Effects of Mo2C on Microstructures and Comprehensive Properties of Ti(C, N)-Based Cermets Prepared Using Spark Plasma Sintering

Abstract

1. Introduction

2. Results and Discussion

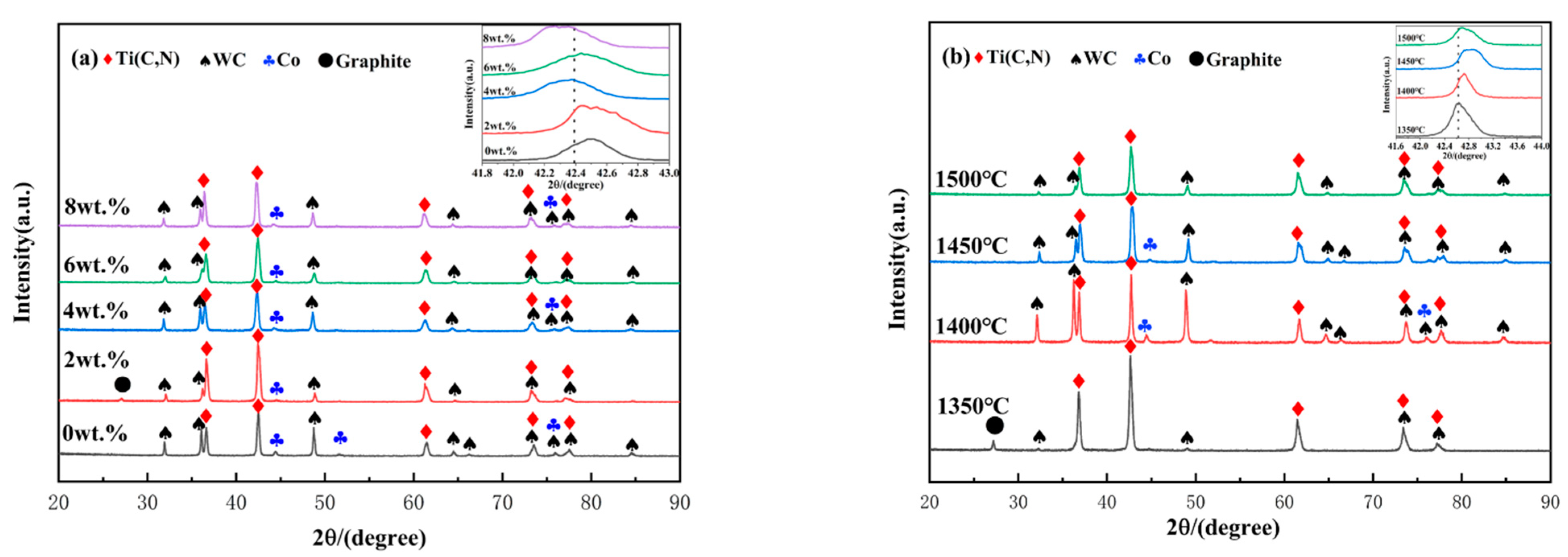

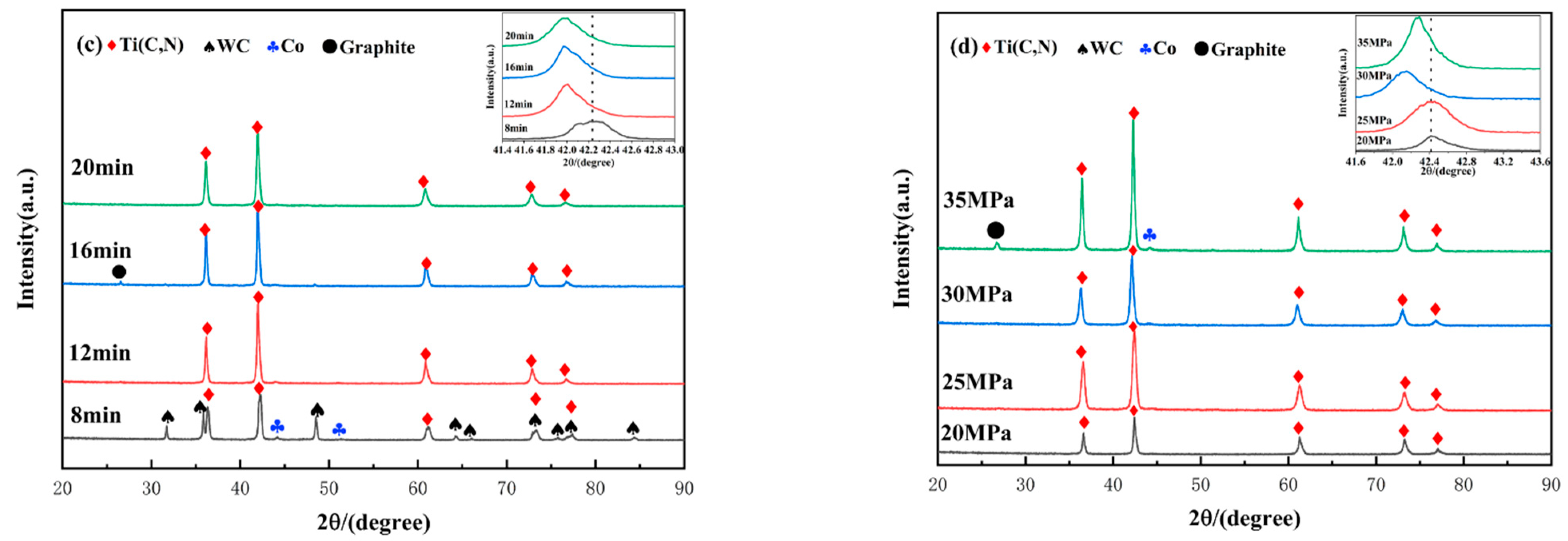

2.1. Phase Compositions and Binding States

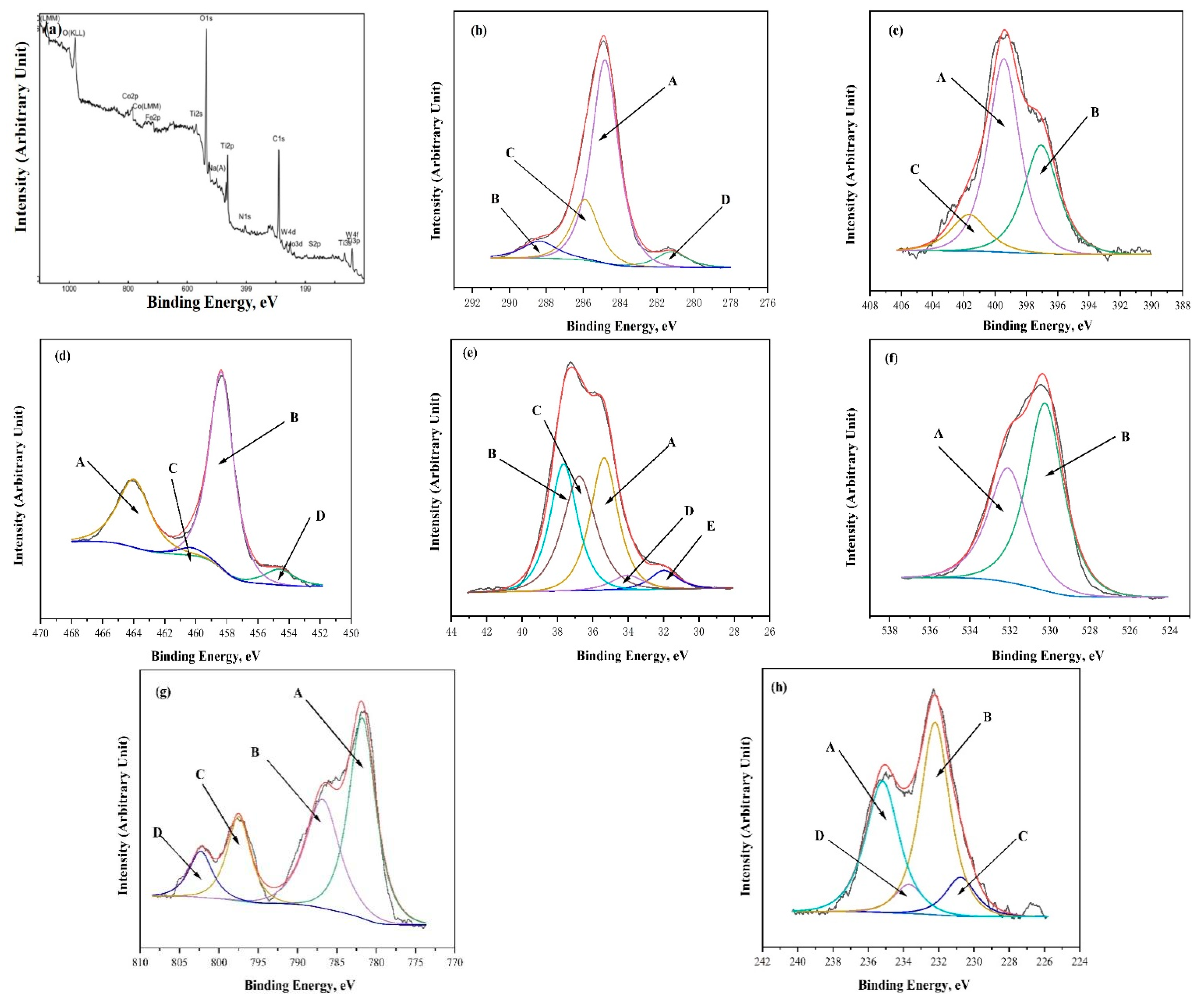

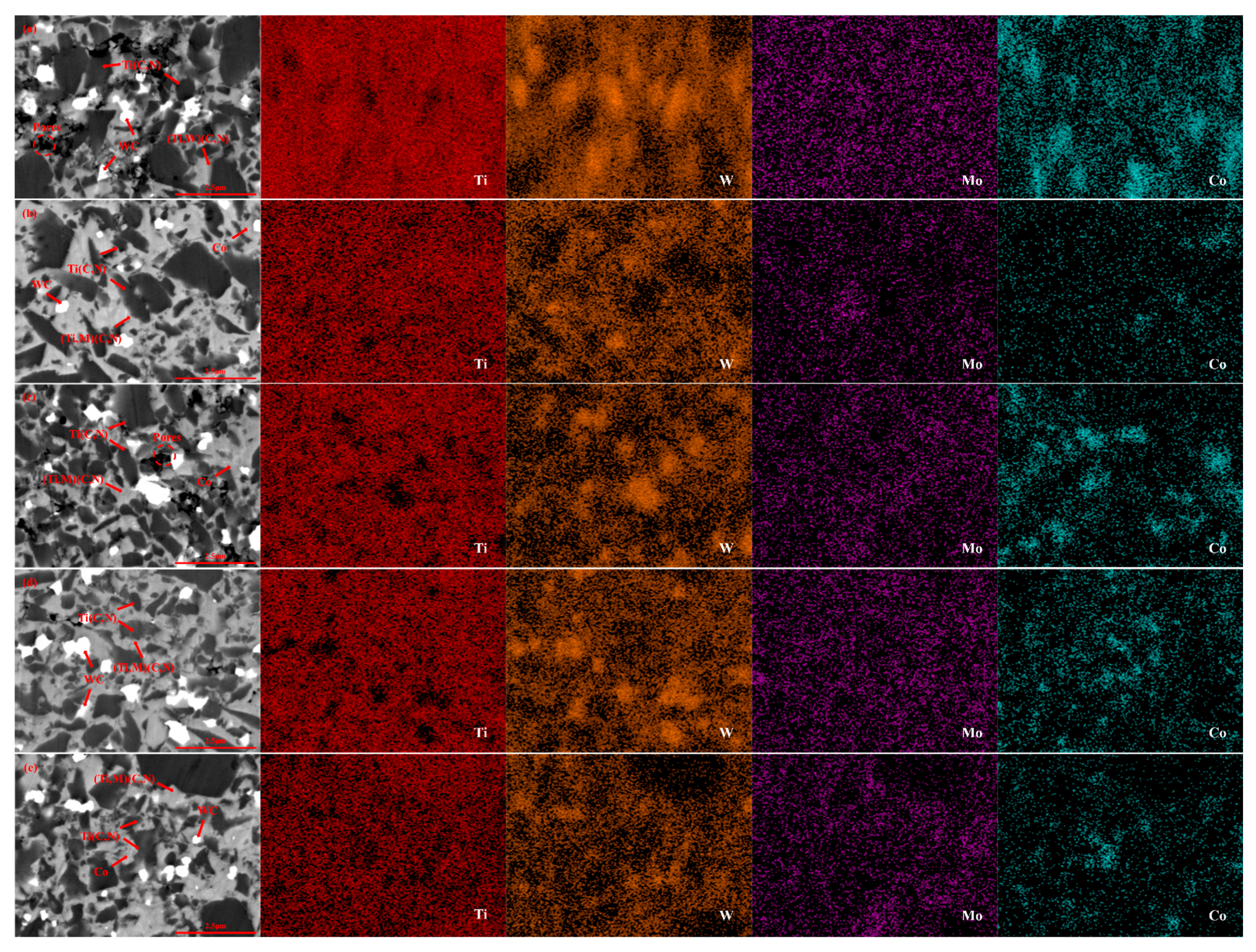

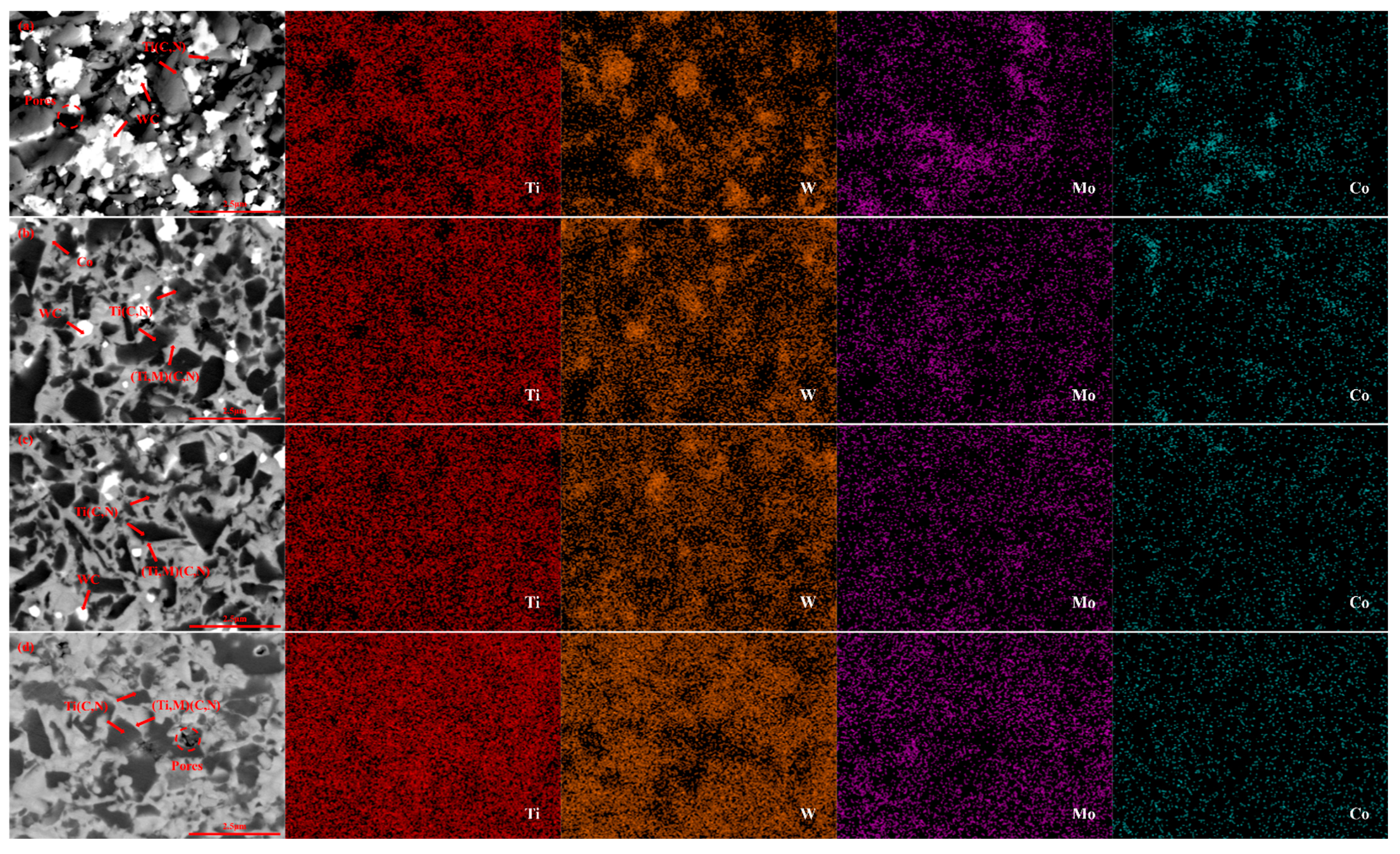

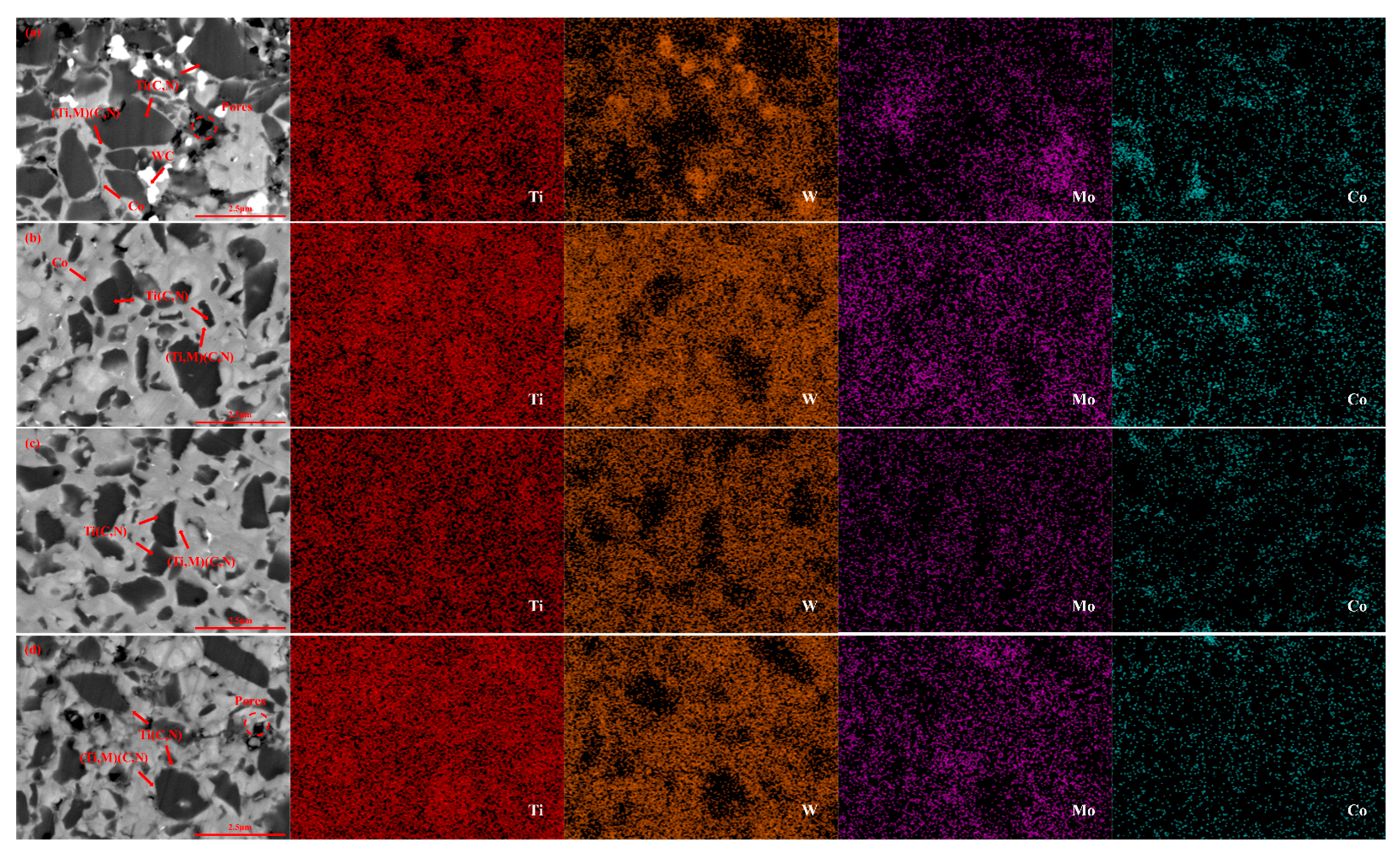

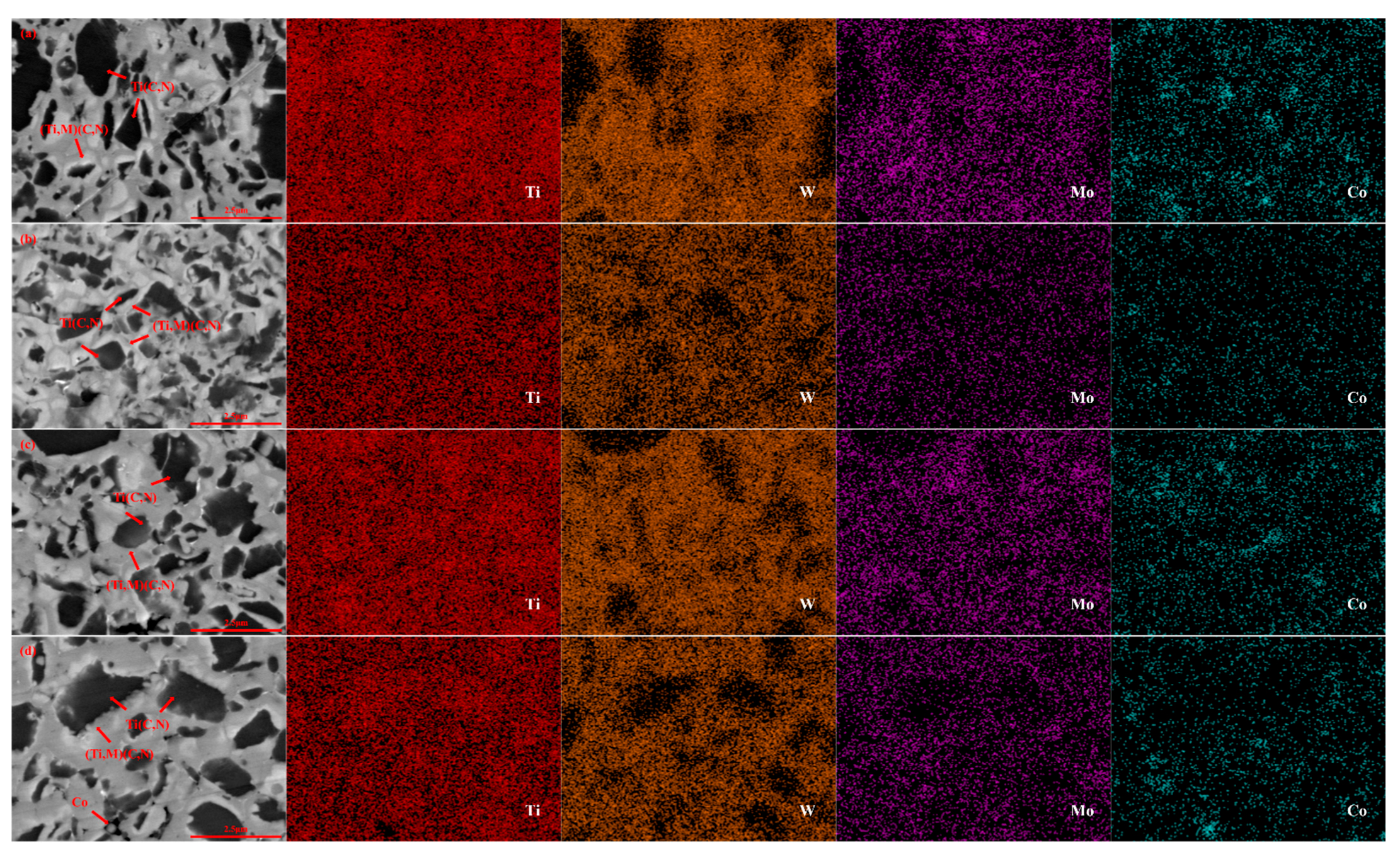

2.2. Microstructures

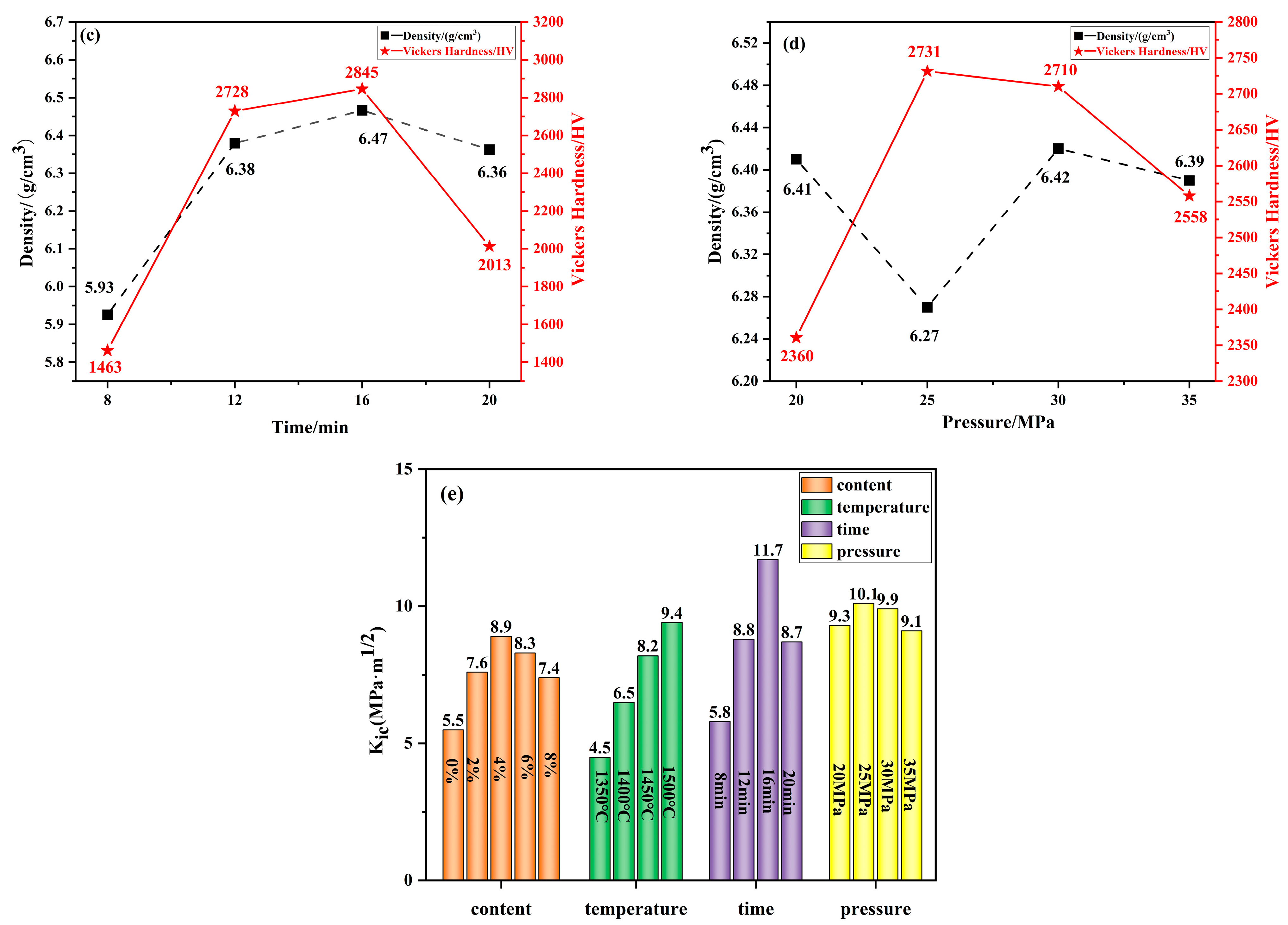

2.3. Mechanical Properties

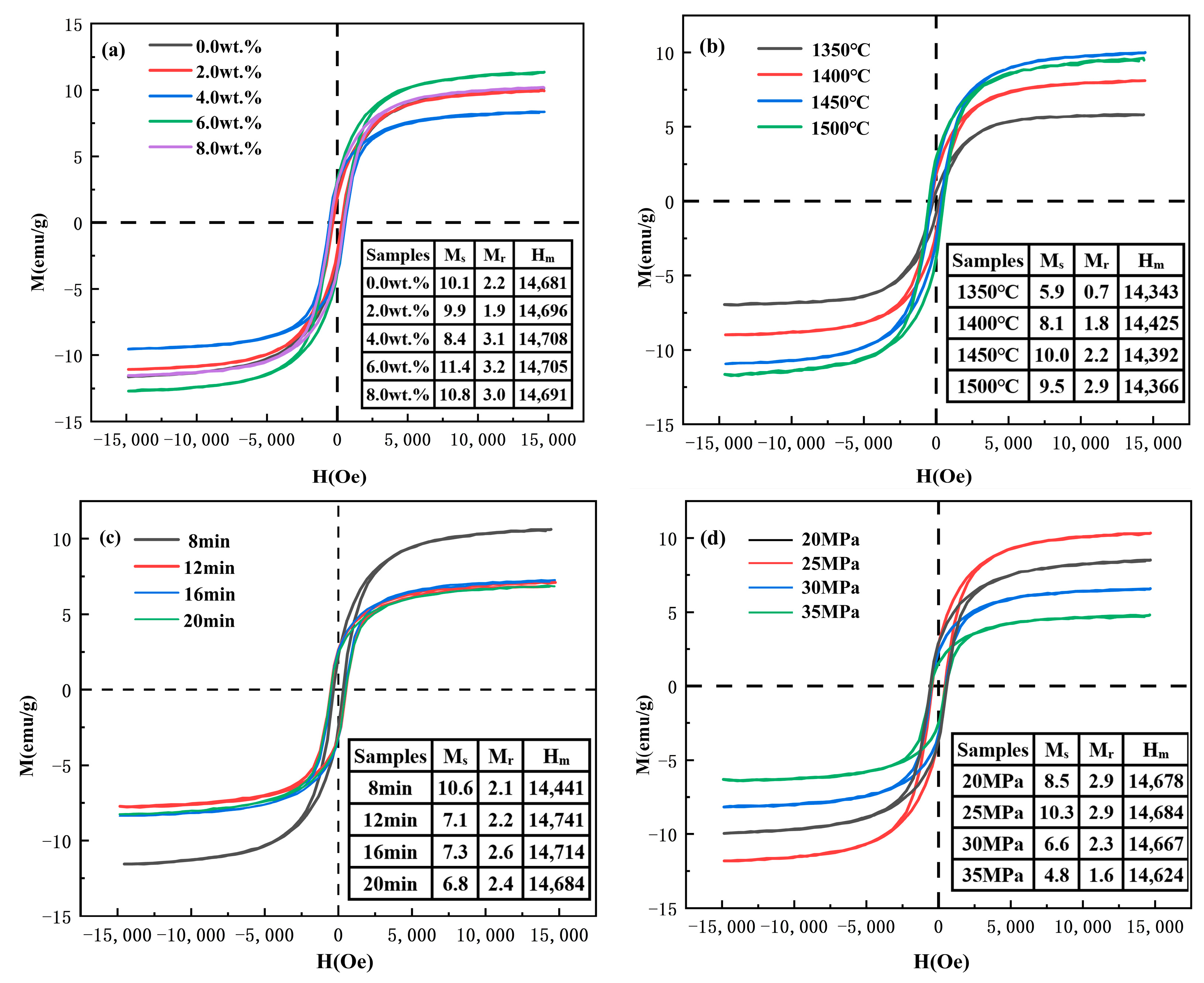

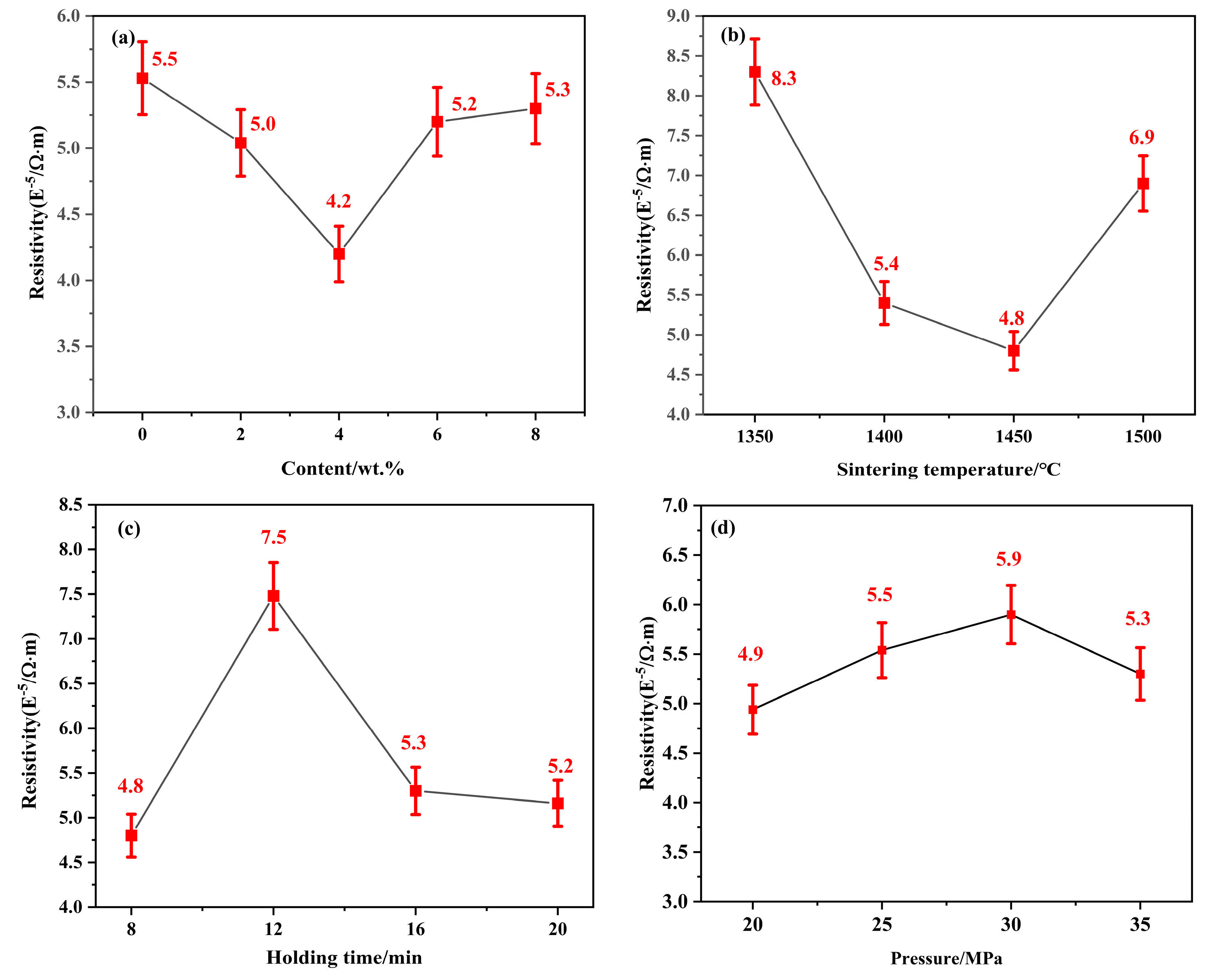

2.4. Magnetic Properties and Resistivity

3. Experiments

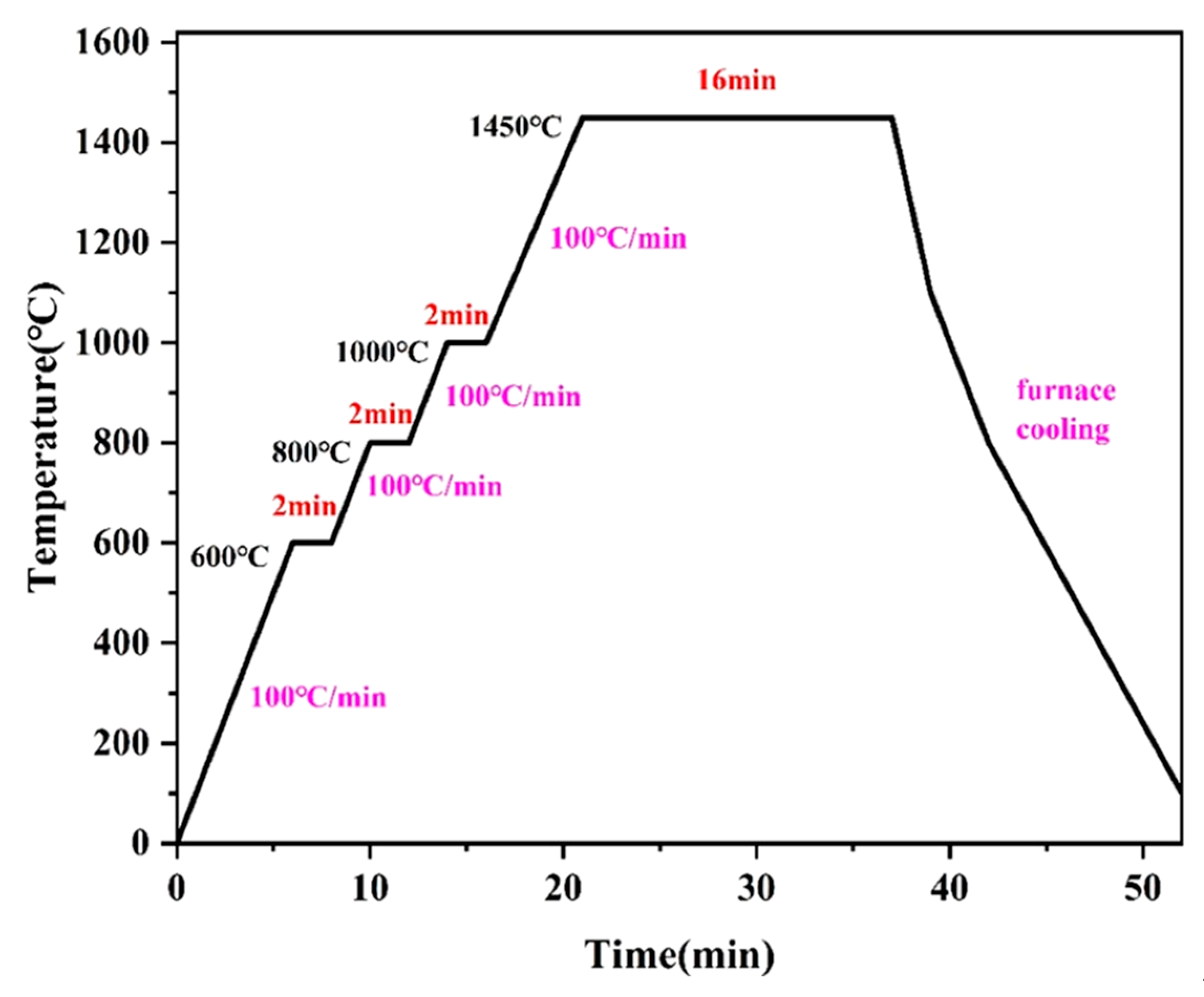

3.1. Preparation of Ti(C, N)-Based Cermet

3.2. Characterization

4. Conclusions

