Fabrication of 3D Porous and Flexible Thermoplastic Polyurethane/Carbon Nanotube Composites Towards High-Performance Microwave Absorption

Abstract

1. Introduction

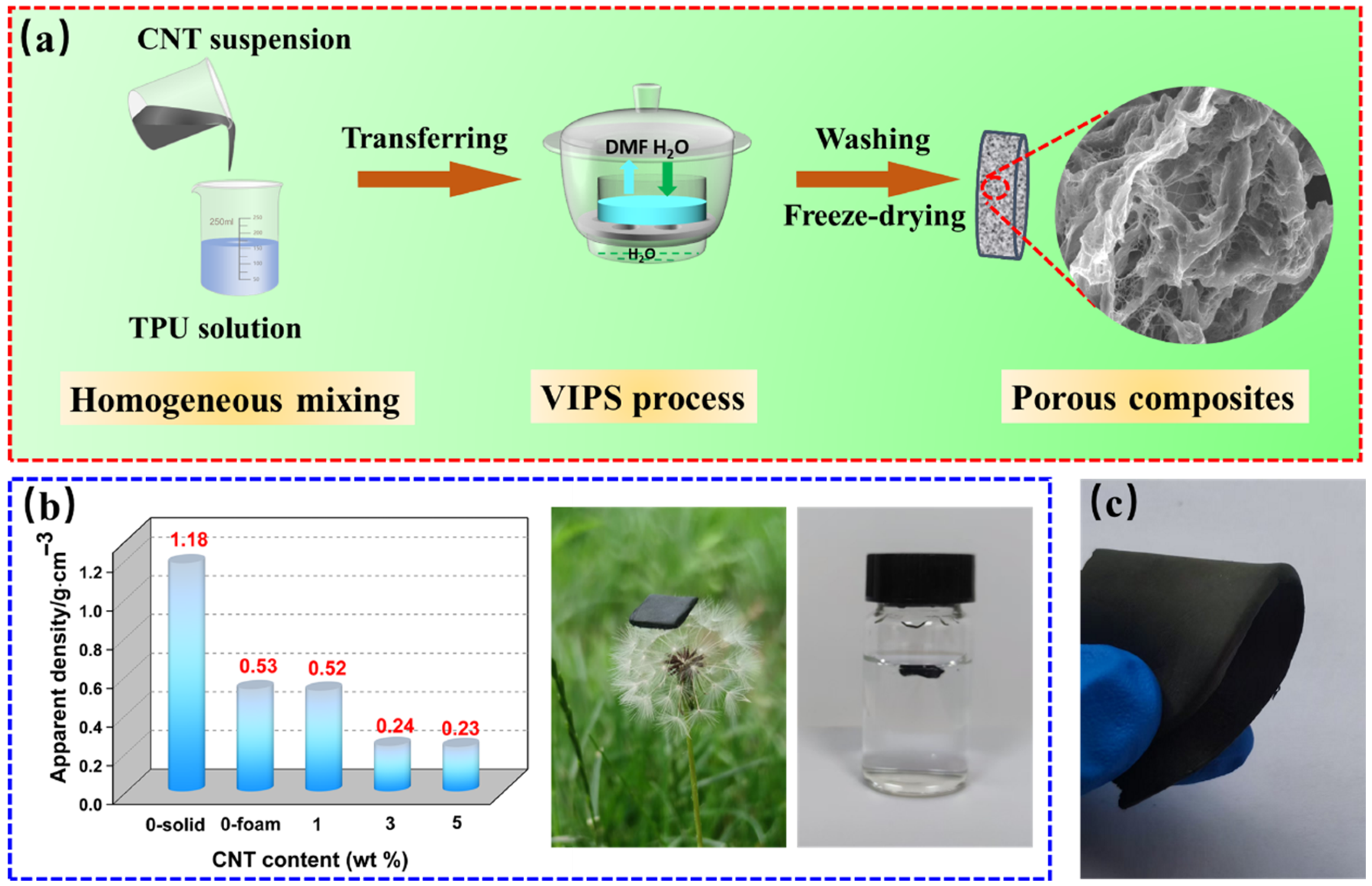

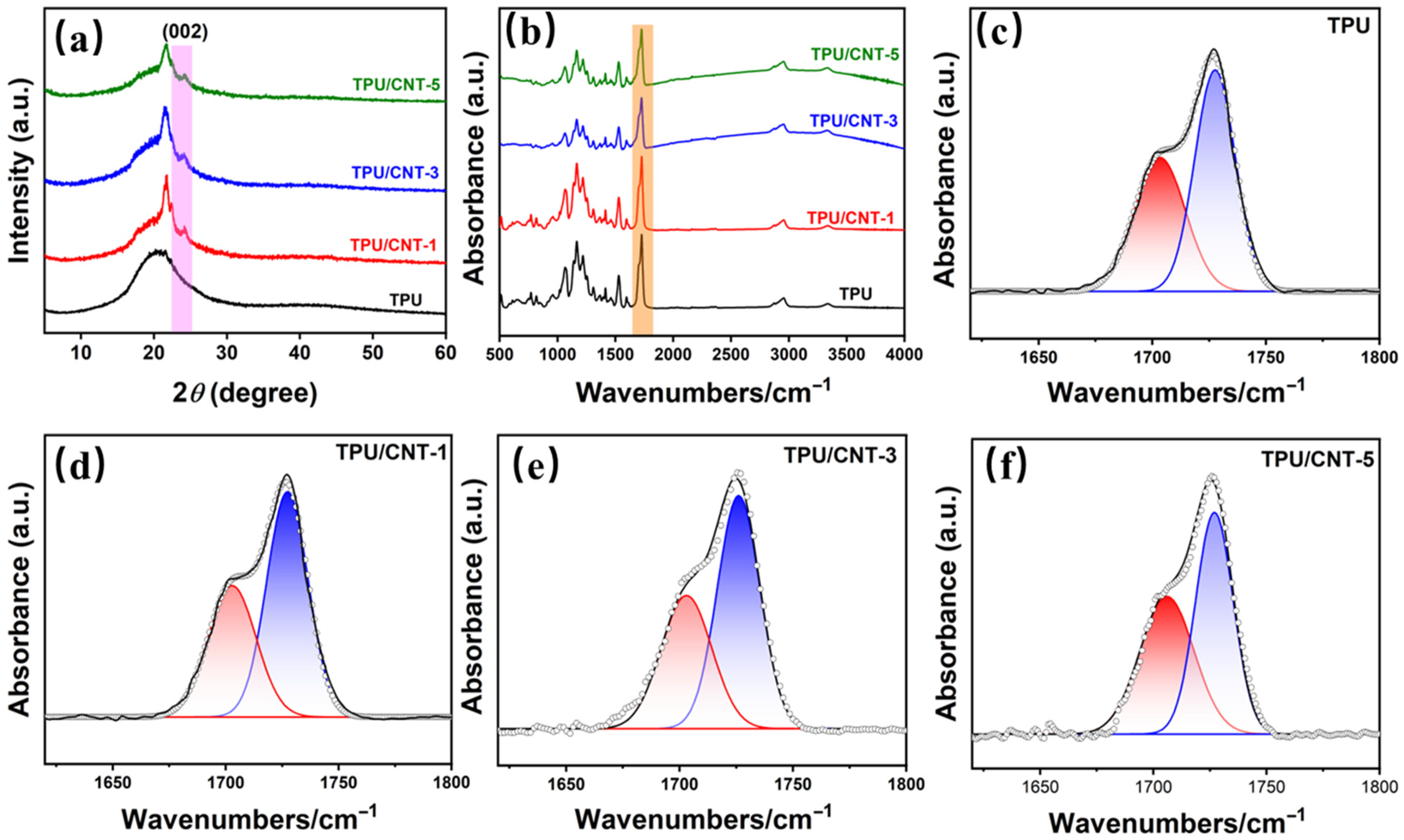

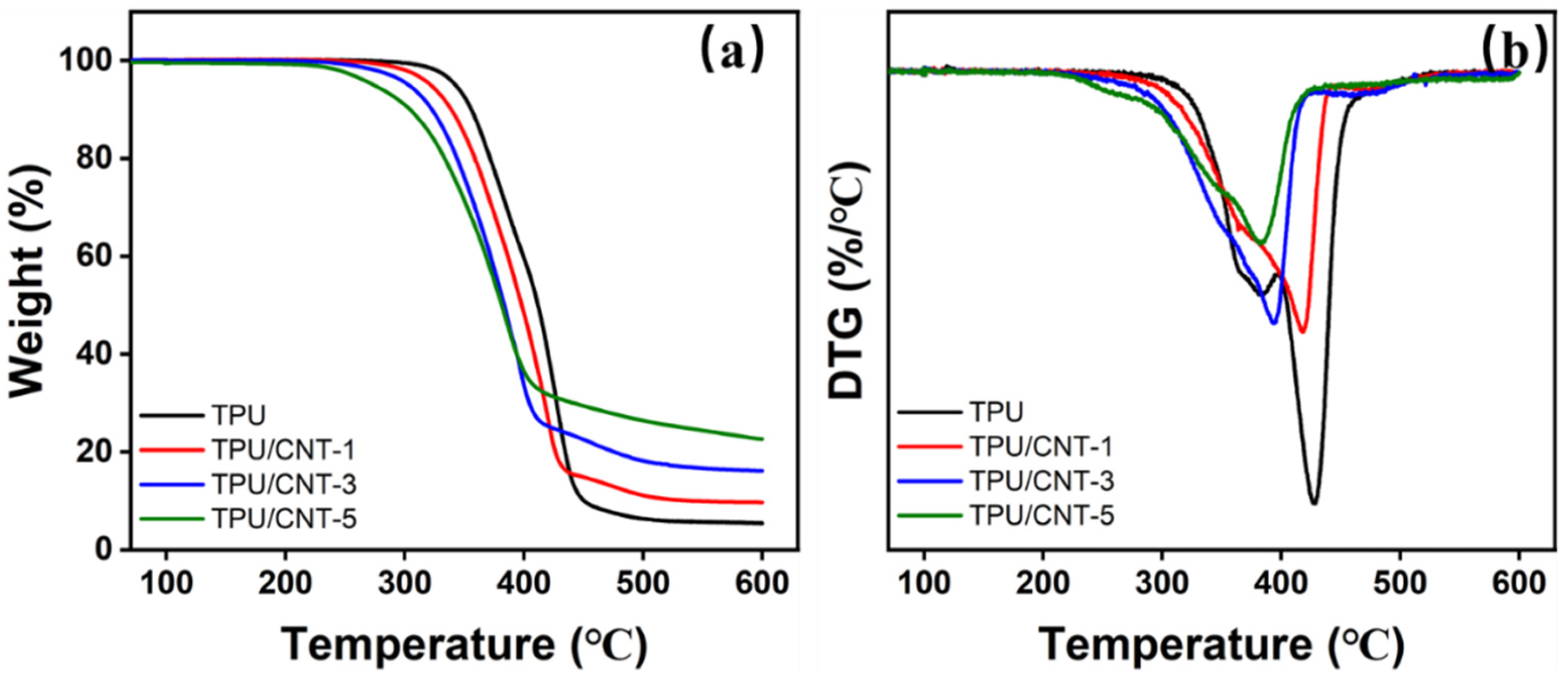

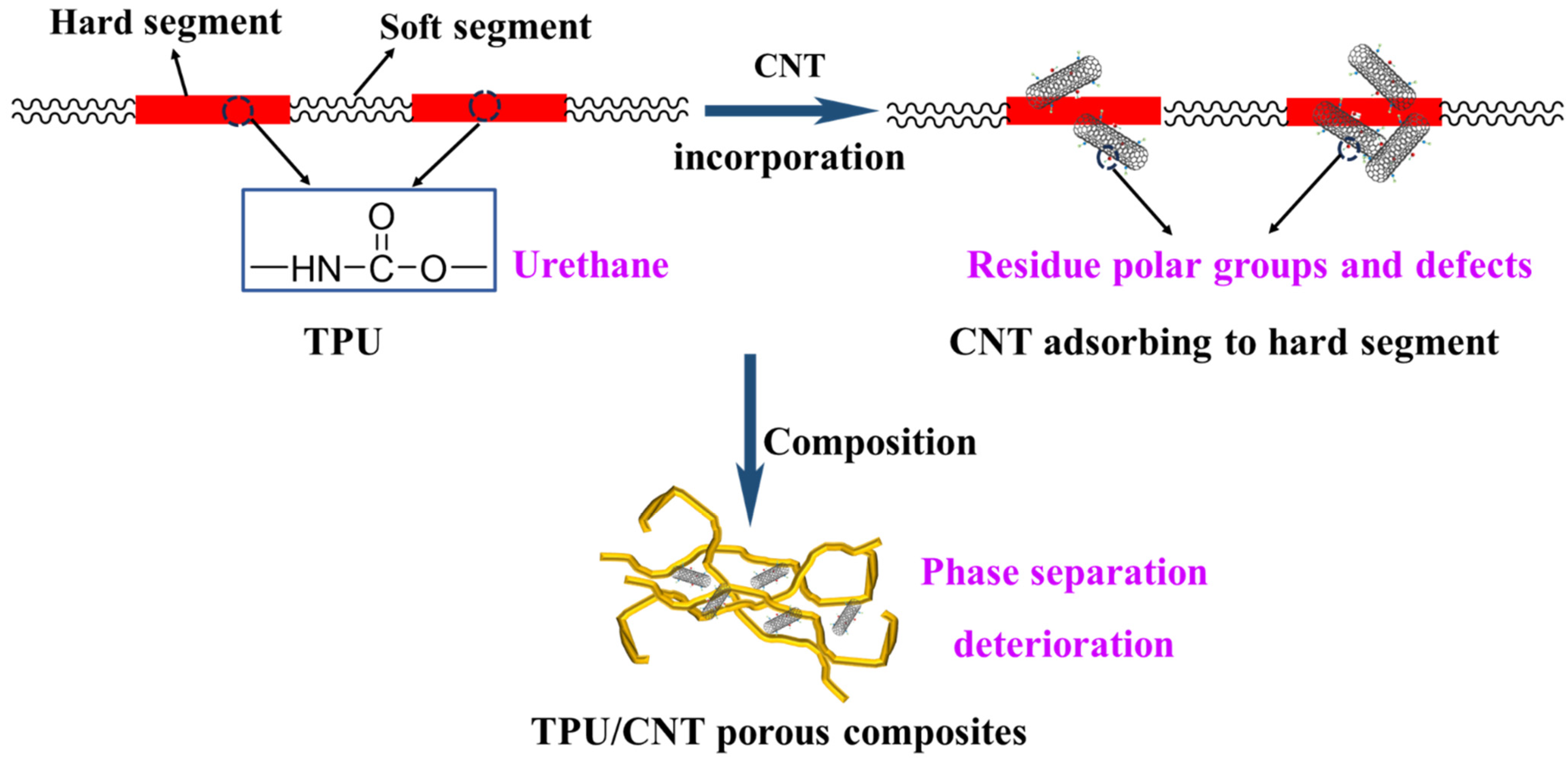

