Preparation and Performance of 3D-Printed TiO2-Supported TPMS Structures for Photocatalytic Applications

Abstract

1. Introduction

2. Results and Discussion

2.1. Structural and Morphological Analysis

2.1.1. X-Ray Diffraction

2.1.2. Contact Angle Test

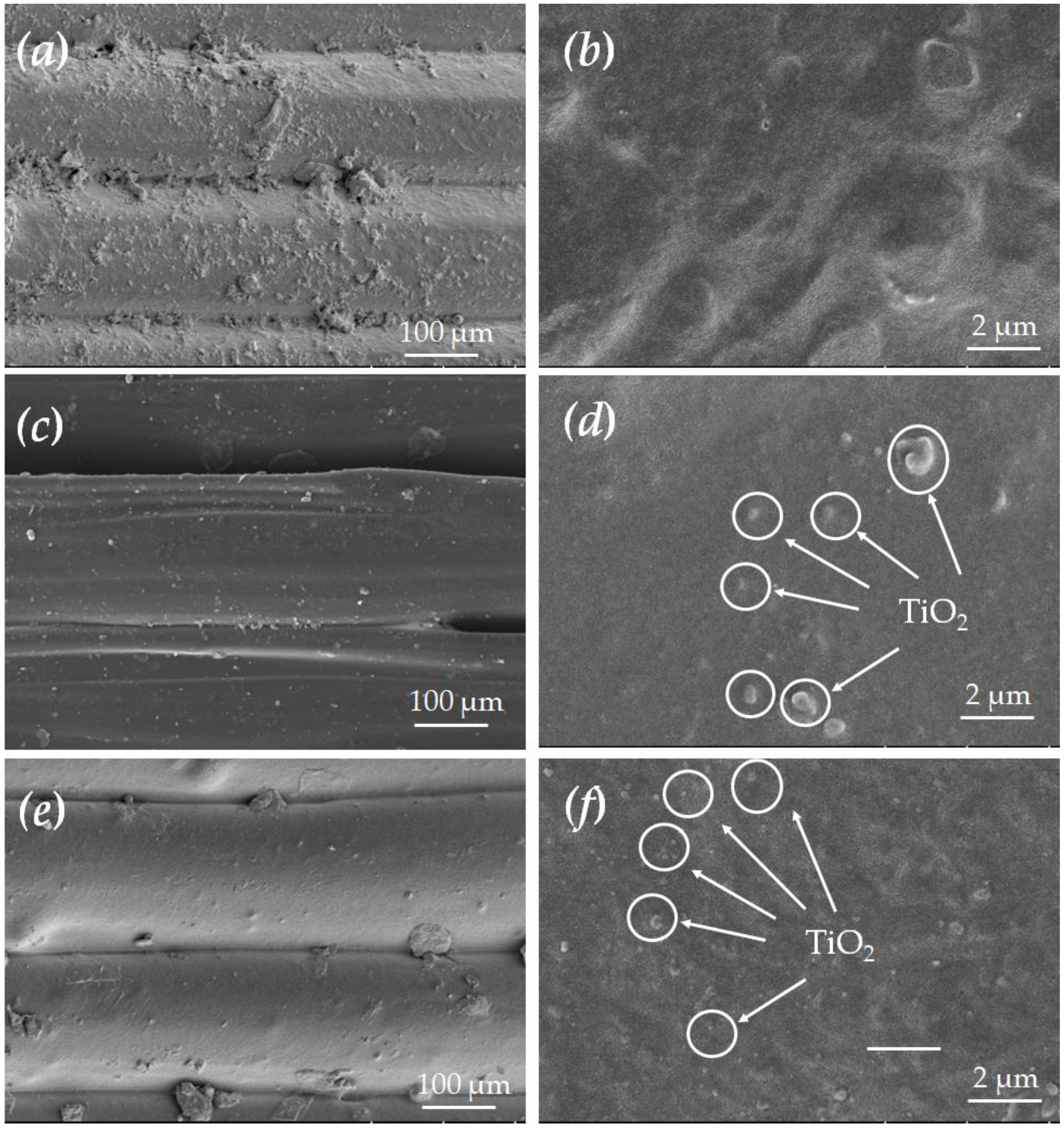

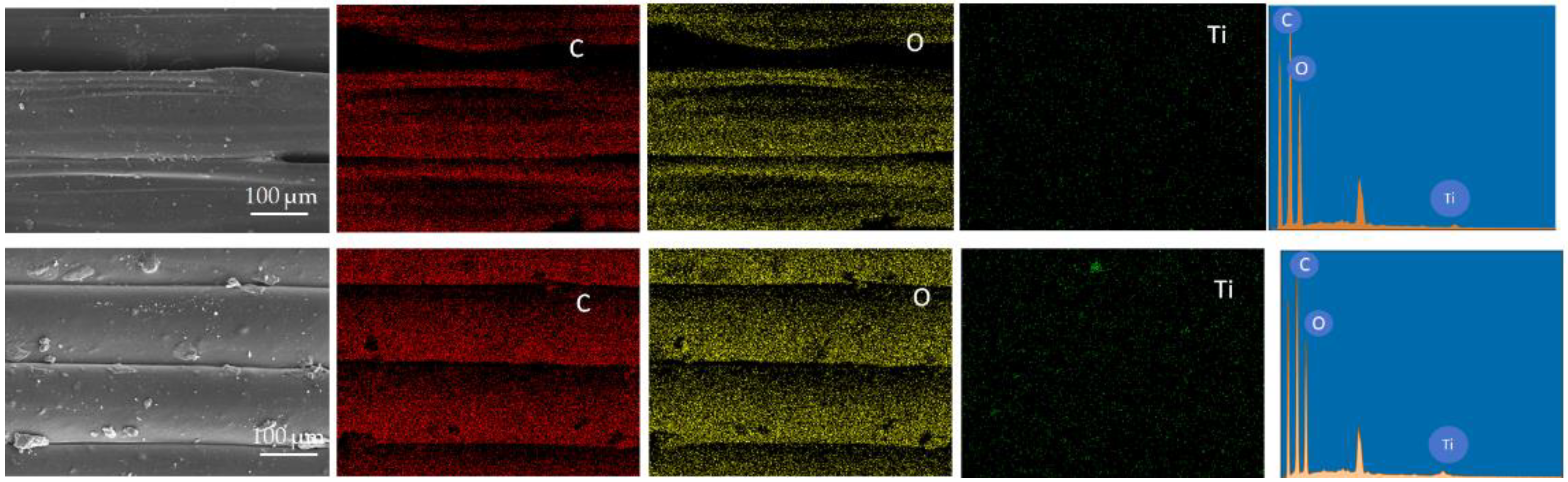

2.1.3. SEM/EDS

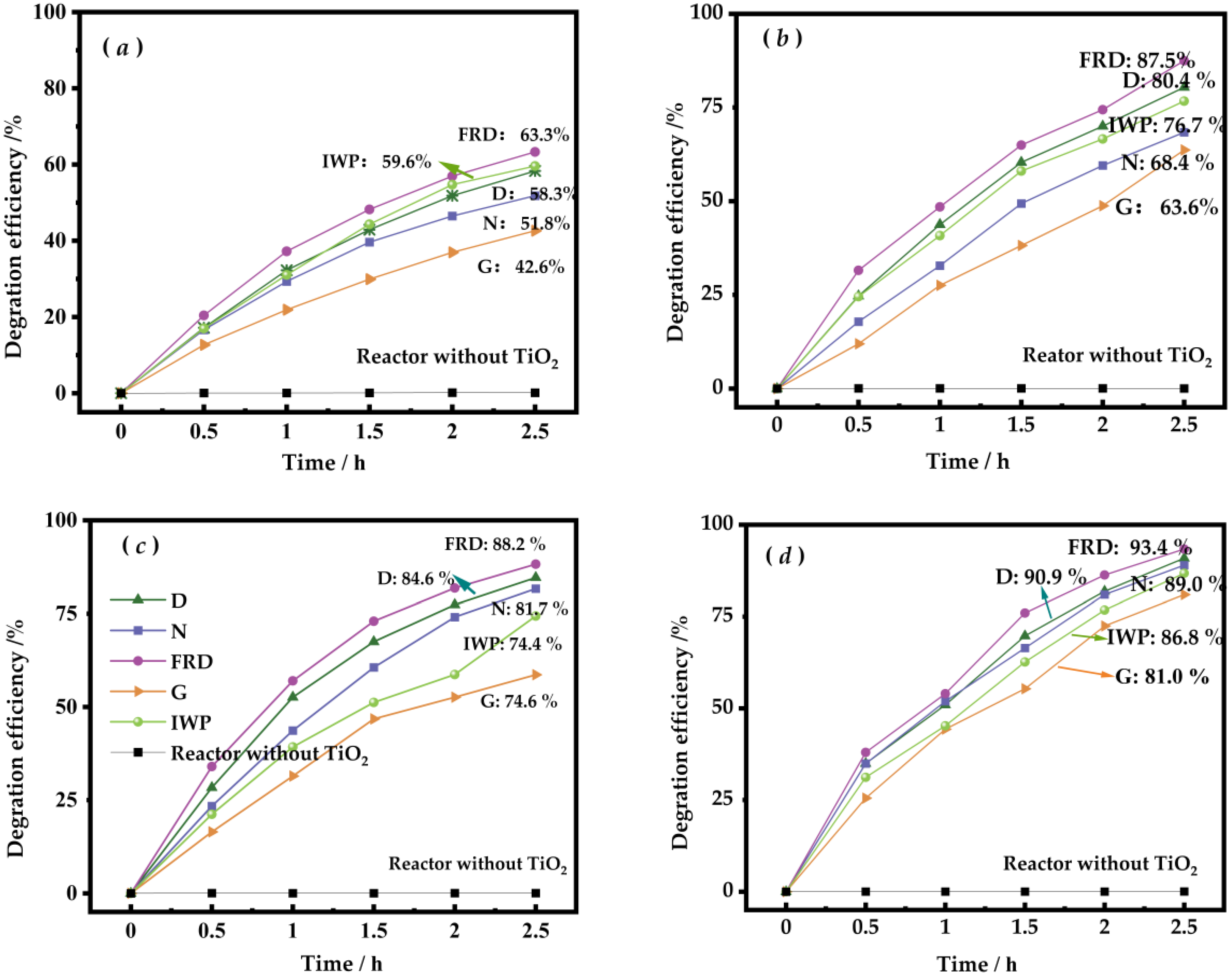

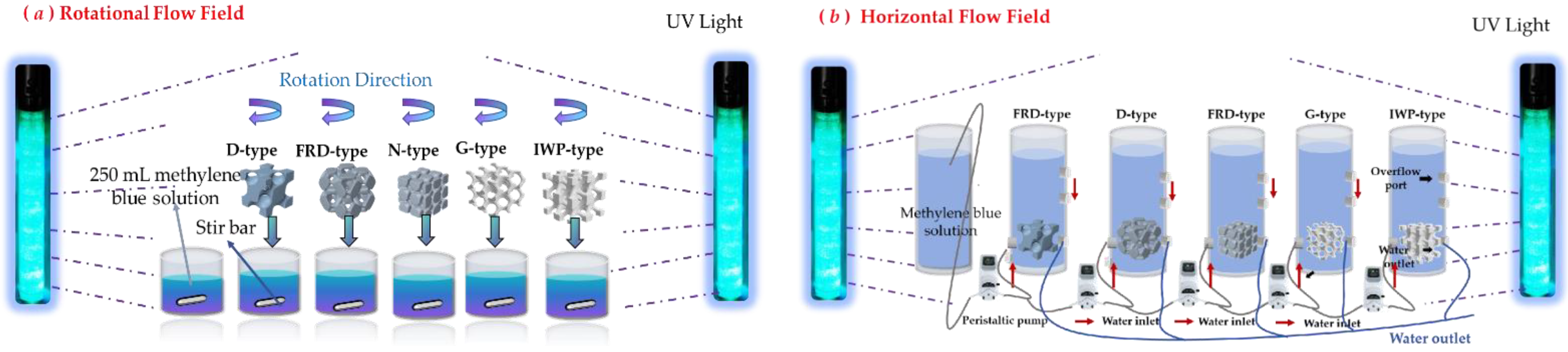

