The Presence of Micro- and Nanoplastics in Food and the Estimation of the Amount Consumed Depending on Dietary Patterns

Abstract

1. Introduction

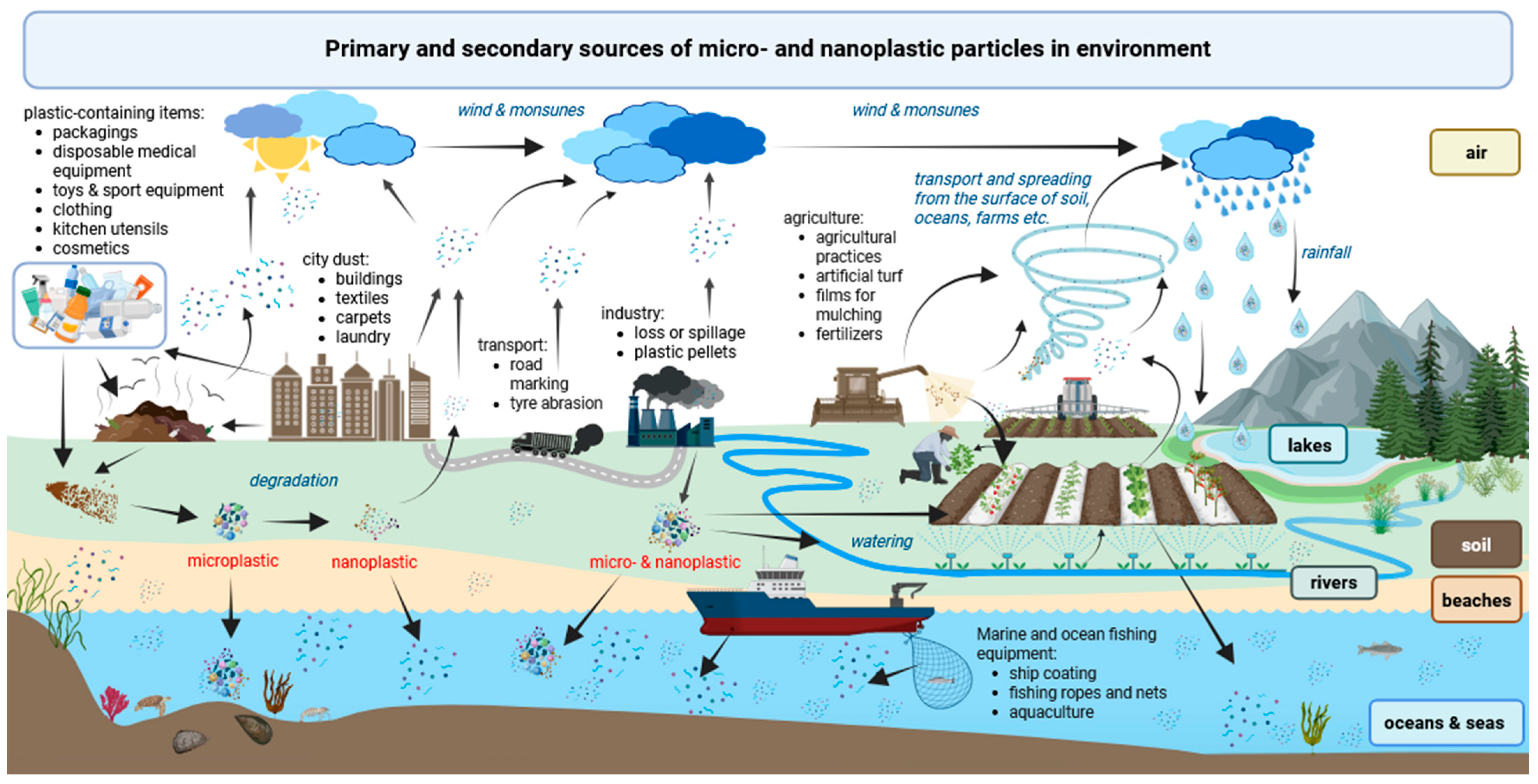

2. Sources of MNPs in the Environment and Pathways of Contamination

- Mechanical fragmentation of plastic products during normal, daily use or as a result of weathering, abrasion, and pouring of particular objects, especially when improperly recycled (synthetic shoe soles, toys, synthetic kitchen utensils, medical devices, infrastructure components, buildings, equipment, carpets, furniture) [99,121,122,123,124],

- Broken plastic fishing ropes and nets [126],

3. Entry Routes of MNPs into the Human Body

3.1. Inhalation of Airborne Plastic Particles

3.2. Dermal Penetration of Nanoplastic Particles

3.3. Ingestion of MNPs

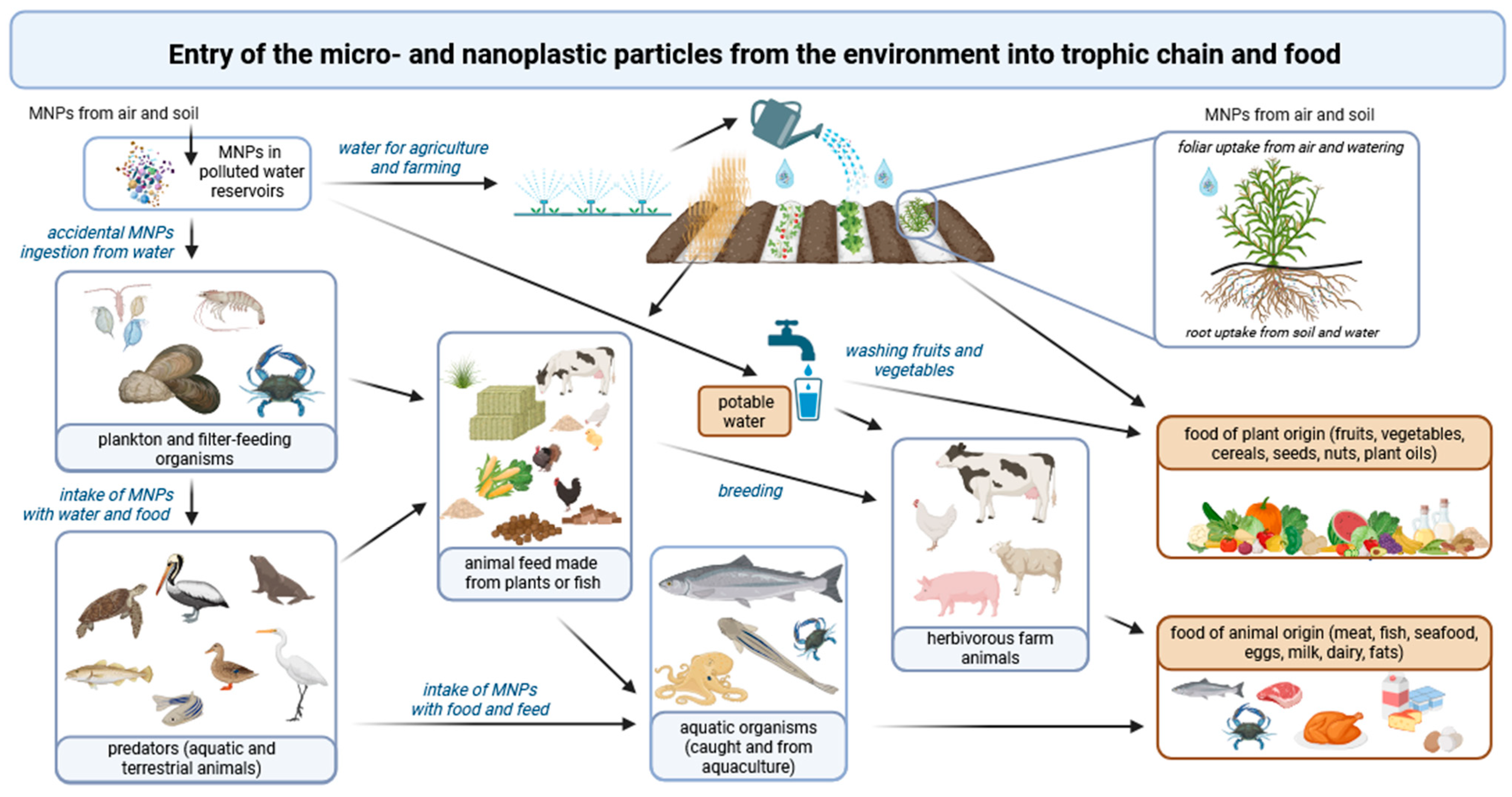

4. Mechanisms of Food Contamination

4.1. Kitchen Accessories, Food Preparation, and Food Packaging as a Source of MNPs in Meals

4.2. Plastics Particles Identified in Various Types of Food

4.3. Plastic-Associated Chemicals and Other Contaminants

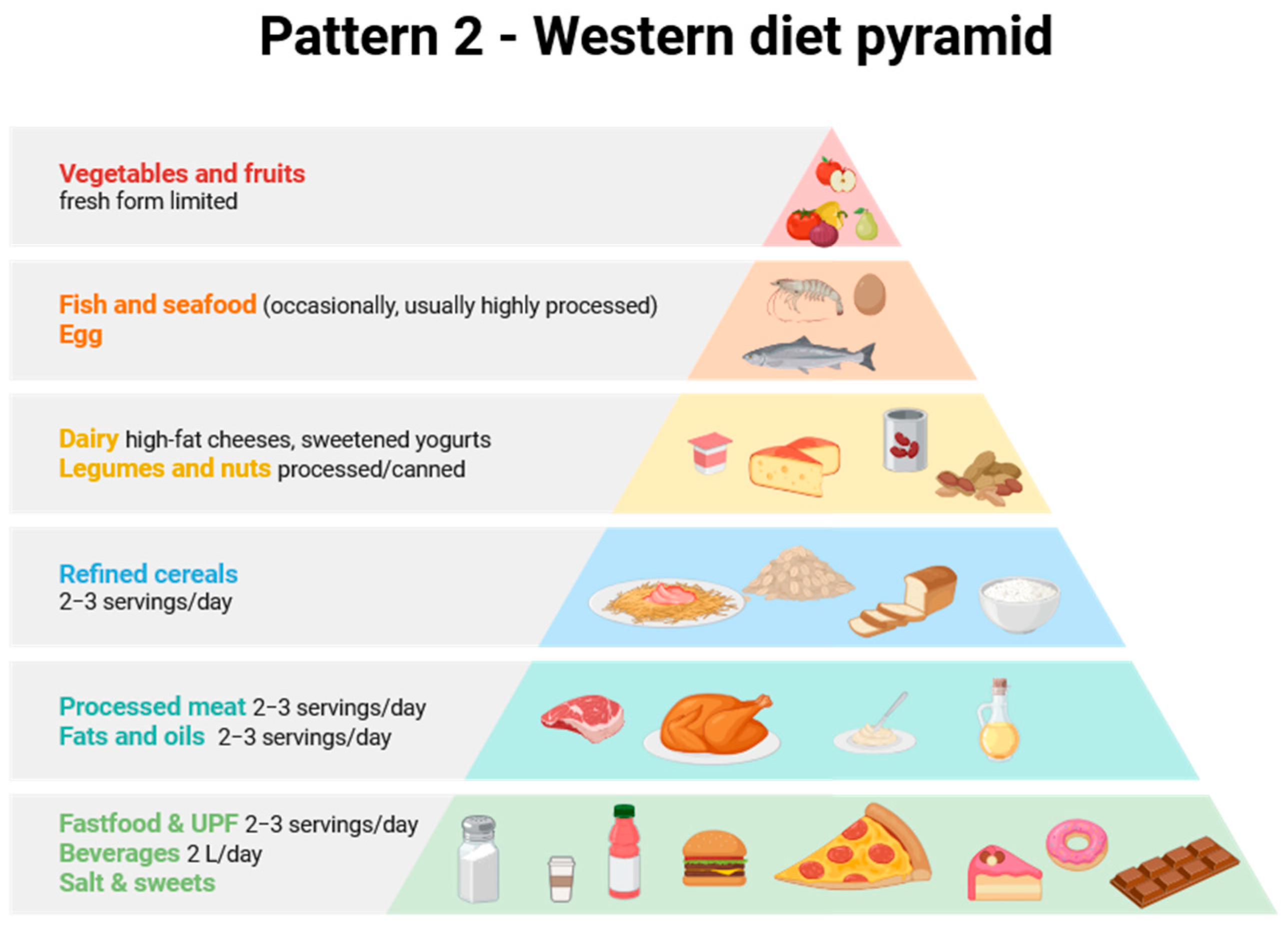

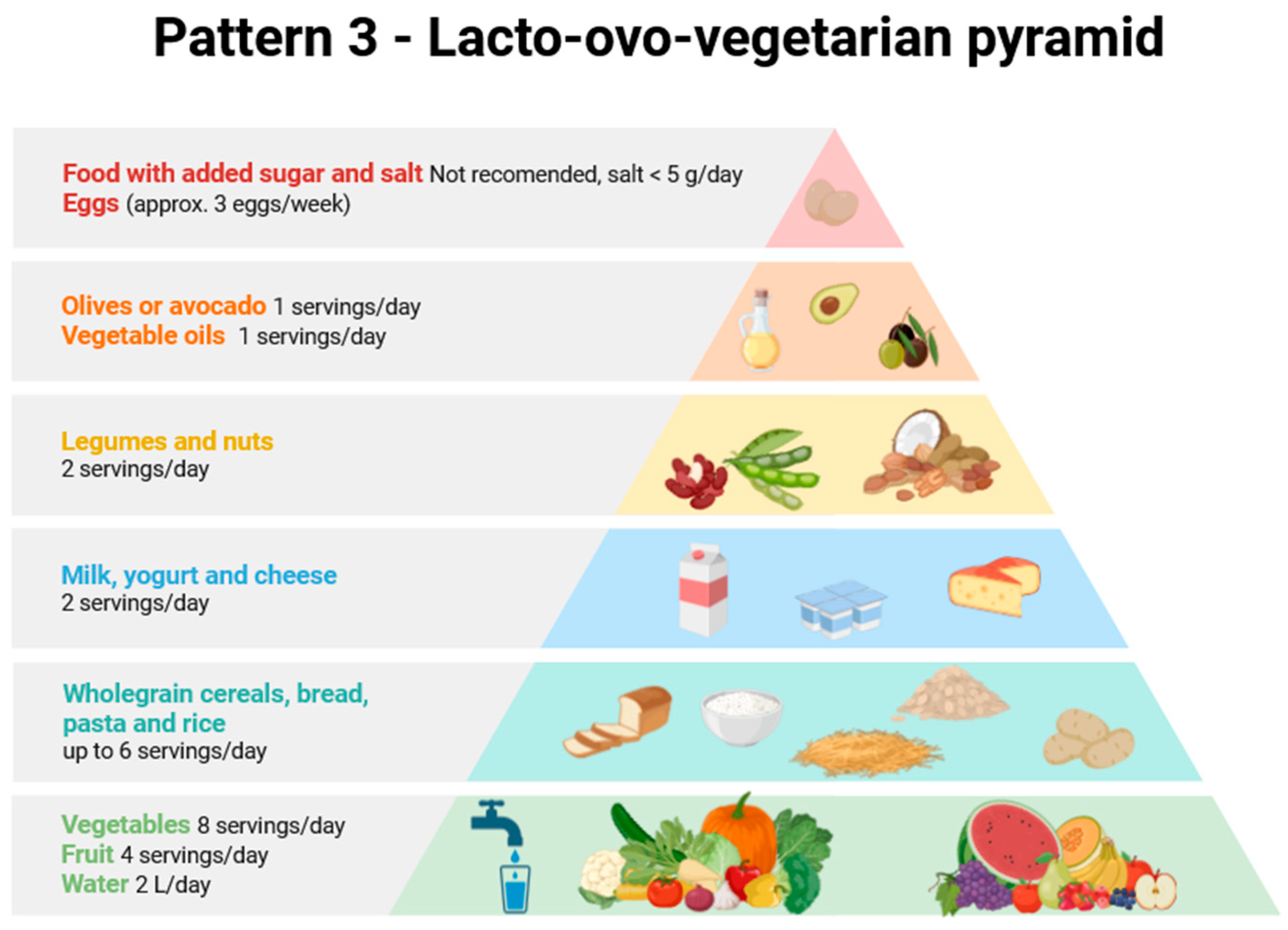

5. Food Pyramid as a Graphical Representation of FDBG and Various Dietary Patterns

- Western Europe (WE): Austria, Belgium, France, Germany, Ireland, Luxembourg, Liechtenstein, the Netherlands, Switzerland, the United Kingdom (Table S1 in Supplementary Material);

