Abstract

The demand for plant-based proteins has grown significantly due to their sustainability and lower environmental impact compared to animal proteins. Shifting from animal-based to plant-based diets, particularly those incorporating protein-rich legumes like beans and peas, can substantially reduce the climate footprint of food production. Underutilized legumes, which are often critical in resource-poor regions, hold immense potential for enhancing food security, nutrition, and agricultural development. Despite their importance, information about these legumes remains limited and region-specific. The shift towards plant proteins is further driven by the growing popularity of vegetarian and vegan diets, alongside mounting concerns over the environmental impacts of livestock farming. Consequently, plant proteins are increasingly favored over their animal-based counterparts in the food industry. Scientists are now exploring novel plant protein sources and developing superior-quality proteins with enhanced functional and nutritional characteristics using cutting-edge technologies. While traditional plant protein sources like wheat and soy present challenges such as allergenicity, pulses like peas, beans, chickpeas, and lentils are gaining prominence due to their agronomic and nutritional advantages. It is anticipated that ongoing research will address the existing knowledge gaps regarding the nutritional and health benefits of fodder seeds such as field bean and field pea seeds, broadening their application across diverse food industries. In this context, the present review focuses on the potential of field bean and field pea as valuable sources of food and functional ingredients. Despite their benefits, current knowledge about these crops is limited to specific geographic areas where they hold cultural or local significance.

1. Introduction

The food market and industry have changed recently due to the increased demand and investments made in new and alternative protein sources [1,2,3,4]. There is a growing interest in the development of plant-based foods due to a number of factors, including the growing global population and protein demand, social awareness of the negative environmental impacts of animal-based food production, fair food production practices, affordability, ethical and health concerns, and a desire for high-quality nutritional sources. It is now evident that a dietary shift away from animal protein is necessary for sustainability and food security [1,2,3,5,6,7,8,9,10,11,12]. By 2050, the global population is projected to reach 10 billion, with agriculture contributing up to 30% of greenhouse gas emissions [1,2,10,13]. Excessive consumption of animal-based protein is linked to non-communicable diseases like obesity, type II diabetes, heart disease, and cancer [1,3]. To address this, shifting towards sustainable, animal-free protein sources is essential [14,15,16]. It is increasingly acknowledged that producing plant crops high in protein for animal feed is frequently less sustainable and effective than consuming plant proteins directly by people. This encourages the development and exploitation of additional plant protein sources, such as pulses [9,17]. Pulses, along with cereals, pseudocereals, and nuts, are increasingly used in the food industry as sustainable protein sources [2,3,18,19,20,21]. In this context, pulses dry edible seeds of leguminous crops like peas, faba beans, lentils, chickpeas, lupins and cowpeas are rich in protein, carbohydrates, dietary fibre, fats, vitamins, and minerals [5,9,11,14]. They promote circulatory health and may help to prevent neurodegenerative diseases [14,16], cancer, and cardiovascular conditions [10]. These qualities make pulses an excellent substitute for animal protein, especially given their wide acceptance and bioaccessibility [5]. Pulses also provide valuable functional properties, including solubility, emulsification, and foaming, making them versatile in food production [14,15,16,22]. From an environmental perspective, pulses offer significant benefits; they provide and mobilise nitrogen in the soil, require minimal fertilisers, have a low carbon footprint, are water-efficient, and are cost-effective to produce [14,15,23]. Furthermore, grain legumes, beyond its nutritional value, is also a rich source of bioactive compounds that have reported health-enhancing properties. These include phenolic compounds, resistant starch, dietary fibres, non-protein amino acids (L-DOPA, GABA), and, foremost, bioactive peptides [11,21,24]. These compounds have countless useful properties like anti-inflammatory, antibacterial, antioxidant, anticarcinogenic, and antidiabetic effects [25,26]. This makes them a sustainable and nutritious protein source for the future [11].

The pulses-based protein market is primarily dominated by soy [2]. However, with rising demand, there is a need to diversify and introduce new sources, such as other pulse crops [21]. One such crop is the fava bean (Vicia faba L.), also known as the field bean, horse bean, or broad bean, and it is commonly cultivated as a food and feed for animal usage [27,28,29,30,31,32]. This cool-season annual pulse has been cultivated for thousands of years across Asia, Africa, Latin America, and the Mediterranean, yet it remains under-utilized in Western countries. Fava beans are adaptable to various climates, including colder regions [21,22,23,33]. There are different varieties based on their seed size: V. faba var. major with large broad flat seeds (mainly grown in China and South Mediterranean countries), V. faba var. equine with medium-sized seeds (mainly grown in North Africa and Middle Eastern countries), and V. faba var. minor with small and rounded seeds (generally grown in Ethiopia and North Europe) [16,27,30]. Faba bean seed size is an important trait in determining market and consumption forms. V. faba var. major is commonly used for food (either as fresh green vegetable or dry seeds). V. faba var. minor and var. equina are mostly used for animal feed [30,32].

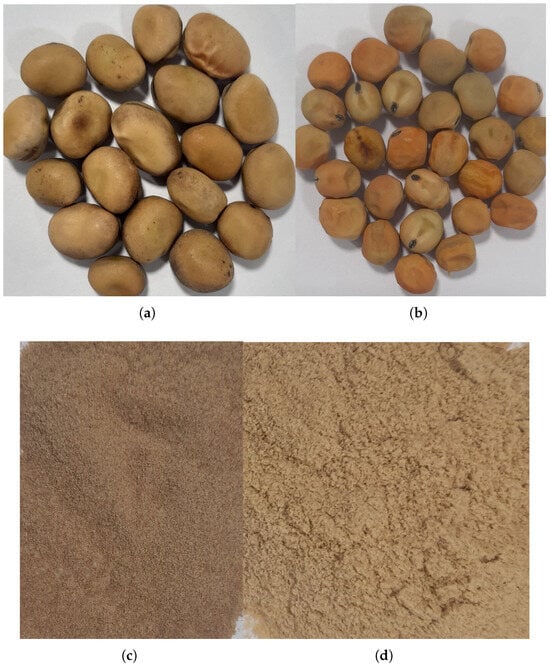

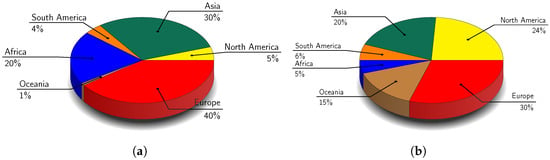

Field bean Vicia faba var. minor (Figure 1a) ranks as the seventh most important protein source amongst grain legumes globally [28,34]. Primarily used as animal feed, it outperforms peas in protein content and resistance to certain pathogens [17]. Beyond being a rich protein source, it also contains beneficial fibres, unsaturated fatty acids, vitamins, and minerals [35]. Its improved protein content and reduced antinutritional factors, such as vicine and convicine glycosides, making it increasingly valuable for food and feed production [30]. Field beans also provide health benefits due to its bioactive compounds, which have hypocholesterolemic, immunostimulatory, and anticancer effects [36]. Moreover, field beans improve soil health through nitrogen fixation by symbiotic bacteria - rhizobia, reduced dependency on nitrogen fertilisers, and lower greenhouse gas emissions [17]. Additionally, they provide functional, nutritional, health, and environmental advantages, making them a valuable crop for sustainable agriculture [28,37]. In terms of production of field bean, Europe led the globe in output, accounting for 40% of global production of field bean (Figure 2a), followed by Asia (30%) and Africa (20%) [38].

Figure 1.

Field bean and Field pea seed and protein isolate. (a) dried seeds of field bean, (b) dried seeds of field pea, (c) protein isolate of field bean, (d) protein isolate of field pea.

Figure 2.

Global production distribution of field bean and field pea by region [38]. (a) Field bean, (b) Field pea.

Peas serve dual purposes as a dietary staple and as animal feed [39,40]. For human consumption, Pisum sativum var. sativum is widely used, with seeds consumed fresh, canned, or dried [39]. In contrast, the field pea (Pisum sativum var. arvense) is primarily grown for animal feed, supplying both flour and biomass [39].