2.2. Photocatalytic Performance of Different Reactors

3. Materials and Methods

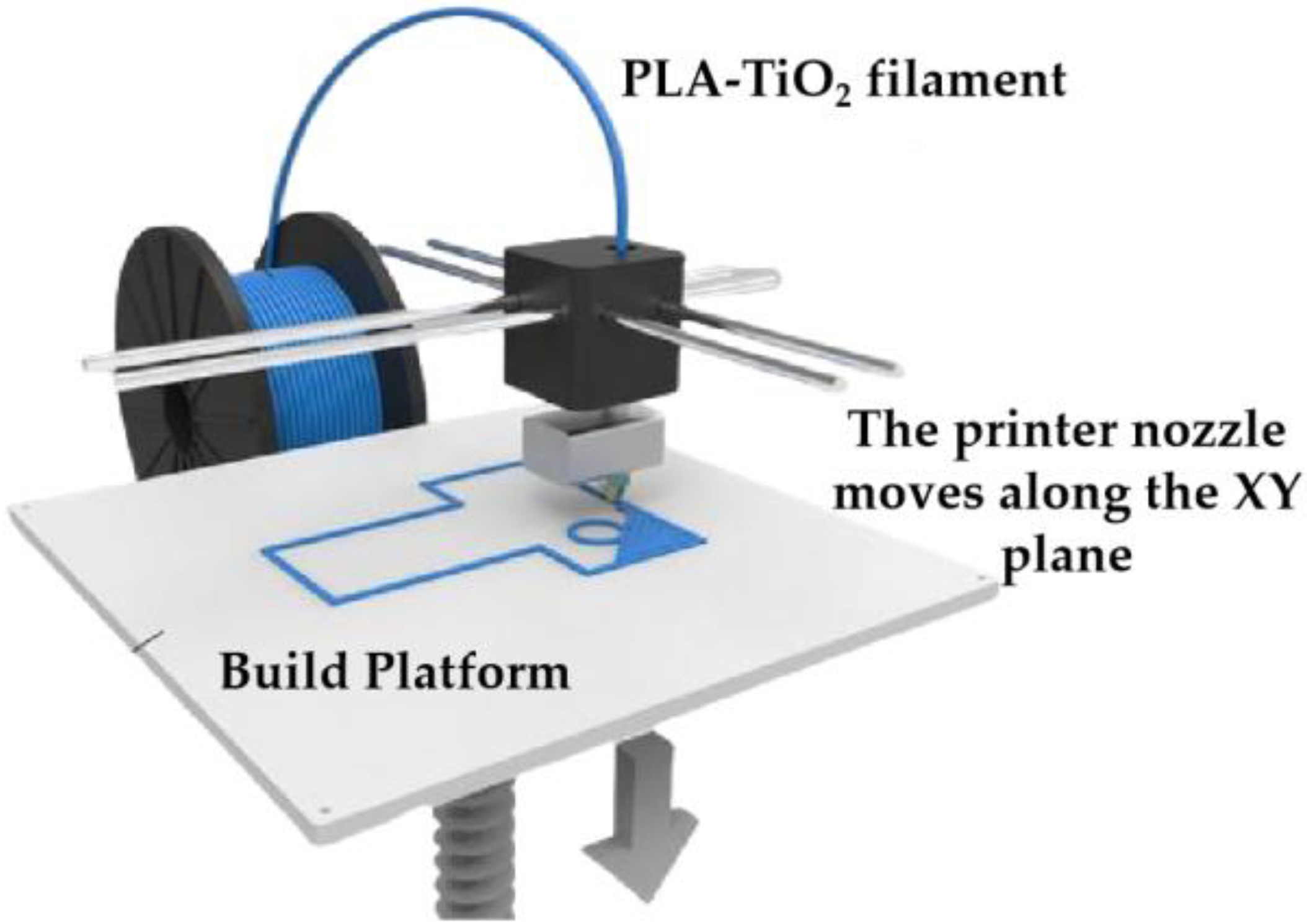

3.1. Synthesis of TiO2/PLA Composite Filament

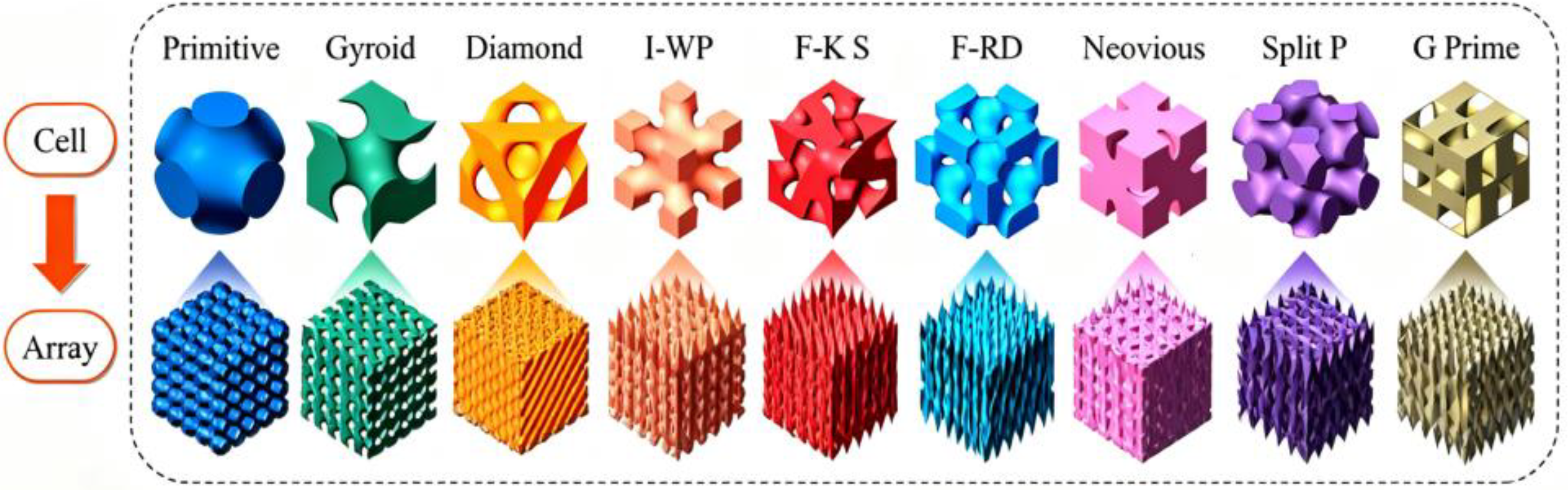

3.2. Fabrication of Triply Periodic Minimal Surface (TPMS) Reactors via 3D Printing

3.3. Photocatalytic Activity Test

4. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TPMS | Triply Periodic Minimal Surface |

| PCR | Photocatalytic Reactors |

| FRD | Fischer-Radin-Dunn |

| N | Neovius |

| D | Diamond |

| IWP | I-graph Wrapped Package |

| G | Gyroid |

Appendix A

| TPMS | Parameter C | Volume (cm3) | Surface Area (cm2) | Poosity (%) | Specific Surface Area (cm2/cm3) |