2. Results and Discussion

2.1. Morphology and Structure

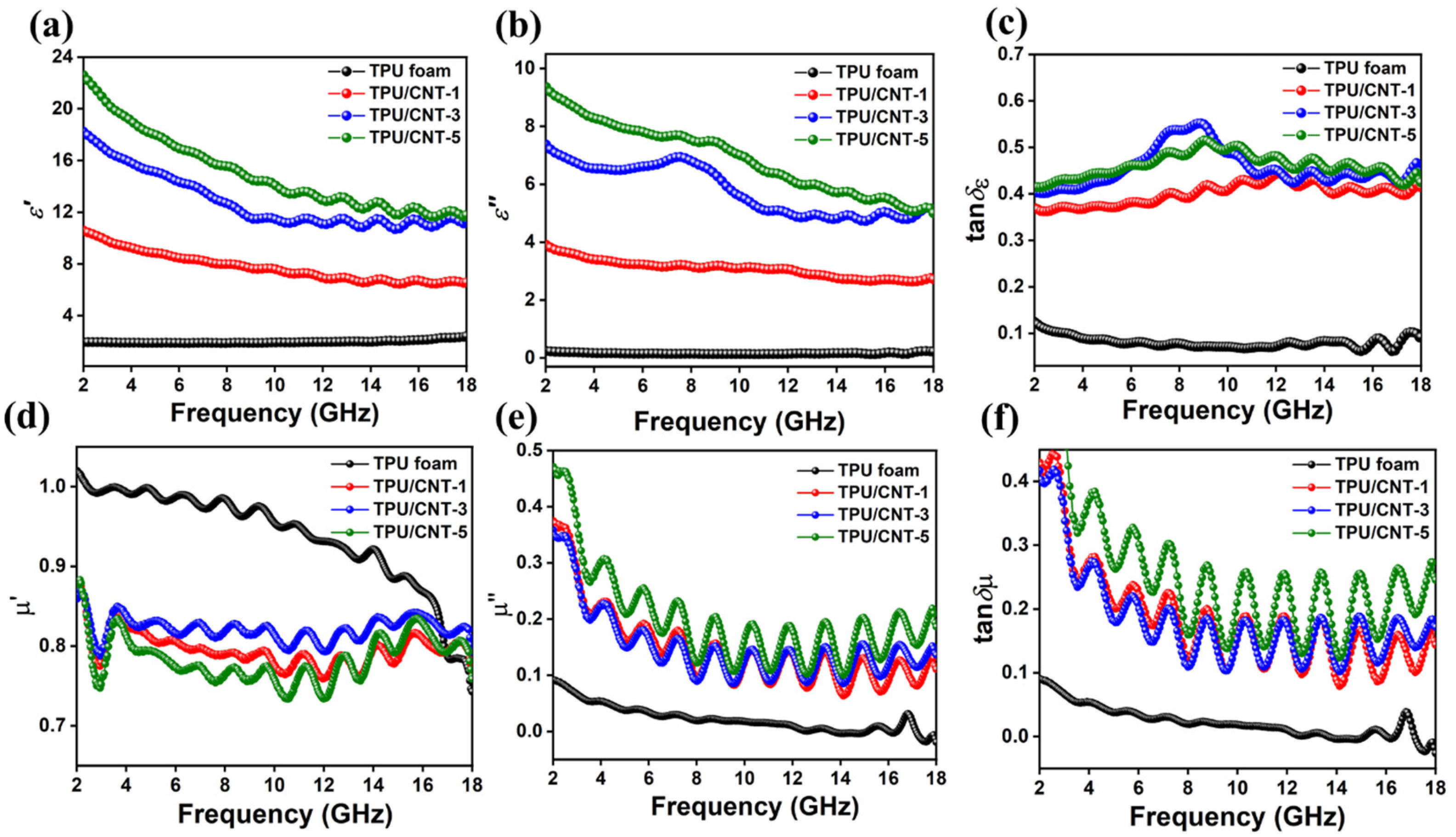

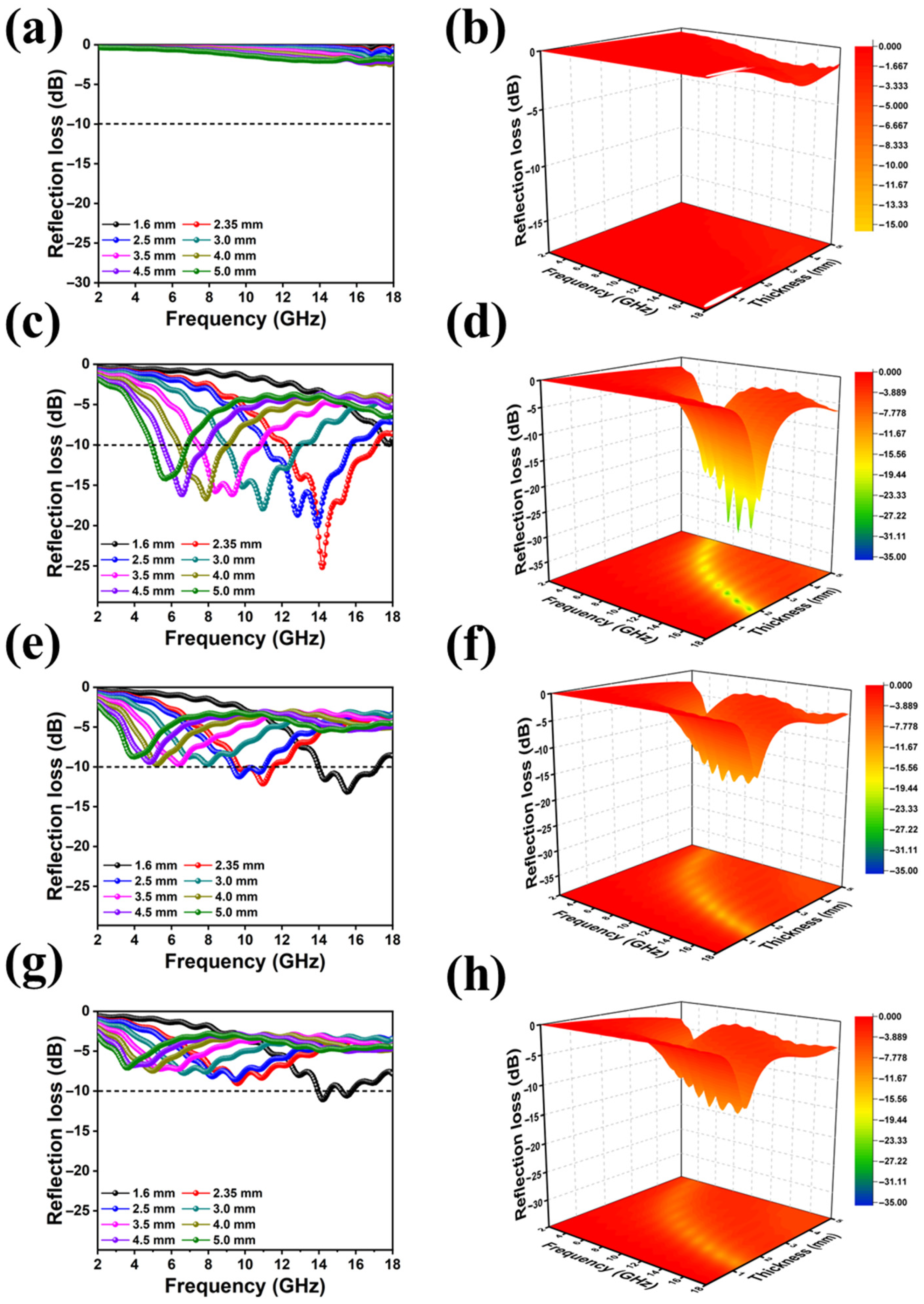

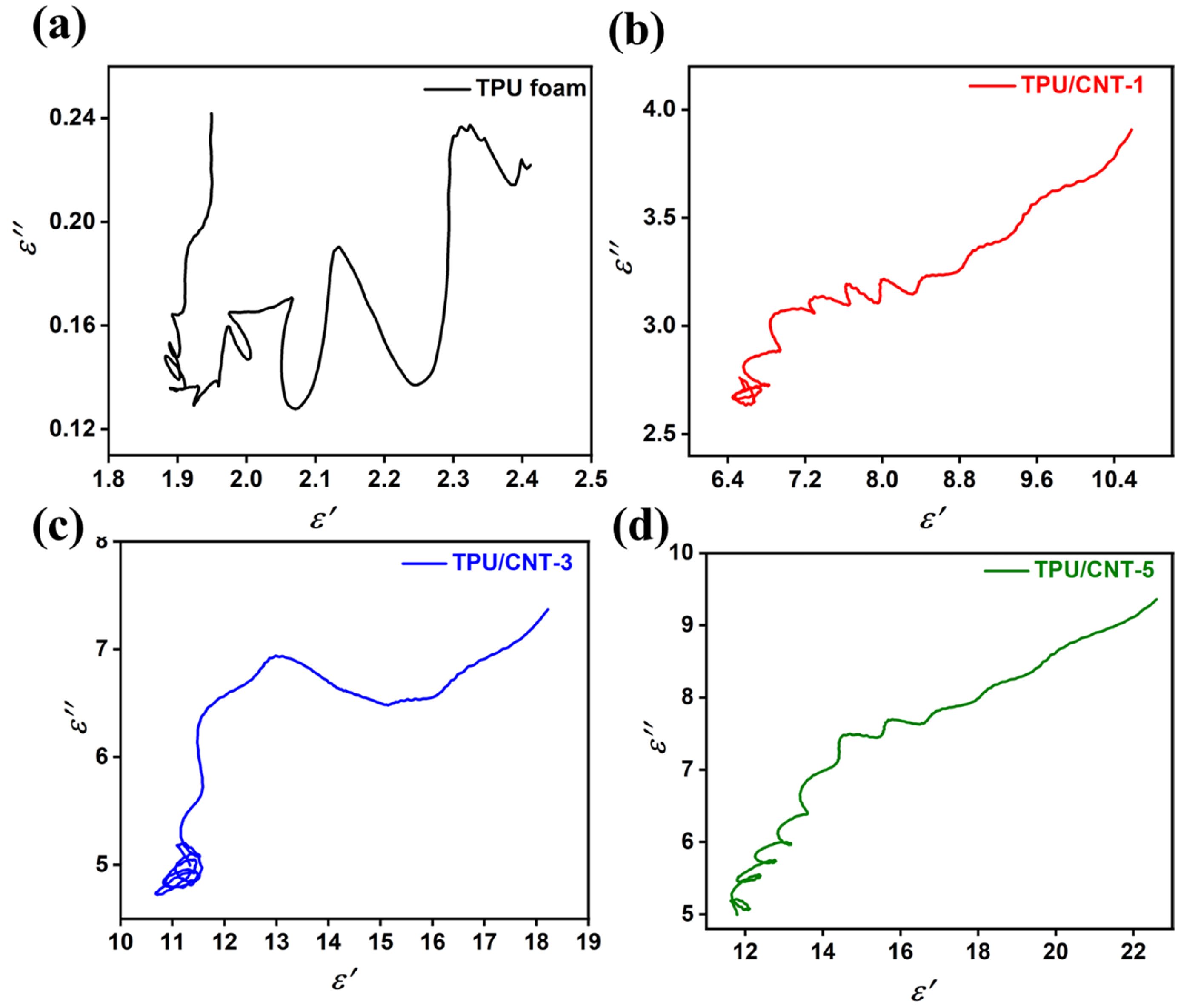

2.2. Microwave Absorption Performance

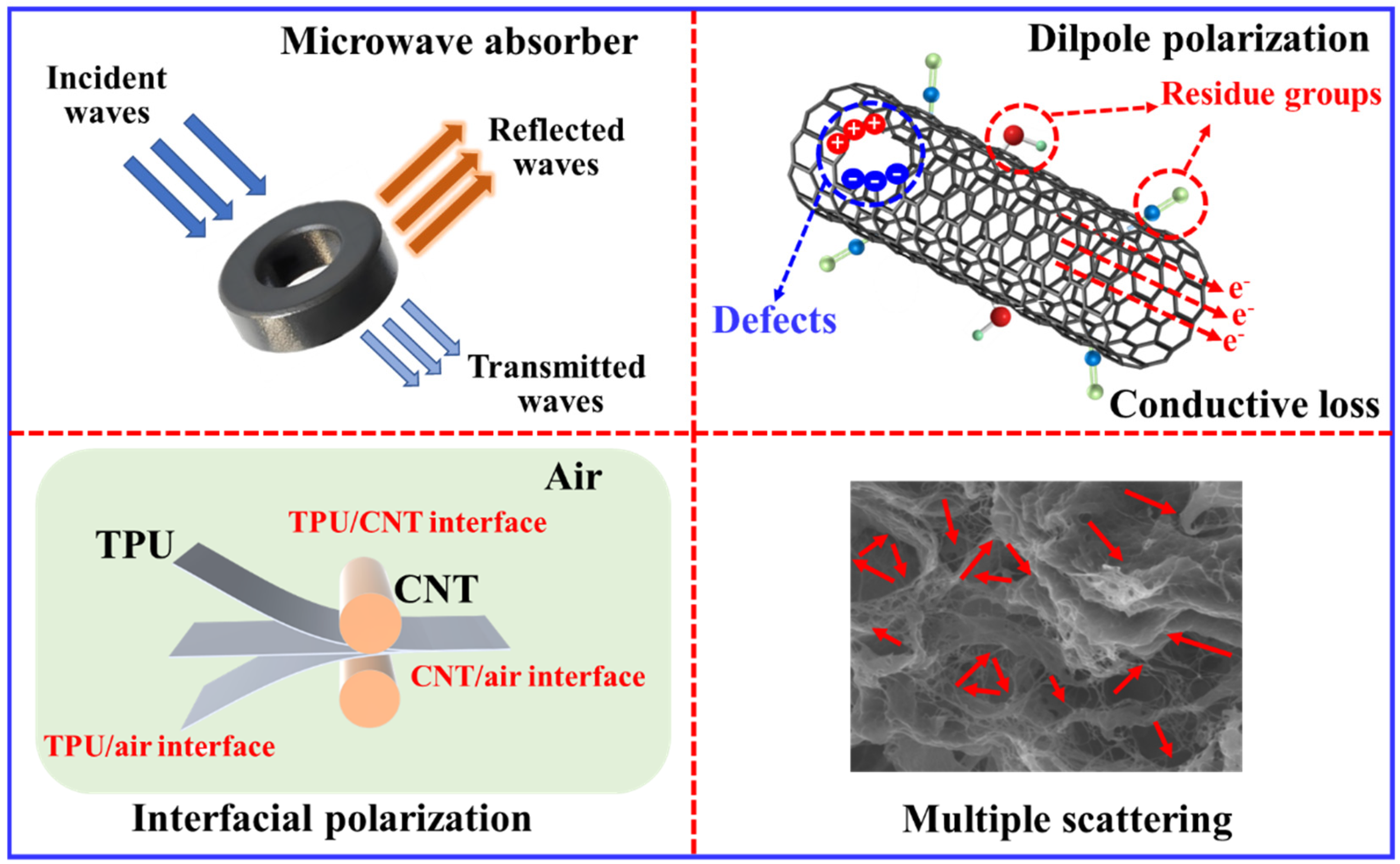

2.3. Microwave Absorption Mechanism

3. Materials and Methods

3.1. Materials

