Abstract

With environmental pollution and energy shortages becoming increasingly severe, developing efficient energy conversion and storage technologies is crucial. Cu2Se has garnered significant attention as a thermoelectric material due to its abundant raw materials, low cost, and high thermoelectric figure of merit (ZT). This paper reviews the synthesis methods and application progress of Cu2Se in the energy field. Regarding synthesis, various methods such as solid-state synthesis, hydrothermal synthesis, and ion exchange can be employed to control its microstructure and properties. In applications, Cu2Se demonstrates significant potential in thermoelectric conversion by harnessing the Seebeck effect to convert waste heat into electricity. Simultaneously, its high carrier mobility and favorable electrochemical properties make it promising for energy storage systems like sodium-ion batteries and aqueous batteries. Furthermore, this material holds considerable potential in emerging fields such as flexible wearable devices and high-efficiency thermoelectric power generation systems. Future research should continue optimizing its comprehensive properties to advance the practical application of Cu2Se in energy conversion and storage.

1. Introduction

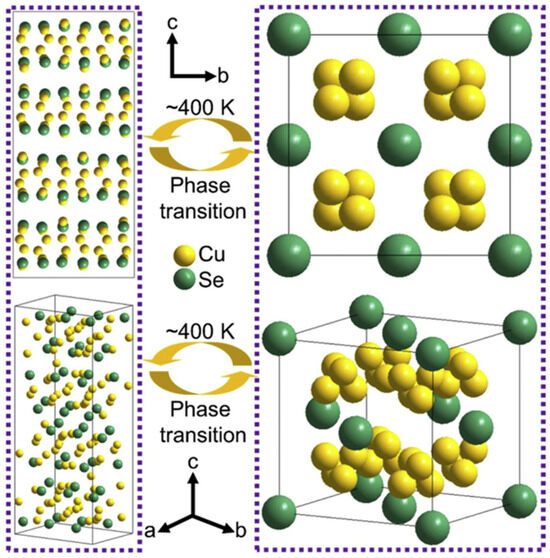

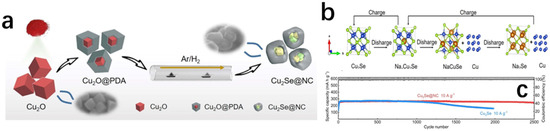

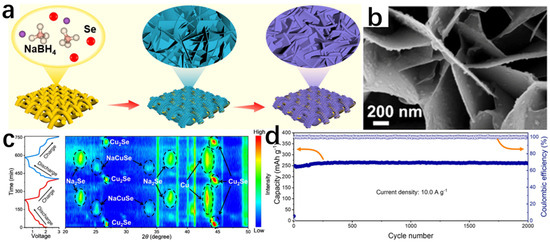

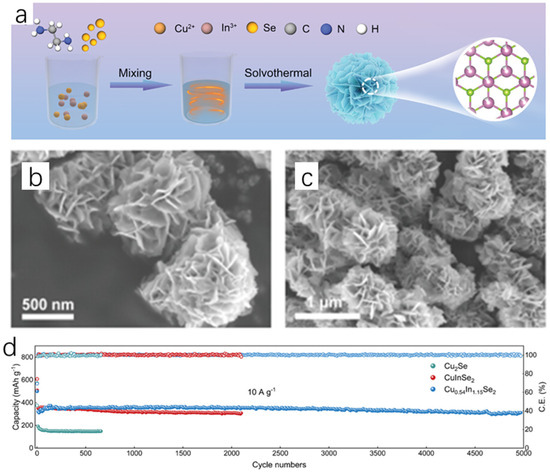

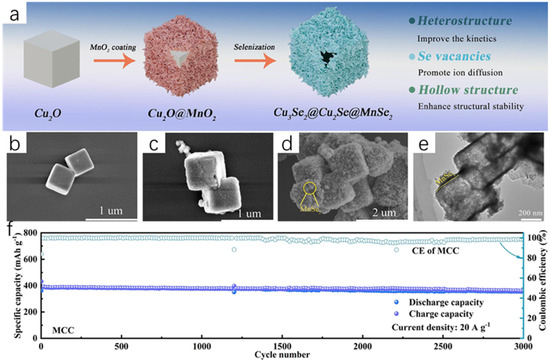

As global environmental pollution and energy shortages intensify, developing efficient and sustainable energy technologies has become a critical challenge facing humanity. The non-renewable nature of traditional fossil fuels and the greenhouse gases emitted during their use have profoundly impacted ecosystems. While clean energy sources like wind and solar power hold immense potential, their low energy density and intermittent nature limit their ability to meet continuously growing energy demands [1]. Against this backdrop, thermoelectric technology has garnered significant attention for its ability to directly convert waste heat into electricity. Among these, Cu2Se, as an emerging thermoelectric material, has emerged as an ideal alternative to traditional lead-containing materials (e.g., PbTe) due to its unique physicochemical properties and environmental friendliness. In recent years, novel thermoelectric materials like poly (3-hexylthiophene)-based materials [2], MXene-based materials [3] and graphene-based materials [4] have demonstrated broad application prospects. Research on optimizing the thermoelectric properties, interface engineering, and composite structure design of these materials provides important references for understanding the multifunctional characteristics of Cu2Se. Compared with traditional thermoelectric materials (e.g., Bi2Te3, PbTe), Cu2Se exhibits significant advantages. The structural properties of its low-temperature monoclinic phase (α-Cu2Se) and high-temperature antifluorite phase (β-Cu2Se) endow it with extremely low lattice thermal conductivity and ultra-high electrical conductivity, and the crystal structures of the low-temperature monoclinic Cu2Se and the high-temperature antifluorite-phase Cu2Se are schematically shown in Figure 1. In β-Cu2Se, the liquid-like migration behavior of Cu+ ions effectively enhances the phonon scattering, which enables the material to maintain excellent thermoelectric properties at high temperatures (up to a ZT value of 2.13 [5]), while the raw material cost is much lower than that of Bi2Te3 [6]. In addition, the narrow bandgap (~1.2 eV) and high Cu+ activity of Cu2Se enable it to perform equally well in the field of energy storage, e.g., the nitrogen-doped carbon-covered Cu2Se@NC composites retained a high capacity of 246.8 mAh g−1 in sodium-ion batteries after 2500 cycles at a current density of 10 A g−1.

Figure 1.

Schematic crystal structures of low-temperature monoclinic Cu2Se and high-temperature antifluorite Cu2Se. Reproduced from ref. [7] with permission. Copyright 2020 Elsevier.

The dual function of Cu2Se in the energy field is reflected in its integrated potential of “waste heat to power–power storage”. Through the Seebeck effect, Cu2Se can convert industrial waste heat into electricity; at the same time, it can be used as an electrode material for sodium-ion batteries or aqueous batteries to realize energy storage. For example, Cu2Se nanosheets (E-Cu2Se) were used as the anode in aqueous zinc-ion batteries, and ZnxMnO2 as the cathode in flexible aqueous zinc-ion batteries, which maintained a capacity of 40 mAh g−1 after 60,000 cycles [8]. This synergistic effect provides a new idea for constructing self-powered energy systems, especially in wearable electronic devices, and Cu2Se-based thermoelectric-energy storage integrated devices show a broad application prospect [9].

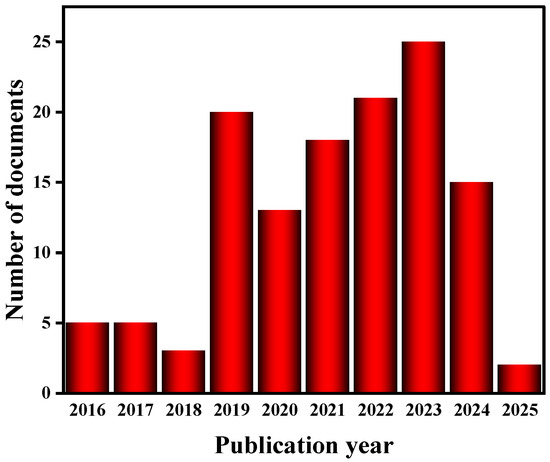

Although copper sulfide-based materials (e.g., CuS, Cu2S) have been extensively studied in the field of thermoelectricity, a systematic review of copper selenide-based materials (Cu2Se) in energy conversion and storage is still lacking. The existing literature mostly focuses on a single application scenario, e.g., Zhang et al. [10] systematically summarized the interfacial engineering strategy of copper sulfide nanomaterials in thermoelectric power generation, while Yang et al. [11] pioneered the proposal of Cu-based ternary heterostructures for asymmetric supercapacitors; their research system is still dominated by sulfides. Selenides (especially Cu2Se) are less reported, especially in the literature on supercapacitors (Web of Science statistics show that there are only 15 relevant papers), and the application of Cu2Se-based materials in energy storage is mainly focused on batteries, especially sodium-ion batteries and aqueous batteries. This manuscript provides a comprehensive and detailed analysis of Cu2Se’s applications in thermoelectric materials. It also compiles a decade’s worth of literature on Cu2Se-based batteries (Figure 2), categorizing them into sodium-ion batteries and aqueous batteries. The current situation highlights two core issues in the field: (1) the multifunctional properties of Cu2Se-based materials have not been fully explored, and the synergistic mechanism across energy conversion and storage has not been systematically analyzed; (2) the existing studies are mostly limited to a single performance optimization, and there is a lack of a whole-chain design perspective from the synthesis of materials to the integration of devices.

Figure 2.

Application of copper–selenium-based materials in batteries in the last decade.

This manuscript aims to fill this gap by comprehensively analyzing copper selenide-based materials from synthesis to application, with a focus on their dual functionality in thermoelectric conversion and electrochemical energy storage. We first review primary synthesis methods, including solid-state, hydrothermal/solvothermal, ion exchange, template-directed, and chemical reduction approaches. Subsequently, we explore pathways to enhance the thermoelectric properties of Cu2Se through a series of strategies. We explore the integration potential of copper selenides in emerging applications such as flexible wearables and self-powered systems, while also highlighting Cu2Se’s role in energy storage. Through interdisciplinary convergence and technological innovation, Cu2Se holds promise as a core material for next-generation energy systems, accelerating humanity’s progress toward a sustainable future characterized by zero waste heat and zero emissions.