|---|---|---|---|---|---|

| FRD | 0.5 | 20.2806 | 252.8271 | 66.20% | 12.47 |

| 0.4 | 24.3341 | 263.4307 | 59.44% | 10.83 | |

| 0.3 | 28.1025 | 262.088 | 53.16% | 9.33 | |

| 0.2 | 31.5176 | 260.35 | 47.47% | 8.26 | |

| 0.1 | 34.7453 | 254.8902 | 42.09% | 7.34 | |

| N | 0.5 | 28.0057 | 276.1458 | 78.02% | 14.17 |

| 0.4 | 29.399 | 283.1603 | 71.65% | 12.12 | |

| 0.3 | 30.7664 | 288.2382 | 65.40% | 10.62 | |

| 0.2 | 32.1576 | 292.0641 | 59.25% | 9.46 | |

| 0.1 | 33.5395 | 294.8173 | 53.14% | 8.51 | |

| D | 0.5 | 13.1894 | 186.8994 | 53.32% | 9.86 |

| 0.4 | 17.0088 | 206.1038 | 51.00% | 9.63 | |

| 0.3 | 20.758 | 220.4739 | 48.72% | 9.37 | |

| 0.2 | 24.453 | 231.291 | 46.40% | 9.08 | |

| 0.1 | 28.114 | 239.2879 | 44.10% | 8.79 | |

| G | 1.2 | 6.265 | 112.3928 | 89.56% | 7.94 |

| 1 | 10.8215 | 141.5935 | 81.96% | 13.08 | |

| 0.8 | 15.175 | 161.8086 | 74.71% | 10.66 | |

| 0.6 | 19.4092 | 177.3254 | 67.65% | 9.14 | |

| IWP | 2.0 | 14.9278 | 172.6605 | 75.12% | 1.57 |

| 1.8 | 16.9145 | 181.4704 | 71.81% | 10.73 | |

| 1.6 | 18.8147 | 188.9283 | 68.64% | 10.04 |

| Samples | Phases | Relative Crystallinity (%) |

|---|---|---|

| The reactor printed using 2.5 wt% TiO2/PLA | TiO2 | 2.3 |

| PLA | 97.7 | |

| The reactor printed using 1.5 wt% TiO2/PLA | TiO2 | 1.4 |

| PLA | 98.6 |

References

- Rostami, M.; Badiei, A.; Ganjali, M.R.; Rahimi-Nasrabadi, M.; Naddafi, M.; Karimi-Maleh, H. Nano-architectural design of TiO2 for high performance photocatalytic degradation of organic pollutant: A review. Environ. Res. 2022, 212, 113347. [Google Scholar] [CrossRef]

- Ijaz, M.; Zafar, M. Titanium dioxide nanostructures as efficient photocatalyst: Progress, challenges and perspective. Int. J. Energy Res. 2021, 45, 3569–3589. [Google Scholar] [CrossRef]

- Li, Y.Z.; Ma, Y.J.; Li, K.; Chen, S.H.; Yue, D.T. Photocatalytic Reactor as a Bridge to Link the Commercialization of Photocatalyst in Water and Air Purification. Catalysts 2022, 12, 724. [Google Scholar] [CrossRef]

- Mei, J.N.; Gao, X.M.; Zou, J.; Pang, F. Research on Photocatalytic Wastewater Treatment Reactors: Design, Optimization, and Evaluation Criteria. Catalysts 2023, 13, 974. [Google Scholar] [CrossRef]

- Al-Yahyaey, S.; Kyaw, H.H.; Myint, M.T.Z.; Al-Hajri, R.; Al-Sabahi, J.; Al-Abri, M. Multi-channel flow reactor design for the photocatalytic degradation of harmful dye molecules. J. Nanopart. Res. 2024, 26, 72. [Google Scholar] [CrossRef]

- Dewada, S.S.; Telang, A. A review of recently developed polymer composite materials for fused deposition modeling 3D printing. Mater. Res. Express 2021, 8, 122001. [Google Scholar] [CrossRef]

- Mackiewicz, E.; Wejrzanowski, T.; Adamczyk-Cieslak, B.; Oliver, G.J. Polymer-Nickel Composite Filaments for 3D Printing of Open Porous Materials. Materials 2022, 15, 1360. [Google Scholar] [CrossRef]

- Sangiorgi, A.; Gonzalez, Z.; Ferrandez-Montero, A.; Yus, J.; Sanchez-Herencia, A.J.; Galassi, C.; Sanson, A.; Ferrari, B. 3D Printing of Photocatalytic Filters Using a Biopolymer to Immobilize TiO2 Nanoparticles. J. Electrochem. Soc. 2019, 166, H3239–H3248. [Google Scholar] [CrossRef]

- Fagundes, A.P.; Neiva, E.G.C.; Zimmermann, L.M.; Padoin, N.; Riella, H.G. Melting and solution mixing in the production of photocatalytic filaments for 3D printing. Chem. Eng. Sci. 2025, 302, 120862. [Google Scholar] [CrossRef]