The field pea (Pisum sativum var. arvense) (Figure 1b), is a cool-season legume widely cultivated for both human and animal nutrition [40,41,42]. Its seeds are rich in protein, complex carbohydrates, and micronutrients such as vitamins (e.g., B group vitamins, vitamin A and folic acid) and minerals (e.g., calcium, iron, and zinc) but low in fats with varying proximate composition across different cultivars [19,40,41,43,44]. Field peas have higher levels of lysine and tryptophan compared to cereals, and they contain fewer trypsin inhibitors (5–20%) than soy, making them nutritionally valuable [19]. Field peas are also rich in bioactive compounds like polyphenolics, especially flavonoids, which give them potential as functional foods or health products [40,43]. Additionally, field peas are beneficial for crop rotations due to their ability to fix nitrogen in the soil [10,40]. In terms of production, Europe led the world in output, accounting for 30% of global production of field pea (Figure 2b), followed by North America (24%) and Asia (20%) [38].

An increasing interest is now emerging for the utilisation of the faba beans and field peas in the food and feed industry [45]. The need for ingredients that meet vegetarian and vegan dietary requirements, particularly more protein from environmentally sustainable sources, is being driven by the growing global market for relatively new types of plant proteins. Field beans and field peas are especially suitable as a new source of protein for food applications because of their worldwide availability, nutritional value, health benefits, hypoallergenic properties, non-GMO status, and ecological advantages [11,31,32,40]. Therefore, there is significant interest in revalorizing this untapped source of sustainable dietary protein for the production of a functional protein for the food industry [2,21,46]. Additionally, field beans and field peas are an under-researched alternative pulses with great potential as functional food ingredients [35,45].

Nevertheless, field beans and field peas protein require more research to optimize protein modification methods and as a functional ingredient in various food applications to increase industrial viability. The rationale for this review is that although there are many plant proteins, the focus will be on field beans and field peas due to their high initial protein content, which makes them suitable for protein derivatization, and their functional properties, which show promise in various of applications, particularly after modification. Research on field beans and field peas is not as common than that of other types of plant proteins, such as soy, but their combination of functionality, economically good protein content, and ease of production makes them an excellent choice for industrial application. Hence, this review aims to fill this gap by providing current insights into its overall chemical composition, bioactive compounds, protein extraction process optimization, techno-functionality, and potential for protein modification of field beans and field peas protein. Furthermore, the limitations for human consumption as well as application of field beans and field peas protein in foods and health benefits are discussed.

2. Chemical Composition of Field Bean and Field Pea

Pulse crops, including beans, lentils, and other legumes, are highly nutritious, offering a rich source of macronutrients like protein, resistant starch, and dietary fibre, as well as micronutrients such as iron, zinc, folate, and riboflavin [43,47,48]. They also contain bioactive compounds, including polyphenols and phenolic acid, which contribute to various health benefits such as reduced risks of colorectal cancer, improved gut health, lower blood cholesterol, and reduced cardiovascular disease risk [11,43,47].

These crops provide essential amino acids such as lysine, leucine, isoleucine, and phenylalanine and are particularly effective when combined with cereals for a well-balanced protein intake [9,19]. Pulse flours, enriched with vitamins, minerals, and phytochemicals, are increasingly being utilised in food innovation to improve nutritional content and address micronutrient deficiencies [9,24].

Although pulses are nutritionally reach and inexpensive, they also contain some antinutritional factors that may require processing or special preparation techniques to mitigate [9,11,47]. Nonetheless, their contribution to both human health and sustainable food systems underscores their value in diets worldwide.

The review of the approximate composition of the field bean and field pea is shown in Table 1. Field beans are nutritionally valuable legumes, rich in proteins (22.7–35.3%), carbohydrates (41.0–51.9%), dietary fibre (7.5–16.59%), unsaturated fatty acids, vitamins (notably B-complex), and minerals [24,30,36,47]. The mineral and vitamin content of the filed bean and field pea is presented in Table 2. They also contain bioactive compounds such as flavonoids, tannins, lignins, gallic acid, stillbenes, phenolic acids, and L-DOPA (L-3,4-dihydroxy phenylalanine), which offer numerous health benefits, including antioxidant, neuroprotective, anticancer (breast, renal, and colon), and anti-inflammatory effects [6,10,24,27,29]. These properties make them suitable for the development of functional foods and nutraceuticals, especially for the management of chronic diseases such as diabetes, cardiovascular disease, and even Parkinson’s disease due to their L-DOPA content [2,29,30,36]. Despite their high yield potential and growing importance as a sustainable protein source, their cultivation remains limited to specific regions (e.g., the Middle East and Europe) due to the presence of antinutritional factors (ANF) [30]. ANFs in field beans, including lectins (0.8–3.2 HU/mg), saponins (0.02–0.12 mg/g), phytic acids (1.12–12.81 mg/g), and condensed tannins (0.27–5.89 mg/g), are listed in Table 3. These substances can decrease digestibility and have negative health effects on vulnerable people, including favism and flatulence [29]. Compared to other legumes, faba beans have a higher concentration of lectins (haemagglutinins). Similarly, faba beans contain oligosaccharides (stachyose, raffinose, and verbascose) that can ferment and cause flatulence, which can cause pain in the abdomen [29]. Processing techniques like dehulling, soaking, fermenting, or cooking can mitigate these effects, enhancing their suitability for broader consumption [29]. In general, faba beans present a promising solution to meet the growing demand for sustainable, nutrient-rich food products while addressing challenges posed by antinutritional factors.

Table 1.

Proximate composition (%) of Vicia faba var. minor and Pisum sativum var. arvense seeds reported by various authors a.

Table 2.

Mineral composition and Vitamin content (mg/100 g) of Vicia faba var. minor and Pisum sativum var. arvense seed reported by various authors a.

The field pea is a significant forage crop and one of the oldest autogamous winter-season legumes. Field Peas are rich sources of nutrients, including protein (16.14–25%), carbohydrates (17.0–64.08%) in the form of starch), fat (1.5–3.0%), dietary fibre (10–20%), sugar (4–10%), vitamins, minerals (2–4%), and antioxidant components like polyphenols, ascorbic acid, phytoprostanes, and phytofurans [52,57]. Fibre content includes both insoluble (10–15%) and soluble fibre (2–9%), contributing to digestive health [40]. It has a high concentration of tryptophan and lysine amino acids and a low level of cysteine and methionine amino acids, making it a nutritious source of protein [19,53,58]. Peas also contain B group vitamins, minerals, polyphenols and non-starch carbohydrates like sucrose, oligosaccharides, and cellulose [10,40,54]. The chemical composition of field pea seeds is summarised as shown in Table 2. The most prominent mineral element present in peas is potassium (1.04%) contained in the dry and dehulled weight of the peas, followed by phosphorous (0.39%), magnesium (0.10%) and calcium (0.08%), respectively [54]. However, like other legumes the presence of antinutritional factors particularly such as tannins, proteases inhibitors, trypsin inhibitors, amylase inhibitors, lectins, polyphenolic substances, raffinose family oligosaccharides (raffinose, stachyose, and verbascose), phytic acid, haemagglutinins, glucosinolates and lectins can limit wider use of field pea seeds in both human and animal nutrition [55,59]. Antinutrients reduce the bioavailability of proteins and trace elements, that are responsible for the low protein digestibility of field pea seeds [60,61]. Variations in nutrient profiles have been linked to different cultivars, locations, several environmental/growth conditions like climate (temperature and precipitation) and soil (temperature, moisture, soil pH, and aeration), harvesting and processing methods [53,62,63]. In temperate climates, both peas and fava beans are a sustainable source of protein. Both are low in fat and offer high nutritional value, making them versatile ingredients in food and feed formulations [46]. In addition, they are known for being rich in fibre, vitamins, and substances that lower blood triglycerides and cholesterol, further contributing to cardiovascular health and the prevention of chronic diseases [16,19,30,53].

Table 3.

Antinutrient composition (mg/g) of Vicia faba var. minor and Pisum sativum var. arvense seed reported by various authors a.

Table 3.