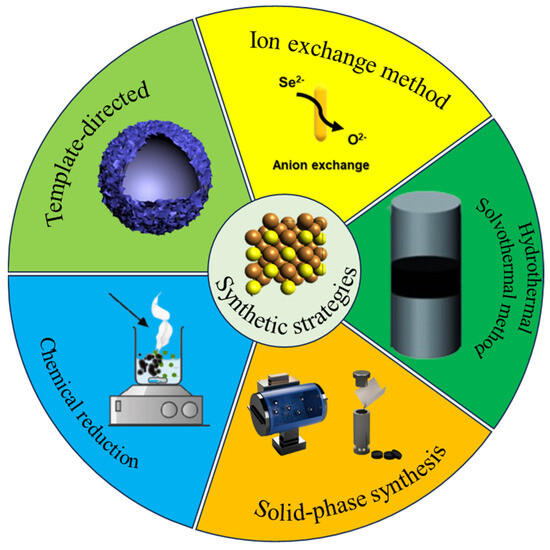

2. Synthetic Strategies

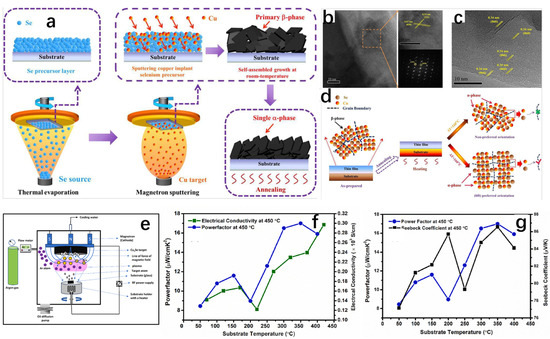

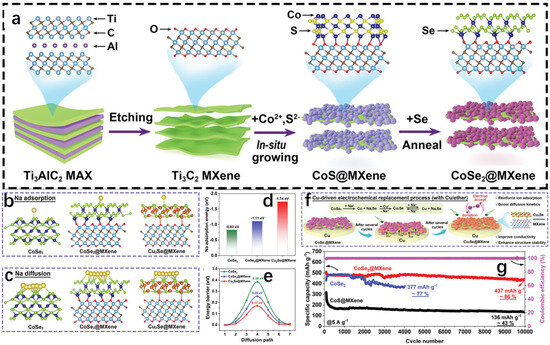

Cu2Se has been synthesized by various methods, such as pulsed laser deposition, solid-phase synthesis, hydrothermal/solvent-thermal, ion exchange, template-directed, chemical reduction, vacuum evaporation, electrochemical deposition [12], and magnetron sputtering. Figure 3 introduces the main synthesis methods of Cu2Se.

Figure 3.

Summary diagram of synthesis methods.

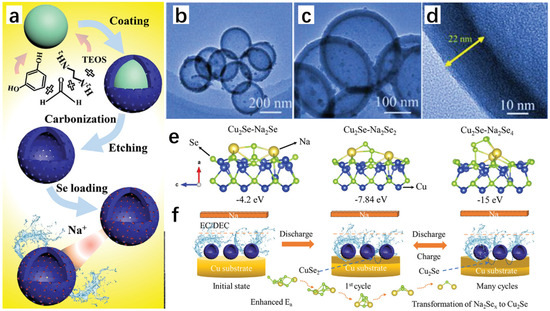

2.1. Template-Directed

The template-directed method is often used for the preparation of hollow-structured nanomaterials, especially in the preparation of hollow spheres. The template-directed method is accompanied by ion exchange reaction, diffusion, coordinated etching and precipitation (CEP), etc. Generally, a specific nanostructured material is selected as a template first, and then the material is deposited on the surface of the template through a series of means, and the final product obtained is very similar to the original template in terms of shape and size. The advantage of the template-directed method is that the size and shape of the product can be precisely controlled by the precise selection of the size and shape of the original template, so as to achieve precise control of the product. In addition, as a common synthesis method, the template-directed method is often used to synthesize heterojunction materials because the synthesized new materials can retain the size and shape of the original materials well. In short, a heterojunction exists as a special type of PN junction within semiconductors, typically formed by sequentially depositing two layers of different semiconductor materials on the same substrate. Due to the differing bandgaps of these materials, the presence of both positive charge carriers (holes) and negative charge carriers (electrons) increases the recombination rate within the diode. This effect brings the ideal diode very close to the characteristics of a real diode.

Of course, more than two semiconductor materials can also be made heterojunction, but it is relatively rare. Heterojunctions can be used to make light-emitting components, diodes, transistors, and so on.

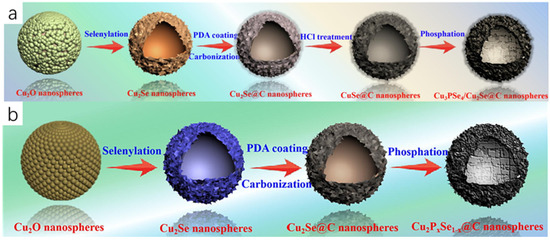

Zhao et al. [13] finally obtained carbon-encapsulated 3D hollow heterostructured Cu3PSe4/Cu2Se nanospheres (Cu3PSe4/Cu2Se@C) by a template-directed method using morphologically regular Cu2O nanospheres as templates and precursors through a series of steps: selenization, carbon-encapsulation, and phosphorylation. Firstly, Cu2O nanospheres were prepared by hydrothermal method using Cu(CH3COO)2·H2O, PVP, glucose, and dimethylformamide (DMF) as raw materials, and then selenide was performed on the Cu2O nanospheres to obtain the black-precipitated hollow Cu2Se nanospheres, and then dopamine hydrochloride was reacted with the hollow Cu2Se nanospheres to obtain the hollow Cu2Se@C nanospheres, and the hollow Cu2Se@C nanorods were immersed in hydrochloric acid solution to obtain pure CuSe@C hollow nanorods, and finally phosphorylated with sodium hypophosphite NaH2PO2 to obtain the final product of hollow Cu3PSe4/Cu2Se@C nanorods (Figure 4a). On the same principle, Zhao et al. [14] prepared hollow Cu2PxSe1−x@C nanorods through a series of steps including selenization, carbonization, and phosphorylation (Figure 4b).

Figure 4.

(a) Flow chart for the preparation of Cu3PSe4/Cu2Se@C nanospheres. Reproduced from ref. [13] with permission. Copyright 2023 Elsevier. (b) Flow chart for the preparation of Cu2PxSe1−x@C nanorods. Reproduced from ref. [14] with permission. Copyright 2023 Elsevier.

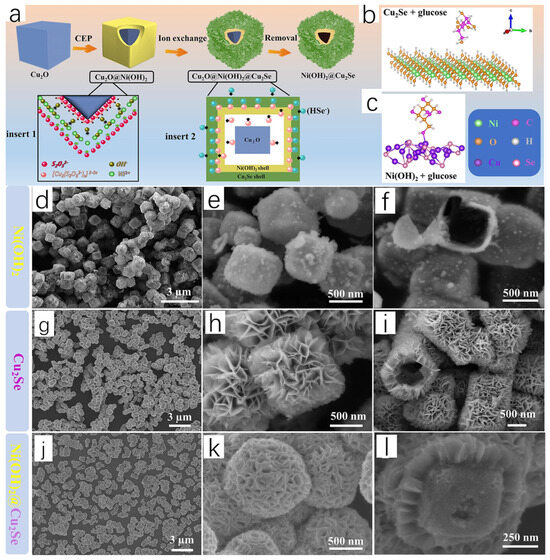

Yang et al. [15] successfully prepared Ni(OH)2@Cu2Se hollow heterostructures by reacting Ni(OH)2 with Cu2Se nanosheets using a template-oriented method. The working group used Cu2O as a template, added Cu2O and NiCl2 into a mixed solution of water and alcohol, sonicated to ensure a homogeneous mixture, and added PVP and Na2S2O3; a large number of Ni2+ particles were absorbed by Cu2O under the synergistic effect of PVP, and the reaction of Cu2O with S2O32− led to the OH− and [Cu2(S2O32−)x]2−2x ion. A large number of OH− and [Cu2(S2O32−)x]2−2x ions appeared in large quantities, and cooperative etching and precipitation (CEP) appeared; Ni(OH)2 diffused into the outer layer to encapsulate the Cu2O, and Cu2O@Ni(OH)2 was formed. Subsequently, the solution obtained by mixing Se powder and NaBH4 was dropped into the Cu2O@Ni(OH)2 solution, and then Na2S2O3 solution was added. Under the action of CEP, [Cu2(S2O32−)x]2−2x ions diffused to the outer layer and interacted with the HSe-ions to produce Cu2Se wrapped around the outer layer of Cu2O@Ni(OH)2, and Ni(OH)2@Ni(OH)2@Cu2Se was formed; finally, Na2S2O3 reacted with Cu2O, forming the final product, which was the Ni(OH)2@Cu2Se hollow heterostructure.

The chemical reaction equations involved in the reaction are as follows:

Cu2O + XS2O32− + H2O → [Cu2(S2O32−)x]2−2x + 2OH−

Ni2+ + 2OH− → Ni(OH)2

[Cu2(S2O32−)x]2−2x + HSe− + (x − 1)H2O → Cu2Se + xHS2O3− + (x − 1)OH−

Figure 5a shows a schematic diagram of the formation of Ni(OH)2@Cu2Se hollow heterostructures, which can be seen to form a heterojunction surface. It is demonstrated in subsequent measurements that the heterostructure resulted in enhanced adsorption of glucose. The structures of glucose adsorbed on Ni(OH)2 and Cu2Se are shown in Figure 5b,c, respectively. Based on this, DFT calculations were performed to determine the glucose adsorption energies on Ni(OH)2 and Cu2Se. Comparing the glucose adsorption energy on Cu2Se (−1.84 eV) with that on Ni(OH)2 (−0.18 eV) indicates that Cu2Se exhibits superior adsorption performance for glucose.

Figure 5.

(a) Schematic diagram of Ni(OH)2@Cu2Se HHSs prepared according to the ion exchange principle. (b) Glucose adsorbed Ni(OH)2 structure. (c) Glucose adsorbed Cu2Se structure. (d–f) High-power transmission electron microscope images of Ni(OH)2 NCs. (g–i) High-power transmission electron microscope images of Cu2Se NCs. (j–l) High-power transmission electron microscope images of Ni(OH)2@Cu2Se HHSs high magnification transmission electron microscopy images. Reproduced from ref. [15] with permission. Copyright 2023 Elsevier.

The research group analyzed the morphology of Cu2Se NCs, Ni(OH)2 NCs, and Ni(OH)2@Cu2Se HHSs by high magnification transmission electron microscopy, and finally observed the morphology of Ni(OH)2 NCs as very small nanoparticles composed of a regular hollow cube (Figure 5d–f). The hollow structure played a crucial role for selenium infiltration. The surface of Cu2Se NCs consists of overlapping stacked nanorods and remains hollow (Figure 5g–i). The morphology of the final synthesized Ni(OH)2@Cu2Se HHSs is similar to that of Cu2Se NCs, which also consists of stacked nanorods but exhibits porous reticulated surfaces (j–l). The morphology of Ni(OH)2@Cu2Se HHSs strongly suggests that Ni(OH)2 NCs are encapsulated within the Cu2Se layer, and the above data demonstrate the structural and functional advantages of Ni(OH)2@Cu2Se HHSs in the adsorption of glucose and their significant role in food monitoring. The study is highly creative and sets a precedent for future research in this area.

It is not difficult to see that the template-directed method has unique advantages and wide applications in the synthesis of Cu2Se-based materials by selecting suitable templates and continuously optimizing the synthesis process to prepare Cu2Se-based materials with specific morphology.