- Nordic and Baltic countries (NBC): Denmark, Finland, Sweden, Iceland, Norway, Estonia, Latvia, and Lithuania (Table S2);

- Central and Eastern Europe (CEE): Belarus, Bulgaria, Czech Republic, Hungary, Poland, Romania, Slovakia, Serbia, North Macedonia, Moldova, Slovenia, Bosnia and Herzegovina, Ukraine (Table S3);

- Southern Europe (SE): Albania, Andorra, Greece, Italy, Malta, Monaco, Portugal, Spain, Croatia, Montenegro, San Marino, and Turkey (Table S4).

6. Assessment of the MNP Intake Depending on Dietary Patterns

6.1. Methodology Used for the Assessment

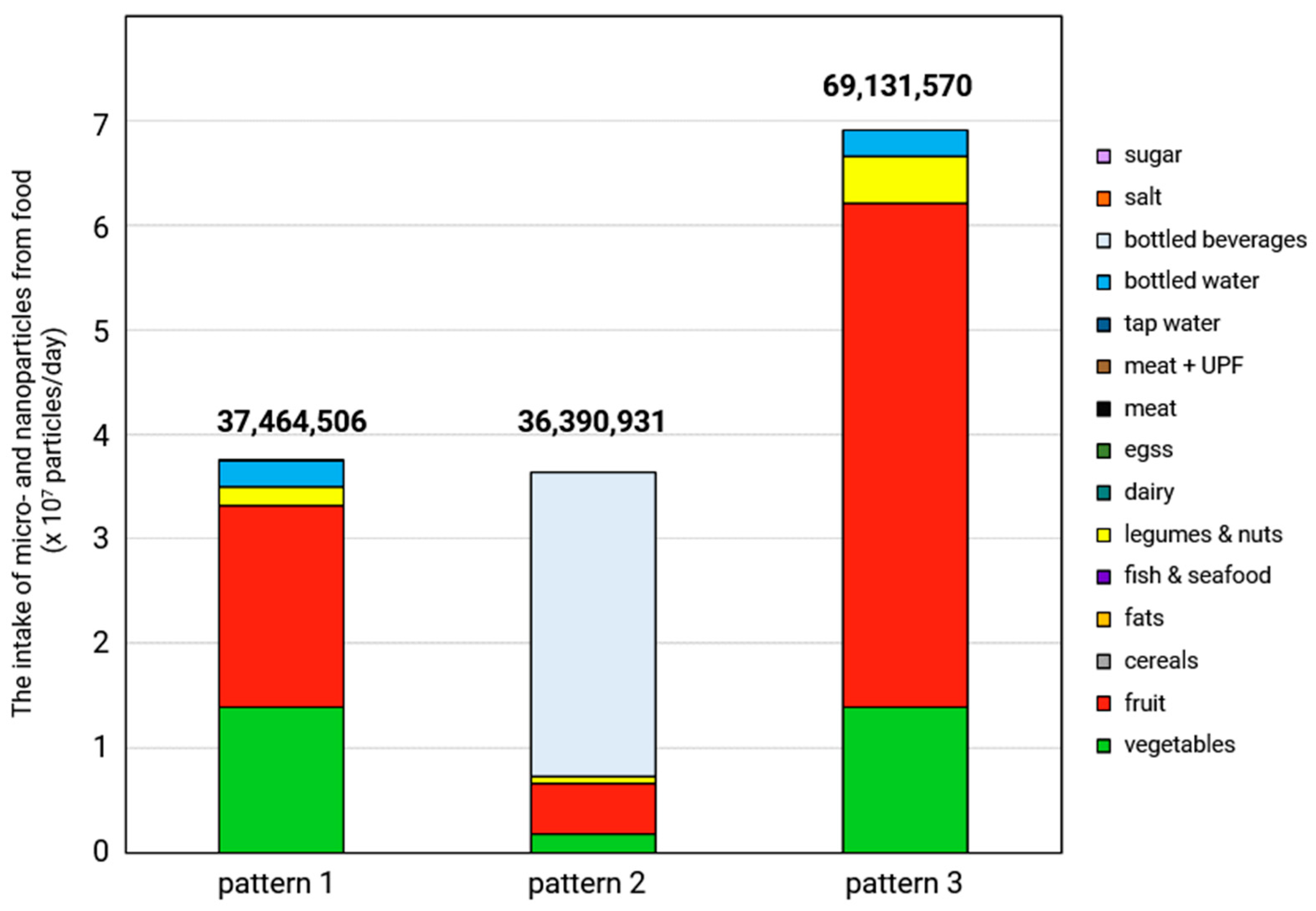

6.2. MNP Intake According to Three Different Dietary Patterns in Europe

| No | Food Group | Daily Amount | Estimated Energy (kcal) | Energy Percentage (%) | Justification/Comments |

|---|---|---|---|---|---|

| 1 | Vegetables | 400 g | 100 | 5.0 | Minimum 4 servings of raw and cooked vegetables per day, which have high volume, but low calories. |

| 2 | Fruit | 200 g | 90 | 4.5 | 2–3 servings (½ cup per portion) per day of fresh, preferably seasonal, colourful fruits, mainly berries. |

| 3 | Cereals and grain products | 250 g | 825 | 41.2 | Main source of energy included whole-grain bread, rice, and pasta. |

| 4 | Fats | 35 g | 309 | 15.5 | The fats consumed are olive oil and other vegetable oils that are rich in monounsaturated fatty acids. |

| 5 | Fish and seafood | 35 g | 100 | 5.0 | It is a source of high-quality protein: 2–3 servings (200–300 g) per week are recommended. |

| 6 | Legumes and nuts | 30 g + 20 g | 90 + 100 | 9.5 | A source of protein and fibre, as well as healthy fats from nuts, is recommended at 2–3 servings per day. |

| 7 | Dairy | 300 g | 225 | 11.2 | It is a source of calcium and protein: 2–3 servings per day, mainly milk, yoghurt, curd, and ripened cheese, but for ripened cheeses, only one slice per day is recommended. |

| 8 | Eggs | 55 g | 75 | 3.8 | Few eggs per week are recommended, including those in pasta or bread. |

| 9a | Meat | 43 g | 86 | 4.3 | Limited consumption is recommended several times a week (no more than 500 g/week), with poultry and lean meat being preferable to red meat and processed meat. |

| 10a | Water (tap water) | 1000 dm3 | 0 | 0 | No energy, but a carrier of MNPs. |

| 10b | Water (bottled) | 1000 dm3 | 0 | 0 | No energy, but a carrier of MNPs. |

| 11 | Salt | 5 g | 0 | 0 | The recommended amount is less than 5 g of salt (2 g of Na) per day. |

| 12 | Sugar | 0 g | 0 | 0 | There is no added sugar in the diet; only carbohydrates that are present naturally in the raw materials. |

| No | Food Group | Daily Amount | Estimated Energy (kcal) | Energy Percentage (%) | Justification/Comments |

|---|---|---|---|---|---|

| 1 | Vegetables | 50 g | 12.5 | 0.6 | Very small quantities, often negligible, consumption significantly below recommendations. |

| 2 | Fruit | 50 g | 22.5 | 1.1 | Very small quantities, often negligible, provided mainly in the form of processed fruit (canned or dried). Fruit juices have been included in group 12. |

| 3 | Cereals and grain products | 80 g | 160 | 8.0 | Mainly in the form of refined grains, white (wheat) rolls/bread, white rice, pasta, and sweet breakfast cereals. |

| 4 | Fats | 70 g | 560 | 28.0 | The fats consumed are mainly butter, animal fats, frying fat, and palm oil, which are rich in saturated and trans fatty acids. Can provide up to 40% of energy. |

| 5 | Fish and seafood | 6,4 | 18 | 0.9 | Very small quantities, often negligible in daily diet. Often in the form of canned fish. |

| 6 | Legumes and nuts | 10 g + 10 g | 30 + 50 | 4.0 | Mainly in the form of processed foods (canned) and sweet/salted snacks. |

| 7 | Dairy | 40 g | 140 | 7.0 | Mainly high-fat melt-type cheese, cream, ready-made sweetened yoghurt, or milk powder. It is a source of calcium, protein, and fat. |

| 8 | Eggs | 25 g | 35 | 1.8 | Average consumption of ½ egg per day, usually eaten in processed foods or breakfast. |

| 9b | Meat and UPF | 260 g | 650 | 32.5 | High consumption of red meat and processed meats (e.g., sausages and bacon), as well as fast food, takeaways, and ready meals. This is a significant source of fat and salt. Meat and UPFs can provide up to 60% of energy. |

| 10a | Water (tap water) | 1000 dm3 | 0 | 0 | No energy, but a carrier of MNPs. |

| 10c | Bottled beverages | 1000 dm3 | 0 | 0 | Includes fruit juices, carbonated and energy drinks, takeaway coffee and tea, sugar-free and sweetened (sugar was reported in group 12). |

| 11 | Salt | 10 g | 0 | 0 | High consumption as a result of processed food, salted snacks, and meat consumption. |

| 12 | Sugar | 80.5 g | 322 | 16.1 | Sugar added to sweets, energy snacks, chocolate bars, ice cream, and additives. |

| No | Food Group | Daily Amount | Estimated Energy (kcal) | Energy Percentage (%) | Justification/Comments |

|---|---|---|---|---|---|

| 1 | Vegetables | 400 g | 100.0 | 5.0 | Low calorie, high volume; approx. 8 servings (½ cup each) of raw and cooked vegetables per day. |

| 2 | Fruit | 500 g | 225 | 11.2 | Approx. 4 servings per day such as 1 cup of fresh and seasonal, colourful fruits, mainly berries; ¾ cup of fruit juice; or ¼ cup of dried fruits. |

| 3 | Cereals and grain products | 180 g | 594 | 29.7 | Main source of energy. Mainly in the form of whole-grain bread, whole-grain pasta, groats, brown rice, and dry cereal. Six servings per day (approx. 30 g each) are recommended. |

| 4 | Fats | 44 g | 396 | 19.8 | Main source of fat; 2 servings per day of vegetable oils rich in monounsaturated fatty acids (14 g per serving) or avocado (50 g) or olives (100 g). |

| 5 | Fish and seafood | - | - | - | - |

| 6 | Legumes and nuts | 100 g + 30 g | 300 + 150 | 22.5 | Main source of protein and fibre, and healthy fats from nuts. |

| 7 | Dairy | 300 g | 200.0 | 10.0 | Source of calcium and protein; 2 servings per day, mainly milk, yoghurt, white and curd cheese, and rennet-free ripened cheeses. |

| 8 | Eggs | 25 g | 35 | 1.8 | Provide a small amount of animal protein (½ an egg per day). |

| 9 | Meat | - | - | - | - |

| 10a | Water (tap water) | 1000 dm3 | 0 | 0 | No energy, but a carrier of MNPs. |

| 10b | Water (bottled) | 1000 dm3 | 0 | 0 | No energy, but a carrier of MNPs. |

| 11 | Salt | 5 g | 0 | 0 | The recommended amount is less than 5 g of salt (2 g of Na) per day. |

| 12 | Sugar | 0 g | 0 | 0 | There is no added sugar in the diet; only carbohydrates that are present naturally in the raw materials. |

7. Impact of MNPs on Human Health

8. Recommendations for Food Producers and Consumers

- (1)

- In agriculture and horticulture, especially with regard to soils where food crops are grown, we should strive to move away from using plastic film for mulching and sewage sludge for fertilisation. We should also avoid covering fertilisers with plastic.

- (2)

- Vegetables and fruit should be thoroughly rinsed with tap water before consumption.

- (3)

- Whenever possible, one should avoid drinking bottled water and beverages (both in glass and plastic containers), replacing them with tap water, as well as coffee and tea brewed directly in a glass or ceramic cup. Using tea bags or coffee capsules and drinking from plastic takeaway cups should be limited to exceptional situations, such as travelling.

- (4)

- For cooking, baking, and frying, cookware that is suitable for high temperatures and has an undamaged non-stick coating should be used.

- (5)

- Wherever possible, plastic kitchen accessories such as cutting boards, spatulas, beaters, spoons, funnels, strainers, whisks, various bowls, kettles, blenders, and mixers should be replaced with glass, cast iron, metal, or wooden ones.

- (6)

- Ready meals and raw ingredients should only be heated or defrosted in containers designed for use at high temperatures, such as in a microwave oven.

- (7)

- When storing food at home, glass containers are preferable to plastic boxes and bags.

- (8)

- Where possible, it is better to prepare meals yourself than to use takeaways or so-called ‘box diets’, as these generate huge amounts of single-use plastic packaging.