- When keeping the sintering temperature, holding time, and sintering pressure constant at 1450 °C, 16 min, and 30 MPa, the addition of Mo2C shifts the XRD diffraction peaks of Ti(C, N) to lower angles, while a more complete core-ring structure emerges in the microstructure of Ti(C, N). This phenomenon induces alterations in the mechanical properties of the cermet samples. With a Mo2C addition of 6 wt.%, the sample exhibits the smallest grain size of the black hard phase (0.64 μm) and a well-distributed core-ring structure. The density of the sample is 6.45 g/cm3, the Vickers hardness is HV 2318, the fracture toughness is 8.3 MPa·m1/2, the saturated magnetization strength is 11.4 emu/g, and the resistivity is 5.2 × 10−5 Ω·m;

- With a Mo2C addition of 6 wt.%, keeping the same sintering pressure (30 MPa) and holding time (16 min) while varying the sintering temperature, the XRD diffraction peak intensities of Ti(C, N) and WC decrease. At a sintering temperature of 1450 °C, the Ti(C, N) grains achieve their smallest size (0.58 μm), accompanied by a uniform thickness of the rim phase and optimal mechanical properties of the sample. Under these conditions, the sample exhibits a density of 5.96 g/cm3, a Vickers hardness of HV 2318, a fracture toughness of 8.2 MPa·m1/2, a saturation magnetization strength of 10.0 emu/g, and a resistivity of 4.8 × 10−5 Ω·m;

- With a Mo2C addition of 6 wt.%, maintaining a sintering temperature of 1450 °C and a sintering pressure of 25 MPa, and varying the holding time, the XRD diffraction peaks of Ti(C, N) shift to lower angles as the holding time increases. At a holding time of 16 min, the sample exhibits a clear core-ring interface, a uniformly thick ring phase, and the smallest hard phase grain size (0.62 µm). Under these conditions, the sample achieves a density of 6.47 g/cm3, a Vickers hardness of HV 2845, a fracture toughness of 11.7 MPa·m1/2 a saturation magnetization strength of 7.25 emu/g, and a resistivity of 5.3 × 10−5 Ω·m;

