Research on Improving Pretreatment Process of Banana Fiber Fabric with Rare Earth

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Pretreatment Process of Banana Fiber Fabric

2.3. Performance Test

2.4. Hydrogen Peroxide Decomposition Ratio Measurement

2.5. Characterization

3. Results and Discussion

3.1. Factors Affecting the Pretreatment Performance of Banana Fiber Fabric

3.1.1. Rare Earth La2O3 Concentration

3.1.2. Hydrogen Peroxide Concentration

3.1.3. Stabilizer Concentration

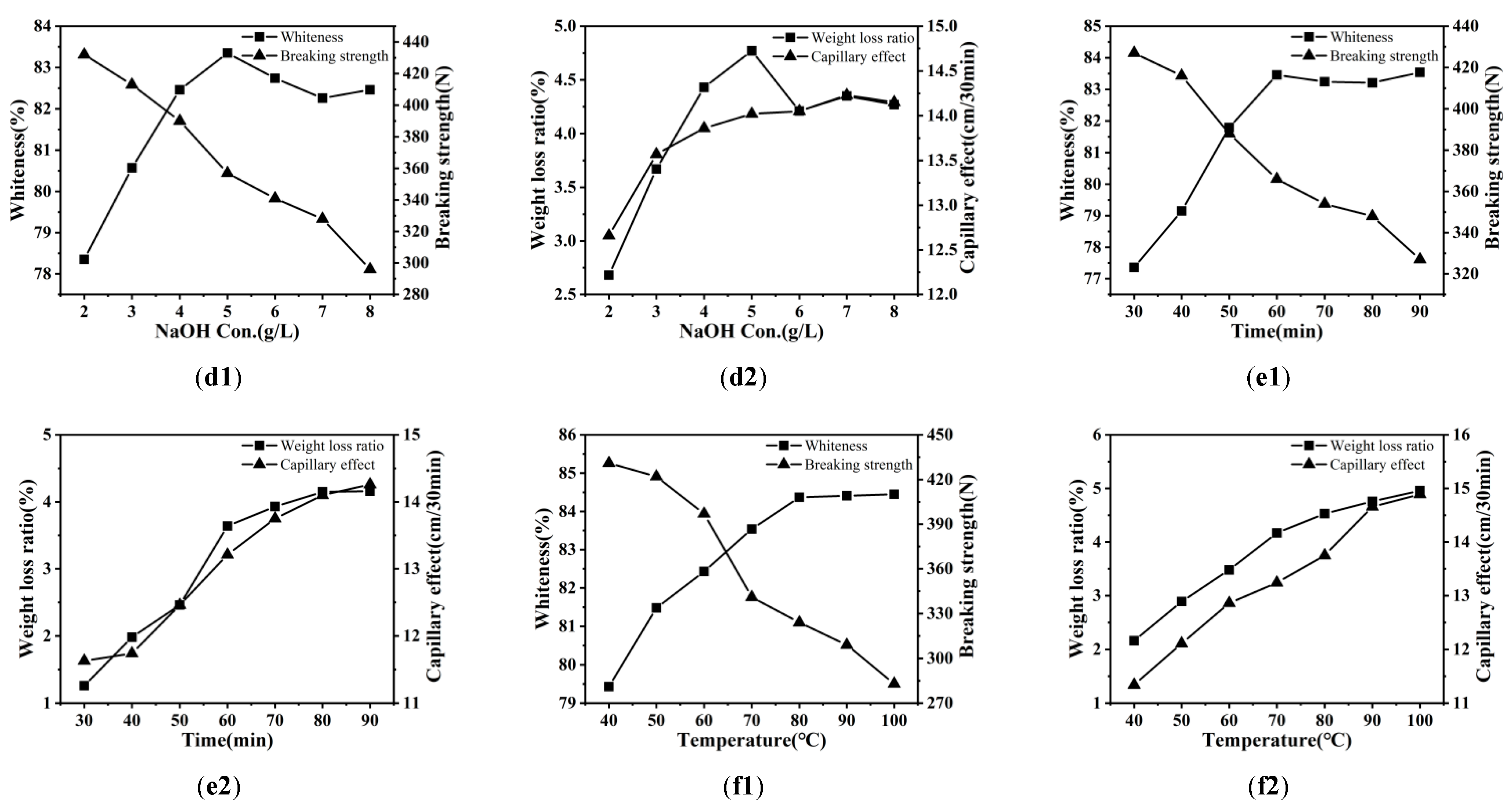

3.1.4. Sodium Hydroxide Concentration

3.1.5. Processing Time

3.1.6. Processing Temperature

3.2. Orthogonal Optimization of the Banana Fiber Fabric Pretreatment Process

3.3. Comparison of Properties Between Rare Earth La2O3/H2O2 Pretreatment and Traditional Pretreatment of Banana Fiber Fabric