- (9)

- Food producers should stop wrapping individual fruits and vegetables in plastic film or foil.

- (10)

- Retail chains offering fresh goods such as fruit, vegetables, and bread should reduce self-service in these departments to limit the use of individual packaging. Where this is not possible, they should replace plastic packaging with paper or fabric alternatives.

- (11)

- As soon as possible, countries and law-making institutions should introduce a simple system of paid collection of glass and plastic packaging (e.g., vending machines or collection points), with plastic packaging being collected based on the weight of the returned items, without the need to scan each individual item. This will encourage consumers to return plastic bottles to collection points instead of throwing them away, which will increase the recovery of this packaging from the market, facilitate its transport for recycling, and reduce environmental pollution.

- (12)

- Every manufacturer, particularly those of food products, should strive to abandon plastic packaging in favour of paper or glass. If these materials do not provide adequate protection for the product, they should replace non-degradable plastic packaging with biodegradable packaging (e.g., made of polyhydroxyalkanoates or polylactic acid) as soon as possible.

- (13)

- In everyday life, people should focus on buying good-quality clothes that will last as long as possible and thus reduce the number of clothes they own. It is also recommended that dishwashers and washing machines be used efficiently. Increasing the load capacity of washing machines and dishwashers, eliminating pre-washing, and shortening the rinsing cycle are effective ways to reduce the number of MNPs released into the water.

- (14)

- We recommend air-drying clothes instead of using tumble dryers, as these release large amounts of microplastics into the air. This will also help to keep your clothes in good condition for longer and reduce your energy consumption.

- (15)

- Parents and grandparents are advised to limit the number of plastic toys their children have, replacing them with healthier wooden toys and activities that promote children’s development, such as physical activity and family games, and play.

9. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AB | acrylonitrile butadiene |

| ABS | acrylonitrile–butadiene–styrene, acrylonitrile butadiene styrene |

| CA | cellulose acetate |

| CMFs | cellulose microfibres |

| CP | cellophane |

| CPE | chlorinated polyethylene |

| EPS | expanded polystyrene = Styrofoam |

| EVA | ethylene-vinyl acetate |

| FNS | poly(fumaronitrile:styrene) |

| HDPE | high-density polyethylene |

| HDPET | high-density polyethylene terephthalate |

| LDPE | low-density polyethylene |

| MNP/MNPs | micro- and nanoplastic/micro- and nanoplastic particles |

| MP/MPs | microplastic/microplastic particles |

| NP/NPs | nanoplastic/nanoplastic particles |

| PA | polyamide |

| PA6 | polyamide 6, poly(caprolactame) = Nylon 6 |

| PA66 | polyamide 66 = Nylon 66 |

| PAC | polyacrylate |

| PAK | polyalkene |

| PAM | polyacrylamide |

| PAN | polyacrylonitrile |

| PB | polybutadiene |

| PBA | poly(butyl acrylate) |

| PC | polycarbonate |

| PCL | polycaprolactone |

| PE | polyethylene |

| PEA | poly(ethyl acrylate) |

| PEAs | poly(ester-amide)s |

| PFCAs | perfluoroalkyl carboxylic acids |

| PEO | polyethylene oxide |

| PES | generic polyester (textiles) |

| PESU | polyethersulfone |

| PET | polyethylene terephthalate |

| PEVA | poly(ethylene-co-vinyl acetate) |

| PLA | polylactic acid |

| PMMA | poly(methyl methacrylate), polymethyl methacrylate = acrylic glass |

| POM | polyoxymethylene |

| PP | polypropylene |

| PPS | polyphenylene sulfide |

| PS | polystyrene |

| PSU or PSF | polysulfone |

| PTFE | polytetrafluoroethylene = Teflon |

| PTT | polytrimethylene terephthalate |

| PU | polyurethane |

| PVA or PVOH | polyvinyl alcohol |

| PVC | poly(vinyl chloride) = polyvinyl chloride |

| PVS | polyvinyl stearate |

| rPET | recycled PET |

| RY | Rayon |

| SAN | styrene–acrylonitrile |

| SEBS | styrene-ethylene-butylene-styrene |

| TPE | thermoplastic elastomer |

| UPF | ultra-processed food |

| XPS | extruded polystyrene |

References

- Andrady, A.L.; Neal, M.A. Applications and Societal Benefits of Plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1977–1984. [Google Scholar] [CrossRef]

- Jadhav, E.B.; Sankhla, M.S.; Bhat, R.A.; Bhagat, D.S. Microplastics from Food Packaging: An Overview of Human Consumption, Health Threats, and Alternative Solutions. Environ. Nanotechnol. Monit. Manag. 2021, 16, 100608. [Google Scholar] [CrossRef]

- Dokl, M.; Copot, A.; Krajnc, D.; Fan, Y.V.; Vujanović, A.; Aviso, K.B.; Tan, R.R.; Kravanja, Z.; Čuček, L. Global Projections of Plastic Use, End-of-Life Fate and Potential Changes in Consumption, Reduction, Recycling and Replacement with Bioplastics to 2050. Sustain. Prod. Consum. 2024, 51, 498–518. [Google Scholar] [CrossRef]

- Thompson, R.C.; Olsen, Y.; Mitchell, R.P.; Davis, A.; Rowland, S.J.; John, A.W.G.; McGonigle, D.; Russell, A.E. Lost at Sea: Where Is All the Plastic? Science 2004, 304, 838. [Google Scholar] [CrossRef] [PubMed]

- Zolotova, N.; Kosyreva, A.; Dzhalilova, D.; Fokichev, N.; Makarova, O. Harmful Effects of the Microplastic Pollution on Animal Health: A Literature Review. PeerJ 2022, 10, e13503. [Google Scholar] [CrossRef]

- Yang, J.; Tu, C.; Li, L.; Li, R.; Feng, Y.; Luo, Y. The Fate of Micro(Nano)Plastics in Soil–Plant Systems: Current Progress and Future Directions. Curr. Opin. Environ. Sci. Health 2023, 32, 100438. [Google Scholar] [CrossRef]

- Roy, T.; Dey, T.K.; Jamal, M. Microplastic/Nanoplastic Toxicity in Plants: An Imminent Concern. Environ. Monit. Assess. 2023, 195, 27. [Google Scholar] [CrossRef]

- Qin, F.; Du, J.; Gao, J.; Liu, G.; Song, Y.; Yang, A.; Wang, H.; Ding, Y.; Wang, Q. Bibliometric Profile of Global Microplastics Research from 2004 to 2019. Int. J. Environ. Res. Public Health 2020, 17, 5639. [Google Scholar] [CrossRef]

- Tirkey, A.; Upadhyay, L.S.B. Microplastics: An Overview on Separation, Identification and Characterization of Microplastics. Mar. Pollut. Bull. 2021, 170, 112604. [Google Scholar] [CrossRef]

- Rani, A. Types and Sources of Microplastics; The Ubiquitous Environment Contaminant: A Review. J. Polym. Mater. 2022, 39, 17–35. [Google Scholar] [CrossRef]

- Vitali, C.; Peters, R.J.B.; Janssen, H.-G.; Nielen, M.W.F. Microplastics and Nanoplastics in Food, Water, and Beverages; Part I. Occurrence. TrAC Trends Anal. Chem. 2023, 159, 116670. [Google Scholar] [CrossRef]

- Mathew, J.T.; Inobeme, A.; Adetuyi, B.O.; Adetunji, C.O.; Popoola, O.A.; Olaitan, F.Y.; Akinbo, O.; Shahnawaz, M.; Oyewole, O.A.; Eniola, K.I.T.; et al. General Introduction of Microplastic: Uses, Types, and Generation. In Microplastic Pollution; Shahnawaz, M., Adetunji, C.O., Dar, M.A., Zhu, D., Eds.; Springer Nature: Singapore, 2024; pp. 3–21. ISBN 978-981-99-8356-8. [Google Scholar]

- Vdovchenko, A.; Resmini, M. Mapping Microplastics in Humans: Analysis of Polymer Types, and Shapes in Food and Drinking Water—A Systematic Review. Int. J. Mol. Sci. 2024, 25, 7074. [Google Scholar] [CrossRef] [PubMed]

- Palanisamy, S.; Saravana Kumar, B.K.; Vetrivel, A.; Michael, R.J.; Babu, N.; Nallamuthu, S.S.; Saravanan, K.; Venkatachalam, S.; R J, N.K.; Selvaraju, G.D.; et al. Nanoplastics in Heat-Sensitive Food Packaging: A Review of Migration, Detection, Health, and Environmental Impacts. Food Control 2025, 169, 111002. [Google Scholar] [CrossRef]

- Dzierżyński, E.; Gawlik, P.J.; Puźniak, D.; Flieger, W.; Jóźwik, K.; Teresiński, G.; Forma, A.; Wdowiak, P.; Baj, J.; Flieger, J. Microplastics in the Human Body: Exposure, Detection, and Risk of Carcinogenesis: A State-of-the-Art Review. Cancers 2024, 16, 3703. [Google Scholar] [CrossRef] [PubMed]

- Yuk, H.; Jo, H.H.; Nam, J.; Kim, Y.U.; Kim, S. Microplastic: A Particulate Matter(PM) Generated by Deterioration of Building Materials. J. Hazard. Mater. 2022, 437, 129290. [Google Scholar] [CrossRef]

- Oßmann, B.E.; Sarau, G.; Holtmannspötter, H.; Pischetsrieder, M.; Christiansen, S.H.; Dicke, W. Small-Sized Microplastics and Pigmented Particles in Bottled Mineral Water. Water Res. 2018, 141, 307–316. [Google Scholar] [CrossRef]

- Koelmans, A.A.; Mohamed Nor, N.H.; Hermsen, E.; Kooi, M.; Mintenig, S.M.; De France, J. Microplastics in Freshwaters and Drinking Water: Critical Review and Assessment of Data Quality. Water Res. 2019, 155, 410–422. [Google Scholar] [CrossRef]

- Moraczewska-Majkut, K.; Nocoń, W.K. Microplastic in Tap Water—Preliminary Tests. Desalination Water Treat. 2022, 275, 116–121. [Google Scholar] [CrossRef]

- Shaw, D.B.; Li, Q.; Nunes, J.K.; Deike, L. Ocean Emission of Microplastic. PNAS Nexus 2023, 2, pgad296. [Google Scholar] [CrossRef]

- Edo, C.; Fernández-Piñas, F.; Leganes, F.; Gómez, M.; Martínez, I.; Herrera, A.; Hernández-Sánchez, C.; González-Sálamo, J.; Borges, J.H.; López-Castellanos, J.; et al. A Nationwide Monitoring of Atmospheric Microplastic Deposition. Sci. Total Environ. 2023, 905, 166923. [Google Scholar] [CrossRef]

- Klein, M.; Bechtel, B.; Brecht, T.; Fischer, E.K. Spatial Distribution of Atmospheric Microplastics in Bulk-Deposition of Urban and Rural Environments—A One-Year Follow-up Study in Northern Germany. Sci. Total Environ. 2023, 901, 165923. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.; Xiong, X.; He, M.; Tsang, D.C.W.; Gupta, J.; Khan, E.; Harrad, S.; Hou, D.; Ok, Y.S.; Bolan, N.S. Microplastics as Pollutants in Agricultural Soils. Environ. Pollut. 2020, 265, 114980. [Google Scholar] [CrossRef] [PubMed]

- Ng, E.L.; Lin, S.Y.; Dungan, A.M.; Colwell, J.M.; Ede, S.; Huerta Lwanga, E.; Meng, K.; Geissen, V.; Blackall, L.L.; Chen, D. Microplastic Pollution Alters Forest Soil Microbiome. J. Hazard. Mater. 2021, 409, 124606. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Cai, C.; Gu, Y.; Shi, Y.; Gao, X. Microplastics in Plant-Soil Ecosystems: A Meta-Analysis. Environ. Pollut. 2022, 308, 119718. [Google Scholar] [CrossRef]

- Moeck, C.; Davies, G.; Krause, S.; Schneidewind, U. Microplastics and Nanoplastics in Agriculture—A Potential Source of Soil and Groundwater Contamination? Grundwasser 2023, 28, 23–35. [Google Scholar] [CrossRef]

- Nicole, W. Microplastics in Seafood: How Much Are People Eating? Environ. Health Perspect. 2021, 129, 034001. [Google Scholar] [CrossRef]

- Sun, H.; Lei, C.; Xu, J.; Li, R. Foliar Uptake and Leaf-to-Root Translocation of Nanoplastics with Different Coating Charge in Maize Plants. J. Hazard. Mater. 2021, 416, 125854. [Google Scholar] [CrossRef]

- Gopal, J.; Sivanesan, I.; Muthu, M.; Oh, J.-W. Overviewing the Ground Reality of Microplastic Effects on Seafoods, Including Fish, Shrimps and Crabs: Future Research Directions. Foods 2022, 11, 3976. [Google Scholar] [CrossRef]

- Cáceres-Farias, L.; Espinoza-Vera, M.M.; Orós, J.; Garcia-Bereguiain, M.A.; Alfaro-Núñez, A. Macro and Microplastic Intake in Seafood Variates by the Marine Organism’s Feeding Behaviour: Is It a Concern to Human Health? Heliyon 2023, 9, e16452. [Google Scholar] [CrossRef]

- Liang, Y.; Cao, X.; Mo, A.; Jiang, J.; Zhang, Y.; Gao, W.; He, D. Micro(Nano)Plastics in Plant-Derived Food: Source, Contamination Pathways and Human Exposure Risks. TrAC Trends Anal. Chem. 2023, 165, 117138. [Google Scholar] [CrossRef]

- Eze, C.G.; Nwankwo, C.E.; Dey, S.; Sundaramurthy, S.; Okeke, E.S. Food Chain Microplastics Contamination and Impact on Human Health: A Review. Environ. Chem. Lett. 2024, 22, 1889–1927. [Google Scholar] [CrossRef]

- Revel, M.; Châtel, A.; Mouneyrac, C. Micro(Nano)Plastics: A Threat to Human Health? Curr. Opin. Environ. Sci. Health 2018, 1, 17–23. [Google Scholar] [CrossRef]

- Lehner, R.; Weder, C.; Petri-Fink, A.; Rothen-Rutishauser, B. Emergence of Nanoplastic in the Environment and Possible Impact on Human Health. Environ. Sci. Technol. 2019, 53, 1748–1765. [Google Scholar] [CrossRef] [PubMed]

- Prata, J.C.; Da Costa, J.P.; Lopes, I.; Duarte, A.C.; Rocha-Santos, T. Environmental Exposure to Microplastics: An Overview on Possible Human Health Effects. Sci. Total Environ. 2020, 702, 134455. [Google Scholar] [CrossRef]

