Reduction Effect of Extra Biochar on PAHs Originating from Corn Stover Pyrolysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Corn Stover Pyrolysis Experiments

2.3. Analytical Methods

2.4. TEQ

3. Results and Discussion

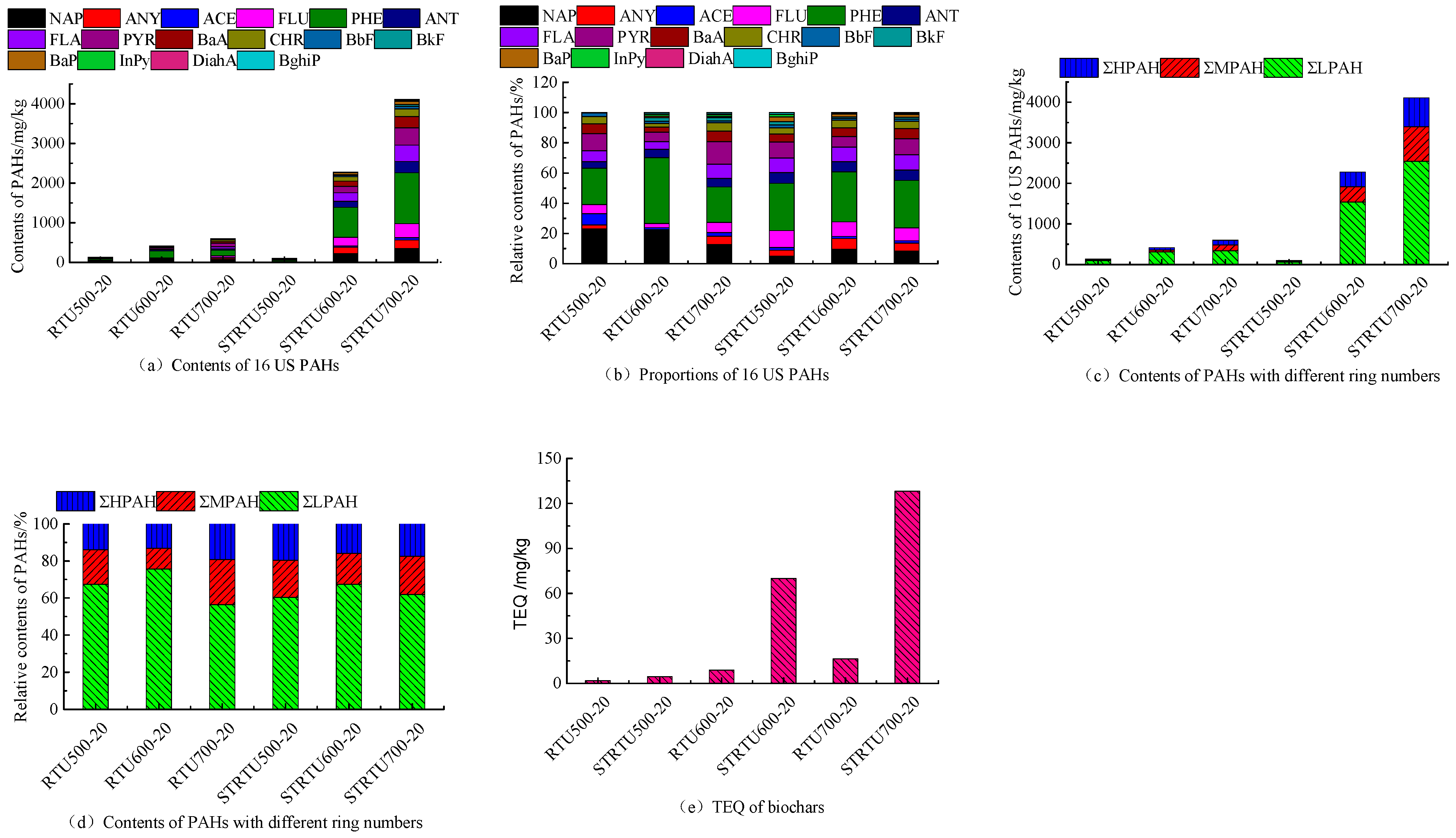

3.1. PAHs in Biochar

3.2. PAHs in Residual Tar

3.3. Correlation Analysis of PAHs Concentrations Between Biochar and Residual Tar