2.2. Chemical Reduction

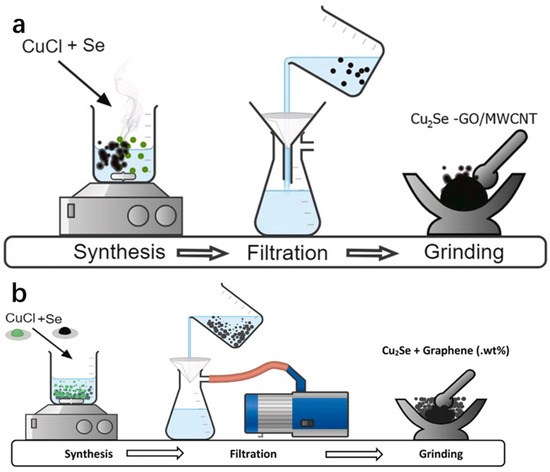

Chemical reduction is a method of obtaining the desired product by gaining or losing electrons using a chemical reagent, often through a strong reducing agent. This method is simple to operate and does not require expensive equipment or tedious steps, but because the reaction is not carried out in a vacuum-tight environment, new impurities that are difficult to remove may be introduced during the synthesis. Sankar et al. [16] prepared Cu2Se powder by using the chemical reduction method and subsequently synthesized Cu2Se-GO (graphene oxide)/MWCNT (multi-walled carbon nanotubes) nanocomposites by using the mechanical milling method. The team firstly took ethylene glycol and water mixed in a beaker as solvent according to the volume ratio of 3:7, and then added CuCl powder and Se powder according to the stoichiometric ratio of Cu2Se, and stirred them well on a magnetic stirrer, keeping the temperature of the hot plate at 100 °C. Then, NaBH4 and NaOH were added and mixed well. After the reaction was complete, the product was filtered with distilled water and ethanol solution, and then dried for 3 h at 100 °C to obtain the Cu2Se powder. Ethylene glycol can be used as a wetting agent in the reaction; in addition, NaBH4 as a reducing agent, has a strong reducing property, and high temperature can accelerate the reaction rate and promote the rapid synthesis of Cu2Se. Subsequently, the research group mixed and milled the obtained Cu2Se powder with GO/MWCNT powder, which was fully milled into round particles and then sealed in Borosil tubes. The product was then placed in the furnace with a high temperature of 600 °C sintering for 2 h and finally obtained the Cu2Se-GO/MWCNT nanocomposites, and the specific synthesis of the process flow diagram is shown in Figure 6a. The preparation of Cu2Se/graphene nanocomposites was carried out by the same group, Rapaka et al. [17], using the same method, and the process flow diagram is shown in Figure 6b. Furthermore, the working group also subsequently tested the Cu2Se-GO/MWCNT nanocomposites and the Cu2Se/graphene nanocomposites and found that both of them have excellent thermoelectric properties.

Figure 6.

(a) Schematic of the synthesis process: Cu2Se and GO/MWCNT nanocomposites. Reproduced from ref. [16] with permission. Copyright 2023 ScienceDirect. (b) Schematic of the synthesis process: Cu2Se and Cu2Se-graphene nanocomposites. Reproduced from ref. [17] with permission. Copyright 2021 Elsevier.

Compared with the template-directed method, the chemical reduction method does not require expensive template materials, requires lower costs, and can have a certain improvement in the purity of the product through the optimization of the reaction conditions. However, since it is carried out in the laboratory, attention must be paid to safety.

2.3. Solid-Phase Synthesis

As a mature synthesis process, the solid-phase method is often used for the synthesis of powders, which has a wide range of applications in the preparation of many materials. It has many advantages, such as having a large yield of the prepared powder, basically no agglomeration phenomenon, good filler, and low production cost. Furthermore, the simple technology is easy to master. Until now, the solid-phase method is still the most commonly used method for powder synthesis. Two common solid-phase synthesis methods are mechanical alloying-sintering and melt synthesis methods.

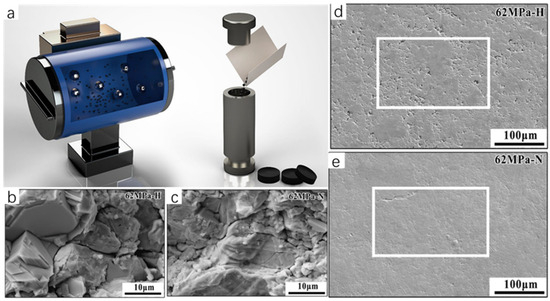

The mechanical alloying–sintering method is often accompanied by high temperature and high pressure conditions, which is generally divided into the following steps: firstly, the reactants are weighed, mixed, and grounded according to a certain ratio, and secondly, the mixture is heated and pressurized in the equipment to produce a solid-phase reaction, and then the product is milled to obtain ultrafine powder (Figure 7a). In order to facilitate testing or to improve the properties of the synthesized powders, this is often accompanied by pressing the synthesized powders into flakes and subsequently sintering the samples. The melting method generally uses the raw material powder as a precursor in accordance with a certain reaction ratio in a quartz glass tube, and passes into the protective gas. The role of the protective gas is to prevent the raw materials in the reaction process and the air in the reaction of the material to produce impurities. Then, the subsequent control of the reaction temperature in the vacuum-sealed heating furnace creates the melting reaction of the raw material powder. The arc melting method, as a type of melting method, generally consists of the following operating steps. The raw material powder is first placed in a mold of the same shape as the pre-made sample and a certain amount of pressure is applied in order to compact the powder and obtain a block sample of a certain shape. This generates an arc between the electrodes or between the melted material and the electrodes to generate heat to melt the metal; the power supply is then cut off to cool to obtain a block sample. The arc melting method is easy to operate and does not require expensive equipment, complex processes, or long reaction times. It also does not require any subsequent sintering, which has attracted much attention compared to the higher temperatures required for the sintering of Cu2Se prepared by SPS and HP. In recent years, there are many examples of Cu2Se synthesized by solid-phase synthesis. For example, Sun et al. [18] used a mechanical pulverization method to directly grind and tablet purchased Cu2Se powders. They subsequently obtained high-density Cu2Se bulk materials with excellent thermoelectric properties by sintering them under high pressure in an atmosphere of hydrogen or nitrogen, and N2 densified the surface of Cu2Se (Figure 7e). Mac et al. [19] prepared Cu2Se with excellent thermoelectric properties by a mechanical alloying–sintering method. The Cu and Se powders were weighed and loaded into a high-energy ball mill at 700 rpm for 10 h according to the stoichiometric ratio of Cu2Se. The powders were subsequently pressed at 523 K and later removed and sintered at different temperatures to obtain a series of Cu2Se bulk samples. In addition, Salam [20] et al. successfully synthesized the Cu2Se thermoelectric material with excellent thermoelectric properties by using the arc melting method, reaching a ZT value of 1.46 at 873 K.

Figure 7.

(a) Schematic diagram of low-temperature grinding and sintering. Reproduced from ref. [21] with permission. Copyright 2018 American Chemical Society. (b) SEM image of fracture morphology of Cu2Se sintered in 62 MPa H2; (c) SEM image of fracture morphology of Cu2Se sintered in 62 MPa N2; (d) SEM image of surface morphology of Cu2Se sintered in 62 MPa H2; (e) surface morphology of Cu2Se sintered in 62 MPa N2 SEM image. Reproduced from ref. [18] with permission. Copyright 2021 Elsevier.

Although the solid-phase synthesis method has many advantages, it also has unavoidable disadvantages, such as low reaction efficiency, high energy consumption, and large powder particles; and impurities are often mixed in the preparation process.

2.4. Hydrothermal/Solvothermal Method

2.4.1. Hydrothermal

Hydrothermal method has a long history as a well-established synthesis method. The hydrothermal method generally involves adding surfactant to a high temperature and high pressure aqueous solution and placing it in a reaction kettle (closed environment) to dissolve those insoluble or difficult-to-melt substances. Then, the crystals are precipitated out through the formation of a supersaturated solution by controlling the temperature difference in the reaction kettle. As a mature synthesis method, the hydrothermal method has many advantages, which includes the reaction process not requiring sintering, which can avoid the overgrowth of the crystal and the mixing of impurities. The synthesized particles are well-dispersed, have high purity, do not need high cost, and the microscopic morphology of the particles is good and controllable. However, the hydrothermal method also has the following unavoidable drawbacks: the growth process of the sample cannot be visually observed as it is conducted in a closed environment; the equipment has certain requirements (corrosion-resistant, high temperature, and high pressure); and there are certain technical requirements, such as the need for strict control of the temperature and pressure.

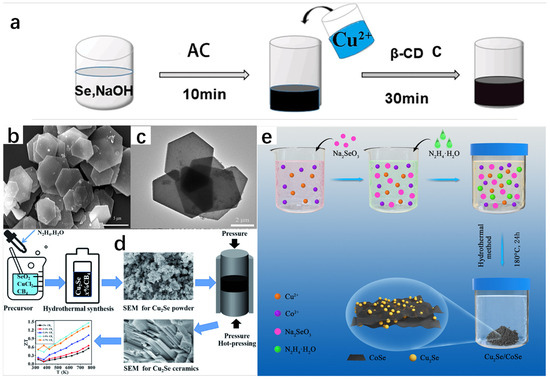

According to the relevant literature, the hydrothermal method has had many successful examples in the synthesis of Cu2Se and has synthesized many Cu2Se with different morphologies [21,22]. Dai et al. [23] successfully prepared Cu2Se materials using a hydrothermal method using CuCl2·H2O and Se as raw materials by adding them to a beaker containing ethylenediamine (EDA), mixing them well and then placing them in an autoclave maintained at 200 °C, and reacting them fully. Yang et al. [24] successfully prepared Cu2Se hexagonal sheets (HSs) using the hydrothermal method under an alkaline environment. In the synthesis, Se powder and NaOH were dissolved in a beaker in which distilled water was placed, and in order to make the dissolution as complete as possible, the beaker was placed on a magnetic stirrer and kept at 50 °C until the powder was completely dissolved. Immediately afterwards, ascorbic acid (AC), which is extremely reducing as a reducing agent, was added to the solution. Another beaker was taken and Cu(CH3COO)2 and β-cyclodextrin (β-CD) were mixed in the beaker in which distilled water was placed and stirred thoroughly. β-CD is a surfactant that increases the solubility of Cu(CH3COO)2 and reduces the surface tension of the liquid, making it easier for the liquid to penetrate the surface of the solid. Finally, the solution from the first beaker was added to the second beaker and it was observed that the mixture slowly changed from black to black-green. The black-green mixture was stirred at 40 °C for 30 min and subjected to hydrothermal treatment in a stainless-steel autoclave at 180 °C for a period of time. Then, it was cooled to room temperature, removed, and placed in a centrifuge for sufficient centrifugation. After that, it was washed repeatedly with anhydrous ethanol and distilled water. Finally, the precipitate was dried in a vacuum oven. A specific schematic diagram is shown in Figure 8a. The chemical equations involved in the reaction are as follows:

3Se + 6OH− → 2Se2− + SeO32− + 3H2O

13SeO32− + 13C6H8O6 → 13Se + 36CO2 + 6H2O + 26OH−

20Cu2+ + C6H8O6 + 20OH− → 20Cu+ + 6CO2 + 20H2O

2Cu+ + Se2− → Cu2Se

Figure 8.

(a) Schematic of the synthesis of Cu2Se hexagonal sheets (HSs). (b) Typical SEM image of Cu2Se HSs. (c) Typical TEM image of Cu2Se HSs. Reproduced from ref. [24] with permission. Copyright 2021 Elsevier. (d) Flowchart, SEM image, and ZT diagram of the preparation of the Cu2Se+x wt%CB4 composite. Reproduced from ref. [25] with permission. Copyright 2022 Royal Society of Chemistry. (e) Flowchart for the preparation of Cu2Se/CoSe composites. Reproduced from ref. [26] with permission. Copyright 2021 Elsevier.

XRD spectrum showed the successful synthesis of Cu2Se and the high purity of the sample. SEM image (Figure 8b) and TEM image (Figure 8c) show that the morphology of Cu2Se is a homogeneous hexagonal flake, with an edge length of 2~3 μm and a thickness of only 50 nm.