3.2. Preparation of 3D Porous TPU/CNT Composites

3.3. Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lv, H.L.; Yang, Z.H.; Pan, H.G.; Wu, R.B. Electromagnetic absorption materials: Current progress and new frontiers. Prog. Mater. Sci. 2022, 127, 100946. [Google Scholar] [CrossRef]

- Zhao, B.; Yan, Z.K.; Liu, L.L.; Zhang, Y.Y.; Guan, L.; Guo, X.Q.; Li, R.S.; Che, R.C.; Zhang, R. A liquid-metal-assisted competitive galvanic reaction strategy toward indium/oxide core−shell nanoparticles with enhanced microwave absorption. Adv. Funct. Mater. 2024, 34, 2314008. [Google Scholar] [CrossRef]

- Wang, Y.L.; Zhao, P.Y.; Liang, B.L.; Chen, K.; Wang, G.S. Carbon nanotubes decorated Co/C from ZIF-67/melamine as high efficient microwave absorbing material. Carbon 2023, 202, 66–75. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, B.; Wei, S.C.; Huang, W.; Wang, Y.J.; Liang, Y. Review of three-dimensional graphene and related composite materials for microwave absorption. ACS Appl. Nano Mater. 2024, 7, 6772–6784. [Google Scholar] [CrossRef]