3.4. Biochar Characteristics

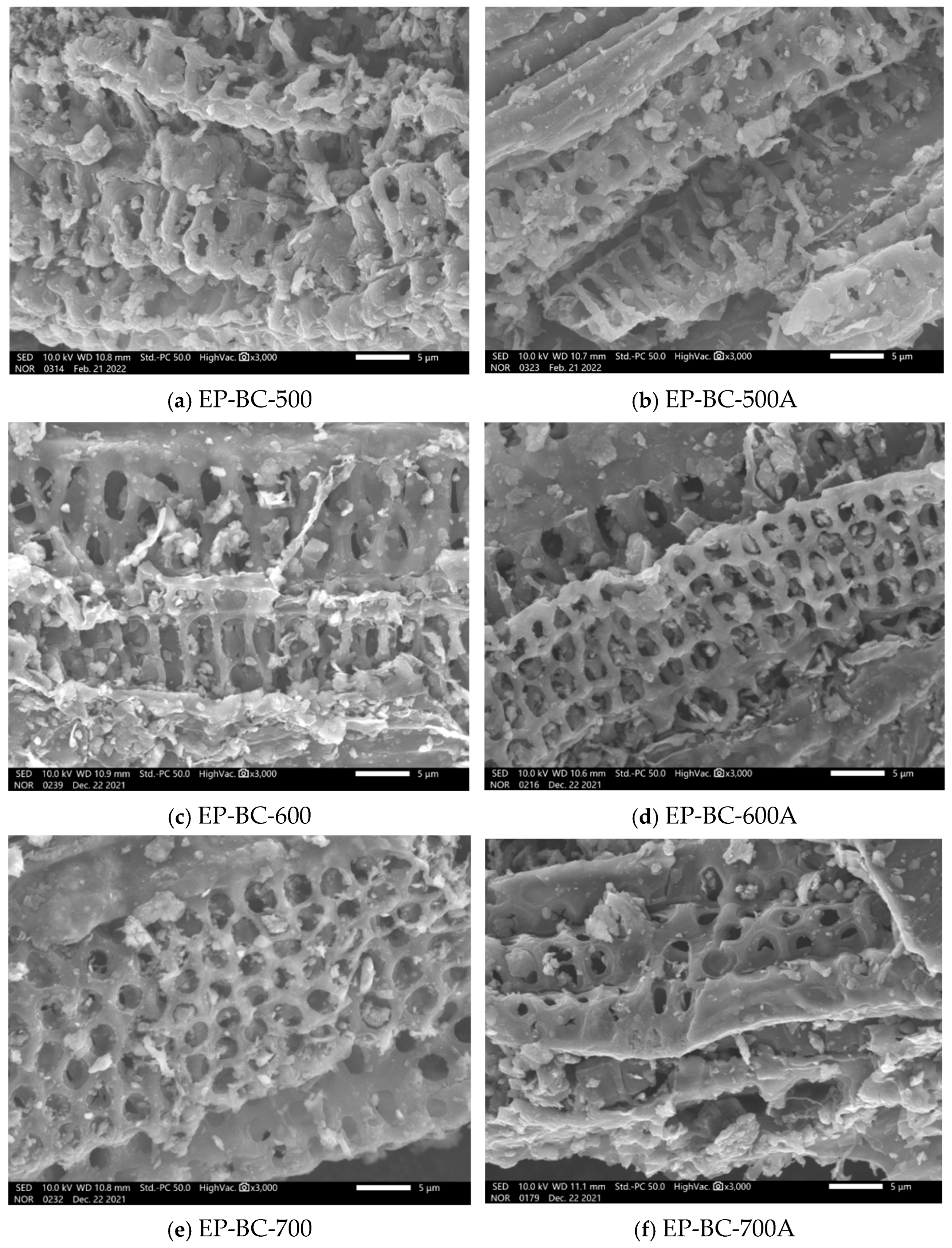

3.4.1. SEM

3.4.2. BET

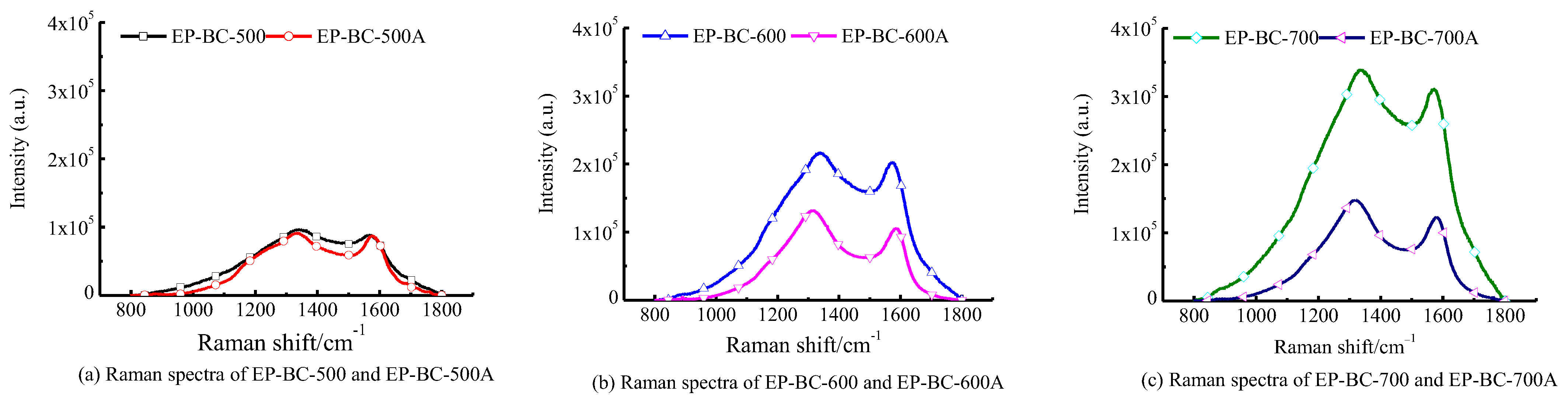

3.4.3. Raman Analysis

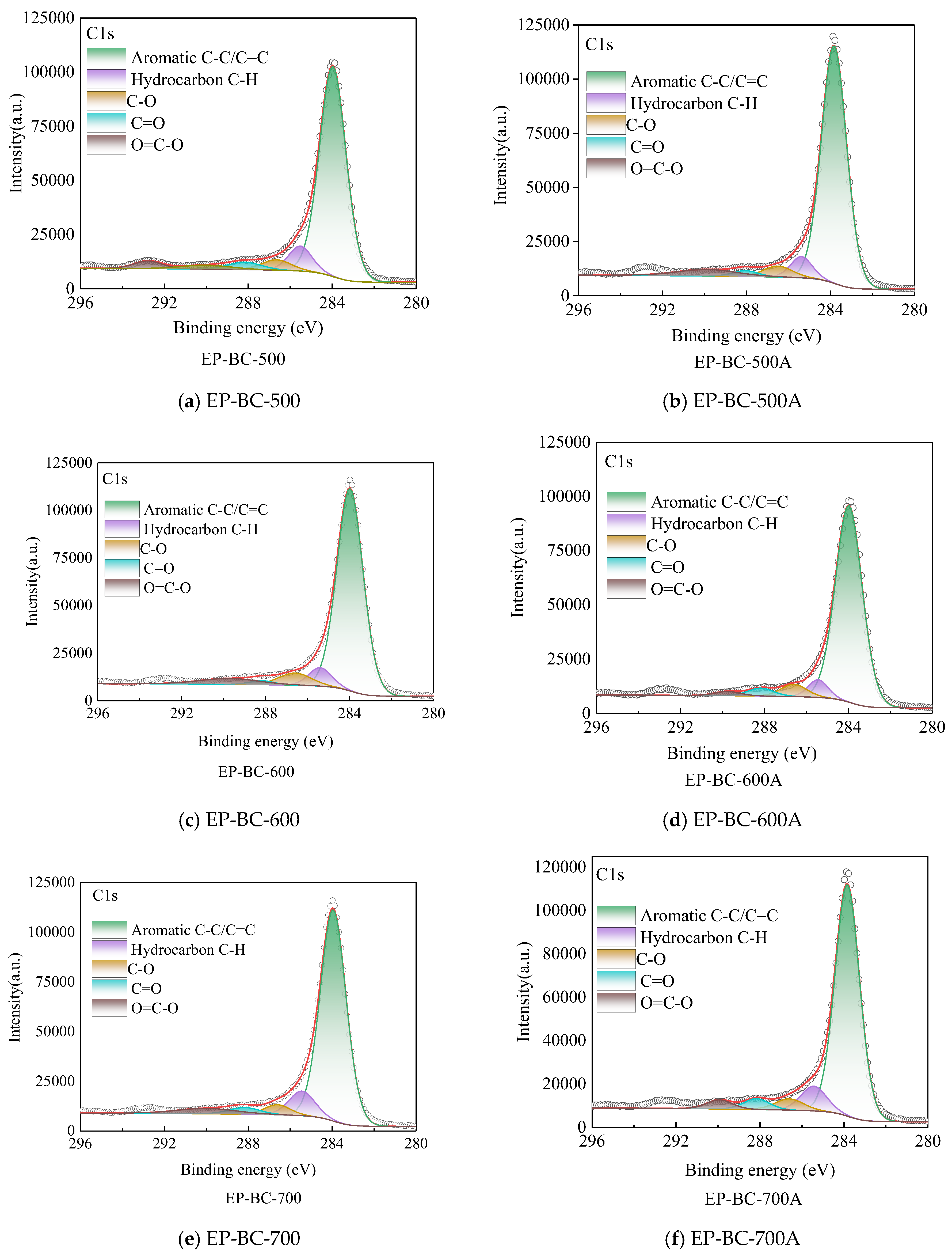