- With a Mo2C addition of 6 wt.%, the optimal sintering conditions of the samples are a sintering temperature of 1450 °C, a holding time of 16 min, and a sintering pressure of 25 MPa. Under these conditions, the prepared samples exhibit the best properties, including a density of 6.27 g/cm3, Vickers hardness of HV 2731, fracture toughness of 10.1 MPa·m1/3, saturated magnetization strength of 10.3 emu/g, and resistivity of 5.5 × 10−5 Ω·m. In comparison to samples without Mo2C, the presence of Mo2C resulted in notable improvements in hardness, density, and fracture toughness, with increases of 63%, 15%, and 84%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, M.M.; Jiang, Y.; Lin, N.; Kang, X.Y.; Yan, Y.; Huang, J.H.; Liu, Y.; Qiu, S.; He, Y.H. Investigation of the oxidation behavior and high oxidation-resistant mechanism of Ti(C, N)-based cermets. Corros. Sci. 2020, 177, 108959. [Google Scholar] [CrossRef]

- Yang, X.H.; Wang, K.F.; Zhang, G.H.; Chou, K.C. Fabrication and performances of WC-Co cemented carbide with a low cobalt content. J. Appl. Ceram. Technol. 2022, 19, 1341–1353. [Google Scholar] [CrossRef]