On the same principle, Xie et al. [25] synthesized Cu2Se+x wt%CB4 composites using the hydrothermal method and the hot pressing technique using copper chloride dehydrate (CuCl2·2H2O) and selenium dioxide (SeO2) as raw materials; hydrazine hydrate (N2H4·H2O) was used as a reductant, and boron carbide (CB4) nanopowders were added with different mass ratios (x = 0, 0.1, 0.3, 0.5, 0.7). CB4 is thermally stable and has superior electrical conductivity and Seebeck coefficient at high temperatures. These materials were added in a beaker containing deionized water and stirred in a magnetic stirrer until completely dissolved. After the solution was loaded into a stainless-steel autoclave and sealed for high-temperature heating for a period of time, it was cooled to room temperature and taken out. The sample was washed several times with ethanol and deionized water in a centrifuge and then placed in a vacuum drying oven for drying. The composite materials were then removed for vacuum sintering to obtain the dense Cu2Se bulk samples. The SEM morphology tests on the precursor of the Cu2Se nanopowder and the bulk Cu2Se revealed that the morphology of the precursor of the Cu2Se powder is an aggregated nanoplatelet, and the bulk sample is a laminated structure, which effectively enhances phonon scattering and reduces thermal conductivity, ultimately leading to the excellent thermoelectric performance of the Cu2Se+x wt%CB4 composites at 773 K. The ZT value also reached 1.46.

In addition to this, Zhu et al. [26] synthesized Cu2Se/CoSe composites using a hydrothermal method by placing Co(NO3)2·6H2O, Cu(NO3)2·3H2O, and distilled water in a hydrothermal autoclave and stirring well. This was followed by the addition of Na2SeO3 as a source of selenium, which was added to the autoclave and stirred well. Then, (N2H4·H2O) was added as a reducing agent, stirred well, and dried in an oven. This was followed by centrifugal washing with anhydrous ethanol and water for several times, and then freeze-dying to obtain Cu2Se/CoSe composites. The flow chart for the preparation of Cu2Se/CoSe composites is shown in Figure 8e. The chemical equations that occurred are as follows:

2SeO32− + 3N2H4·H2O → 2Se2− + 3N2 + 9H2O

4Cu2+ + N2H4·H2O → 4Cu+ + 4H+ + N2 + H2O

2Cu+ + 2Co2+ + 3Se2− → Cu2Se + 2CoSe

Hydrothermal methods are also widely used in the preparation of heterojunction materials. Generally, the intermediates of the materials are first prepared by hydrothermal method, and then the heterojunction materials are obtained by a series of means.

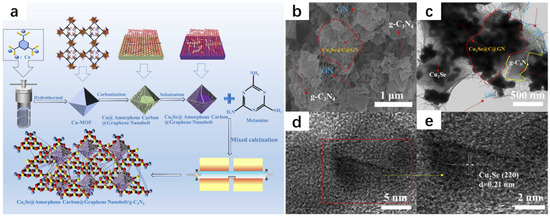

With the rapid development of human society, we are faced with the problem of the energy crisis. In the past, development was achieved at the expense of the environment, and in recent years, people have introduced the concept of carbon neutrality and accelerated the pace of searching for green energy, and hydrogen happens to be a type of green energy that is easy to be transported and stored [27,28,29]. There is an urgent need for a heterojunction material with high photocatalytic activity [30,31]. Liu et al. [32] successfully synthesized Cu2Se@Amorphous Carbon@Graphene Nanobelt/g-C3N4 (Cu2Se@C@GN/g-CN) composites (Figure 9a) by using the hydrothermal method and calcined annealing. The synthesis of Cu-MOF was first carried out by the hydrothermal method; 1,3,5-benzenetricarboxylic acid (C9H6O6) and copper nitrate hexahydrate (Cu(NO3)2·6H2O) were put into a beaker and added to the configured solution (N,N-dimethylformamide, ethanol, and water were mixed according to a certain ratio). In order to ensure sufficient mixing, the solution was subjected to ultrasonic stirring. The surfactant PVP was added for ultrasonic stirring and the solution was taken out and placed in an autoclave reactor, followed by drying, washing, and drying to obtain the Cu-MOF powder. The powder was then carbonized and selenized to obtain Cu2Se@Amorphous Carbon@Graphene Nanobelt powder, which was then reacted with melamine to obtain the Cu2Se@Amorphous Carbon@Graphene Nanobelt/g-C3N4 (Cu2Se@C@GN/g-CN) composite. The morphology was analyzed (Figure 9b–e). The photocatalytic hydrogen precipitation activity of the composite was extremely high, exceeding most of the currently known photocatalysts, and its photocatalytic properties were almost unaffected after 24 h of continuous light irradiation due to the creation of an efficiently oriented electronic channel among 2D g-C3N4 and 3D Cu2Se. This study is of great significance for the protection of the environment and the development of green energy.

Figure 9.

(a) Schematic of the synthesis process of Cu2Se@C@GN/g-CN. FESEM images of Cu2Se@C@GN/g-CN (b); TEM and HRTEM images of Cu2Se@C@GN/g-CN (c–e). Reproduced from ref. [32] with permission. Copyright 2024 Elsevier.

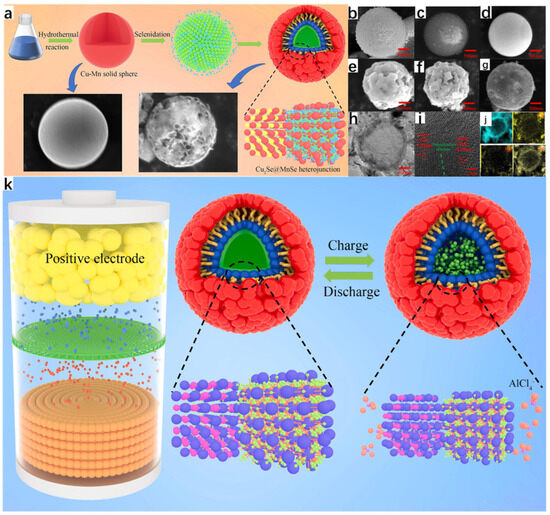

Zhang et al. [33] successfully synthesized new Cu2Se@MnSe heterojunction hollow spherical shells with excellent properties through a series of processes using Cu(NO3)2·3H2O and Mn(NO3)2·4H2O as raw materials, and using hydrothermal and melt-diffusion methods, which can be used as cathode materials for aluminum-ion batteries because the hydrothermal method has the advantage of synthesizing a regular morphology, so the final Cu-Mn solid spheres obtained are regular (Figure 10a). As seen from the SEM images, Figure 10b shows the Cu solid spheres; Figure 10c shows the Mn solid spheres, which have a relatively rough surface with a large number of particles attached; and Figure 10d shows the Cu-Mn solid spheres, which have a smooth surface and all three of them are relatively homogeneous in morphology. The subsequent Cu2Se spheres, MnSe spheres, and Cu2Se@MnSe heterojunction spherical shells were obtained by selenization of all three, and the Cu2Se@MnSe heterojunction spherical shells were obtained by selenization of Cu2Se@MnSe heterojunction spherical shells. MnSe heterojunction spheres have a rougher surface, which increases the contact area between the electrolyte and the spheres, resulting in a more rapid and efficient reaction. Figure 10g shows the TEM image of the Cu2Se@MnSe heterojunction spherical shell; it is obvious that it is a hollow structure, which prevents the volume expansion of the material in the reactant. From the lattice stripes in Figure 10i, it can be seen that the Cu2Se@MnSe heterojunction has been formed; Figure 10j is the EDS image, from which it can be seen that the elements of Mn, Cu, and Se are uniformly distributed, and the appearance of the C element is presumed to be because of the carbon in the spherical shell. Figure 10k shows the reaction schematic of Cu2Se@MnSe heterojunction spherical shells with

Charge:

Cu2Se + nAlCl4− → CuSe[AlCl4−]n + ne−

MnSe + nAlCl4− → MnSe[AlCl4−]n + ne−

Discharge:

4Al2Cl7− + 3e− → 7AlCl4− + Al

Figure 10.

(a) Schematic diagram of the preparation of Cu2Se@MnSe heterojunction hollow spherical shells. (b) SEM images of Cu solid spheres. (c) SEM images of Mn solid spheres. (d) SEM images of Cu-Mn solid spheres. (e) SEM images of Cu2Se solid spheres. (f) SEM images of MnSe solid spheres. (g) SEM images of Cu2Se@MnSe heterojunction spherical shells. (h) TEM image of Cu2Se@MnSe heterojunction spherical shell. (i) HR-TEM image of Cu2Se@MnSe heterojunction spherical shell. (j) Elemental mapping image of Cu2Se@MnSe heterojunction. (k) Reaction schematic of Cu2Se@MnSe heterojunction spherical shell. Reproduced from ref. [33] with permission. Copyright 2023 Elsevier.

2.4.2. Solvothermal Method

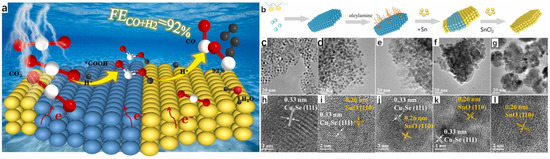

The solvothermal method is in the process of further developing the hydrothermal method, and its process as well as its principle is more or less the same; the difference is that the solvent is no longer water, but organic matter. The electrochemical reduction of CO2 is a well-established method to reduce CO2 emissions to combat environmental pollution and to convert it into usable and efficient chemical fuels [34,35,36,37]. However, due to a number of reasons, the Faraday efficiency (FE) of the CO2 reduction reaction is still low. To solve this problem, Wang et al. [38] successfully synthesized two-phase Cu2Se-SnO heterojunction catalysts on the same plane by using the hot solvent method and the high temperature thermal reduction method, which is excellent in the selection of syngas, and the Faraday efficiency (FE) once exceeded 60% at various potentials. The team first carried out the synthesis of Cu2Se hexagonal nanosheets by the hot solvent method; the specific experimental procedure was to mix Se powder with oleylamine (OLAM) and 1-dodecanethiol (DDT), with OLAM as a surfactant and DDT as a reducing agent, and by keeping it at 50 °C for a certain period of time in a vacuum until the DDT dissolves Se powder completely to obtain the brown-colored solution A, which is then cooled to room temperature and filled with nitrogen. Copper acetate monohydrate (Cu(CO2CH3)2·H2O), DDT, and OLAM were mixed, degassed, stirred, and then heated with nitrogen until CO2CH3)2·H2O was completely dissolved to obtain the yellow-orange solution B. A syringe was used to inject solution A into solution B, and it was observed that the solution rapidly changed from yellow-orange to dark green. The dark green solution was treated at 220 °C for a period of time and then cooled to room temperature, and then washed and precipitated with methanol for several times to obtain Cu2Se nanosheets, which were subsequently synthesized by a high-temperature reduction method through a series of steps to synthesize Cu2Se-SnO heterojunctions, and the specific synthesis of Cu2Se-SnO heterojunction catalysts is shown in the schematic diagram in Figure 11b. The team analyzed and compared the microscopic morphology of the Cu2Se-SnO heterojunction catalyst, Cu2Se nanosheets, and SnO nanosheets. Transmission electron microscopy showed that Cu2Se is a uniform cubic nanosheet (Figure 11c), and the morphology of Cu2Se-SnO heterojunction catalyst behaves similarly to that of Cu2Se, which is still a uniform hexagonal nanosheet (Figure 11d–f), whereas SnO nanosheets are more heavily stacked. From the high-resolution transmission electron microscopy (HR-TEM), it can be seen that the Cu2Se-SnO heterojunction catalyst contains 0.33 nm planar row spacing value with 0.26 nm lattice spacing, which corresponds to the (111) planes of the hexagonal Cu2Se and the (110) planes of SnO, respectively, which successfully proves the synthesis of Cu2Se-SnO heterojunction catalyst; and this point is of course evident from the XRD spectrum which can also be illustrated. Among them, Cu2Se-SnO0.04 has a larger contact surface between Cu2Se and SnO, indicating that it has more heterojunction interfaces, and it is not difficult to see that Cu2Se-SnO0.04 has a 2D nanosheet structure in the EDX diagram. The team subsequently conducted a series of electrochemical tests, and the results showed that the Cu2Se-SnO0.04 catalyst had the best stability and selectivity in synthesis gas, and its unique 2D nanosheet structure led to a much higher rate of charge transfer, and more heterojunction interfaces led to a substantial enhancement of the charge distribution on the surface of the catalyst, which greatly improved the Faraday efficiency (FE), which reaches an amazing 92% at −0.97 V vs. RHE.