3.3.1. Whiteness, Breaking Strength, and Capillary Effect of the Fabric

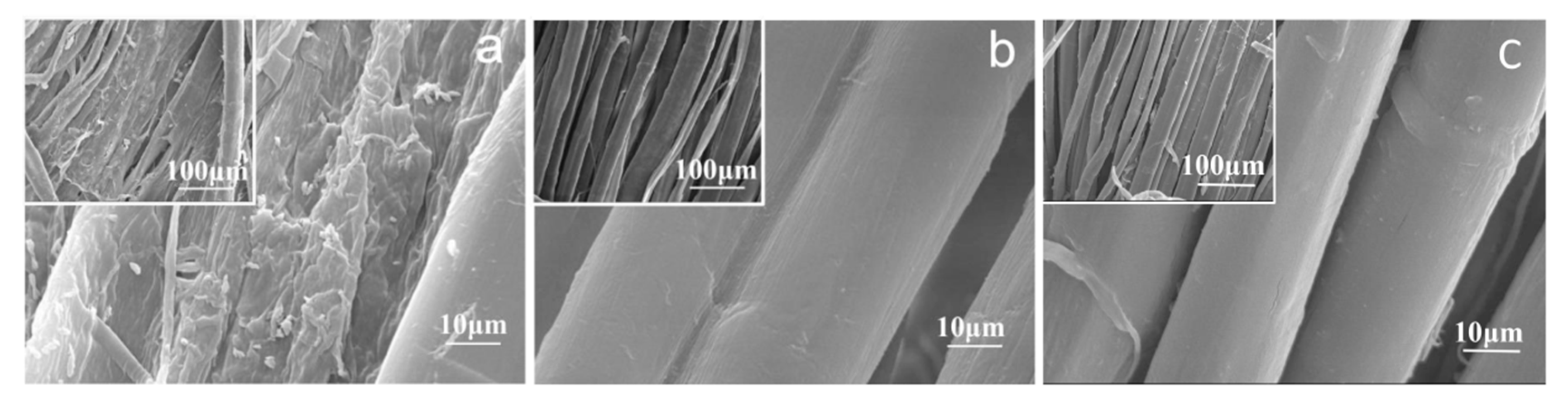

3.3.2. Scanning Electron Microscopy (SEM)