- Rogachev, A.S.; Vadchenko, S.G.; Kochetov, N.A.; Kovalev, D.Y.; Politano, O. Combustion synthesis of TiC-based ceramic-metal composites with high entropy alloy binder. J. Eur. Ceram. Soc. 2019, 40, 2527–2532. [Google Scholar] [CrossRef]

- Chicardi, E.; Bermejo, R.; Gotor, F.J.; Llanes, L.; Torres, Y. Influence of tempe-rature on the biaxial strength of cemented carbides with different microstructures. Int. J. Refract. Met. Hard Mater. 2018, 71, 82–91. [Google Scholar] [CrossRef]

- Willersinn, S.; Bart, H.J. Reactive extraction and critical raw materials: Industrial recovery of tungsten. Chem. Ing. Tech. 2017, 89, 82–91. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, H.B.; Zhao, C.; Hu, H.X.; Liu, X.M.; Song, X.Y. Nanocrystalline WC-Co composite with ultrahigh hardness and toughness. Compos. Part B Eng. 2020, 197, 108161. [Google Scholar] [CrossRef]

- Xian, G.; Xiong, J.; Fan, H.Y.; Jiang, F.; Zhao, H.B.; Xian, L.J.; Qin, Z.H. Mechanical and wear properties of TiN films on differently pretreated TiCN-based cermets. Appl. Surf. Sci. 2021, 570, 151180. [Google Scholar] [CrossRef]

- Kang, X.Y.; Lin, N.; He, Y.H.; Zhang, Q.K.; Zhang, M.M.; Yan, Y.; Liu, Y. Improvement of microstructure, mechanical properties and cutting performance of Ti(C, N)-based cermets by ultrafine La2O3 additions. Ceram. Int. 2021, 47, 19934–19944. [Google Scholar] [CrossRef]

- Besharatloo, H.; de Nicolás, M.; Roa, J.J.; Dios, M.; Mateo, A.; Ferrari, B.; Gordo, E.; Llanes, L. Assessment of mechanical properties at microstructural length scale of Ti(C, N)–FeNi ceramic-metal composites by means of massive nano-indentation and statistical analysis. Ceram. Int. 2019, 45, 20202–20210. [Google Scholar] [CrossRef]

- Liang, L.Q.; Wei, B.X.; Wang, D.; Fang, W.B.; Chen, L.; Wang, Y.J. Densification, microstructures, and mechanical properties of (Zr, Ti)(C, N) ceramics fabricated by spark plasma sintering. J. Eur. Ceram. Soc. 2022, 42, 6445–6456. [Google Scholar] [CrossRef]