Figure 11.

(a) Structural diagram showing unique 2D nanosheet structure of Cu2Se-SnO0.04 catalyst exhibiting efficient Faraday efficiency (FE). (b) Synthesis of Cu2Se-SnO heterojunction catalyst. (c) TEM image of Cu2Se. (d) TEM image of Cu2Se-SnO0.02. (e) TEM image of Cu2Se-SnO0.04. (f) TEM image of Cu2Se-SnO0.075. (g) TEM image of SnO. (h) HR-TEM image of Cu2Se. (i) HR-TEM image of Cu2Se-SnO0.02. (j) HR-TEM image of Cu2Se-SnO0.04. (k) HR-TEM image of Cu2Se-SnO0.075. (l) HR-TEM images of SnO. Reproduced from ref. [38] with permission. Copyright 2024 Elsevier.

2.5. Ion Exchange Method

The ion exchange method is an equivalent and reversible chemical reaction carried out by ions in the liquid phase or ions in the solid phase. As a common material synthesis method, the ion exchange method can retain the morphology of the precursor well and does not require expensive equipment. The process is simple, easy to operate, causes less pollution, and has been widely used in the preparation of many materials. However, the ion exchange method also has the following limitations: in the synthesis process, it may produce impurities that are difficult to remove; and the synthesis cycle is relatively long. In the following, we will mainly introduce the cation exchange method and anion exchange method.

2.5.1. Cation Exchange

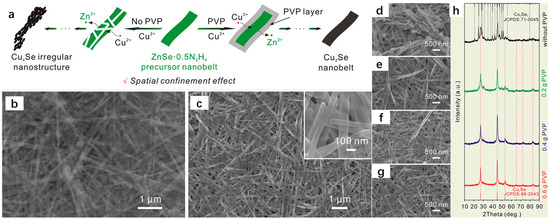

Cation exchange is a common method for material synthesis. Yuan et al. [39] successfully synthesized hollow CuZnS nanoboxes (CuZnS NBs) with abundant Zn-S bonding electronic bridges at the interface by cation exchange, which greatly improved the rate of photocatalytic hydrogen precipitation, which at one time reached an astonishing 2.06 mmolg−1h−1. Yoon et al. [40] enabled the zeolite adsorbent to substantially improve its thermal storage performance by cation exchange, which was 120% of the original one. Xie et al. [41] achieved an innovative breakthrough in the preparation of Co-BiOBr by cation exchange, which greatly improved the electron–hole separation and light absorption efficiencies, with Co-BiBOR-0.5’s CO yield even reaching 11.71 μmolg−1h−1, which substantially exceeded the previous CO yield. The success of these cases is sufficient to demonstrate the superiority and feasibility of the cation exchange method. The cation exchange (CE) reaction is often used by people to synthesize nanomaterials, and the interconversion between a large number of nanocrystals is carried out by cation exchange, which is essentially the substitution of one cation by another in an intact anionic lattice; thus, this method can retain the morphology of the material precursor very well, and it has been widely accepted by the people [42]. The cation exchange method generally consists of the preparation of the precursor of the higher Ksp system to prepare products with lower Ksp, but the preparation of materials by the cation exchange method is also limited by the high or low Ksp. The Cu2Se nanomaterial, as a type of copper-based nanomaterial, has received wide attention for its applications in thermoelectric conversion, sensors, etc. A number of scholars have successfully synthesized Cu2Se with excellent thermoelectric properties by the cation exchange method. Based on the previous report by Su et al. [43], after a series of reactions of the synthesized ZnSe-0.5N2H4 nanoribbons with PVP and Cu(NO3)2, Cu2+ and Zn2+ were ion exchanged, and Cu2+ was reduced to Cu+ due to the reducing effect of N2H4, and the formed Cu2Se nanoribbons had a similar morphology to the original nanoribbons with the encapsulation of PVP, which was attributed to the fact that the cation exchange method could well retain the morphology of the precursor and the good coalescence of PVP. According to the XRD spectrum results, Cu2Se was successfully synthesized in the experiments of Su et al. Figure 12b shows the SEM image of ZnSe-0.5N2H4 nanoribbons, which can be seen as a regular ribbon structure, and Figure 12c shows the SEM image of Cu2Se, which is almost the same as that of the ZnSe-0.5N2H4 nanoribbons, which further reflects the advantages of the cation exchange method for the preparation of materials. Figure 12d shows the SEM image of the product obtained without the addition of PVP, and it can be clearly seen that its shape is an irregular nanostructure. Figure 12e–g show the SEM images of the product with the addition of 0.2 gPVP, 0.4 gPVP, and 0.6 gPVP, respectively, and it can be seen that it is a regular band structure, which is almost the same as that of the precursor. Figure 12h shows the XRD spectrum; it can be seen that in the composition of the phase without the addition of PVP, in addition to Cu2Se, there is Cu3Se2, showing that the phase obtained is a complex multi-phase. With the increase in the amount of PVP added, the final phase is only left with the phase of Cu2Se, so it can be seen that the role of the PVP surfactant is crucial. This point is also evident in the morphology of the product in Figure 12a, where the total reaction of the preparative chemical equation is 4Cu2+ + N2H4 = 4Cu+ + N2 + 4H+.

Figure 12.

(a) Effect of the absence or presence of PVP on the synthesizer. (b) SEM images of ZnSe-0.5N2H4 nanoribbons. (c) SEM images of Cu2Se. (d–g) SEM images of PVP generators with the addition of 0 g, 0.2 g, 0.4 g, and 0.6 g. (h) XRD spectrum of PVP generators with the addition of 0 g, 0.2 g, 0.4 g, and 0.6 g. Reproduced from ref. [43] with permission. Copyright 2018 American Chemical Society.

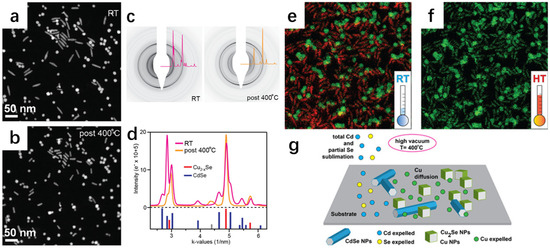

Similarly, Casu et al. [44] successfully synthesized Cu2−xSe nanocrystals by slow cation exchange by heating Cu2Se nanocrystals, Cu nanocrystals, and CdSe nanocrystals in situ on an amorphous solid substrate. Observation with transmission electron microscopy revealed that Cu2Se and Cu nanocrystals lost some of their Cu atoms; Cd in CdSe was completely sublimated; Se was partially sublimated; and finally CdSe was slowly converted to Cu2−xSe. Because it is a reaction between solids, it is relatively slow compared to that of the liquid phase, but it is precisely because of this slowness that it is convenient to propose improvements during the tracing of the experiment. From Figure 13a,b, it can be seen that there are obvious differences in the morphology before and after the annealing; before the annealing, the morphology of spherical- and rod-shaped intertwined, and the arrangement was sparse; the arrangement after annealing was more compact. Figure 13c,d show the stable coexistence of CdSe and Cu2−xSe before the annealing; in Figure 13e,f, the green represents the Cu atoms and the red represents the Cd atoms; the Cu atoms did not completely replace the Cd atoms; and after annealing at 400 degrees Celsius, it has been completely turned into a solid. Based on these observations, there are some proposed measures for improvement. At 400 degrees Celsius, it has completely turned into Cu2−xSe. Figure 13g shows the process of ion exchange. With this experience, the subsequent synthesis of other materials by the solid-state exchange method can provide a better way to observe the intermediate process and summarize the shortcomings of its synthesis as a way to improve the process.

Figure 13.

(a,b) SEM images of Cu2Se and CdSe NCs at room temperature versus 400 °C. (c) Electron diffractograms of Cu2Se nanorods and CdSe nanorods after heat treatment at room temperature and 400 °C superimposed on 1D profiles of ED signals obtained by integrating and by rounding off the angle in mutual inverse space. (d) Integrated linear spectrum of ED modes collected before 400 °C treatment and after 400 °C treatment. (e) Normalized energy-filtered TEM map obtained at RT. (f) Normalized energy-filtered TEM map obtained at 400 °C. (g) Schematic Diagram of Ion Exchange. Reproduced from ref. [44] with permission. Copyright 2016 American Chemical Society.

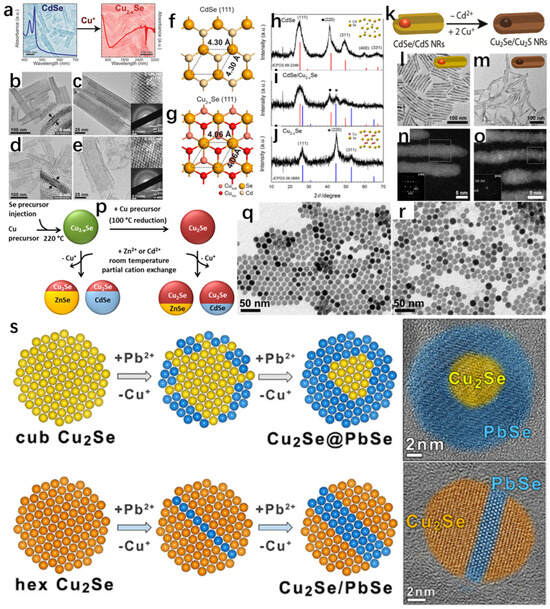

Wang et al. [45] successfully synthesized Cu2−xSe NSs using CdSe NSs by cation exchange (Figure 14a), which is not only extremely stable, but also has a thickness of only 1.6 nm. The cation exchange maintained the original morphology, as well as the crystal structure of pristine CdSe NSs, which is attributed to the fact that the anionic sublattice of the precursor did not change, which is effectively demonstrated in Figure 14f,g. Figure 14b,c are low–high magnification TEM images of the pristine thickness of 1.6 nm CdSe, which is seen to have a uniform rectangular shape. Figure 14d,e are low–high magnification TEM images of the thickness of 1.6 nm Cu2−xSe, and it can be clearly seen that there is no major difference in morphology from that of the pristine CdSe. The inset in the upper right corner of Figure 14d illustrates that the obtained Cu2−xSe NSs are crystalline and distinctly cubic, due to the fact that the lattice striations in the planes of cubic Cu2−xSe (111) preserve the cubic structure of CdSe. The XRD spectrum also demonstrates this well, owing to the fact that the cation exchange method can well preserve the sublattice structure. Bladt et al. [46] have also successfully synthesized CdSe/CdS NRs that were successfully prepared as Cu2Se/Cu2S NRs by cation exchange (Figure 14k), which also preserved the original morphology according to their TEM images.