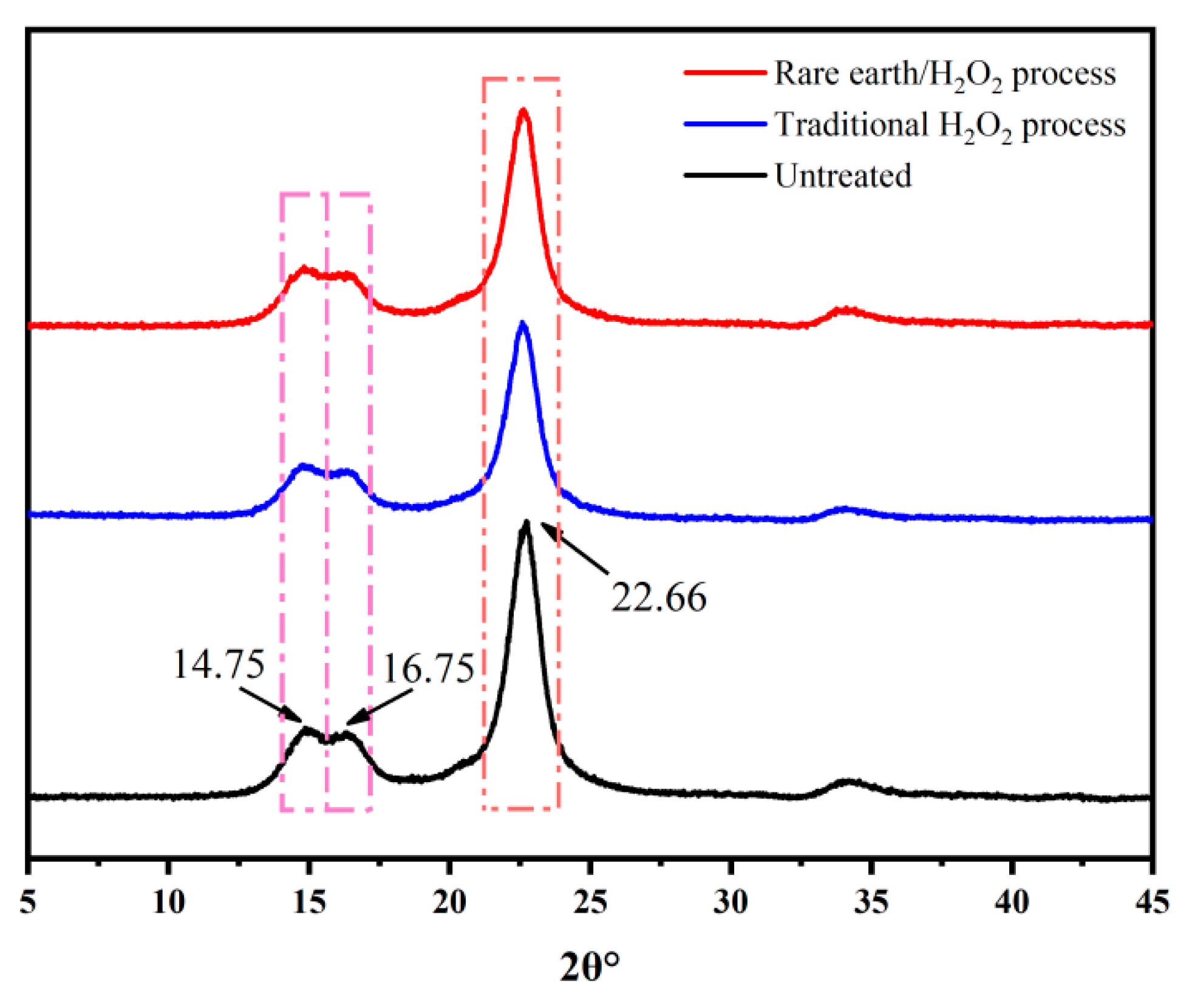

3.3.3. XRD

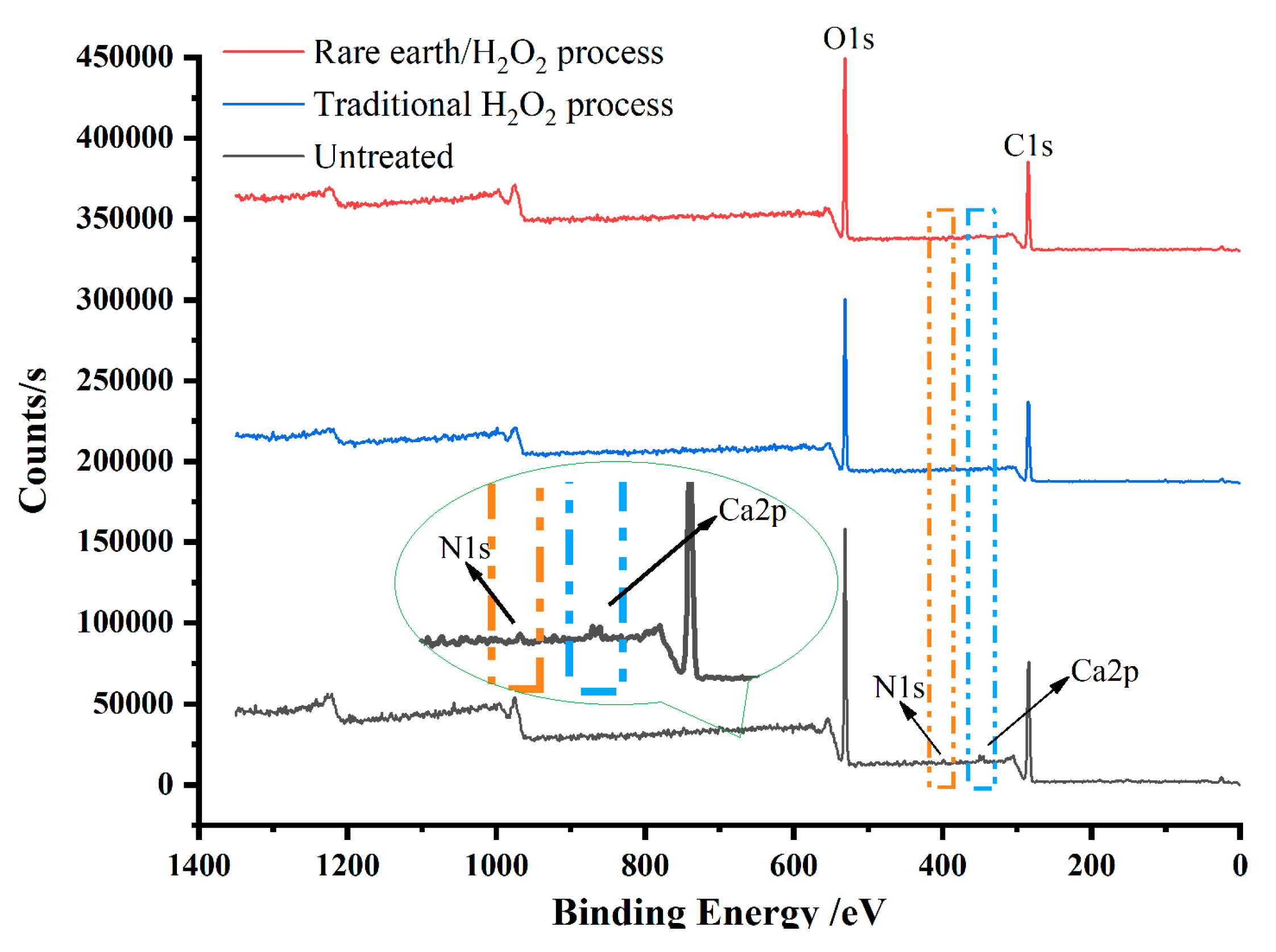

3.3.4. XPS

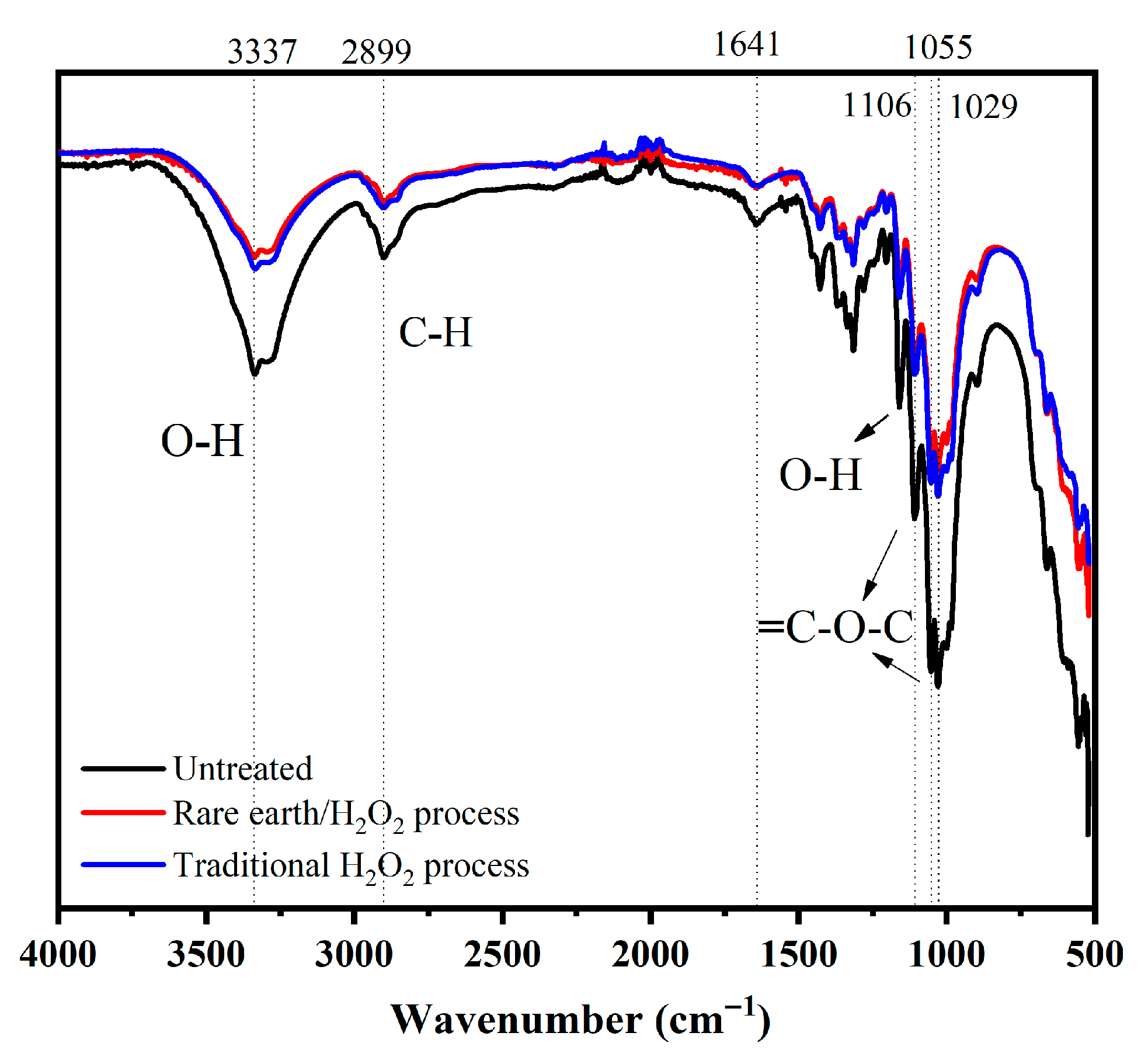

3.3.5. Infrared Spectrogram (FT-IR)