- Matzui, L.Y.; Syvolozhskyi, O.A.; Vovchenko, L.L.; Yakovenko, O.S.; Len, T.A.; Ischenko, O.V.; Vakaliuk, A.V.; Oliynyk, V.V.; Zagorodnii, V.V.; Naumenko, A.; et al. Segregated conductive polymer composite with Fe3O4-decorated graphite nanoparticles for microwave shielding. Materials 2024, 17, 2808. [Google Scholar] [CrossRef] [PubMed]

- Kasgoz, A.; Korkmaz, M.; Durmus, A. Compositional and structural design of thermoplastic polyurethane/carbon based single and multi-layer composite sheets for high-performance X-band microwave absorbing applications. Polymer 2019, 180, 121672. [Google Scholar] [CrossRef]

- Li, R.S.; Gao, Q.; Xing, H.N.; Su, Y.Z.; Zhang, H.M.; Zeng, D.; Fan, B.B.; Zhao, B. Lightweight, multifunctional MXene/polymer composites with enhanced electromagnetic wave absorption and high-performance thermal conductivity. Carbon 2021, 183, 301–312. [Google Scholar] [CrossRef]

- Han, X.J.; Feng, Y.F.; Zhang, N.; Du, W.; Zhang, W.L.; Yu, Q.Q.; Liu, Y.F.; Wang, B.; Jiang, F.Y.; Liu, L.Y.; et al. Bio-based multifunctional carbon aerogels for ultrawide electromagnetic wave absorption and thermal insulation. Carbon 2025, 238, 120231. [Google Scholar] [CrossRef]

- Wei, H.W.; Dong, J.D.; Fang, X.J.; Zheng, W.H.; Sun, Y.T.; Qian, Y.; Jiang, Z.X.; Huang, Y.D. Ti3C2Tx MXene/polyaniline (PANI) sandwich intercalation structure composites constructed for microwave absorption. Compos. Sci. Technol. 2019, 169, 52–59. [Google Scholar] [CrossRef]

- Li, S.S.; Ma, T.T.; Zhu, M.Y.; Lu, Y.Z.; Tang, X.W.; Li, W.; Hong, W.; Yang, S.Y.; Li, Y.F.; Zheng, P.L.; et al. Magnetic isocyanate-based polyimide composite foam for efficient microwave absorption. Compos. Part B Eng. 2025, 291, 112011. [Google Scholar] [CrossRef]

- Ting, T.H.; Jau, Y.N.; Yu, R.P. Microwave absorbing properties of polyaniline/multi-walled carbon nanotube composites with various polyaniline contents. Appl. Surf. Sci. 2012, 258, 3184–3190. [Google Scholar] [CrossRef]

- Zhou, C.Q.; Ni, L.; Lu, J.Y.; Meng, H.C.; Luo, Y.F.; Liang, M.; Zou, H.W. Robust and multifunctional polyimide composite foams via microsphere foaming towards efficient thermal insulation and broadband microwave absorption. Polymer 2024, 313, 127684. [Google Scholar] [CrossRef]

- Guo, T.; Chen, X.L.; Zeng, G.J.; Yang, J.L.; Huang, X.Z.; Li, C.G.; Tang, X.Z. Impregnating epoxy into N-doped-CNTs@carbon aerogel to prepare high-performance microwave-absorbing composites with extra-low filler content. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106159. [Google Scholar] [CrossRef]

- Zhu, X.J.; Dong, Y.Y.; Xiang, Z.; Cai, L.; Pan, F.; Zhang, X.; Shi, Z.; Lu, W. Morphology-controllable synthesis of polyurethane-derived highly cross-linked 3D networks for multifunctional and efficient electromagnetic wave absorption. Carbon 2021, 182, 254–264. [Google Scholar] [CrossRef]

- Anjana; Chandra, A. Facile synthesis and characterization of polymer composites with cobalt ferrite and biomass based activated carbon for microwave absorption. Mater. Today Commun. 2023, 37, 107397. [Google Scholar] [CrossRef]

- Deng, Y.M.; Ren, B.; Jia, Y.J.; Wang, Q.; Li, H.J. Layered composites made of polymer derived SiOC/ZrB2 reinforced by ZrO2/SiO2 fibers with simultaneous microwave absorption and thermal insulation. J. Mater. Sci. Technol. 2024, 196, 50–59. [Google Scholar] [CrossRef]

- Ling, Q.C.; Sun, J.Z.; Zhao, Q.; Zhou, Q.Y. Microwave absorbing properties of linear low density polyethylene/ethylene–octene copolymer composites filled with short carbon fiber. Mater. Sci. Eng. B 2009, 162, 162–166. [Google Scholar] [CrossRef]

- Phadtare, V.D.; Parale, V.G.; Lee, K.Y.; Kim, T.; Puri, V.R.; Park, H.H. Flexible and lightweight Fe3O4/polymer foam composites for microwave-absorption applications. J. Alloys Compd. 2019, 805, 120–129. [Google Scholar] [CrossRef]

- Bi, S.; Song, Y.Z.; Hou, G.L.; Li, H.; Liu, Z.H.; Hou, Z.L.; Zhang, J.Y. Sandwich nanoarchitectonics of heterogenous CB/CNTs honeycomb composite for impedance matching design and microwave absorption. J. Alloys Compd. 2023, 943, 169154. [Google Scholar] [CrossRef]

- Dai, M.W.; Zhai, Y.H.; Wu, L.; Zhang, Y. Magnetic aligned Fe3O4-reduced graphene oxide/waterborne polyurethane composites with controllable structure for high microwave absorption capacity. Carbon 2019, 152, 661–670. [Google Scholar] [CrossRef]

- Duan, Y.P.; Liu, Y.; Cui, Y.L.; Ma, G.J.; Wang, T.M. Graphene to tune microwave absorption frequencies and enhance absorption properties of carbonyl iron/polyurethane coating. Prog. Org. Coat. 2018, 125, 89–98. [Google Scholar] [CrossRef]

- Sheng, A.; Ren, W.; Yang, Y.Q.; Yan, D.X.; Duan, H.J.; Zhao, G.Z.; Liu, Y.Q.; Li, Z.M. Multilayer WPU conductive composites with controllable electro-magnetic gradient for absorption-dominated electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105692. [Google Scholar] [CrossRef]

- Xu, Y.D.; Lin, Z.Q.; Yang, Y.Q.; Duan, H.J.; Zhao, G.Z.; Liu, Y.Q.; Hu, Y.G.; Sun, R.; Wong, C.P. Integration of efficient microwave absorption and shielding in a multistage composite foam with progressive conductivity modular design. Mater. Horiz. 2022, 9, 708–719. [Google Scholar] [CrossRef]