In addition to this, in recent years, copper–sulfur carbon nanotubes have attracted widespread attention because they can maintain a large number of copper vacancies; and the more of these vacancies, the faster the rate of cation exchange [47]. Lesnyak et al. [48] used trioctylphosphine (TOP) as an exchange promoter, and the first set of Cu2−xSe was used in room temperature with Cu2−xSe and Zn(NO3)2·6H2O and Cd(NO3)2·4H2O, and an ion exchange reaction was carried out. For the second group, Cu+ ions were injected into Cu2−xSe to turn it into Cu2Se, and then the operation of the first group was repeated, which showed that the ion exchange rate of Cu2−xSe with Zn(NO3)2·6H2O and Cd(NO3)2·4H2O was faster at room temperature due to the fact that the concentration of Cu vacancies in Cu2−xSe was larger than the concentration of Cu vacancies in Cu2Se, and some of the Cu vacancies were more than the concentration of Cu vacancies in Cu2Se. The concentration of vacancies is larger, and some of the Cu ions are exchanged with Zn ions or Cd ions, forming the heterojunction shown in Figure 14p. The SEM images of Cu2−xSe and Cu2Se in Figure 14q,r, respectively, are seen to have retained their original sizes, shapes, and crystal structures, which are all cubic gabbro-like, after the reduction treatment. This work strongly demonstrates that the presence of Cu vacancies accelerates the rate of cation exchange in copper–selenium compounds and provides new ideas to reduce the time for cation exchange to prepare new materials in the future.

In addition to this, cation exchange (CE) reactions have been used for the synthesis of some specific structures, such as nano-heterostructures (NHs), and the synthesized materials have specific morphologies and compositions [49,50]. To better tune the morphology, structure, and properties of the materials through cation exchange reactions, an in-depth understanding of the mechanisms or kinetics of the transformations is necessary [51,52,53,54,55,56,57,58,59,60]. Gariano et al. [61] investigated the cation exchange between different phases of Cu2Se nanocrystals (NCs) and Pb2+ ions and showed that due to the different mechanisms, when the reactant is cubic Cu2Se, the Cu2Se@PbSe core@ nano-heterogeneous structure is eventually formed due to the homogeneous diffusion of Pb2+ ions through the Cu2Se crystals and low diffusion rate; when the reactant is cubic Cu2Se, the Pb2+ ions diffuse uniformly and with low diffusivity in the shell nano-heterostructure; when the reactant is hexagonal Cu2Se, the Pb2+ ions enter the (002) lattice plane and form the Cu2Se/PbSe-striped intermediate structure (Figure 14s). The experimental results strongly illustrate that when different phases undergo cation exchange reactions, different products are formed due to their different structures.

Figure 14.

(a) Schematic representation of the transformation of CdSe to Cu2−xSe by ion exchange between Cd2+ and Cu+. (b) Edge TEM image of CdSe. (c) Top TEM image of CdSe, with the SAED image of the selected bottom region in the upper-right corner. (d) Edge TEM image of Cu2−xSe. (e) Top TEM image of Cu2−xSe, with the selected bottom SAED image of the region. (f) Top view of the (111) face of CdSe. (g) Top view of the (111) face of Cu2−xSe with a common anionic sublattice. (h) Powder XRD spectrum of CdSe. (i) Powder XRD spectrum of CdSe/Cu2−xSe. (j) Powder XRD spectrum of Cu2−xSe NSs. Reproduced from ref. [45] with permission. Copyright 2014 American Chemical Society. (k) CdSe/Schematic representation of the transformation of CdSNRs into Cu2Se/Cu2S NRs by ion exchange between Cd2+ and Cu+. (l) TEM image of CdSe/CdS NRs. (m) TEM image of Cu2Se/Cu2S NRs. (n) HRTEM image of CdSe/CdS NRs. (o) HRTEM image of Cu2Se/Cu2S NRs. Reproduced from ref. [46] with permission. Copyright 2015 American Chemical Society. (p) Cu2−xSe and Cu2Se undergo cation exchange with Zn2+ and Cd2+ to form heterojunctions at room temperature. (q) TEM image of Cu2−xSeNCs. (r) TEM image of Cu2Se. Reproduced from ref. [48] with permission. Copyright 2015 American Chemical Society. (s) Cation exchange reactions between cubic or hexagonal Cu2Se NCs and Pb2+ cations. Reproduced from ref. [61] with permission. Copyright 2017 American Chemical Society.

Above, we presented several typical examples of the successful synthesis of Cu2Se-based materials by the cation exchange method, and it can be found that most of the products retain the morphology of the precursors, and the reaction in the liquid phase is extremely rapid, while the reaction in the solid phase is slower. We suspect that this is because the reaction dynamics required in the solid phase is much greater than that required in the liquid phase, where the reaction proceeds from high Ksp to low Ksp, whereas in the solid phase it requires high temperatures, high pressures, and many other conditions as the driving force. Later, we will introduce the anion exchange method, which is more similar to the cation exchange method.

2.5.2. Anion Exchange

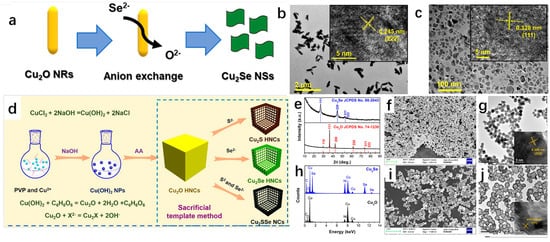

The anion exchange method has been widely used for the synthesis of Cu2Se as a common material synthesis method. Zhao et al. [62] successfully synthesized Cu2Se nanorods using Cu2O nanosheets as precursors by using the anion exchange method. They first synthesized Cu2O nanosheets and subsequently obtained Cu2Se nanorods by the exchange of Se2− ions with O2− ions. The successful preparation of both Cu2O nanosheets and Cu2Se nanorods was demonstrated by XRD spectrum. The possible reactions involved in the synthesis process are as follows:

Cu2+ + 2OH− = Cu(OH)2↓

Cu(OH)2 + C6H8O6 = Cu2O + 2H2O + C6H6O6

Cu2O + Se2− + H2O = 2OH− + Cu2Se

Figure 15a shows the schematic diagram of Se2− ion exchange with O2− ion, which can briefly describe the synthesis process of Cu2Se nanorods. Figure 15b,c show the TEM images of Cu2O and Cu2Se, respectively, and it can be seen that the morphology of Cu2O is a rod with uniform size, while the morphology of Cu2Se is a denser flake. Similarly, Wang et al. [63] successfully synthesized Cu2Se hollow nanocubes (HNCs) by the anion exchange method using Cu2O nanocubes (NCs) as templates, and by changing the type of reactants. This method can also synthesize Cu2S HNCs or Cu2SSe NCs with similar structures. The schematic diagram of their synthesis is shown in Figure 15d, in which PVP acts as a capping agent and AA is ascorbic acid. It is easy to see that the morphology of the synthesized product without PVP will be heterogeneous morphology; X2− ion is S2− ion or Se2− ion or S2− and Se2− ion, and the synthesized product is different according to the X2−. Figure 15e shows the XRD spectrum, which proves that Cu2O was successfully synthesized and converted to Cu2Se, and the purity of the synthesized Cu2Se is relatively high. According to the general conclusion in the literature, the reaction proceeds in the direction from the substance with large Ksp to the substance with small Ksp. These two works not only successfully synthesized Cu2Se but also conveyed a message that the Ksp of Cu2Se is lower than that of Cu2O.

Figure 15.

(a) Schematic diagram of the synthesis of Cu2SeNSS by Cu2O NRS via S2− ion exchange with O2− ion exchange. (b) TEM image of Cu2O. (c) TEM image of Cu2Se. Reproduced from ref. [62] with permission. Copyright 2020 American Chemical Society. (d) Synthesized diagram of Cu2X (X = S, Se, SSe). (e) XRD spectrum of Cu2Se with Cu2O. (f) SEM image of Cu2O NCs. (g) TEM image of Cu2O HNCs; inset is the corresponding HRTEM image. (h) EDS map of Cu2Se and Cu2O. (i) SEM image of Cu2Se HNCs. (j) TEM image of Cu2Se HNCs; inset is the corresponding HRTEM image. Reproduced from ref. [63] with permission. Copyright 2019 American Chemical Society.

However, although the ion exchange method has many advantages, the ion exchange often occurs in the chemical reaction and is limited by the size of Ksp and the ability to control the reaction conditions accurately, etc. These factors affect the final synthesis of Cu2Se. These factors affect the final synthesis results.

2.6. Summary of Methods

In order to facilitate the reader to have a deeper understanding of the five common methods, this manuscript summarizes the advantages and disadvantages of these methods in Table 1.

Table 1.

Summary of advantages and disadvantages of template-directed, chemical reduction, solid-phase synthesis, hydrothermal/solvothermal method, and ion exchange methods.

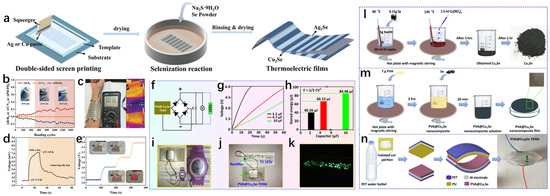

3. Energy Conversion and Storage

3.1. Energy Conversion

Sulfur compounds can be used in many fields such as light-emitting diodes, photodetectors, photovoltaic cells, and supercapacitors due to their unique optical properties and catalytic activity [64,65,66,67]. As a typical sulfur genus compound, Cu2Se has attracted much attention for its excellent carrier mobility and significant thermoelectric figure of merit (ZT value) and shows a broad application prospect in the field of thermoelectric energy conversion. It has been shown that the thermoelectric properties of Cu2Se-based materials can be significantly enhanced by optimizing the synthesis process and modulating the material microstructure, thus achieving more efficient thermoelectric conversion efficiency. An in-depth discussion of the optimization strategy of the thermoelectric properties of Cu2Se-based materials and their intrinsic mechanism not only helps to build understanding about the nature of the thermoelectric material performance enhancement, but also lays a theoretical foundation for the development of high-performance thermoelectric devices. Given that its optimal performance occurs at higher temperatures, Cu2Se-based materials show broad application prospects in industrial waste heat recovery power generation systems. Research into their application in wearable devices remains in its early stages, facing challenges such as achieving near-room-temperature performance and material flexibility.

3.1.1. Electronic and Phonon Transport Properties of Cu2Se

To achieve the design of high-performance Cu2Se-based thermoelectric or energy storage materials, it is essential to gain a deep understanding of their unique electronic and phonon transport behaviors and the interactions between them. The exceptional performance of Cu2Se, particularly its extremely high thermoelectric figure of merit (ZT), fundamentally stems from its “phonon glass-electron crystal” characteristics, which maintains high electronic conductivity, while possessing extremely low lattice thermal conductivity.

The electronic properties of Cu2Se are intrinsically linked to its crystal structure, most notably in the β phase (face-centered cubic structure) that remains stable at elevated temperatures. Within this phase, the Se sublattice forms a rigid framework, while Cu+ ions exhibit highly disordered, “quasi-liquid-like” migration behavior at interstitial sites. This mobile Cu+ system not only provides abundant hole carriers but also endows the material with an intrinsic conductivity approaching that of metals. Practically synthesized Cu2Se often exhibits non-stoichiometric compositions (Cu2−xSe), where the copper vacancy concentration (x) is the key factor in regulating carrier density. By precisely controlling synthesis conditions or introducing dopant elements, carrier density can be effectively optimized to balance conductivity and Seebeck coefficient, thereby achieving higher PF.