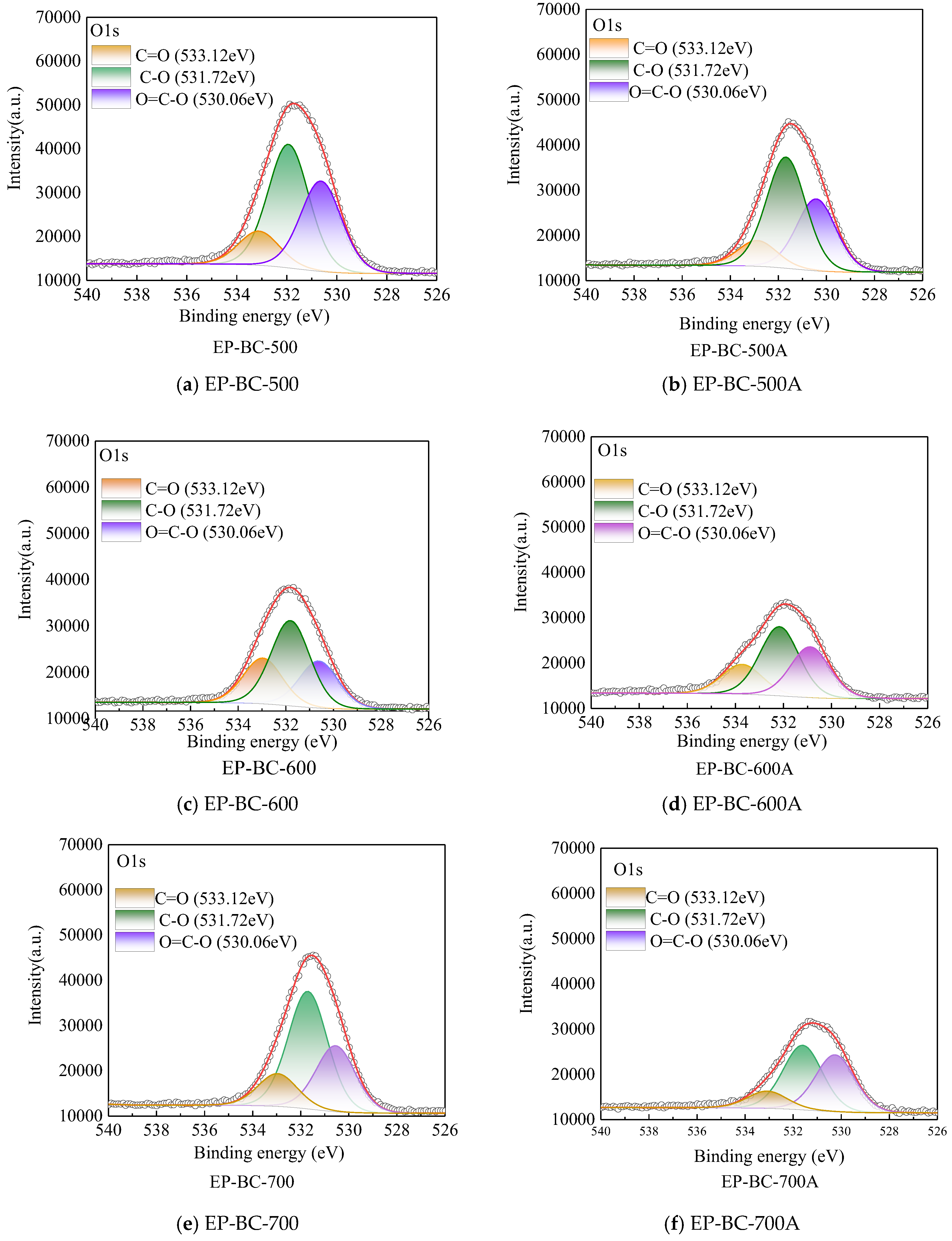

3.4.4. XPS

3.5. Analysis of Pathways for Reducing PAHs in Biochar

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PAHs | polycyclic aromatic hydrocarbons |

