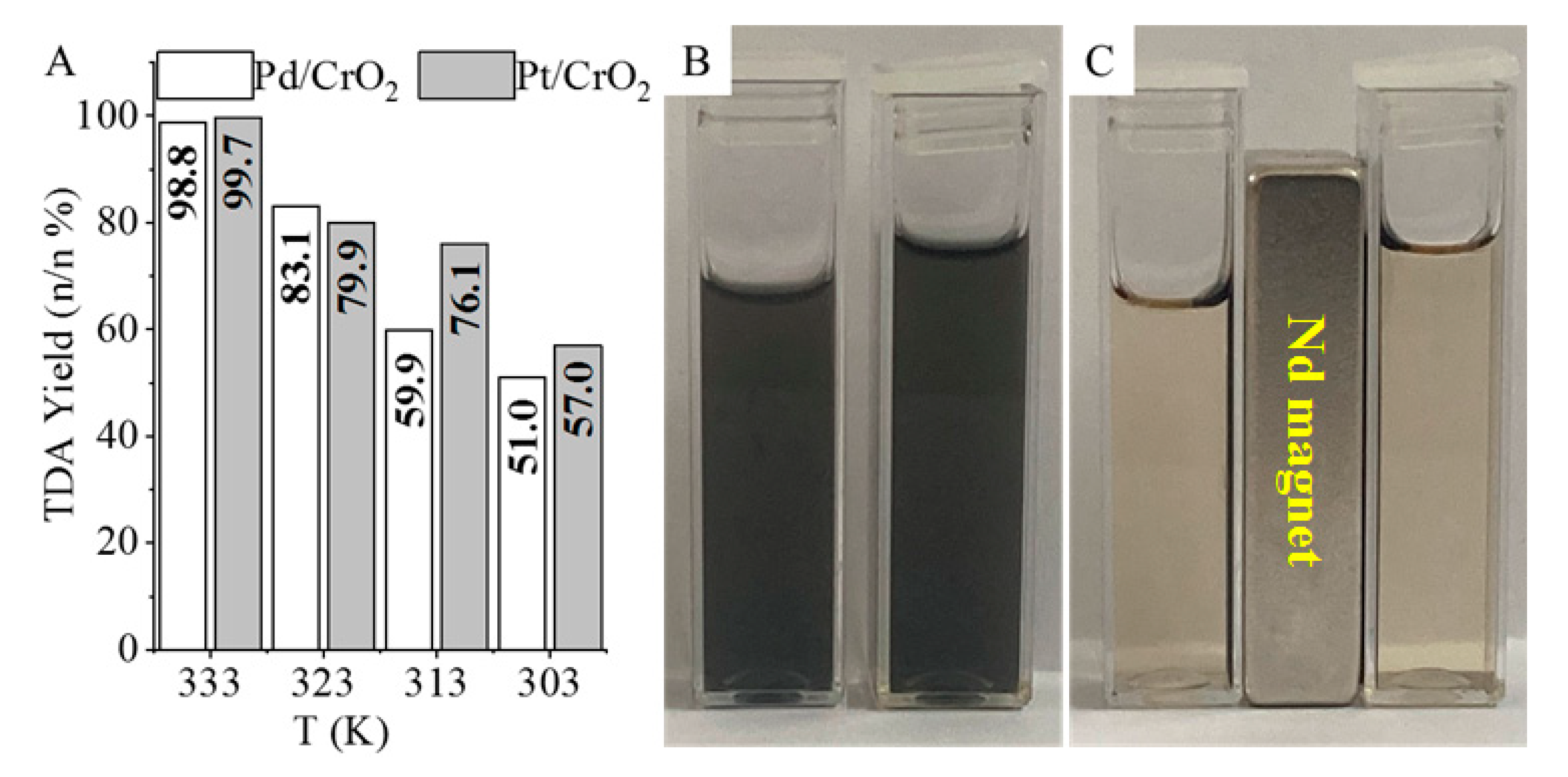

2.2. Comparison of the Catalytic Activity of the Synthesized Pd and Pt Decorated Chromium(IV) Oxide Nanowires

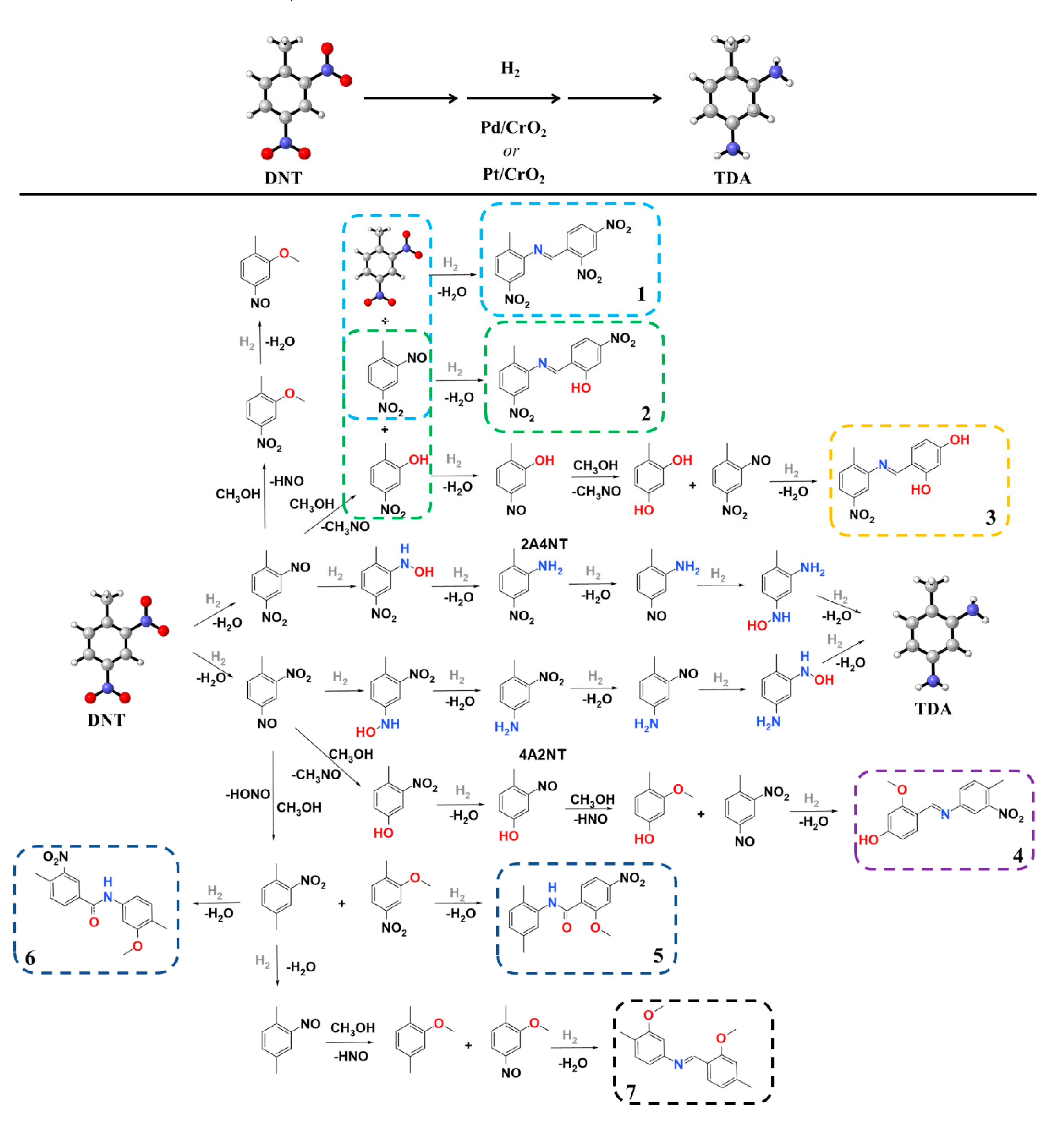

2.3. Possible Mechanism for the Hydrogenation

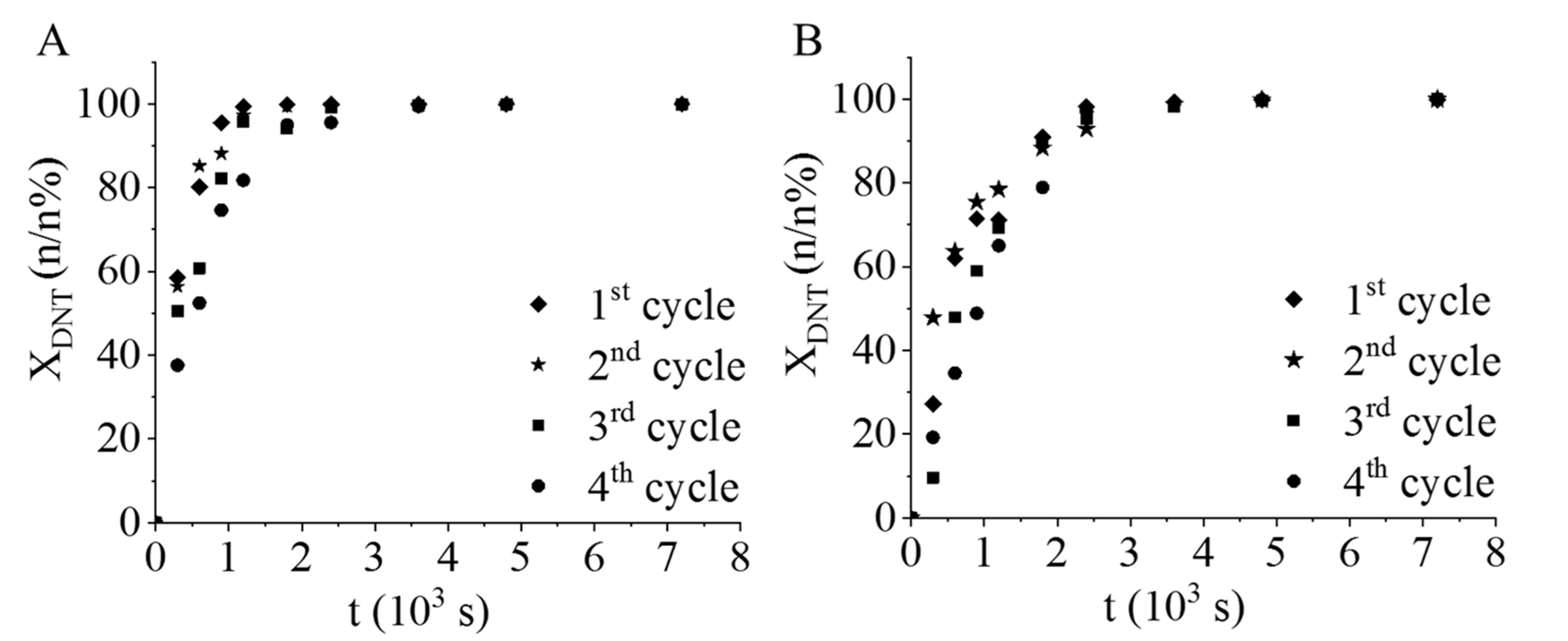

2.4. Turnover Number and Reusability

3. Materials and Methods

3.1. Materials

3.2. The Preparation of Pd/CrO2 and Pt/CrO2 Catalysts

3.3. Characterization Technics

3.4. Catalytic Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Neri, G.; Musolino, M.G.; Milone, C.; Visco, A.M.; Di