- Basterrechea, G.F.B.; Montesinos, V.N.; Quici, N. Photocatalytic NOx removal with TiO2-impregnated 3D-printed PET supports. Heliyon 2023, 9, e22635. [Google Scholar] [CrossRef]

- Liu, D.Y.; Cai, H.J.; Zhou, W.M.; Lei, D.D.; Cao, C.L.; Xia, X.S.; Xiao, L.R.; Qian, Q.R.; Chen, Q.H. Application of 3D printing technology for green synthesis of Fe2O3 using ABS/TPU/chlorella skeletons for methyl orange removal. RSC Adv. 2024, 14, 1501–1512. [Google Scholar] [CrossRef]

- Rentz, R.; Widerlund, A.; Viklander, M.; Öhlander, B. Impact of Urban Stormwater on Sediment Quality in an Enclosed Bay of the Lule River, Northern Sweden. Water Air Soil Pollut. 2010, 218, 651–666. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, C.; Chen, Q.; Chen, X.; Li, N. Photocatalytic Performance of 3D-Printed Triply Periodic Minimal Surface Photocatalytic Reactors. Coatings 2025, 15, 953. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, K.; Jia, J. Recent Developments of Light-Harvesting Excitation, Macroscope Transfer and Multi-Stage Utilization of Photogenerated Electrons in Rotating Disk Photocatalytic Reactor. Processes 2023, 11, 838. [Google Scholar] [CrossRef]

- Molinari, R.; Lavorato, C.; Argurio, P. The Evolution of Photocatalytic Membrane Reactors over the Last 20 Years: A State of the Art Perspective. Catalysts 2021, 11, 775. [Google Scholar] [CrossRef]

- Yeranee, K.; Rao, Y. A Review of Recent Research on Flow and Heat Transfer Analysis in Additively Manufactured Transpiration Cooling for Gas Turbines. Energies 2025, 18, 3282. [Google Scholar] [CrossRef]

- Han, L.; Che, S. An Overview of Materials with Triply Periodic Minimal Surfaces and Related Geometry: From Biological Structures to Self-Assembled Systems. Adv. Mater. 2018, 30, e1705708. [Google Scholar] [CrossRef]

- Arsentev, M.; Topalov, E.; Balabanov, S.; Sysoev, E.; Shulga, I.; Akhmatnabiev, M.; Sychov, M.; Skorb, E.; Nosonovsky, M. Crystal-Inspired Cellular Metamaterials and Triply Periodic Minimal Surfaces. Biomimetics 2024, 9, 285. [Google Scholar] [CrossRef]

- D’Accolti, L.; De Cataldo, A.; Montagna, F.; Corcione, C.E.; Maffezzoli, A. The Role of 3D Printing in the Development of a Catalytic System for the Heterogeneous Fenton Process. Polymers 2023, 15, 580. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.H.; Wei, M.S.; Dan, D.; Zheng, S.Y.; Tian, R.; Meng, S.; Nan, X. Hybrid design of triply periodic minimal surface (TPMS) structures for loop heat pipe wicks to enhance heat and mass transfer. Int. J. Heat Mass Transf. 2025, 242, 126874. [Google Scholar] [CrossRef]

- Li, N.N.; Zhan, H.W.; Tong, K.; Chen, Z.D.; Kong, Y.Q.; Yang, L.J.; Du, X.Z. Lattice Boltzmann method to simulate photocatalytic reduction of CO2 over PCN-601 coated on transparent porous substrate. Phys. Scr. 2025, 100, 015532. [Google Scholar] [CrossRef]

| Sample | Left contact Angle/° | Right Contact Angle/° |

|---|---|---|

| Pure PLA | 80.771 | 80.771 |

| 1.5 wt% TiO2/PLA | 62.587 | 62.587 |

| 2.5 wt% TiO2/PLA | 62.301 | 62.301 |

| Parameter C | Photocatalytic Degradation Efficiency After 2.5 h | |

|---|---|---|

| (1.5 wt% TiO2/PLA, Rotational Flow Field) | (1.5 wt% TiO2/PLA, Horizontal Flow Field) | |