Antinutrient composition (mg/g) of Vicia faba var. minor and Pisum sativum var. arvense seed reported by various authors a.

| Field Bean | Field Pea | |||||||

|---|---|---|---|---|---|---|---|---|

| References | ||||||||

| Antinutritional Factors | [35] | [24] | [34] | [17] | [64] | [50] | [55] | [65] |

| Total polyphenols | 10.9–19.86 | 1.4–5.0 | 2.66–2.81 | NR | 6.6–7.9 | NR | NR | NR |

| Total flavonoids | 5.25–6.96 | NR | NR | NR | NR | NR | NR | NR |

| Condensed tannin | 0.27–0.67 | NR | 1.12–1.24 | NR | 4.54–5.89 | NR | 5.24 | 0.34 |

| Phytate | NR | 1.12–12.81 | NR | NR | NR | NR | NR | 2.1 |

| Saponins | NR | 0.02–0.12 | NR | 0.02–0.04 | NR | NR | NR | NR |

| Vicine | NR | 0.40–7.01 | NR | 0.86–5.46 | NR | NR | NR | NR |

| Convicine | NR | 0.04–3.12 | NR | 0.52–4.02 | NR | NR | NR | NR |

| Raffinose | NR | 1.1–3.9 | NR | NR | NR | 1.7 | 37.5 | 10.1 |

| Stachyose | NR | 4.4–13.7 | NR | NR | NR | 8.1 | NR | 39.4 |

| Verbascose | NR | 8.0–15.0 | NR | NR | NR | 20 | NR | 39 |

| Trypsin inhibitor (TIU/mg) | NR | 1.2–23.1 | NR | NR | NR | NR | 1.1 | 0.4 |

| Lectin (HU/mg) | NR | 0.8–3.2 | NR | NR | NR | NR | NR | NR |

a Results are expressed on a dry weight basis. NR—Not Reported.

3. Extraction Process of Protein

With an increasing global demand for plant-based proteins, extracting high-quality proteins from pulses has become a research and industrial priority [10]. In addition, to increasing the protein content and reducing the impact of antinutrients, proteins are extracted to produce isolates and concentrates [66]. Protein extraction aims to isolate the protein fraction while preserving valuable coproducts such as dietary fibre, vitamins, and bioactive compounds, enhancing the overall nutritional and functional value of pulse-based foods [5,67,68]. There are two types of extraction techniques: conventional extraction methods and innovative extraction methods. A long extraction time with limited extraction selectivity, poor extraction yields, high-purity solvent cost, changes in protein techno-functional properties, low stability, an undesirable colour, high solvent evaporation, and thermolabile protein degradation are the limitations of conventional approaches [69,70]. Common extraction methods include pretreatment, solubilization, and precipitation. Solubilization typically uses aqueous or alkaline conditions to maximise yield, followed by precipitation techniques such as isoelectric precipitation or ultrafiltration to concentrate and purify proteins [71]. Eco-innovative techniques are desperately needed to maximise protein extraction output without sacrificing environmental sustainability or the functional, nutritional, and technological properties of proteins [72]. Recent advances, such as enzyme-assisted extraction and membrane filtration, have improved efficiency, protein quality, and sustainability by valorizing coproducts, including fibres and starches [73,74]. The extraction of protein isolates and concentrates employs various techniques to optimise yield and maintain structural and functional properties of the protein. Among the most widely used legume-derived protein extraction methods used are dry fractionation, wet fractionation, alkaline extraction followed by isoelectric precipitation, salt extraction, dialysis, micellar precipitation, and aqueous extraction at pH levels greater than 7. Each method has distinct advantages and limitations, influencing the quality and characteristics of the resulting protein products. For example, heat treatment or enzymatic hydrolysis may destroy essential functional properties such as solubility, emulsifying ability, and gelling properties [71,72,75,76]. Since proteins impart superior functional characteristics, their extraction and purification lead to changes in their nutritional (amino acid composition), physicochemical (surface charge, surface hydrophobicity) and functional properties (water absorption capacity, oil holding capacity and solubility). According to Badjona et al. [77], these changes ultimately impact final products when they are incorporated into foods [2,24]. The choice of the extraction method significantly impacts the proteins composition, structure, and ultimately its functional properties, such as solubility, emulsification, and gelation. These properties are crucial for the applicability of protein in various food products, including meat alternatives, dairy substitutes, and protein-enriched formulations [14,75]. Furthermore, the extraction process can influence the presence of antinutritional factors and bioactive compounds, thereby affecting the nutritional profile of the extracted proteins. Techniques such as salt extraction and mild fractionation aim to mitigate these issues while maximising protein yield [10]. Understanding these extraction techniques allows food scientists and manufacturers to tailor pea protein products to meet specific nutritional and functional requirements in the ever-evolving food industry [24].

3.1. Preprocessing: For a Better Functionality

The main goal of pretreatments is to increase protein separation efficiency during the milling and air classification processes [78]. The preprocessing of pulse seeds includes cleaning, drying, sorting, dehulling, splitting, soaking, cooking, fermentation, and germination before protein extraction [10,44,63,79]. Pre-processing procedures can greatly improve the extraction processes effectiveness and quality. The majority of pretreatments are applied in the separation of the hulls and cotyledons, which facilitates the extraction of proteins while maintaining their techno-functional qualities [10,44]. Dehulling seeds is an optional pretreatment when flour is prepared from legume seeds [22]. This process improves colour, removes bitter or astringent components, reduces antinutritional factors such as phytic acid and condensed tannins, and slightly raises protein content [10,22,80]. By removing the fibrous seed coat digestibility, palatability, textural and cooking qualities of legume flours are potentially improved [22]. For example, dehulling is generally applied to reduce antinutritional factors present in grain legumes. However, these pretreatments can also affect the colour of the produced ingredients and process performance [80]. Dehulling, where the cotyledons are physically separated from the hulls via (air) sieving, can remove polyphenols and condensed tannins since these are mostly present in the hull of the seed. Polyphenols and condensed tannins are both ANFs and contribute to “beany” flavour perception [80]. Furthermore, pretreatment techniques like soaking, boiling, or fermentation might improve the solubility and digestibility of proteins by reducing antinutritional components found in legumes, such as oligosaccharides, tannins, and phytates [78,81,82]. For instance, chickpea seeds are soaked overnight, there is a considerable decrease in tannin concentration by 53%, along with a reduction in carbohydrate content by 20–21% [83]. On the hand, soaking chickpeas seeds for (8 h, 35 °C), exhibited increases in protein content by 1.59%, crude oil content by 18.81%, and protein digestibility by 12.81%. This treatment on chickpeas also reduced antinutritional factors such as tannin and phytate by 21.68% and 22.72%. The ash and carbohydrate contents in the chickpea were also reduced by 10.29 and 1.49% [83]. Also, soaking and heat treatments can be effective at reducing ANFs and off-flavour concentrations in pulse ingredients [80]. Pulse seeds (peas, lentils, chickpeas, fava beans and common beans) that are soaked in water (1:5 w/v seeds to water) for four hours and subsequently rinsed with the same water ratio show significant decreases in lectins, and total oxalates, but no effect on phytic acid [80]. For longer soaking times, greater phytic acid reductions have been reported: after 12 h soaking (1:5 w/v seeds to water), dehulled faba and kidney beans had 32.7% and 5.66% less phytic acid, respectively [80]. Whole chickpeas soaked for 2, 8, 12 h (1:5 w/v seeds to water) had their phytic acid content decreased by 47.4%, 49.1%, and 55.7% respectively. Longer soaking times reduce phytic acid more extensively due to the activation of endogenous plant phytases [80]. A study shows that when chickpea protein underwent milling treatment, the protein content increased by 9.3%, but the overall protein yield decreased by 48.93%. Furthermore, functional attributes such as solubility, foaming capacity, and oil holding capacity increased by 1.78%, 5.12%, and 37.33%, respectively. On the other hand, water holding capacity and emulsion activity decreased by 43.39% and 1.30% [83]. Studies indicate that the protein solubility of chickpea protein increases by 6.67% and 2.79% after 24 h of germination, compared to non-germinated seeds [83]. Another interesting preprocessing method is germination, which increases antioxidant capacity and mitigates antinutritional components while simultaneously improving the nutritional content of seed storage proteins. This is accomplished during the germination phase by activating hydrolytic enzymes [14]. The water, oil holding, and foaming capacity of germinated chickpea verities increased by 21.24%, 16.39%, and 25% in Arerti and 13.88%, 22.16%, and 39.5% in Natoli as compared to native chickpea protein [83]. On the other hand cooking the pre-soaked pulses for 1 h at 95 °C decreased the concentration of all measured ANFs. Lectin was almost entirely deactivated, and phytic acid reduction varied (10–80%) [80]. The quality and functionality of grain legumes are influenced by multiple factors, including the cultivar, agronomic conditions, maturity at harvest, and post-harvest handling practices such as storage and transport. Pre-milling treatments, milling conditions for producing pulse flours, and processes used to manufacture fractionated ingredients all play critical roles in determining the quality and functionality of the resulting protein extracts [47]. The extraction process, pH, solubilization time, number of washes, ionic strength, solvation ratio, temperature, extraction apparatus, and filtration or purification methods are some of the factors that affect the effectiveness of extraction and the properties of the protein isolate [10]. Seeds can also be preconditioned, such as soaking in water, to improve yields and overall product quality. Additional pre-milling treatments may include roasting, conventional or microwave heating, cooking, germination, and micronization using high-intensity infrared radiation. Post-milling treatments, such as heat treatment of flours, can further enhance nutritional and functional properties while minimising off-flavour development [47].