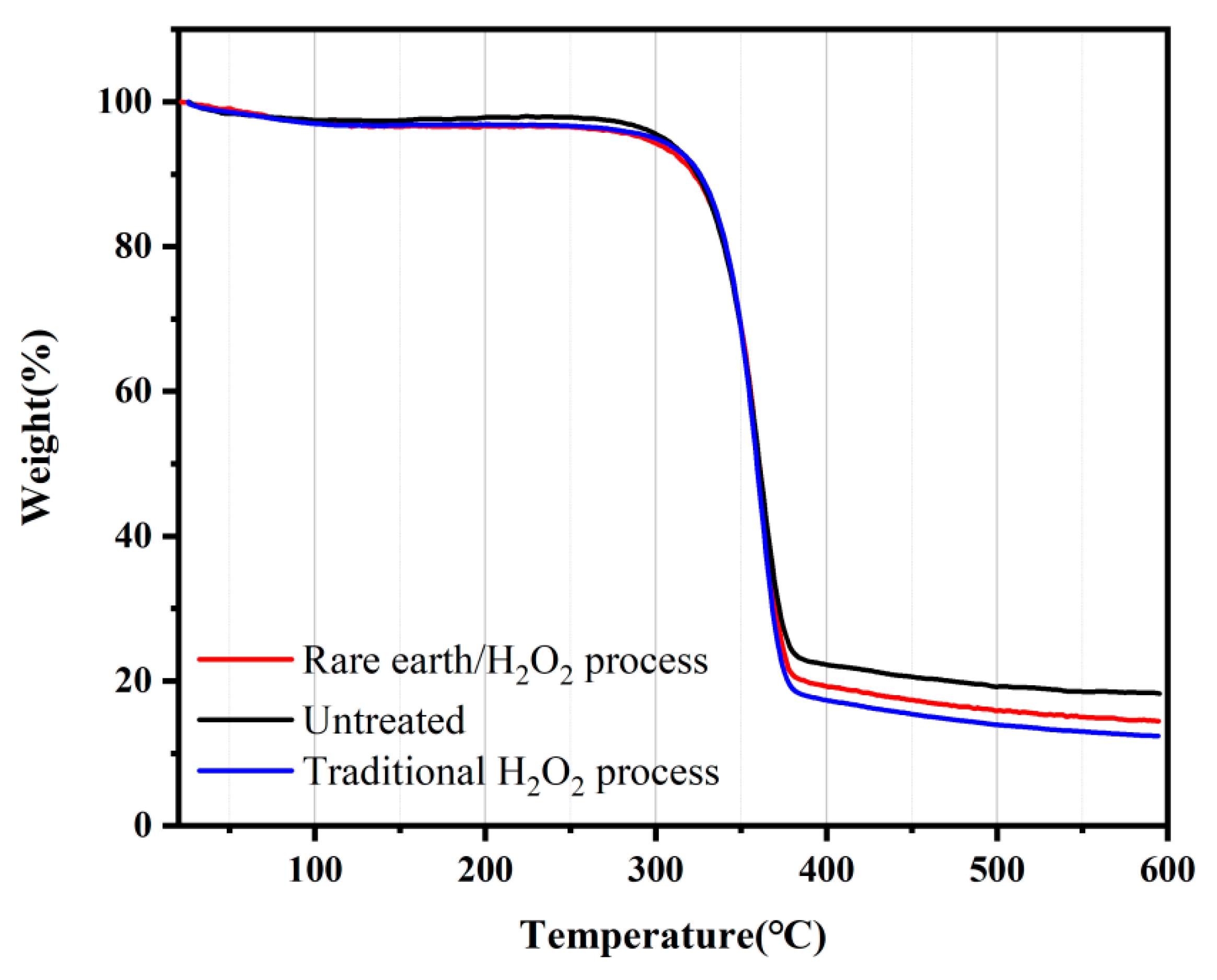

3.3.6. Thermal Gravimetric Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, P. The Analysis of the Production, Consumption, Import and Export, and Price Trend of the Global and Chinese Banana Industry in 2023 [www Document]. 2023. Available online: https://m.huaon.com/detail/912398.html (accessed on 21 July 2023).