- Zhang, C.M.; Li, H.; Zhuo, Z.Z.; Dugnani, R.; Sun, C.Y.; Chen, Y.J.; Liu, H.Z. Facile fabrication of ultra-light and highly resilient PU/RGO foams for microwave absorption. RSC Adv. 2017, 7, 41321. [Google Scholar] [CrossRef]

- Zheng, X.Y.; Zhang, H.W.; Jiang, R.J.; Liu, Z.H.; Zhu, S.S.; Li, W.Y.; Jiang, L.; Zhou, X. Lightweight polyurethane composite foam for electromagnetic interference shielding with high absorption characteristic. J. Colloid Interface Sci. 2023, 649, 279–289. [Google Scholar] [CrossRef]

- Zhang, W.; Li, K.; Han, L.; Wu, T.; Zhang, J.; Cheng, J. Ultra-strength polyurethane/MOF-derived composites with self-healing and recycling capabilities and highly efficient microwave absorption properties. J. Mater. Chem. C 2024, 12, 1446–1458. [Google Scholar] [CrossRef]

- Yan, T.M.; Ye, X.C.; He, E.Y.; Gao, Q.; Wang, Y.M.; Gong, L.; Ye, Y.S.; Wu, H.H. Preparation of a double-layer bionic bamboo structure absorber based on CB/PLA-TPU composites and its broadband microwave absorption characteristics. J. Alloys Compd. 2024, 990, 174461. [Google Scholar] [CrossRef]

- Zhang, F.X.; Liu, S.K.; Chao, B.; Deng, S.X.; Zhou, Y.M.; Wu, H.H.; Wang, Q.S. Study on FDM preparation and properties of carbon black/nickel/polylactic acid/thermoplastic polyurethane electromagnetic wave absorbing composites. Compos. Commun. 2025, 56, 102384. [Google Scholar] [CrossRef]

- Sun, Z.X.; Shen, J.H.; Chen, W.; Chen, Y.M.; Li, X.P.; Zheng, J.J.; Jiang, S.H.; Zhou, L.J. High-performance polyurethane composite elastomers with coral reef-like hierarchical heterostructures for electromagnetic wave absorption and flexible sensing. Mater. Today Chem. 2024, 35, 101840. [Google Scholar] [CrossRef]

- Ali, M.S.; Santhosi, B.V.S.R.N.; Garugubilli, R.; Syed, J. Effective microwave absorbing polymer nanocomposites in X-band: The role of graphene in polyurethane/polypropylene multilayered structures. Vacuum 2025, 238, 114212. [Google Scholar] [CrossRef]

- Han, Q.Q.; Wang, S.; Cheng, X.; Du, X.S.; Wang, H.B.; Du, Z.L. Self-healing polyurethane coating based on porous carbon/Ni hybrid composites for electromagnetic wave absorption. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107830. [Google Scholar] [CrossRef]

- Han, Q.Q.; Xu, J.H.; Shi, J.Y.; Zhou, M.; Wang, H.B.; Geng, L.; Xiong, J.J.; Du, Z.L. Structural and hetero-interfacial engineering of magnetic bimetallic composites based polyurethane microwave absorbing coating for marine environment. Compos. Part A Appl. Sci. Manuf. 2025, 192, 108770. [Google Scholar] [CrossRef]

- Tahalyani, J.; Akhtar, M.J.; Kar, K.K. Flexible, stretchable and lightweight polyurethane and graphene nanoplatelets nanocomposite for high performance EMI shielding application. Mater. Today Commun. 2022, 33, 104586. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhu, D.M.; Chen, Q.; Nan, H.Y. Efficiently enhanced microwave absorption of oriented flaky carbonyl iron&MoS2/polyurethane composite with thin thickness. Chem. Phys. Lett. 2020, 758, 137908. [Google Scholar] [CrossRef]

- Menon, A.V.; Madras, G.; Bose, S. Shape memory polyurethane nanocomposites with porous architectures for enhanced microwave shielding. Chem. Eng. J. 2018, 352, 590–600. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, C.Z.; Li, J.; Guo, S.Y. Adjustment of dielectric permittivity and loss of graphene/thermoplastic polyurethane flexible foam: Towards high microwave absorbing performance. Compos. Part A Appl. Sci. Manuf. 2019, 117, 65–75. [Google Scholar] [CrossRef]

- Zheng, J.J.; Wei, X.L.; Li, Y.C.; Dong, W.P.; Li, X.P.; E, S.; Wu, Z.Y.; Wen, J.M. Stretchable polyurethane composite foam triboelectric nanogenerator with tunable microwave absorption properties at elevated temperature. Nano Energy 2021, 89, 106397. [Google Scholar] [CrossRef]

- Zhu, G.; Li, H.; Peng, M.; Zhao, G.; Chen, J.; Zhu, Y. Highly-stretchable porous thermoplastic polyurethane/carbon nanotubes composites as a multimodal sensor. Carbon 2022, 195, 364–371. [Google Scholar] [CrossRef]

- Pan, B.; Lee, K.J. Preparation of thermoplastic polyurethane blend foams with controlled hydrophobicity via vapor induced phase separation. J. Appl. Polym. Sci. 2023, 140, 1–8. [Google Scholar] [CrossRef]

- Li, Y.F.; Li, X.Y.; Li, Q.F.; Zhao, Y.H.; Wang, J.W. Low-energy-consumption fabrication of porous TPU/graphene composites for high-performance microwave absorption and the influence of Fe3O4 incorporation. J. Alloys Compd. 2022, 909, 164627. [Google Scholar] [CrossRef]

- Guo, T.; Li, C.G.; Yang, J.L.; Wang, P.F.; Yue, J.L.; Huang, X.Z.; Wang, J.; Tang, X.Z. Holey, anti-impact and resilient thermoplastic urethane/carbon nanotubes fabricated by a low-cost “vapor induced phase separation” strategy for the detection of human motions. Compos. Part A Appl. Sci. Manuf. 2020, 136, 105974. [Google Scholar] [CrossRef]

- Shin, B.; Mondal, S.; Lee, M.; Kim, S.; Huh, Y.-I.; Nah, C. Flexible thermoplastic polyurethane-carbon nanotube composites for electromagnetic interference shielding and thermal management. Chem. Eng. J. 2021, 418, 129282. [Google Scholar] [CrossRef]