Mario, A. Mechanism of 2,4-dinitrotoluene hydrogenation over Pd/C. J. Mol. Catal. A Chem. 1995, 95, 235–241. [Google Scholar] [CrossRef]

- Neri, G.; Musolino, M.G.; Rotondo, E.; Galvagno, S. Catalytic hydrogenation of 2,4-dinitrotoluene over a Pd/C catalyst: Identification of 2-(hydroxyamino)-4-nitrotoluene (2HA4NT) as reaction intermediate. J. Mol. Catal. A Chem. 1996, 111, 257–260. [Google Scholar] [CrossRef]

- Musolino, M.G.; Neri, G.; Milone, C.; Minicò, S.; Galvagno, S. Liquid chromatographic separation of intermediates of the catalytic hydrogenation of 2,4-dinitrotoluene. J. Chromatogr. A 1998, 818, 123–126. [Google Scholar] [CrossRef]

- Neri, G.; Musolino, M.G.; Milone, C.; Pietropaolo, D.; Galvagno, S. Particle size effect in the catalytic hydrogenation of 2,4-dinitrotoluene over Pd/C catalysts. Appl. Catal. A Gen. 2001, 208, 307–316. [Google Scholar] [CrossRef]

- Neri, G.; Rizzo, G.; Milone, C.; Galvagno, S.; Musolino, M.G.; Capannelli, G. Microstructural characterization of doped-Pd/C catalysts for the selective hydrogenation of 2,4-dinitrotoluene to arylhydroxylamines. Appl. Catal. A Gen. 2003, 249, 303–311. [Google Scholar] [CrossRef]