- Jiang, W.; Liu, J. Research status and prospect of banana fiber. Cellul. Sci. Tech. 2021, 29, 70–76. [Google Scholar] [CrossRef]

- Sengupta, S.; Debnath, S.; Ghosh, P.; Mustafa, I. Development of Unconventional Fabric from Banana (Musa Acuminata) Fibre for Industrial Uses. J. Nat. Fibres. 2020, 17, 1212–1224. [Google Scholar] [CrossRef]

- Khan, A.; Iftikhar, K.; Mohsin, M.; Ubaidullah, M.; Ali, M.; Mueen, A. Banana agro-waste as an alternative to cotton fibre in textile applications. Yarn to fabric: An ecofriendly approach. Ind. Crop. Prod. 2022, 189, 115687. [Google Scholar] [CrossRef]

- Subramanya, R.; Satyanarayana, K.G.; Pilar, B. Evaluation of Structural, Tensile, and Thermal Properties of Banana Fiber. J. Nat. Fibers. 2017, 14, 485–497. [Google Scholar] [CrossRef]

- Monzón, M.; Paz, R.; Verdaguer, M.; Suárez, L.; Badallό, P.; Ortega, Z.; Diaz, N. Experimental analysis and simulation of novel technical textile reinforced composite of banana fibre. Materials 2019, 12, 1134. [Google Scholar] [CrossRef] [PubMed]

- Chen, M. Characteristics difference between banana fiber and flax, ramie fiber. J. Ningbo Univ. (Sci. Tech.) 2010, 23, 109–112. [Google Scholar] [CrossRef]

- Pothan, L.A.; Thomas, S.; Neelakantan, N.R. Short banana fiber reinforced polyester composites: Mechanical, failure and aging characteristics. J. Reinf. Plast. Compos. 1997, 16, 744–765. [Google Scholar] [CrossRef]

- Wan, M.; Meng, J. New environmentally friendly fiber-banana fiber. Guangxi Text. Sci. Tech. 2009, 38, 38–40. [Google Scholar]

- Xiong, Y.; Cui, Y. Research status and development and application prospect of banana fiber. J. Text. Res. 2007, 9, 122–124. [Google Scholar]

- Ji, R. Application status and development prospect of banana fabric. Shandong Text. Tech. 2010, 51, 45–47. [Google Scholar]

- Chattopadhyay, S.N.; Pan, N.C.; Roy, A.N.; Samanta, K.K. Pretreatment of jute and banana fibre-its effect on blended yarn and fabric. J. Nat. Fibers. 2020, 17, 75–83. [Google Scholar] [CrossRef]

- Cheng, F.; Xu, L.; Dai, J.; Yi, X.; He, J.; Li, H. N,O-carboxymethyl chitosan/oxidized cellulose composite sponge containing ε-Poly-L-Lysine as a potential wound dressing for the prevention and treatment of postoperative adhesion. Int. J. Biol. Macromol. 2022, 209, 2151–2164. [Google Scholar] [CrossRef] [PubMed]

- Balakrishnan, S.; Wickramasinghe, G.L.D.; Wijayapala, U.G.S. A novel approach for banana (Musa) Pseudo-stem fibre grading Method: Extracted fibres from Sri Lankan Banana Cultivars. J. Eng. Fibers Fabr. 2020, 15, 1558925020971766. [Google Scholar] [CrossRef]

- Sheng, Z.; Gao, J.; Jin, Z.; Dai, H.; Zheng, L.; Wang, B. Effect of steam explosion on degumming efficiency and physicochemical characteristics of banana fiber. J. Appl. Polym. Sci. 2014, 131, 500–600. [Google Scholar] [CrossRef]

- Wang, C.; Wang, C.; Zhou, T. Study on degumming of banana stalk fiber by ultrasonic method. J. Guangdong Ins. Petro. Chem. Eng. 2015, 25, 19–22. [Google Scholar]