Understanding the effects of preprocessing on protein extraction is crucial, as these steps can significantly influence the compositional, nutritional, and functional characteristics of the final protein powder [14]. Various studies have focused on improving the process efficacy and protein quality of pulse seeds by optimising process parameters or applying novel techniques. However, the impact of pre-processing steps, especially dehulling and milling, on the final protein isolate remains a critical area of research that warrants further investigation [47,63,80].

3.2. Dry Fractionation: Air Classification and Size Reduction

Dry fractionation methods are viewed as a more sustainable alternative for producing protein-enriched fractions from pulses [84]. The dry process can produce protein-enriched flours (<40–50% protein) or protein concentrates (60–70% protein). There are two main methods for extracting plant proteins: air classification and electrostatic separation [85]. The fractionated materials can also be used as a feedstock for wet extraction to further increase the protein content to produce a “protein isolate” [47,80]. This method primarily consists of size reduction and air classification, which allows the separation of protein-rich fractions from pulse flours based on particle size and density [41,84]. Dehulling and dry milling are preprocessing techniques that optimise protein enrichment during air classification [41]. In order to create flours with fine particles, size reduction involves milling the seeds. Different milling technologies, such as roller, hammer, stone, pin, and jet milling, are employed for this purpose [79]. Pin milling is one of these methods to reduce the size of the flour particles [10]. The flour then undergoes air classification, a process in which centrifugal and gravitational forces are used to separate the coarse starch rich fraction and the fine protein rich fraction by exploiting their differing densities and aerodynamic properties [14,36,86]. In dry milling of pulses, the protein bodies and starch granules are separated from each other and from other larger cellular structures, allowing size and density-based protein-enrichment during the subsequent air classification [44]. These techniques rely on physical properties like particle size and density to fractionate protein-rich components without the use of solvents or extensive thermal treatments [18]. Protein enrichment is usually favoured by large starch granule size since proteins are located in small protein bodies. For peas, the common size of a protein body is 2 m and the common size of a starch granule is 15 m [44]. For faba beans, the greatest proportion of a starch granule is in the range of 7–18 m but some literature reported values in the ranges from 25 to 40 m [44]. The impact of milling can influence the protein separation efficiency due to differences in the particle size distribution after milling. For instance, on pea samples protein separation efficiency is higher for the fine fractions, the protein separation efficiencies exhibited higher values for the twice milled pea samples. Regarding faba beans, the effect of milling intensity on protein separation is less pronounced and no clear conclusions can be made regarding the effect of milling intensity on protein separation efficiency of faba bean fine fraction [44]. The hardness or softness of seeds, as well as their fibre, ash, and oil contents have all been identified as factors that impact the effectiveness of protein separation. For example, a high fat content limits milling to smaller particle sizes and increases the likelihood of aggregation of flour particles, which hinders separation [41,79]. During classification, the flowability or dispersibility of the flours in the air is measured by a metric called de-agglomeration [79]. Particle-particle adhesion, high humidity and size, all affect how easily flours spread; for instance, finer flour particles would disperse more readily under low pressure. Food grade flowability aids can be used to improve air classification and dispersibility of oil-rich flours [41,79]. In dry fractionation, the inherent pH and ionic strength of the seed material can influence protein charge and interactions, thereby affecting the separation efficiency. Although dry methods do not involve adjusting these parameters directly, understanding their impact is essential. For instance, proteins exhibit minimal solubility near their isoelectric point (pI), which for faba bean and pea proteins is around pH 4.5. At this pH, proteins tend to aggregate, potentially impacting the efficiency of dry separation. Therefore, ensuring that the milling and fractionation processes occur under conditions that maintain the native pH away from the can help preserve protein dispersibility and separation efficiency [18]. Protein-rich faba bean flour prepared by dry fractionation was reported to exhibit superior functionality, protein solubility (85% at pH 7), foaming capacity, and gelling ability compared to isolate produced through isoeectric precipitation or acid extraction [87]. Maintaining the native ionic strength of the seed material is also important, as it influences protein-protein interactions and the overall effectiveness of the fractionation process [18]. Beyond pH and ionic strength, other parameters significantly influence dry fractionation outcomes. Moisture content of the flour should be controlled within 10–12% to prevent particle agglomeration, which can hinder efficient separation [80]. Additionally, achieving a fine particle size through pin milling, typically below 50 m, enhances the differential behavior of protein and starch particles during air classification, thereby improving the yield and purity of the protein-enriched fraction [79]. While dry fractionation minimizes alterations to protein functionality, certain technical parameters are crucial to optimize the efficiency and reproducibility of the process [18,44,87]. A novel dry fractionation technique called electrostatic separation uses electrical forces acting on charged materials to separate particles [85]. It can be used as a post-enrichment step post air classification, a pre-enrichment phase before air classification, or as an alternative for air classification [80,84]. Electrostatic separation improves protein enrichment in dry fractionation by leveraging the triboelectric properties of materials to separate proteins from starches [10,79]. Triboelectric charge characteristics brought forth by the particle-wall and particle-particle interactions are used in this method to separate the particles. These interactions give protein a positive charge while giving fibre components a minor negative charge. As a result, the protein can be separated in an electrostatic field to obtain higher protein purity than the air classification [10,84,88]. The hybrid of air classification and electrostatic separation obtained high purity protein concentrate. Electrostatic separation is an efficient and sustainable alternative for producing [41,78] high-quality protein concentrates [41,78]. However, more research is needed to improve and optimise this fractionation method [10]. Compared to wet fractionation, dry fractionation preserves the native functionality of proteins, yielding protein concentrates with desirable functional properties such as solubility, emulsification, foaming ability and foam stability and gelation [41]. However, protein purity in dry fractionation is often lower, usually around 50–60%, compared to the higher purity achieved with wet processes, and can result in lower protein solubility [14,48]. Recent advancements focus on optimising air classification parameters, pretreatments and size reduction techniques to improve protein yield and quality [79,80,84]. Additionally, new milling technologies and enhanced air classification strategies aim to increase protein recovery and minimise energy consumption [84]. Dry processing by milling and air classification can be used to produce protein concentrates with protein content up to 70%, depending on the pulse used [9]. Dry fractionation is a sustainable, cost-effective, energy-efficient method for extracting pulse proteins that maintains the native structure (charge) of the proteins while minimising water and chemical consumption [14,41,78,84].