- Saboktakin, M.R.; Tabatabaie, R.M.; Maharramov, A.; Ramazanov, M.A. Hydrogenation of 2,4-Dinitrotoluene to 2,4-Diaminotoluene over Platinum Nanoparticles in a High-Pressure Slurry Reactor. Synth. Commun. 2011, 41, 1455–1463. [Google Scholar] [CrossRef]

- Pinna, F.; Selva, M.; Signoretto, M.; Strukul, G.; Boccuzzi, F.; Benedetti, A.; Canton, P.; Fagherazzi, G. Pd-Fe/SiO2 Catalysts in the Hydrogenation of 2,4-Dinitrotoluene. J. Catal. 1994, 150, 356–367. [Google Scholar] [CrossRef]

- Benedetti, A.; Fagherazzi, G.; Pinna, F.; Rampazzo, G.; Selva, M.; Strukul, G. The influence of a second metal component (Cu, Sn, Fe) on Pd/SiO2 activity in the hydrogenation of 2,4-dinitrotoluene. Catal. Lett. 1991, 10, 215–223. [Google Scholar] [CrossRef]

- Molga, E.J.; Westerterp, K.R. Kinetics of the hydrogenation of 2,4-dinitrotoluene over a palladium on alumina catalyst. Chem. Eng. Sci. 1992, 47, 1733–1749. [Google Scholar] [CrossRef]

- Rajashekharam, M.V.; Nikalje, D.D.; Jaganathan, R.; Chaudhari, R.V. Hydrogenation of 2,4-Dinitrotoluene Using a Pd/Al2O3 Catalyst in a Slurry Reactor: A Molecular Level Approach to Kinetic Modeling and Nonisothermal Effects. Ind. Eng. Chem. Res. 1997, 36, 592–604. [Google Scholar] [CrossRef]

- Tsang, S.C.; Caps, V.R.; Paraskevas, I.; Chadwick, D.; Thompsett, D. Magnetically Separable, Carbon-Supported Nanocatalysts for the Manufacture of Fine Chemicals. Angew. Chem. 2004, 116, 5763–5767. [Google Scholar] [CrossRef]

- Rossi, L.M.; Costa, N.J.S.; Silva, F.P.; Wojcieszak, R. Magnetic nanomaterials in catalysis: Advanced catalysts for magnetic separation and beyond. Green Chem. 2014, 16, 2906. [Google Scholar] [CrossRef]

- Kainz, Q.M.; Linhardt, R.; Grass, R.N.; Vilé, G.; Pérez-Ramírez, J.; Stark, W.J.; Reiser, O. Palladium Nanoparticles Supported on Magnetic Carbon-Coated Cobalt Nanobeads: Highly Active and Recyclable Catalysts for Alkene Hydrogenation. Adv. Funct. Mater. 2014, 24, 2020–2027. [Google Scholar] [CrossRef]

- Stadler, L.; Homafar, M.; Hartl, A.; Najafishirtari, S.; Colombo, M.; Zboril, R.; Martin, P.; Gawande, M.B.; Zhi, J.; Reiser, O. Recyclable Magnetic Microporous Organic Polymer (MOP) Encapsulated with Palladium Nanoparticles and Co/C Nanobeads for Hydrogenation Reactions. ACS Sustain. Chem. Eng. 2018, 7, 2388–2399. [Google Scholar] [CrossRef]

- Purohit, G.; Rawat, D.S.; Reiser, O. Palladium Nanocatalysts Encapsulated on Porous Silica @ Magnetic Carbon-Coated Cobalt Nanoparticles for Sustainable Hydrogenation of Nitroarenes, Alkenes and Alkynes. ChemCatChem 2019, 12, 569–575. [Google Scholar] [CrossRef]

- Ye, L.; Liu, X.; Lu, Y. A highly controllable, effective, and recyclable magnetic-nanoparticle-supported palladium catalyst for the Suzuki–Miyaura cross-coupling reaction. J. Catal. 2021, 397, 36–43. [Google Scholar] [CrossRef]

- Bogdal, D.; Lukasiewicz, M.; Pielichowski, J.; Miciak, A.; Bednarz, S. Microwave-assisted oxidation of alcohols using Magtrieve™. Tetrahedron 2003, 59, 649–653. [Google Scholar] [CrossRef]

- Ding, Y.; Yuan, C.; Wang, Z.; Liu, S.; Shi, J.; Xiong, R.; Yin, D.; Lu, Z. Improving thermostability of CrO2 thin films by doping with Sn. Appl. Phys. Lett. 2014, 105, 092401. [Google Scholar] [CrossRef]