On the other hand, Cu2Se’s low thermal conductivity, particularly its extremely low lattice thermal conductivity, is another key factor in its outstanding thermoelectric performance. The quasi-liquid behavior of Cu+ ions causes strong point defect scattering of phonons, which is the primary reason for its low intrinsic thermal conductivity. This scattering mechanism originates from the dynamic interaction between lattice vibrations (phonons) and migrating copper ions. Furthermore, synthetic strategies such as nanostructuring, introducing second phases, or constructing porous microstructures can introduce additional scattering centers like grain boundaries and interfaces. This enhances scattering effects on medium-to-long-wavelength phonons, thereby further suppressing lattice thermal conductivity. The synergistic mechanism between electrons and phonons is central to achieving high performance. In Cu2Se, charge carriers achieve efficient transport via high mobility, while phonons undergo strong scattering due to multiscale defects. The rigid Se framework provides a stable channel for electron transport, whereas migrating Cu+ ions, while contributing to conductivity, also disrupt lattice vibrations like a “phonon solvent,” partially decoupling the transport pathways of electrons and phonons.

In summary, an in-depth understanding of the electronic and phonon behavior in Cu2Se reveals that its exceptional thermoelectric performance stems from the inherent electron–phonon decoupling properties of its crystal structure. Future material design should continue to focus on microstructural control, introducing multiscale phonon scattering mechanisms while maintaining excellent electrical transport capabilities. This will further enhance the decoupling effect, driving breakthroughs in thermoelectric performance.

3.1.2. Optimization of Thermoelectric Properties

Based on the above understanding of the electronic and phonon transport properties of Cu2Se, researchers have developed various performance optimization strategies. It is a simple and easy way to optimize the thermoelectric properties of Cu2Se by using different reaction methods to control different reaction conditions. The design of specific components requires selecting appropriate synthesis methods while precisely controlling certain parameters, such as precursor design, reaction atmosphere control, and annealing process regulation. In precursor design, the ratio of Cu to Se (e.g., Cu2.2Se, Cu1.9Se) can be engineered to precisely regulate copper vacancy concentration, thereby optimizing carrier concentration. More reactive Se sources can be employed to prevent Se agglomeration or incomplete reactions. High-energy ball milling can achieve nanoscale mixing of raw materials, ensuring more uniform material reactions. Controlling the atmosphere, particularly during high-temperature synthesis (e.g., sintering, melting), is crucial. Ensuring sealing integrity and introducing a controlled atmosphere (e.g., vacuum, inert gas protection) prevents Se volatilization, thereby controlling the composition of the final product. Regarding annealing process regulation, a carefully designed annealing process can eliminate the internal stresses generated during synthesis, and promote atomic diffusion and rearrangement, thereby improving crystallinity and compositional uniformity, and stabilizing specific crystal phases. For microwave synthesis, its unique “bulk heating” characteristic inherently promotes more uniform nucleation and growth compared to traditional external heating. Simultaneously, optimizing the distribution of microwave absorbers (e.g., SiC) and reactor design can further enhance thermal field uniformity. For ball milling, controlling grain refinement and amorphization levels is achieved by optimizing milling parameters (rotation speed, ball-to-material ratio, duration), thereby avoiding impurity introduction or composition segregation caused by excessive grinding.

The thermoelectric properties of Cu2Se strongly depend on its microstructure, phase composition, and grain size. Therefore, selecting an appropriate synthesis method is crucial for achieving target performance. Solid-state synthesis methods (e.g., mechanical alloying-sintering) readily produce high-density bulk materials and are commonly employed to achieve high thermoelectric figure of merit (ZT). Conversely, hydrothermal/solvothermal methods facilitate precise control over nanosheet morphology, reducing thermal conductivity by enhancing phonon scattering. This section will explore how these synthesis approaches optimize thermoelectric performance by regulating material microstructure.

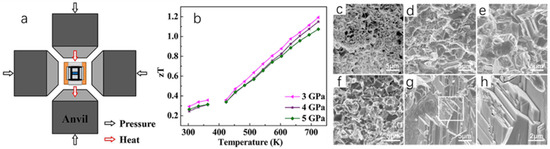

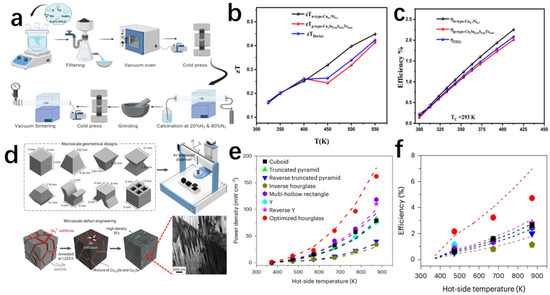

Xue et al. [68] successfully prepared Cu2Se bulk samples by mechanical alloying–sintering under high temperature and high pressure (HPHT) conditions, and regulated their thermoelectric properties by controlling the pressure and temperature of the synthesis. The team first weighed a certain amount of Cu and Se and mixed them according to the stoichiometry of Cu2Se, and subsequently grounded the mixture. This was followed by cold pressing the powder into a disk shape and obtaining different samples by varying the pressure and temperature of the synthesis and treating them for 30 min in a device (Figure 16a). Finally, the disk-shaped samples are pulverized and milled to measure their thermoelectric properties. The increase in the temperature of the synthesis affects the microscopic morphology of the Cu2Se samples, as seen in Figure 16c–h. The microscopic morphology of the Cu2Se samples is a layered, stacked structure; and the higher the synthesis temperature, the larger the particle size of the samples, and the higher the crystallinity. This structure suppresses the lattice thermal conductivity of the sample. The increase in synthesis temperature also has an effect on the carrier concentration of Cu2Se, which in turn increases the power factor of the material. Lattice distortion and yield deformation occur under high pressure, which reduces the activation energy between Se and Cu atoms, and shortens the reaction time to 30 min, which greatly improves the reaction efficiency [69]. The results show that the best thermoelectric properties of the Cu2Se powders occur when they are prepared at 1000 °C and 3 GPa, with the ZT value of 1.19 at 723 K (Figure 16b). It is reasonable to believe that mechanical alloying–sintering under HPHT conditions is also capable of synthesizing other thermoelectric materials with excellent thermoelectric properties.

Figure 16.

(a) HPHT-synthesized Cu2Se device. (b) Temperature dependence of ZT values of Cu2Se synthesized at different pressures. (c–h) SEM images of Cu2Se synthesized at different temperatures and pressures of 3 GPa: (c) 25 °C, (d) 240 °C, (e) 540 °C, (f) 840 °C, (g) 1000 °C, and (h) selected regions of 1000 °C. Reproduced from ref. [68] with permission. Copyright 2019 Elsevier.

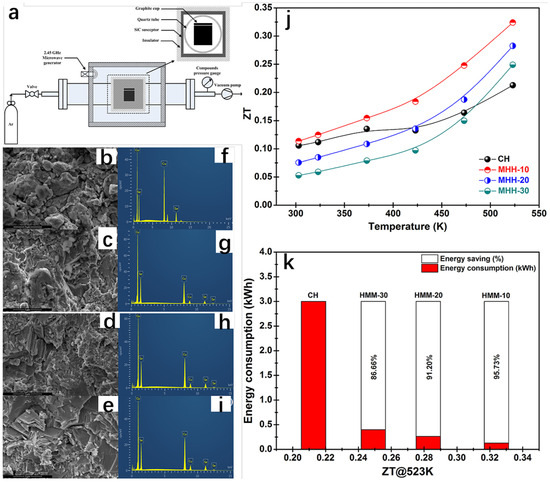

The microwave hybrid heating method, as a type of mechanical alloying–sintering method, is often used to synthesize β-Cu2Se. In addition to this, there are a number of other methods of synthesizing β-Cu2Se, such as ball milling [70], solvent-heated and hydrothermal synthesis [71,72]. The microwave hybrid heating (MHH) method requires a short period of time and less energy. It improves the powder with larger particles by heating in two directions, from the outside to the inside by using a silicon carbide sensitizer, and from the inside to the outside directly by microwave energy [73,74]. Rudradawong et al. [75] successfully synthesized Cu2Se thermoelectric materials dominated by β-Cu2Se using the microwave hybrid heating technique (MHH) and exhibited very low thermal conductivity and excellent thermoelectric properties. The Cu2Se thermoelectric materials were synthesized using microwave mixing and heating (MHH). The Cu and Se were weighed according to the stoichiometric ratio of 2:1 and ball-milled in a ball mill, and subsequently the mixed powders were placed in a microwave mixing and heating oven (Figure 17a) with the power maintained at 800 W, and different samples were obtained by regulating the heating time (10 min, 20 min, 30 min). In order to compare with the Cu2Se samples obtained by the conventional method, the mixed powder of Cu and Se was calcined at high temperature to obtain Cu2Se powder. The powders obtained by the conventional method and the microwave hybrid heating method were milled, pressed, sintered, and cooled to facilitate the subsequent measurement of thermoelectric properties. The ZT value of Cu2Se synthesized under the 10 min microwave hybrid heating technique reaches 0.32 at 523 K. We all know that Cu2Se is a monoclinic phase α-Cu2Se at low temperatures and transforms into a face-centered cubic phase β-Cu2Se when the temperature reaches 410 K [76]. Moreover, β-Cu2Se has a high concentration of Cu+ ions as compared to α-Cu2Se. These Cu+ ions exist in the lattice in a disordered manner, which reduces the free range of motion of phonons, and the vibrations of phonons are partially eliminated [77], resulting in a decrease in lattice thermal conductivity. The high concentration of Cu+ ions also gives the material a high electrical conductivity and a low Seebeck coefficient. XRD spectrum tests are conducted on Cu2Se samples, which are synthesized by heating for different time periods using the MHH method, and by heating for 3h using the conventional method. While only α-Cu2Se was observed for the Cu2Se synthesized by the conventional method at room temperature, a mixed phase of α-Cu2Se and β-Cu2Se was observed for the Cu2Se synthesized by the MHH method, and the proportion of β-Cu2Se increased with the increase in the MHH time. The group then performed SEM analysis (Figure 17b–e) and EDS analysis (Figure 17f–i) on the samples and found that the SEM images of the samples showed thin lamellar layers stacked on top of each other, with a very small size of just a few micrometers. The EDS spectra showed that the Cu:Se was becoming bigger and bigger, and the samples obtained by MHH were above two, which was due to the evaporation of the Se which made an overabundance of Cu. The conductivity of the samples is shown to decrease with increasing temperature, which exhibits a distinctly condensed semiconductor behavior. Simplified semiconductors are impurity semiconductors with a high doping concentration, which are close to the properties of metals. The conductivity of metals decreases with increasing temperature because the formation of an electric current is the result of the directional movement of electrons, and as the temperature increases, the original atoms in the metal move at a faster rate and collide with the electrons, resulting in a decrease in conductivity. And as the time of MHH processing increases, the proportion of β-Cu2Se increases, and the concentration of carriers becomes higher and higher, as the mobility becomes lower; this increases the carrier concentration by an order of magnitude greater than that of the carrier mobility, which becomes lower. So, the conductivity of Cu2Se samples increases with the increase in MHH treatment time. The Seebeck coefficient decreases as the carrier concentration rises, while the carrier concentration rises with the MHH treatment time, which can be interpreted as a decrease in the Seebeck coefficient with an increase in the MHH treatment time. Combining the Seebeck coefficient and conductivity, we can deduce that the PF of MHH-30 achieves the maximum value of 7.90 × 10−4 W m−1K−2 at 673 K. Analyzing the basics of thermoelectricity in conjunction with this study, it is easy to conclude that the increase in conductivity is due to an increase in carrier concentration, which is due to an increase in β-Cu2Se. That is, the longer the MHH treatment, the higher the carrier concentration, and the higher the conductivity, the higher the Kc, and the higher the K. Combining the power factor PF and thermal conductivity K, in general, the Cu2Se sample of MHH-10 has the highest ZT value of about 0.32 at 573 K, which exceeds the 0.21 of the conventional synthesis method, and it saves 85% for energy consumption, while greatly shortening the reaction time (Figure 17j,k).