3.3. Wet Extraction: Alkali Extraction/Isoelectric Precipitation (AE-IEP)

Wet extraction, also known as wet fractionation, is one of the most widely used techniques for producing protein components [41]. Various studies have explored the use of wet extraction processes to isolate proteins from legumes such as peas, lentils, and beans [84,89]. Traditionally, wet extraction techniques have been used primarily to produce protein isolates and concentrates [66]. Precipitation or ultrafiltration are the two basic methods of wet extraction. Pulse seeds are first ground into flour during the wet protein extraction process, and then they are transformed into a suspension in an acidic or alkaline environment [90]. It typically consists of an alkaline extraction, an isoelectric precipitation, and a final drying step into a fine powder (referred to as concentrate or isolate) by freeze-drying or spray-drying techniques for ease of storage and transportation [10,41]. This method apitalises on the pH-dependent solubility of proteins, where extraction at an alkaline pH solubilises most protein fractions, and subsequent precipitation at their isoelectric point enables protein isolation [75]. In contrast, albumins remain soluble across a broader pH range, allowing for effective separation and concentration of different protein fractions [75]. Proteins are solubilised at an alkaline pH (8–11) using an alkali, such as sodium hydroxide (NaOH) or potassium hydroxide (KOH) [10,41,84,91]. At this pH, the protein fractions, particularly globulins like legumin and vicilin become more soluble because they carry a net negative charge, leading to the dissociation of protein aggregates [10,41]. After the proteins are solubilised, the solution is subjected to isoelectric precipitation. This involves lowering the pH by acid-induced precipitation to the isoelectric point of the protein, usually between pH 4 and 5, where the net charge on the proteins is neutral [41,75]. At this pH, protein solubility is minimised, leading to protein aggregation and precipitation [92]. The precipitated protein is then separated by centrifugation or filtration, washed, and neutralised to produce the final protein isolate [74]. The non-protein components, such as starch, fibres, and lipids, remain insoluble and can be separated by centrifugation or filtration [14,41,80]. After neutralisation, the precipitated protein is dried, either by spray drying or freeze drying to obtain protein concentrates or isolates with purities between 80% and 90%, respectively, on a dry weight basis. This step optimises protein extraction while preserving key functional properties such as emulsification and gelation [41]. A number of factors, including particle size, solvent type, solubilisation pH, temperature, extraction duration, and flour-to-solvent ratio, influence protein yield [10,41,75,80]. Furthermore, factors like the concentration of the alkaline solution and the length of processing have a big impact on protein recovery [41,75]. The AE-IEP process offers several advantages that have contributed to its widespread use in the food industry. These are AE-IEP can produce protein isolates with over 80–90% protein content, which makes it highly suitable for applications where high protein levels are desired [75]. Proteins isolated through AE-IEP generally exhibit good solubility, emulsification, and foaming properties, making them suitable for various food applications, including dairy and meat analogues [14,84]. Alkaline conditions and subsequent processing steps can help reduce or eliminate certain antinutritional factors, such as phytates, tannins, and protease inhibitors, improving the nutritional quality of the protein isolate [75,84]. AE-IEP has a number of drawbacks despite its benefits, such as the loss of sulfur-containing amino acids and the decreased bioavailability of important amino acids such as histidine (80%) and sulfur-containing amino acids (71%). The protein composition and quality can also be changed by the conversion of cysteine and serine residues into dehydroalanine, which can then react with lysine. Achieving a balance between low functional and nutritional losses and high protein yield requires optimising these factors [41,84]. Furthermore, a major challenge is the possibility of protein denaturation, which could impact its functionality, particularly its solubility and digestibility [41,78]. In addition, alkaline conditions can cause undesirable reactions like Maillard browning, which would change the protein isolate’s colour and flavour. The objective of promoting a sustainable food system is contradicted by the high energy, water, and chemical resources used in wet extraction [20,78,79]. The techno-functional properties of protein isolates obtained via alkali extraction and isoelectric precipitation are often suitable for applications in food products that require emulsification, foaming, and gelling capabilities. However, the loss of solubility during isoelectric precipitation can limit the use of these proteins in beverages or other liquid food systems [9,10,14]. To address this, additional processing steps such as enzymatic hydrolysis or heat treatments may be applied to enhance solubility without compromising functionality [9,93].

3.4. Ultrafiltration Processing

Ultrafiltration processing (UF) is a pressure-driven non-thermal membrane filtration process that is frequently used as an alternative to isoelectric precipitation following alkaline extraction. It has uses in protein fractionation, concentration, desalting, and clarification [41,80]. UF is a technique for separating dissolved proteins that uses a selectively semipermeable membrane. The protein solution is passed through ultrafiltration membranes with pores that allow smaller soluble substances, such as carbohydrates, to flow through while selectively retaining proteins [83]. Ultrafiltration preserves the natural structure and functions of the protein, making it a gentle process. Because it does not employ hazardous chemicals or effluents, it can be considered a green technique [41]. In order to preserve proteins of interest, the UF method isolates proteins according to their molecular size, which ranges from 1000 to 100,000 kDa. Different molecular weight cut-offs are available [10,80]. A molecular weight cut-off is a common characteristic of membrane UF technology, which uses membranes with opening diameters of 0.001–0.1 m that function as physical sieves that can retain molecules with a molecular weight of about 30,000 kDa [41]. To obtain fractions with distinct sizes, the solubilised protein is sequentially passed through a smaller membrane (e.g., 10 kDa), and the permeate is collected as the <10 kDa fraction. The retained solution is further passed through a bigger membrane size (e.g., 30 kDa), and the permeate is collected as the 10–30 kDa fraction while the retentate is the >30 kDa fraction. A reversed technique could start with a larger molecular membrane and the retentate collected from one size to the other [41].

In order to provide components with a high native content and usefulness, membrane UF is utilised in combination with other protein extraction methods [41]. In order to increase product recovery and purity, diafiltration, which dilutes the retentate by adding water, is frequently used in conjunction with UF [80]. Diafiltration is a technique used to decrease the viscosity of the solution and speed up membrane penetration by periodically adding distilled water to the retentate [41,88]. Following mild wet fractionation, proteins in the supernatant can also be concentrated by ultrafiltration or diafiltration. To increase protein yield from roughly 78% to 87%, several washing stages and ultrafiltration were applied to the protein and starch-rich fractions [88]. In general, UF is a new application that produces high-purity, high-quality components for pulse protein processing. UF is also applicable to industry because it may be utilised widely. By eliminating contaminants such as fibre and carbohydrates and concentrating protein-rich streams, UF can produce high-purity protein fractions (90–95%). The study showed that UF produced the highest protein content and purity at pH values of 9 and 6. At a pH of 9, DF and UF resulted in a lower phenol concentration. But the levels of trypsin inhibitors were high in both techniques [83]. Being a non-thermal procedure, UF aids in keeping the natural structure of proteins, protecting their ability to dissolve, emulsify, and gel [41,80]. Overall, UF/diafiltration, especially when combined with alkaline extraction/isoelectric precipitation, has shown potential to enhance protein extraction yield and functionality. These techniques also inactivate protease and amylase inhibitors while reducing lectins and anti-nutritional factors [70]. Proteins from peas, chickpeas, and lentils were extracted using alkali-combined ultrafiltration in earlier research. The findings demonstrated the good water-holding capabilities, emulsifying, foaming, and gelling qualities of pea, chickpea, and lentil proteins [76]. According to Asen et al. [41], UF is a non-invasive, user friendly, environmentally friendly technology that has demonstrated efficacy in protein processing [41]. A significant challenge of UF is membrane fouling and concentration polarisation, where particles accumulate on the membrane surface, reducing efficiency and increasing operational costs. Fouling reduces the efficiency of the process and reduces protein yield, and the remedy is the selection of appropriate membranes for protein separation [41].

3.5. Salt Extraction and Micellization

Salt extraction and micellization is a novel method of extracting pulse proteins that separates proteins based on their solubility in salt solutions. This process involves the principles of salt-in (solubilisation) and salt-out (concentration) proteins, followed by a desalting process that reduces the ionic strength of the protein environment [10,74,83]. According to Asen et al. [41], dialysis or membrane ultrafiltration could be used in place of the concentration stage of salting out. When pulse flours are dissolved in saline solutions, proteins dissolve, while fibre, carbohydrates, and other components do not. Micellar or salt-induced extraction and precipitation use a solution with a high ionic strength to solubilise proteins while avoiding extremely high or low pH levels or elevated temperature are not required. The proteins are then precipitated and aggregated by further dilution. It is believed that the proteins are shielded from complete denaturation by residual ionic strength [10,88]. Proteins typically exhibit salting-in at low ionic strengths, 0.1–1 M. The extraction takes place at the natural pH level of 5.5–6.5. A slightly higher legumin concentration is often extracted via alkaline extraction. However, because legumin is less soluble in diluted salt solution than vicilin, salt extraction is a better method for obtaining vicilin and convicilin [10]. Protein isolates from salt extraction often showed lower water holding capacity but higher solubility, oil holding capacity, and foaming capacity than others. According to Shanthakumar et al. [10], isolates with higher extraction yield and functionality are produced using salt extraction. Furthermore, the salt extraction approach had the advantages of preserving the original structure of the protein and preventing denaturation, but also had the drawback of having a low protein extraction rate and purity [76].