- Azeem, I.; Adeel, M.; Ahmad, M.A.; Shakoor, N.; Jiangcuo, G.D.; Azeem, K.; Ishfaq, M.; Shakoor, A.; Ayaz, M.; Xu, M.; et al. Uptake and Accumulation of Nano/Microplastics in Plants: A Critical Review. Nanomaterials 2021, 11, 2935. [Google Scholar] [CrossRef]

- Kim, D.; An, S.; Kim, L.; Byeon, Y.M.; Lee, J.; Choi, M.-J.; An, Y.-J. Translocation and Chronic Effects of Microplastics on Pea Plants (Pisum sativum) in Copper-Contaminated Soil. J. Hazard. Mater. 2022, 436, 129194. [Google Scholar] [CrossRef]

- Jiang, X.; Chen, H.; Liao, Y.; Ye, Z.; Li, M.; Klobučar, G. Ecotoxicity and Genotoxicity of Polystyrene Microplastics on Higher Plant Vicia faba. Environ. Pollut. 2019, 250, 831–838. [Google Scholar] [CrossRef]

- Dong, Y.; Gao, M.; Qiu, W.; Song, Z. Uptake of Microplastics by Carrots in Presence of As (III): Combined Toxic Effects. J. Hazard. Mater. 2021, 411, 125055. [Google Scholar] [CrossRef]

- Yu, Y.; Kumar, M.; Bolan, S.; Padhye, L.P.; Bolan, N.; Li, S.; Wang, L.; Hou, D.; Li, Y. Various Additive Release from Microplastics and Their Toxicity in Aquatic Environments. Environ. Pollut. 2024, 343, 123219. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, H.; Liu, Y.; Jin, L.; Peng, R. Factors Affecting the Adsorption of Heavy Metals by Microplastics and Their Toxic Effects on Fish. Toxics 2023, 11, 490. [Google Scholar] [CrossRef]

- Hou, B.; Wang, F.; Liu, T.; Wang, Z. Reproductive Toxicity of Polystyrene Microplastics: In Vivo Experimental Study on Testicular Toxicity in Mice. J. Hazard. Mater. 2021, 405, 124028. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Liang, Y.; Cheng, Y.; Peng, C.; Sun, Y.; Liu, K.; Li, Y.; Lou, Y.; Jiang, X.; Zhang, A.; et al. Microplastics Cause Reproductive Toxicity in Male Mice through Inducing Apoptosis of Spermatogenic Cells via P53 Signaling. Food Chem. Toxicol. 2023, 179, 113970. [Google Scholar] [CrossRef] [PubMed]

- Djouina, M.; Vignal, C.; Dehaut, A.; Caboche, S.; Hirt, N.; Waxin, C.; Himber, C.; Beury, D.; Hot, D.; Dubuquoy, L.; et al. Oral Exposure to Polyethylene Microplastics Alters Gut Morphology, Immune Response, and Microbiota Composition in Mice. Environ. Res. 2022, 212, 113230. [Google Scholar] [CrossRef] [PubMed]

- Tang, K.H.D. Genotoxicity of Microplastics on Living Organisms: Effects on Chromosomes, DNA and Gene Expression. Environments 2025, 12, 10. [Google Scholar] [CrossRef]

- Dehghanian, Z.; Asgari Lajayer, B.; Biglari, Z.; Nayeri, S.; Ahmadabadi, M.; Taghipour, L.; Senapathi, V.; Astatkie, T.; Price, G.W. Micro (Nano) Plastics Uptake, Toxicity and Detoxification in Plants: Challenges and Prospects. Ecotoxicol. Environ. Saf. 2023, 268, 115676. [Google Scholar] [CrossRef]

- Ge, J.; Li, H.; Liu, P.; Zhang, Z.; Ouyang, Z.; Guo, X. Review of the Toxic Effect of Microplastics on Terrestrial and Aquatic Plants. Sci. Total Environ. 2021, 791, 148333. [Google Scholar] [CrossRef]

- Preda, O.-T.; Vlasceanu, A.-M.; Andreescu, C.V.; Tsatsakis, A.; Mezhuev, Y.; Negrei, C.; Baconi, D.L. Health Implications of Widespread Micro- and Nanoplastic Exposure: Environmental Prevalence, Mechanisms, and Biological Impact on Humans. Toxics 2024, 12, 730. [Google Scholar] [CrossRef]

- Cox, K.D.; Covernton, G.A.; Davies, H.L.; Dower, J.F.; Juanes, F.; Dudas, S.E. Human Consumption of Microplastics. Environ. Sci. Technol. 2019, 53, 7068–7074. [Google Scholar] [CrossRef]

- Senathirajah, K.; Attwood, S.; Bhagwat, G.; Carbery, M.; Wilson, S.; Palanisami, T. Estimation of the Mass of Microplastics Ingested—A Pivotal First Step towards Human Health Risk Assessment. J. Hazard. Mater. 2021, 404, 124004. [Google Scholar] [CrossRef]

- Enyoh, C.E.; Shafea, L.; Verla, A.W.; Verla, E.N.; Qingyue, W.; Chowdhury, T.; Paredes, M. Microplastics Exposure Routes and Toxicity Studies to Ecosystems: An Overview. Environ. Anal. Health Toxicol. 2020, 35, e2020004. [Google Scholar] [CrossRef]

- Zhang, K.; Hamidian, A.H.; Tubić, A.; Zhang, Y.; Fang, J.K.H.; Wu, C.; Lam, P.K.S. Understanding Plastic Degradation and Microplastic Formation in the Environment: A Review. Environ. Pollut. 2021, 274, 116554. [Google Scholar] [CrossRef]

- González-Pleiter, M.; Edo, C.; Velázquez, D.; Casero-Chamorro, M.C.; Leganés, F.; Quesada, A.; Fernández-Piñas, F.; Rosal, R. First Detection of Microplastics in the Freshwater of an Antarctic Specially Protected Area. Mar. Pollut. Bull. 2020, 161, 111811. [Google Scholar] [CrossRef]

- Jiang, Y.; Yang, F.; Zhao, Y.; Wang, J. Greenland Sea Gyre Increases Microplastic Pollution in the Surface Waters of the Nordic Seas. Sci. Total Environ. 2020, 712, 136484. [Google Scholar] [CrossRef]

- Kelly, A.; Lannuzel, D.; Rodemann, T.; Meiners, K.M.; Auman, H.J. Microplastic Contamination in East Antarctic Sea Ice. Mar. Pollut. Bull. 2020, 154, 111130. [Google Scholar] [CrossRef]

- Wang, S.; Chen, H.; Zhou, X.; Tian, Y.; Lin, C.; Wang, W.; Zhou, K.; Zhang, Y.; Lin, H. Microplastic Abundance, Distribution and Composition in the Mid-West Pacific Ocean. Environ. Pollut. 2020, 264, 114125. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Wang, X.; Liu, K.; Zhu, L.; Wei, N.; Zong, C.; Li, D. Pelagic Microplastics in Surface Water of the Eastern Indian Ocean during Monsoon Transition Period: Abundance, Distribution, and Characteristics. Sci. Total Environ. 2021, 755, 142629. [Google Scholar] [CrossRef] [PubMed]

- Pakhomova, S.; Berezina, A.; Lusher, A.L.; Zhdanov, I.; Silvestrova, K.; Zavialov, P.; Van Bavel, B.; Yakushev, E. Microplastic Variability in Subsurface Water from the Arctic to Antarctica. Environ. Pollut. 2022, 298, 118808. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Chen, M.; Chen, S.; Dasgupta, S.; Xu, H.; Ta, K.; Du, M.; Li, J.; Guo, Z.; Bai, S. Microplastics Contaminate the Deepest Part of the World’s Ocean. Geochem. Perspect. Lett. 2018, 9, 1–5. [Google Scholar] [CrossRef]

- Carbery, M.; Herb, F.; Reynes, J.; Pham, C.K.; Fong, W.-K.; Lehner, R. How Small Is the Big Problem? Small Microplastics <300 Μm Abundant in Marine Surface Waters of the Great Barrier Reef Marine Park. Mar. Pollut. Bull. 2022, 184, 114179. [Google Scholar] [CrossRef]

- Samandra, S.; Johnston, J.M.; Jaeger, J.E.; Symons, B.; Xie, S.; Currell, M.; Ellis, A.V.; Clarke, B.O. Microplastic Contamination of an Unconfined Groundwater Aquifer in Victoria, Australia. Sci. Total Environ. 2022, 802, 149727. [Google Scholar] [CrossRef]

- Aytan, U.; Valente, A.; Senturk, Y.; Usta, R.; Esensoy Sahin, F.B.; Mazlum, R.E.; Agirbas, E. First Evaluation of Neustonic Microplastics in Black Sea Waters. Mar. Environ. Res. 2016, 119, 22–30. [Google Scholar] [CrossRef]

- Sarkar, D.J.; Das Sarkar, S.; Das, B.K.; Manna, R.K.; Behera, B.K.; Samanta, S. Spatial Distribution of Meso and Microplastics in the Sediments of River Ganga at Eastern India. Sci. Total Environ. 2019, 694, 133712. [Google Scholar] [CrossRef]

- Lisina, A.A.; Platonov, M.M.; Lomakov, O.I.; Sazonov, A.A.; Shishova, T.V.; Berkovich, A.K.; Frolova, N.L. Microplastic Abundance In Volga River: Results Of A Pilot Study In Summer 2020. Geogr. Environ. Sustain. 2021, 14, 82–93. [Google Scholar] [CrossRef]

- Sekudewicz, I.; Dąbrowska, A.M.; Syczewski, M.D. Microplastic Pollution in Surface Water and Sediments in the Urban Section of the Vistula River (Poland). Sci. Total Environ. 2021, 762, 143111. [Google Scholar] [CrossRef]

- Khedre, A.M.; Ramadan, S.A.; Ashry, A.; Alaraby, M. Abundance and Risk Assessment of Microplastics in Water, Sediment, and Aquatic Insects of the Nile River. Chemosphere 2024, 353, 141557. [Google Scholar] [CrossRef] [PubMed]

- Saad, D.; Alamin, H. The First Evidence of Microplastic Presence in the River Nile in Khartoum, Sudan: Using Nile tilapia Fish as a Bio-Indicator. Heliyon 2024, 10, e23393. [Google Scholar] [CrossRef] [PubMed]

- Stanković, J.; Milošević, D.; Paunović, M.; Jovanović, B.; Popović, N.; Tomović, J.; Atanacković, A.; Radulović, K.; Lončarević, D.; Raković, M. Microplastics in the Danube River and Its Main Tributaries—Ingestion by Freshwater Macroinvertebrates. Water 2024, 16, 962. [Google Scholar] [CrossRef]

- Stratmann, C.N.; Dris, R.; Gasperi, J.; Buschman, F.A.; Markus, A.A.; Guerin, S.; Vethaak, A.D.; Tassin, B. Monitoring Microplastics in the Seine River in the Greater Paris Area. Front. Earth Sci. 2024, 12, 1386547. [Google Scholar] [CrossRef]

- Piskuła, P.; Astel, A.M. Microplastics Occurrence in Two Mountainous Rivers in the Lowland Area—A Case Study of the Central Pomeranian Region, Poland. Microplastics 2022, 1, 167–185. [Google Scholar] [CrossRef]

- Prikler, B.; Svigruha, R.; Háhn, J.; Harkai, P.; Fodor, I.; Kaszab, E.; Kriszt, B.; Tóth, G.; Szabó, I.; Csenki, Z.; et al. Spatial Variations in Microplastics in the Largest Shallow Lake of Central Europe and Its Protecting Wetland Area. Water 2024, 16, 1014. [Google Scholar] [CrossRef]

- Bowszys, M. Microplastics in the Waters of European Lakes and Their Potential Effect on Food Webs: A Review. Pol. J. Nat. Sci. 2022, 37, 345–364. [Google Scholar]

- Emberson-Marl, H.; Coppock, R.L.; Cole, M.; Godley, B.J.; Mimpriss, N.; Nelms, S.E.; Lindeque, P.K. Microplastics in the Arctic: A Transect through the Barents Sea. Front. Mar. Sci. 2023, 10, 1241829. [Google Scholar] [CrossRef]

- Materić, D.; Kjær, H.A.; Vallelonga, P.; Tison, J.-L.; Röckmann, T.; Holzinger, R. Nanoplastics Measurements in Northern and Southern Polar Ice. Environ. Res. 2022, 208, 112741. [Google Scholar] [CrossRef] [PubMed]

- Jones-Williams, K.; Rowlands, E.; Primpke, S.; Galloway, T.; Cole, M.; Waluda, C.; Manno, C. Microplastics in Antarctica—A Plastic Legacy in the Antarctic Snow? Sci. Total Environ. 2025, 966, 178543. [Google Scholar] [CrossRef]

- Napper, I.E.; Davies, B.F.R.; Clifford, H.; Elvin, S.; Koldewey, H.J.; Mayewski, P.A.; Miner, K.R.; Potocki, M.; Elmore, A.C.; Gajurel, A.P.; et al. Reaching New Heights in Plastic Pollution—Preliminary Findings of Microplastics on Mount Everest. One Earth 2020, 3, 621–630. [Google Scholar] [CrossRef]

- Ambrosini, R.; Azzoni, R.S.; Pittino, F.; Diolaiuti, G.; Franzetti, A.; Parolini, M. First Evidence of Microplastic Contamination in the Supraglacial Debris of an Alpine Glacier. Environ. Pollut. 2019, 253, 297–301. [Google Scholar] [CrossRef]

- Abbasi, S. Microplastics Washout from the Atmosphere during a Monsoon Rain Event. J. Hazard. Mater. Adv. 2021, 4, 100035. [Google Scholar] [CrossRef]

- Hinojosa, I.A.; Thiel, M. Floating Marine Debris in Fjords, Gulfs and Channels of Southern Chile. Mar. Pollut. Bull. 2009, 58, 341–350. [Google Scholar] [CrossRef]

- Matias, R.S.; Gomes, S.; Barboza, L.G.A.; Almeida, C.M.R.; Marques, A.; Guilhermino, L.; Valente, L.M.P. Occurrence of Microplastics and Metals in European Seabass Produced in Different Aquaculture Systems: Implications for Human Exposure, Risk, and Food Safety. Sci. Total Environ. 2024, 929, 172535. [Google Scholar] [CrossRef]

- Donohue, M.J.; Timmers, M.A.; Kistner, C.A. Marine Debris of the Northwestern Hawaiian Islands: Ghost Net Identification. 2005. Report Number: UNIHI-SEAGRANT-AR-05-01, University of Hawaii, Sea Grant College Program, U.S. National Oceanic and Atmospheric Administration. Available online: https://www.researchgate.net/publication/280238108_Marine_Debris_of_the_Northwestern_Hawaiian_Islands_Ghost_Net_Identification?channel=doi&linkId=55aead5d08ae98e661a6ef54&showFulltext=true#fullTextFileContent (accessed on 5 September 2025).