| FTIR | Fourier transform infrared |

| BET | Balanced-Emitter Transistor |

| SEM | scanning electron microscope |

| XPS | X-ray photoelectron spectroscopy |

| TEF | Toxic Equivalency Factor |

| TEQ | toxic equivalency |

References

- Zhou, Z.; Li, Z.; Zhang, Z.; You, L.; Xu, L.; Huang, H.; Wang, X.; Gao, Y.; Cui, X. Treatment of the saline-alkali soil with acidic corn stalk biochar and its effect on the sorghum yield in western Songnen Plain. Sci. Total Environ. 2021, 797, 149190. [Google Scholar] [CrossRef]

- Zhang, D.X.; Jie, H.B.; Zhang, W.J.; Yuan, Q.S.; Ma, Z.H.; Wu, H.Z.; Rao, W.; Liu, S.L.; Wang, D.C. Combined biochar and water-retaining agent application increased soil water retention capacity and maize seedling drought resistance in Fluvisols. Sci. Total Environ. 2024, 907, 167885. [Google Scholar] [CrossRef]

- Bolster, C.H. Kinetics of phosphorous sorption to biochar-amended soils. Chemosphere 2023, 345, 140523. [Google Scholar] [CrossRef] [PubMed]

- Ríos Guayasamín, P.D.; Smith, S.M.; Thomas, S.C. Biochar effects on NTFP-enriched secondary forest growth and soil properties in Amazonian Ecuador. J. Environ. Manag. 2023, 350, 119068. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Meng, H.; Shen, Y.; Ding, J.; Zhou, H.; Cong, H.; Li, L. A comprehensive assessment on bioavailability, leaching characteristics and potential risk of polycyclic aromatic hydrocarbons in biochars produced by a continuous pyrolysis system. Chemosphere 2022, 287, 132116. [Google Scholar] [CrossRef] [PubMed]

- Reizer, E.; Viskolcz, B.; Fiser, B. Formation and growth mechanisms of polycyclic aromatic hydrocarbons: A mini-review. Chemosphere 2022, 291, 132793. [Google Scholar] [CrossRef]

- Jiang, C.; Xue, S.; Zhao, S.; Sun, J.; Zhang, Z. Indirect photodegradation of anthracene and pyrene induced by dissolved organic matter derived reactive species in ice. J. Environ. Chem. Eng. 2023, 11, 111086. [Google Scholar] [CrossRef]

- Bensabath, T.; Monnier, H.; Glaude, P.-A. Detailed kinetic modeling of the formation of toxic polycyclic aromatic hydrocarbons (PAHs) coming from pyrolysis in low-pressure gas carburizing conditions. J. Anal. Appl. Pyrolysis 2016, 122, 342–354. [Google Scholar] [CrossRef][Green Version]

- Mohd Nor Azman, N.A.N.; Asmadi, M.; Amin, N.A.S.; Shamjuddin, A.; Mohammad Zainol, M.; Phaiboonsilpa, N.; Kawamoto, H. Polycyclic Aromatic Hydrocarbons Occurrences in Biomass Char and Its Mitigation Approaches: A Mini Review. ChemBioEng. Rev. 2023, 10, 462–479. [Google Scholar] [CrossRef]

- Hung, C.-M.; Cheng, J.-W.; Chen, C.-W.; Huang, C.-P.; Dong, C.-D. Pyrolysis processes affecting polycyclic aromatic hydrocarbon profile of pineapple leaf biochar exemplified by atmosphere/temperature and heteroatom doping. Bioresour. Technol. 2023, 379, 129047. [Google Scholar] [CrossRef]