A mild extraction technique called micellar precipitation yields proteins with a high concentration of native structure. The micellization method induces precipitation of protein and micelle formation, which occurs by adding cold water in the ratio of 1:3 to 1:10 (v/v) of high salt protein extract to water [10,41]. Dilution of the protein solution forces solubilised proteins to regulate the low ionic strength through a series of dissociation reactions to form lower molecular aggregates. When it reaches a critical protein concentration, the aggregates combine into a comparatively low molecular weight micelles, precipitated from solutions. Micelles are nanoscale aggregates that form in water, with the hydrophobic moieties in the centre and the polar heads oriented toward the surrounding environment. To maximise micelle formation, the diluted solution is left to stand for some time [10,41]. Centrifugation is used to separate the insoluble components after the proteins have been extracted in a neutral pH salt solution. Reverse micellar precipitation is a further variation of this technique that creates nanostructured aggregates of surfactant molecules in a non-polar environment with water in the centre of the structure [41]. One advantage of the micellization process is that it is milder and involves less drastic pH shifts, which means that less protein is denaturated during the process. Due to a lack of protein solubilisation, the micellization approach has a low protein recovery rate [10]. Another approach is to extract using only water. The extraction process is frequently repeated since the yield from a water-only technique is lower than with an adjusted (more alkaline) pH or ionic strength. Proteins were first extracted at a higher pH, then purified and concentrated using ultrafiltration in a different technique that did not include protein precipitation. They demonstrated how albumins, which often do not precipitate due to their superior water solubility and are thus lost, may be recovered from raw materials by employing ultrafiltration to bypass a precipitation phase. In terms of emulsion and foam stability, the fractions produced by such a gentle technique have essentially distinct characteristics [88].

3.6. Mild Fractionation

A mild fractionation process is proposed to produce protein isolates using a hybrid approach [94]. For instance, after dry fractionation, the fine fraction of pea flour was recovered and suspended in water. It was then separated layer by layer using centrifugation forces or, if necessary, further purification (such as dialysis or ultrafiltration) to increase purity (up to 75–90 g protein/100 g dry matter). Dry and mild fractionations both need physical separation according to density distribution and size. The yields of the dry method, which requires no water, depend on the number of passages (milling-air classification) while maintaining its native form [14]. Conversely, wet processing decreases the amount of non-protein materials, yields a more pure protein isolate (80–90% protein), and uses a lot of water, chemicals, and energy, but also decreases native functionality [14,88]. However, it was discovered that the modestly fractionated protein concentrates performed better overall than the heavily fractionated ones. Furthermore, it is possible to optimise the protein composition for particular functional behaviour by utilising fractionation procedures. Previous research showed that fractionation could impact the functional characteristics of pea protein because they found that the extent of fractionation could change the protein composition and viscosity of the fractions and that the limited fractionated samples had a better gelling capacity [94]. These three protein fractions an albumin-enriched fraction, a globulin-enriched fraction, and a fraction containing both globulins and albumins, could be produced using a standard aqueous fractionation procedure. The ability of globulins to precipitate at pH 4.5 is the basis for the separation of these proteins [94].

3.7. Ultrasound-Assisted Extraction

Ultrasound-assisted extraction (UAE) is an efficient, eco-innovative and promising method for enhancing protein yield and functionality from peas and beans. UAE uses cavitation-induced shear forces to break down plant cell walls, enhancing solvent penetration and protein release. This technique significantly reduces extraction time, temperature, cost, and environmental impact compared to traditional methods [23,95,96]. UAE works by generating high-intensity sound waves that collapse microbubbles, leading to cell wall disruption and improved protein extractability [95,96]. Ultrasound has also various effects on the bioactivity and functionality of food proteins [97]. Various studies on protein isolation have been conducted using different sources, with ultrasound serving as an effective technique. The most common ultrasound frequencies used in food processing range between 20 and 100 kHz and are known as high-power ultrasound waves [98,99]. Ultrasound is an effective tool for protein extraction only when suitable frequencies are applied. Hence, the selection and application of appropriate ultrasound frequencies are the most critical factors in protein extraction. Numerous studies have also shown that using ultrasound as a pretreatment increased protein yield or protein release rate [98,99]. In the case of faba beans, optimized UAE conditions led to a protein extraction yield of 19.75%, surpassing the 16.41% yield obtained through conventional methods. The extracted proteins exhibited superior water and oil holding capacities, with minimal impact on thermal properties [95]. Additionally, field bean protein isolates obtained via UAE showed a 76.84% improvement in extraction yield, with enhanced functional properties suitable for food applications [23]. Similarly, research on chickpea proteins demonstrated that UAE achieved a higher extraction yield (66.1%) compared to conventional alkaline methods (55.1%), while also enhancing water and oil absorption capacities, as well as foaming properties [100]. Additionally, UAE reduces antinutritional factors (e.g., phytates) in beans, enhancing protein bioavailability [23]. Several ultrasound- and sample-related process factors affect the efficacy of the ultrasound [100]. The energy density, ultrasound intensity and treatment time are the ultrasound-related factors, while the type of sample/protein and sample/solvent ratio are sample-related parameters [100]. UAE poses challenges for various protein sources and process parameters. However, optimizing the process for ultrasound-assisted extraction remains limited [95]. Therefore, optimization based on the different plant sources is needed [100]. Effective UAE can lead to improved extraction yields and modified functional properties of proteins. Successful protein extraction relies on understanding how UAE parameters such as time, power, frequency, solvent-to-sample ratio, and temperature affect the extraction of faba bean proteins [68,95,98]. Effective UAE applications rely on proper optimization of these parameters, which can significantly impact both the protein extraction yield and the functional characteristics of the resulting protein concentrate [68,99,101]. High-intensity ultrasound waves can be utilized for emulsification, diffusion, and extraction, whereas low-intensity ultrasound waves are typically used in nondestructive procedures [68]. Ultrasound treatment enhances the emulsifying properties of proteins by creating turbulence that improves protein adsorption at the oil-water interface. It also increases solubility and hydrophobicity while promoting protein denaturation, exposing hydrophobic groups, and reducing water-holding capacity. This process improves oil-holding capacity through physical entrapment. Additionally, ultrasound enhances foaming capacity and stability by promoting homogenization, increasing solubility, and reducing particle size [99]. The disadvantages of UAE include the denaturation of soluble protein fractions, which reduces the protein concentration, and its high energy consumption, which is thought to be a barrier to its industrial application In addition, high energy consumption is considered a limitation for the use of UAE on an industrial scale [68,98,100].

3.8. Enzyme-Assisted Extraction (EAE)

Protein extraction from various plant sources is aided by the ecologically friendly green processing method known as enzyme-assisted extraction. By hydrolyzing the plant cell wall and the proteins therein, a variety of food grade protease and carbohydrase preparations, including pepsin and pancreatic enzymes, have been used to facilitate protein extraction and solubilisation from various plant sources [77,83,102]. Stiff cell walls make it difficult to remove cellular proteins. Hemicellulose, cellulose, and pectin are the components of cell walls that EAE primarily aims to break down enzymatically in order to damage the integrity of the walls [70]. The specialized functions of pectinases and carbohydrases in the cell wall facilitate the release of cellular proteins from legume seeds [68]. According to Badjona et al. [77], Rashwan et al. [72], this results in an increased protein yield and better functional qualities, including solubility. The optimal pH is maintained by proteases to avoid denaturing proteins. A typical protease enzyme/substrate concentration of 1% to 5% is optimal for a range of extraction methods. These enzymes can also prevent interactions between the released proteins and various cellular components, including phytates and carbohydrates, under specific physiological conditions. For enzymes to function at their best, a variety of acidic and alkaline environments are necessary. Although some proteases prefer somewhat alkaline environments, carbohydrases often function best in mildly acidic environments. For proteases functioning in an alkaline environment, the optimal pH and temperature ranges are 8–10 and 45–60 °C, respectively [68,98]. In contrast to chemical and physical extraction methods, EAE’s mild operating conditions, low energy consumption, and decreased waste formation led researchers to use it [68,77,102]. When protease-assisted extraction is employed, EAE can improve the nutritional (digestibility) and technological and biofunctional properties of the extracted proteins in addition to aiding in protein recovery. Plant cell wall disruption can be improved by combining EAE with physical methods, such as ultrasonic processing, for biomass pre-treatment. This will increase the efficiency of protein extraction/high protein extraction rate. This method can help make the extraction process more economically feasible by using less energy and enzyme, which lowers the extraction process’s total cost [76,102,103]. Despite its advantage, EAE requires specific enzymes, which can be expensive and have a long reaction time, especially at industrial scales [76]. Moreover, enzymatic activity needs to be tightly controlled to avoid incomplete protein extraction or unwanted degradation [102]. The maintenance of optimal conditions such as pH, temperature, and enzyme concentration adds complexity to the extraction process. Deviation from these conditions can lead to inconsistent results and affect protein functionality [68].