- Zhang, X.; Guo, J.; Ma, Y.; Yu, L.; Ji, Y.; Guo, Y.; Hao, X. Green Degumming Technology of Hemp and a Comparison between Chemical and Biological Degumming. ACS Omega 2021, 6, 35067–35075. [Google Scholar] [CrossRef] [PubMed]

- Pooja, K.; Reena, G. Application of calcium alginate immobilized and crude pectinlyase from Bacillus cereus in degumming of plant fibres. Biocatal. Biotransfor. 2019, 37, 1–8. [Google Scholar] [CrossRef]

- Perumalsamy, M. Green degumming of banana pseudostem fibers for yarn manufacturing in textile industries. Biomass Conv. Bioref. 2024, 14, 5285–5294. [Google Scholar] [CrossRef]

- Twebaze, C.; Zhang, M.; Zhuang, X.; Kimani, M.; Zheng, G.; Wang, Z. Banana Fiber Degumming by Alkali Treatment and Ultrasonic Methods. J. Nat. Fibers 2022, 19, 12911–12923. [Google Scholar] [CrossRef]

- Ortega, Z.; Morón, M.; Monzón, M.D.; Badallό, P.; Paz, R. Production of banana fiber yarns for technical textile reinforced composites. Materials 2016, 9, 370. [Google Scholar] [CrossRef]

- Wu, X.; Wang, F.; Cui, Y. Banana Bast Fiber and Its Manufacturing Method and Use. Patent CN1317434C, 22 June 2005. [Google Scholar]

- Shen, X.; Hu, Q.; Ge, M. Fabrication and characterization of multi stimuli-responsive fibers via wet-spinning process. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2020, 250, 119245. [Google Scholar] [CrossRef] [PubMed]

- Ezeamaku, U.L.; Onukwuli, O.D.; Ezeh, M.E. Experimental investigation on influence of selected chemical treatment on banana fibre. Ind. Crop. Prod. 2022, 185, 115–135. [Google Scholar] [CrossRef]

- Xiao, H.; Li, J.; Guo, R.; Song, Q.; Ren, E. Comprehensive experimental design of reactive dyeing for cotton fabrics. J. Lab. Sci. 2021, 24, 6-8+12. [Google Scholar]

- Liu, J.; Jiang, W.; Sun, L.; Lv, C. Bleaching flax roving with poly (acrylic acid) magnesium salt as oxygen bleaching stabilizer for hydrogen peroxide. Cellulose 2021, 28, 11701–11712. [Google Scholar] [CrossRef]

- Massari, S.; Ruberti, M. Rare earth elements as critical raw materials: Focus on international markets and future strategies. Resour. Policy 2013, 38, 36–43. [Google Scholar] [CrossRef]

- Lupi, J.F.; Vermillac, M.; Blanca, W.; Mady, F.; Benabdesselam, M.; Dussardier, B.; Neuville, D.R. Impact of cerium and lanthanum on the photo-darkening and photobleaching mechanisms in thulium-doped fibre. Opt. Mater. 2017, 72, 106–114. [Google Scholar] [CrossRef]

- Yu, X.; Gao, T.; Cao, H.; Ge, R.; Hen, M.; Zhou, X. Research Developments in Mechanism of Rare Earth Flameretardant Polymer Materials. Chinese Rare Earths 2021, 42, 131–141. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Du, Q. The Utilization and Approach on the Catalysis Mechanism of the Rare-Earths Element Used in the Cotton Fabrics. Heilongjiang Text. 2001, 19–20. [Google Scholar]

- GB/T 17644-2008; Textile Fiber Whiteness Chroma Test Method. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- GB/T 3923.1-2013; Textiles—Tensile Properties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- FZ/T 01071-2008; Textiles—Test Method for Capillary Effect. National Development and Reform Commission of the People’s Republic of China: Beijing, China, 2008.

- Liu, Z.; Zhang, J.; Zhu, P.; Wang, B.; Dong, C. Application of rare earth in textile industry. J. Text. Dye Fini. 2006, 28, 13–16. [Google Scholar]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose. 2014, 21, 885–896. [Google Scholar] [CrossRef]

- French, A.D. Increment in evolution of cellulose crystallinity analysis. Cellulose 2020, 27, 5445–5448. [Google Scholar] [CrossRef]