- Pyo, S.; Lee, J.; Kim, Y.M.; Park, Y.; Lee, I.H.; Choi, Y.J.; Rhee, G.H.; Jung, S.C.; Park, Y.K. Suppression of the hazardous substances in catalytically upgraded bio-heavy oil as a precautious measure for clean air pollution controls. J. Hazard. Mater. 2022, 421, 126732. [Google Scholar] [CrossRef]

- Li, L.; Niu, W.; Cong, H.; Meng, H.; Niu, Z.; Shen, X.; Cao, L.; Kong, X. Effects of pyrolysis temperature on the release characteristics of polycyclic aromatic hydrocarbons during pyrolysis of corn stover pellet. BioResources 2023, 18, 2112–2136. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Y.; Herath, H.M.S.K. Polycyclic aromatic hydrocarbons (PAHs) in biochar—Their formation, occurrence and analysis: A review. Org. Geochem. 2017, 114, 1–11. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, Y.; Nan, H.; Yang, F.; Qiu, H.; Xu, X.; Cao, X. Suppressed formation of polycyclic aromatic hydrocarbons (PAHs) during pyrolytic production of Fe-enriched composite biochar. J. Hazard. Mater. 2020, 382, 121033. [Google Scholar] [CrossRef]

- Gilbert, P.; Ryu, C.; Sharifi, V.; Swithenbank, J. Tar reduction in pyrolysis vapours from biomass over a hot char bed. Bioresour. Technol. 2009, 100, 6045–6051. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Lee, Y.; Ryu, C. Reduction of primary tar vapor from biomass by hot char particles in fixed bed gasification. Biomass Bioenergy 2016, 90, 114–121. [Google Scholar] [CrossRef]

- Rosa, J.M.D.L.; Sánchez-Martín, Á.M.; Campos, P.; Miller, A.Z. Effect of pyrolysis conditions on the total contents of polycyclic aromatic hydrocarbons in biochars produced from organic residues: Assessment of their hazard potential. Sci. Total Environ. 2019, 667, 578–585. [Google Scholar] [CrossRef] [PubMed]

- Fagernäs, L.; Kuoppala, E.; Simell, P. Polycyclic Aromatic Hydrocarbons in Birch Wood Slow Pyrolysis Products. Energy Fuels 2012, 26, 6960–6970. [Google Scholar] [CrossRef]

- Fei, L.; Jing, S.; Meng-fang, C. Generation, distribution and toxicity characteristics of polycyclic aromatic hydrocarbons during the preparation of biochar from rapeseed cake. J. Agro-Environ. Sci. 2016, 35, 2210–2215. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Mourant, D.; Gunawan, R.; Zhang, S.; Li, C.-Z. Formation of Aromatic Structures during the Pyrolysis of Bio-oil. Energy Fuels 2011, 26, 241–247. [Google Scholar] [CrossRef]

- Xiong, Z.; Wang, Y.; Syed-Hassan, S.S.A.; Hu, X.; Han, H.; Su, S.; Xu, K.; Jiang, L.; Guo, J.; Berthold, E.E.S.; et al. Effects of heating rate on the evolution of bio-oil during its pyrolysis. Energy Convers. Manag. 2018, 163, 420–427. [Google Scholar] [CrossRef]

- Wang, B.; Hu, J.; Chen, W.; Chang, C.; Pang, S.; Li, P. Exploring the characteristics of coke formation on biochar-based catalysts during the biomass pyrolysis. Fuel 2024, 357, 129859. [Google Scholar] [CrossRef]

- El-Rub, Z.A.; Bramer, E.A.; Brem, G. Experimental comparison of biomass chars with other catalysts for tar reduction. Fuel 2008, 87, 2243–2252. [Google Scholar] [CrossRef]

- Pang, Y.; Liu, X.; Chen, Y.; Xu, Y.; Shen, S. Catalytic reforming of volatiles in pyrolysis by using biomass carbon particle loading Ca and Fe and improving biogas yield. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 211–217, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Li, L.; Wenjuan, N.; Haibo, M.; Lixin, Z.; Hongbin, C.; Zhiyou, N. Effects of biochar on sunflower straw pyrolysis characteristics and gas products. Trans. Chin. Soc. Agric. Eng. 2020, 36, 227–233. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Duan, D.L.; Lei, H.W.; Villota, E.; Ruan, R. Jet fuel production from waste plastics via catalytic pyrolysis with activated carbons. Appl. Energy 2019, 251, 113337. [Google Scholar] [CrossRef]