3.9. Fermentation

An innovative method for extracting and modifying pulse proteins is fermentation. This technique uses microbial action, usually in the form of bacteria, yeast, or fungi, to break down antinutritional components, modify the structure of the protein, and improve the digestibility and techno-functional properties of pulse proteins [3,104]. In addition to extracting proteins, fermentation improves their nutritional profile by reducing substances such as phytic acid and increasing the bioaccessibility and bioavailability of essential amino acids [104]. Legumes protein composition and structure can be affected by lactic acid fermentation. This is explained by the mechanism of the bacteria’s proteolytic activity during fermentation, which breaks down the polypeptide chain and forms new, lower molecular weight polypeptides. Protein structure and conformational variations impact the end products nutritional value and functionality [104]. Many studies have highlighted the benefits of LAB species, including Streptococcus thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, Lactobacillus acidophilus, Lactobacillus helveticus, and Lactobacillus plantarum, on the organoleptic characteristics of legume protein [104]. The growth of LAB during the fermentation of pulse proteins contributes to the enhancement of flavour and aroma by hiding undesirable green notes or decreasing the presence of compounds that cause off-flavours [14,104]. Given the benefits of LAB fermentation for legume characteristics and the pH drop caused by lactic acid production, an alternate protein extraction technique based on alkaline solubilization/isoelectric precipitation was used, in which lactic fermentation rather than the addition of mineral acid produced the pH drop [104]. The advantages, limitations, functional characteristics, applications and future research trends of pulse protein extraction methods are summarized in Table 4.

4. Protein Fractions

The protein subunit is of crucial importance since its investigation can disclose the composition and corresponding functionality of seed storage proteins. Furthermore, this supports research on the nutritional value of protein in human diets and animal feed, as well as breeding goals for enhancing the protein composition of pulses [57,77]. The Osborne fractions of pulse proteins are as follows: (i) salt-soluble globulin fraction; (ii) water-soluble albumin fraction; (iii) prolamins, which dissolve in a solution of ethanol and water; and (iv) insoluble glutelins [48,53]. The dominant protein fractions in pulses are globulins and albumins [53,77]. Typically, globulins are present in higher amounts than albumins, affecting the rheological and textural properties of the proteins [31,105]. However, the relative amounts can vary considerably between different pulses, and also due to variety and cultivation conditions, and the albumin/globulin ratio has been reported as high as 0.5 [9]. Protein fraction and their composition, molecular structure, charge distribution determine protein isolate physical and chemical properties [53]. In globulins, there are legumin and vicilin (salt soluble proteins) comprising of high molecular weight and complex structures but their ratio plays a vital role in utilizing these proteins for fortification in various products like breads and biscuits [29,106]. The storage proteins contain two subunits one is globulins, having 7–11 Svedberg unit (S) fractions but lacks sulphur containing amino acids, and the other one is prolamins, having trypsin inhibitors and phytolectins, comprising of sulphur containing amino acids, with minor amounts of convicilin [106,107]. However, the faba bean is classified into two type’s likely globulins and non-globulins [105].

4.1. Globulins

In peas, the globulin-to-albumin ratio ranges from 55 to 80%, while in faba bean seeds, globulins make up 70 to 80% of the storage protein [75,77]. Globulins, a major class of pulse proteins, are categorised by sedimentation coefficient into legumin (11 S), vicilin (7 S), and convicilin [63]. Legumin and vicilin dominate faba bean and pea proteins, typically in a 2:1 ratio, with legumin being richer in sulfur-containing amino acids [2,7,16,46,48,53,77,108]. Legumin is a hexamer (∼340–400 kDa (Kilo Dalton)) composed of six subunits (60–65 kDa), has an acidic (∼40 kDa) and a basic (∼20 kDa) linked via disulfide bonds, with hydrophilic and hydrophobic regions affecting its water interaction [9,53]. In fava bean, globulins (legumin, vicilin, convicilin) are predominant seed storage proteins (approximately 85% w/w) which exist in different structural conformations, with legumin constituting about 50% of the storage proteins [77,109]. The legumin-to-vicilin ratio varies among different genotypes, typically ranging from 1:1 to 3:1 [46]. Legumin exists in two subtypes, A (∼38–40 kDa) methionine-rich and B (∼23 kDa) methionine-lacking, and is encoded by multiple gene families, each containing - and -chains linked by disulfide bridges [46,77,105]. These subunits exhibit heterogeneity, with molecular weights around 75 and 80 kDa [46,105]. Vicilin is a trimeric protein (∼175–180 kDa) composed of heterogeneous polypeptides without cysteine residues, preventing the formation of disulfide bonds. Its subunits (∼50 kDa) are glycosylated, hydrophilic, and cleavable into low-molecular-weight fragments. Vicilin shares structural similarities with convicilin [53]. Convicilin (8 S, 180–210 kDa), a polymorphic form of vicilin, shares 80% amino acid sequence homology with uncleaved vicilin but differs by its highly charged N-terminal extension and the presence of a single cysteine residue, enabling potential disulfide linkages. Both proteins are stabilised by noncovalent interactions, with structural differences influencing their properties. Convicilin’s unique features, like its cysteine content, set it apart functionally and structurally from vicilin [53,110]. Legumin and vicilin proteins exhibit varying solubility, emulsifying properties, and structural responses to pH and ionic strength [53]. Their functional and nutritional properties depend on their composition, structural differences, and the legumin/vicilin ratio, which processing methods like isoelectric precipitation can alter. These structural and surface properties are critical for understanding pulse protein functionality [9]. The thermal properties of faba bean proteins show that 7 S proteins denature at 84 °C, while 11 S proteins denature at 95 °C. Faba bean proteins, particularly legumin, have a high degree of structural homology with vicilin and are part of the cupin superfamily [27]. Despite their abundance, faba bean proteins are less soluble and functional compared to animal proteins, limiting their widespread use in food products. Isoelectric precipitation can be used to isolate these proteins based on their isoelectric points. The isoelectric point of convicilin is 5.5, while that of vicilin is 4.8 [77]. In field peas, the globulin fraction is mainly composed of legumin (11 S), vicilin (7 S) and convicilin (7 S), with a typical legumin-to-vicilin ratio close to 2:1 [104,111]. Pea legumin is hexamer with a molecular weight (Mw) of ∼300–400 kDa. Legumin has a 40 kDa acidic–20 kDa basic, (-) subunits which is linked by a covalent disulfide bond representing one monomer within a quaternary structure linked with non-covalent bond [106]. Vicilin is a trimeric protein of 170 kDa that lacks cysteine residues and hence cannot form disulfide bonds. Each monomer (∼50 kDa) can undergo post-translational cleavage, resulting in polypeptides of approximately 20 kDa (), 13 kDa (), and 12–16 kDa (). Additionally, the -subunit near the C terminus is sometimes N-glycosylated, while no glycosylation has been observed in legumin [104,111]. Vicilin consists of low amounts of sulfur-containing amino acids such as tryptophan, methionine, and cysteine, and higher amounts of basic and acidic amino acids such as arginine, lysine, aspartic acid, and glutamic acid amino acids. N-terminal amino groups are typically represented by aspartic acid, glutamic acid, and serine [104,111]. Convicilin has a subunit of ∼71 kDa and a molecular weight in its native form of 290 kDa, which can form trimers of three convicilin molecules or heteromeric trimers with vicilin [104,106]. Convicilin contains sulfur-containing amino acids and a highly charged N-terminal extension, thus the amino acid profile of convicilin is different than both vicilin and legumin. Within this group of proteins, two major fractions were identified: a larger albumin protein comprised of two polypeptides with a molecular mass of ∼25 kDa and a minor fraction with a molecular mass of ∼6 kDa [106]. The legumin fraction has the higher emulsifying and foaming stability compared to vicilin. Moreover, the nutritional values of legumin and vicilin are different. Vicilin has higher amounts in arginine, isoleucine, leucine, phenylalanine, and lysine compared to legumin, while the latter is richer in sulfur-containing amino acids. Thus, the 11 S/7 S ratio may play an important role in the functionality and nutritive value of pea proteins, which are critical for their performance in food formulations [112]. The concentration and types of globulins vary across legume species and varieties, influencing their nutritional value and functional properties [77]. It is also important to note that faba bean protein are not a complete protein due to their deficiency in some essential amino acids, specifically methionine and tryptophan [63]. Understanding globulins composition and functionality is crucial for enhancing legume crops and improving their applications in food and animal feed [77]. Protein structure can vary significantly depending on the extraction method used, as well as extrinsic factors such as temperature, pH, salt concentration, and ingredient modifications, all of which alter the protein’s surface characteristics and conformational stability, ultimately influencing functionality [106]. Additionally, variations in the ratios of protein fractions like legumin and vicilin are determined by genetic factors, environmental conditions, and processing techniques, leading to differences in functional performance [21,80]. For instance, a higher legumin content is generally linked to improved gelation, whereas elevated vicilin levels enhance emulsifying properties. As such, understanding and strategically modifying the globulin-to-albumin ratios in field peas and faba beans is essential for designing plant-based protein ingredients with targeted functional properties for diverse food applications. A higher globulin/albumin ratio is often associated with better protein stability and gelling properties, making legumes suitable for food processing. However, excessive globulin content may reduce protein solubility and digestibility due to its compact structure. Recent studies suggest that field peas have a more balanced globulin/albumin ratio compared to field beans, contributing to their higher protein bioavailability [53]. Understanding globulins nutritional, functional, and technological properties is crucial for enhancing legume crops and improving their applications in food and animal feed [77].