- Kosuth, M.; Mason, S.A.; Wattenberg, E.V. Anthropogenic Contamination of Tap Water, Beer, and Sea Salt. PLoS ONE 2018, 13, e0194970. [Google Scholar] [CrossRef]

- De Falco, F.; Di Pace, E.; Cocca, M.; Avella, M. The Contribution of Washing Processes of Synthetic Clothes to Microplastic Pollution. Sci. Rep. 2019, 9, 6633. [Google Scholar] [CrossRef]

- Belzagui, F.; Gutiérrez-Bouzán, C.; Álvarez-Sánchez, A.; Vilaseca, M. Textile Microfibers Reaching Aquatic Environments: A New Estimation Approach. Environ. Pollut. 2020, 265, 114889. [Google Scholar] [CrossRef]

- Akyildiz, S.H.; Fiore, S.; Bruno, M.; Sezgin, H.; Yalcin-Enis, I.; Yalcin, B.; Bellopede, R. Release of Microplastic Fibers from Synthetic Textiles during Household Washing. Environ. Pollut. 2024, 357, 124455. [Google Scholar] [CrossRef] [PubMed]

- Klinkhammer, K.; Kolbe, S.; Brandt, S.; Meyer, J.; Ratovo, K.; Bendt, E.; Rabe, M. Release of Fibrous Microplastics from Functional Polyester Garments through Household Washing. Front. Environ. Sci. 2024, 12, 1330922. [Google Scholar] [CrossRef]

- Bashir, S.M.; Kimiko, S.; Mak, C.-W.; Fang, J.K.-H.; Gonçalves, D. Personal Care and Cosmetic Products as a Potential Source of Environmental Contamination by Microplastics in a Densely Populated Asian City. Front. Mar. Sci. 2021, 8, 683482. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Oanh, L.T.K.; Chi, N.D.T. The Presence of Microplastics in Personal Care and Cosmetic Products (PCCPs) Commonly Used in Ho Chi Minh City. IOP Conf. Ser. Earth Environ. Sci. 2024, 1349, 012012. [Google Scholar] [CrossRef]

- Rehm, R.; Zeyer, T.; Schmidt, A.; Fiener, P. Soil Erosion as Transport Pathway of Microplastic from Agriculture Soils to Aquatic Ecosystems. Sci. Total Environ. 2021, 795, 148774. [Google Scholar] [CrossRef]

- Dris, R.; Gasperi, J.; Mirande, C.; Mandin, C.; Guerrouache, M.; Langlois, V.; Tassin, B. A First Overview of Textile Fibers, Including Microplastics, in Indoor and Outdoor Environments. Environ. Pollut. 2017, 221, 453–458. [Google Scholar] [CrossRef]

- O’Brien, S.; Rauert, C.; Ribeiro, F.; Okoffo, E.D.; Burrows, S.D.; O’Brien, J.W.; Wang, X.; Wright, S.L.; Thomas, K.V. There’s Something in the Air: A Review of Sources, Prevalence and Behaviour of Microplastics in the Atmosphere. Sci. Total Environ. 2023, 874, 162193. [Google Scholar] [CrossRef]

- Liao, Z.; Ji, X.; Ma, Y.; Lv, B.; Huang, W.; Zhu, X.; Fang, M.; Wang, Q.; Wang, X.; Dahlgren, R.; et al. Airborne Microplastics in Indoor and Outdoor Environments of a Coastal City in Eastern China. J. Hazard. Mater. 2021, 417, 126007. [Google Scholar] [CrossRef]

- Abbasi, S.; Jaafarzadeh, N.; Zahedi, A.; Ravanbakhsh, M.; Abbaszadeh, S.; Turner, A. Microplastics in the Atmosphere of Ahvaz City, Iran. J. Environ. Sci. 2023, 126, 95–102. [Google Scholar] [CrossRef]

- Ding, J.; Sun, C.; He, C.; Zheng, L.; Dai, D.; Li, F. Atmospheric Microplastics in the Northwestern Pacific Ocean: Distribution, Source, and Deposition. Sci. Total Environ. 2022, 829, 154337. [Google Scholar] [CrossRef]

- Caracci, E.; Vega-Herrera, A.; Dachs, J.; Berrojalbiz, N.; Buonanno, G.; Abad, E.; Llorca, M.; Moreno, T.; Farré, M. Micro(Nano)Plastics in the Atmosphere of the Atlantic Ocean. J. Hazard. Mater. 2023, 450, 131036. [Google Scholar] [CrossRef]

- Cabrera, M.; Moulatlet, G.M.; Valencia, B.G.; Maisincho, L.; Rodríguez-Barroso, R.; Albendín, G.; Sakali, A.; Lucas-Solis, O.; Conicelli, B.; Capparelli, M.V. Microplastics in a Tropical Andean Glacier: A Transportation Process across the Amazon Basin? Sci. Total Environ. 2022, 805, 150334. [Google Scholar] [CrossRef]

- Sommer, F.; Dietze, V.; Baum, A.; Sauer, J.; Gilge, S.; Maschowski, C.; Gieré, R. Tire Abrasion as a Major Source of Microplastics in the Environment. Aerosol Air Qual. Res. 2018, 18, 2014–2028. [Google Scholar] [CrossRef]

- Yang, T.; Gao, M.; Nowack, B. Formation of Microplastic Fibers and Fibrils during Abrasion of a Representative Set of 12 Polyester Textiles. Sci. Total Environ. 2023, 862, 160758. [Google Scholar] [CrossRef] [PubMed]

- Suh, W.D.; Jo, H.H.; Kim, Y.U.; Kim, S. Degradation of Floor Finishing Materials Owing to Continuous Gait: A Comprehensive Study on the Generation and Impact of Microplastics. J. Hazard. Mater. 2025, 484, 136726. [Google Scholar] [CrossRef] [PubMed]

- Bullard, J.E.; Ockelford, A.; O’Brien, P.; McKenna Neuman, C. Preferential Transport of Microplastics by Wind. Atmos. Environ. 2021, 245, 118038. [Google Scholar] [CrossRef]

- Ferrero, L.; Scibetta, L.; Markuszewski, P.; Mazurkiewicz, M.; Drozdowska, V.; Makuch, P.; Jutrzenka-Trzebiatowska, P.; Zaleska-Medynska, A.; Andò, S.; Saliu, F.; et al. Airborne and Marine Microplastics from an Oceanographic Survey at the Baltic Sea: An Emerging Role of Air-Sea Interaction? Sci. Total Environ. 2022, 824, 153709. [Google Scholar] [CrossRef]

- Sa’adu, I.; Farsang, A. Plastic Contamination in Agricultural Soils: A Review. Environ. Sci. Eur. 2023, 35, 13. [Google Scholar] [CrossRef]

- Cusworth, S.J.; Davies, W.J.; McAinsh, M.R.; Gregory, A.S.; Storkey, J.; Stevens, C.J. Agricultural Fertilisers Contribute Substantially to Microplastic Concentrations in UK Soils. Commun. Earth Environ. 2024, 5, 7. [Google Scholar] [CrossRef]

- Xu, J.; Yang, A.; Yan, Y.; Xu, Y.; Tang, M.; Li, P.; Zhao, L.; Zhang, X.; Ren, Z. Quantification and Identification of Microplastics in Organic Fertilizers: The Implication for the Manufacture and Safe Application. Water Air Soil Pollut. 2024, 235, 169. [Google Scholar] [CrossRef]

- Thomas, D.; Bloem, E. Visible Intruders: Tracing (Micro-) Plastic in Organic Fertilizers. Sci. Total Environ. 2024, 947, 174311. [Google Scholar] [CrossRef]

- Akhbarizadeh, R.; Moore, F.; Keshavarzi, B.; Moeinpour, A. Microplastics and Potentially Toxic Elements in Coastal Sediments of Iran’s Main Oil Terminal (Khark Island). Environ. Pollut. 2017, 220, 720–731. [Google Scholar] [CrossRef] [PubMed]

- Vaughan, R.; Turner, S.D.; Rose, N.L. Microplastics in the Sediments of a UK Urban Lake. Environ. Pollut. 2017, 229, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Abidli, S.; Antunes, J.C.; Ferreira, J.L.; Lahbib, Y.; Sobral, P.; Trigui El Menif, N. Microplastics in Sediments from the Littoral Zone of the North Tunisian Coast (Mediterranean Sea). Estuar. Coast. Shelf Sci. 2018, 205, 1–9. [Google Scholar] [CrossRef]

- Bosker, T.; Guaita, L.; Behrens, P. Microplastic Pollution on Caribbean Beaches in the Lesser Antilles. Mar. Pollut. Bull. 2018, 133, 442–447. [Google Scholar] [CrossRef]

- Hengstmann, E.; Tamminga, M.; Vom Bruch, C.; Fischer, E.K. Microplastic in Beach Sediments of the Isle of Rügen (Baltic Sea)—Implementing a Novel Glass Elutriation Column. Mar. Pollut. Bull. 2018, 126, 263–274. [Google Scholar] [CrossRef]

- Bridson, J.H.; Patel, M.; Lewis, A.; Gaw, S.; Parker, K. Microplastic Contamination in Auckland (New Zealand) Beach Sediments. Mar. Pollut. Bull. 2020, 151, 110867. [Google Scholar] [CrossRef]

- Wang, F.; Lai, Z.; Peng, G.; Luo, L.; Liu, K.; Huang, X.; Xu, Y.; Shen, Q.; Li, D. Microplastic Abundance and Distribution in a Central Asian Desert. Sci. Total Environ. 2021, 800, 149529. [Google Scholar] [CrossRef]

- Li, H.; Liu, H.; Lin, Q.; Chen, T.; Peng, R. The Hidden Threat of Microplastics in Desert Environments: Environmental Impact, Challenges, and Response Measures. Sustainability 2025, 17, 1897. [Google Scholar] [CrossRef]

- Boucher, J.; Friot, D. Primary Microplastics in the Oceans: A Global Evaluation of Sources; IUCN International Union for Conservation of Nature: Gland, Switzerland, 2017; ISBN 978-2-8317-1827-9. [Google Scholar]

- Yee, M.S.-L.; Hii, L.-W.; Looi, C.K.; Lim, W.-M.; Wong, S.-F.; Kok, Y.-Y.; Tan, B.-K.; Wong, C.-Y.; Leong, C.-O. Impact of Microplastics and Nanoplastics on Human Health. Nanomaterials 2021, 11, 496. [Google Scholar] [CrossRef]

- Goßmann, I.; Halbach, M.; Scholz-Böttcher, B.M. Car and Truck Tire Wear Particles in Complex Environmental Samples—A Quantitative Comparison with “Traditional” Microplastic Polymer Mass Loads. Sci. Total Environ. 2021, 773, 145667. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Ho, S.S.H.; Niu, X.; Xu, H.; Qu, L.; Shen, Z.; Cao, J.; Chuang, H.-C.; Ho, K.-F. Explorations of Tire and Road Wear Microplastics in Road Dust PM2.5 at Eight Megacities in China. Sci. Total Environ. 2022, 823, 153717. [Google Scholar] [CrossRef] [PubMed]

- Dris, R.; Gasperi, J.; Saad, M.; Mirande, C.; Tassin, B. Synthetic Fibers in Atmospheric Fallout: A Source of Microplastics in the Environment? Mar. Pollut. Bull. 2016, 104, 290–293. [Google Scholar] [CrossRef] [PubMed]

- Duda, A. Created in BioRender. 2025. Available online: https://BioRender.Com/v9ihwlv (accessed on 5 September 2025).

- Enfrin, M.; Lee, J.; Gibert, Y.; Basheer, F.; Kong, L.; Dumée, L.F. Release of Hazardous Nanoplastic Contaminants Due to Microplastics Fragmentation under Shear Stress Forces. J. Hazard. Mater. 2020, 384, 121393. [Google Scholar] [CrossRef]

- Jander, J.; Hummel, D.; Stürmer, S.; Monteleone, A.; Neumaier, T.; Broghammer, F.; Lewin-Kretzschmar, U.; Brock, T.; Knoll, M.; Fath, A.S. Release of Microplastics from Reusable Kitchen Plasticware and Generation of Thermal Potential Toxic Degradation Products in the Oven. Appl. Sci. 2022, 12, 2535. [Google Scholar] [CrossRef]

- Yu, Y.; Craig, N.; Su, L. A Hidden Pathway for Human Exposure to Micro- and Nanoplastics—The Mechanical Fragmentation of Plastic Products during Daily Use. Toxics 2023, 11, 774. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, Y.; Li, H.; Liu, H.; Bi, L.; Chen, Q.; Peng, R. A Systematic Review of Microplastics Emissions in Kitchens: Understanding the Links with Diseases in Daily Life. Environ. Int. 2024, 188, 108740. [Google Scholar] [CrossRef]

- Luo, Y.; Naidu, R.; Fang, C. Toy Building Bricks as a Potential Source of Microplastics and Nanoplastics. J. Hazard. Mater. 2024, 471, 134424. [Google Scholar] [CrossRef]

- Baensch-Baltruschat, B.; Kocher, B.; Stock, F.; Reifferscheid, G. Tyre and Road Wear Particles (TRWP)—A Review of Generation, Properties, Emissions, Human Health Risk, Ecotoxicity, and Fate in the Environment. Sci. Total Environ. 2020, 733, 137823. [Google Scholar] [CrossRef] [PubMed]

- Andrady, A.L. Microplastics in the Marine Environment. Mar. Pollut. Bull. 2011, 62, 1596–1605. [Google Scholar] [CrossRef] [PubMed]

- O’Brien, S.; Okoffo, E.D.; O’Brien, J.W.; Ribeiro, F.; Wang, X.; Wright, S.L.; Samanipour, S.; Rauert, C.; Toapanta, T.Y.A.; Albarracin, R.; et al. Airborne Emissions of Microplastic Fibres from Domestic Laundry Dryers. Sci. Total Environ. 2020, 747, 141175. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Kwon, M.; Park, M.-J.; Kim, J. Analysis of Microplastics Released from Plain Woven Classified by Yarn Types during Washing and Drying. Polymers 2021, 13, 2988. [Google Scholar] [CrossRef]