- Yameen, M.Z.; AlMohamadi, H.; Naqvi, S.R.; Noor, T.; Chen, W.-H.; Amin, N.A.S. Advances in production & activation of marine macroalgae-derived biochar catalyst for sustainable biodiesel production. Fuel 2023, 337, 127215. [Google Scholar] [CrossRef]

- Yuan, X.; Cao, Y.; Li, J.; Patel, A.K.; Dong, C.-D.; Jin, X.; Gu, C.; Yip, A.C.K.; Tsang, D.C.W.; Ok, Y.S. Recent advancements and challenges in emerging applications of biochar-based catalysts. Biotechnol. Adv. 2023, 67, 108181. [Google Scholar] [CrossRef]

- Godvin Sharmila, V.; Kumar Tyagi, V.; Varjani, S.; Rajesh Banu, J. A review on the lignocellulosic derived biochar-based catalyst in wastewater remediation: Advanced treatment technologies and machine learning tools. Bioresour. Technol. 2023, 387, 129587. [Google Scholar] [CrossRef] [PubMed]

- Lyu, H.; Lim, J.Y.; Zhang, Q.; Senadheera, S.S.; Zhang, C.; Huang, Q.; Ok, Y.S. Conversion of organic solid waste into energy and functional materials using biochar catalyst: Bibliometric analysis, research progress, and directions. Appl. Catal. B Environ. 2024, 340, 123223. [Google Scholar] [CrossRef]

- Krzyszczak, A.; Dybowski, M.P.; Czech, B. Formation of polycyclic aromatic hydrocarbons and their derivatives in biochars: The effect of feedstock and pyrolysis conditions. J. Anal. Appl. Pyrolysis 2021, 160, 105339. [Google Scholar] [CrossRef]

- Zhou, W.J.; Zhang, X.L.; Zhou, W.X.; Yang, L. Inhibition mechanism of electric field on polycyclic aromatic hydrocarbon formation during n-decane pyrolysis: A ReaxFF MD and DFT study. J. Energy Inst. 2022, 102, 82–91. [Google Scholar] [CrossRef]

- Keiluweit, M.; Kleber, M.; Sparrow, M.A.; Simoneit, B.R.; Prahl, F.G. Solvent-extractable polycyclic aromatic hydrocarbons in biochar: Influence of pyrolysis temperature and feedstock. Env. Sci. Technol. 2012, 46, 9333–9341. [Google Scholar] [CrossRef] [PubMed]

- Buss, W.; Graham, M.C.; MacKinnon, G.; Mašek, O. Strategies for producing biochars with minimum PAH contamination. J. Anal. Appl. Pyrolysis 2016, 119, 24–30. [Google Scholar] [CrossRef]

- Xiao, X.; Chen, B. A Direct Observation of the Fine Aromatic Clusters and Molecular Structures of Biochars. Environ. Sci. Technol. 2017, 51, 5473–5482. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.-F.; Su, S.; Zhang, L.-P.; Jiang, L.; Qing, M.-X.; Chi, H.-Y.; Ling, P.; Han, H.-D.; Xu, K.; Wang, Y.; et al. Insights into evolution mechanism of PAHs in coal thermal conversion: A combined experimental and DFT study. Energy 2021, 222, 119970. [Google Scholar] [CrossRef]

- Ye, W.; Xu, X.; Zhan, M.; Huang, Q.; Li, X.; Jiao, W.; Yin, Y. Formation behavior of PAHs during pyrolysis of waste tires. J. Hazard. Mater. 2022, 435, 128997. [Google Scholar] [CrossRef]

- Wan Mahari, W.A.; Awang, S.; Zahariman, N.A.Z.; Peng, W.; Man, M.; Park, Y.K.; Lee, J.; Sonne, C.; Lam, S.S. Microwave co-pyrolysis for simultaneous disposal of environmentally hazardous hospital plastic waste, lignocellulosic, and triglyceride biowaste. J. Hazard. Mater. 2022, 423, 127096. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, B.; Yang, H.; Wang, X.; Zhang, X.; Chen, H. Generalized two-dimensional correlation infrared spectroscopy to reveal the mechanisms of lignocellulosic biomass pyrolysis. Proc. Combust. Inst. 2019, 37, 3013–3021. [Google Scholar] [CrossRef]

- Keown, D.M.; Hayashi, J.I.; Li, C.Z.J.F. Drastic changes in biomass char structure and reactivity upon contact with steam. Fuel 2008, 87, 1127–1132. [Google Scholar] [CrossRef]