4.2. Non-Globulin Proteins

The majority of faba bean seed albumins are metabolic proteins that have the ability to function as enzymes. These proteins include Bowman-Brik inhibitors, albumin-2, defensins, protease inhibitors, and lectins. In comparison to other seed proteins, the albumin fraction contains significant levels of sulfur-containing acid [77]. Albumins in faba beans comprising approximately 10–20% of storage protein [46]. Pea albumins (2 S), which are water-soluble and represent 18 to 25% of total pea seed protein, are primarily metabolic and enzymatic proteins with roles in seed germination [10,53]. They include proteins such as PA-2, PA-1, lipoxygenase, protease inhibitors, phytate, -galactosides and lectins [9,53,75]. Two small molecular weight albumins, PA1a (∼6 kDa, has 53 amino acids) and PA1b (∼4 kDa, has 37 amino acids), have been characterised [9]. The molecular weight of albumins PA1a and PA1b have exceptionally high levels of cysteine (7.5% and 16.2%, respectively), and PA1b has the ability to act as an insecticide in biological control [10]. Despite their functional and nutritional potential, albumins are often discarded due to their lower protein content and the presence of anti-nutritional compounds [75]. Albumins contain higher concentrations of the essential amino acids such as lysine, methionine tryptophan, and threonine [104,106]. Overall, albumins are vital for the nutritional and functional characteristics of legumes and play a supporting role in various biological processes in seeds [77]. Prolamin is another group of plant storage protein and presents a small amount in faba bean and pea seeds. Prolamins are alcohol-soluble and characterised by a high content of proline, glutamic acid, and leucine, while lacking lysine and tryptophan. They dissolve in ethanol/water (70–80%) and propan-1-ol/water mixtures, light acid, and alkaline solutions [10,53]. Prolamin does not coagulate by heat but hydrolyzes to proline and ammonia [10]. Similarly, glutelins, a prolamin-like protein class, have a similar amino acid profile but are more soluble in dilute bases (sodium hydroxide) or acids, chaotropic or reducing agents, and surfactants, and contain high levels of glycine, histidine, and methionine [10,53]. Glutelins, found primarily in seed endosperms, are minor components in peas, but are significant in protein composites like gluten [53]. Electrophoretic analyses, such as size-exclusion high-performance liquid chromatography (SDS-PAGE), have demonstrated that under non-reducing conditions, faba bean glutelin exhibits a wider range of polypeptides (∼12–104 kDa) compared to globulin (∼12–82 kDa) and albumin (∼12–41 kDa) fractions [46,113]. In general, albumins are vital for the nutritional and functional characteristics of legumes and play a supporting role in various biological processes in seeds [77].

4.3. Others Compounds

Anti-nutritional compounds are considered non-nutritive compounds since they interfere with nutrient availabilities or cause host digestive discomfort or health problems [75,114]. For example, low molecular weight proteins called trypsin inhibitors can bind to the digestive enzyme trypsin and render it inactive, lowering protein digestibility, amino acid absorption, and mineral availability. The second most prevalent soluble carbohydrate in legumes is the -galactosides of sucrose, sometimes referred to as the raffinose family of oligosaccharides (RFOs). Due to their fermentation by gut bacteria in the large intestine, -galactosides cause flatulence and digestive discomfort [75]. Conversely, phytic acid affects the solubility of proteins by binding different molecules, including proteins, through a variety of interactions. Enzymes and specific minerals can also be bound by phytic acid, which decreases the gut’s ability to absorb nutrients. For those who consume a lot of pulses each day, this can result in iron deficiency anaemia [75].

4.4. Protein Concentrate

The primary objective of producing protein concentrates and isolates is to improve the usability of the product by removing non-protein components and increasing the concentration of proteins. This enables the use of a smaller amount of protein in food formulation to provide particular functional and nutritional properties [63,68]. Protein concentrates, which can be derived from a variety of sources such as dairy products, plants, and insects, offer an option. According to Fatima et al. [68] the food industry uses these concentrates to formulate functional foods, enhance dietary profiles, and satisfy the growing demand for plant-based and alternative protein sources. Faba bean and pea protein ingredients, available as flours, concentrates, or isolates, are widely used in the food industry to enhance nutritional profiles and improve sensory characteristics such as texture, structure, taste and colour [9,14,19]. Legumes, such as peas and faba beans, are emerging as cost-effective, high-protein alternatives to dominant sources like soy, whey, and wheat. They are ideal for producing protein concentrates and isolates due to their high protein content, affordability, low allergenicity, non-GMO status, and nearly complete essential amino acid profile. This makes them increasingly popular in the market [19,27,94]. Pulse protein concentrate is produced through dehulling and milling, often without defatting due to its low fat content. Protein concentrates are by-products of air classification and include more protein than raw samples [68]. For instance, processing methods have achieved protein-rich faba bean flours with up to 65% protein content and eco-friendly concentrates with 56% protein, showcasing promising functional properties for food applications [77]. Furthermore, pea protein concentrate is typically produced via water-based physical separation and contains up to 85% protein, including a high proportion of branched-chain amino acids (BCAAs), making it suitable for sports nutrition, meal replacements, and infant formulas. Its functionality can be enhanced through “green” modifications; for example, enzymatic crosslinking with transglutaminase has been shown to double its water-holding capacity, while conjugation with polysaccharides like guar gum improves emulsifying properties [115]. Additionally, faba bean protein concentrate, produced via dry fractionation, offers approximately 61% protein content and is rich in fiber. It exhibits excellent solubility, making it ideal for applications such as protein-enriched smoothies and vegan dairy drinks. Dry-heat treatment of faba baen protein concentrate can enhance its water-holding capacity by inducing partial protein denaturation, which exposes hydrophobic sites and leads to protein aggregation, thereby improving its functional properties [116].

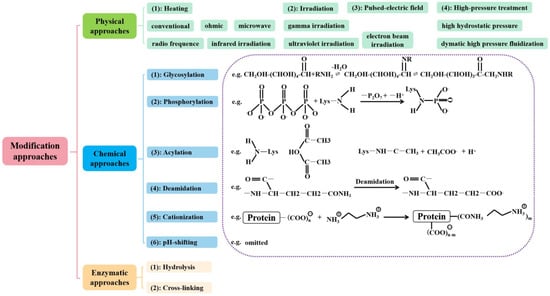

4.5. Protein Isolate