- West, K.G.; Osofsky, M.; Mazin, I.I.; Dao, N.N.H.; Wolf, S.A.; Lu, J. Magnetic properties and spin polarization of Ru doped half metallic CrO2. Appl. Phys. Lett. 2015, 107, 012402. [Google Scholar] [CrossRef]

- Solovyev, I.V.; Kashin, I.V.; Mazurenko, V.V. Mechanisms and origins of half-metallic ferromagnetism in CrO2. Phys. Rev. B 2015, 92, 9664–9670. [Google Scholar] [CrossRef]

- Duarte, A.C.; Franco, N.; Viana, A.S.; Polushkin, N.I.; Silvestre, A.J.; Conde, O. Argon assisted chemical vapor deposition of CrO2: An efficient process leading to high quality epitaxial films. J. Alloy. Compd. 2016, 684, 98–104. [Google Scholar] [CrossRef]

- Anger, G.; Halstenberg, J.; Hochgeschwender, K.; Scherhag, C.; Korallus, U.; Knopf, H.; Schmidt, P.; Ohlinger, M. Chromium Compounds. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005; pp. 157–191. [Google Scholar]

- Ko, K.-Y.; Kim, J.-Y. Generation of Diphenyldiazomethane by Oxidation of Benzophenone Hydrazone with Magtrieve TM. Bull. Korean Chem. Soc. 1999, 20, 771–772. [Google Scholar]

- Wan, H.; Peng, Y. Clean synthesis of azo compounds using Magtrieve™ in the ionic liquid [bmim][Br]. Mon. für Chemie Chem. Mon. 2008, 139, 909–912. [Google Scholar] [CrossRef]

- Liu, Y.-H. MagtrieveTM (CrO2): A Versatile Oxidant in Organic Synthesis. Synlett 2008, 2008, 1103–1104. [Google Scholar] [CrossRef]

- Lee, R.A.; Donald, D.S. Magtrieve™ an efficient, magnetically retrievable and recyclable oxidant. Tetrahedron Lett. 1997, 38, 3857–3860. [Google Scholar] [CrossRef]

- Few, C.S.; Williams, K.R.; Wagener, K.B. Magtrieve™: A convenient catalyst for the oxidation of alcohols. Tetrahedron Lett. 2014, 55, 4452–4454. [Google Scholar] [CrossRef]

- Prekob, Á.; Muránszky, G.; Kocserha, I.; Fiser, B.; Kristály, F.; Halasi, G.; Kónya, Z.; Viskolcz, B.; Vanyorek, L. Sonochemical Deposition of Palladium Nanoparticles Onto the Surface of N-Doped Carbon Nanotubes: A Simplified One-Step Catalyst Production Method. Catal. Lett. 2019, 150, 505–513. [Google Scholar] [CrossRef]

- Hajdu, V.; Prekob, Á.; Muránszky, G.; Kocserha, I.; Kónya, Z.; Fiser, B.; Viskolcz, B.; Vanyorek, L. Catalytic activity of maghemite supported palladium catalyst in nitrobenzene hydrogenation. React. Kinet. Mech. Catal. 2020, 129, 107–116. [Google Scholar] [CrossRef]

- Suslick, K.S. Sonochemistry. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2000. [Google Scholar]

- Feng, Q.X.; Jie, Z.J. Synthesis of Palladium Nanoparticles by A Sonochemical Method. Chin. J. Inorg. Chem. 2003, 19, 766–770. [Google Scholar]

- Qiu, X.-F.; Zhu, J.-J.; Chen, H.-Y. Controllable synthesis of nanocrystalline gold assembled whiskery structures via sonochemical route. J. Cryst. Growth 2003, 257, 378–383. [Google Scholar] [CrossRef]

- Ying, Y.; Qi-Yun, Z.; Xing-Guo, L. Reduction Process of Transition Metal Ions by Zinc Powder to Prepare Transition Metal Nanopowder. Acta Phys. Chim. Sin. 2003, 19, 436–440. [Google Scholar] [CrossRef]

- Wu, S.-H.; Chen, D.-H. Synthesis and characterization of nickel nanoparticles by hydrazine reduction in ethylene glycol. J. Colloid Interface Sci. 2003, 259, 282–286. [Google Scholar] [CrossRef]