- De Haan, W.P.; Quintana, R.; Vilas, C.; Cózar, A.; Canals, M.; Uviedo, O.; Sanchez-Vidal, A. The Dark Side of Artificial Greening: Plastic Turfs as Widespread Pollutants of Aquatic Environments. Environ. Pollut. 2023, 334, 122094. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, Y.; Ma, J.; An, Y.; Liu, Q.; Yang, S.; Qu, Y.; Chen, H.; Zhao, W.; Tian, Y. Microplastics Pollution in the Soil Mulched by Dust-Proof Nets: A Case Study in Beijing, China. Environ. Pollut. 2021, 275, 116600. [Google Scholar] [CrossRef]

- Liu, B.; Li, W.; Pan, X.; Zhang, D. The Persistently Breaking Trade-Offs of Three-Decade Plastic Film Mulching: Microplastic Pollution, Soil Degradation and Reduced Cotton Yield. J. Hazard. Mater. 2022, 439, 129586. [Google Scholar] [CrossRef]

- Katsumi, N.; Kusube, T.; Nagao, S.; Okochi, H. Accumulation of Microcapsules Derived from Coated Fertilizer in Paddy Fields. Chemosphere 2021, 267, 129185. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Jiang, L.; Chen, X.; Zhao, Y.; Shi, W.; Xing, Z. From Organic Fertilizer to the Soils: What Happens to the Microplastics? A Critical Review. Sci. Total Environ. 2024, 919, 170217. [Google Scholar] [CrossRef]

- Burghardt, T.E.; Pashkevich, A.; Babić, D.; Mosböck, H.; Babić, D.; Żakowska, L. Microplastics and Road Markings: The Role of Glass Beads and Loss Estimation. Transp. Res. Part Transp. Environ. 2022, 102, 103123. [Google Scholar] [CrossRef]

- Klavins, M.; Klavins, L.; Stabnikova, O.; Stabnikov, V.; Marynin, A.; Ansone-Bertina, L.; Mezulis, M.; Vaseashta, A. Interaction between Microplastics and Pharmaceuticals Depending on the Composition of Aquatic Environment. Microplastics 2022, 1, 520–535. [Google Scholar] [CrossRef]

- Nagato, E.G.; Noothalapati, H.; Kogumasaka, C.; Kakii, S.; Hossain, S.; Iwasaki, K.; Takai, Y.; Shimasaki, Y.; Honda, M.; Hayakawa, K.; et al. Differences in Microplastic Degradation in the Atmosphere and Coastal Water Environment from Two Island Nations: Japan and New Zealand. Environ. Pollut. 2023, 333, 122011. [Google Scholar] [CrossRef]

- Ali, S.S.; Elsamahy, T.; Koutra, E.; Kornaros, M.; El-Sheekh, M.; Abdelkarim, E.A.; Zhu, D.; Sun, J. Degradation of Conventional Plastic Wastes in the Environment: A Review on Current Status of Knowledge and Future Perspectives of Disposal. Sci. Total Environ. 2021, 771, 144719. [Google Scholar] [CrossRef]

- Zhang, X.; Yin, Z.; Xiang, S.; Yan, H.; Tian, H. Degradation of Polymer Materials in the Environment and Its Impact on the Health of Experimental Animals: A Review. Polymers 2024, 16, 2807. [Google Scholar] [CrossRef]

- Delre, A.; Goudriaan, M.; Morales, V.H.; Vaksmaa, A.; Ndhlovu, R.T.; Baas, M.; Keijzer, E.; de Groot, T.; Zeghal, E.; Egger, M.; et al. Plastic Photodegradation under Simulated Marine Conditions. Mar. Pollut. Bull. 2023, 187, 114544. [Google Scholar] [CrossRef]

- Lee, S.; Alam, M.B.; Lee, S.-H.; Jung, M.-J.; Shim, W.J.; Kim, S. Identification and Quantification of Photodegradation Products of Disposed Expanded Polystyrene Buoy Used in Aquaculture. Mar. Pollut. Bull. 2023, 192, 114998. [Google Scholar] [CrossRef]

- Zha, F.; Dai, J.; Han, Y.; Liu, P.; Wang, M.; Liu, H.; Guo, X. Release of Millions of Micro(Nano)Plastic Fragments from Photooxidation of Disposable Plastic Boxes. Sci. Total Environ. 2023, 858, 160044. [Google Scholar] [CrossRef]

- Subair, A.; G, M.; Chellappan, S.; Chinglenthoiba, C.; S, I.M. Techniques for Removal and Degradation of Microplastics. In Environmental Chemistry for a Sustainable World; Springer Nature: Cham, Switzerland, 2023; pp. 127–153. ISBN 978-3-031-36350-4. [Google Scholar]

- Wagner, S.; Hüffer, T.; Klöckner, P.; Wehrhahn, M.; Hofmann, T.; Reemtsma, T. Tire Wear Particles in the Aquatic Environment—A Review on Generation, Analysis, Occurrence, Fate and Effects. Water Res. 2018, 139, 83–100. [Google Scholar] [CrossRef] [PubMed]

- Winkler, A.; Santo, N.; Ortenzi, M.A.; Bolzoni, E.; Bacchetta, R.; Tremolada, P. Does Mechanical Stress Cause Microplastic Release from Plastic Water Bottles? Water Res. 2019, 166, 115082. [Google Scholar] [CrossRef] [PubMed]

- Cesa, F.S.; Turra, A.; Checon, H.H.; Leonardi, B.; Baruque-Ramos, J. Laundering and Textile Parameters Influence Fibers Release in Household Washings. Environ. Pollut. 2020, 257, 113553. [Google Scholar] [CrossRef] [PubMed]

- He, Y.-J.; Qin, Y.; Zhang, T.-L.; Zhu, Y.-Y.; Wang, Z.-J.; Zhou, Z.-S.; Xie, T.-Z.; Luo, X.-D. Migration of (Non-) Intentionally Added Substances and Microplastics from Microwavable Plastic Food Containers. J. Hazard. Mater. 2021, 417, 126074. [Google Scholar] [CrossRef]

- Xu, C.; Hu, J.; Dong, B.; Lin, Q.; Wu, S.; Chen, J.; Wang, J.; Li, D.; Zhong, H. Safety Assessment of Polypropylene Self-Heating Food Container: The Release of Microplastics and Volatile Organic Compounds. Food Packag. Shelf Life 2024, 44, 101307. [Google Scholar] [CrossRef]

- Jin, T.; Liu, Y.; Lyu, H.; He, Y.; Sun, H.; Tang, J.; Xing, B. Plastic Takeaway Food Containers May Cause Human Intestinal Damage in Routine Life Usage: Microplastics Formation and Cytotoxic Effect. J. Hazard. Mater. 2024, 475, 134866. [Google Scholar] [CrossRef] [PubMed]

- Hernandez, L.M.; Xu, E.G.; Larsson, H.C.E.; Tahara, R.; Maisuria, V.B.; Tufenkji, N. Plastic Teabags Release Billions of Microparticles and Nanoparticles into Tea. Environ. Sci. Technol. 2019, 53, 12300–12310. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.S.; Islam, Z.; Hasan, R.; Islam Molla Jamal, A.S. Acidic Hydrolysis of Recycled Polyethylene Terephthalate Plastic for the Production of Its Monomer Terephthalic Acid. Prog. Rubber Plast. Recycl. Technol. 2023, 39, 12–25. [Google Scholar] [CrossRef]

- Shah, A.A.; Hasan, F.; Hameed, A.; Ahmed, S. Biological Degradation of Plastics: A Comprehensive Review. Biotechnol. Adv. 2008, 26, 246–265. [Google Scholar] [CrossRef]

- De Oliveira, C.R.S.; Da Silva Júnior, A.H.; Mulinari, J.; Ferreira, A.J.S.; Da Silva, A. Fibrous Microplastics Released from Textiles: Occurrence, Fate, and Remediation Strategies. J. Contam. Hydrol. 2023, 256, 104169. [Google Scholar] [CrossRef]

- Zhao, X.; Gao, P.; Zhao, Z.; Wu, Y.; Sun, H.; Liu, C. Microplastics Release from Face Masks: Characteristics, Influential Factors, and Potential Risks. Sci. Total Environ. 2024, 921, 171090. [Google Scholar] [CrossRef]

- Bhat, M.A. Unravelling the Microplastic Contamination: A Comprehensive Analysis of Microplastics in Indoor House Dust. Indoor Built Environ. 2024, 33, 1519–1541. [Google Scholar] [CrossRef]

- Catarino, A.I.; León, M.C.; Li, Y.; Lambert, S.; Vercauteren, M.; Asselman, J.; Janssen, C.R.; Everaert, G.; De Rijcke, M. Micro- and Nanoplastics Transfer from Seawater to the Atmosphere through Aerosolization under Controlled Laboratory Conditions. Mar. Pollut. Bull. 2023, 192, 115015. [Google Scholar] [CrossRef]

- Lambert, S.; Vercauteren, M.; Catarino, A.I.; Li, Y.; Van Landuyt, J.; Boon, N.; Everaert, G.; De Rijcke, M.; Janssen, C.R.; Asselman, J. Aerosolization of Micro- and Nanoplastics via Sea Spray: Investigating the Role of Polymer Type, Size, and Concentration, and Potential Implications for Human Exposure. Environ. Pollut. 2024, 351, 124105. [Google Scholar] [CrossRef]

- Van Den Berg, P.; Huerta-Lwanga, E.; Corradini, F.; Geissen, V. Sewage Sludge Application as a Vehicle for Microplastics in Eastern Spanish Agricultural Soils. Environ. Pollut. 2020, 261, 114198. [Google Scholar] [CrossRef] [PubMed]

- Hatinoğlu, M.D.; Sanin, F.D. Sewage Sludge as a Source of Microplastics in the Environment: A Review of Occurrence and Fate during Sludge Treatment. J. Environ. Manag. 2021, 295, 113028. [Google Scholar] [CrossRef] [PubMed]

- Qaiser, Z.; Aqeel, M.; Sarfraz, W.; Fatima Rizvi, Z.; Noman, A.; Naeem, S.; Khalid, N. Microplastics in Wastewaters and Their Potential Effects on Aquatic and Terrestrial Biota. Case Stud. Chem. Environ. Eng. 2023, 8, 100536. [Google Scholar] [CrossRef]

- Dris, R.; Gasperi, J.; Rocher, V.; Saad, M.; Renault, N.; Tassin, B. Microplastic Contamination in an Urban Area: A Case Study in Greater Paris. Environ. Chem. 2015, 12, 592. [Google Scholar] [CrossRef]

- Militký, J.; Novotná, J.; Wiener, J.; Křemenáková, D.; Venkataraman, M. Microplastics and Fibrous Fragments Generated during the Production and Maintenance of Textiles. Fibers 2024, 12, 51. [Google Scholar] [CrossRef]

- Periyasamy, A.P.; Tehrani-Bagha, A. A Review on Microplastic Emission from Textile Materials and Its Reduction Techniques. Polym. Degrad. Stab. 2022, 199, 109901. [Google Scholar] [CrossRef]

- Tao, D.; Zhang, K.; Xu, S.; Lin, H.; Liu, Y.; Kang, J.; Yim, T.; Giesy, J.P.; Leung, K.M.Y. Microfibers Released into the Air from a Household Tumble Dryer. Environ. Sci. Technol. Lett. 2022, 9, 120–126. [Google Scholar] [CrossRef]

- Wieland, S.; Balmes, A.; Bender, J.; Kitzinger, J.; Meyer, F.; Ramsperger, A.F.; Roeder, F.; Tengelmann, C.; Wimmer, B.H.; Laforsch, C.; et al. From Properties to Toxicity: Comparing Microplastics to Other Airborne Microparticles. J. Hazard. Mater. 2022, 428, 128151. [Google Scholar] [CrossRef]

- Morawska, L.; Buonanno, G. The Physics of Particle Formation and Deposition during Breathing. Nat. Rev. Phys. 2021, 3, 300–301. [Google Scholar] [CrossRef]

- Prietl, B.; Meindl, C.; Roblegg, E.; Pieber, T.R.; Lanzer, G.; Fröhlich, E. Nano-Sized and Micro-Sized Polystyrene Particles Affect Phagocyte Function. Cell Biol. Toxicol. 2014, 30, 1–16. [Google Scholar] [CrossRef]

- Jayavel, S.; Govindaraju, B.; Michael, J.R.; Viswanathan, B. Impacts of Micro and Nanoplastics on Human Health. Bull. Natl. Res. Cent. 2024, 48, 110. [Google Scholar] [CrossRef]

- Amato-Lourenço, L.F.; Carvalho-Oliveira, R.; Júnior, G.R.; dos Santos Galvão, L.; Ando, R.A.; Mauad, T. Presence of Airborne Microplastics in Human Lung Tissue. J. Hazard. Mater. 2021, 416, 126124. [Google Scholar] [CrossRef] [PubMed]

- Alvarez-Román, R.; Naik, A.; Kalia, Y.N.; Guy, R.H.; Fessi, H. Skin Penetration and Distribution of Polymeric Nanoparticles. J. Control. Release 2004, 99, 53–62. [Google Scholar] [CrossRef] [PubMed]

- Jatana, S.; Callahan, L.; Pentland, A.; DeLouise, L. Impact of Cosmetic Lotions on Nanoparticle Penetration through Ex Vivo C57BL/6 Hairless Mouse and Human Skin: A Comparison Study. Cosmetics 2016, 3, 6. [Google Scholar] [CrossRef]

- Singh, A.; Mishra, B.K. Microbeads in Personal Care Products: An Overlooked Environmental Concern. J. Clean. Prod. 2023, 427, 139082. [Google Scholar] [CrossRef]

- Wu, C.-C.; Chen, C.-Y.; Zhong, L.-S.; Bao, L.-J.; Zeng, E.Y. Particle Transfer Mediates Dermal Exposure of Consumers to Plasticizers in Eraser and Pen Accessories. Environ. Int. 2023, 180, 108191. [Google Scholar] [CrossRef]

- Sykes, E.A.; Dai, Q.; Tsoi, K.M.; Hwang, D.M.; Chan, W.C.W. Nanoparticle Exposure in Animals Can Be Visualized in the Skin and Analysed via Skin Biopsy. Nat. Commun. 2014, 5, 3796. [Google Scholar] [CrossRef]

- Baroli, B.; Ennas, M.G.; Loffredo, F.; Isola, M.; Pinna, R.; Arturo López-Quintela, M. Penetration of Metallic Nanoparticles in Human Full-Thickness Skin. J. Investig. Dermatol. 2007, 127, 1701–1712. [Google Scholar] [CrossRef]