- Liu, L.J.; Zhang, X.; Li, X.Y.; Wang, Q.; Li, H.T.; Zhang, Y.P.; Li, Y.F.; Li, Q.F.; Zhao, Y.H.; Wang, J.W.; et al. Study on effect of boric acid on the stability of 1,5-naphthalene diisocyanate-based prepolymer and properties of the elastomers therefrom. Mater. Today Chem. 2025, 44, 102578. [Google Scholar] [CrossRef]

- Liu, W.F.; Zhao, Z.P.; Sun, L.; Wang, M.Z. Formation of polyethersulfone film with regular microporous structure by water vapor induced phase separation. Chin. J. Chem. Eng. 2010, 18, 529–532. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Fan, Z.; Li, B.; Ren, D.X.; Xu, M.Z. Study on structure–function integrated polymer-based microwave-absorption composites. Polymers 2024, 16, 2472. [Google Scholar] [CrossRef]

- Li, Y.F.; Li, X.Y.; Kang, M.Q.; Zhao, Y.H.; Li, Q.F.; Wang, J.W. Fabrication of flexible waterborne polyurethane/Fe-doped residual carbon from coal hydrogasification semi-coke composites for high-performance microwave absorption. Compos. Part A Appl. Sci. Manuf. 2023, 174, 107710. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Wu, X.F.; Huang, J.; Chen, S.Y.; Zhang, Y.; Dong, C.J.; Chen, G.; Wang, L.H.; Guan, H.T. Enhanced microwave absorption of biomass carbon/nickel/polypyrrole (C/Ni/PPy) ternary composites through the synergistic effects. J. Alloys Compd. 2022, 890, 161887. [Google Scholar] [CrossRef]

- Bi, S.; Zhao, Y.K.; Hou, G.L.; Zhang, J.Y.; Li, H.; Song, Y.Z.; Hou, Z.L.; Liu, Z.H. Microwave absorption and mechanical properties of CNTs/PU composites with honeycomb structure. Appl. Compos. Mater. 2022, 29, 1393–1407. [Google Scholar] [CrossRef]

- Grishchenko, L.M.; Diyuk, V.E.; Trachevskiy, V.V.; Zhytnyk, D.O.; Moiseienko, V.A.; Mischanchuk, O.V.; Skryshevsky, V.A.; Zaderko, A.N.; Boldyrieva, O.Y.; Lisnyak, V.V. Polyurethane-based thin-film composites with carbon micro- to nanoscale fillers and their microwave properties. Mol. Cryst. Liq. Cryst. 2024, 768, 286–297. [Google Scholar] [CrossRef]

- Ye, X.; Lv, Y.; Zhang, L.; Chen, H.; Chen, S.; Wu, Y.; Ma, L.A.; Wang, Q. Hierarchical carbon nanotubes-modified heterogeneous composites derived from melamine-mixed ZIF-67/MXene for broadband microwave absorption. Carbon 2024, 216, 118585. [Google Scholar] [CrossRef]

- Liu, Z.; Bai, G.; Huang, Y.; Li, F.; Ma, Y.; Guo, T.; He, X.; Lin, X.; Gao, H.; Chen, Y. Microwave absorption of single-walled carbon nanotubes/soluble cross-linked polyurethane composites. J. Phys. Chem. C 2007, 111, 13696–13700. [Google Scholar] [CrossRef]

- Hussein, M.I.; Jehangir, S.S.; Rajmohan, I.J.; Haik, Y.; Abdulrehman, T.; Clément, Q.; Vukadinovic, N. Microwave Absorbing properties of metal functionalized-CNT-polymer composite for stealth applications. Sci. Rep. 2020, 10, 16013. [Google Scholar] [CrossRef]

- Bhattacharya, P.; Sahoo, S.; Das, C.K. Microwave absorption behaviour of MWCNT based nanocomposites in X-band region. Express Polym. Lett. 2013, 7, 212–223. [Google Scholar] [CrossRef]

- Han, Y.X.; Guo, H.; Qiu, H.; Hu, J.W.; He, M.K.; Shi, X.T.; Zhang, Y.L.; Kong, J.; Gu, J.W. Multimechanism decoupling for low-frequency microwave absorption hierarchical Fe-doped Co magnetic microchains. Adv. Funct. Mater. 2025, 2506803. [Google Scholar] [CrossRef]

| Absorber | Matrix | Loading/wt% | Thickness/mm | RLmin/dB | EAB/GHz | Ref |

|---|---|---|---|---|---|---|

| CNT/iron | paraffin | 15 | 2.92 | −58.56 | 5.6 | [10] |

| Co@C/CNTs | PVDF | 15 | 3.01 | −57.6 | 5.4 | [3] |

| CNT | PU | 0.1–0.5 | 2.3 | −6 | 0 | [49] |

| CNT | TPU | 5 | 1.87 | −41.66 | 2.73 | [6] |

| TiO2/C/Co@C | paraffin | 30 | 1.8 | −41.35 | 5.06 | [50] |

| CNT | PU | 5 | 2 | −22 | 8.7 | [51] |

| CNT | PU | 5 | 1 | −36 | ~3 | [52] |

| Ti@MWCNT/Fe | TPU | 30 | 2 | −42.53 | 4.2 | [53] |

| CNT | TPU | 1 | 2.35 | −25.33 | 4.89 (1.6 mm) | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Xu, Y.; Wen, G.; Wang, J. Fabrication of 3D Porous and Flexible Thermoplastic Polyurethane/Carbon Nanotube Composites Towards High-Performance Microwave Absorption. Molecules 2025, 30, 3610. https://doi.org/10.3390/molecules30173610

Li Y, Xu Y, Wen G, Wang J. Fabrication of 3D Porous and Flexible Thermoplastic Polyurethane/Carbon Nanotube Composites Towards High-Performance Microwave Absorption. Molecules. 2025; 30(17):3610. https://doi.org/10.3390/molecules30173610

Chicago/Turabian StyleLi, Yanfang, Yandong Xu, Guangming Wen, and Junwei Wang. 2025. "Fabrication of 3D Porous and Flexible Thermoplastic Polyurethane/Carbon Nanotube Composites Towards High-Performance Microwave Absorption" Molecules 30, no. 17: 3610. https://doi.org/10.3390/molecules30173610

APA StyleLi, Y., Xu, Y., Wen, G., & Wang, J. (2025). Fabrication of 3D Porous and Flexible Thermoplastic Polyurethane/Carbon Nanotube Composites Towards High-Performance Microwave Absorption. Molecules, 30(17), 3610. https://doi.org/10.3390/molecules30173610