- Wang, C.; Yang, F.; Yang, W.; Ren, L.; Zhang, Y.; Jia, X.; Zhang, L.; Li, Y. PdO nanoparticles enhancing the catalytic activity of Pd/carbon nanotubes for 4-nitrophenol reduction. RSC Adv. 2015, 5, 27526–27532. [Google Scholar] [CrossRef]

- Neri, G.; Musolino, M.G.; Milone, C.; Galvagno, S. Kinetic Modeling of 2,4-Dinitrotoluene Hydrogenation over Pd/C. Ind. Eng. Chem. Res. 2002, 34, 2226–2231. [Google Scholar] [CrossRef]

- Malyala, R.V.; Chaudhari, R.V. Hydrogenation of 2,4-Dinitrotoluene Using a Supported Ni Catalyst: Reaction Kinetics and Semibatch Slurry Reactor Modeling. Ind. Eng. Chem. Res. 1999, 38, 906–915. [Google Scholar] [CrossRef]

- Brandt, A.; RanguMagar, A.B.; Szwedo, P.; Wayland, H.A.; Parnell, C.M.; Munshi, P.; Ghosh, A. Highly economical and direct amination of sp3 carbon using low-cost nickel pincer catalyst. RSC Adv. 2021, 11, 1862–1874. [Google Scholar] [CrossRef]

- Pang, S.; Yuan, H.-K.; Wu, Y.; Shi, F. In Co@N-graphene/C Catalyzed Oxidative Amination of Toluene Derivatives. J. Mol. Catal. 2017, 31, 105–120. [Google Scholar]

| k (s−1) | Ea | ||||

|---|---|---|---|---|---|

| 303 K | 313 K | 323 K | 333 K | (kJ/mol) | |

| Pt/CrO2 | 1.2 × 10−3 ± 5.5 × 10−5 | 1.8 × 10−3 ± 5.6 × 10−5 | 1.9 × 10−3 ± 1.4 × 10−4 | 2.9 × 10−3 ± 8.6 × 10−5 | 24.1 ± 3.3 |

| Pd/CrO2 | 6.4 × 10−4 ± 7.1 × 10−5 | 7.9 × 10−4 ± 8.1 × 10−5 | 9.3 × 10−4 ± 9.4 × 10−5 | 1.5 × 10−3 ± 1.2 × 10−4 | 24.2 ± 4.9 |

| TON [molTDA/molPd/Pt] | ||||

|---|---|---|---|---|

| 303 K | 313 K | 323 K | 333 K | |

| Pt/CrO2 | 18.90 | 85.37 | 87.89 | 304.08 |

| Pd/CrO2 | 12.71 | 17.27 | 43.69 | 60.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hajdu, V.; Jakab-Nácsa, A.; Muránszky, G.; Kocserha, I.; Fiser, B.; Ferenczi, T.; Nagy, M.; Viskolcz, B.; Vanyorek, L. Precious-Metal-Decorated Chromium(IV) Oxide Nanowires as Efficient Catalysts for 2,4-Toluenediamine Synthesis. Int. J. Mol. Sci. 2021, 22, 5945. https://doi.org/10.3390/ijms22115945

Hajdu V, Jakab-Nácsa A, Muránszky G, Kocserha I, Fiser B, Ferenczi T, Nagy M, Viskolcz B, Vanyorek L. Precious-Metal-Decorated Chromium(IV) Oxide Nanowires as Efficient Catalysts for 2,4-Toluenediamine Synthesis. International Journal of Molecular Sciences. 2021; 22(11):5945. https://doi.org/10.3390/ijms22115945

Chicago/Turabian StyleHajdu, Viktória, Alexandra Jakab-Nácsa, Gábor Muránszky, István Kocserha, Béla Fiser, Tibor Ferenczi, Miklós Nagy, Béla Viskolcz, and László Vanyorek. 2021. "Precious-Metal-Decorated Chromium(IV) Oxide Nanowires as Efficient Catalysts for 2,4-Toluenediamine Synthesis" International Journal of Molecular Sciences 22, no. 11: 5945. https://doi.org/10.3390/ijms22115945

APA StyleHajdu, V., Jakab-Nácsa, A., Muránszky, G., Kocserha, I., Fiser, B., Ferenczi, T., Nagy, M., Viskolcz, B., & Vanyorek, L. (2021). Precious-Metal-Decorated Chromium(IV) Oxide Nanowires as Efficient Catalysts for 2,4-Toluenediamine Synthesis. International Journal of Molecular Sciences, 22(11), 5945. https://doi.org/10.3390/ijms22115945