| 0.5 | 87.5% | 63.3% |

| 0.3 | 76.4% | 54.4% |

| TPMS Type | Parameter C | Porosity (%) | Specific Surface Area (cm2/cm3) | Average Pore Size (mm) | Photocatalytic Efficiency | Interpretation |

|---|---|---|---|---|---|---|

| FRD | 0.5 | 66.20% | 12.47 | 8.41 | 93.4% | The largest pore size provides excellent mass transfer, enabling rapid diffusion of reactants/products. Although porosity and specific surface area are moderate, its performance is superior under rotational flow conditions due to enhanced convective transport. |

| N | 0.5 | 78.02% | 14.17 | 6.74 | 89.0% | A balanced structure with relatively high porosity and specific surface area, combined with a moderate pore size, achieves an optimal trade-off among light harvesting, mass transfer, and active site availability |

| D | 0.5 | 53.32% | 9.86 | 5.1 | 90.9% | Possesses the lowest porosity, specific surface area, and smallest pore size. Although typically associated with inferior performance, its high efficiency here may be attributed to unique pore connectivity and optimized light distribution under specific flow conditions (e.g., low velocity). |

| G | 1.2 | 89.56% | 17.94 | 7.89 | 81.0% | Exhibits the highest porosity and specific surface area, which facilitate light transmission and catalyst loading. However, the relatively large pore size may lead to insufficient light utilization (e.g., partial light penetration without reaction) or non-uniform flow distribution, resulting in sub-optimal efficiency. |

| IWP | 2.0 | 75.12% | 11.57 | 7.83 | 86.8% | Displays well-balanced properties. The large pore size enhances mass transfer, but the relatively low specific surface area limits the number of reactive sites. |

| Feed Port Speed (rad/min) | Heating Zone Temperature Control (°C) | Discharge Port Temperature Control (°C) | ||||

|---|---|---|---|---|---|---|

| (Pellet) Feed Port Speed | (Powder) Feed Port Speed | Zone 1 | Zone 2 | Zone 3 | Discharge Zone 1 | Discharge Zone 2 |

| 10 | 8 | 175 | 185 | 190 | 180 | 175 |

| TPMS | Parameter C | Volume (cm3) | Surface Area (cm2) | Porosity (%) | Specific Surface Area (cm2/cm3) |

|---|---|---|---|---|---|

| FRD | 0.5 | 20.2806 | 252.8271 | 66.20% | 12.47 |

| 0.3 | 28.1025 | 262.088 | 53.16% | 9.33 | |

| N | 0.5 | 28.0057 | 276.1458 | 78.02% | 14.17 |

| D | 0.5 | 13.1894 | 186.8994 | 53.32% | 9.86 |

| G | 1.2 | 6.265 | 112.3928 | 89.56% | 17.94 |

| IWP | 2.0 | 14.9278 | 172.6605 | 75.12% | 11.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Zhang, C.; Chen, X.; Li, N. Preparation and Performance of 3D-Printed TiO2-Supported TPMS Structures for Photocatalytic Applications. Molecules 2025, 30, 3891. https://doi.org/10.3390/molecules30193891

Chen X, Zhang C, Chen X, Li N. Preparation and Performance of 3D-Printed TiO2-Supported TPMS Structures for Photocatalytic Applications. Molecules. 2025; 30(19):3891. https://doi.org/10.3390/molecules30193891

Chicago/Turabian StyleChen, Xi, Chenxi Zhang, Xiao Chen, and Ningning Li. 2025. "Preparation and Performance of 3D-Printed TiO2-Supported TPMS Structures for Photocatalytic Applications" Molecules 30, no. 19: 3891. https://doi.org/10.3390/molecules30193891

APA StyleChen, X., Zhang, C., Chen, X., & Li, N. (2025). Preparation and Performance of 3D-Printed TiO2-Supported TPMS Structures for Photocatalytic Applications. Molecules, 30(19), 3891. https://doi.org/10.3390/molecules30193891