- Schneider, M.; Stracke, F.; Hansen, S.; Schaefer, U.F. Nanoparticles and Their Interactions with the Dermal Barrier. Dermatoendocrinol. 2009, 1, 197–206. [Google Scholar] [CrossRef]

- Labouta, H.I.; El-Khordagui, L.K.; Kraus, T.; Schneider, M. Mechanism and Determinants of Nanoparticle Penetration through Human Skin. Nanoscale 2011, 3, 4989. [Google Scholar] [CrossRef]

- Menichetti, A.; Mordini, D.; Montalti, M. Penetration of Microplastics and Nanoparticles Through Skin: Effects of Size, Shape, and Surface Chemistry. J. Xenobiotics 2024, 15, 6. [Google Scholar] [CrossRef]

- Kuo, T.-R.; Wu, C.-L.; Hsu, C.-T.; Lo, W.; Chiang, S.-J.; Lin, S.-J.; Dong, C.-Y.; Chen, C.-C. Chemical Enhancer Induced Changes in the Mechanisms of Transdermal Delivery of Zinc Oxide Nanoparticles. Biomaterials 2009, 30, 3002–3008. [Google Scholar] [CrossRef]

- Madhumitha, C.T.; Karmegam, N.; Biruntha, M.; Arun, A.; Al Kheraif, A.A.; Kim, W.; Kumar, P. Extraction, Identification, and Environmental Risk Assessment of Microplastics in Commercial Toothpaste. Chemosphere 2022, 296, 133976. [Google Scholar] [CrossRef] [PubMed]

- Chengappa S, K.; Rao, A.; K S, A.; Jodalli, P.S.; Shenoy Kudpi, R. Microplastic Content of Over-the-Counter Toothpastes—A Systematic Review. F1000Research 2023, 12, 390. [Google Scholar] [CrossRef] [PubMed]

- Fang, C.; Gopalan, S.; Zhang, X.; Xu, L.; Niu, J.; Naidu, R. Raman Imaging to Identify Microplastics Released from Toothbrushes: Algorithms and Particle Analysis. Environ. Pollut. 2023, 337, 122510. [Google Scholar] [CrossRef] [PubMed]

- Saha, U.; Jena, S.; Simnani, F.Z.; Singh, D.; Choudhury, A.; Naser, S.S.; Lenka, S.S.; Kirti, A.; Nandi, A.; Sinha, A.; et al. The Unseen Perils of Oral-Care Products Generated Micro/Nanoplastics on Human Health. Ecotoxicol. Environ. Saf. 2025, 290, 117526. [Google Scholar] [CrossRef]

- Novotna, K.; Cermakova, L.; Pivokonska, L.; Cajthaml, T.; Pivokonsky, M. Microplastics in Drinking Water Treatment—Current Knowledge and Research Needs. Sci. Total Environ. 2019, 667, 730–740. [Google Scholar] [CrossRef]

- Brancaleone, E.; Mattei, D.; Fuscoletti, V.; Lucentini, L.; Favero, G.; Cecchini, G.; Frugis, A.; Gioia, V.; Lazzazzara, M. Microplastic in Drinking Water: A Pilot Study. Microplastics 2024, 3, 31–45. [Google Scholar] [CrossRef]

- Li, H.; Zhu, L.; Ma, M.; Wu, H.; An, L.; Yang, Z. Occurrence of Microplastics in Commercially Sold Bottled Water. Sci. Total Environ. 2023, 867, 161553. [Google Scholar] [CrossRef]

- Diaz-Basantes, M.F.; Conesa, J.A.; Fullana, A. Microplastics in Honey, Beer, Milk and Refreshments in Ecuador as Emerging Contaminants. Sustainability 2020, 12, 5514. [Google Scholar] [CrossRef]

- Socas-Hernández, C.; Miralles, P.; González-Sálamo, J.; Hernández-Borges, J.; Coscollà, C. Assessment of Anthropogenic Particles Content in Commercial Beverages. Food Chem. 2024, 447, 139002. [Google Scholar] [CrossRef]

- Mortensen, N.P.; Fennell, T.R.; Johnson, L.M. Unintended Human Ingestion of Nanoplastics and Small Microplastics through Drinking Water, Beverages, and Food Sources. NanoImpact 2021, 21, 100302. [Google Scholar] [CrossRef] [PubMed]

- Nocoń, W.; Moraczewska-Majkut, K.; Wiśniowska, E. Microplastics in Bottled Water and Bottled Soft Drinks. Desalination Water Treat. 2023, 312, 64–69. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, H.; Luo, Y.; Ding, Y.; Huang, J.; Wu, H.; Han, J.; Du, L.; Kang, A.; Jia, M.; et al. Plastic Bottles for Chilled Carbonated Beverages as a Source of Microplastics and Nanoplastics. Water Res. 2023, 242, 120243. [Google Scholar] [CrossRef] [PubMed]

- Kirstein, I.V.; Hensel, F.; Gomiero, A.; Iordachescu, L.; Vianello, A.; Wittgren, H.B.; Vollertsen, J. Drinking Plastics?—Quantification and Qualification of Microplastics in Drinking Water Distribution Systems by µFTIR and Py-GCMS. Water Res. 2021, 188, 116519. [Google Scholar] [CrossRef]

- Kasim, S.; Daud, A.; Birawida, A.B.; Mallongi, A.; Arundana, A.I.; Rasul, A.; Hatta, M. Analysis of Environmental Health Risks from Exposure to Polyethylene Terephthalate Microplastics in Refilled Drinking Water. Glob. J. Environ. Sci. Manag. 2023, 9, 301–318. [Google Scholar] [CrossRef]

- Aleksander-Kwaterczak, U.; Gaj, D.; Stelmach, A.; Wróbel, T.P. Investigating the Content of Microplastics and Other Extraneous Particles in Polish Bottled Water. Geol. Geophys. Environ. 2023, 49, 335–353. [Google Scholar] [CrossRef]

- Prata, J.C.; Paço, A.; Reis, V.; Da Costa, J.P.; Fernandes, A.J.S.; Da Costa, F.M.; Duarte, A.C.; Rocha-Santos, T. Identification of Microplastics in White Wines Capped with Polyethylene Stoppers Using Micro-Raman Spectroscopy. Food Chem. 2020, 331, 127323. [Google Scholar] [CrossRef]

- Joseph, A.; Parveen, N.; Ranjan, V.P.; Goel, S. Drinking Hot Beverages from Paper Cups: Lifetime Intake of Microplastics. Chemosphere 2023, 317, 137844. [Google Scholar] [CrossRef]

- Wang, H.-P.; Huang, X.-H.; Chen, J.-N.; Dong, M.; Zhang, Y.-Y.; Qin, L. Pouring Hot Water through Drip Bags Releases Thousands of Microplastics into Coffee. Food Chem. 2023, 415, 135717. [Google Scholar] [CrossRef]

- Ranjan, V.P.; Joseph, A.; Goel, S. Microplastics and Other Harmful Substances Released from Disposable Paper Cups into Hot Water. J. Hazard. Mater. 2021, 404, 124118. [Google Scholar] [CrossRef]

- Shi, Y.; Li, D.; Xiao, L.; Sheerin, E.D.; Mullarkey, D.; Yang, L.; Bai, X.; Shvets, I.V.; Boland, J.J.; Wang, J.J. The Influence of Drinking Water Constituents on the Level of Microplastic Release from Plastic Kettles. J. Hazard. Mater. 2022, 425, 127997. [Google Scholar] [CrossRef]

- Mintenig, S.M.; Löder, M.G.J.; Primpke, S.; Gerdts, G. Low Numbers of Microplastics Detected in Drinking Water from Ground Water Sources. Sci. Total Environ. 2019, 648, 631–635. [Google Scholar] [CrossRef] [PubMed]

- Pivokonsky, M.; Cermakova, L.; Novotna, K.; Peer, P.; Cajthaml, T.; Janda, V. Occurrence of Microplastics in Raw and Treated Drinking Water. Sci. Total Environ. 2018, 643, 1644–1651. [Google Scholar] [CrossRef] [PubMed]

- Pivokonský, M.; Pivokonská, L.; Novotná, K.; Čermáková, L.; Klimtová, M. Occurrence and Fate of Microplastics at Two Different Drinking Water Treatment Plants within a River Catchment. Sci. Total Environ. 2020, 741, 140236. [Google Scholar] [CrossRef] [PubMed]

- Oladoja, N.A.; Unuabonah, I.E. The Pathways of Microplastics Contamination in Raw and Drinking Water. J. Water Process Eng. 2021, 41, 102073. [Google Scholar] [CrossRef]

- Chu, X.; Zheng, B.; Li, Z.; Cai, C.; Peng, Z.; Zhao, P.; Tian, Y. Occurrence and Distribution of Microplastics in Water Supply Systems: In Water and Pipe Scales. Sci. Total Environ. 2022, 803, 150004. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Tang, Y. Fragmentation of Microplastics in the Drinking Water Treatment Process—A Case Study in Yangtze River Region, China. Sci. Total Environ. 2022, 806, 150545. [Google Scholar] [CrossRef]

- Weisser, J.; Beer, I.; Hufnagl, B.; Hofmann, T.; Lohninger, H.; Ivleva, N.P.; Glas, K. From the Well to the Bottle: Identifying Sources of Microplastics in Mineral Water. Water 2021, 13, 841. [Google Scholar] [CrossRef]

- Rummel, C.D.; Löder, M.G.J.; Fricke, N.F.; Lang, T.; Griebeler, E.-M.; Janke, M.; Gerdts, G. Plastic Ingestion by Pelagic and Demersal Fish from the North Sea and Baltic Sea. Mar. Pollut. Bull. 2016, 102, 134–141. [Google Scholar] [CrossRef] [PubMed]

- Akhbarizadeh, R.; Moore, F.; Keshavarzi, B. Investigating Microplastics Bioaccumulation and Biomagnification in Seafood from the Persian Gulf: A Threat to Human Health? Food Addit. Contam. Part A 2019, 36, 1696–1708. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Liang, W.; Liu, Q.-X.; Fu, S.; Ma, C.; Chen, Q.; Su, L.; Craig, N.J.; Shi, H. Fish Ingest Microplastics Unintentionally. Environ. Sci. Technol. 2021, 55, 10471–10479. [Google Scholar] [CrossRef] [PubMed]

- Daniel, D.B.; Ashraf, P.M.; Thomas, S.N.; Thomson, K.T. Microplastics in the Edible Tissues of Shellfishes Sold for Human Consumption. Chemosphere 2021, 264, 128554. [Google Scholar] [CrossRef]

- Nalbone, L.; Cincotta, F.; Giarratana, F.; Ziino, G.; Panebianco, A. Microplastics in Fresh and Processed Mussels Sampled from Fish Shops and Large Retail Chains in Italy. Food Control 2021, 125, 108003. [Google Scholar] [CrossRef]

- Lackner, M.; Branka, M. Microplastics in Farmed Animals—A Review. Microplastics 2024, 3, 559–588. [Google Scholar] [CrossRef]

- Vega-Herrera, A.; Savva, K.; Lacoma, P.; Santos, L.H.M.L.M.; Hernández, A.; Marmelo, I.; Marques, A.; Llorca, M.; Farré, M. Bioaccumulation and Dietary Bioaccessibility of Microplastics Composition and Cocontaminants in Mediterranean Mussels. Chemosphere 2024, 363, 142934. [Google Scholar] [CrossRef]

- Aydın, R.B.; Yozukmaz, A.; Şener, İ.; Temiz, F.; Giannetto, D. Occurrence of Microplastics in Most Consumed Fruits and Vegetables from Turkey and Public Risk Assessment for Consumers. Life 2023, 13, 1686. [Google Scholar] [CrossRef]

- Liu, K.; Wang, X.; Song, Z.; Wei, N.; Li, D. Terrestrial Plants as a Potential Temporary Sink of Atmospheric Microplastics during Transport. Sci. Total Environ. 2020, 742, 140523. [Google Scholar] [CrossRef]

- Yu, Z.; Song, S.; Xu, X.; Ma, Q.; Lu, Y. Sources, Migration, Accumulation and Influence of Microplastics in Terrestrial Plant Communities. Environ. Exp. Bot. 2021, 192, 104635. [Google Scholar] [CrossRef]

- Makhdoumi, P.; Pirsaheb, M.; Amin, A.A.; Kianpour, S.; Hossini, H. Microplastic Pollution in Table Salt and Sugar: Occurrence, Qualification and Quantification and Risk Assessment. J. Food Compos. Anal. 2023, 119, 105261. [Google Scholar] [CrossRef]

- Snekkevik, V.K.; Cole, M.; Gomiero, A.; Haave, M.; Khan, F.R.; Lusher, A.L. Beyond the Food on Your Plate: Investigating Sources of Microplastic Contamination in Home Kitchens. Heliyon 2024, 10, e35022. [Google Scholar] [CrossRef]

- Choi, H.S.; Ashitate, Y.; Lee, J.H.; Kim, S.H.; Matsui, A.; Insin, N.; Bawendi, M.G.; Semmler-Behnke, M.; Frangioni, J.V.; Tsuda, A. Rapid Translocation of Nanoparticles from the Lung Airspaces to the Body. Nat. Biotechnol. 2010, 28, 1300–1303. [Google Scholar] [CrossRef] [PubMed]

- Kreyling, W.G.; Hirn, S.; Schleh, C. Nanoparticles in the Lung. Nat. Biotechnol. 2010, 28, 1275–1276. [Google Scholar] [CrossRef] [PubMed]

- Domenech, J.; Marcos, R. Pathways of Human Exposure to Microplastics, and Estimation of the Total Burden. Curr. Opin. Food Sci. 2021, 39, 144–151. [Google Scholar] [CrossRef]

- Du, F.; Cai, H.; Zhang, Q.; Chen, Q.; Shi, H. Microplastics in Take-out Food Containers. J. Hazard. Mater. 2020, 399, 122969. [Google Scholar] [CrossRef]

- Cole, M.; Gomiero, A.; Jaén-Gil, A.; Haave, M.; Lusher, A. Microplastic and PTFE Contamination of Food from Cookware. Sci. Total Environ. 2024, 929, 172577. [Google Scholar] [CrossRef]

- Brenz, F.; Linke, S.; Simat, T. Linear and Cyclic Oligomers in Polybutylene Terephthalate for Food Contact Materials. Food Addit. Contam. Part A 2018, 35, 583–598. [Google Scholar] [CrossRef]

- Canellas, E.; Vera, P.; Song, X.-C.; Nerin, C.; Goshawk, J.; Dreolin, N. The Use of Ion Mobility Time-of-Flight Mass Spectrometry to Assess the Migration of Polyamide 6 and Polyamide 66 Oligomers from Kitchenware Utensils to Food. Food Chem. 2021, 350, 129260. [Google Scholar] [CrossRef]