- Zhang, G.T.; Zheng, Y.; Ke, Z.; Zhang, J.J.; Zhao, Y.J.; Lu, X.P. Effect of WC content on the microstructure and mechanical properties of Ti(C, N)-based cermets fabricated by insitu carbothermal reduction of TiO2. Mat. Sci. Eng. A-Struct. 2019, 761, 138024. [Google Scholar] [CrossRef]

- Arvidsson, R.; Söderman, M.L.; Sandén, B.A.; Nordelöf, A.; André, H.; Tillman, A.M. A crustal scarcity indicator for long-term global elemental resource assessment in LCA. Int. J. Life Cycle Assess. 2020, 25, 1805–1817. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, Q.F.; Dong, Z.J.; Zhou, X.Q.; Zhang, B.Y.; Meng, C. Microstructure and mechanical properties of multicomponent metal Ti(C, N)-based cermets. Metals 2020, 10, 927. [Google Scholar] [CrossRef]

- Liu, J.B.; Huo, Y.L.; Xiong, J.; Guo, Z.X.; Yang, T.E.; Ye, J.L.; Zhao, J.F.; Liu, Y. Growth and prope-rties of multi-layer nano CrAlN/TiAlN composite coating on the cermets with CrFeCoNiMo, CrFeCoNiMn, CrFeCoNiAl high entropy alloy phase. Appl. Surf. Sci. 2022, 572, 151309. [Google Scholar] [CrossRef]

- Lengauer, W.; Scagnetto, F. Ti(C, N)-based cermets: Critical review of achievements and recent developments. Solid State Phenom. 2018, 274, 53–100. [Google Scholar] [CrossRef]

- Yu, H.J.; Liu, Y.; Jin, Y.Z.; Ye, J.W. Effect of secondary carbides addition on the microstructure and mechanical properties of (Ti, W, Mo, V)(C, N)-based cermets. Int. J. Refract. Met. Hard Mater. 2011, 29, 586–590. [Google Scholar] [CrossRef]

- Wan, W.C.; Wang, J.; Liang, M.X.; Fan, K.Y.; Wang, Z.Y.; Li, Y.H. Fracture behaviors of Ti(C, N)-based cermets with different contents of metal binder. Ceram. Int. 2022, 48, 32399–32408. [Google Scholar] [CrossRef]

- Guo, S.Q. Physical and mechanical behaviours of hot-pressed TaC–HfC ceramics with La2O3 additive. Adv. Appl. Ceram. 2021, 120, 117–126. [Google Scholar] [CrossRef]

- Wan, W.C.; Xiong, J.; Liang, M.X. Effects of secondary carbides on the microstructure, mechanical properties and erosive wear of Ti(C, N)-based cermets. Ceram. Int. 2017, 43, 944–952. [Google Scholar] [CrossRef]

- Yin, Z.B.; Yuan, J.T.; Xu, W.W.; Ye, J.D.; Liu, K.; Yan, S.Y. Improvement in microstructure and mechanical properties of Ti(C, N) cermets prepared by two-step spark plasma sintering. Ceram. Int. 2019, 45, 752–758. [Google Scholar] [CrossRef]

- Patel, U.S.; Rawal, S.K.; Arif, A.F.M.; Veldhuis, S.C. Influence of secondary carbides on microstructure, wear mechanism, and tool performance for different cermet grades during high-speed dry finish turning of AISI 304 stainless steel. Wear 2020, 452, 203285. [Google Scholar] [CrossRef]

- Qiu, H.; Li, X.Q.; Pan, C.L.; Fan, J.F.; Qu, S.G. Effect of Mo2C addition on the form-ation of core-rim structure and mechanical properties of Ti(C, N)-WC-Mo2C-(Ni, Co) cermet. J. Mater. Res. Technol. 2023, 25, 750–762. [Google Scholar] [CrossRef]

- Wang, S.Y.; Xiong, W.H.; Yan, M.S.; Fan, C. Effects of molybdenum on the microstructure and mechanical properties of Ti(C, N)-based cermets with low Ni. Rare Met. 2006, 25, 90–95. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Wan, W.C.; Wang, J.; Fan, K.Y.; Li, Y.H.; Xiong, J.; Du, H. Carburization and wear behavior of self-lubricating Ti(C, N)-based cermets with various secondary carbides. Ceram. Int. 2021, 47, 26678–26691. [Google Scholar] [CrossRef]

- Zhao, L.B.; Lin, N.; Han, X.Q.; Ma, C.; Wang, Z.Y.; He, Y.H. Influence of microstructure evolution on mechanical properties, wear resistance and corrosion resistance of Ti(C, N)-based cermet tools with various WC additions. Met. Mater. Int. 2021, 27, 2773–2781. [Google Scholar] [CrossRef]

- Song, J.P.; Gao, J.J.; Rafiq, A.; Lv, M. Cutting performances of TiCN–HfC and TiCN–HfC–WC ceramic tools in dry turning hardened AISI H13. Adv. Appl. Ceram. 2020, 119, 380–386. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Zhang, Z.H.; Cheng, X.W.; Wang, F.C.; Zhang, Y.F.; Li, S.L. A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 2020, 191, 108662. [Google Scholar] [CrossRef]

- Tokita, M. Progress of spark plasma sintering (SPS) method, systems, ceramics applications and industrialization. Ceramics 2021, 4, 160–198. [Google Scholar] [CrossRef]

- Babapoor, A.; Asl, M.S.; Ahmadi, Z.; Namini, A.S. Effects of spark plasma sintering temperature on densification, hardness and thermal conductivity of titanium carbide. Ceram. Int. 2018, 44, 14541–14546. [Google Scholar] [CrossRef]

- Han, C.L.; Tian, C.G. Effect of Mo2C on the microstructure and mechanical properties of (Ti,W)C–Ni cermets. Powder Metall. Met. Ceram. 2014, 53, 57–63. [Google Scholar] [CrossRef]

- Li, P.P.; Ye, J.W.; Liu, Y.; Yang, D.J.; Yu, H.J. Study on the formation of core–rim structure in Ti(CN)-based cermets. Int. J. Refract. Met. Hard Mater. 2012, 35, 27–31. [Google Scholar] [CrossRef]

- Xiao, P.; Ge, X.M.; Wang, H.B.; Liu, Z.L.; Fisher, A.; Wang, X. Novel molybdenum carbide–tungsten carbide composite nanowires and their electrochemical activation for efficient and stable hydrogen evolution. Adv. Funct. Mater. 2015, 25, 1520–1526. [Google Scholar] [CrossRef]

- Pang, X.M.; Zhou, F.L.; Li, B.; Jiang, J.X.; Zhou, J.X. Optical thermostability and weatherability of TiN/TiC-Ni/Mo cermet-based spectral selective absorbing coating by laser cladding. Opt. Mater. 2021, 117, 111195. [Google Scholar] [CrossRef]

- Li, M.S.; Li, X.F.; Li, W.H.; Meng, X.B.; Yu, Y.; Sun, X.L. Atomic layer deposition derived amorphous TiO2 thin film decorating graphene nanosheets with superior rate capability. Electrochem. Commun. 2015, 57, 43–47. [Google Scholar] [CrossRef]

- Xiong, B.Y.; Zhao, W.B.; Chen, L.S.; Shi, J.L. One-step synthesis of W2C@N,P-C nanocatalysts for efficient hydrogen electrooxidation across the whole pH range. Adv. Funct. Mater. 2019, 29, 1902505. [Google Scholar] [CrossRef]

- Ke, Z.; Zheng, Y.; Zhang, G.T.; Wu, H.; Xu, X.Y.; Lu, X.P.; Zhu, X.G. Fabrication of dual-grain structure WC-Co cemented carbide by in-situ carbothermal reduction of WO3 and subsequent liquid sintering. Ceram. Int. 2020, 46, 12767–12772. [Google Scholar] [CrossRef]