- Yang, H.; Gong, M.; Hu, J.; Liu, B.; Chen, Y.; Xiao, J.; Li, S.; Dong, Z.; Chen, H. Cellulose Pyrolysis Mechanism Based on Functional Group Evolutions by Two-Dimensional Perturbation Correlation Infrared Spectroscopy. Energy Fuels 2020, 34, 3412–3421. [Google Scholar] [CrossRef]

- Xiong, Z.; Guo, J.; Chaiwat, W.; Deng, W.; Hu, X.; Han, H.; Chen, Y.; Xu, K.; Su, S.; Hu, S.; et al. Assessing the chemical composition of heavy components in bio-oils from the pyrolysis of cellulose, hemicellulose and lignin at slow and fast heating rates. Fuel Process. Technol. 2020, 199, 106299. [Google Scholar] [CrossRef]

- Zhang, X.S.; Jiang, H.; Zeng, F.X.; Liu, W.J. Preparation of high adsorption capacity bio-chars from waste biomass. Bioresour. Technol. 2011, 102, 8247–8252. [Google Scholar]

| Sample | U500-20 | ST500-20 | U600-20 | ST600-20 | U700-20 | ST700-20 |

|---|---|---|---|---|---|---|

| Correlation coefficient | 0.862894 | 0.059431 | 0.751019 | 0.452046 | 0.798589 | 0.885022 |

| Statistical significance | ** | ** | ** | ** |

| Sample | BET Surface Area (m2/g) | Pore Volume (cm3/g) | Pore Size (nm) | |||||

|---|---|---|---|---|---|---|---|---|

| Total | Mesopore | Macroporous | Mesoporous | Macroporous | Mesopore | Macroporous | Average Value | |

| EP-BC-500 | 3.30 | 2.32 | 3.206 | 0.013 | 0.013 | 1.410 | 3.799 | 15.67 |

| EP-BC-500A | 3.29 | 2.54 | 3.30 | 0.012 | 0.012 | 4.75 | 4.91 | 14.25 |

| EP-BC-600 | 3.08 | 2.20 | 3.55 | 0.013 | 0.013 | 4.75 | 3.80 | 17.06 |

| EP-BC-600A | 2.92 | 2.05 | 2.94 | 0.011 | 0.012 | 1.41 | 3.85 | 15.78 |

| EP-BC-700 | 2.03 | 1.56 | 2.46 | 0.011 | 0.010 | 4.75 | 4.92 | 20.37 |

| EP-BC-700A | 2.45 | 1.84 | 3.30 | 0.012 | 0.012 | 4.54 | 4.93 | 19.57 |

| Extra Biochar | ID/IG | IS/IG | ID/I(GR+VL+VR) |

|---|---|---|---|

| EP-BC-500 | 2.08 | 1.13 | 0.32 |

| EP-BC-500A | 1.40 | 0.63 | 0.38 |

| EP-BC-600 | 2.77 | 1.73 | 0.37 |

| EP-BC-600A | 1.98 | 0.71 | 0.63 |

| EP-BC-700 | 2.34 | 1.25 | 0.44 |

| EP-BC-700A | 2.02 | 0.65 | 0.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Shen, X.; Meng, H.; Shen, Y.; Ding, J.; Cong, H.; Chen, M. Reduction Effect of Extra Biochar on PAHs Originating from Corn Stover Pyrolysis. Molecules 2025, 30, 4238. https://doi.org/10.3390/molecules30214238

Li L, Shen X, Meng H, Shen Y, Ding J, Cong H, Chen M. Reduction Effect of Extra Biochar on PAHs Originating from Corn Stover Pyrolysis. Molecules. 2025; 30(21):4238. https://doi.org/10.3390/molecules30214238

Chicago/Turabian StyleLi, Lijie, Xiuli Shen, Haibo Meng, Yujun Shen, Jingtao Ding, Hongbin Cong, and Mingsong Chen. 2025. "Reduction Effect of Extra Biochar on PAHs Originating from Corn Stover Pyrolysis" Molecules 30, no. 21: 4238. https://doi.org/10.3390/molecules30214238

APA StyleLi, L., Shen, X., Meng, H., Shen, Y., Ding, J., Cong, H., & Chen, M. (2025). Reduction Effect of Extra Biochar on PAHs Originating from Corn Stover Pyrolysis. Molecules, 30(21), 4238. https://doi.org/10.3390/molecules30214238