- Kaseke, T.; Lujic, T.; Cirkovic Velickovic, T. Nano- and Microplastics Migration from Plastic Food Packaging into Dairy Products: Impact on Nutrient Digestion, Absorption, and Metabolism. Foods 2023, 12, 3043. [Google Scholar] [CrossRef]

- Kappenstein, O.; Ebner, I.; Förster, C.; Richter, S.; Weyer, J.; Pfaff, K.; Luch, A. Validation and Application of an LC-MS/MS Method for the Determination of Cyclic Oligomers Originating from Polyamide 6 and Polyamide 66 in Food Simulant. Food Addit. Contam. Part A 2018, 35, 1410–1420. [Google Scholar] [CrossRef]

- Luo, Y.; Chuah, C.; Amin, M.A.; Khoshyan, A.; Gibson, C.T.; Tang, Y.; Naidu, R.; Fang, C. Assessment of Microplastics and Nanoplastics Released from a Chopping Board Using Raman Imaging in Combination with Three Algorithms. J. Hazard. Mater. 2022, 431, 128636. [Google Scholar] [CrossRef]

- Habib, R.Z.; Kindi, R.A.; Salem, F.A.; Kittaneh, W.F.; Poulose, V.; Iftikhar, S.H.; Mourad, A.-H.I.; Thiemann, T. Microplastic Contamination of Chicken Meat and Fish through Plastic Cutting Boards. Int. J. Environ. Res. Public Health 2022, 19, 13442. [Google Scholar] [CrossRef]

- Yadav, H.; Khan, M.R.H.; Quadir, M.; Rusch, K.A.; Mondal, P.P.; Orr, M.; Xu, E.G.; Iskander, S.M. Cutting Boards: An Overlooked Source of Microplastics in Human Food? Environ. Sci. Technol. 2023, 57, 8225–8235. [Google Scholar] [CrossRef] [PubMed]

- Hussain, K.A.; Romanova, S.; Okur, I.; Zhang, D.; Kuebler, J.; Huang, X.; Wang, B.; Fernandez-Ballester, L.; Lu, Y.; Schubert, M.; et al. Assessing the Release of Microplastics and Nanoplastics from Plastic Containers and Reusable Food Pouches: Implications for Human Health. Environ. Sci. Technol. 2023, 57, 9782–9792. [Google Scholar] [CrossRef] [PubMed]

- Castle, L.; Jickells, S.M.; Gilbert, J.; Harrison, N. Migration Testing of Plastics and Microwave-active Materials for High-temperature Food-use Applications. Food Addit. Contam. 1990, 7, 779–796. [Google Scholar] [CrossRef] [PubMed]

- Rondinella, A.; Andreatta, F.; Turrin, D.; Fedrizzi, L. Degradation Mechanisms Occurring in PTFE-Based Coatings Employed in Food-Processing Applications. Coatings 2021, 11, 1419. [Google Scholar] [CrossRef]

- Luo, Y.; Gibson, C.T.; Chuah, C.; Tang, Y.; Naidu, R.; Fang, C. Raman Imaging for the Identification of Teflon Microplastics and Nanoplastics Released from Non-Stick Cookware. Sci. Total Environ. 2022, 851, 158293. [Google Scholar] [CrossRef]

- Schlummer, M.; Sölch, C.; Meisel, T.; Still, M.; Gruber, L.; Wolz, G. Emission of Perfluoroalkyl Carboxylic Acids (PFCA) from Heated Surfaces Made of Polytetrafluoroethylene (PTFE) Applied in Food Contact Materials and Consumer Products. Chemosphere 2015, 129, 46–53. [Google Scholar] [CrossRef]

- Sajid, M.; Ilyas, M. PTFE-Coated Non-Stick Cookware and Toxicity Concerns: A Perspective. Environ. Sci. Pollut. Res. 2017, 24, 23436–23440. [Google Scholar] [CrossRef]

- Addo Ntim, S.; Norris, S.; Scott, K.; Thomas, T.A.; Noonan, G.O. Consumer Use Effects on Nanoparticle Release from Commercially Available Ceramic Cookware. Food Control 2018, 87, 31–39. [Google Scholar] [CrossRef]

- Luo, Y.; Awoyemi, O.S.; Naidu, R.; Fang, C. Detection of Microplastics and Nanoplastics Released from a Kitchen Blender Using Raman Imaging. J. Hazard. Mater. 2023, 453, 131403. [Google Scholar] [CrossRef] [PubMed]

- Levin, B.C. A Summary of the NBS Literature Reviews on the Chemical Nature and Toxicity of the Pyrolysis and Combustion Products from Seven Plastics: Acrylonitrile–Butadiene–Styrenes (ABS), Nylons, Polyesters, Polyethylenes, Polystyrenes, Poly(Vinyl Chlorides) and Rigid Polyurethane Foams. Fire Mater. 1987, 11, 143–157. [Google Scholar] [CrossRef]

- Lund, K.H.; Petersen, J.H. Migration of Formaldehyde and Melamine Monomers from Kitchen- and Tableware Made of Melamine Plastic. Food Addit. Contam. 2006, 23, 948–955. [Google Scholar] [CrossRef]

- Liu, Q.; Fang, J.; Liu, Z.; Chen, Y.; Chen, Q.; Chen, Z.; Yuan, S.; Yu, H.; Yao, W. Influence of Different Food Matrices on the Abundance, Characterization, Migration Kinetics and Hazards of Microplastics Released from Plastic Packaging (PP and PET). Food Chem. 2025, 478, 143691. [Google Scholar] [CrossRef]

- Sturm, M.T.; Kluczka, S.; Wilde, A.; Schuhen, K. Determination of Particles Produced During Boiling in Differenz Plastic and Glass Kettles via Comparative Dynamic Image Analysis Using FlowCam®. Analytik News. Technical Papers, 2019. Available online: https://analytik.news/en/papers/pdf/wasserdreinull4e.pdf (accessed on 5 September 2025).

- Liu, G.; Wang, J.; Wang, M.; Ying, R.; Li, X.; Hu, Z.; Zhang, Y. Disposable Plastic Materials Release Microplastics and Harmful Substances in Hot Water. Sci. Total Environ. 2022, 818, 151685. [Google Scholar] [CrossRef]

- Alak, G.; Köktürk, M.; Atamanalp, M. Evaluation of Different Packaging Methods and Storage Temperature on MPs Abundance and Fillet Quality of Rainbow Trout. J. Hazard. Mater. 2021, 420, 126573. [Google Scholar] [CrossRef]

- Zangmeister, C.D.; Radney, J.G.; Benkstein, K.D.; Kalanyan, B. Common Single-Use Consumer Plastic Products Release Trillions of Sub-100 Nm Nanoparticles per Liter into Water during Normal Use. Environ. Sci. Technol. 2022, 56, 5448–5455. [Google Scholar] [CrossRef]

- Zhou, G.; Wu, Q.; Tang, P.; Chen, C.; Cheng, X.; Wei, X.-F.; Ma, J.; Liu, B. How Many Microplastics Do We Ingest When Using Disposable Drink Cups? J. Hazard. Mater. 2023, 441, 129982. [Google Scholar] [CrossRef]

- Mei, T.; Wang, J.; Xiao, X.; Lv, J.; Li, Q.; Dai, H.; Liu, X.; Pi, F. Identification and Evaluation of Microplastics from Tea Filter Bags Based on Raman Imaging. Foods 2022, 11, 2871. [Google Scholar] [CrossRef]

- Yang, L.; Li, D.; Shi, Y.; Hill, C.; Pilliadugula, R.; Page, L.; Wang, J.J.; Boland, J.J.; Xiao, L. High Levels of Microparticles Release from Biodegradable Polylactic Acid Paper Cups Compared with Polyethylene-Lined Cups. Chem. Eng. J. 2023, 468, 143620. [Google Scholar] [CrossRef]

- Banaei, G.; García-Rodríguez, A.; Tavakolpournegari, A.; Martín-Pérez, J.; Villacorta, A.; Marcos, R.; Hernández, A. The Release of Polylactic Acid Nanoplastics (PLA-NPLs) from Commercial Teabags. Obtention, Characterization, and Hazard Effects of True-to-Life PLA-NPLs. J. Hazard. Mater. 2023, 458, 131899. [Google Scholar] [CrossRef] [PubMed]

- Shruti, V.C.; Kutralam-Muniasamy, G. Migration Testing of Microplastics in Plastic Food-Contact Materials: Release, Characterization, Pollution Level, and Influencing Factors. TrAC Trends Anal. Chem. 2024, 170, 117421. [Google Scholar] [CrossRef]

- El Hayany, B.; Rumpel, C.; Hafidi, M.; El Fels, L. Occurrence, Analysis of Microplastics in Sewage Sludge and Their Fate during Composting: A Literature Review. J. Environ. Manag. 2022, 317, 115364. [Google Scholar] [CrossRef] [PubMed]

- Bai, C.-L.; Liu, L.-Y.; Guo, J.-L.; Zeng, L.-X.; Guo, Y. Microplastics in Take-out Food: Are We over Taking It? Environ. Res. 2022, 215, 114390. [Google Scholar] [CrossRef]

- Fadare, O.O.; Wan, B.; Guo, L.-H.; Zhao, L. Microplastics from Consumer Plastic Food Containers: Are We Consuming It? Chemosphere 2020, 253, 126787. [Google Scholar] [CrossRef]

- Katsara, K.; Viskadourakis, Z.; Kenanakis, G.; Papadakis, V.M. Microplastic Migration from Food Packaging on Cheese. Microplastics 2025, 4, 17. [Google Scholar] [CrossRef]

- Moreno-Gordaliza, E.; Dolores Marazuela, M.; Milagros Gómez-Gómez, M. Risk Assessment of Silver and Microplastics Release from Antibacterial Food Containers under Conventional Use and Microwave Heating. Food Chem. 2023, 420, 136097. [Google Scholar] [CrossRef]

- Akbulut, S.; Akman, P.K.; Tornuk, F.; Yetim, H. Microplastic Release from Single-Use Plastic Beverage Cups. Foods 2024, 13, 1564. [Google Scholar] [CrossRef]

- Kedzierski, M.; Lechat, B.; Sire, O.; Le Maguer, G.; Le Tilly, V.; Bruzaud, S. Microplastic Contamination of Packaged Meat: Occurrence and Associated Risks. Food Packag. Shelf Life 2020, 24, 100489. [Google Scholar] [CrossRef]

- Ziino, G.; Nalbone, L.; Giarratana, F.; Romano, B.; Cincotta, F.; Panebianco, A. Microplastics in Vacuum Packages of Frozen and Glazed Icefish (Neosalanx spp.): A Freshwater Fish Intended for Human Consumption. Ital. J. Food Saf. 2021, 10, 9974. [Google Scholar] [CrossRef]

- Mohamed Hadeed, M.D.; Al-Ahmady, K.K. The Effect of Different Storage Conditions for Refilled Plastic Drink Bottles on the Concentration of Microplastic Release in Water. J. Res. Appl. Sci. Biotechnol. 2022, 1, 71–77. [Google Scholar] [CrossRef]

- Chaïb, I.; Doyen, P.; Merveillie, P.; Dehaut, A.; Duflos, G. Microplastic Contaminations in a Set of Beverages Sold in France. J. Food Compos. Anal. 2025, 144, 107719. [Google Scholar] [CrossRef]

- Gambino, I.; Malitesta, C.; Bagordo, F.; Grassi, T.; Panico, A.; Fraissinet, S.; De Donno, A.; De Benedetto, G.E. Characterization of Microplastics in Water Bottled in Different Packaging by Raman Spectroscopy. Environ. Sci. Water Res. Technol. 2023, 9, 3391–3397. [Google Scholar] [CrossRef]

- Tisler, S.; Christensen, J.H. Non-Target Screening for the Identification of Migrating Compounds from Reusable Plastic Bottles into Drinking Water. J. Hazard. Mater. 2022, 429, 128331. [Google Scholar] [CrossRef]

- Giese, A.; Kerpen, J.; Weber, F.; Prediger, J. A Preliminary Study of Microplastic Abrasion from the Screw Cap System of Reusable Plastic Bottles by Raman Microspectroscopy. ACS EST Water 2021, 1, 1363–1368. [Google Scholar] [CrossRef]

- Zhou, P.; Zhang, K.; Zhang, T.; Cen, C.; Zheng, Y.; Shuai, Y. Release Characteristics of Small-Sized Microplastics in Bottled Drinks Using Flow Cytometry Sorting and Nile Red Staining. Water 2024, 16, 1898. [Google Scholar] [CrossRef]

- Mason, S.A.; Welch, V.G.; Neratko, J. Synthetic Polymer Contamination in Bottled Water. Front. Chem. 2018, 6, 407. [Google Scholar] [CrossRef]

- Zuccarello, P.; Ferrante, M.; Cristaldi, A.; Copat, C.; Grasso, A.; Sangregorio, D.; Fiore, M.; Oliveri Conti, G. Exposure to Microplastics (<10 Μm) Associated to Plastic Bottles Mineral Water Consumption: The First Quantitative Study. Water Res. 2019, 157, 365–371. [Google Scholar] [CrossRef]

- Schymanski, D.; Goldbeck, C.; Humpf, H.-U.; Fürst, P. Analysis of Microplastics in Water by Micro-Raman Spectroscopy: Release of Plastic Particles from Different Packaging into Mineral Water. Water Res. 2018, 129, 154–162. [Google Scholar] [CrossRef]

- Luo, Y.; Qi, F.; Gibson, C.T.; Lei, Y.; Fang, C. Investigating Kitchen Sponge-Derived Microplastics and Nanoplastics with Raman Imaging and Multivariate Analysis. Sci. Total Environ. 2022, 824, 153963. [Google Scholar] [CrossRef]

- Sobhani, Z.; Lei, Y.; Tang, Y.; Wu, L.; Zhang, X.; Naidu, R.; Megharaj, M.; Fang, C. Microplastics Generated When Opening Plastic Packaging. Sci. Rep. 2020, 10, 4841. [Google Scholar] [CrossRef] [PubMed]

- Hahladakis, J.N.; Iacovidou, E. Closing the Loop on Plastic Packaging Materials: What Is Quality and How Does It Affect Their Circularity? Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Lin, T.; Chen, W. Occurrence and Removal of Microplastics in an Advanced Drinking Water Treatment Plant (ADWTP). Sci. Total Environ. 2020, 700, 134520. [Google Scholar] [CrossRef] [PubMed]