- Wang, L.; Wu, L.; Wang, C.; Zhang, Q.; Xia, X. Preparation of apocynum nanocellulose fiber by TEMPO oxidation method. J. Ind. Text. 2021, 39, 11–16. [Google Scholar]

| No | A (La2O3 Con.) % | B (H2O2 Con.) g/L | C (NaOH Con.) g/L | D (Temperature) °C | Whiteness % | Breaking Strength N |

|---|---|---|---|---|---|---|

| 1 | 0.20 | 7.0 | 4.5 | 65 | 82.30 | 368.60 |

| 2 | 0.20 | 7.5 | 5.0 | 75 | 82.87 | 386.00 |

| 3 | 0.20 | 8.0 | 5.5 | 85 | 82.81 | 375.40 |

| 4 | 0.20 | 8.5 | 6.0 | 95 | 82.97 | 368.00 |

| 5 | 0.25 | 7.0 | 5.0 | 85 | 83.71 | 367.40 |

| 6 | 0.25 | 7.5 | 4.5 | 95 | 83.89 | 387.20 |

| 7 | 0.25 | 8.0 | 6.0 | 65 | 82.51 | 413.00 |

| 8 | 0.25 | 8.5 | 5.5 | 75 | 83.53 | 400.40 |

| 9 | 0.30 | 7.0 | 5.5 | 95 | 81.85 | 371.40 |

| 10 | 0.30 | 7.5 | 6.0 | 85 | 82.73 | 376.20 |

| 11 | 0.30 | 8.0 | 4.5 | 75 | 82.87 | 418.20 |

| 12 | 0.30 | 8.5 | 5.0 | 65 | 83.25 | 375.40 |

| 13 | 0.35 | 7.0 | 6.0 | 75 | 83.03 | 354.80 |

| 14 | 0.35 | 7.5 | 5.5 | 65 | 83.56 | 397.00 |

| 15 | 0.35 | 8.0 | 5.0 | 95 | 83.05 | 369.40 |

| 16 | 0.35 | 8.5 | 4.5 | 85 | 82.86 | 387.60 |

| K1 | 82.74 | 82.72 | 82.98 | 82.91 | ||

| K2 | 83.41 | 83.26 | 83.22 | 83.08 | ||

| K3 | 82.68 | 82.81 | 82.94 | 83.03 | ||

| K4 | 83.13 | 83.15 | 82.81 | 82.94 | ||

| R | 0.73 | 0.54 | 0.41 | 0.17 | ||

| K1′ | 374.50 | 365.60 | 390.40 | 388.50 | ||

| K2′ | 392.00 | 386.60 | 374.50 | 389.80 | ||

| K3′ | 385.30 | 394.00 | 386.00 | 376.60 | ||

| K4′ | 377.20 | 382.90 | 378.00 | 374.00 | ||

| R’ | 17.50 | 28.40 | 15.60 | 15.80 |

| Processing Method | Whiteness (%) | Breaking Strength (N) | Capillary Effect (cm/30 min) |

|---|---|---|---|

| Untreated | 68.35 ± 0.05 | 453.80 ± 4.56 | 10.35 ± 0.02 |

| Traditional H2O2 process | 82.66 ± 0.14 | 376.00 ± 3.76 | 14.08 ± 0.01 |

| Rare earth La2O3/H2O2 process | 84.25 ± 0.07 | 416.00 ± 5.20 | 14.26 ± 0.02 |

| Processing Method | Surface Element Content (%) | |||

|---|---|---|---|---|

| C1s | O1s | N1s | Ca2p | |

| Untreated | 63.53 | 33.19 | 2.21 | 1.07 |

| Traditional H2O2 process | 61.98 | 38.02 | 0 | 0 |

| Rare earth La2O3/H2O2 process | 60.21 | 39.79 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Jiang, W.; Lv, C.; Sun, L.; Zheng, Y. Research on Improving Pretreatment Process of Banana Fiber Fabric with Rare Earth. Molecules 2025, 30, 4535. https://doi.org/10.3390/molecules30234535

Liu J, Jiang W, Lv C, Sun L, Zheng Y. Research on Improving Pretreatment Process of Banana Fiber Fabric with Rare Earth. Molecules. 2025; 30(23):4535. https://doi.org/10.3390/molecules30234535

Chicago/Turabian StyleLiu, Jie, Wenqi Jiang, Chun Lv, Lingfang Sun, and Yongjie Zheng. 2025. "Research on Improving Pretreatment Process of Banana Fiber Fabric with Rare Earth" Molecules 30, no. 23: 4535. https://doi.org/10.3390/molecules30234535

APA StyleLiu, J., Jiang, W., Lv, C., Sun, L., & Zheng, Y. (2025). Research on Improving Pretreatment Process of Banana Fiber Fabric with Rare Earth. Molecules, 30(23), 4535. https://doi.org/10.3390/molecules30234535