Figure 17.

(a) Schematic diagram of the microwave hybrid heating device. (b) SEM micrographs of Cu2Se particulate samples fabricated by the conventional heating (CH) method. (c) SEM micrographs of Cu2Se particulate samples fabricated by the MHH-10 method. (d) SEM micrographs of Cu2Se particulate samples fabricated by the MHH-20 method. (e) MHH-30 method fabricated by the SEM micrographs of Cu2Se particulate samples. (f) EDS spectra of Cu2Se particulate samples produced by the conventional heating (CH) method. (g) EDS spectra of Cu2Se particulate samples produced by the MHH-10 method. (h) EDS spectra of Cu2Se particulate samples produced by the MHH-20 method. (i) The MHH-30 method produced Cu2Se particle samples by MHH and conventional heating (CH) methods. (j) The variation in the preferred value of Cu2Se samples synthesized by MHH and conventional heating (CH) methods with temperature. (k) The ZT value of Cu2Se samples synthesized by MHH and conventional heating (CH) methods with energy consumption at 523 K. Reproduced from ref. [75] with permission. Copyright 2021 Elsevier.

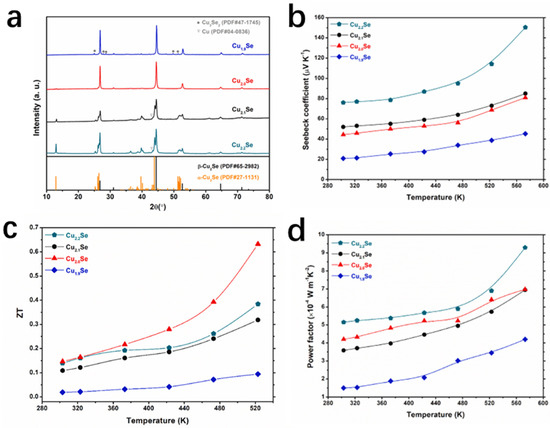

Similarly, Sakulkalavek et al. [78] synthesized β-Cu2.0Se with excellent thermoelectric properties by the MHH method. It is well known that the thermoelectric properties and structures of Cu2Se-based thermoelectric materials are inextricably linked to their stoichiometry [79,80,81]. The research group synthesized CuxSey compounds with different ratios (x:y = 2.2:1.0, 2.1:1.0, 2.0:1.0, and 1.9:1.0) by controlling the stoichiometric ratios of Cu and Se, and the mixed powders were subsequently milled well, and prepared by the MHH method. The bulk sample was grounded and sieved then pressed, and finally sintered under an atmosphere of argon gas and cooled to room temperature and removed. XRD spectrum (Figure 18a) illustrates that by controlling the ratio of Cu:Se, the ratio of β-Cu2Se can be controlled, optimizing the carrier concentration and thermal conductivity, which ultimately results in Cu2.2Se reaching the maximum PF at 573 K. However, due to the excess of Cu, the thermal conductivity of Cu2.2Se is too high, while the thermal conductivity of Cu2.0Se is low, and combined with the high PF of Cu2.0Se, the final ZT value of Cu2.0Se reaches a high level of 0.65 at 523 K (Figure 18d).

Figure 18.

(a) XRD spectrum of Cu1.9Se, Cu2.0Se, Cu2.1Se and Cu2.2Se samples synthesized by the 10 min MHH method. (b–d) Temperature dependence of TE properties of Cu2.2Se, Cu2.1Se, Cu2.0Se, and Cu1.9Se samples. (b) Seebeck coefficient. (c) ZT value. (d) Power factor. Reproduced from ref. [78] with permission. Copyright 2024 Elsevier.

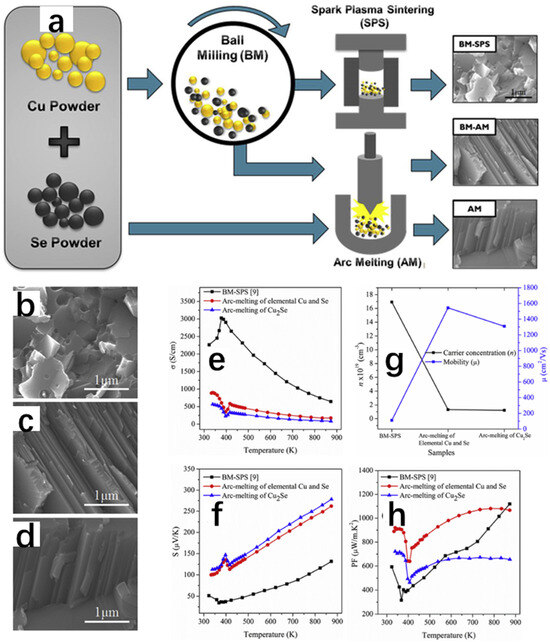

In another work, Butt et al. [20] successfully synthesized Cu2Se thermoelectric materials by arc melting, and the thermoelectric properties were excellent, with a ZT value of 1.46 at 873 K. As shown in Figure 19a, the team used three methods to synthesize Cu2Se. The first one was to synthesize the polycrystalline Cu2Se powders by ball milling [82], followed by the synthesis of polycrystalline Cu2Se powders by sparking at a temperature of 500 °C and 50 MPa at a pressure of 500 °C. The first method was to synthesize the polycrystalline Cu2Se powders by ball milling with a pressure of 500 °C into solid pellets by spark plasma sintering; the second method included first obtaining polycrystalline Cu2Se powder by ball milling, then compressing it into a solid with a pressure of 4 MPa, and finally compressing the Cu2Se into pellets by arc melting; and the third method was basically the same as the second one, except that the polycrystalline Cu2Se powder obtained by ball milling was replaced by a stoichiometric mixture of 2Cu and Se. The three samples obtained were subjected to XRD spectrum and SEM characterization, and the results of the XRD spectrum showed that the Cu2Se samples synthesized by these three methods all possessed both α-Cu2Se and β-Cu2Se mixed phases at room temperature, and all of them turned into β-Cu2Se again at 473 K, which illustrated the transition of the Cu2Se crystals from the room-temperature α-Cu2Se to the high-temperature β-Cu2Se. Although the crystal phases obtained by all three methods are consistent, the third method is faster, has the lowest economic loss, and has the highest degree of crystallinity, which is not difficult to prove from the intensity of their diffraction peaks. Figure 19b shows the scanning electron microscope images of the crushed samples obtained by BM-SPS (ball-milling method with spark plasma sintering) treatment, and we can see that the samples show smaller grains and fewer pores, which may be due to the evaporation of selenium caused by too high temperatures under the SPS treatment. Furthermore, we can see some grain boundaries at the same time, which may have a detrimental impact on the transport of carriers, and consequently on the thermoelectric properties. Figure 19c,d show the SEM images of the crushed samples obtained by BM-AM (ball milling with arc melting) and AM (arc melting), respectively, and it can be seen that the grains are presented as lamellar, and the porosity is also small, which is favorable for carrier transport. Figure 19e–h show the thermoelectric properties, and the final results show that the arc melting method has successfully synthesized pure Cu2Se with good thermoelectric properties, which is a simple process with less loss cost, providing stable properties and a 70% increase in ZT relative to Cu2Se obtained by spark plasma sintering after ball milling, but we have no way of knowing how this method can be applied to the synthesis of other thermoelectric materials, and it needs to be further researched.

Figure 19.

(a) Scanning electron micrographs of Cu2Se samples synthesized by three different methods: ball milling with spark plasma sintering technique, ball milling with arc melting, and arc melting. (b) Scanning electron microscope diagrams of Cu2Se samples synthesized by ball milling with spark plasma sintering technique. (c) Sweep electron microscope diagrams of Cu2Se samples synthesized by ball milling with arc melting. (d) Arc melting method for synthesizing Cu2Se samples. Scanning electron micrographs. (e) Variation in conductivity with temperature of Cu2Se samples synthesized by three different methods. (f) Variation in Seebeck coefficient with temperature of Cu2Se samples synthesized by three different methods. (g) Variation in carrier concentration and carrier mobility of Cu2Se samples synthesized by three different methods. (h) Variation in power factor with temperature of Cu2Se samples synthesized by three different methods. Reproduced from ref. [20] with permission. Copyright 2019 Elsevier.

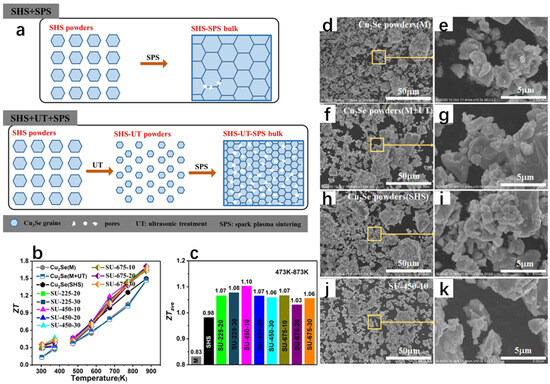

Compared to the melt-only synthesis of Cu2Se, Zhang et al. [83] discovered a new path to improve the thermoelectric properties of Cu2Se by synthesizing Cu2Se materials with excellent thermoelectric properties through a combined method of self-propagating high-temperature synthesis (SHS), ultrasonic treatment (UT), and spark plasma sintering (SPS) (Figure 20a), which led to the enhancement of phonon scattering and the decrease in thermal conductivity, which was only 0.40–0.45 Wm−1K−1 at 873 K, compared to the molten samples. The ZT value was substantially increased by 16% at 873 K (Figure 20b), and further FESEM analysis was performed for the samples synthesized by different methods (Figure 20d–k), and it can be seen that the morphology of the material does not change significantly after ultrasonic treatment, and the grain size is refined, which in turn leads to enhanced phonon scattering and reduced thermal conductivity. The thermoelectric properties of SHS+SPS samples are improved by ultrasonic treatment, which is not only low cost but also very efficient, and is of great significance for the improvement in the thermoelectric properties of Cu2Se.

Figure 20.

(a) Schematic representation of in situ hole formation in self-propagating pyrosynthesized Cu2Se bulk after UT and without UT. (b) ZT values of Cu2Se prepared by melting, melting + ultrasound preparation, self-propagating pyrosynthesis, and self-propagating pyrosynthesis + ultrasound, respectively. (c) Average ZT values of Cu2Se from 473 K to 873 K for different preparation methods. (d) FESEM image of melt-synthesized Cu2Se powder. (e) Magnified image of the yellow rectangle-marked area in (d). (f) Melt synthesized Cu2Se powder followed by sonication. (g) Magnified image of the yellow rectangle-marked area in (f). (h) Cu2Se powder synthesized by self-propagating high temperature synthesis only. (i) Magnified image of the yellow rectangularly marked area in (h). (j) Cu2Se powder synthesized by the self-propagating high-temperature synthesis method followed by ultrasonication (450 W for 10 min). (k) Magnified image of the yellow rectangularly marked area in (j). Reproduced from ref. [83] with permission. Copyright 2021 Elsevier.