- Xi, Z.W.; Jia, W.Z.; Zhu, Z.R. WO3–ZrO2–TiO2 Composite oxide supported Pt as an efficient catalyst for continuous hydrogenolysis of glycerol. Catal. Lett. 2021, 151, 124–137. [Google Scholar] [CrossRef]

- YMa, Y.; Wang, C.Y.; Qin, Z.H.; Chen, G.Q.; Xia, L.; Zhong, B. Preparation of cauliflower shaped hp-Co/GNs composite microwave absorbing materials. Mater. Charact. 2022, 189, 111907. [Google Scholar] [CrossRef]

- Wang, C.G.; Zhao, S.S.; Song, X.X.; Wang, N.N.; Peng, H.L.; Su, J.; Zeng, S.Y.; Xu, X.J.; Yang, J. Suppressed Dissolution and Enhanced Desolvation in Core-Shell MoO3@ TiO2 Nanorods as a High-Rate and Long-Life Anode Material for Proton Batteries. Adv. Energy Mater. 2022, 12, 2200157. [Google Scholar] [CrossRef]

- Gou, Q.S.; Xiong, J.; Guo, Z.X.; Liu, J.B.; Yang, L.; Li, X.R. Influence of NbC additions on microstructure and wear resistance of Ti(C, N)-based cermets bonded by CoCrFeNi high-entropy alloy. Int. J. Refract. Met. Hard Mater. 2021, 94, 105375. [Google Scholar] [CrossRef]

- Kang, X.Y.; Lin, N.; He, Y.H.; Zhang, M.M. Influence of ZrC addition on the microstructure, mechanical properties and oxidation resistance of Ti(C, N)-based cermets. Ceram. Int. 2018, 44, 11151–11159. [Google Scholar] [CrossRef]

- Xiong, H.W.; Wu, Y.X.; Li, Z.Y.; Gan, X.P.; Zhou, K.C.; Chai, L.Y. Comparison of Ti(C, N)-based cermets by vacuum and gas-pressure sintering: Microstructure and mechanical properties. Ceram. Int. 2018, 44, 805–813. [Google Scholar] [CrossRef]

- Rafiaei, S.M.; Bahrami, A.; Shokouhimehr, M. Influence of Ni/Co binders and Mo2C on the microstructure evolution and mechanical properties of (Ti0.93W0.07)C–based cermets. Ceram. Int. 2018, 44, 17655–17659. [Google Scholar] [CrossRef]

- Dong, D.Q.; Yang, W.; Xiang, X.; Huang, B.; Xiong, H.W.; Zhang, L.; Shi, K.H. Microstructural evolution and phase transition mechanism of Ti(C, N)-based cermets during vacuum sintering process. Ceram. Int. 2021, 47, 8020–8029. [Google Scholar] [CrossRef]

- Gao, J.J.; Song, J.P.; Lv, M. Microstructure and mechanical properties of TiC0.7N0.3-HfC-WC-Ni-Mo cermet tool materials. Materials 2018, 11, 968. [Google Scholar] [CrossRef]

- Lu, Z.Y.; Du, J.; Sun, Y.J.; Su, G.S.; Zhang, C.Y.; Kong, X.M. Effect of ultrafine WC contents on the microstructures, mechanical properties and wear resistances of regenerated coarse grained WC-10Co cemented carbides. Int. J. Refract. Met. Hard Mater. 2021, 97, 105516. [Google Scholar] [CrossRef]

- Rafiaei, S.M.; Kim, J.H.; Kang, S. Effect of nitrogen and secondary carbide on the microstructure and properties of (Ti0.93W0.07)C–Ni cermets. Int. J. Refract. Met. Hard Mater. 2014, 44, 123–128. [Google Scholar] [CrossRef]

- Huang, J.H.; Huang, S.G.; Zhou, P.; Lauwers, B.; Qian, J.; Vleugels, J. Microstructure and mechanical properties of WC or Mo2C modified NbC-Ni cermets. Int. J. Refract. Met. Hard Mater. 2021, 95, 105440. [Google Scholar] [CrossRef]

- Zhou, H.J.; Huang, M.C.; Yang, H.; Tao, H.L.; Yin, Y.H.; Luo, F.H. Densification kinetics and sintering behaviour of a Ti(C0.7N0.3)-WC-Mo2C–NbC-(Co,Ni) compact. J. Alloys Compd. 2020, 843, 156072. [Google Scholar] [CrossRef]

- Aramian, A.; Sadeghian, Z.; Narimani, M.; Razavi, N.; Berto, F. A review on the microstructure and properties of TiC and Ti(C, N) based cermets. Int. J. Refract. Met. Hard Mater. 2023, 115, 106320. [Google Scholar] [CrossRef]

- Heydari, L.; Lietor, P.F.; Corpas-Iglesias, F.A.; Laguna, O.H. Ti(C, N) and WC-based cermets: A review of synthesis, properties and applications in additive manufacturing. Materials 2021, 14, 6786. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.Q.; Xiong, W.H.; Zhou, S.Q.; Zhang, M.; Huang, B.; Chen, S. Magnetization of TiC–10TiN–xMC–yNi (MC=Mo2C, WC) cermets. Mater. Des. 2017, 115, 255–261. [Google Scholar] [CrossRef]

- Lóh, N.J.; Simão, L.; Faller, C.A.; De Noni, A.; Montedo, O.R.K. A review of two-step sintering for ceramics. Ceram. Int. 2018, 42, 12556–12572. [Google Scholar] [CrossRef]

- Akhtar, K.; Khan, S.A.; Khan, S.B.; Asiri, A.M. Scanning Electron Microscopy: Principle and Applications in Nanomaterials Characterization. In Handbook of Materials Characterization; Sharmam, S.K., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 113–145. [Google Scholar] [CrossRef]

- Shetty, D.K.; Wright, I.G.; Mincer, P.N.; Clauer, A.H. Indentation fracture of WC-Co cermets. J. Mater. Sci. 1985, 20, 1873–1882. [Google Scholar] [CrossRef]

| Powder | Ti(C, N) | WC | Co | Mo2C |

|---|---|---|---|---|

| Particle size (μm) | 0.62 | 0.2 | 0.05 | 3 |

| Purity | 99.9% | 99.9% | 99.9% | 99.9% |

| Ti(C, N) (wt.%) | WC (wt.%) | Co (wt.%) | Mo2C (wt.%) |

|---|---|---|---|

| 67 | 25 | 8 | 0.0 |

| 65 | 25 | 8 | 2.0 |

| 63 | 25 | 8 | 4.0 |

| 61 | 25 | 8 | 6.0 |

| 59 | 25 | 8 | 8.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, M.; Zhao, Z.; Zhang, G.; Zheng, H. Effects of Mo2C on Microstructures and Comprehensive Properties of Ti(C, N)-Based Cermets Prepared Using Spark Plasma Sintering. Molecules 2025, 30, 492. https://doi.org/10.3390/molecules30030492

Qiao M, Zhao Z, Zhang G, Zheng H. Effects of Mo2C on Microstructures and Comprehensive Properties of Ti(C, N)-Based Cermets Prepared Using Spark Plasma Sintering. Molecules. 2025; 30(3):492. https://doi.org/10.3390/molecules30030492

Chicago/Turabian StyleQiao, Mu, Zhiwei Zhao, Guoguo Zhang, and Hongjuan Zheng. 2025. "Effects of Mo2C on Microstructures and Comprehensive Properties of Ti(C, N)-Based Cermets Prepared Using Spark Plasma Sintering" Molecules 30, no. 3: 492. https://doi.org/10.3390/molecules30030492

APA StyleQiao, M., Zhao, Z., Zhang, G., & Zheng, H. (2025). Effects of Mo2C on Microstructures and Comprehensive Properties of Ti(C, N)-Based Cermets Prepared Using Spark Plasma Sintering. Molecules, 30(3), 492. https://doi.org/10.3390/molecules30030492